Rotating filter cartridge type air dust remover

A technology of rotating filter cartridges and dust collectors, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of electrostatic precipitator corona, isolation bags that cannot withstand high temperatures, and bag paste, so as to avoid air flow short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

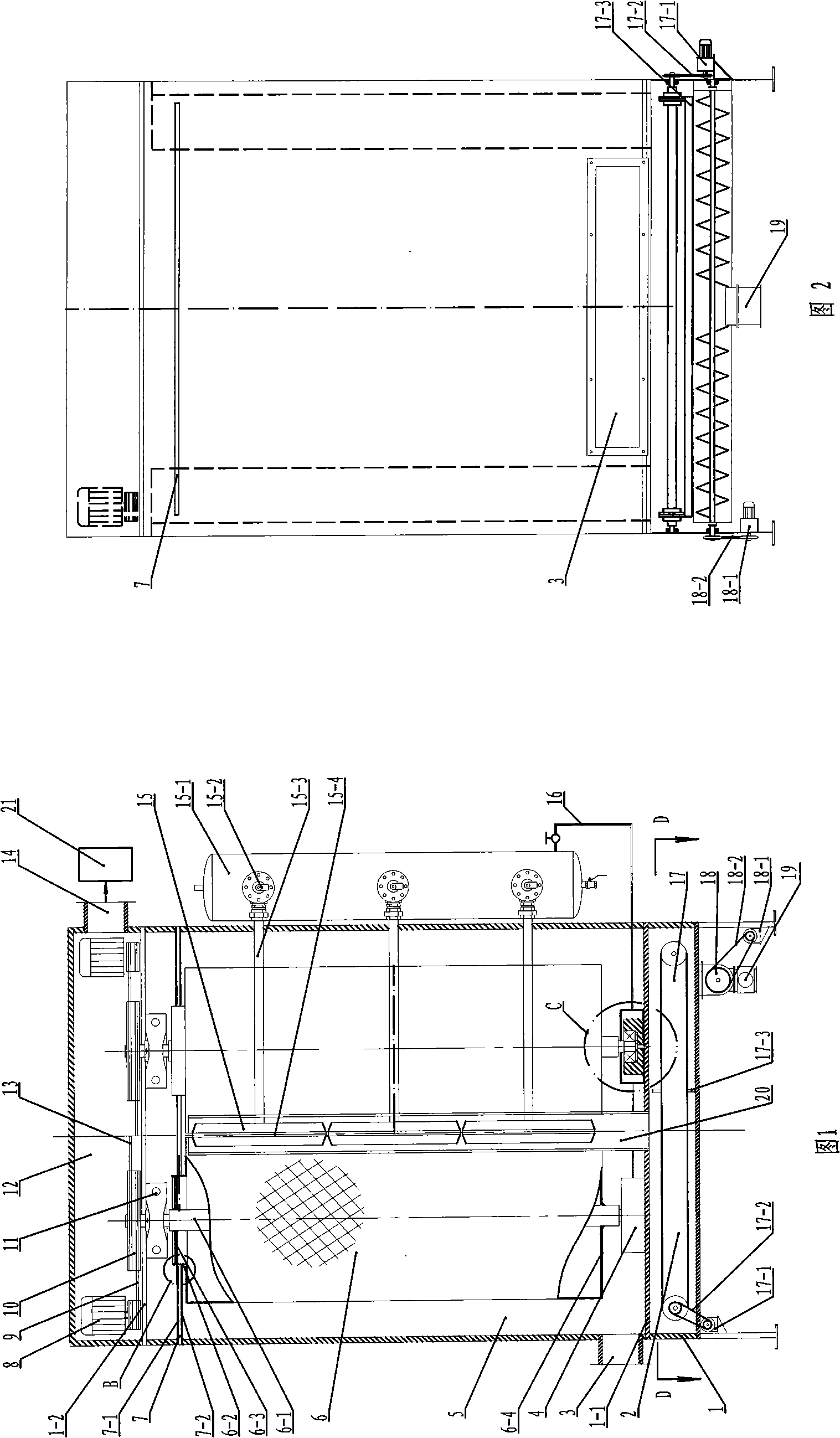

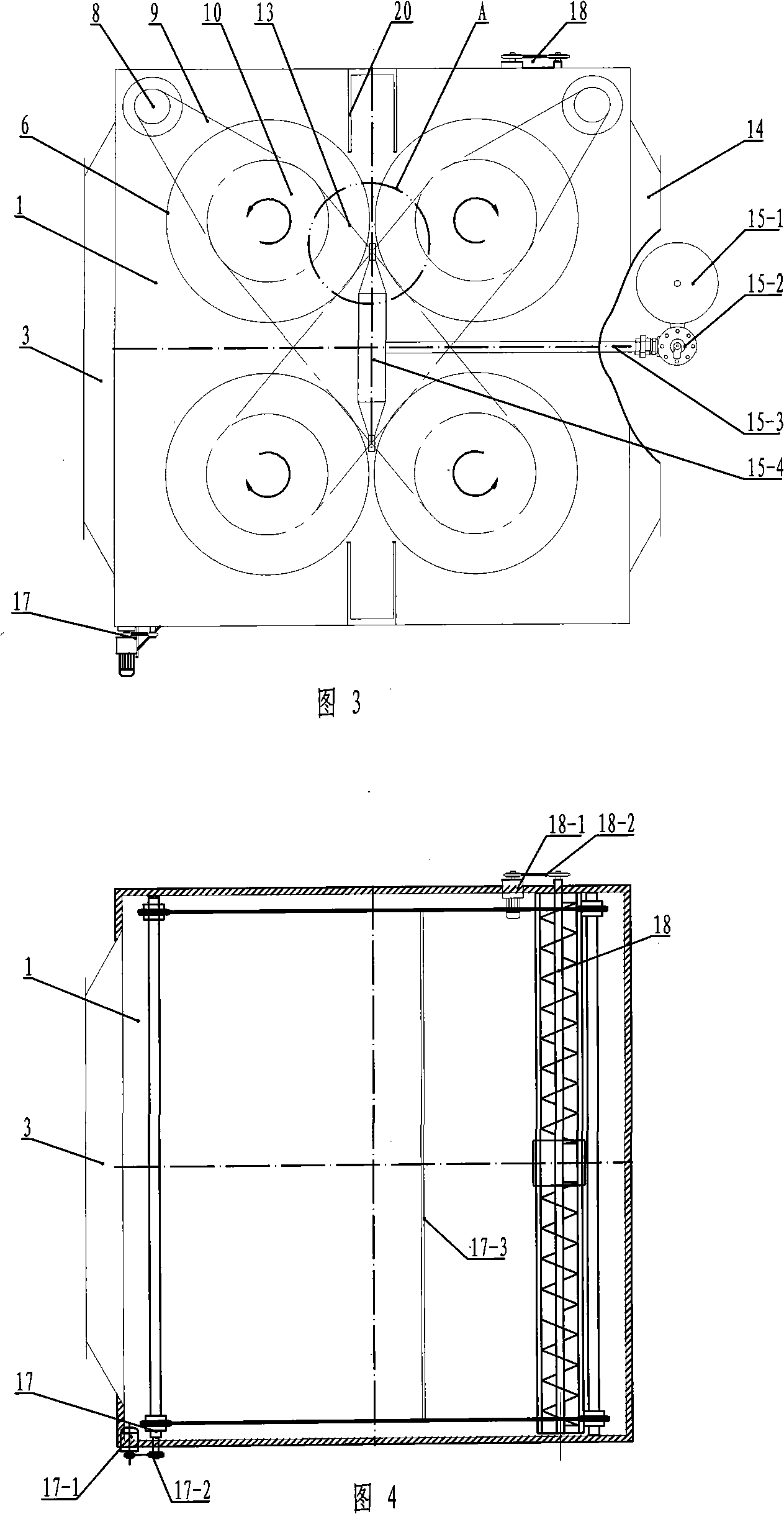

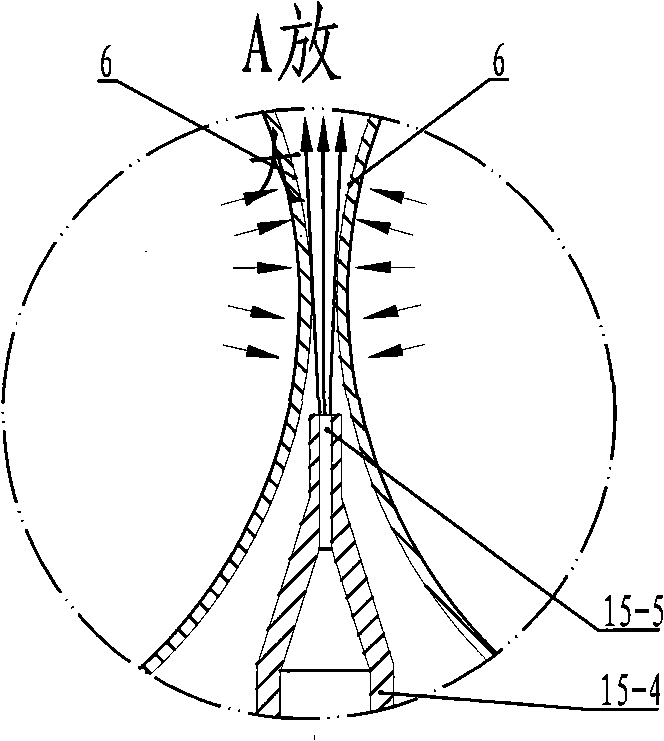

[0026] As shown in Figures 1, 2, 3, and 4: the rotary filter cartridge air dust collector, the box body 1 is a steel structure rectangular cabinet frame, and the outside of the cabinet frame is surrounded by guard plates to form a fully enclosed box body; the side of the box body 1 Make a rectangular air inlet 3 to be purified in the lower part, and make a rectangular purified air outlet 14 in the upper part of the other side; the upper part of the inner cavity of the box body 1 is fixed with the upper connecting plate 1-2, and the lower part is fixed with the lower connecting partition 1-1; the upper connecting plate The lower side of 1-2 fixes the upper partition 7-1 and the lower partition 7-2 horizontally; the gap between the upper and lower partitions 7-1 and 7-2 cuts off the side plates on both sides of the box body 1 , forming the normal-pressure air inlet 7 connected to the outside of the box; the lower partition 7-2 and the lower connecting partition 1-1 divide the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com