Three-dimensional printing device and forming method for three-dimensional object

A technology of three-dimensional printing and molding methods, which is applied in the direction of additive processing, etc., can solve the problems of platform components such as decreased precision, failure to work normally, and increased manufacturing costs, so as to avoid waste, improve rotation flexibility and work efficiency, and improve flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

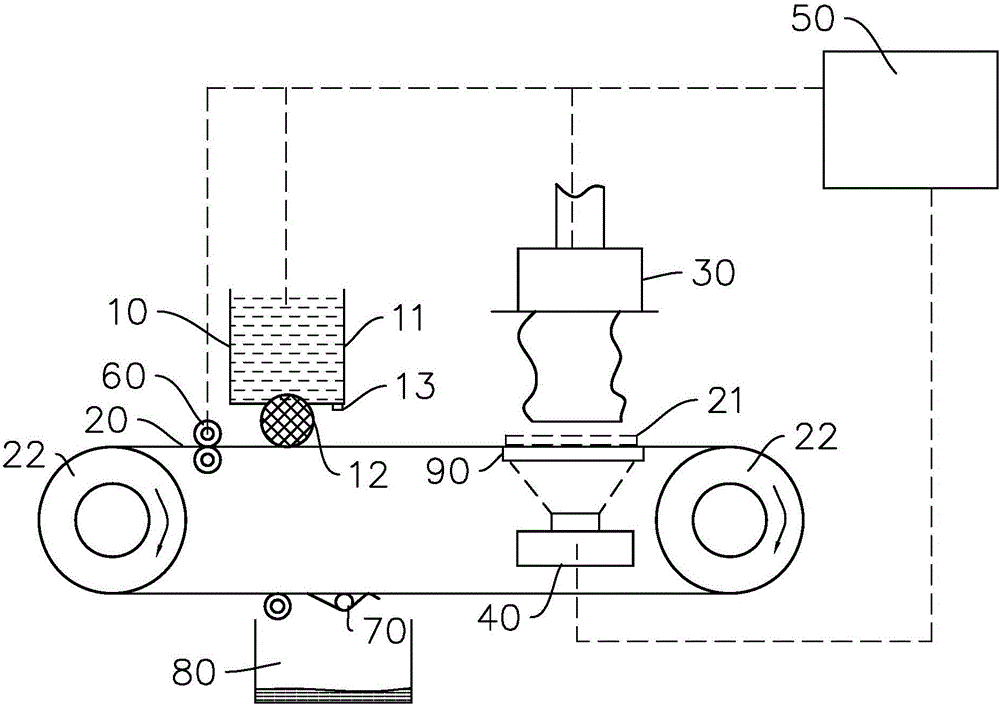

[0036] like figure 1 As shown, the three-dimensional printing device of this embodiment includes a photosensitive resin supply device 10, an endless conveyor belt 20, a printing platform 30, a light processing device 40, a control device 50, a tension adjustment wheel 60, a collecting scraper 70, a recycling tank 80 and a supporting platform 90 . Both the endless conveyor belt 20 and the support platform 90 are transparent to ultraviolet light. The control device 50 is respectively connected with the photosensitive resin supply device 10 , the endless conveyor belt 20 , the printing platform 30 , the light processing device 40 and the tension adjustment wheel 60 , so as to control these components.

[0037]The photosensitive resin supply device 10 contains photosensitive resin. The photosensitive resin supply device 10 includes a constant pressure tank 11 , a photosensitive resin spraying device 12 and a liquid level detection device 13 . The photosensitive resin is stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com