High-strength lightweight aggregate concrete and preparation method thereof

A lightweight aggregate concrete and lightweight aggregate technology, applied in the field of building material concrete, can solve problems such as the failure to effectively improve the slump of lightweight aggregate concrete, reduce interface defects, improve mechanical properties and working performance, reduce The effect of slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

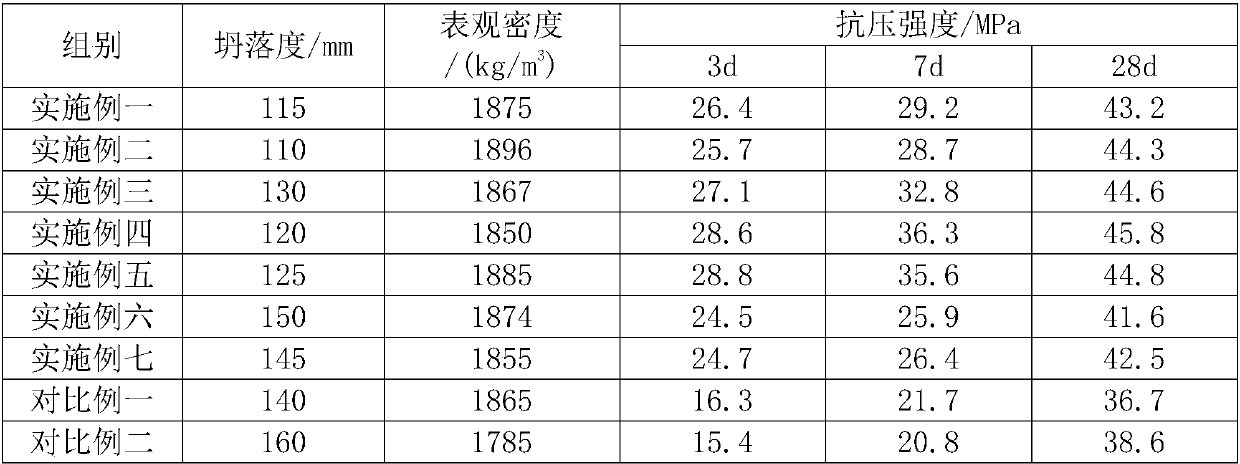

Examples

preparation example 1

[0029] Preparation Example 1 Mix 30kg of polypropylene, 3.2kg of vinyl silane, and 0.4kg of dibenzoyl peroxide in a mixer, mix them evenly, and use a short fiber spinning machine to melt, plasticize and extrude at 190°C After stretching, spinning, winding and chopping, the modified polypropylene fiber with an average diameter of about 0.3±0.1mm and a length of 15mm is obtained.

preparation example 2

[0030] Preparation Example 2 Put 30kg of polypropylene, 3kg of vinyl silane, and 0.3kg of dibenzoyl peroxide in a mixer and mix them evenly. After stretching, spinning, winding and chopping, the modified polypropylene fiber with an average diameter of about 0.3±0.1mm and a length of 15mm is obtained.

[0031] Preparation Example 3 Mix 30kg of polypropylene, 2.8kg of vinyl silane, and 0.2kg of dibenzoyl peroxide in a mixer, mix them evenly, and melt, plasticize and extrude them with a short fiber spinning machine at 210°C After stretching, spinning, winding and chopping, the modified polypropylene fiber with an average diameter of about 0.3±0.1mm and a length of 15mm is obtained.

Embodiment 1

[0033] Embodiment 1 The embodiment provides a preparation method of high-strength lightweight aggregate concrete, comprising the following steps: weighing 262.5kg of cement, 187.5kg of fly ash ceramsite, 125kg of gangue ceramsite, and 137.5kg of shale Ceramsite, 212.5kg machine-made sand, 87.5kg river sand, 162.5kg fly ash, 22.5kg modified polypropylene fiber, 6.25kg water reducer, 0.75kg slump retaining agent, 0.25kg cellulose Ether, 0.05 kg of polyvinyl alcohol, 1.2 kg of polyacrylamide and 162.5 kg of water. Among them, the stone powder content of the machine-made sand is 5%. The modified polypropylene fiber used in this example is the modified polypropylene fiber prepared in Preparation Example 1. The water reducer used in this example is a polycarboxylate water reducer. The slump-retaining agent used in this embodiment is sodium citrate, and other ingredients and materials are common commercially available products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com