CT slip ring conductive disc forming method

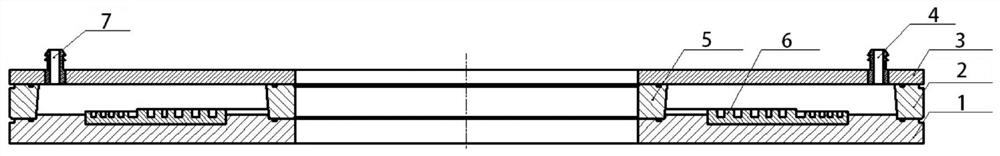

A molding method and conductive plate technology, which is applied in the field of CT slip rings, can solve the problems affecting the use of CT slip ring conductive plates and the large size of CT slip ring conductive plates, so as to facilitate subsequent installation and use, improve coaxiality, and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: According to the above steps, the mass percentage of the casting material is: E44 epoxy resin 40%, methyltetrahydrophthalic anhydride 13%, polysebacic anhydride 13%, accelerator 0.7%, fumed silica 10%, the balance is hollow glass beads;

[0039] Wherein, 60% of the total mass of the above-mentioned fumed silica and hollow glass beads and 40% of the E44 epoxy resin are premixed to obtain the A component.

[0040] Wherein, 40% of the total mass of the above-mentioned fumed silica and hollow glass beads, methyltetrahydrophthalic anhydride, polysebacic anhydride, and an accelerator are premixed to obtain the B component.

[0041] Embodiment 2: According to the above steps, the mass percentage of the casting material is 36% of E44 epoxy resin, 9% of methyltetrahydrophthalic anhydride, 9% of polysebacic anhydride, 0.3% of accelerator, and 6% of fumed silica. %, the balance is hollow glass beads;

[0042] Wherein, 60% of the total mass of the above-mentioned fu...

Embodiment 3

[0044] Embodiment 3: According to the above steps, the mass percentage of the casting material is 44% of E44 epoxy resin, 17% of methyltetrahydrophthalic anhydride, 17% of polysebacic anhydride, 1.4% of accelerator, and 14% of fumed silica. %, the balance is hollow glass beads;

[0045] Wherein, 60% of the total mass of the above-mentioned fumed silica and hollow glass beads and 40% of the E44 epoxy resin are premixed to obtain the A component.

[0046]Wherein, 40% of the total mass of the above-mentioned fumed silica and hollow glass beads, methyltetrahydrophthalic anhydride, polysebacic anhydride, and an accelerator are premixed to obtain the B component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com