All-hydraulic guillotines machine

A paper cutter, full hydraulic technology, which is applied in the field of improvement and invention of paper cutters, can solve the problems of no effective support of the knife bed, unstable cutting, falling down of the knife bed, etc., and achieves outstanding substantive features and simple structure. , Crop stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

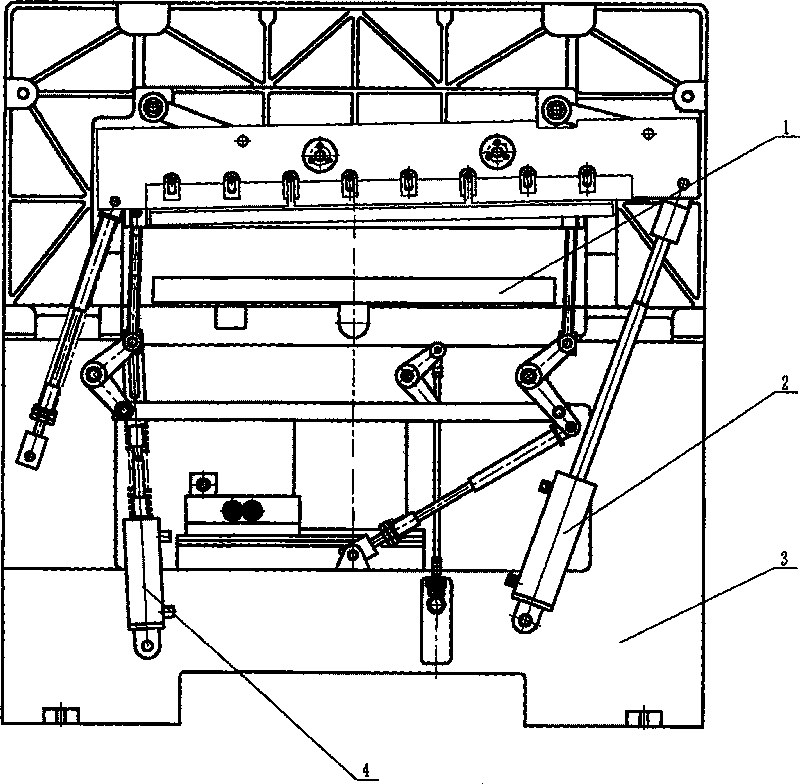

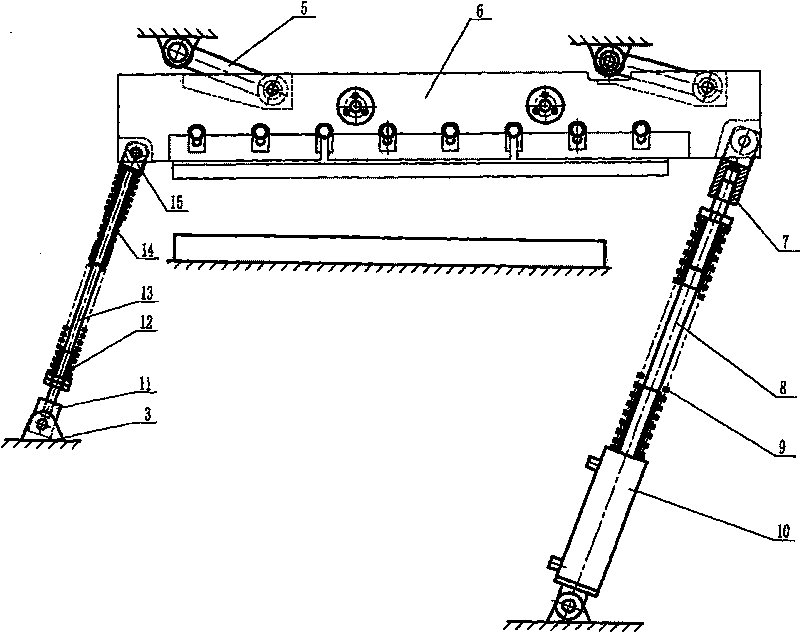

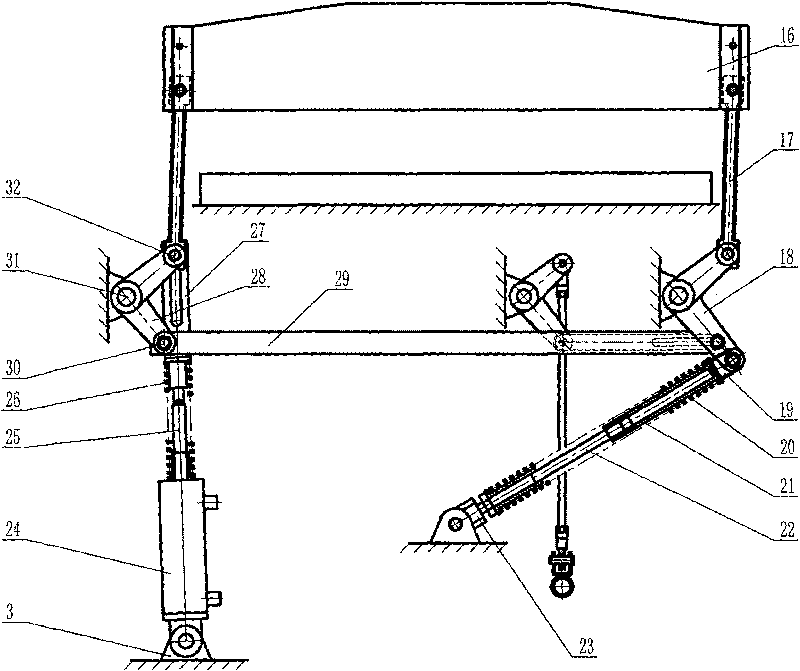

[0013] Refer to attached figure 1 , 2 , the full hydraulic paper cutter includes a body 3, a workbench 1, a paper pressing system 4, and a cutting system 2. The cutting system has a four-bar linkage, and the four-bar linkage includes a knife bed 6 and is connected to it. Two knife bed booms 5 and two cutting spring return mechanisms on the left and right, the knife bed boom 5 is arranged above the knife bed, one end is hinged with the body 3, the other end is hinged with the knife bed (6), the knife bed boom The movement trajectory of the knife bed is limited, and the left and right cutting spring return mechanisms are located on both sides below the knife bed, wherein the left cutting spring return mechanism includes guide rod 13, guide sleeve 14, left cutting spring 12, upper and lower support Seats 15, 11, the upper support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com