Patents

Literature

51results about How to "Uniform pumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

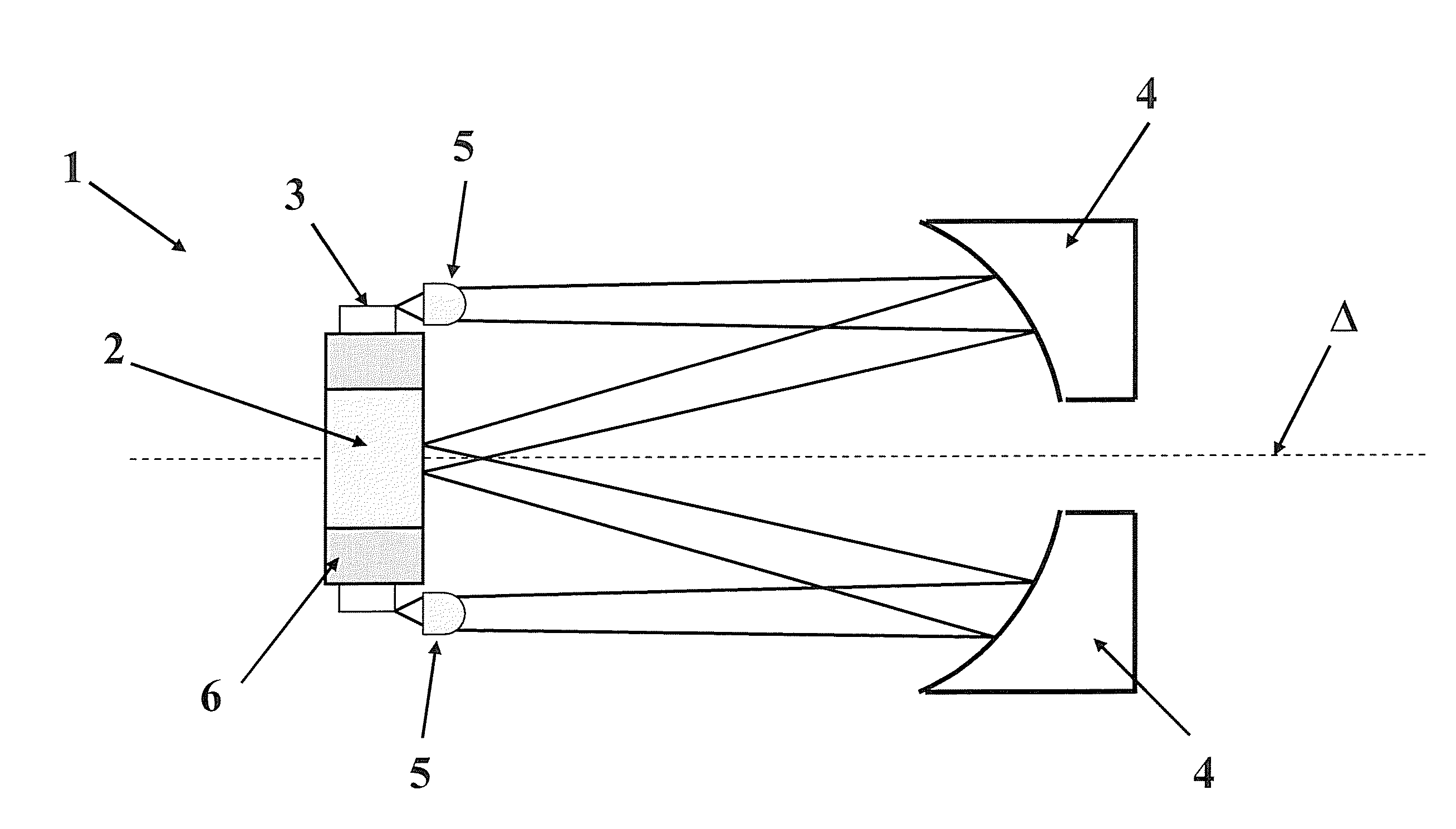

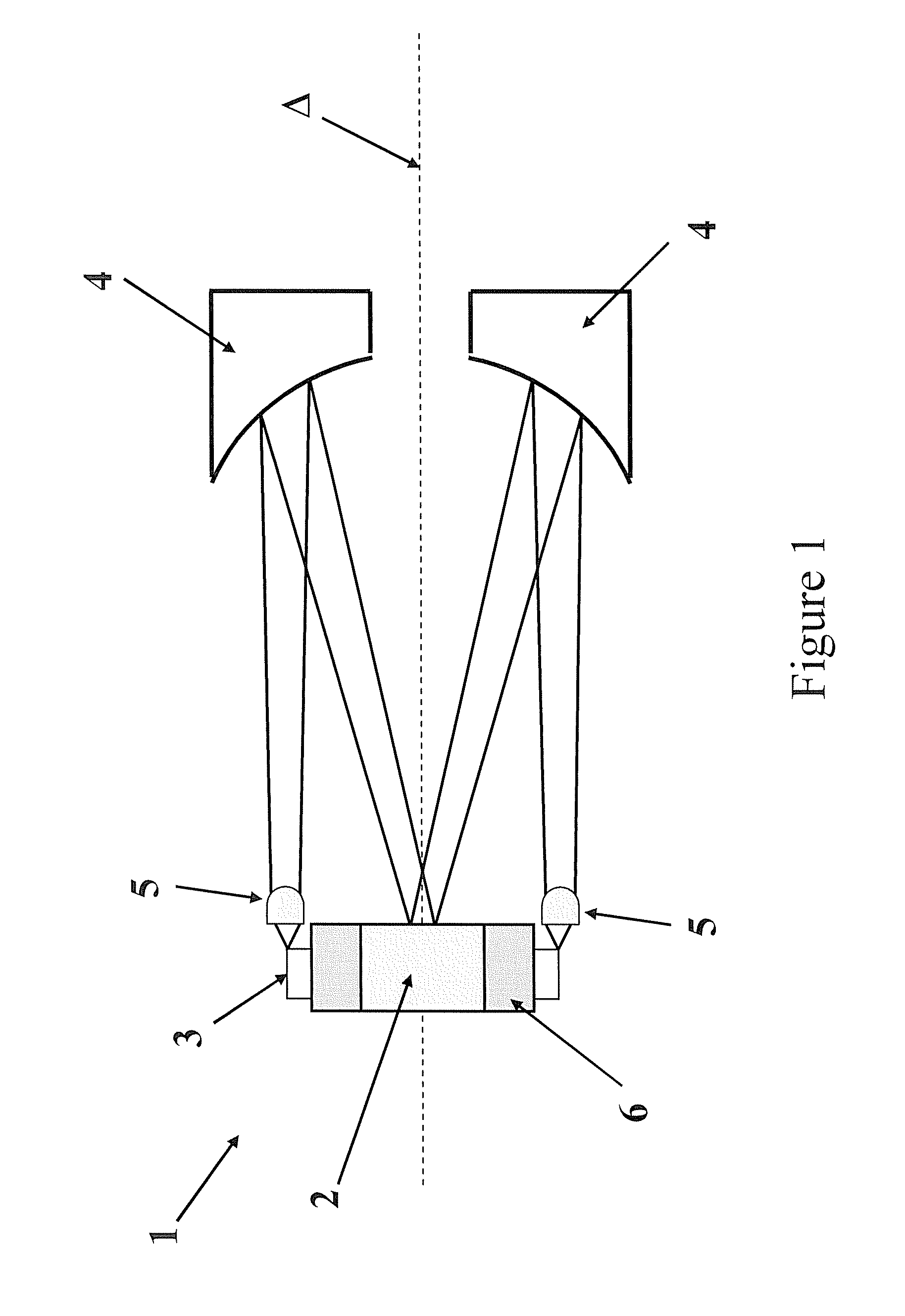

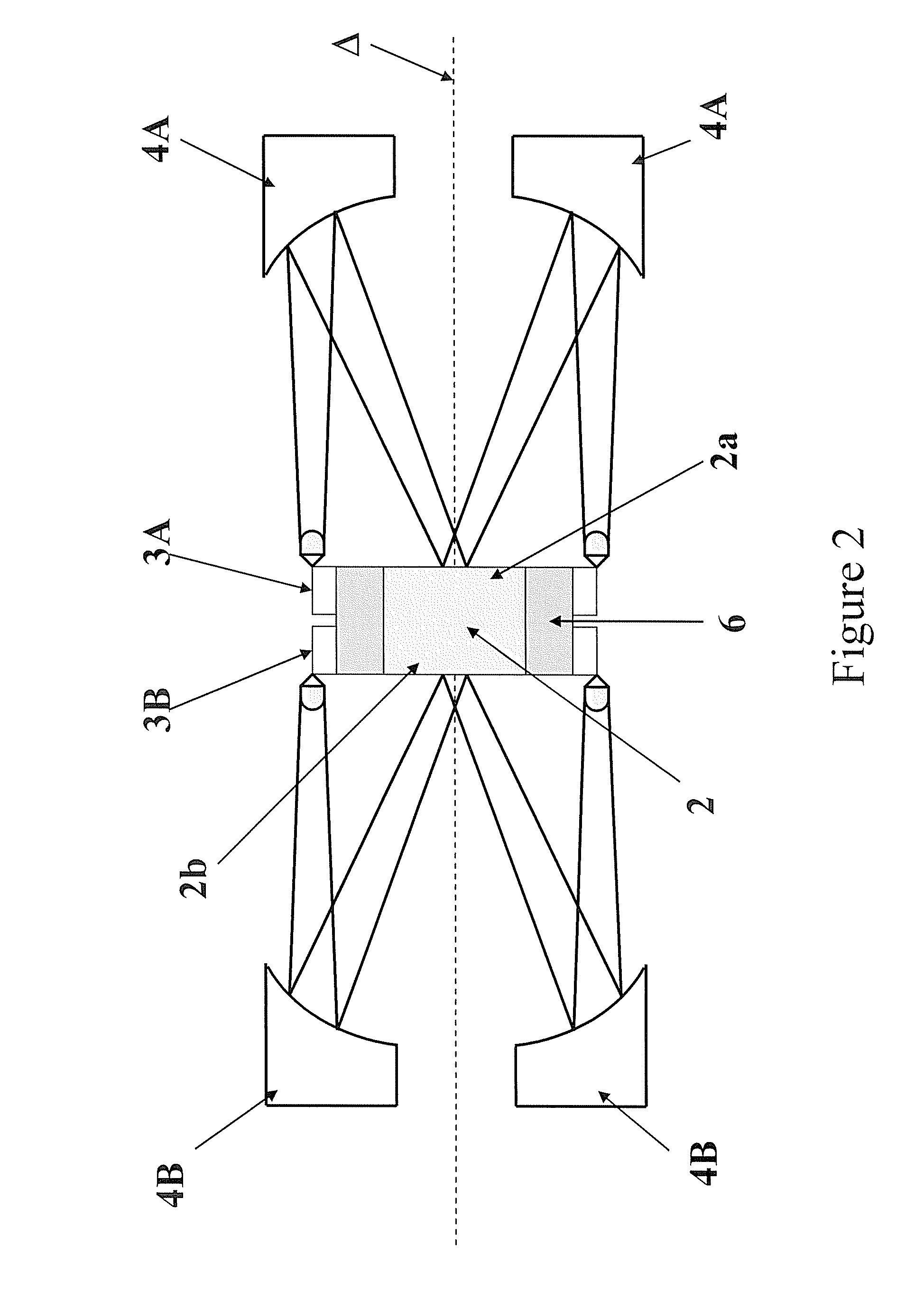

Device For Longitudinal Pumping Of A Laser Medium

InactiveUS20100014547A1Improve compactnessIncrease energy levelActive medium shape and constructionSemiconductor lasersLight beamOptoelectronics

The invention concerns a device for longitudinal pumping of an amplifying laser medium comprising at least one laser diode capable of emitting at least one laser beam, means for focusing said laser beam onto said amplifying laser medium and means for collimating said laser beam capable of generating a collimated laser beam. The invention is characterized in that said focusing means comprise at least one mirror, said mirror being arranged such that said collimated beam is reflected towards the amplifying medium.

Owner:CENT NAT DE LA RECHERCHE SCI

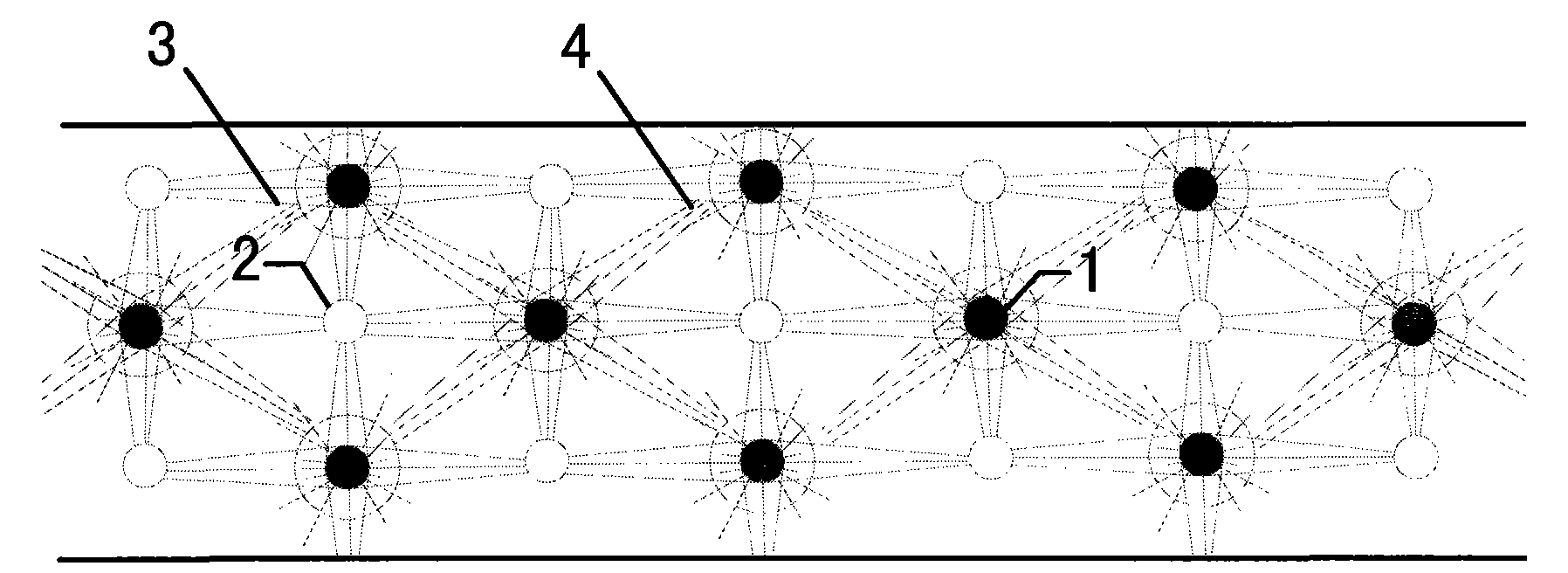

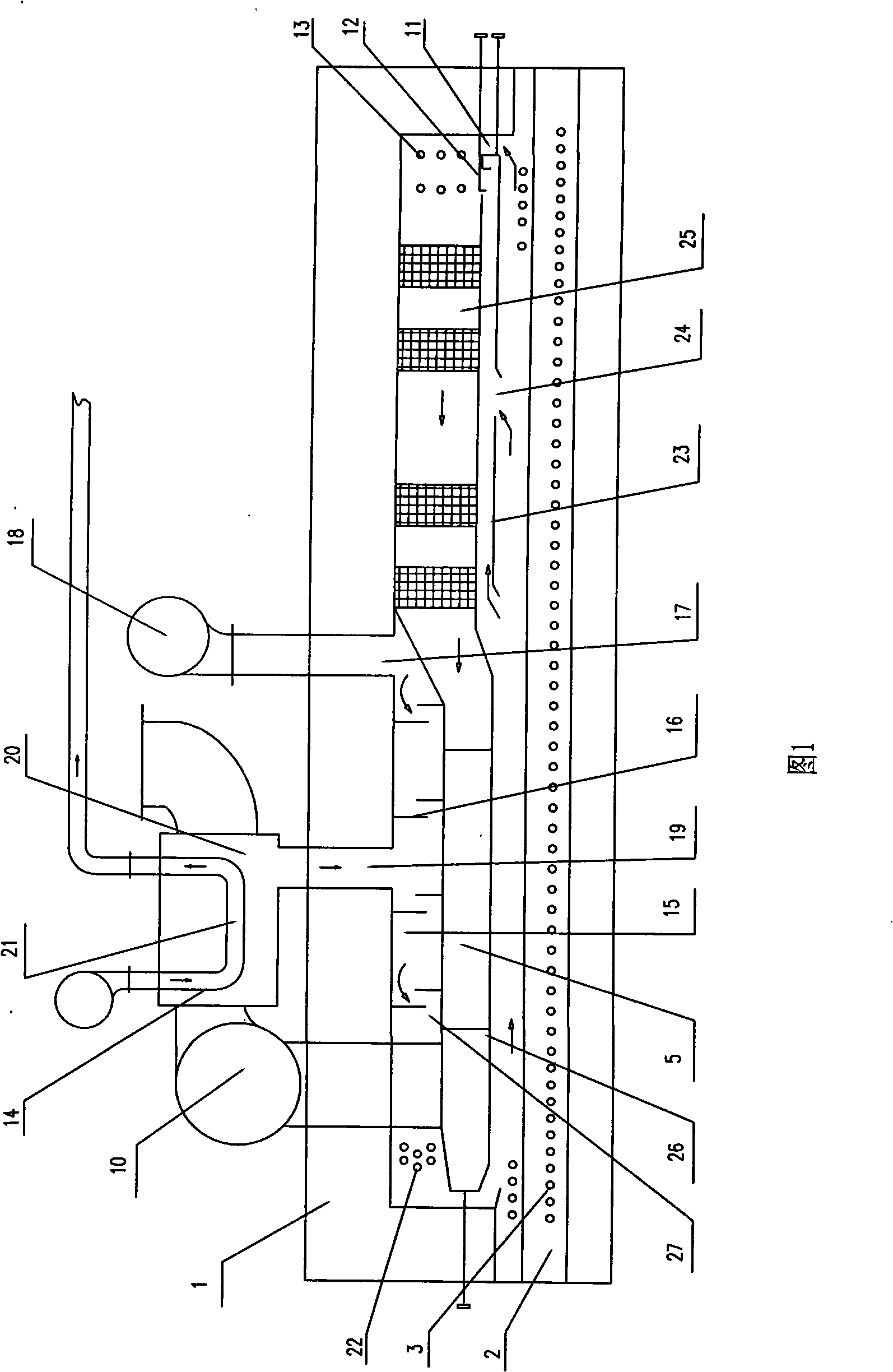

Drilling-explosion-pumping triadic gas extraction method

The invention relates to a drilling-explosion-pumping triadic gas extraction method, which is most suitable for regional gas extraction of a high gas and low permeability coal seam. The method comprises the following steps: alternately arranging hole positions of drainage holes and blast holes of an along bed or a cross seam on a coal seam in front of a coal mining or tunneling working surface; and performing construction work on the drainage holes one by one, and performing blasting operation, wherein through the edgetone effect of denotation gas in the blast holes, a columnar compression crushing circle and a crack body which passes through and blasts in the direction of a line of centers of the blast holes and the extraction holes are generated on the periphery of a blasting hole to transfer the ground stress, improve the gas permeability of a coal body, relieve the pressure in a coal body and facilitate for drainage of gas in the coal body. The gas permeability of the coal body can be improve by around 20 to 50 times, the gas extraction quantity of haplopore can be increased by 5 to 10 times averagely, the gas extraction concentration is more than or equal to 50 percent, and the gas extraction rate of a robbing working surface is more than or equal to 80 percent. After pressure releasing and permeability improving of drilling, explosion and pumping, the gas pre-extraction time can be shortened by half, and the number of drilling holes of gas extraction is decreased by 20 to 30 percent; and the method achieves safe, high-efficiency and uniform extraction of the gas in the high gas and low permeability outburst coal seam.

Owner:CHINA UNIV OF MINING & TECH

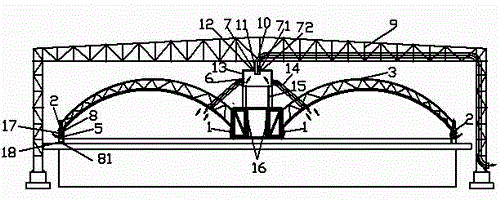

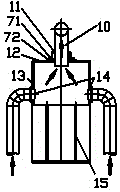

Steam sterilization process and steam sterilization apparatus employed the same

The invention relates to a steam sterilizing process for the disinfection of medical appliances in hospital, and the steam sterilizer employing the steam sterilizing process, which comprises the steps of vacuumizing, preheating, sterilizing and cooling down. The steam sterilizer comprises a steam sterilizing box, a valve group, an air filter, a steam generator, a vacuum pump and an automatic control system.

Owner:何德贤

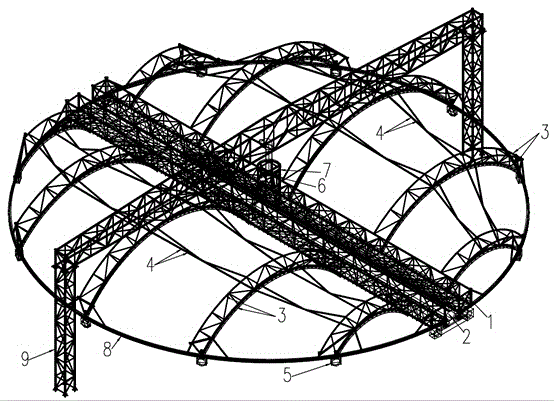

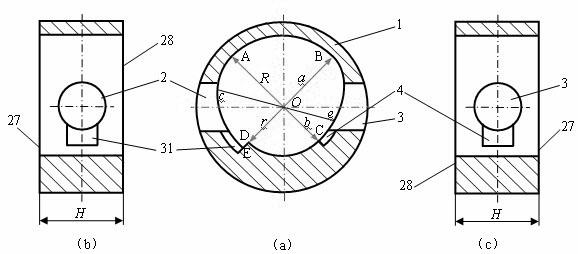

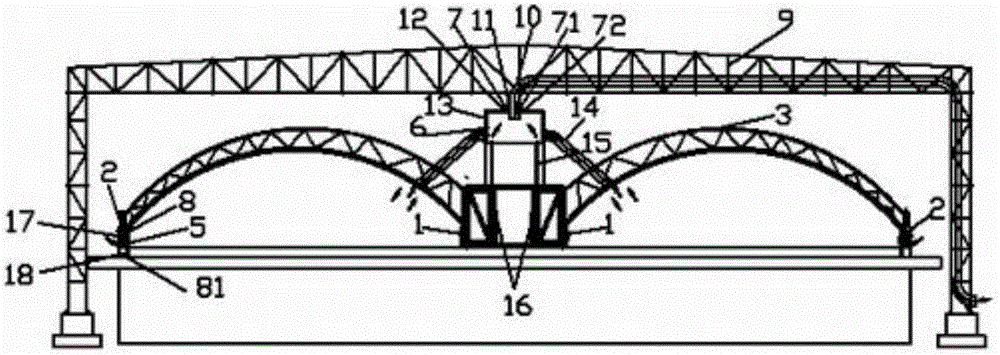

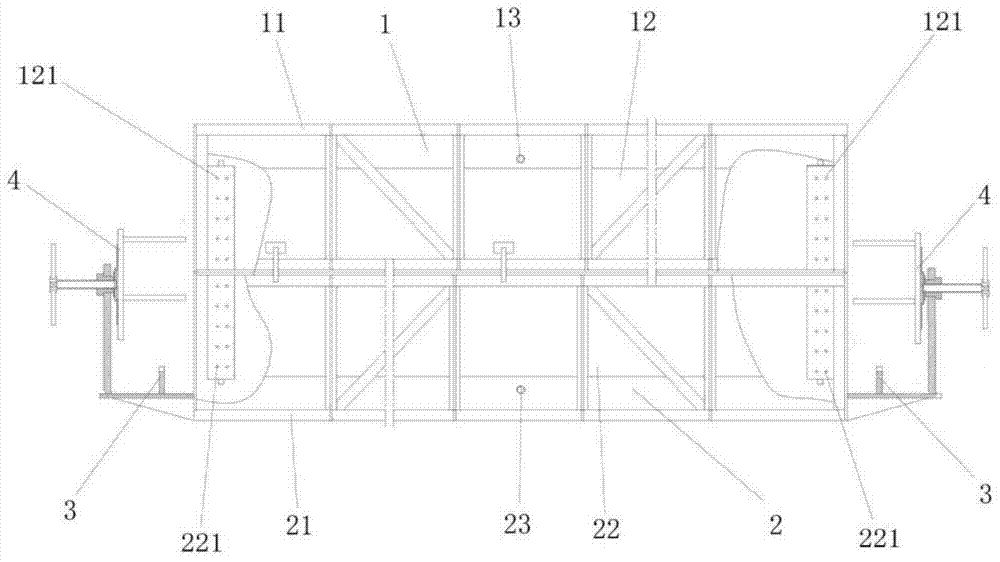

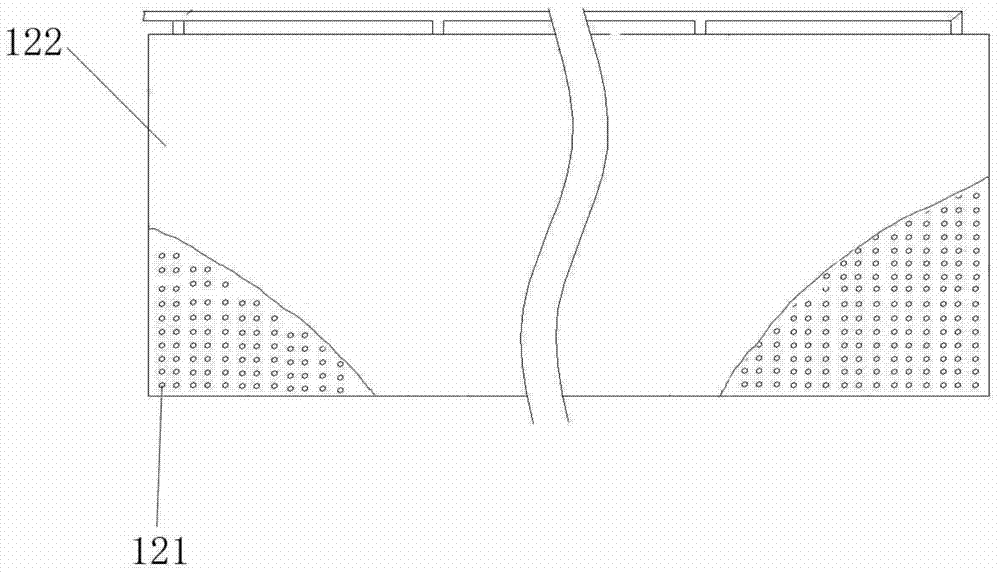

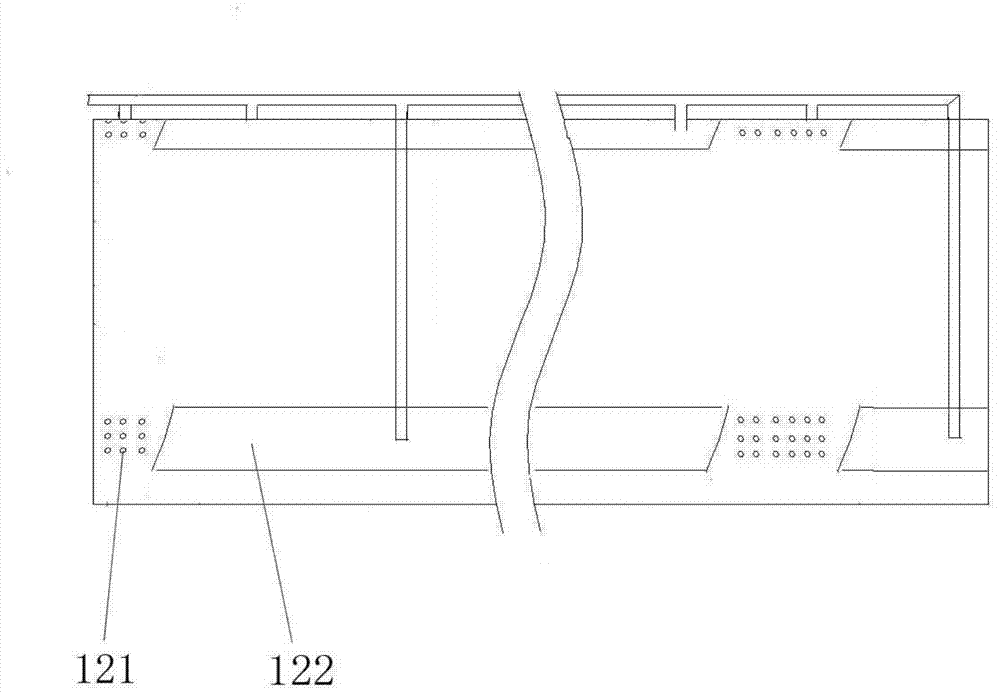

Sealing cover for circular pond body of synchronous-rotation reverse hanging membrane structure

The invention discloses a sealing cover for a circular pond body of a synchronous-rotation reverse hanging membrane structure. The sealing cover comprises a girder and a circular track beam. The girder is in rigid connection with the circular track beam. Upward-arch truss beams are connected between the circular track beam and the girder in a spaced mode. A connecting truss beam is arranged between every two adjacent upward-arch truss beams. The girder, the circular track beam, the upward-arch truss beams and the connecting truss beams form a rigid support. A sealing membrane is fixedly arranged on the lower face of the rigid support in a reverse hanging mode. The periphery of the sealing membrane falls naturally and forms a sliding sealing face with a concrete walkway plane of the circular pond body. Bearing travelling wheels are installed on the lower edge of the circular track beam. The sealing cover is further provided with a gas collecting device for collecting gas inside the circular pond body. The gas collecting device collects gas inside the pond body in the mode of middle shaft air and peripheral air supplementation. The sealing cover is rapid to install, good in mobility, long in service life and applicable to any large-span pond body, and reduces occupation of a site.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

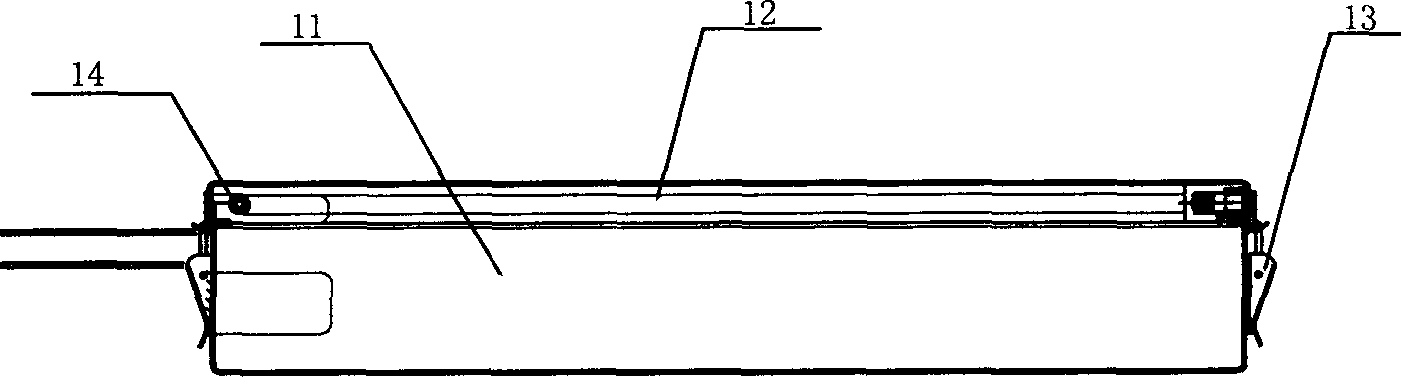

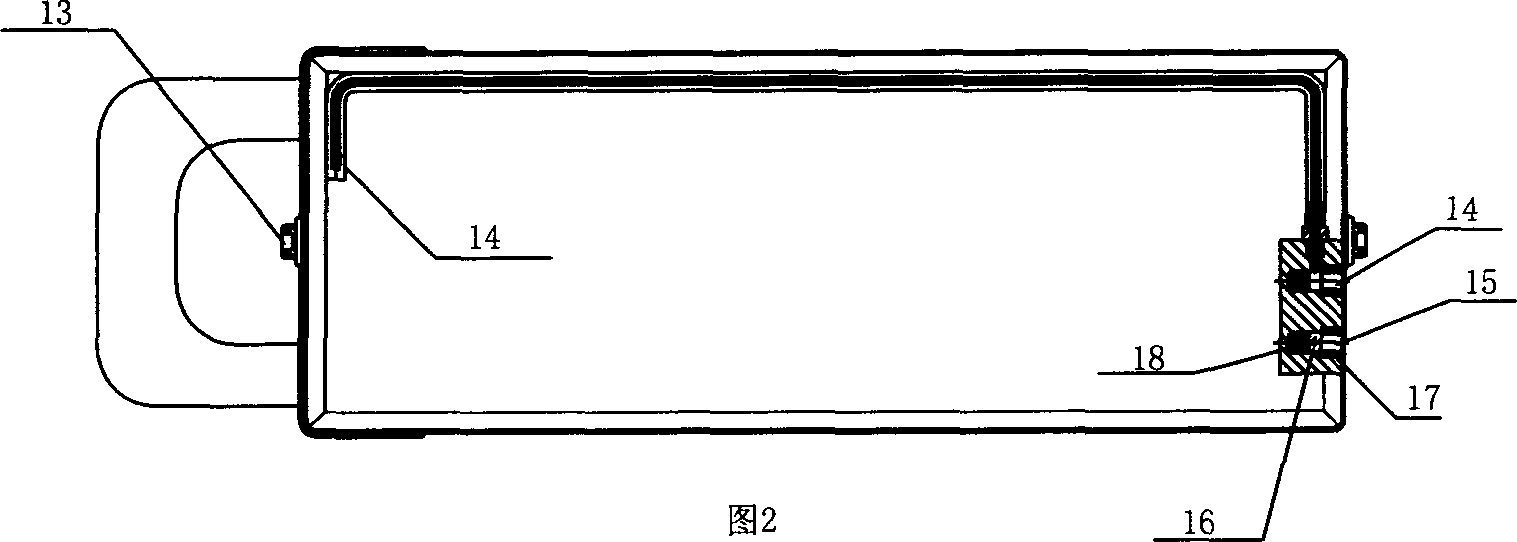

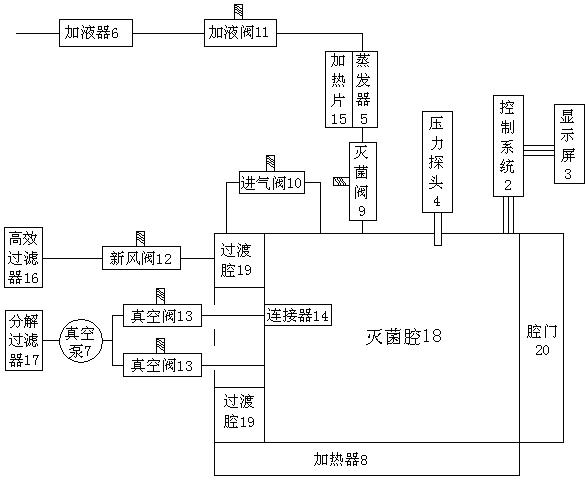

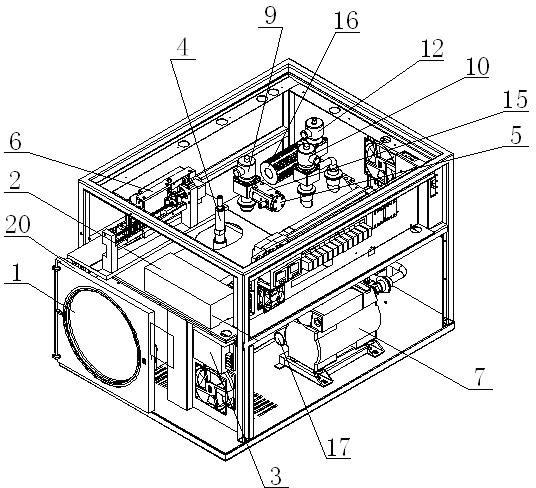

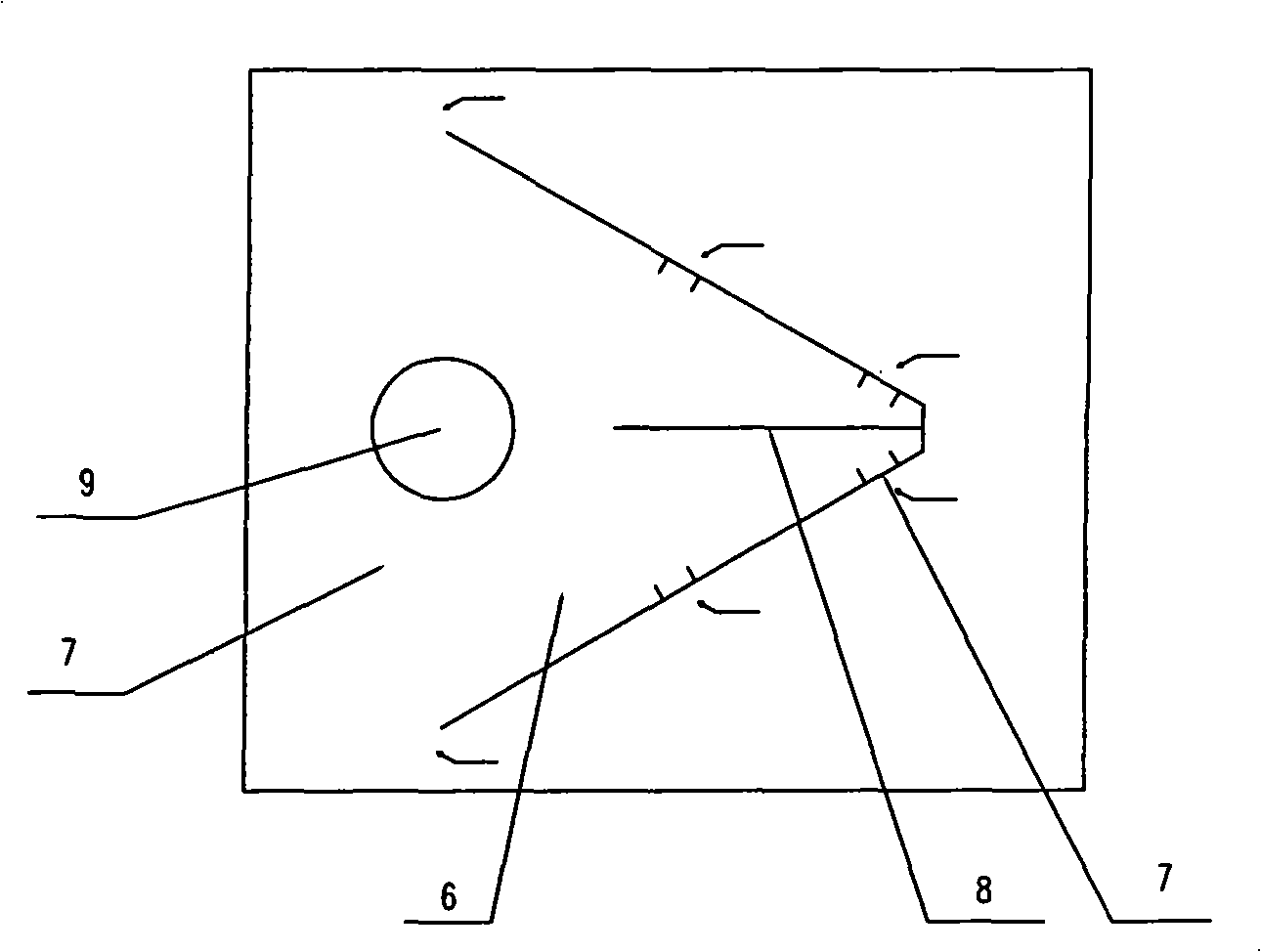

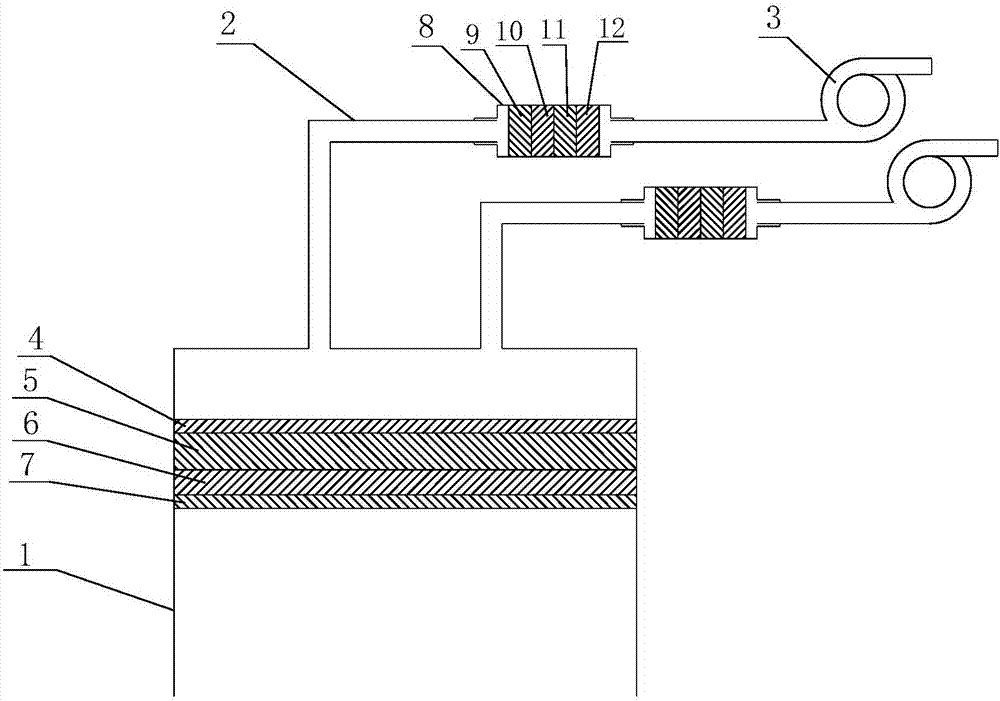

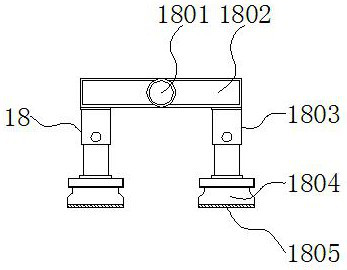

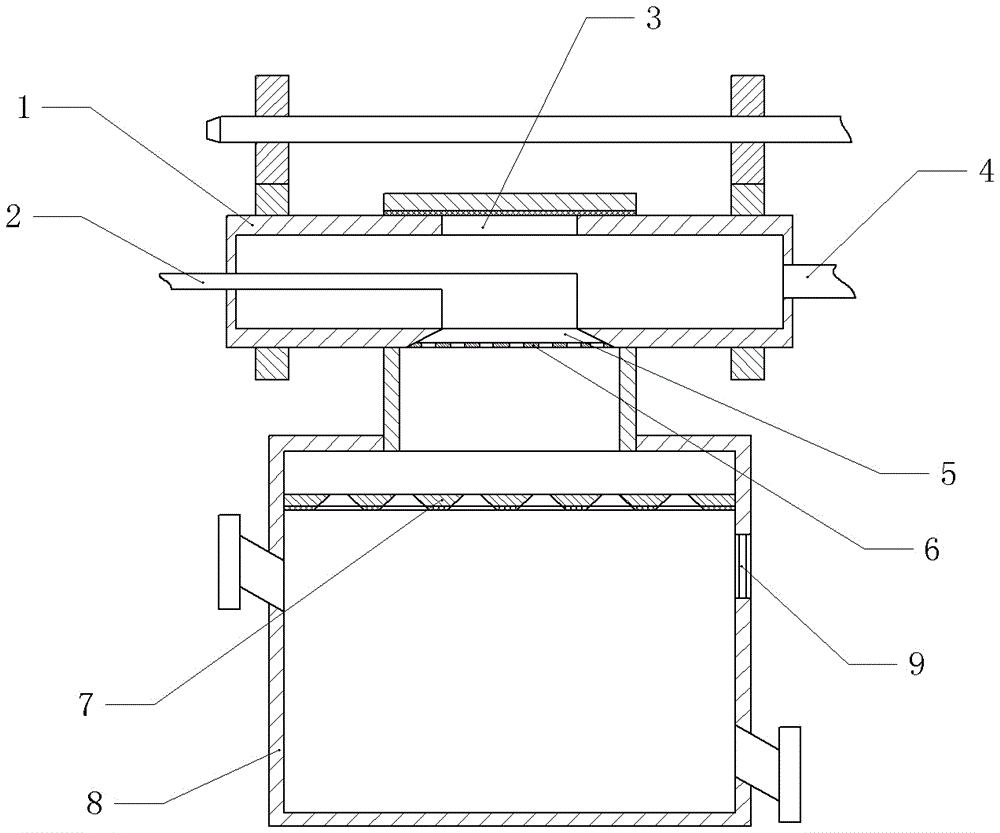

Hydrogen peroxide low-temperature sterilizing equipment and use method thereof

ActiveCN102350003AImproved vaporizationEasy dischargeChemicalsVacuum pumpLow temperature sterilization

The invention discloses hydrogen peroxide low-temperature sterilizing equipment and a use method thereof. The sterilizing equipment comprises a cavity body (1), an evaporator (5), a liquid feeder (6), a vacuum pump (7), a heater (8) and a high-efficiency filter (16), wherein the cavity body (1) is divided into a sterilizing cavity (18) and a transition cavity (19); the sterilizing cavity (18) is connected with the outlet end of the evaporator (5) through a sterilizing valve (9); the inlet end of the evaporator (5) is connected with the liquid feeder (6) through a liquid feeding valve (11); a heating sheet is arranged on the evaporator (5); the air suction end of the vacuum pump (7) is connected with the sterilizing cavity (18) through a vacuum valve (13); and the air outflow end of the vacuum pump (7) is connected with a decomposition filter (17). The sterilizing equipment can sterilize medical appliances at a low temperature, can carry out sufficient sterilization on the pipelines of the medical appliances with slender holes, and can also carry out filtration and decomposition on the used hydrogen peroxide vapor.

Owner:LAOKEN MEDICAL TECH

Pulsed steam sterilization process and steam sterilizer thereof

ActiveCN102423495AEvenly distributedShorten heating timeLavatory sanitoryHeatAutomatic controlMedical equipment

The invention discloses a pulsed steam sterilization process suitable for sterilizing medical equipment and a steam sterilizer for the steam sterilization process. The sterilization process comprises the following steps of vacuumizing, preheating, sterilizing, performing vacuum drying and the like. The steam sterilizer comprises a steam sterilization box, a valve bank, an air filter, a steam generator, a vacuum pump and an automatic control system. Compared with the prior art, the invention has the advantages that: by the pulsed steam sterilization process and the steam sterilizer thereof, a sterilization apparatus can be transported without packaging, the temperature raising and reduction time of the sterilization is shortened, the sterilization time of the apparatus is shortened, the labor intensity of medical care personnel is reduced, and the disinfection and sterilization are more complete and have a better effect.

Owner:何德贤

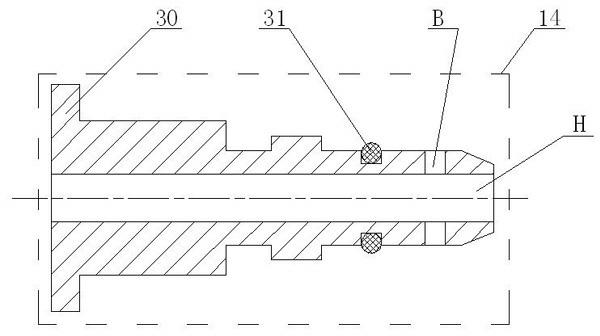

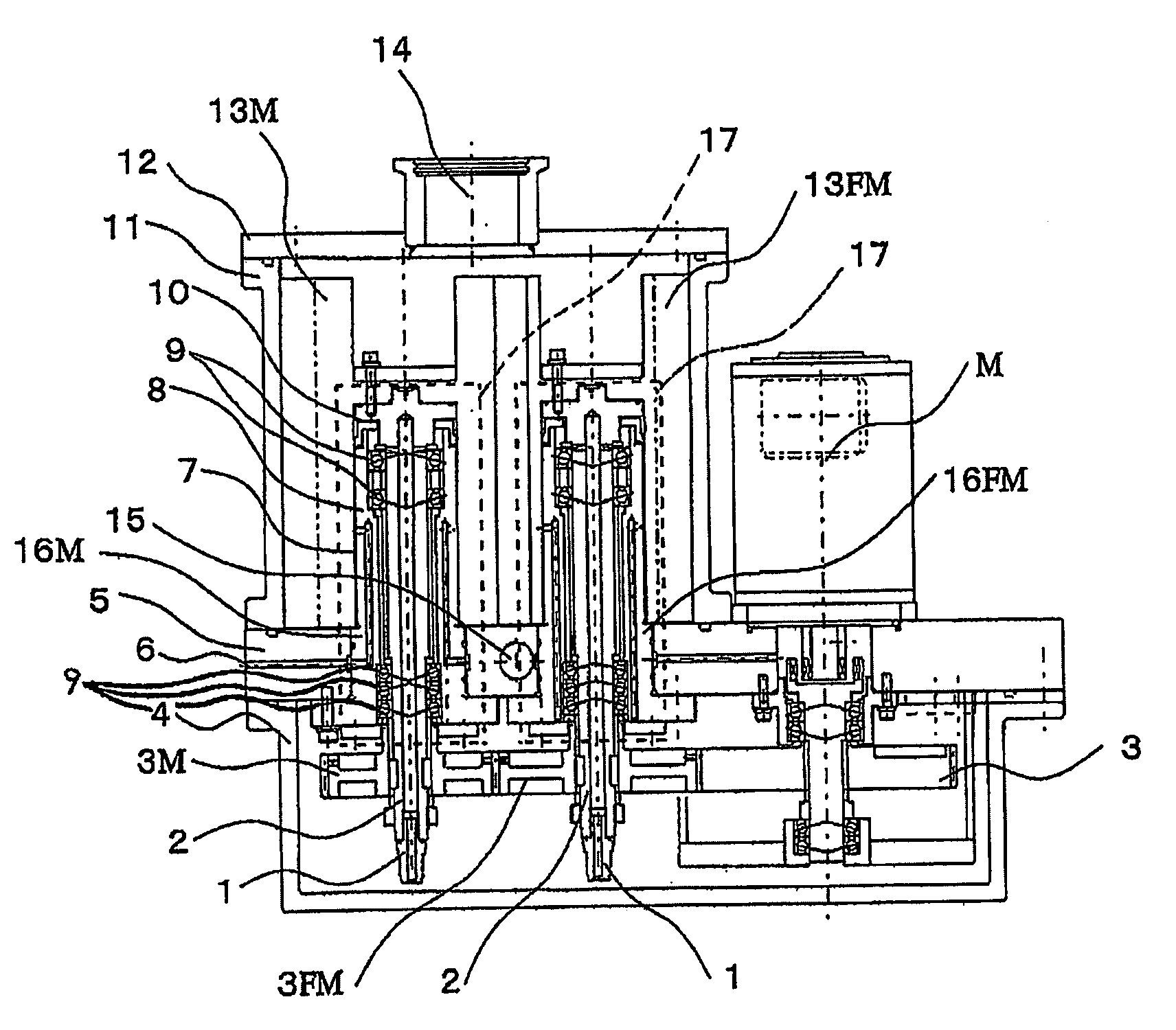

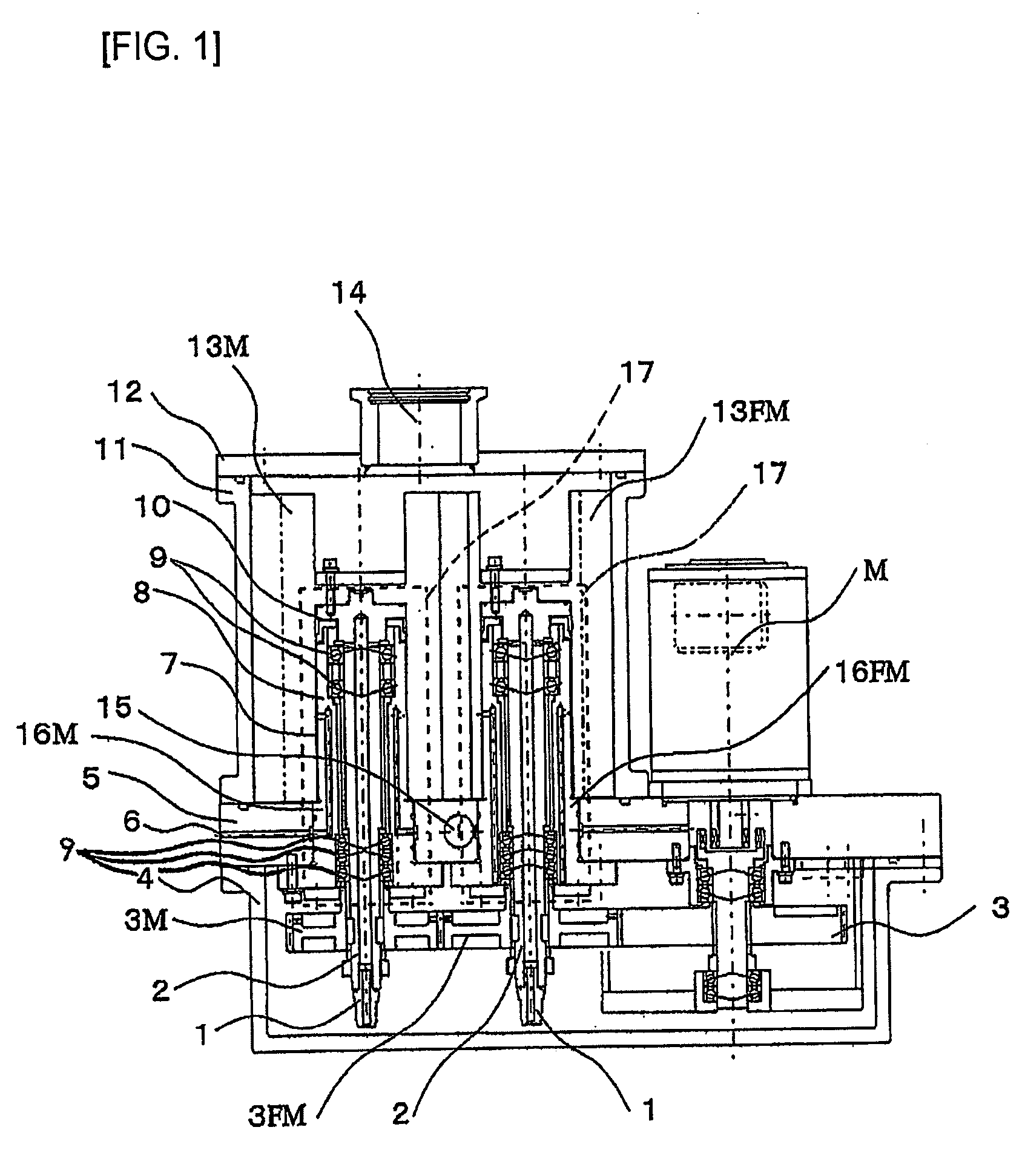

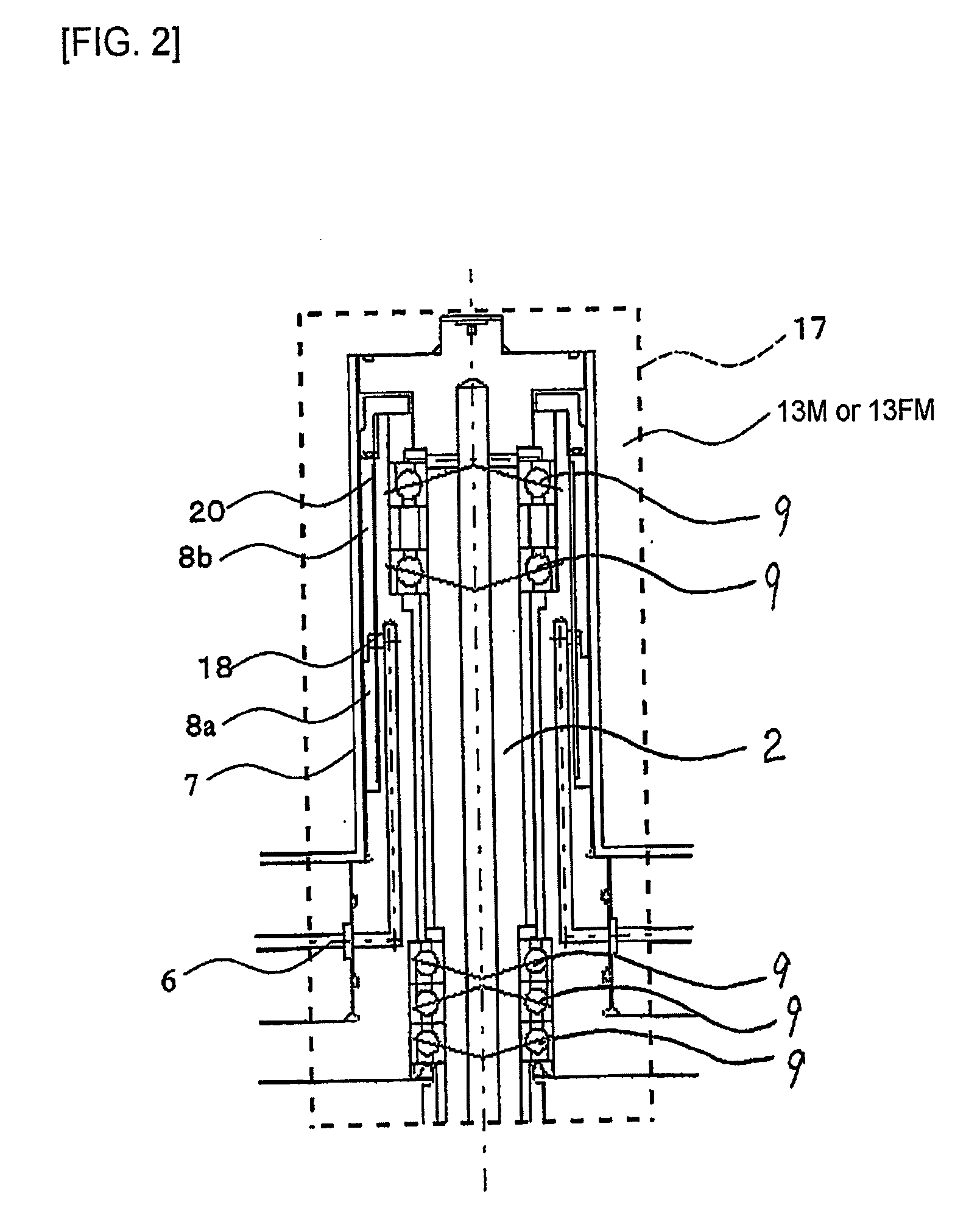

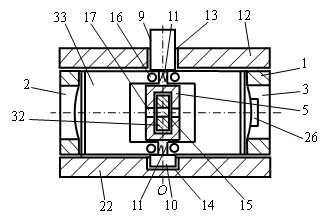

Vacuum pump

InactiveUS20070172376A1Consumption amount can be reducedAvoid corrosionEngine of counter-engagement typeEngine of intermeshing engagement typeEngineeringVacuum pump

An object of this invention is to provide a vacuum pump having shaft seals that prevent corrosion due to corrosive gas and further ensure smooth operation. A shaft seal structure (17) is provided around an outer circumferential surface of the bearing member (16M, 16FM) located on the cylinder inside of each of the screw rotors (13M, 13FM). The shaft seal structure (17) forms a static pressure seal. A seal gas is introduced between the outer circumferential surfaces of the bearing members (16M, 16FM) and the inner circumferential surfaces (7) of the rotor cylinders of the screw rotors (13M, 13FM) through the bearing members (16M, 16FM).

Owner:FOUND FOR ADVANCEMENT OF INT SCI

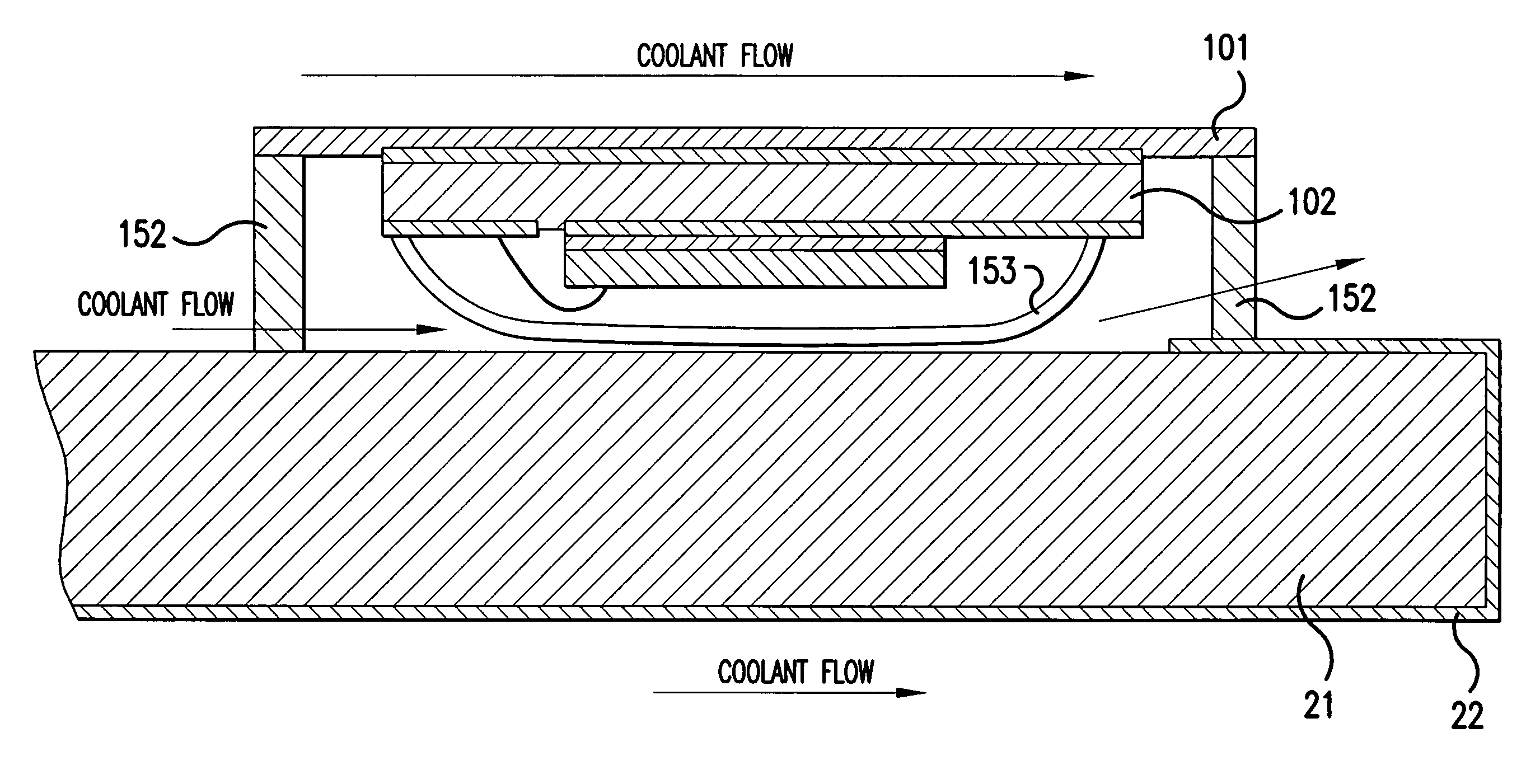

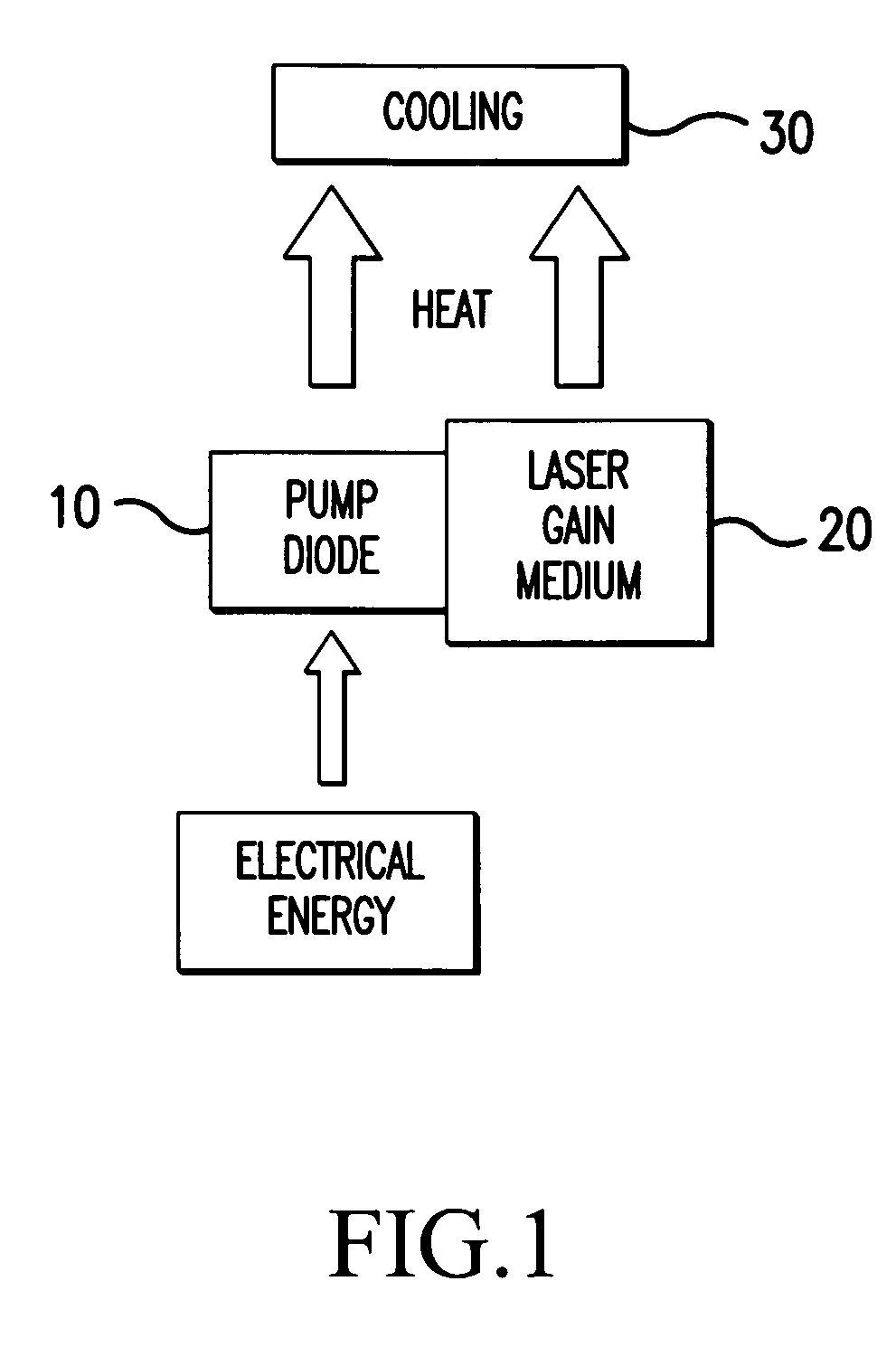

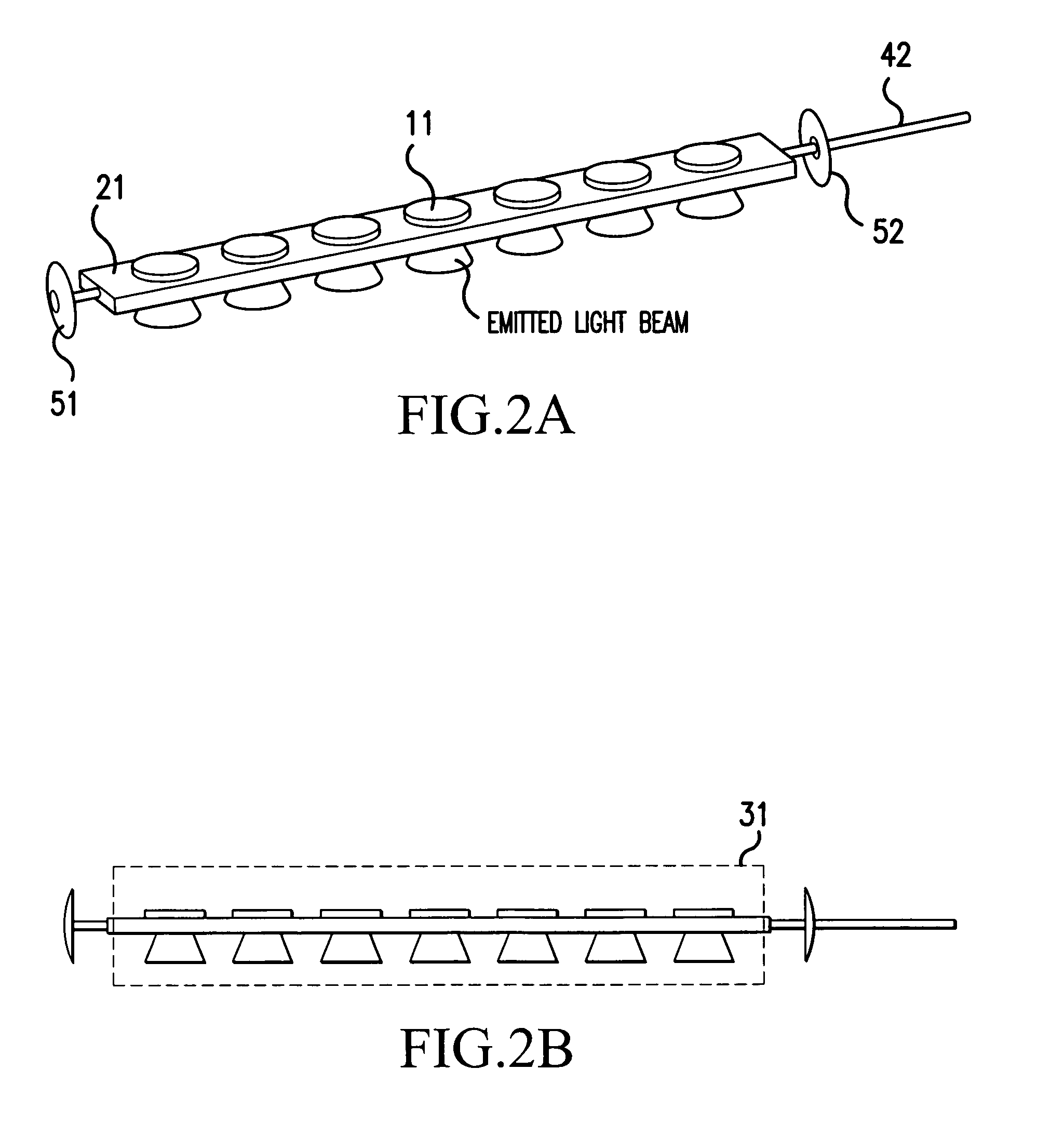

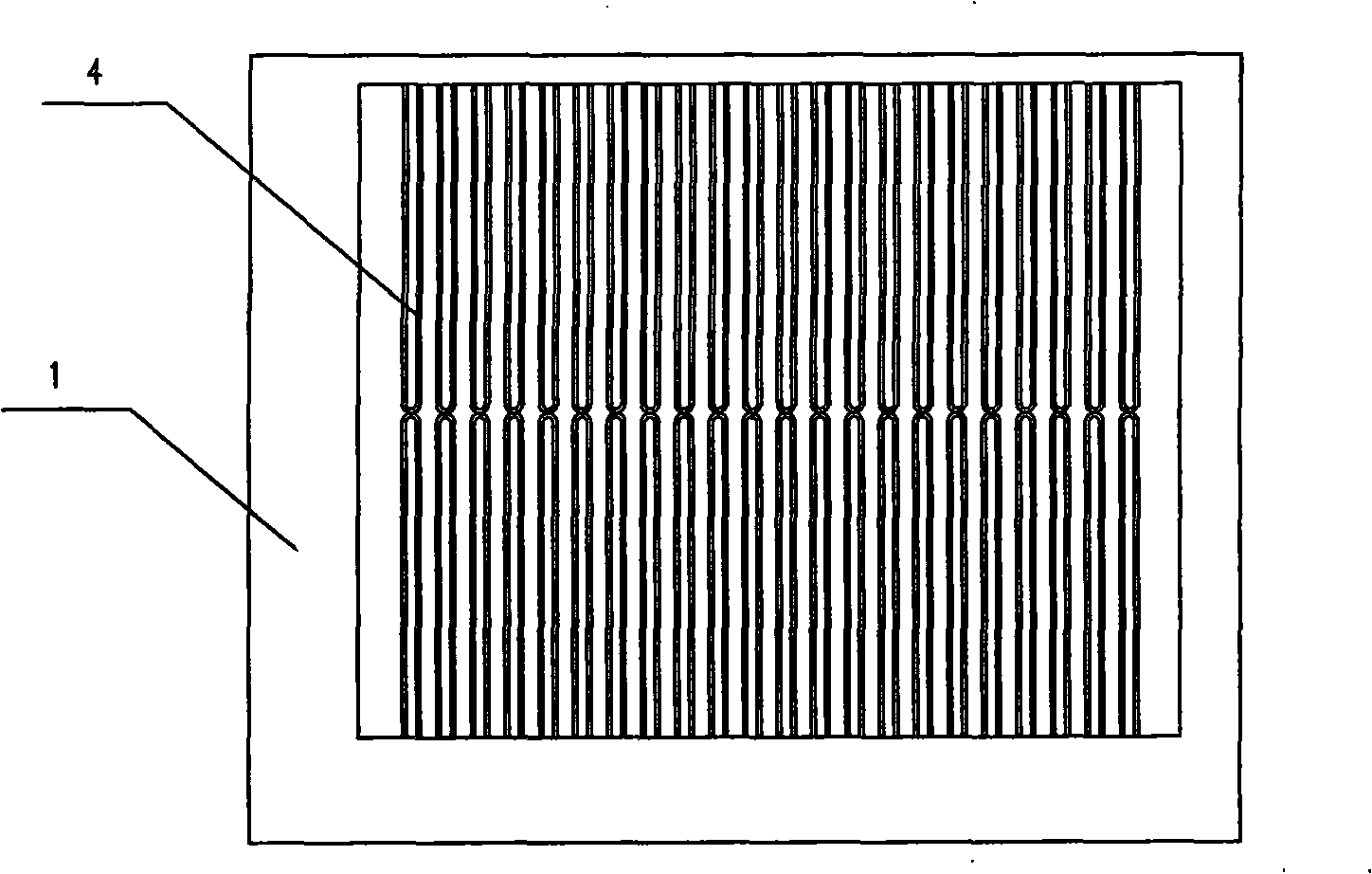

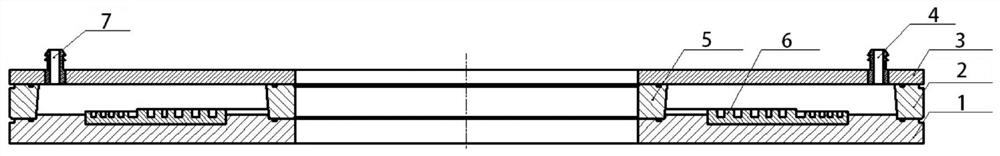

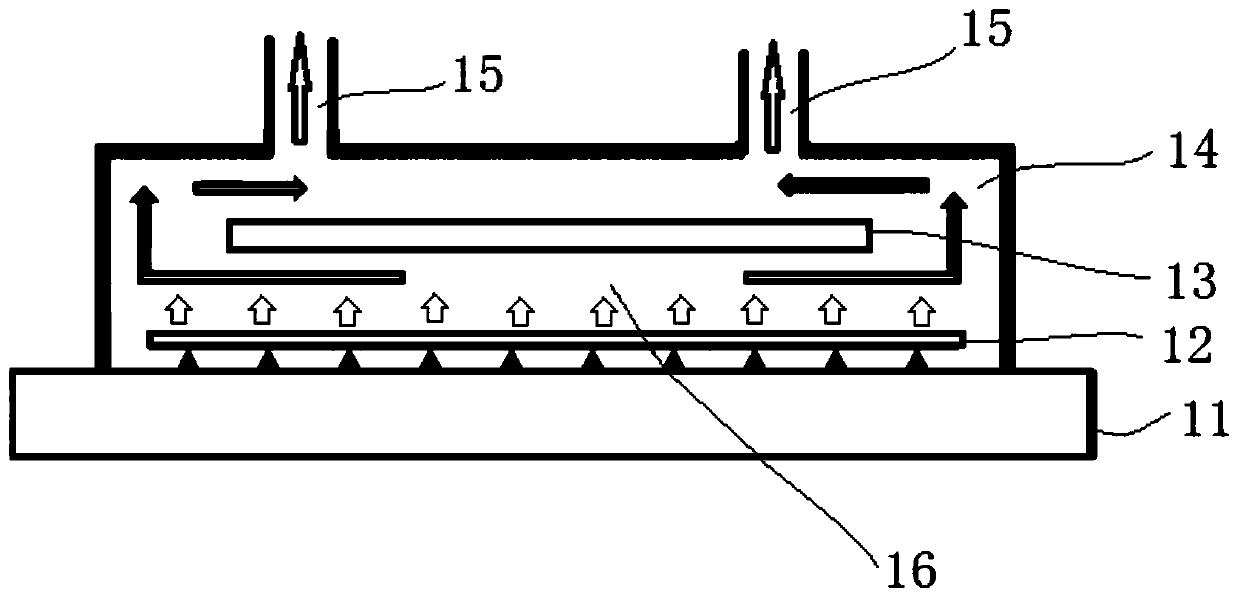

Diode pumping of a laser gain medium

ActiveUS7949022B2Uniform pumpingIncrease powerSemiconductor lasersLaser cooling arrangementsVertical-cavity surface-emitting laserHigh power lasers

An integrated, low profile, high power laser light emission device is disclosed. The integrated laser light emission device provides uniform heat dissipation, as well as uniform pumping of the laser gain medium without the need for a pumping cavity. The laser system includes a pump diode array that can be mounted directly to a laser gain medium without intervening correcting optics hardware. Heat generated by the laser light emission device is cooled by a single cooling system. In the laser device, a pump diode array is preferably a Vertical-Cavity Surface-Emitting Laser (VCSEL) array. VCSEL arrays are mounted on the laser gain crystal by a metal cavity frame or metal stilts. The slightly elevated mounting of the VCSEL's enables increased cooling and maximizing the quantity of VCSEL's on the laser gain medium in order to achieve highly efficient and high power laser light output.

Owner:PRINCETON OPTRONICS

Film covering and turnover integrated equipment and woven bag processing system

InactiveCN107745568AEven by forceSimple structureLamination ancillary operationsLaminationMachining processFilm coating

The invention relates to the field of woven bag processing equipment, and provides film covering and turnover integrated equipment and a woven bag processing system. The film covering and turnover integrated equipment comprises a glue extruding device, a film covering device, a turnover device and a conveying device, wherein the film covering device comprises a first frame, and a first film covering roller, a second film covering roller and a guide roller which are arranged on the first frame and used for conveying covering films; and the turnover device comprises a second frame, a feeding belt assembly, an adsorption turnover belt assembly, a pressing belt assembly, a discharging belt assembly and an adsorption chamber, wherein the moving directions of the feeding belt assembly and the discharging belt assembly are vertical to the moving direction of the adsorption turnover belt assembly, and the pressing belt assembly is positioned on the circumference of one side of the adsorption turnover belt assembly. The integrated equipment can realize double-layer film coating by using a single device, is simple in operation and low in equipment cost. In addition, the woven bag processingsystem provided by the invention comprises shearing equipment and the film covering and turnover integrated equipment, and can simplify a processing process of a woven bag.

Owner:重庆恒茂包装制品有限公司

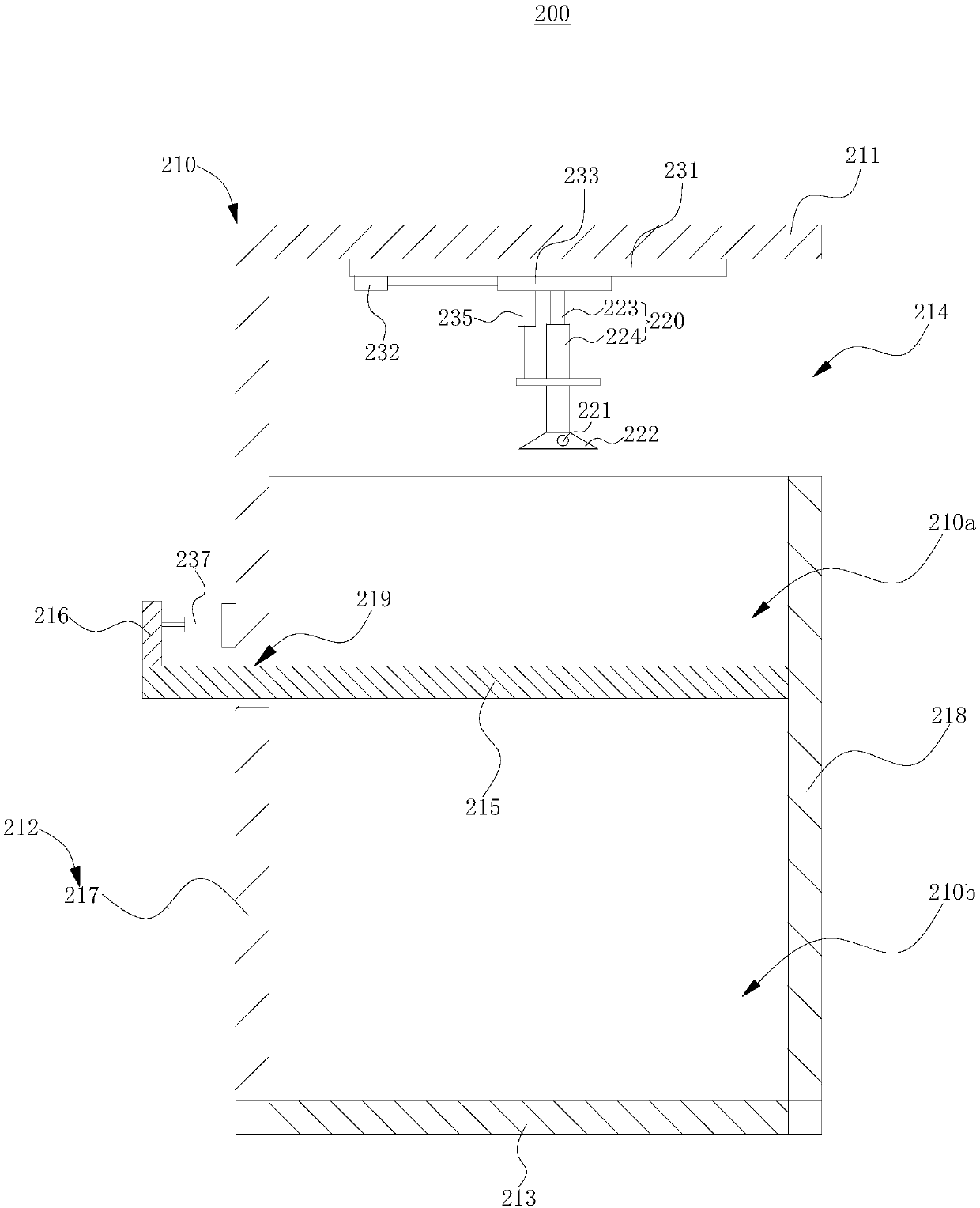

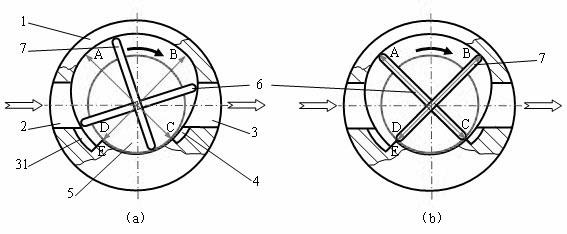

Lower-extraction type etching device

ActiveCN1851854AGuaranteed axisymmetricSmall difference in chemical reaction speedSemiconductor/solid-state device manufacturingChemical reactionPump chamber

This invention relates to an etching device in the process of semiconductor wafers including a reacting chamber with an inlet and a pumping chamber with an air vent, in which, said pumping chamber is set under the reacting chamber connected with symmetrically arranged left ventilation channel and a right ventilation channel and said air vent and the inlet are at the same axes and arranged symmetrically, so the gas above the static chuck surface flows to either side symmetrically and realizes uniform pumping to the reacting chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Horizontal enameling machine oven with ultra-wide combustion chamber

InactiveCN101403560AReduce the difficulty of operationMany headsDrying solid materials with heatDrying gas arrangementsCombustion chamberCombustor

The invention discloses a horizontal enameling machine drying oven with a superwide furnace which comprises furnace and heat irradiation equipment arranged in the furnace, wherein, the upper part of the furnace is provided with a catalytic combustor and a catalytic post suction and discharge room which are communicated. Two ends of the catalytic combustor are provided with an air inlet and an air outlet, a heat exchange room is arranged on the periphery of the catalytic post suction and discharge room, and the furnace is separated from a solvent suction and discharge area in the middle. The horizontal enameling machine drying oven is characterized in that more than two air inlets are arranged in the solvent suction and discharge area and the air inlet of the catalytic combustor is respectively communicated with the air inlets at the ends of the furnace and in the solvent suction and discharge area. A multi-channel air-flow distribution device is arranged in the catalytic post suction and discharge room and comprises a solvent distillation channel, the left and right sides and the back end of the channel are all provided with stream inlets, and the middle part thereof is provided with an air flow demarcation strip; and a pump line provided with an exhaust fan is arranged on the periphery of the air flow demarcation strip and communicated with the solvent distillation channel. The horizontal enameling machine drying oven has reasonable structure, uniform airflow direction and temperature, energy conservation and environmental protection, and good popularization value.

Owner:林兆欣 +1

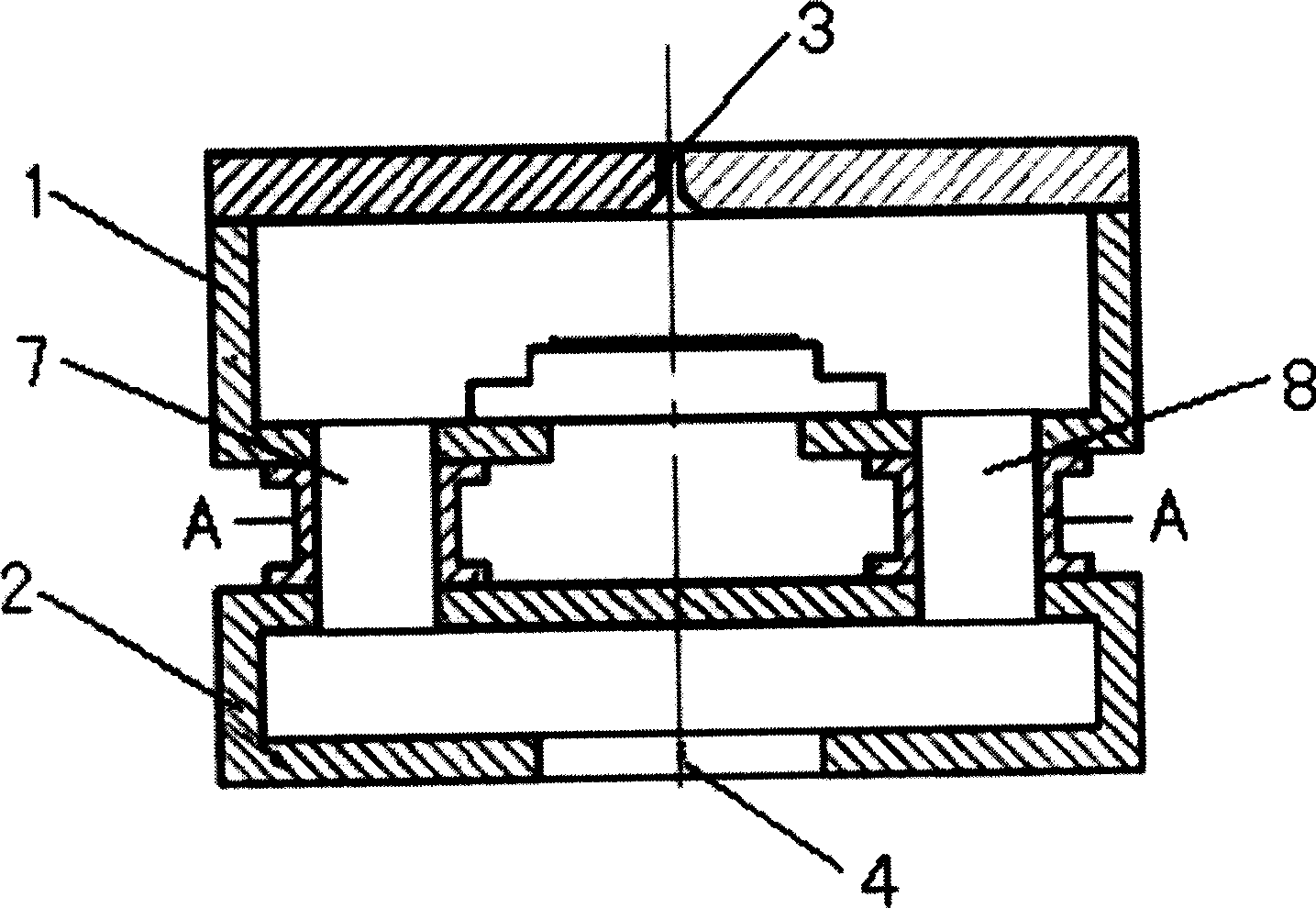

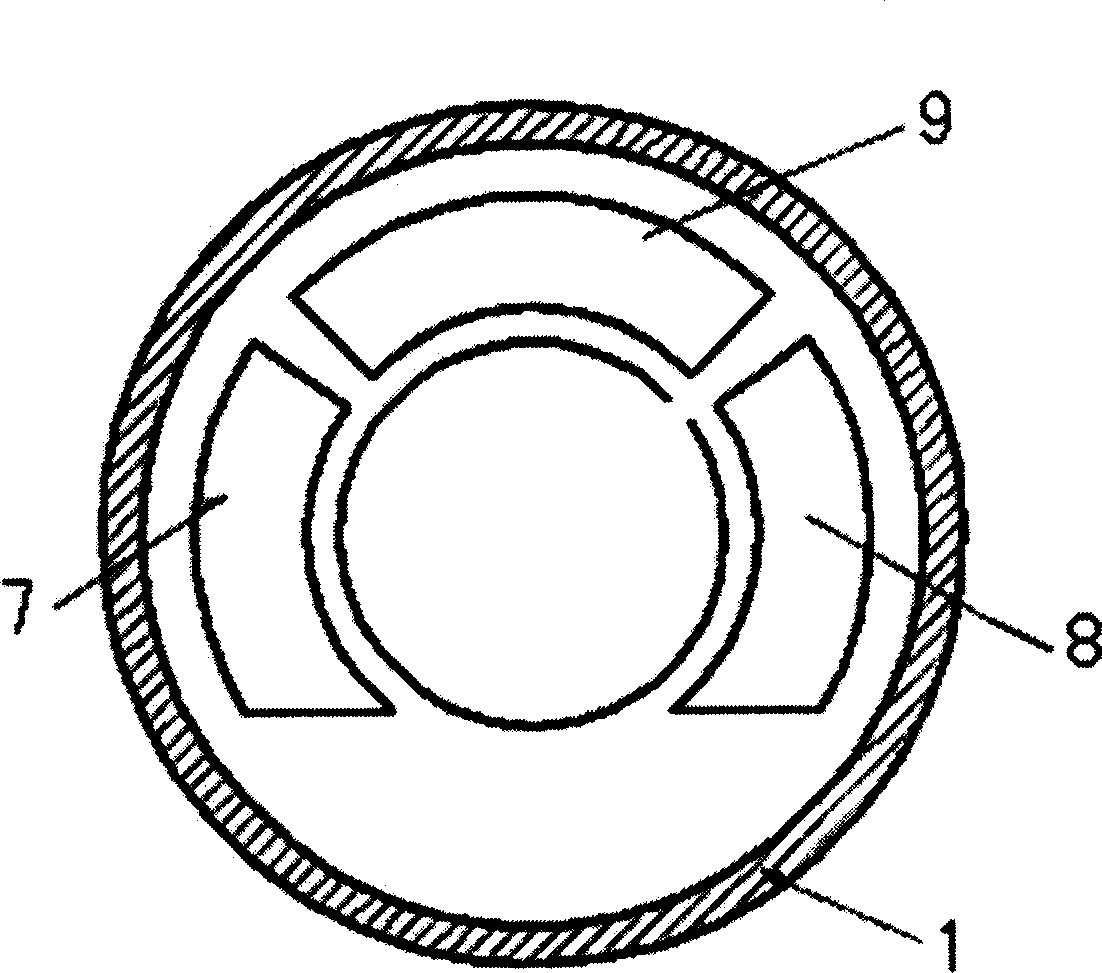

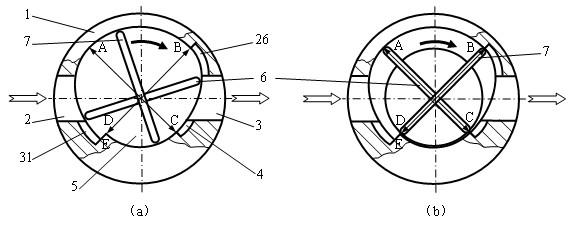

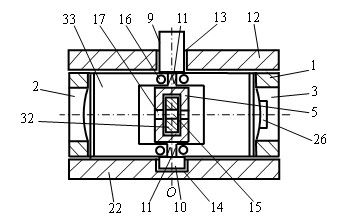

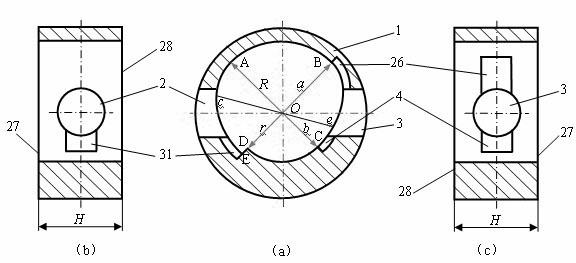

Vacuum pump with special-shaped cavity

InactiveCN102678553AReduce in quantitySimple structureRotary piston pumpsRotary piston liquid enginesDrive shaftSlide plate

The invention discloses a vacuum pump with a special-shaped cavity; the vacuum pump comprises a stator and a rotor; wherein the stator is a cylinder body provided with a special-shaped cylindrical-surface inner cavity, an inlet and an outlet; the special-shaped cylindrical-surface inner cavity is formed by two arc surfaces and two non-arc surfaces; the rotor is formed by a rotor body and two pairs of combination slide plates; the rotor body is a circular cylinder body provided with a transmission shaft, a centering shaft and a crossed guide groove; the two pairs of combination slide plates are vertically arranged in the guide groove; a cover plate is a flat plate provided with a bearing hole; the two end faces of the stator are matched with the cover plate to form into a sealing cavity; the rotor is matched with the bearing hole on the cover plate by the transmission shaft and the centering shaft; the external drive couple drives the rotor to rotate by the transmission shaft. When the rotor rotates, the combined arc surface of the special-shaped cylindrical-surface inner cavity matches with the rotor to control the two pairs of combination slide plates to slide alternatively to intake air through the inlet and press air out through the outlet, thereby forming negative pressure in the inlet area.

Owner:NINGBO YINZHOU FUCHUN PRECISION CASTING

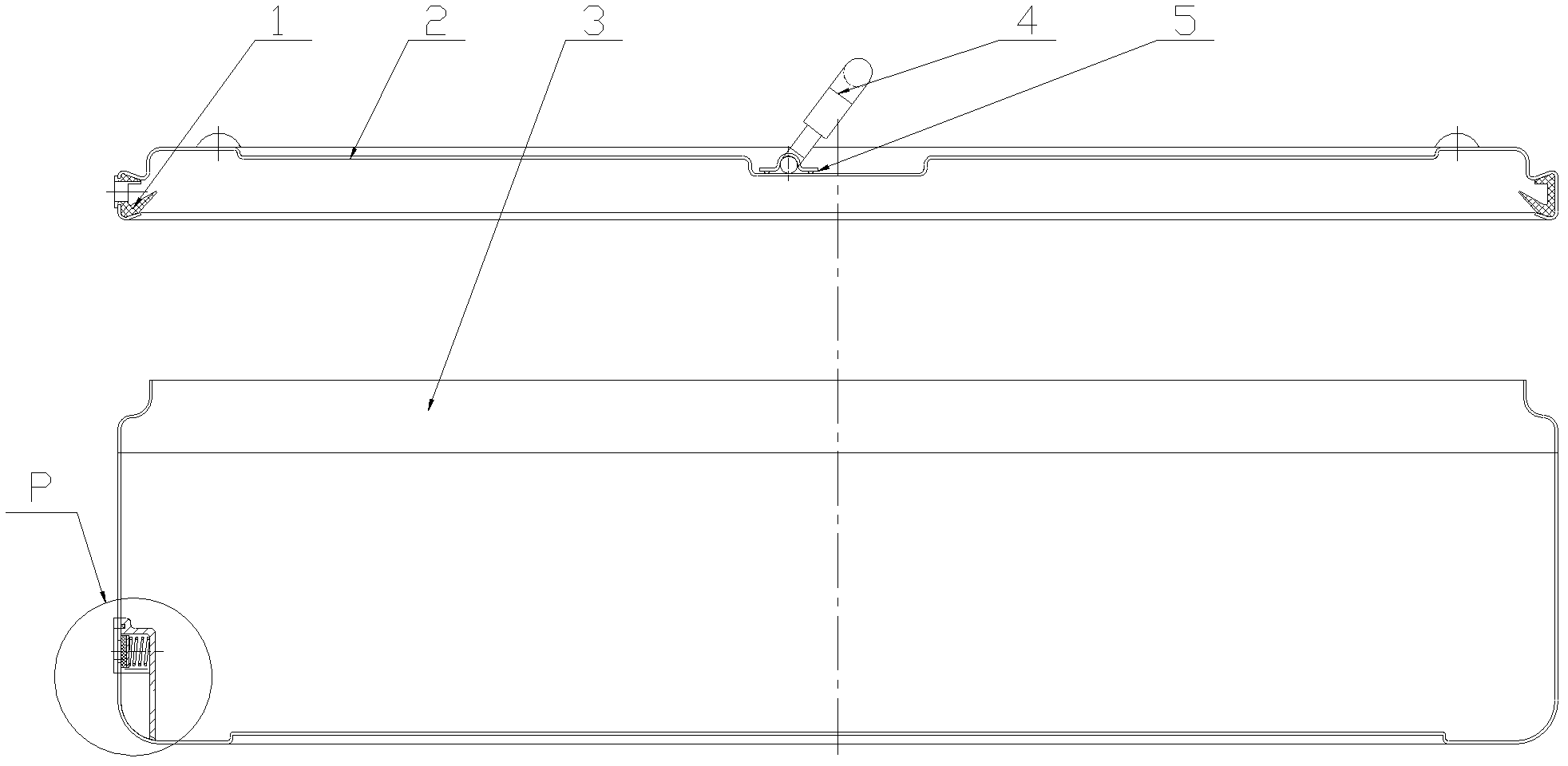

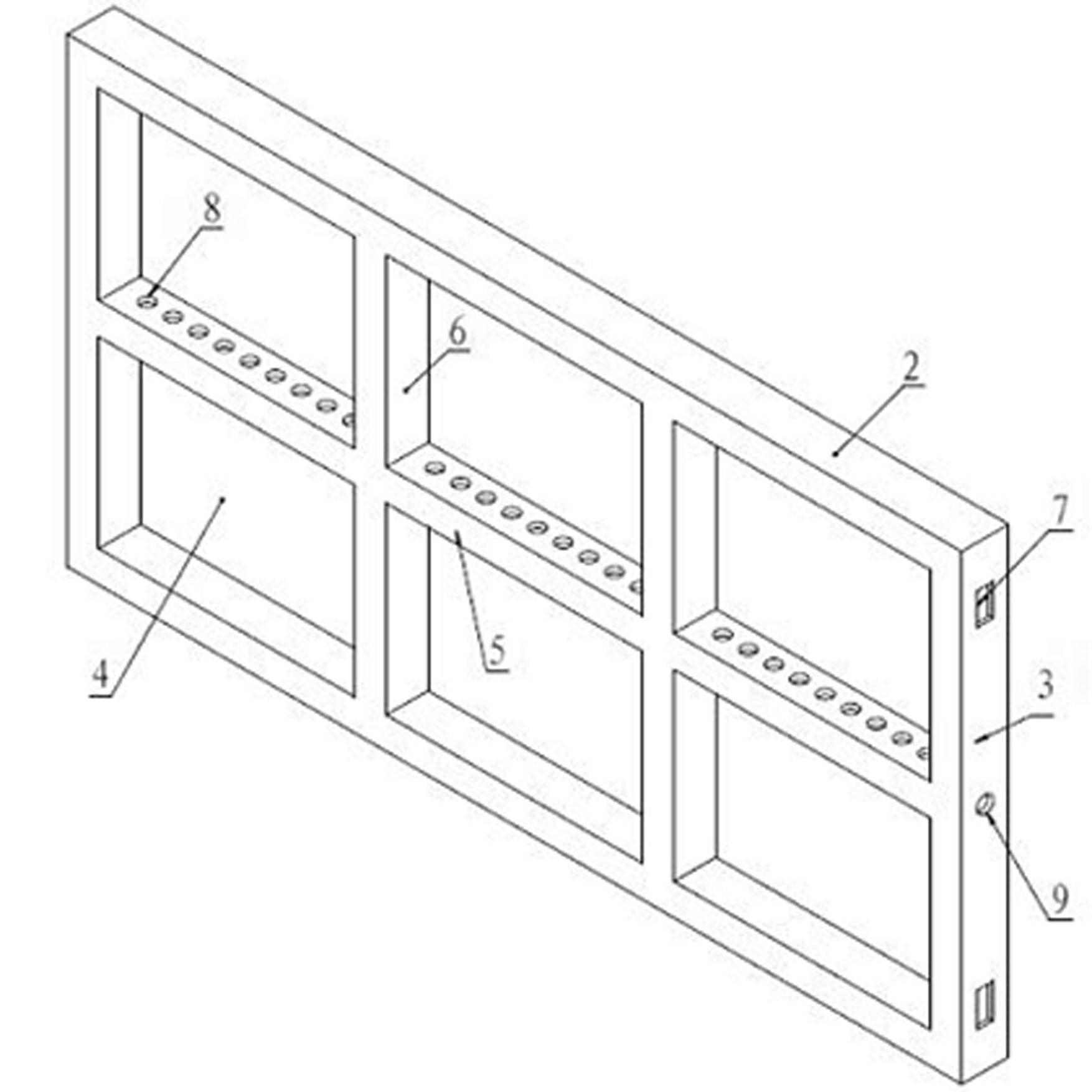

Electrolytic tank cover for preventing and controlling acid mist

InactiveCN102618890AHigh strengthReduce the number of lifting and unloadingElectrolysis componentsEngineeringMental detachment

The invention relates to an electrolytic tank cover for preventing and controlling acid mist. The electrolytic tank cover is a cube and is provided with long and short side walls and a top plate, and a netlike supporting structure is arranged on the inner surface of the cube; the netlike supporting structure comprises an air draft branch pipe arranged along the longitudinal central line of the cube and reinforcing ribs arranged on two sides of the air draft branch pipe at equal intervals; two side walls of the air draft branch pipe are provided with air draft holes; and the short side wall of the cube is provided with a hole, and the hole is communicated with the air draft branch pipe. The electrolytic tank cover has the characteristics of reasonable structural design, high strength, light mass, convenience in artificial lifting and detachment, high acid mist pumping efficiency, capability of realizing thorough prevention and control of the acid mist and the like.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

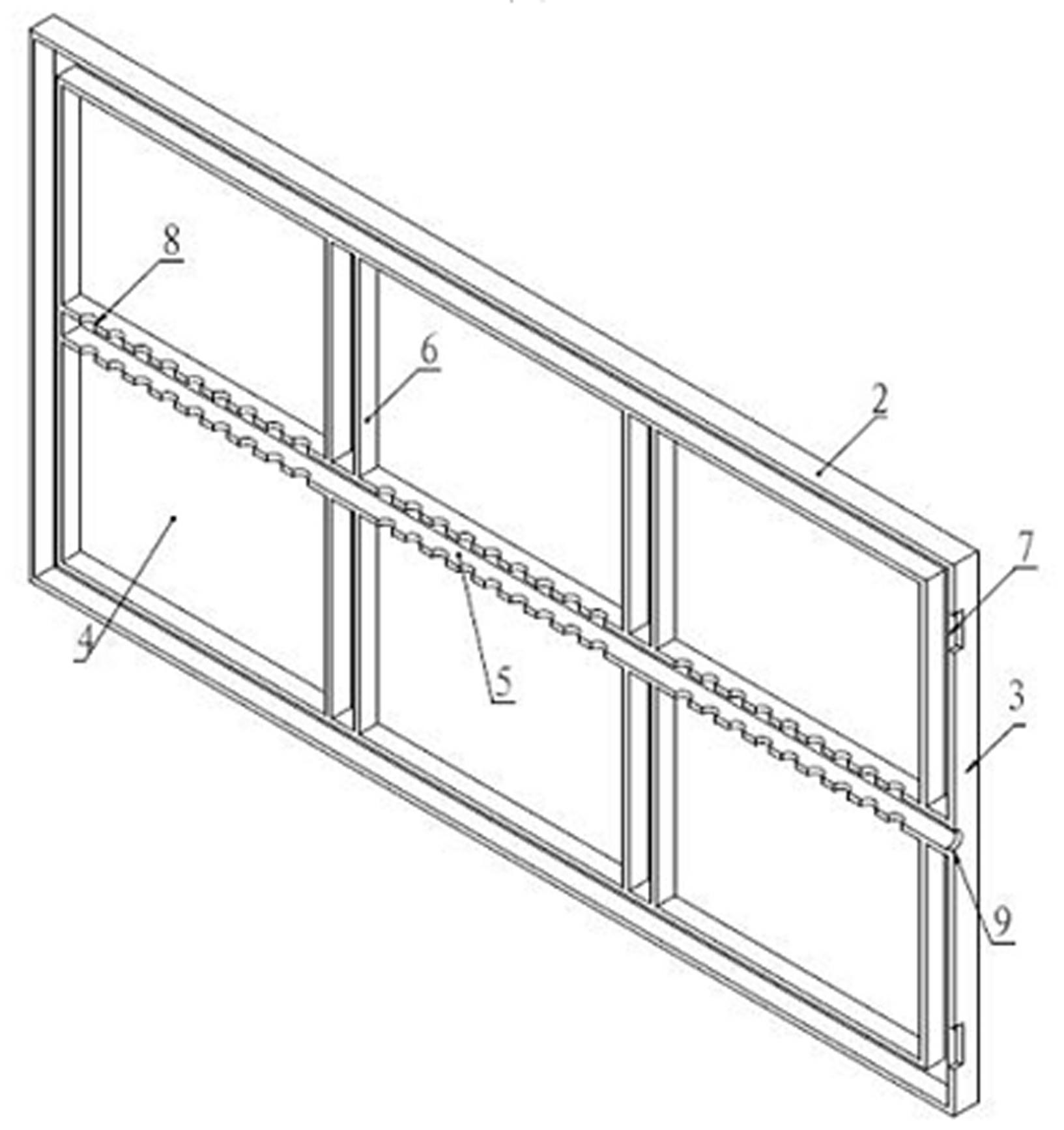

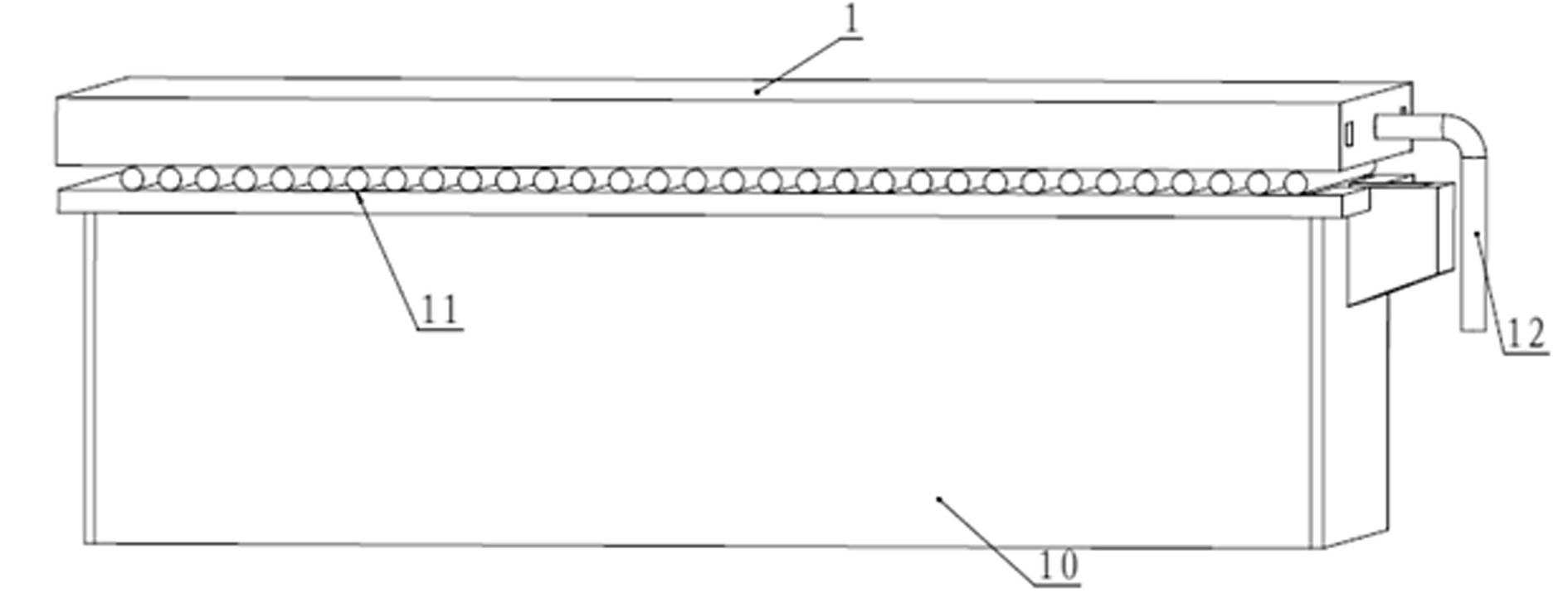

Steel-structure double-layer glass curtain wall

InactiveCN105113682AUniform pumpingFit tightlyLighting and heating apparatusWallsActive carbonTitanium dioxide

The invention discloses a steel-structure double-layer glass curtain wall and belongs to the technical field of building decoration engineering. The steel-structure double-layer glass curtain wall comprises a steel support frame and a glass wallboard and is characterized by further comprising a solar vacuum heat collector composed of a heat exchange pipe, an aluminum heat absorbing plate and a glass box body, the aluminum heat absorbing plate is connected to the interior of the glass box body in a clamped mode, a first clamping layer and a second clamping layer are embedded in the steel support frame, a fixed frame is connected to one side of the steel support frame, a filtering plate in which an active carbon net layer is embedded is connected to the second clamping layer, reinforcing strips are distributed on the filtering plate and coated with titanium dioxide coatings, the glass wallboard comprises inner layer glass, a first connecting piece, a second connecting piece and outer layer glass, the first connecting piece is composed of a connecting column, a first rubber sucker and a second rubber sucker, and the second connecting piece is connected with the inner layer glass and the outer layer glass. The curtain wall is good in heat collecting effect and capable of effectively decomposing indoor harmful gas, and the whole curtain wall has good sound insulation and environmental protection effects due to the double-layer glass wallboard.

Owner:SICHUAN LANTIAN NET RACK & STEEL STRUCTURE ENG CO LTD

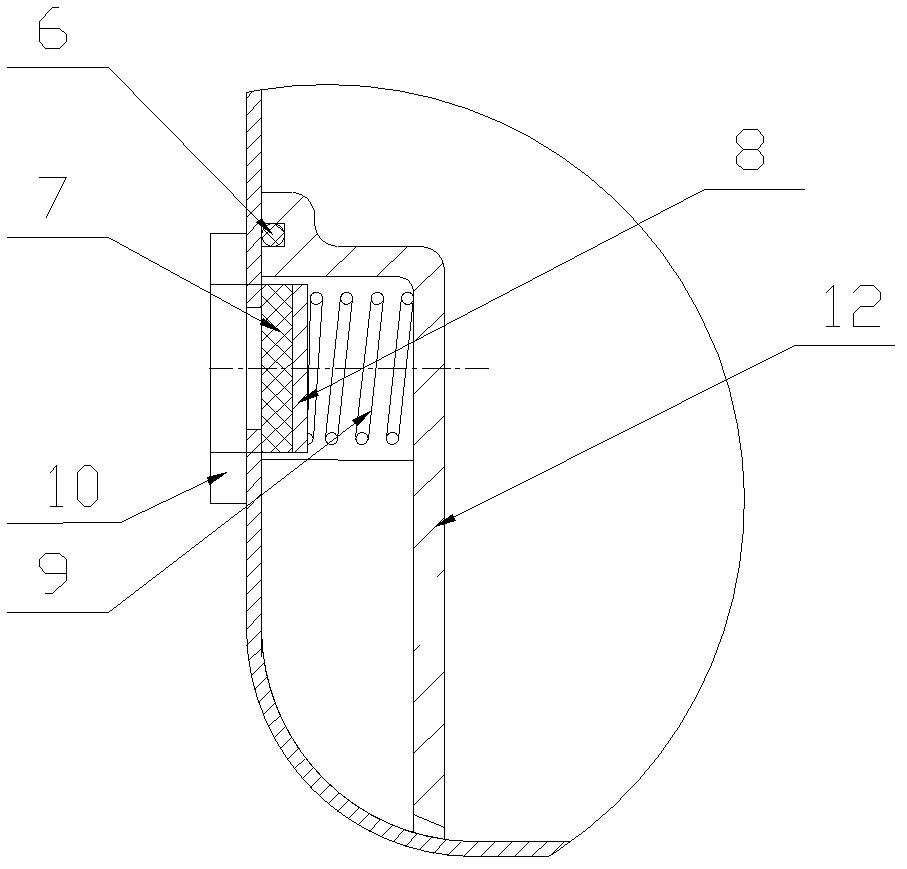

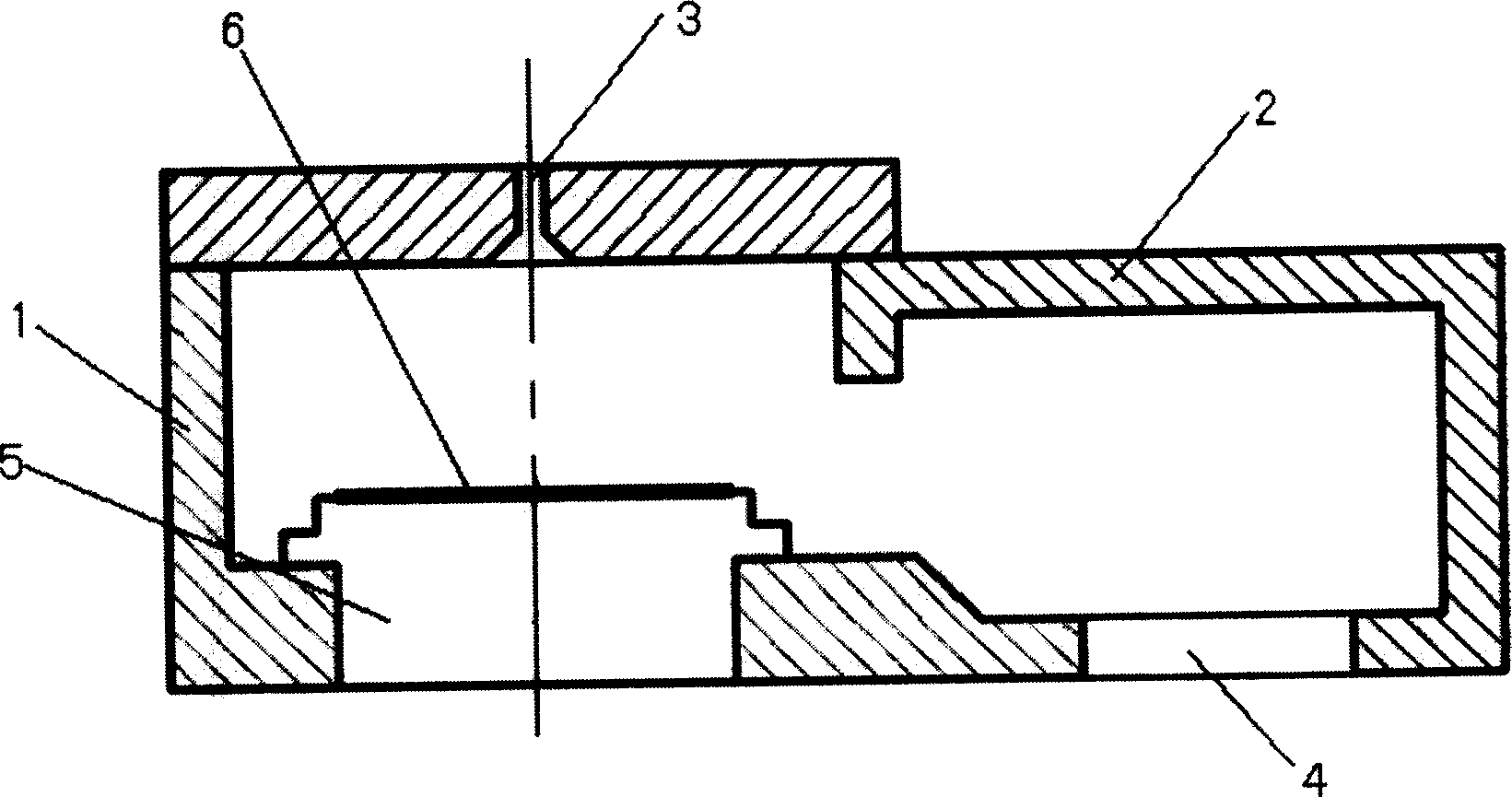

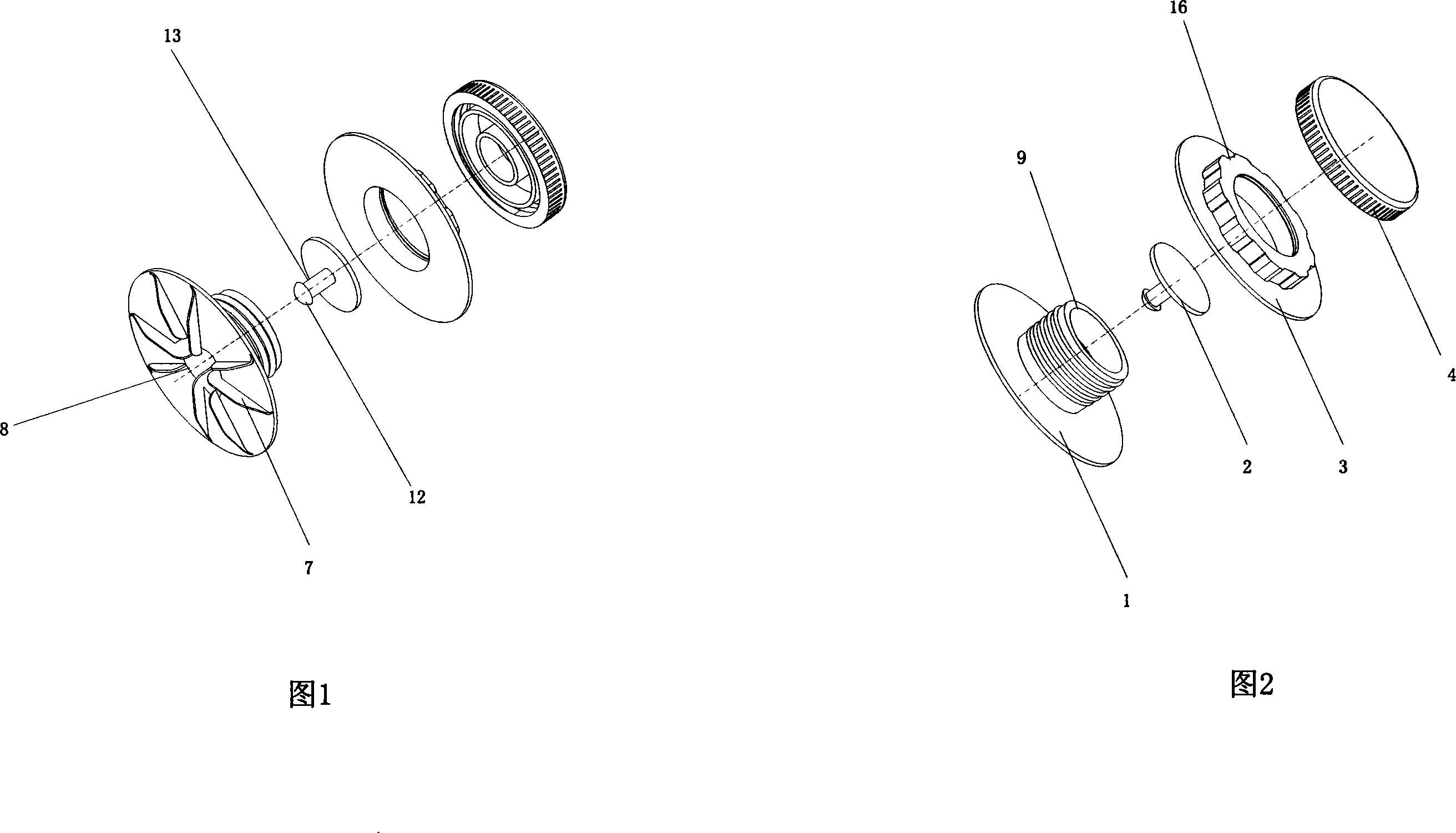

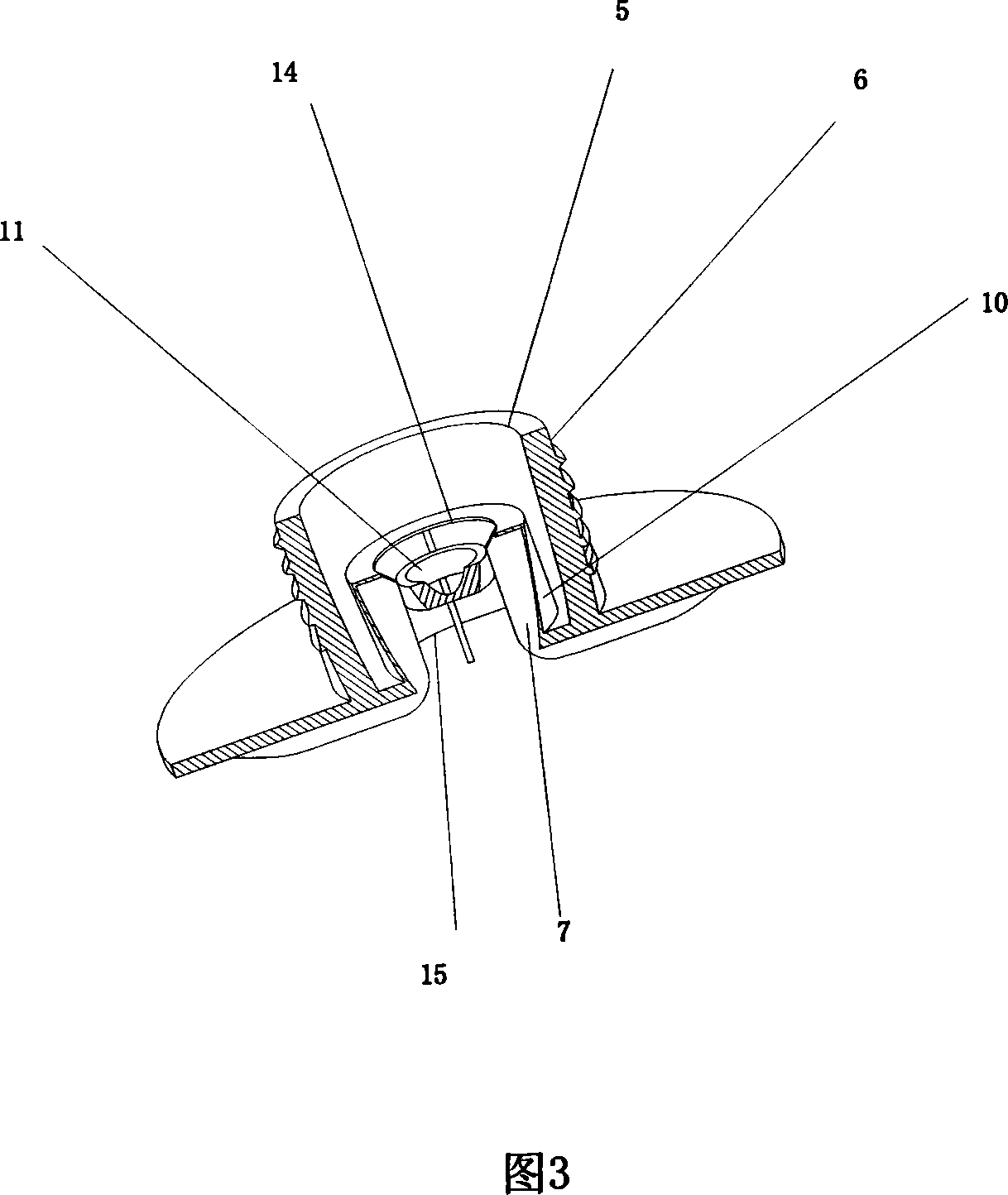

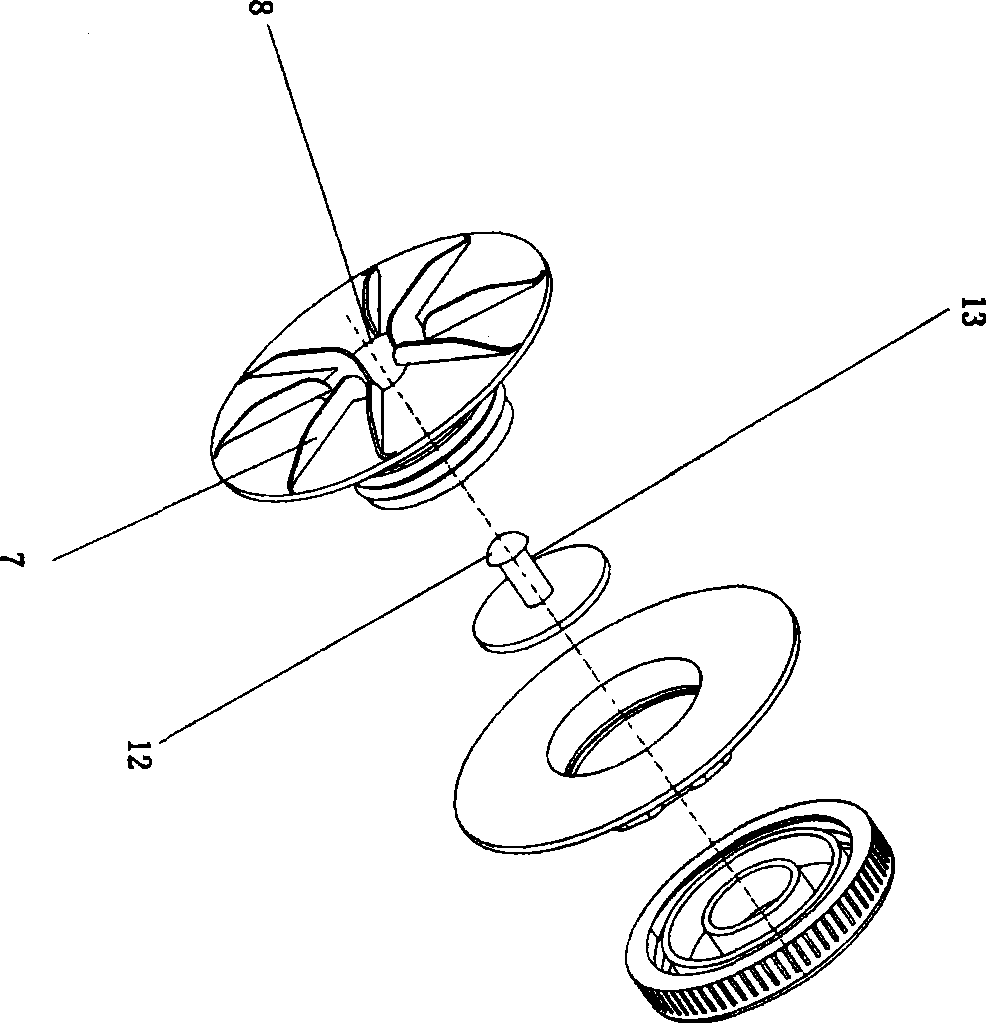

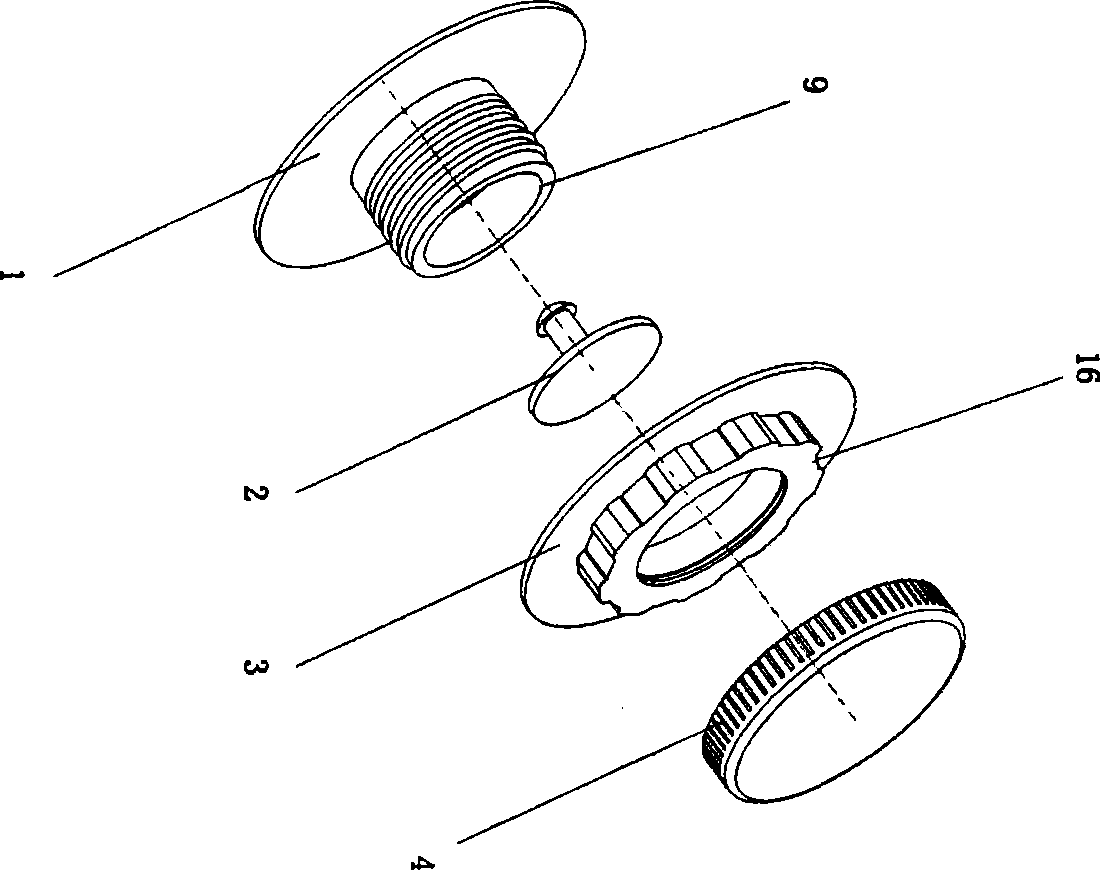

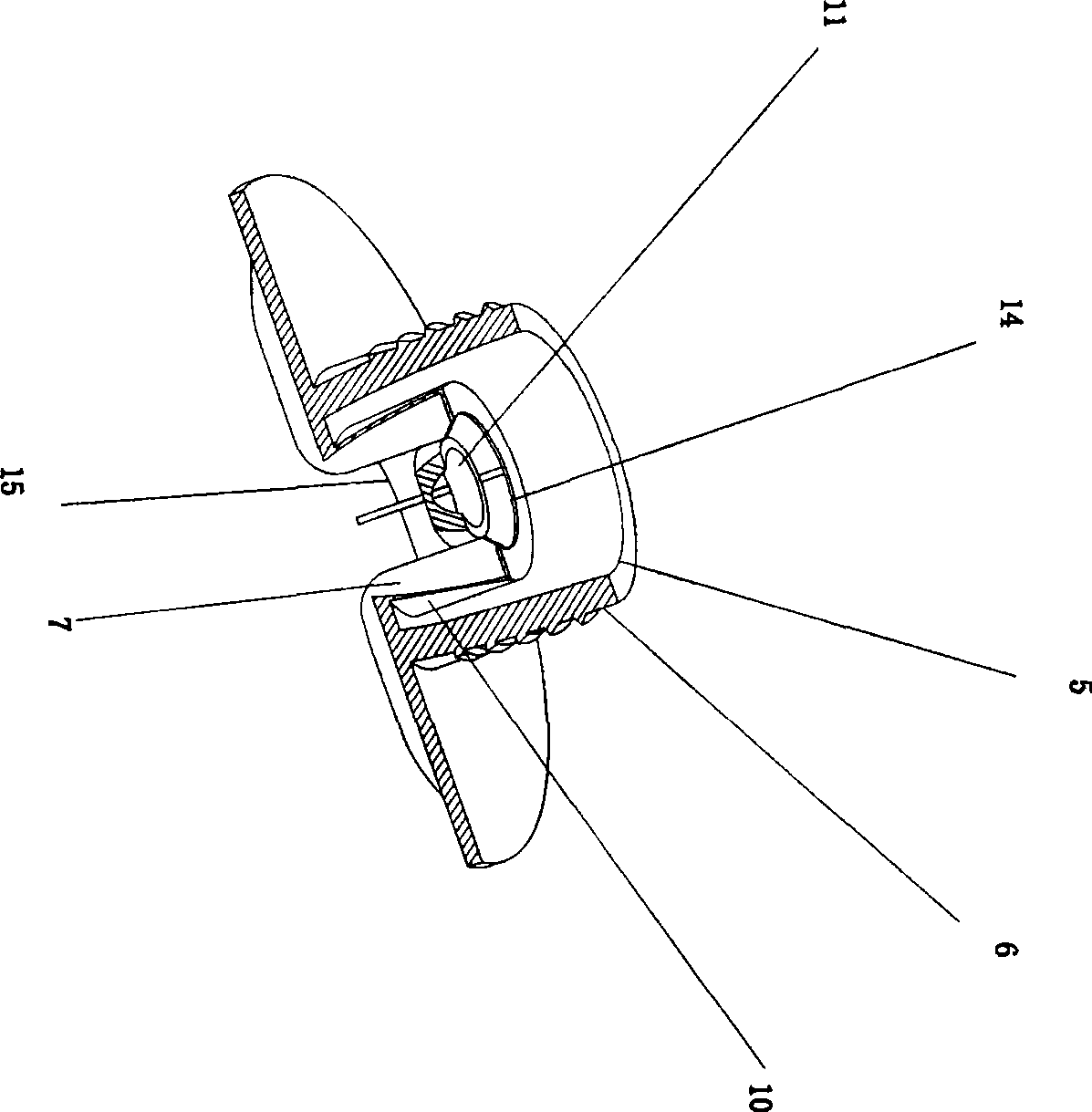

Vacuum compression bag gas nozzle with improved structure

The invention discloses an improved structure of vacuum compressive bag air valve which comprises a valve seat, a sealing ring and an end cover. The valve seat comprises an inlet port and an outlet port and the sealing ring and the end cover are screwed at the outlet port respectively. The air valve is characterized in that the valve seat is constituted by an inner casing and an outer casing. The inner casing has an exhaust passage, the inlet end of the exhaust passage extends out of the outer casing bottom and forms the inlet port of the seat. The outlet port is arranged at the top opening of the outer casing. The inner wall of the exhaust passage is provided with a flow deflector which extends out of the inlet end of the exhaust passage which is also fixed with a ring. A piston packing is arranged at the outlet end of the exhaust passage of the inner casing and the piston packing is equipped with an inserted pivot with a drawing gear. The drawing gear of the inserted pivot passes through the ring and is blocked at the outside of the ring. The piston packing is arranged in the top part of the inner casing and seals the outlet end of the exhaust passage. The invention has the positive effects that such structure has good tightness, when air is exhausted, sufficient space is provided for air flow, thus bringing about satisfactory exhaust result.

Owner:梁灼权

Gas compression pump with special-shaped cavity

InactiveCN102678552AReduce in quantitySimple structureRotary piston pumpsRotary piston liquid enginesPositive pressureDrive shaft

The invention discloses a gas compression pump with a special-shaped cavity. The pump comprises a stator and a rotor, wherein the stator is a cylinder with a special-shaped cylindrical surface inner cavity, an inlet and an outlet; the special-shaped cylindrical surface inner cavity is formed by combining two arc surfaces and two non-arc surfaces; the rotor consists of a rotor body and two pairs of combined sliding plates; the rotor body is a cylinder with a transmission shaft, a centering shaft and cross guide grooves; the two pairs of combined sliding plates are vertically arranged in the guide grooves; each cover plate is a flat plate with a bearing hole; the two end faces of the stator are matched with the cover plates to form a sealed cavity; the rotor is matched with the bearing holes in the cover plates through the transmission shaft and the centering shaft; an external driving couple makes the rotor rotate through the transmission shaft; and when the rotor rotates, the combined arc surfaces of the special-shaped cylindrical surface inner cavity are matched with the rotor, the two pairs of combined sliding plates are controlled to slide crosswise, gas is sucked into the inlet and pressed out of the outlet, and positive pressure is formed in an outlet area.

Owner:NINGBO YINZHOU FUCHUN PRECISION CASTING

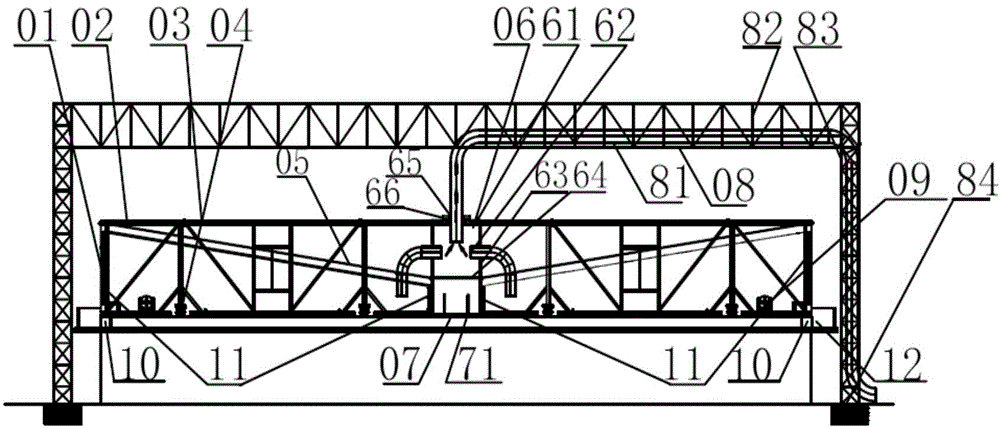

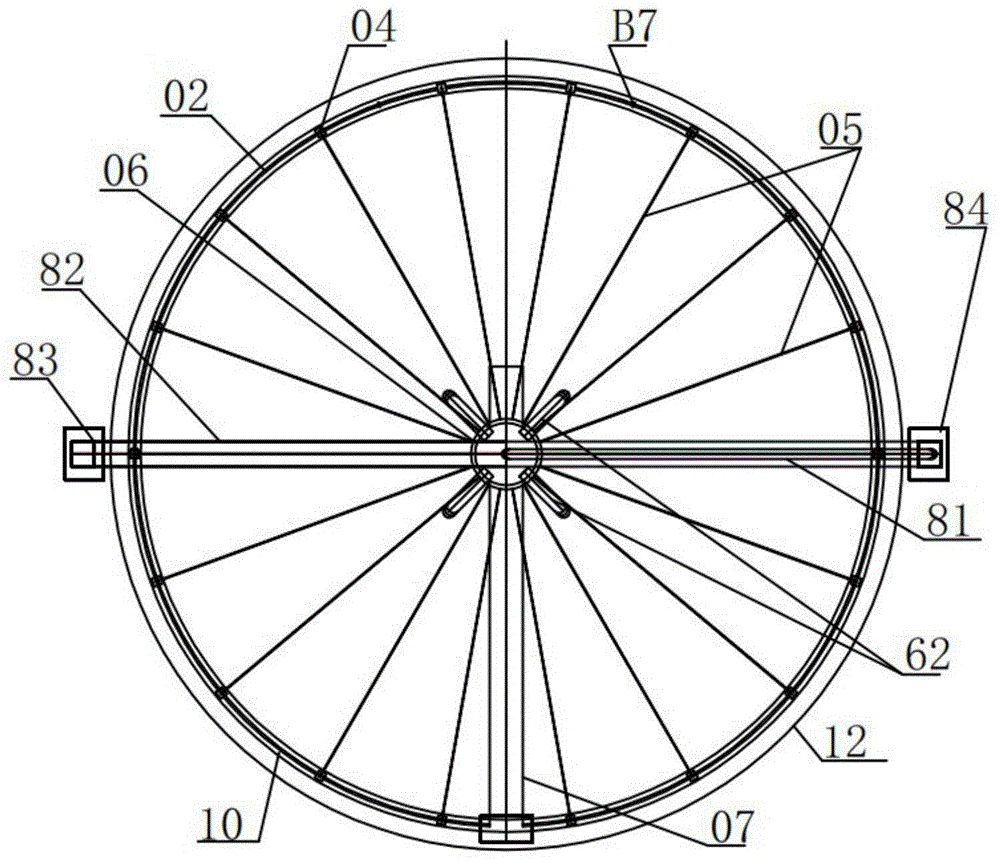

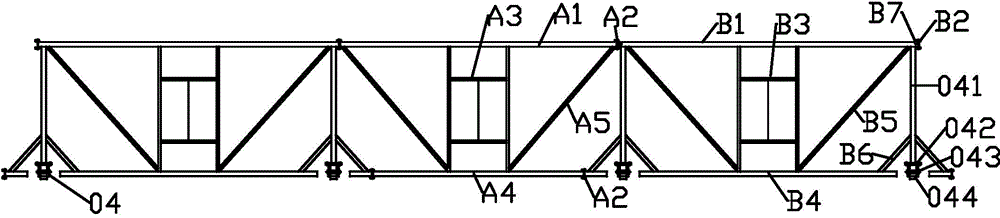

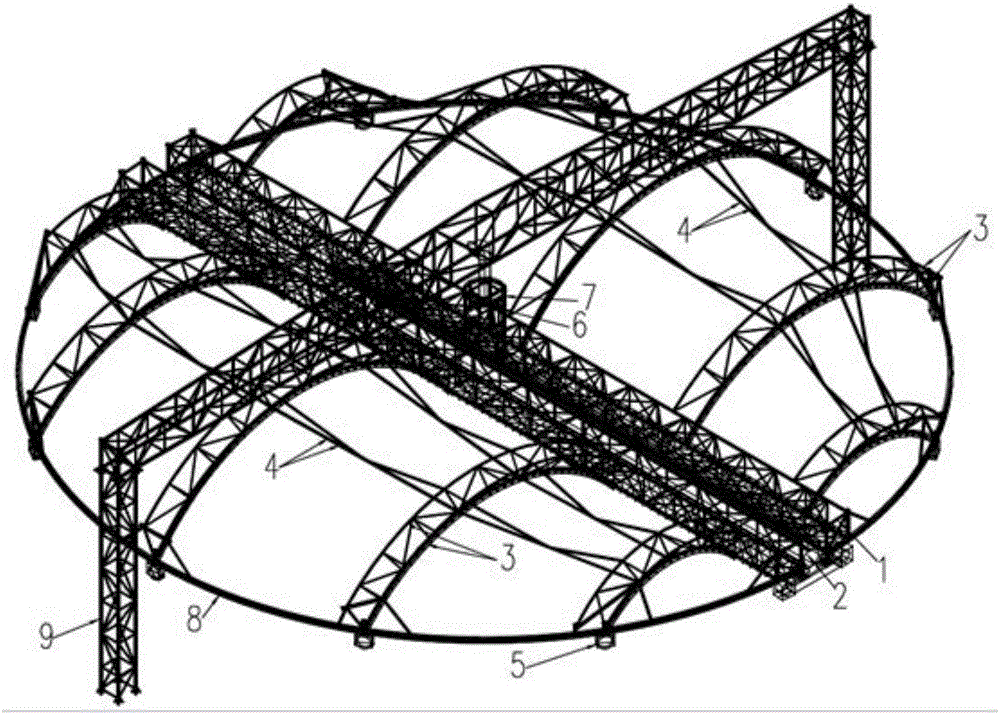

Holosymmetrical cable membrane reversed hanging structure synchronous rotation sealing system

The invention discloses a holosymmetrical cable membrane reversed hanging structure synchronous rotation sealing system which comprises a sealing cover, a circular track beam formed by a first holosymmetrical flange connection rectangular truss module and a second holosymmetrical flange connection rectangular truss module in flanged connection, a universal adjustable bearing wheel device, a middle exhaust pipeline, and a holosymmetrical motive seal centre gas collection device connected to the circular track beam, wherein the sealing cover is fixedly connected with the circular track beam; the sealing cover and the circular track beam rotate together with a mud scraper traveling crane in a round tank synchronously; the holosymmetrical motive seal centre gas collection device comprises a seal joint and a seal joint connecting base; the connection between the seal joint and the seal joint connecting base is a rotation connected relation of a rotating shaft and a rotating hole; a motive seal structure of a bulge embedded groove is arranged between the seal joint and the seal joint connecting base. According to the holosymmetrical cable membrane reversed hanging structure synchronous rotation sealing system, the service life is long; the cost is low; the sealing work is reliable; the installation cost and the maintenance cost are low.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

Full mold casting smoke treatment device

InactiveCN107335800AImprove the environmentKeep healthyDispersed particle filtrationTransportation and packagingExhaust pipeMetal

The invention relates to the technical field of full mold casting, in particular to a full mold casting smoke treatment device. The device comprises an exhaust cover box; the top of the exhaust cover box is connected with at least one exhaust pipe; the exhaust pipes are respectively connected with an exhaust fan; and a first metal filter screen, a refractory cotton layer, a refractory ceramic filter layer and a second metal filter screen are arranged in the exhaust cover box in sequence from top to bottom. The exhaust pipes are respectively provided with exhaust filter cylinders; and first refractory cotton layers, active carbon layers, second refractory cotton layers and third refractory cotton layers are arranged in the exhaust filter cylinder in an exhaust flowing direction. The first metal filter screen, the refractory cotton layer, the refractory ceramic filter layer and the second metal filter screen are arranged in the exhaust cover box in sequence from top to bottom for absorbing smoke and dust generated in the full mold casting process to optimize the workshop environment, so that the health of operators is effectively guaranteed, and meanwhile, the environment is protected.

Owner:CHENGDU XINGYU PRECISION CASTING

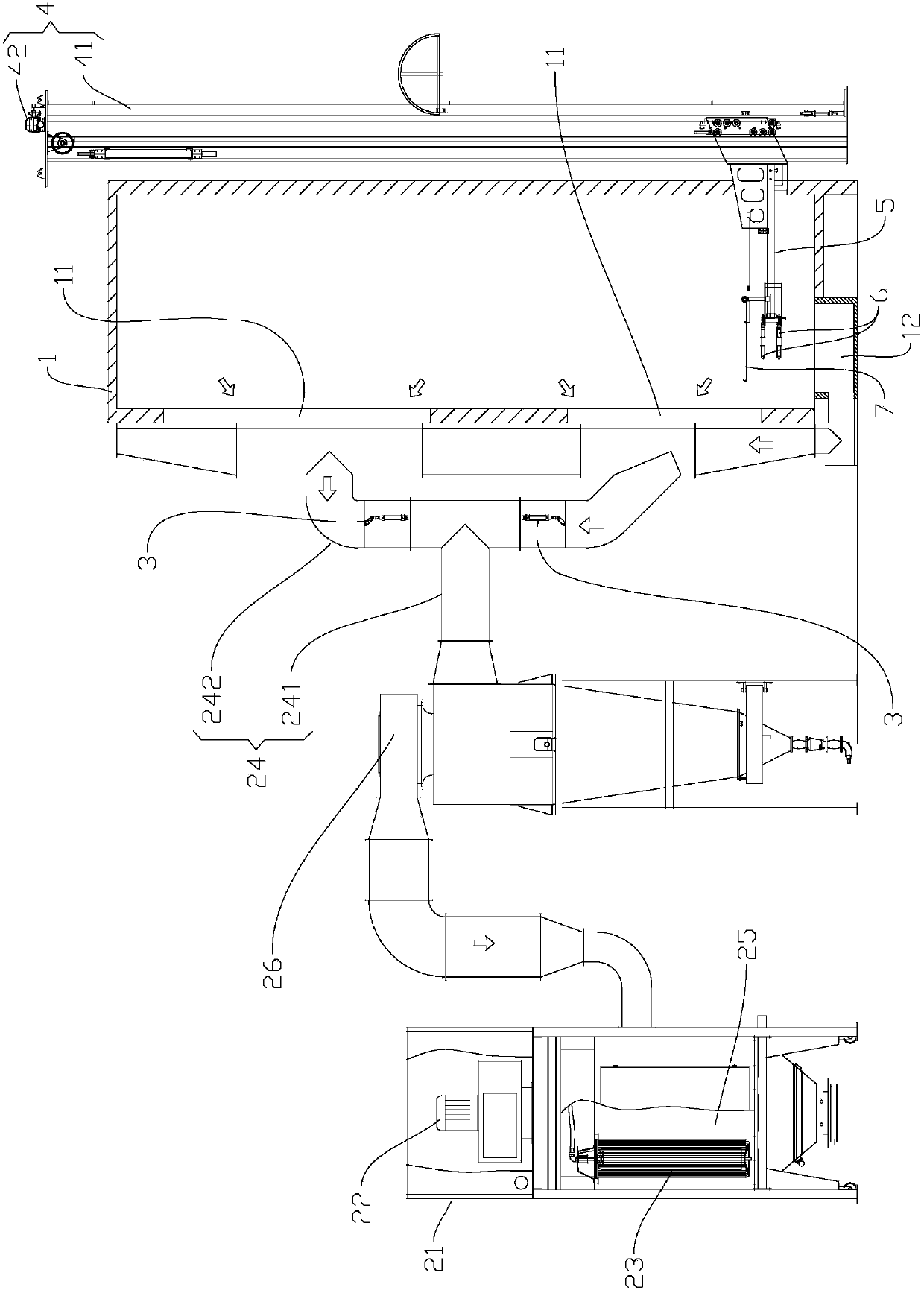

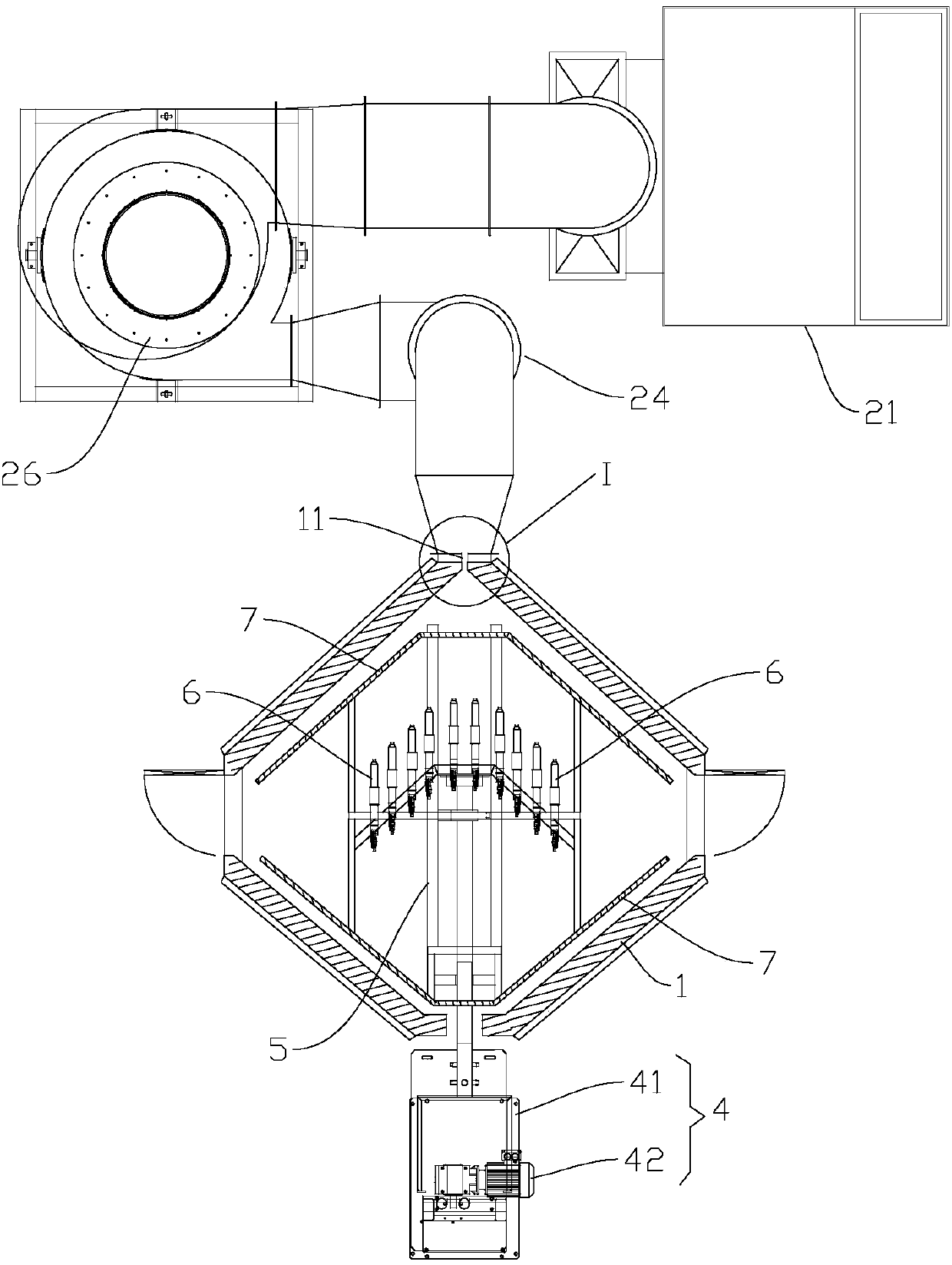

Vertical-type spraying chamber system

The invention discloses a vertical-type spraying chamber system. The vertical-type spraying chamber system comprises a spraying chamber and a filtering system, air pumping openings are formed in the side wall of the spraying chamber, the filtering system is communicated with the air pumping openings and can pump away air in the spraying chamber, and air containing powder is directly pumped away bya filtering device. By the adoption of the structure, the air in the whole spraying chamber is uniformly pumped, powder is effectively prevented from drifting away, the powder recycling effect is good, the environment of the spraying chamber is optimized, and the decomposition of powder is reduced, so that the spraying chamber is easy to clean.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

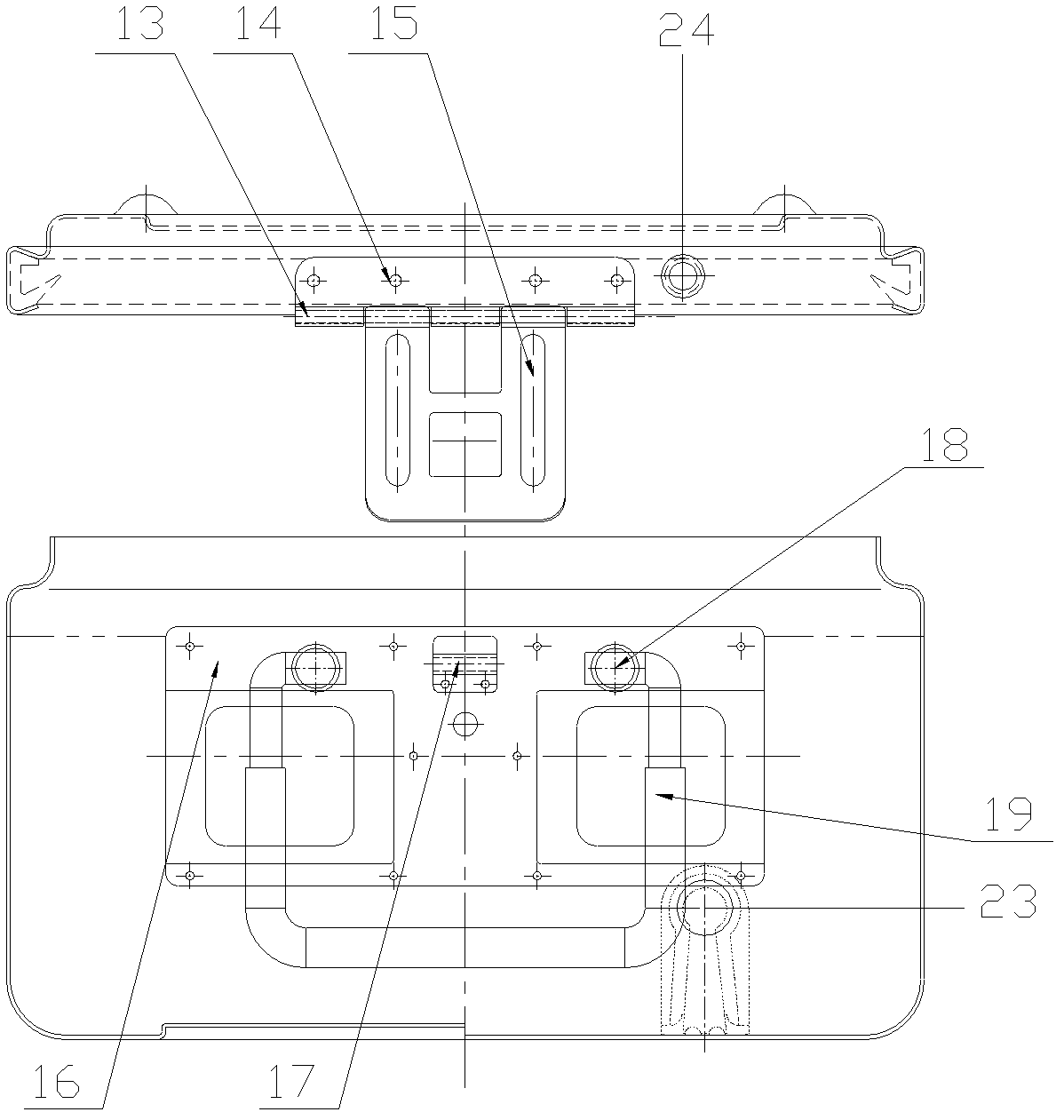

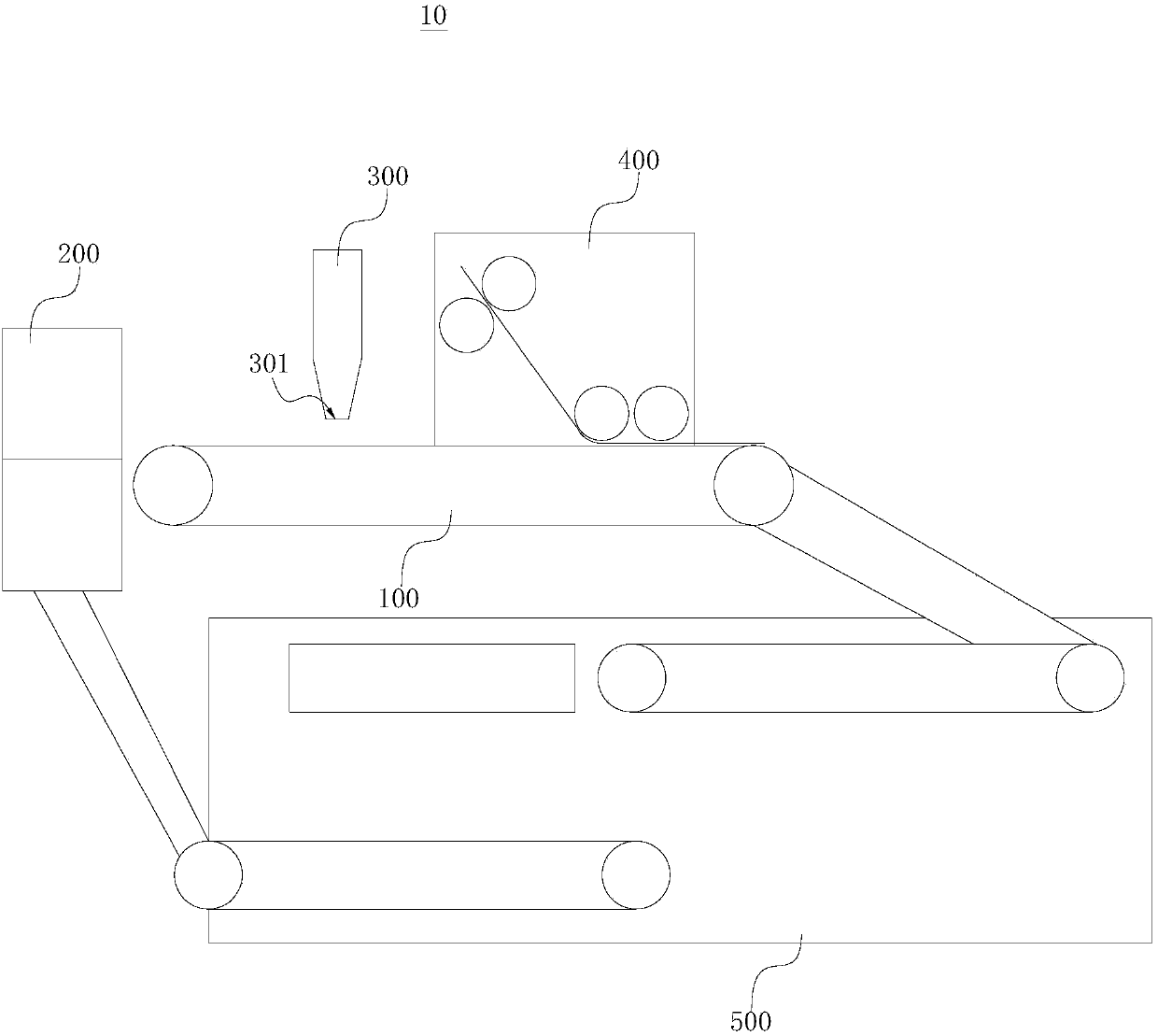

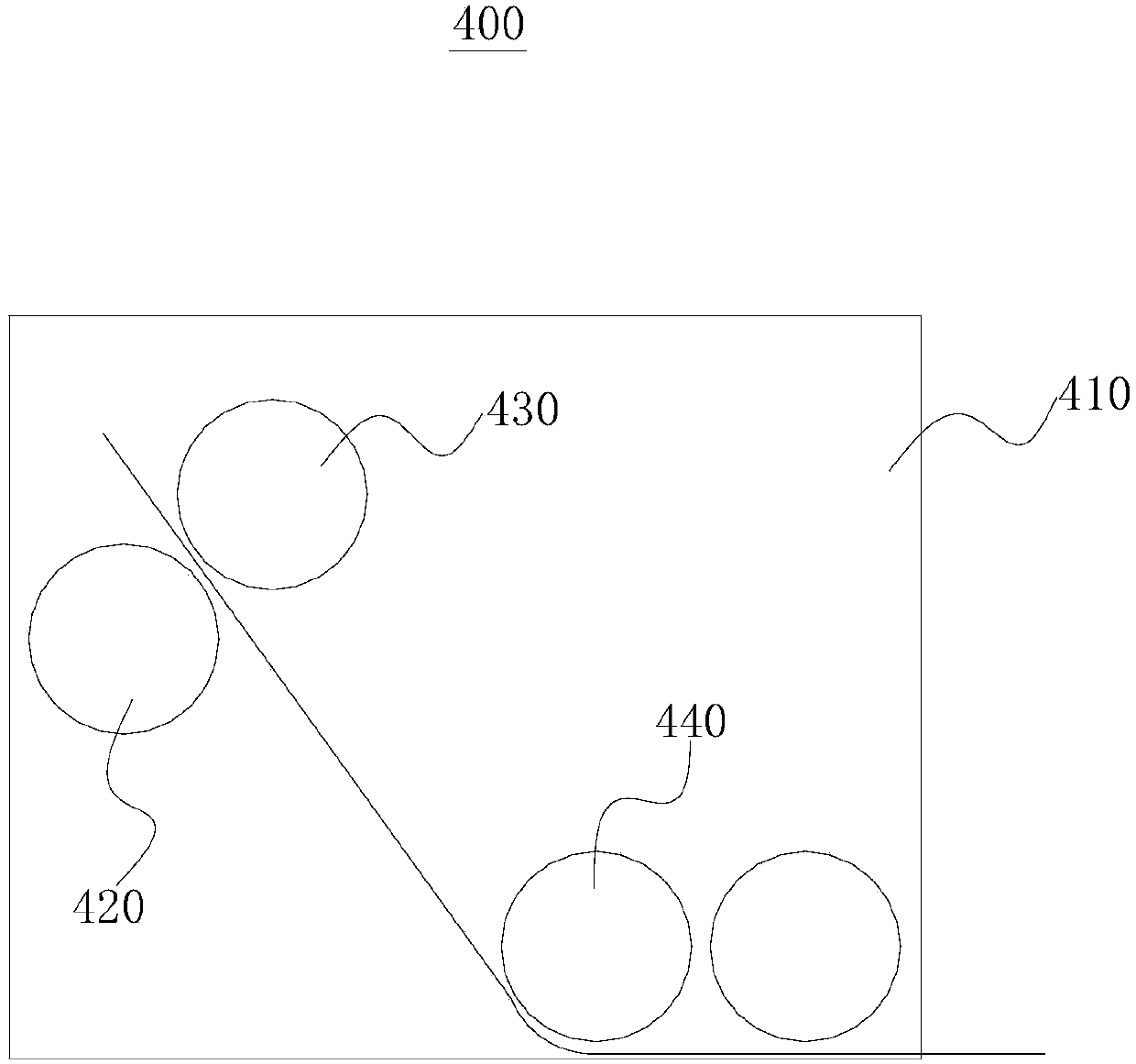

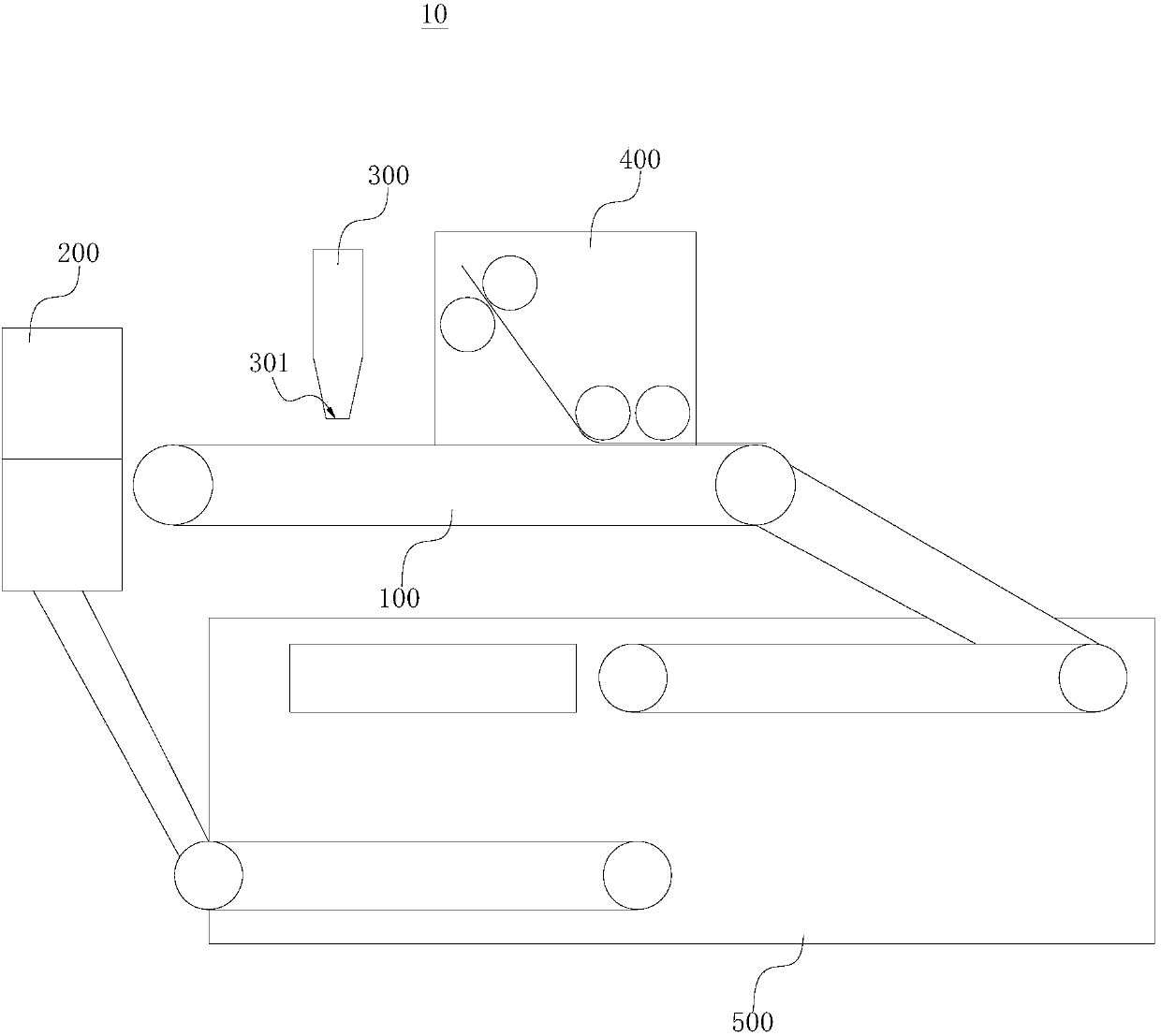

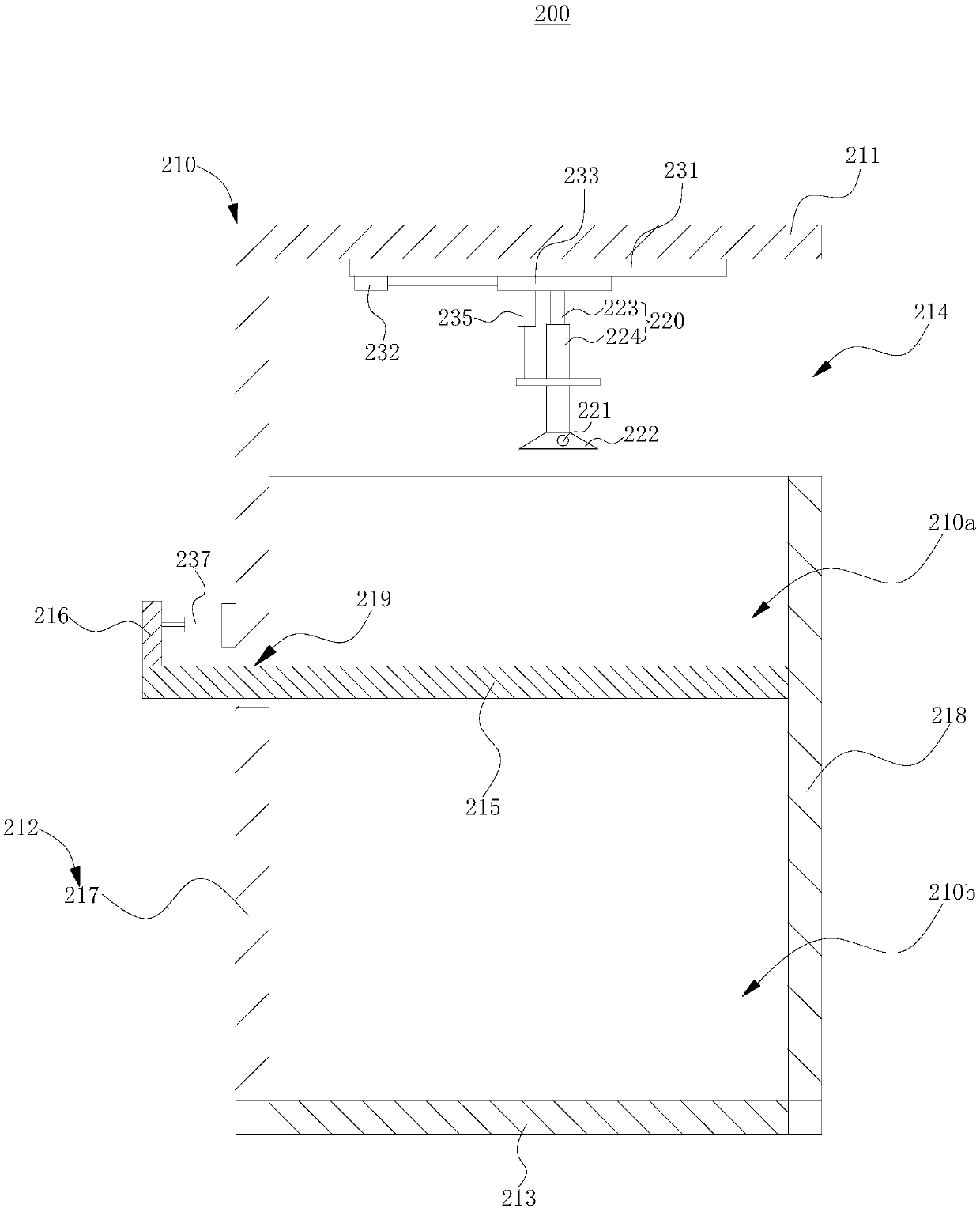

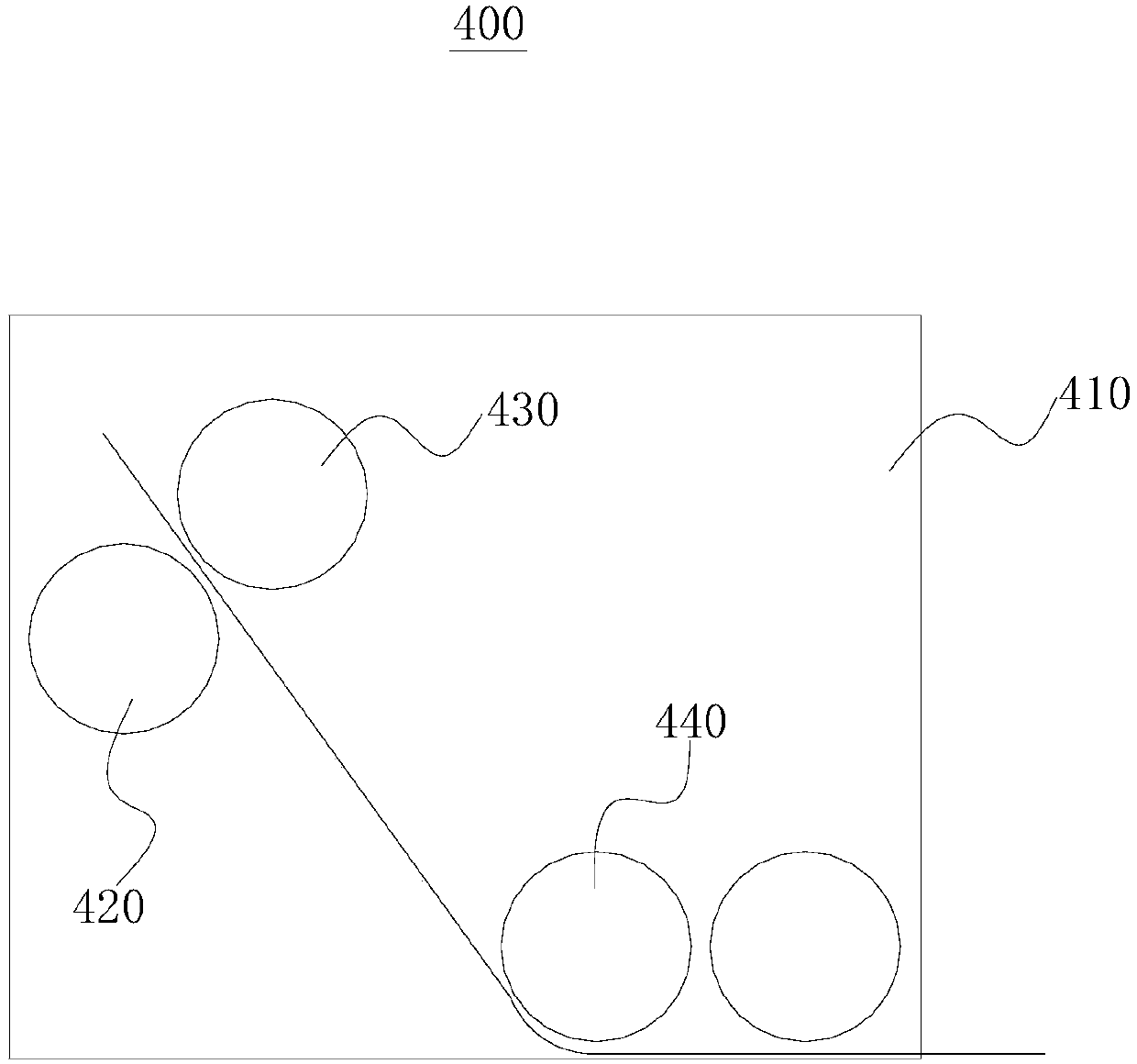

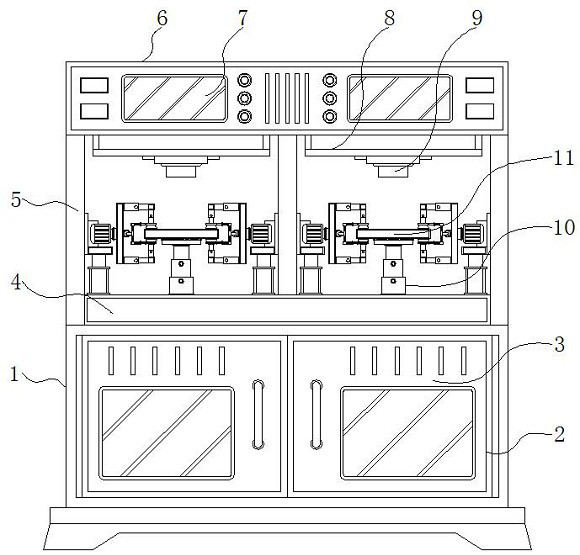

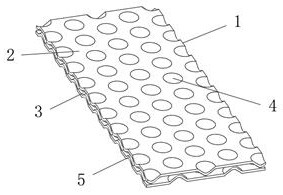

Woven bag double-sided laminating apparatus and woven bag processing system

InactiveCN107901573AEven by forceUniform pumpingLamination ancillary operationsBag making operationsEngineeringMechanical engineering

The invention relates to the field of woven bag processing apparatuses, and provides a woven bag double-sided laminating apparatus and a woven bag processing system. The woven bag double-sided laminating apparatus comprises a glue extruding device, a film laminating device, an overturning device and a conveying device, the overturning device comprises an overturning frame, and a feeding belt assembly, an adsorbing and overturning belt assembly, a compacting belt assembly, a discharging belt assembly, an adsorption chamber and a tensioning assembly which are arranged on the overturning frame, the movement direction of the feeding belt assembly and the discharging belt assembly are perpendicular to the movement direction of the adsorbing and overturning belt assembly, the adsorption chamberis positioned below the adsorbing and overturning belt assembly, the compacting belt assembly is positioned on the circumference at one side of the adsorbing and overturning belt assembly, and the tensioning assembly is pressed on the compacting belt assembly. The apparatus has the advantages of realization of double-sided film lamination through using one apparatus, simplicity in operation, and low device cost. Additionally, the woven bag processing system comprises a shearing apparatus and the woven bag double-sided laminating apparatus. The woven bag processing system can simplify the wovenbag processing process.

Owner:重庆恒茂包装制品有限公司

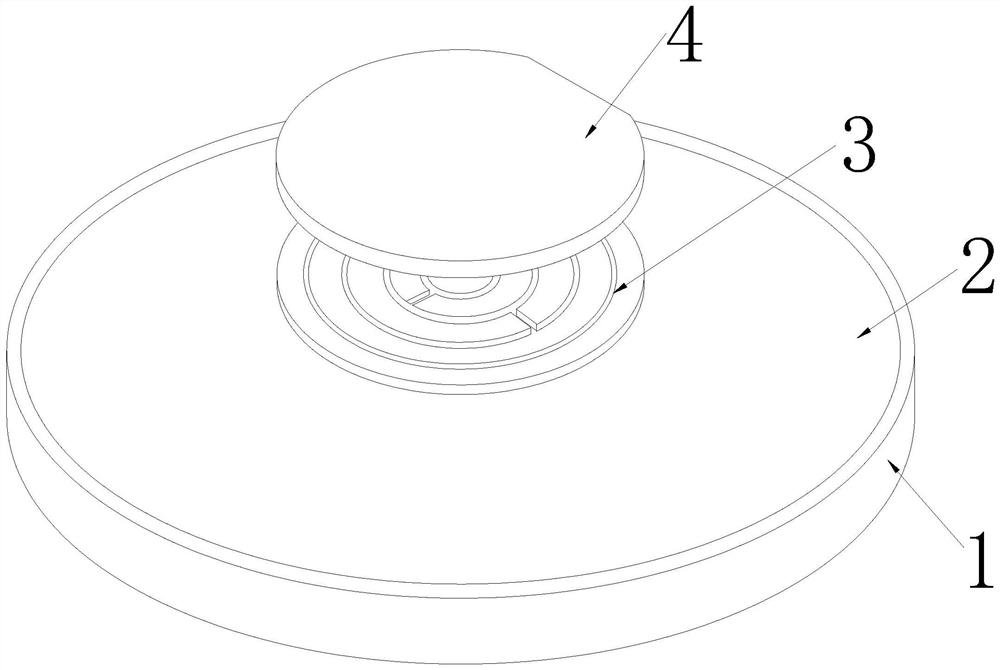

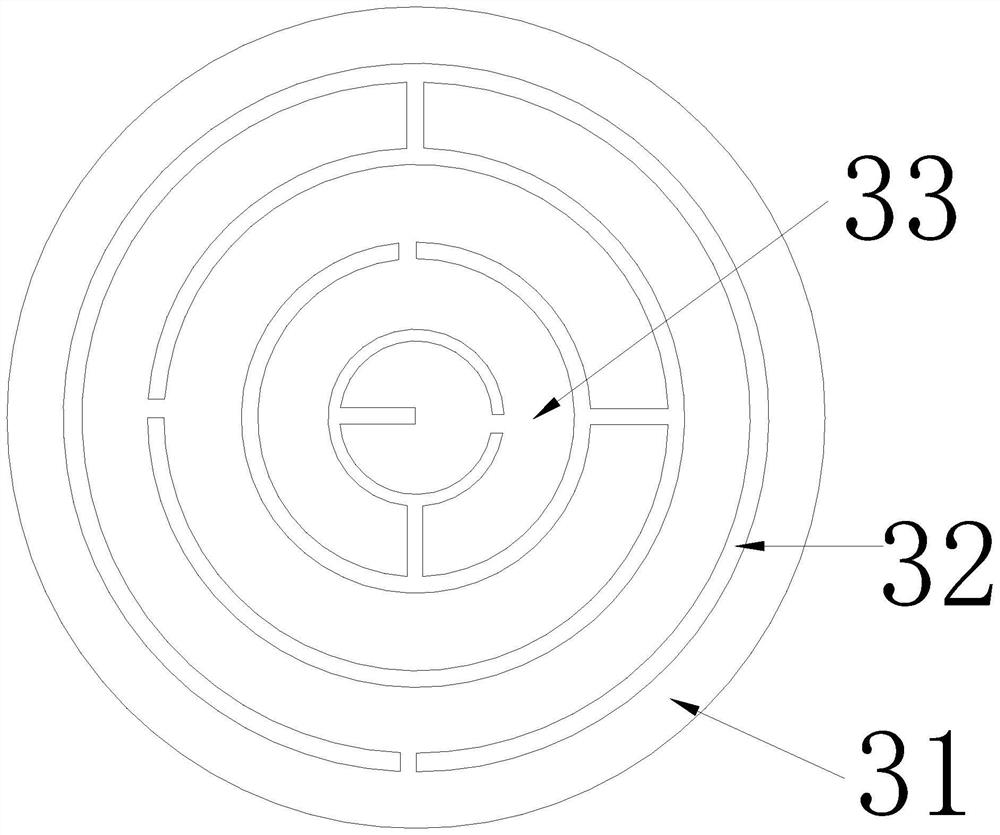

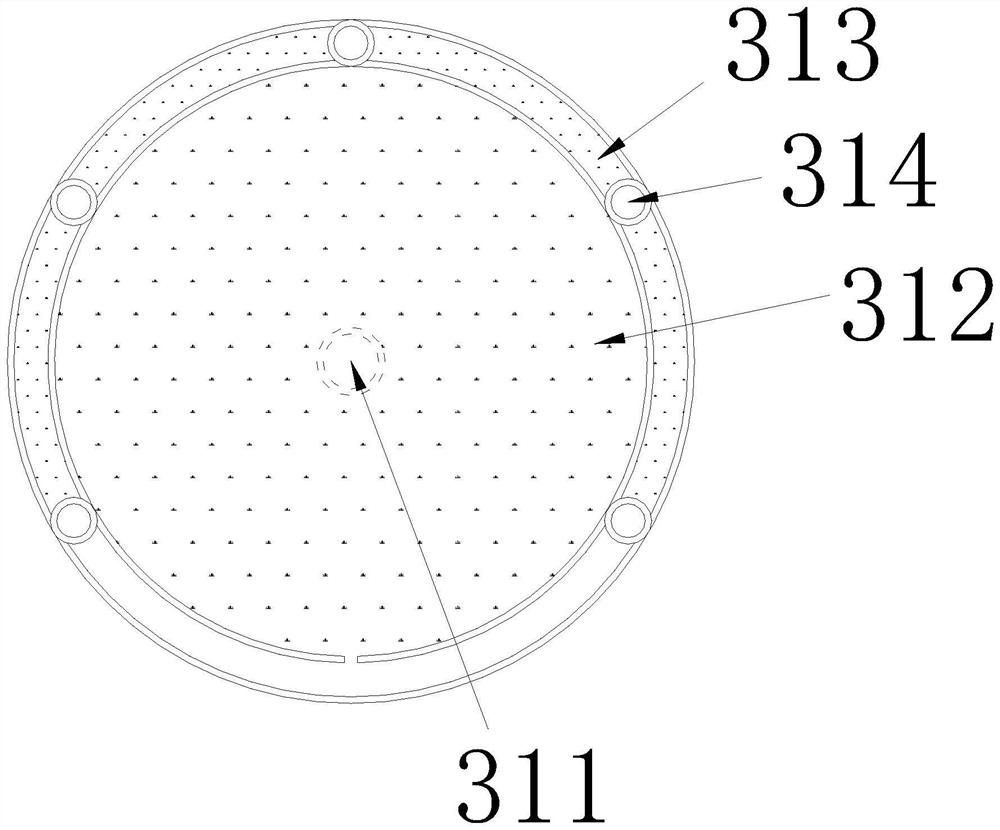

Vacuum adsorption adapter gasket

The invention provides a vacuum adsorption switching gasket which structurally comprises a main body, a vacuum chuck, a switching gasket and a wafer, the main body and the vacuum chuck are of an integrated structure, and the switching gasket is installed at the upper end of the vacuum chuck; according to the invention, after the adapter gasket is further improved, when the adapter gasket is used, the replaced gasket can be used to be matched with the vacuum chuck after the adapter gasket is directly replaced, so that one vacuum chuck can complete adsorption of wafers of various sizes by replacing the gasket; and meanwhile, the auxiliary soft body arranged on the outer layer can effectively slow down the sliding performance of the wafer, and can operate at the same time according to the mutual cooperation of the suction head and the vacuum chuck, so that the balance effect is kept in the air exhaust process, the uniform air suction effect is further achieved, and the service life of the wafer is prolonged. Therefore, the phenomenon that a smooth wafer is prone to slipping on the switching gasket can be effectively solved, air can be evenly sucked into the wafer, and wafer damage caused by unbalanced air suction is prevented.

Owner:SHANGHAI LEADING SEMICON TECH DEV CO LTD

Synchronously rotating anti-hanging membrane structure circular pool body seal cover

The invention discloses a sealing cover for a circular pond body of a synchronous-rotation reverse hanging membrane structure. The sealing cover comprises a girder and a circular track beam. The girder is in rigid connection with the circular track beam. Upward-arch truss beams are connected between the circular track beam and the girder in a spaced mode. A connecting truss beam is arranged between every two adjacent upward-arch truss beams. The girder, the circular track beam, the upward-arch truss beams and the connecting truss beams form a rigid support. A sealing membrane is fixedly arranged on the lower face of the rigid support in a reverse hanging mode. The periphery of the sealing membrane falls naturally and forms a sliding sealing face with a concrete walkway plane of the circular pond body. Bearing travelling wheels are installed on the lower edge of the circular track beam. The sealing cover is further provided with a gas collecting device for collecting gas inside the circular pond body. The gas collecting device collects gas inside the pond body in the mode of middle shaft air and peripheral air supplementation. The sealing cover is rapid to install, good in mobility, long in service life and applicable to any large-span pond body, and reduces occupation of a site.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

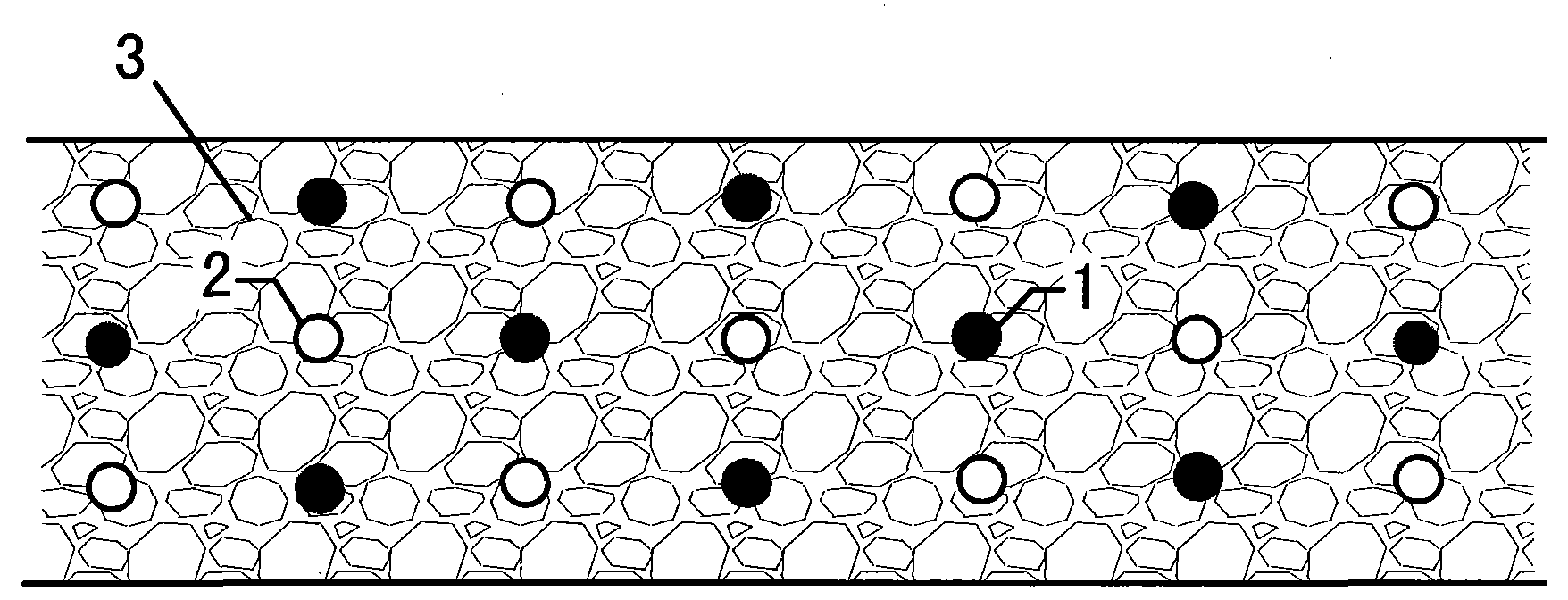

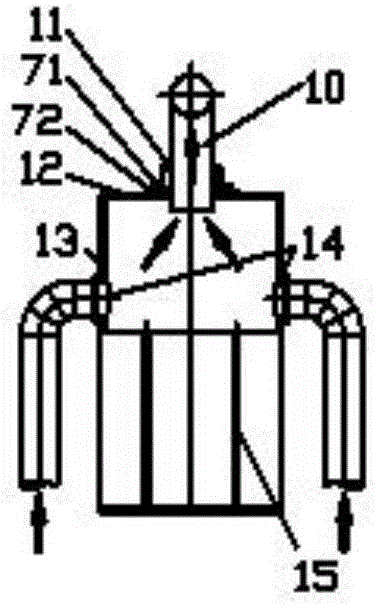

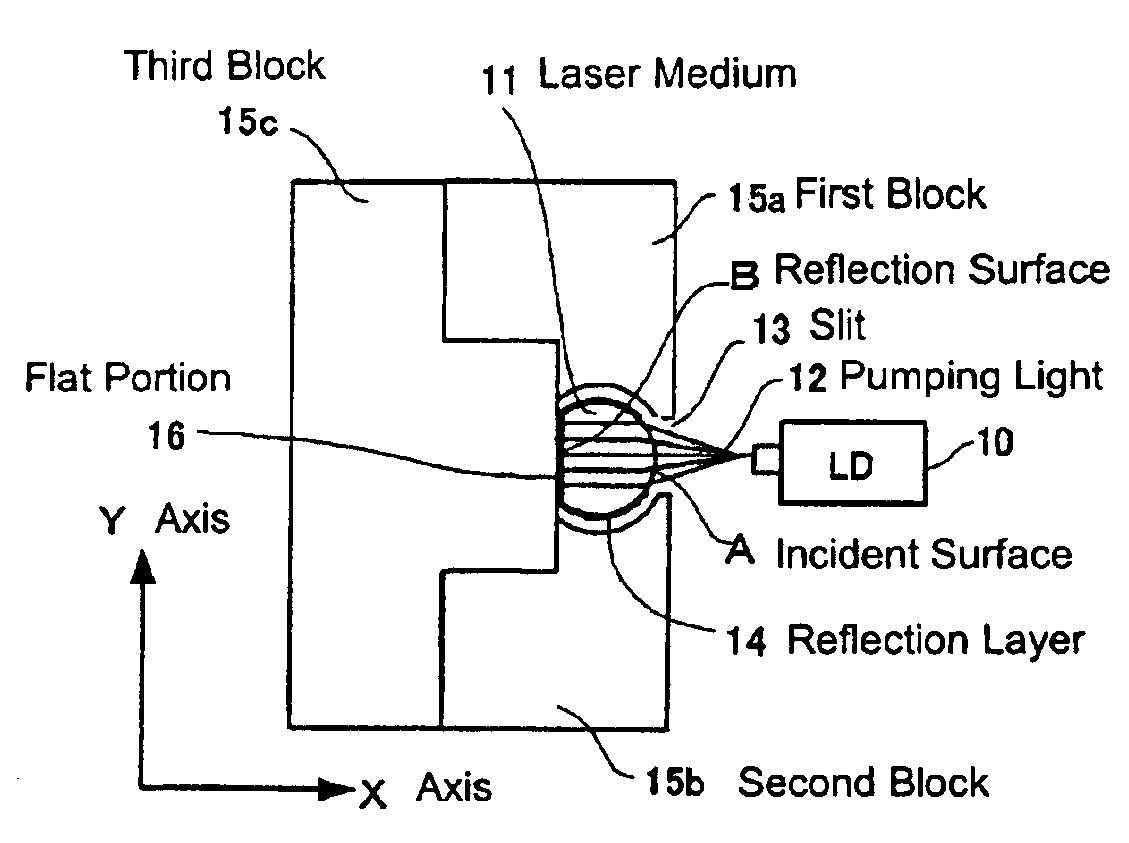

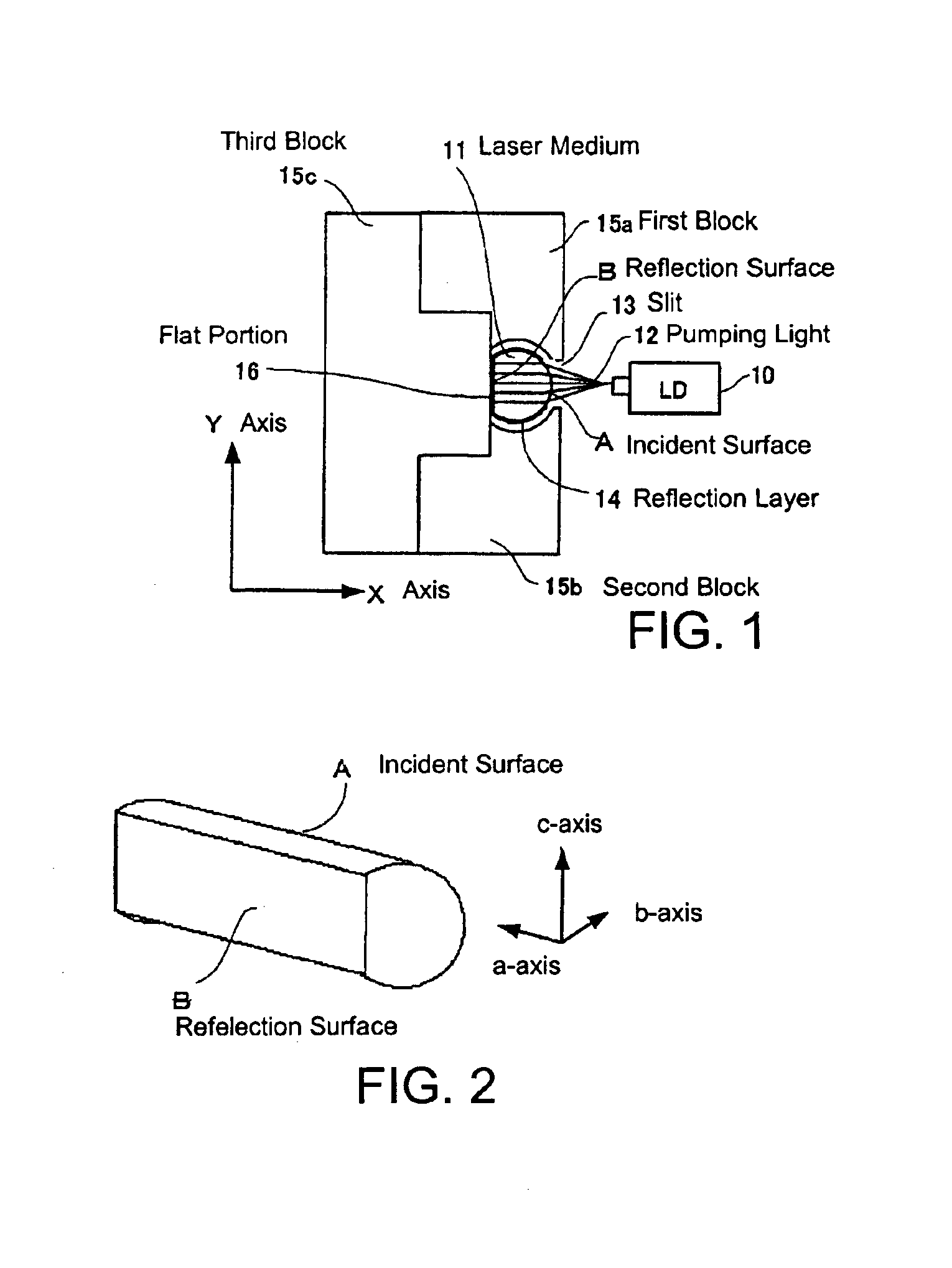

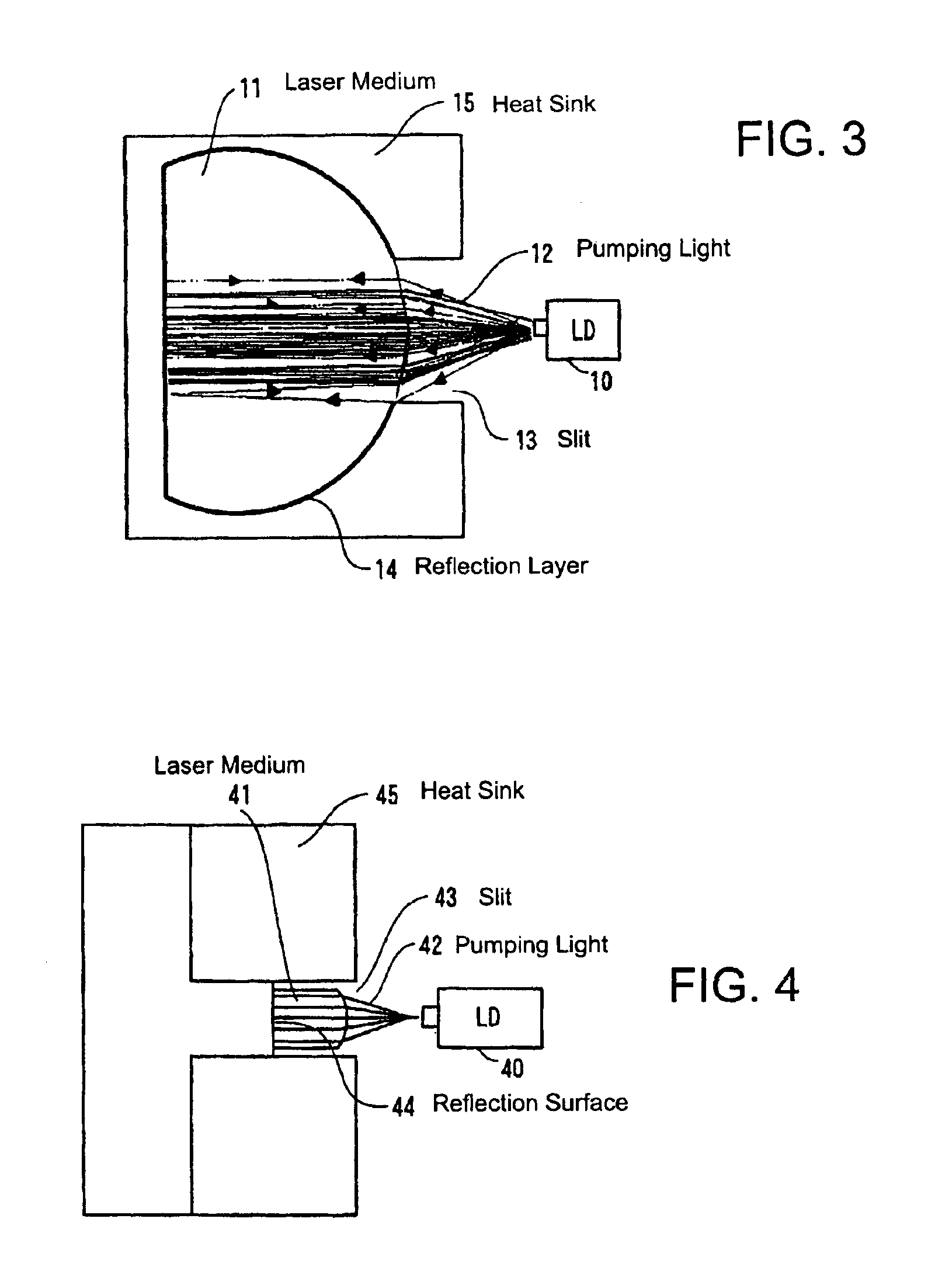

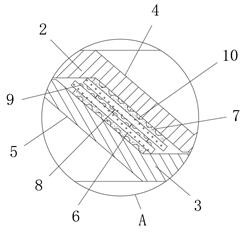

Solid state laser

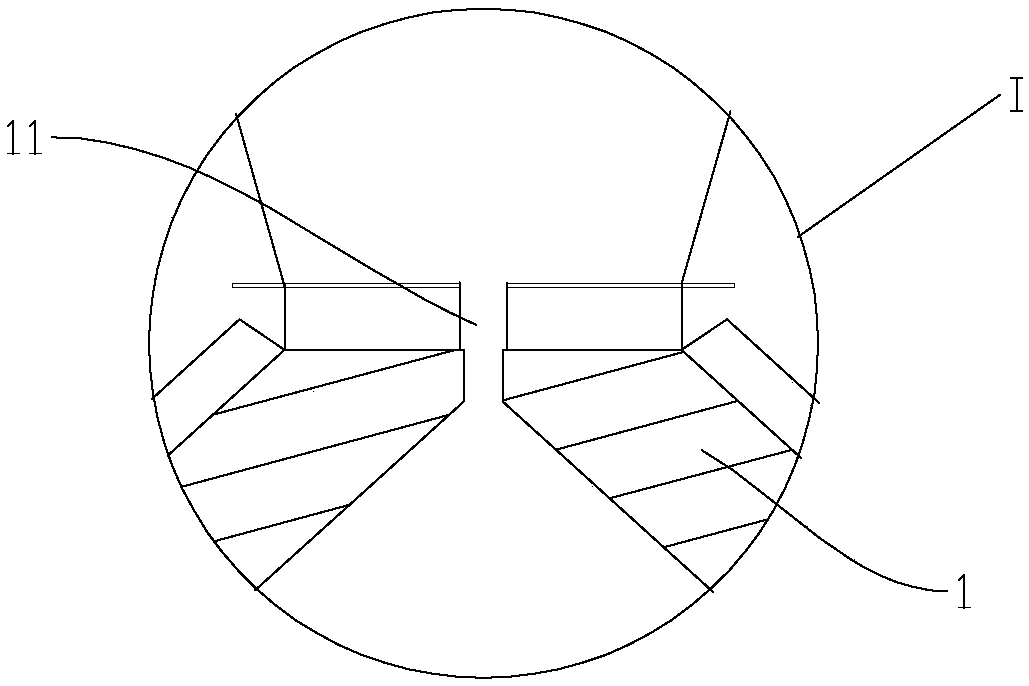

InactiveUS6947465B2Improve distributionImprove efficiencyExcitation process/apparatusOptical resonator shape and constructionOptoelectronicsHeat sink

The solid state laser comprises the laser medium 11 for absorbing the pumping light 12 from the LD 10 and generating or amplifying the light having a predetermined wavelength and a heat sink comprising the first block 15a, the second block 15b and the third block 15c for aligning the laser medium 11, cooling the laser medium 11 and reflecting the pumping light 12. The laser medium 11 has an arcuate light incident surface A and a flat reflection portion. The pumping light 12 having a diffusing angle is converted into parallel light by the light incident surface A, thereby pumping the laser medium 11 uniformly. The flat reflection portion makes it easy to align laser medium 11 having anisotropic characteristic and helps to efficiently pump the laser medium 11 by reflecting the reflection light substantially in parallel with the incident light.

Owner:ORC MFG

CT slip ring conductive disc forming method

The invention discloses a CT slip ring conductive disc forming method. The method comprises the steps of (1) preparing a conductive disc mold; (2) turning a copper plate ring groove on an annular copper plate at one time, and putting the annular copper plate into the conductive disc mold; (3) preparing a pouring material; (4) dividing the material into a component A and a component B; (5) respectively adding the component A and the component B into static mixing vacuum pouring equipment to be heated, stirred and subjected to vacuum defoaming; (6) spraying a polytetrafluoroethylene coating on the inner surface of the conductive disc mold, smearing an organic silicon release agent, and heating the conductive disc mold and preserving heat in a constant-temperature hot air oven; (7) vacuumizing the air pressure in a mold cavity through a vacuum pump; (8) pouring the inside of the mold cavity through the static mixing vacuum pouring equipment; (9) after the pouring is completed, carrying out heating curing on the conductive disc mold, and after furnace cooling, carrying out demolding; and (10) integrally milling and forming after demolding. According to the CT slip ring conductive disc forming method, the batch production can be realized, and the produced conductive disc is high in coaxiality.

Owner:杭州全盛机电科技有限公司

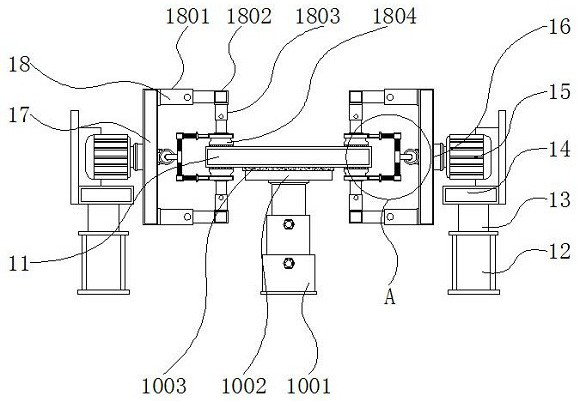

Electronic chip crack detection device with turnover structure convenient for double-sided detection

InactiveCN112051332AEasy to useEasy to absorb and fixAnalysing solids using sonic/ultrasonic/infrasonic wavesWorkbenchComputer hardware

The invention discloses an electronic chip crack detection device with a turnover structure convenient for double-sided detection, and relates to the technical field of electronic chip detection, theelectronic chip crack detection device comprises a machine body, a workbench and a supporting mechanism, a cabinet is installed below the machine body, a cabinet door is arranged on the outer side ofthe cabinet, and the workbench is fixed above the cabinet. A supporting column is fixed to the outer side of the workbench, a control chamber is installed above the supporting column, a display screenis arranged in front of the control chamber, a rack is fixed to the lower middle portion of the control chamber, and a detection sensor is installed below the middle portion of the rack; the device has the beneficial effects that the front side and the rear side of the electronic chip main body can be elastically clamped under the elastic action of the springs through the two sets of symmetricalpositioning pads, and hard damage to the electronic chip main body is avoided; and the soft velvet layer on the upper side surface of the bearing plate is attached to the lower side surface of the electronic chip main body, so that the electronic chip main body can be prevented from being abraded.

Owner:东莞市夯牛机电科技有限公司

Corn peeling device

The invention belongs to processing equipment for grain products, and discloses a corn peeling device. A glass window is arranged on the side wall of a peeling box; a vertical ventilation pipeline is arranged at the upper end of the peeling box; the upper end of the ventilation pipeline is sealed; a lateral roller is arranged in the ventilation pipeline; two ends of the roller are sealed; the roller penetrates through side walls on two sides of the ventilation pipeline; an inflating pipe and an exhausting pipe are respectively arranged at two ends of the roller; the inflating pipe communicates with an inner cavity of the roller; an inflating opening and an exhausting opening are formed in the side wall of the roller; when one of the inflating opening and the exhausting opening communicates with the inner cavity of the peeling box, the other of the exhausting opening and the inflating opening is propped against the upper end of the ventilation pipeline in a sealing manner; the exhausting pipe penetrates through the roller to communicate with the exhausting opening; and a mesh screen is arranged at the end part of the outer side of the exhausting opening, and the hole diameters of mesh holes are 0.1-0.3mm. Through the adoption of the corn peeling device provided by the invention, the technical problems that in the prior art, when corn beans are produced, peeling of corn is liable to cause damage of the corn, so that the appearance of the corn beans is influenced, and waste is caused, are solved.

Owner:GUIZHOU XUYANG FOOD GROUP

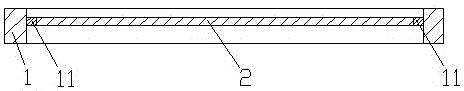

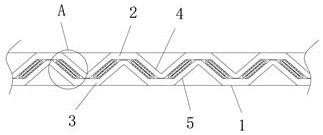

Building carbon fiber reinforcing band and reinforcing band winding device

InactiveCN112499335AImprove compactnessAvoid affecting the effect of useLayered productsBuilding repairsFiberCarbon fibers

The invention discloses a building carbon fiber reinforcing band and a reinforcing band winding device. The reinforcing band structure comprises a reinforcing band body, the reinforcing band body is provided with an upper band film and a lower band film which are attached to each other, the top of the upper band film is provided with concave parts distributed at equal intervals, and the top of thelower band film is provided with convex parts distributed at equal intervals; the concave parts and the convex parts are arranged to be of a conical structure, the concave parts and the convex partsare distributed at intervals, and concave holes are formed in the positions, corresponding to the concave parts, of the top of the upper band film and the positions, corresponding to the convex parts,of the bottom of the lower band film; and the reinforcing band winding device comprises a positioning frame, a winding roller is rotationally connected between the inner walls of the two sides of thepositioning frame, and one end of the winding roller is in transmission connection with a driving motor. The tightness of contact between portions of the band body is improved through adsorption force generated by the concave holes, and therefore the situation that the actual use effect is affected due to the fact that the reinforcing band body are in a tightened state due to excessive stretchingand winding is avoided.

Owner:杜亮

Vacuum compression bag gas nozzle with improved structure

An air nozzle for a vacuum compression bag with an improved structure, including a seat body, a sealing ring and an end cover, the seat body has an air inlet and an air outlet, and the air outlet of the seat body is respectively screwed with a sealing ring and an end cover. The base body is composed of an inner sleeve and an outer sleeve. The inner sleeve has an exhaust channel. The air inlet end of the exhaust channel of the inner sleeve extends out of the bottom of the outer sleeve and forms the air inlet of the base body. The air outlet of the base body is located at the top opening of the outer sleeve. The inner wall of the exhaust passage is provided with a deflector, and the deflector extends out of the air inlet end of the exhaust passage. A circular ring is also fixed in the exhaust passage, and a piston pad is provided at the outlet end of the exhaust passage of the inner sleeve, and a There is an inserting shaft with a chuck, and the chuck on the inserting shaft passes through the ring and is clamped outside the ring, and the piston pad is placed on the upper part of the inner sleeve and seals the outlet end of the exhaust passage. The beneficial effect of the present invention is that such a structure has good airtightness, and there is sufficient space for the gas to flow during pumping, and the pumping effect is ideal.

Owner:梁灼权

Forming mould of thermal-insulation layer of thermal-insulation pipeline

The invention relates to a forming mould of a thermal-insulation layer of a thermal-insulation pipeline. The forming mould comprises a mould body, wherein the mould body comprises an upper mould and a lower mould, the upper mould and the lower mould form a bi-parting mould, and are respectively provided with a mould housing and a mould liner which corresponds to the mould housing and internally provided with a semicircular cavity; by forming a plurality of through holes in the inner wall of the mould liners, a cavity communicated with the through holes is arranged on the outer wall of each mould liner, at least one extraction opening communicated with the through holes by virtue of the corresponding cavity is formed in each mould housing, and the extraction openings are connected with a mould external vacuumizing assembly. By arranging the through holes, the cavities and the extraction openings, the vacuumizing assembly is started to ensure that negative pressure is formed in each cavity, and thus a film can be firmly adsorbed on the inner walls of the mould liners, the inner walls of the mould liners can be well separated from a thermal-insulation layer without damaging the thermal-insulation layer, and the surface thickness of the thermal-insulation is relatively uniform.

Owner:BEIJING HTN PIPELINE EQUIP

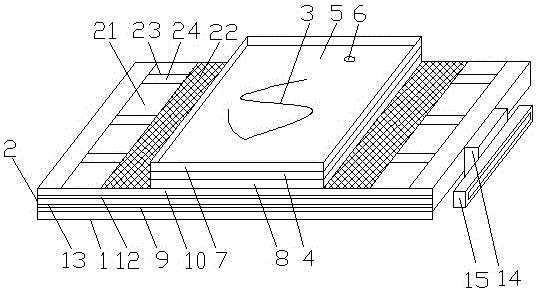

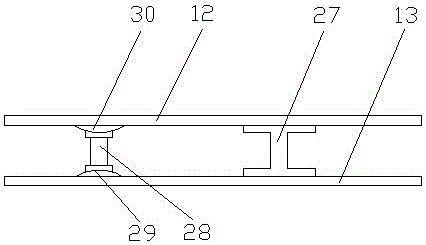

A baffle and a vacuum dryer comprising the baffle

ActiveCN106773169BImprove efficiencyEven airflowPhotosensitive material processingNon-linear opticsLiquid-crystal displayEngineering

The invention relates to the technical field of liquid crystal display panel manufacturing, and provides a blocking plate. The blocking plate comprises a first plate face and a second plate face, wherein the first plate face and the second plate face are parallel to each other, the first plate face and the second plate face are arranged at the two sides of the blocking plate respectively, observed from the normal direction of the first plate face, the central area of the blocking plate is provided with a hole, the hole penetrates through the first plate face and the second plate face of the blocking plate, in a vacuum drier, the blocking plate is put above an array substrate to be dried, an exhaust air duct can conduct air exhaust drying on the array substrate directly from the central part of the blocking plate so as to make the airflow path in the central area of the array substrate shorten, the air exhaust effect in the central area of the array substrate is improved, thus the airflow above the array substrate is more even, a central defect caused by unevenness of the air exhaust is avoided, and the quality of a product is improved. The invention provides the vacuum drier comprising the blocking plate at the same time.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com