Glue-pasting module and glue-pasting device and flexible circuit board processing machine

A gluing device and gluing technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of low processing efficiency and achieve high processing efficiency, stable feeding, precise cutting, and non-slip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

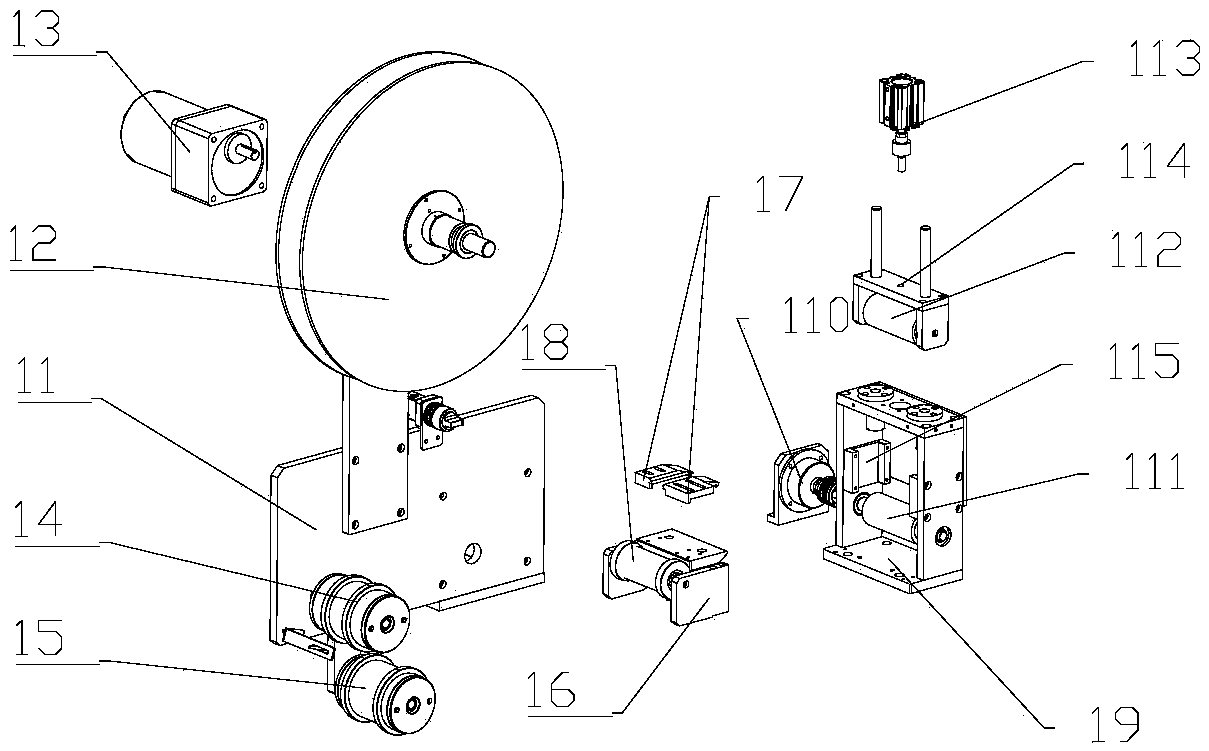

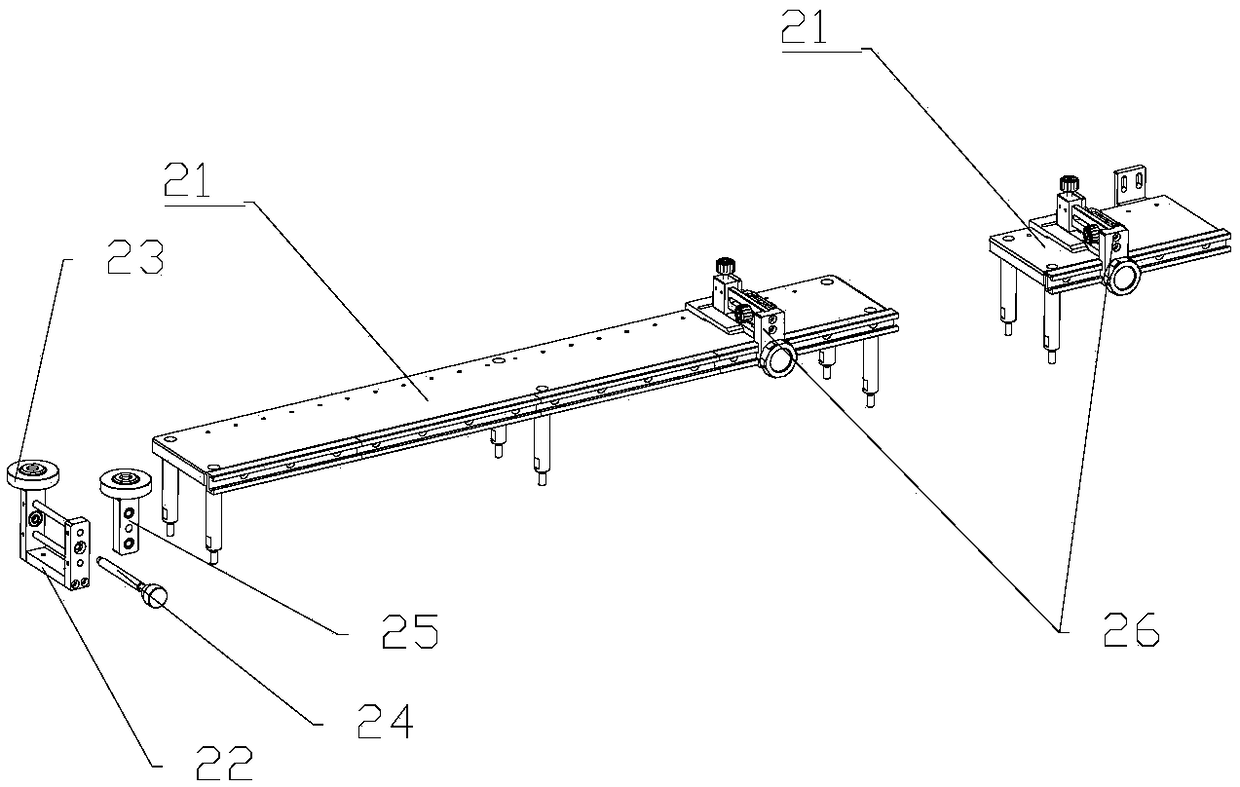

[0032] Such as Figure 5-Figure 14 The shown gluing device 3 includes a fixed support plate 31, a second cylinder 32, a gluing module 33, an adjustment guide wheel assembly 34, a gluing lower function module 35 and a first linear rail moving assembly 36; the second cylinder 32 is vertically installed on the back of the fixed support plate 31; the glue-applying module 33 is connected on the fixed support plate 31 through the first linear rail shift assembly 36, and the glue-applying module 33 is connected to the telescopic mandrel of the second cylinder 32 through the connecting block 37 Connect; the function module 35 under the adhesive tape is located directly below the adhesive tape module 33; the adhesive tape module 33 and the functional module 35 under the adhesive tape work together to realize the processes of feeding, pasting, cutting, and testing of the adhesive tape; adjust Guide wheel assembly 34 is two groups, is respectively positioned at the two ends of function m...

Embodiment 2

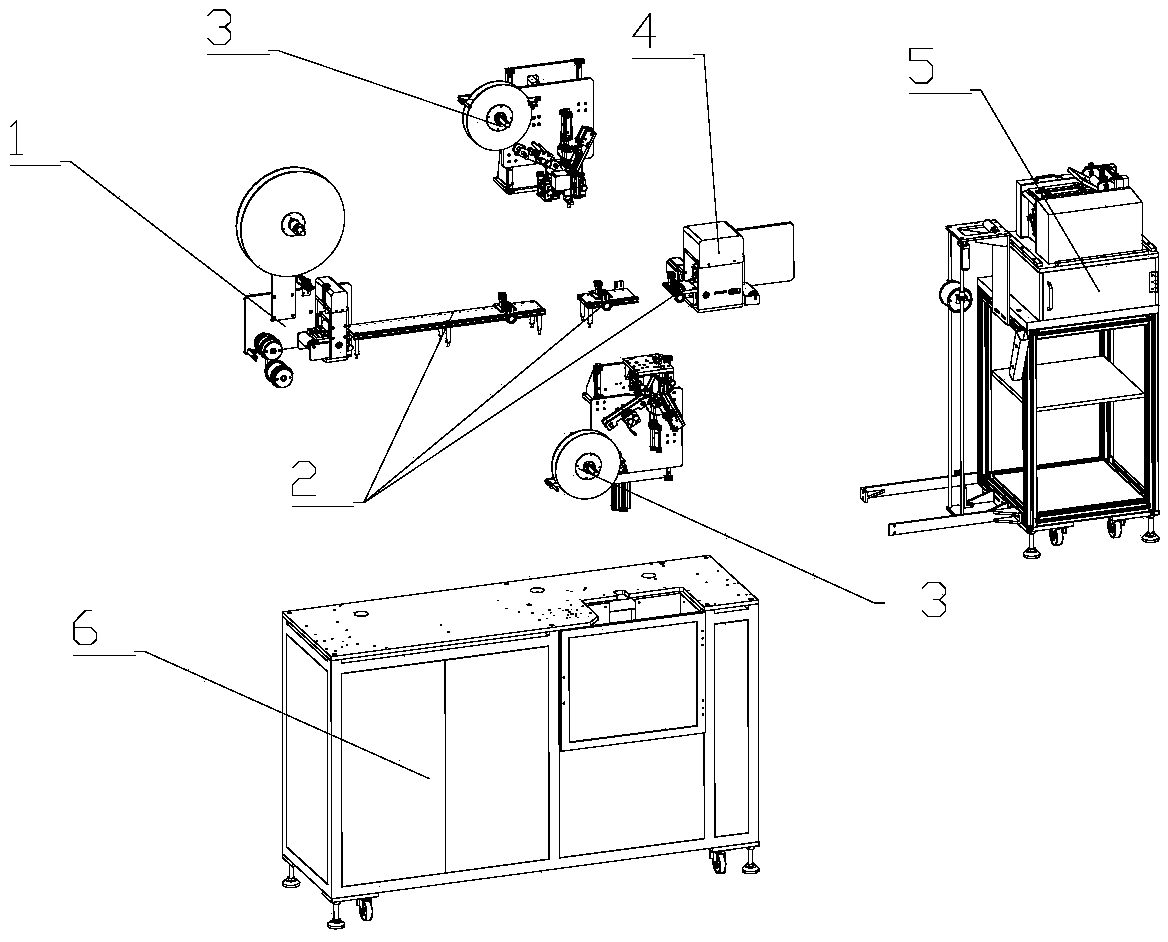

[0036] Such as Figure 1-Figure 22 The shown flexible circuit board processing machine includes a frame 6, a feeding device 1, a material passing platform assembly 2, a gluing device 3, a gluing device 4 and a cutting device 5, a feeding device 1, a material passing platform assembly 2, The gluing device 3 and the gluing device 4 are installed on the frame 6, the feeding device 1 is connected with the feeding platform assembly 2, the position of the gluing device 4 corresponds to the feeding platform assembly 2, the gluing device 3, the gluing device 4 and the The cutting device 5 is sequentially engaged.

[0037] Feeding device 1 is used to feed the pre-made coiled wire; material passing platform assembly 2 is used to guide the wire into a straight line, and realize gluing at this place; there are two gluing devices 3, upper and lower Arrangement, used to paste the upper and lower adhesive tapes; the glue pressing device 4 is connected with the end of the glue applying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com