Vacuum pump with special-shaped cavity

A vacuum pump, special-shaped cavity technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., to achieve the effect of high volumetric efficiency, simple structure, and small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

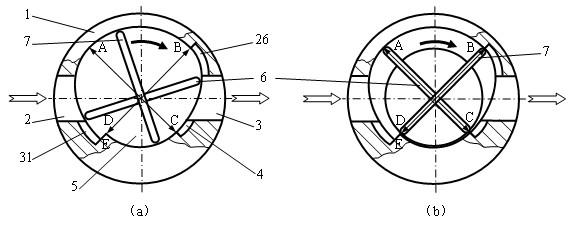

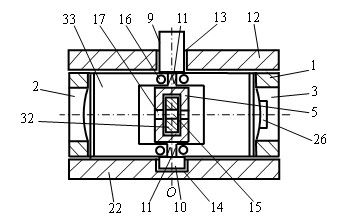

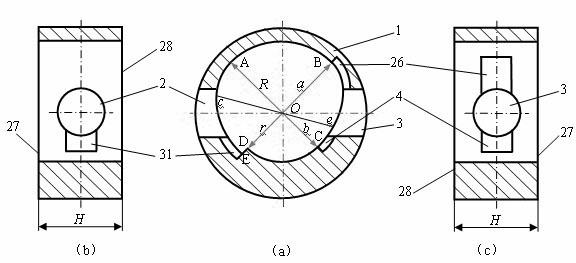

[0043] Reference Figure 1 to Figure 7 . The special-shaped cavity vacuum pump of the present invention includes a stator 1 with a special-shaped cylindrical inner cavity, an inlet 2, an outlet 3, a first unloading slot 4, a second unloading slot 26, and a pressure balance slot 31, and a stator 1 installed on both ends of the stator 1. The upper cover plate 12 and the lower cover plate 22 constitute a sealed cavity, and a rotor is installed in the sealed cavity.

[0044] The special-shaped cylindrical cavity of the stator 1 is composed of a quarter arc surface AB, a transition arc surface BC, a quarter arc surface CD, a turning plane DE, and a limit curved surface EA in sequence; a quarter arc surface The surface AB and the quarter arc surface CD are coaxial, and the common axis is O (see figure 2 , image 3 ); The center of curvature of the B and C ends of the transition arc BC is located on the common axis O of the quarter arc surface AB and the quarter arc surface CD; the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com