Cutting device

A cutting and attracting device technology, applied in the directions of transportation and packaging, thin material processing, printing, etc., can solve the problem that the sheet does not have a predetermined length, and achieve the effect of preventing unstable behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

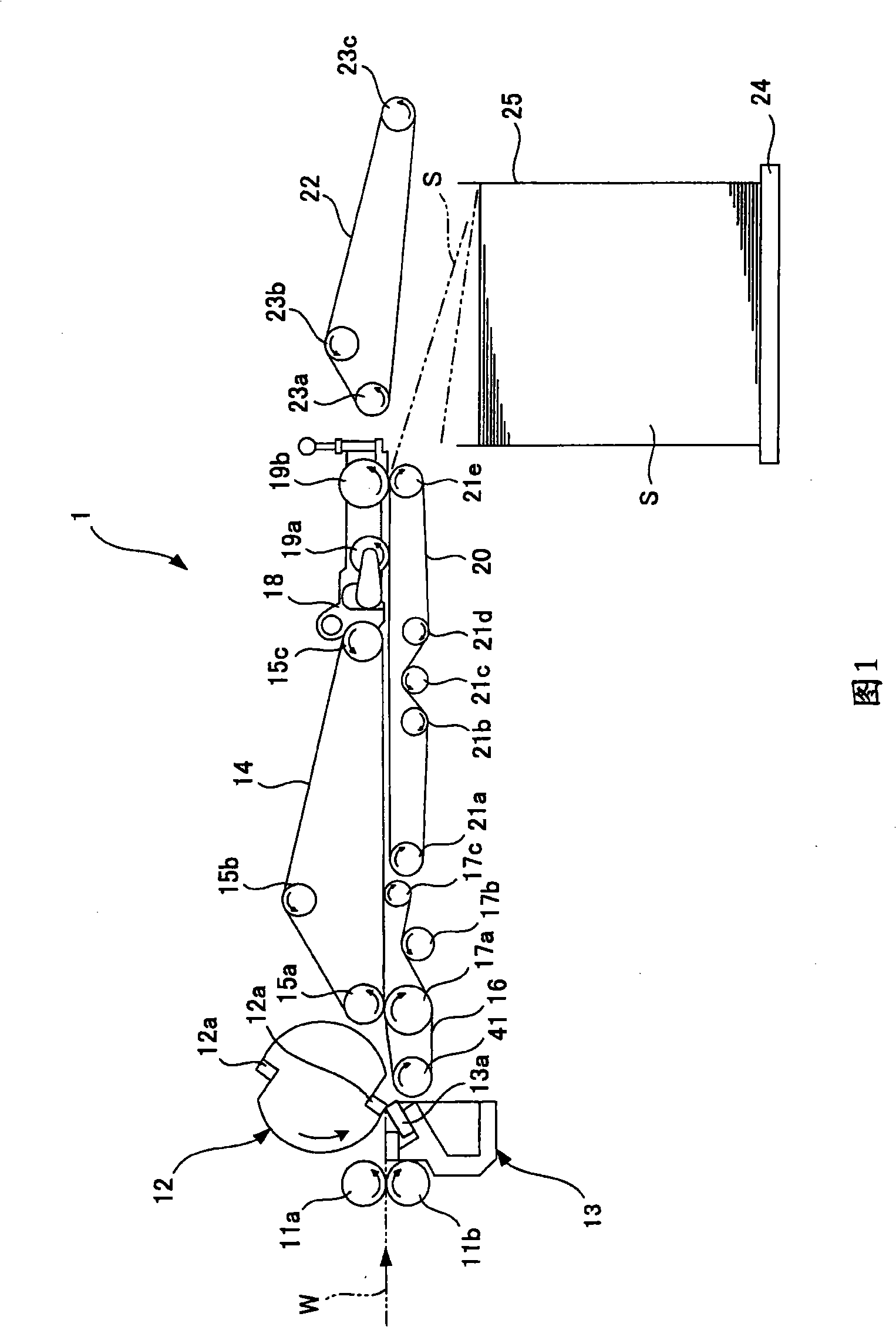

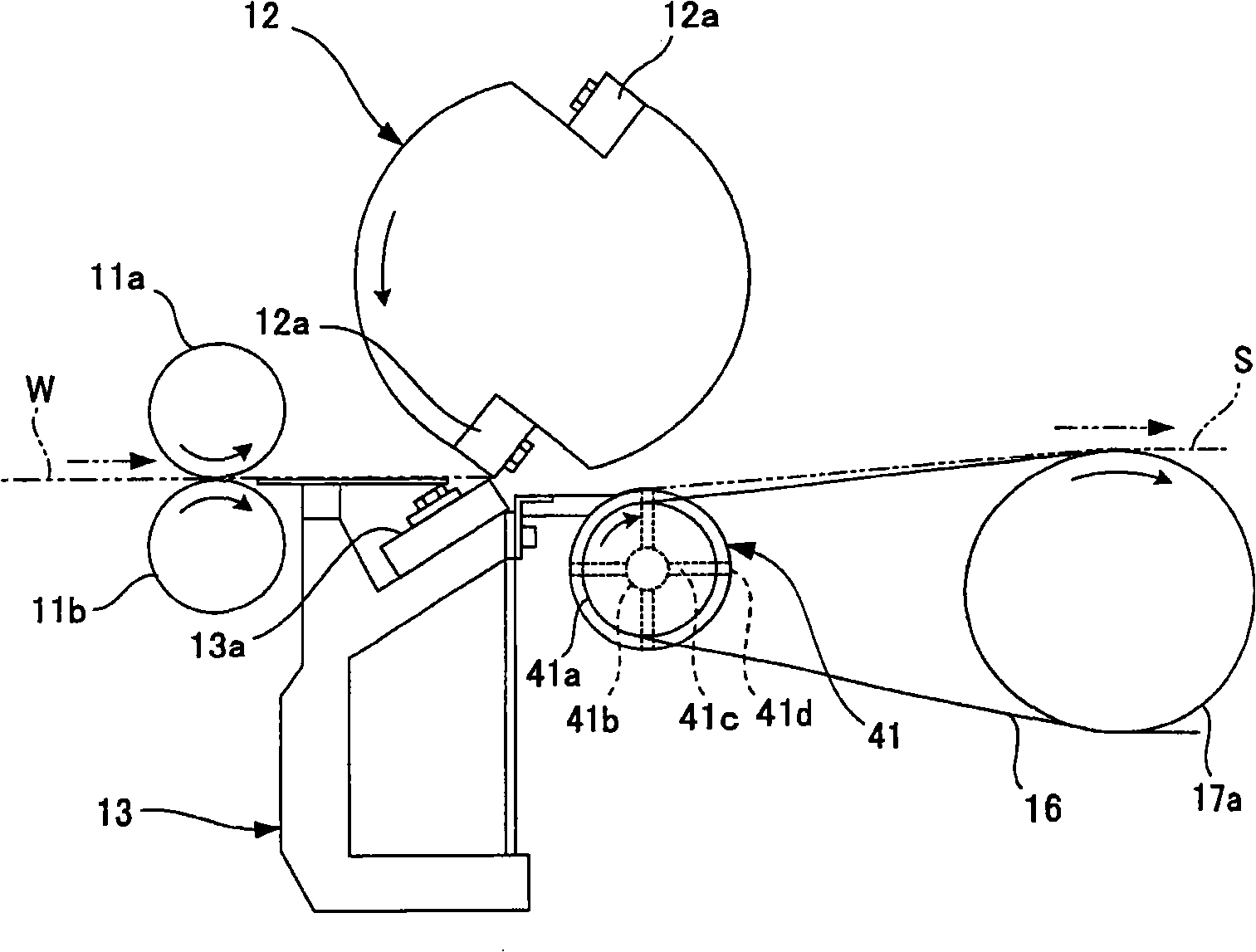

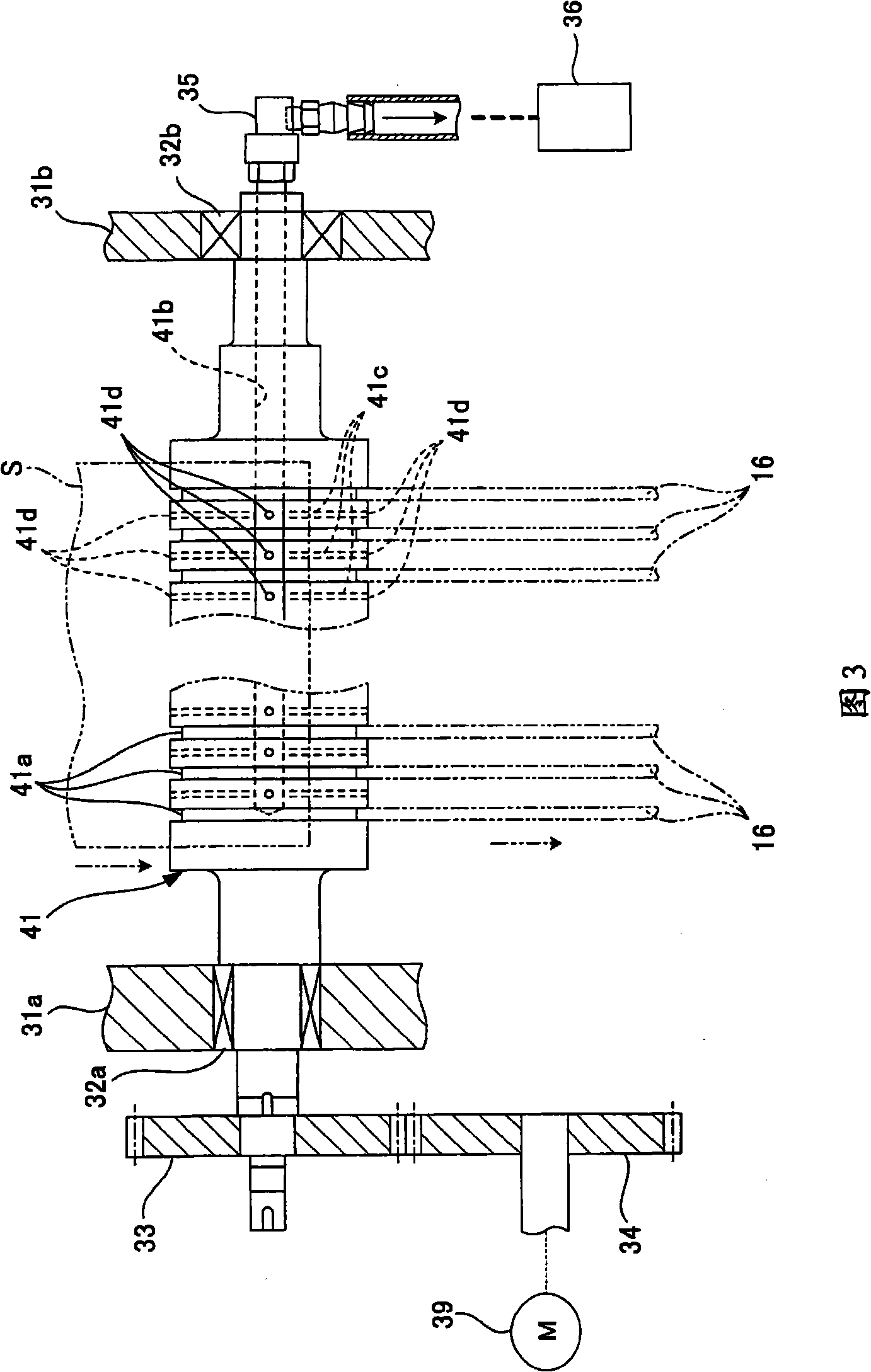

[0032] FIG. 1 is an overall schematic diagram of a cutting device according to a first embodiment of the present invention. figure 2 It is an enlarged view of main parts of the cutting device shown in FIG. 1 . Figure 3 is figure 2 The top view of the main part of the cutting device shown.

[0033] As shown in FIG. 1 , the web rotary printing press not shown in the figure includes a cutting device 1 . The cutting device is configured to cut the printed web W dried and cooled after printing into a predetermined length of sheet S, and then stack the resulting sheet while flattening the edge of the sheet.

[0034] The cutting device 1 includes a pair of nip rollers 11a and 11b rotatably supported at upstream positions thereof in a direction in which a roll paper is conveyed (hereinafter referred to as "roll paper conveyance direction"). The nip rollers 11a and 11b are arranged to be vertically opposed to each other so that the nip rollers can nip the web being transported. At ...

no. 2 example

[0055] Figure 4 It is an enlarged view of main parts of the cutting device according to the second embodiment of the present invention. Figure 5 is Figure 4 The top view of the main part of the cutting device shown. In addition, those elements having the same or similar structure and function as those of the cutting device of the first embodiment are denoted by the same reference numerals, and their repeated descriptions are omitted.

[0056] Such as Figure 4 As shown, the web rotary printing machine not shown in the figure includes a cutting device 2 for cutting the printed web W which is dried and cooled after printing into a sheet S of predetermined length, and then The resulting sheet S is stacked while flattening the edge of the sheet S.

[0057] A plurality of lower high-speed conveyor belts 37 are in opposite contact with the upper high-speed conveyor belt 14 (see FIG. 1 ). Such as Figure 4 As shown in FIG. 5 , the lower high-speed conveyor belt 37 is stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com