Building carbon fiber reinforcing band and reinforcing band winding device

A carbon fiber reinforcement and winding device technology, applied in building maintenance, construction, building construction, etc., can solve problems affecting the use effect of reinforcement tapes, and achieve the effect of avoiding wrinkles, avoiding excessive stretching, and avoiding carbon fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

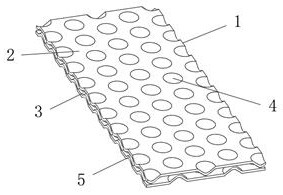

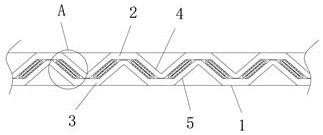

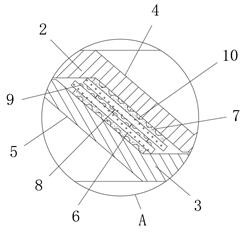

[0026] refer to Figure 1-3 , a kind of construction carbon fiber reinforced belt, comprising a reinforced belt body 1, the reinforced belt body 1 is provided with a pasted upper belt film 2 and a lower belt film 3, and the top of the upper belt membrane 2 is provided with equidistantly distributed depressions 4, and The top of the lower film 3 is provided with protruding portions 5 distributed equidistantly, the recessed portion 4 and the protruding portion 5 are all arranged in a conical structure, and the recessed portion 4 and the protruding portion 5 are arranged at intervals, and the upper film 2 top The position corresponding to the recessed portion 4 and the position corresponding to the bottom of the lower tape film 3 and the protruding portion 5 are all provided with concave holes, the bottom end of the recessed portion 4 is fixed with the top of the lower tape film 3, and the top of the protruding portion 5 is in contact with the upper tape. The bottom of the film 2...

Embodiment 2

[0031] refer to Figure 4-6 , a winding device for a building carbon fiber reinforced belt, comprising a positioning frame 11, a winding roller 12 is rotatably connected between the inner walls of both sides of the positioning frame 11, and one end of the winding roller 12 is connected to a drive motor, and the reinforcement belt body 1 is wound on the outer circumferential wall of the winding roller 12, the bottom of the inner wall on both sides of the positioning frame 11 is fixed with electric guide rails 13, and a connecting plate 14 is connected between the two electric guide rails 13, and a drawer is fixed on both sides of the connecting plate 14. Air pipe 15, the nozzles at the bottom of the two suction pipes 15 correspond to both sides of the wound reinforcement tape body 1, and the device winds the reinforcement tape body 1 around the outer wall of the winding roller 12 when the carbon fiber reinforcement tape is wound and rotates with a drive motor Rewinding, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com