Power transmission and transformation line interval maintaining device

A technology for power transmission and transformation lines and fixtures, applied in the field of spacers, can solve the problems of unstable support force, increased difficulty and danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

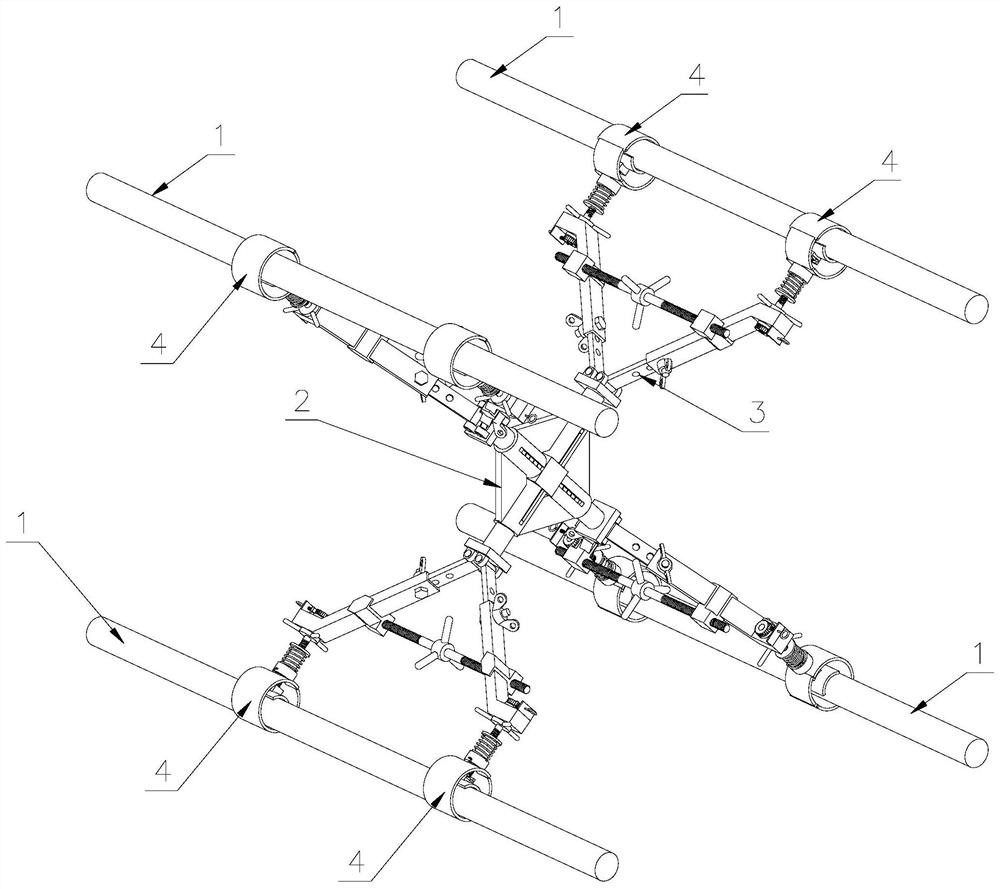

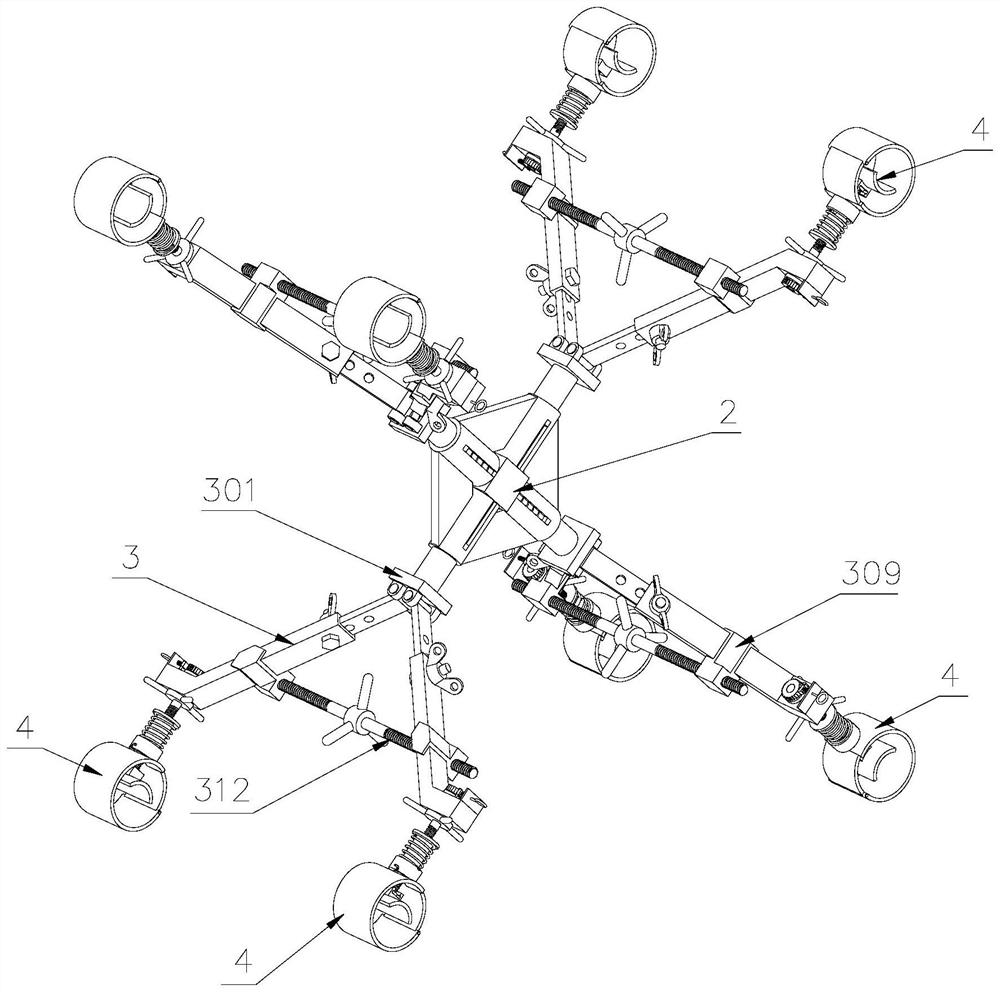

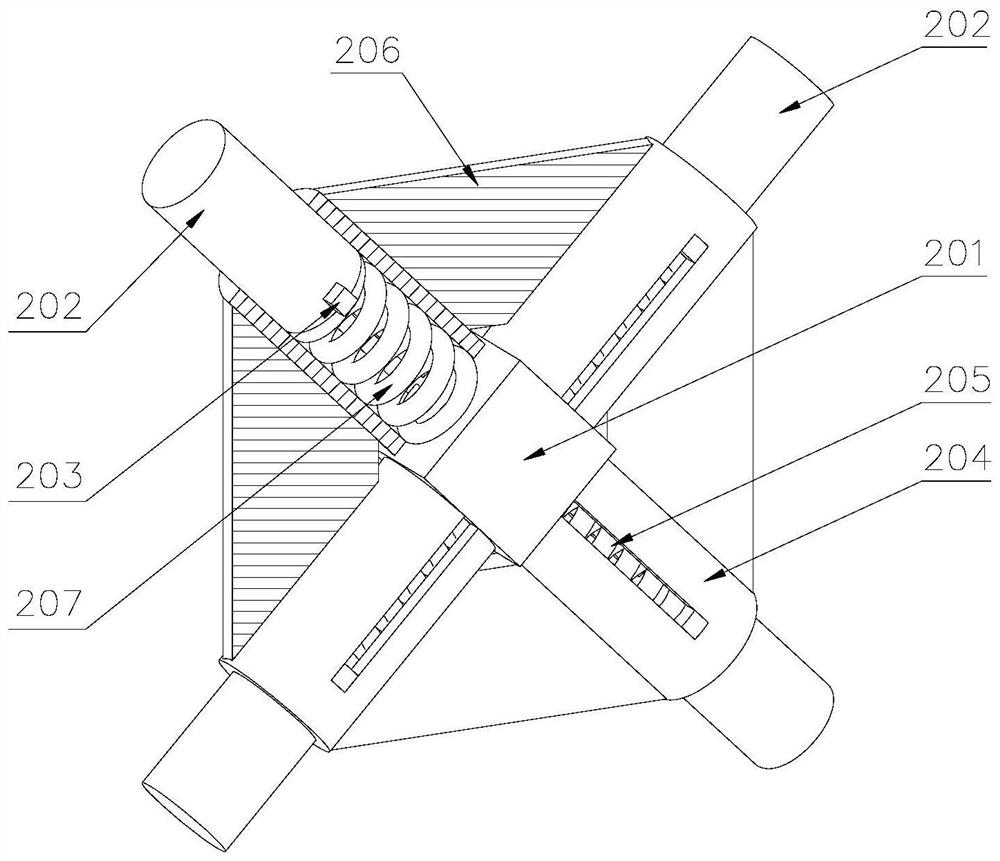

[0043] Such as Figure 1-7 As shown, a power transmission and transformation line spacing maintenance device includes a fixing seat 2, a supporting device 3, and a fixing device 4. The fixing seat 2 includes a fixing block 201 and a connecting rod 202 arranged on the outer end surface of the fixing block 201. The cross-section of the fixing block 201 is a square or a regular hexagon or a regular octagon, thereby forming a distance maintaining device for two splits, four splits, six splits or eight splits of the wire 1; Plate 301, the support arms 305 that are arranged on the front and rear sides of the fixed plate 301, the connecting rod 202 and the two support arms 305 form a Y-shaped structure, and one end of the support arm 305 is provided with a mounting head 307, and the fixing device 4 is arranged on the installation On the head 307, and the fixing device 4 on the front and rear sides is coaxially arranged, the fixing device 4 includes a tightening screw 407 installed on...

Embodiment 2

[0053] Such as Image 6 As shown, the difference from Embodiment 1 is that in this embodiment, the engaging device includes a sliding sleeve 418 sleeved on the outside of the connecting handle 416, and one end of the connecting handle 416 is provided with a ring plate 417, the The outside of the connecting handle 416 is provided with a second clamping spring 419, one end of the second clamping spring 419 is fixedly connected with the ring plate 417, and the other end of the second clamping spring 419 is fixedly connected with the sliding sleeve 418; Pull back to open the movable plate 402, after the wire 1 is stuck between the outer splint 401 and the inner splint 404, buckle the buckle plate 403 inside the buckle groove 415, and then loosen the sliding sleeve 418, the sliding sleeve 418 Under the action of the elastic force of the second tightening spring 419, one end of the connecting handle 416 is intended to be tightened, so that the buckle plate 403 is limited to the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com