Horizontal enameling machine oven with ultra-wide combustion chamber

A horizontal enamelling machine and hearth technology, which is applied to hearth type furnaces, furnaces, drying, etc., can solve the problems of human health damage, high air flow temperature, and high heat energy of iron wires, and achieve reduced operation difficulty, uniform heat, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

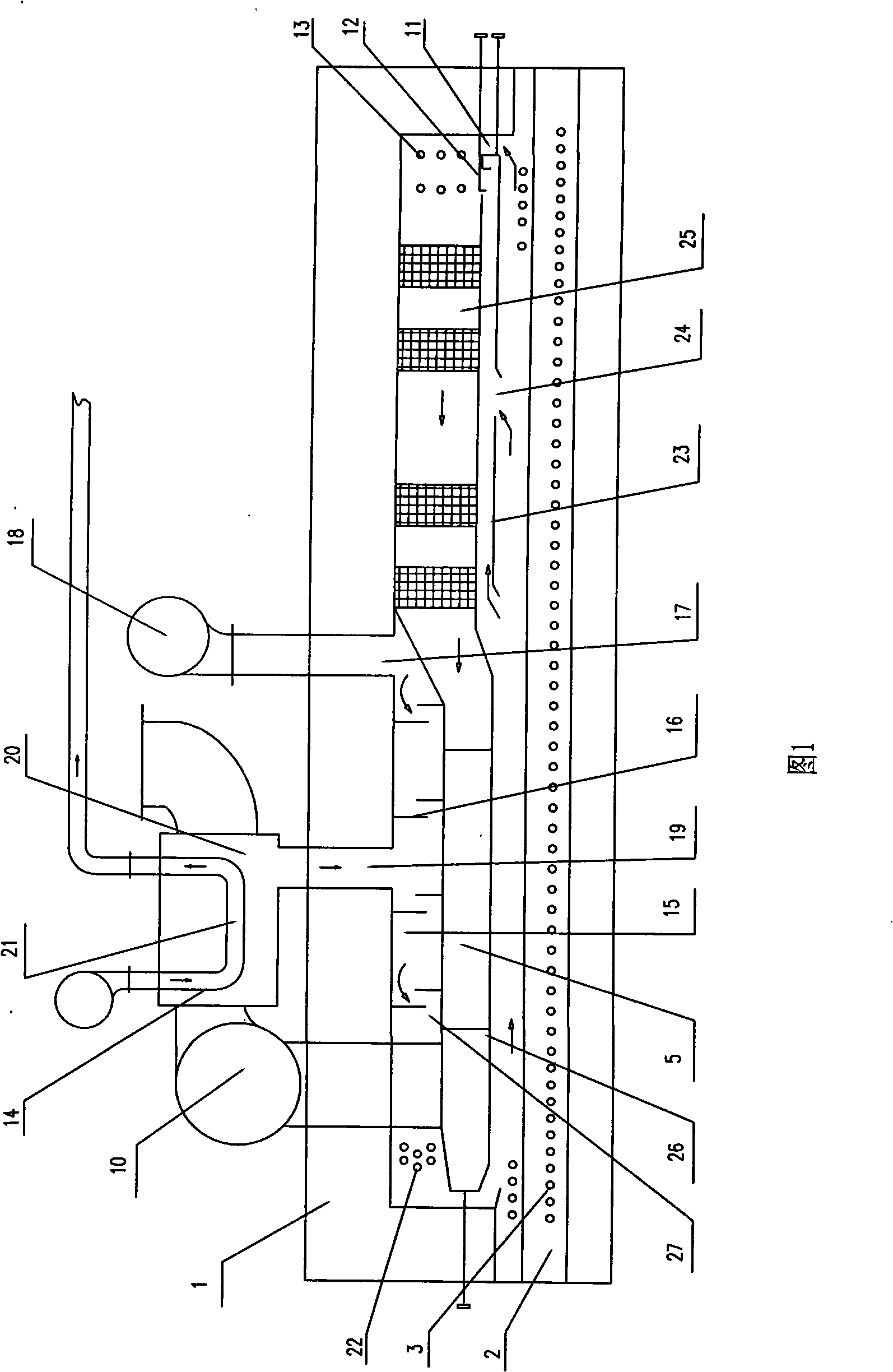

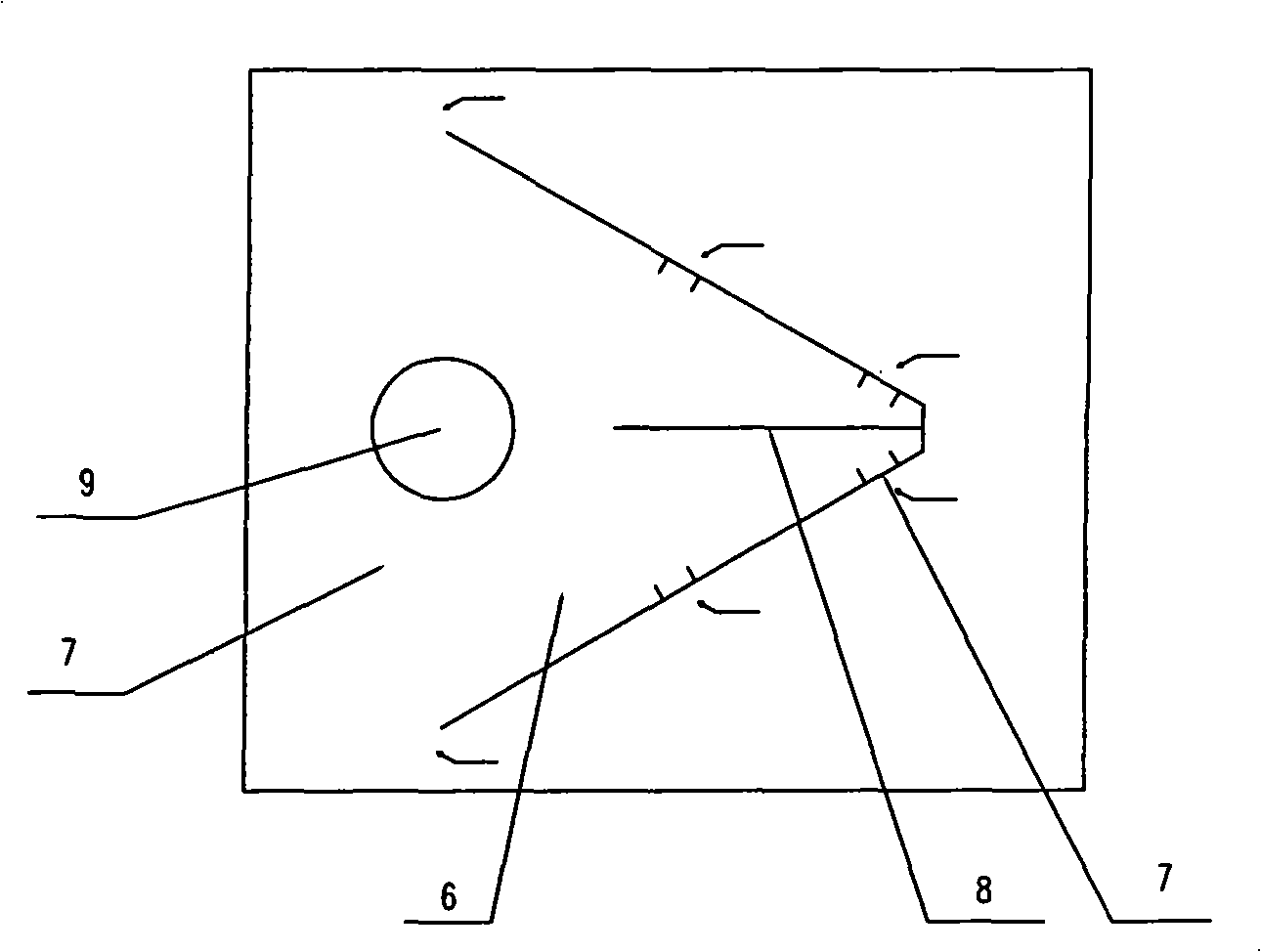

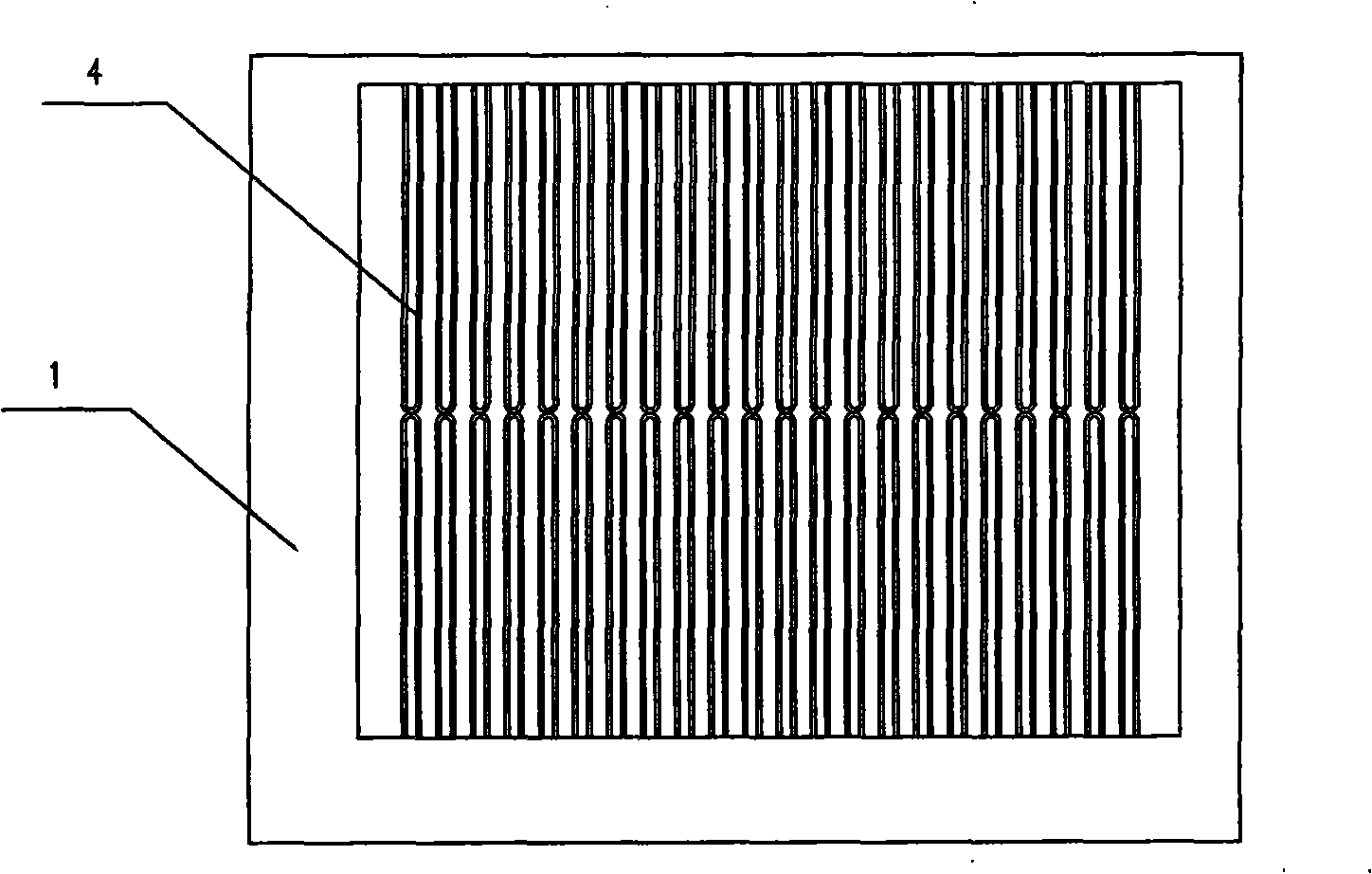

[0023] Figure 1~ Figure 4 As shown, an ultra-wide hearth horizontal enamelling machine oven of the present invention includes a hearth 1, the hearth 1 is 3758mm long, and the hearth 1 is divided into three layers, the first layer is an electric heating layer 2, and a heat radiation device 3 is distributed underneath , it is composed of a plurality of U-shaped U-shaped electric heating tubes 4 arranged side by side, and the multiple electric heating tubes 4 are installed in groups on the left and right sides separated by the center of the furnace 1, and the two groups of electric heating tubes 4 are respectively externally connected with temperature control The device has a total of 6 temperature control points, all of which are independently controllable. Among them, a plurality of electric heating tubes are densely distributed at the air inlet and outlet of the furnace 1, and are located in the middle of the furnace with large intervals. The furnace 1 separates a solvent su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com