Patents

Literature

59results about How to "Fast vacuuming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

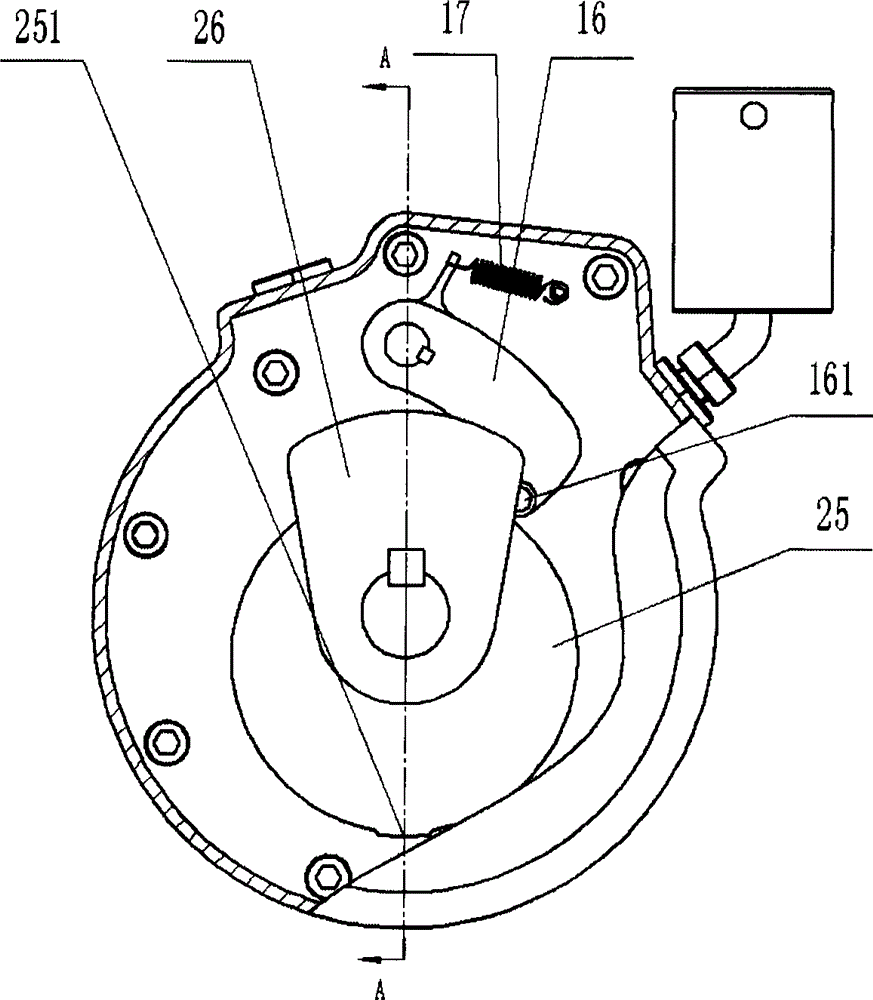

Vacuum refreshing system

InactiveCN101767686AFast vacuumingClosure with auxillary devicesRemovable lids/coversMotor driveMarine engineering

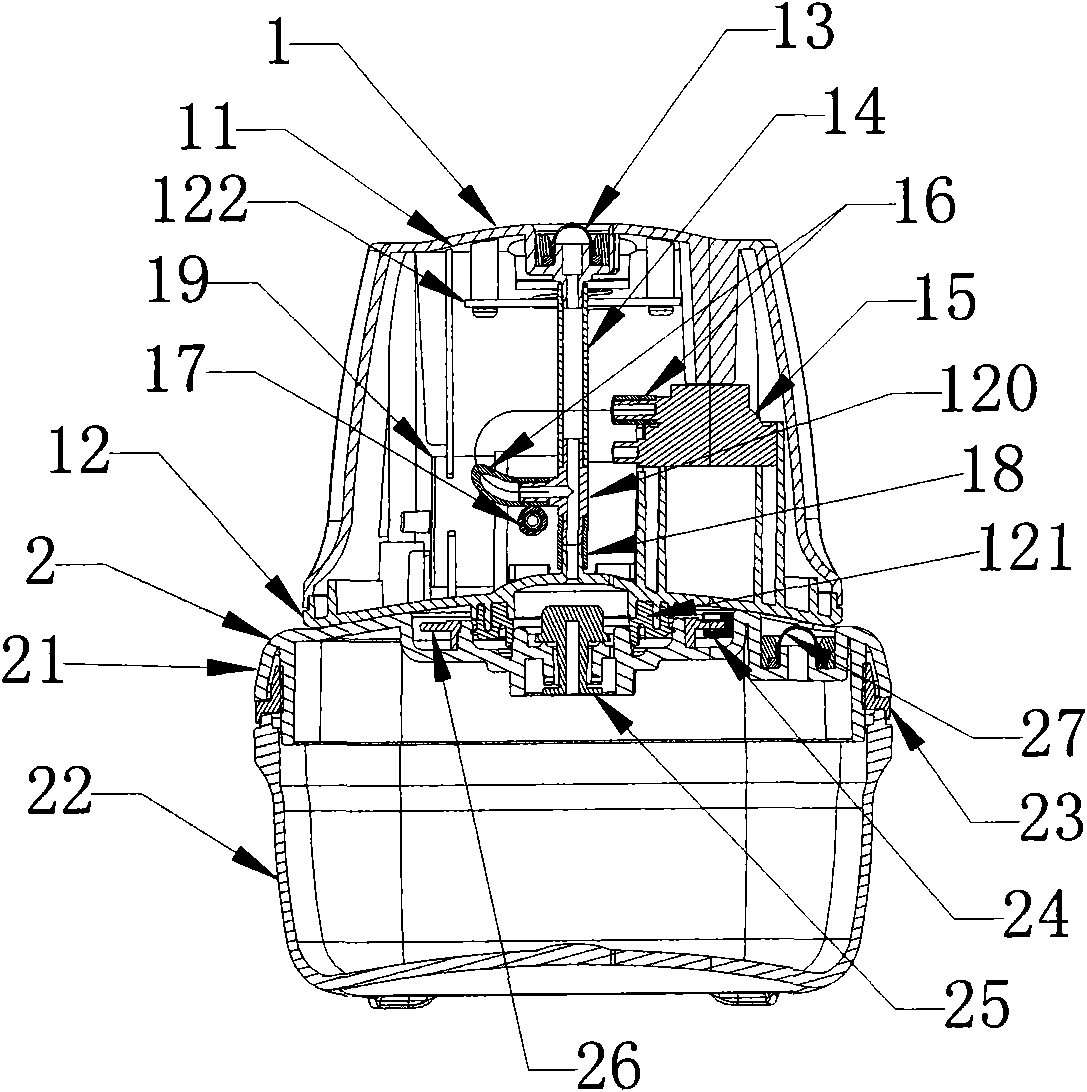

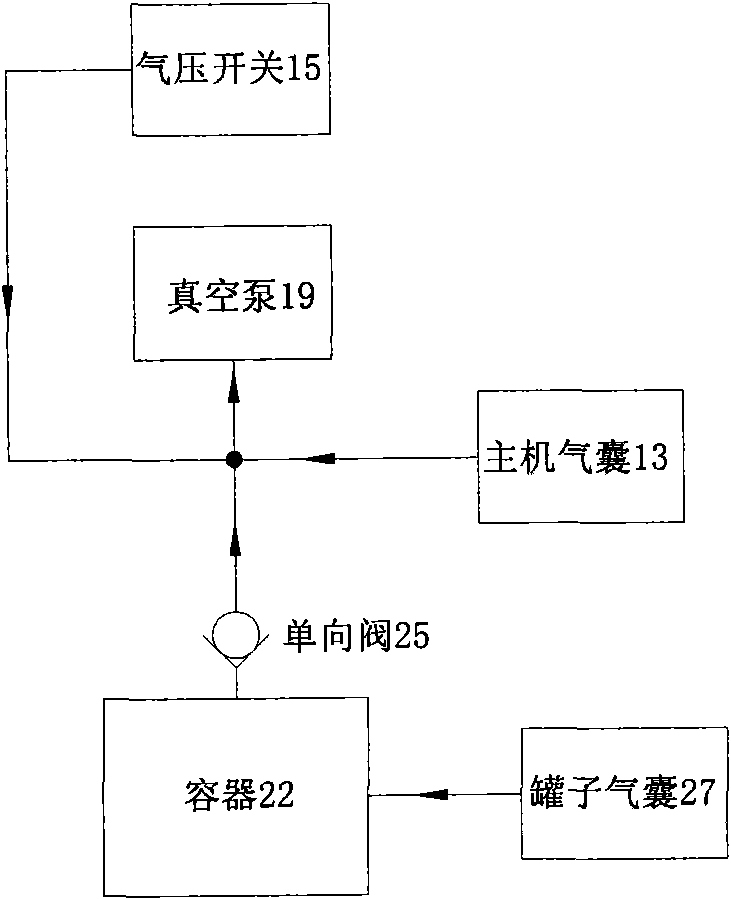

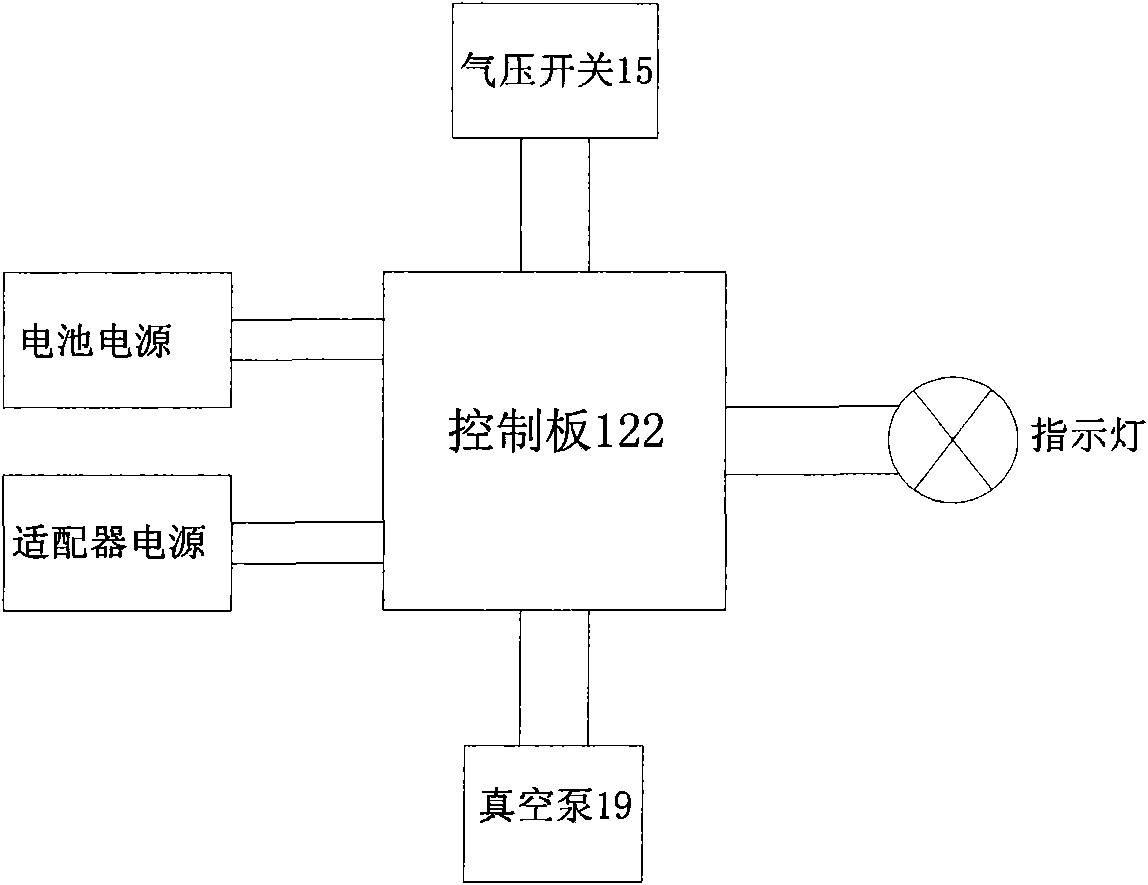

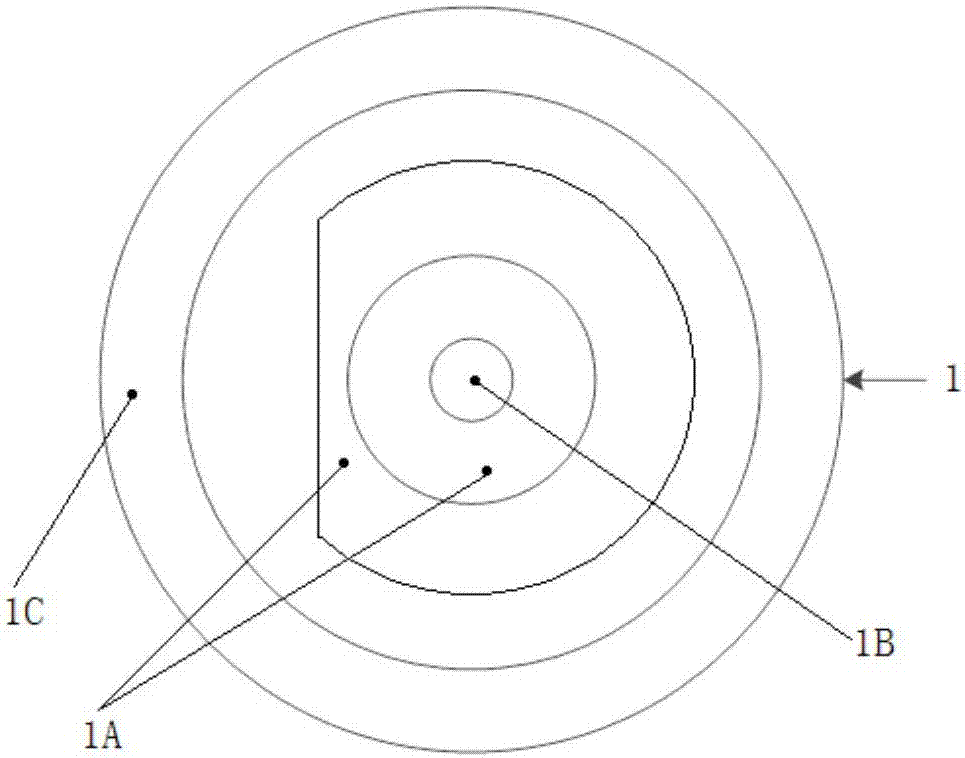

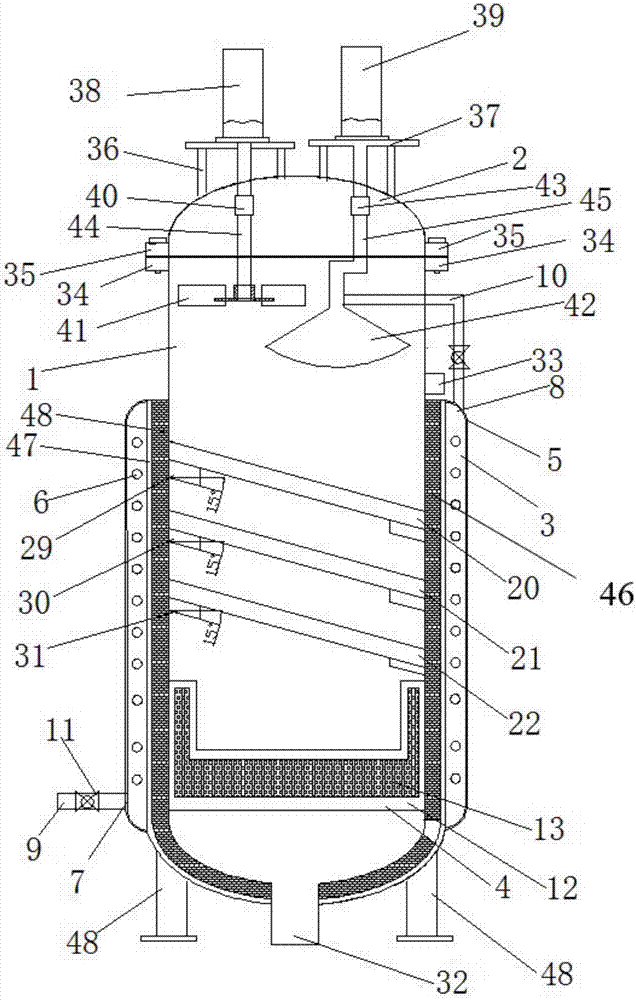

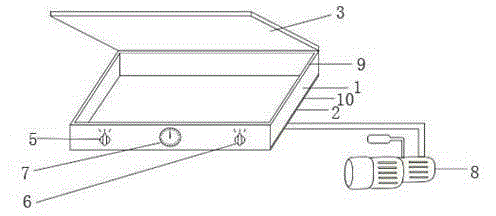

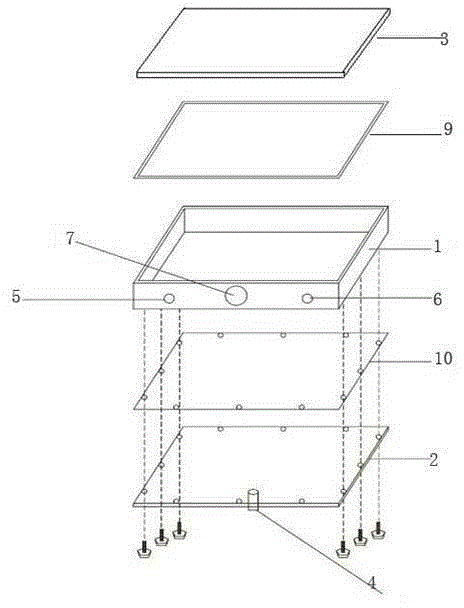

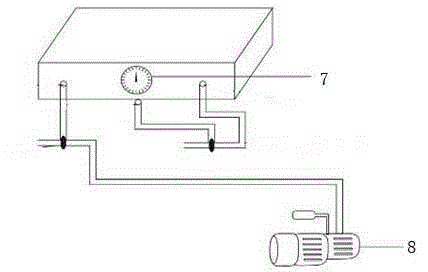

The invention relates to a vacuum refreshing system, comprising a tank (2) and a vacuumizing host machine (1) above the tank (2); the vacuum refreshing system is characterized in that: the tank (2) comprises a vessel (22) and a vessel cover (21) arranged at the top part of the vessel (22); a sealing ring (23) is arranged at the periphery of the vessel cover (21), a dial plate (26) is arranged in the middle part of the vessel cover (21), figures 1-31 for indication and one picking sheet (24) are arranged on the scale zone of the dial plate (26), a one-way valve (25) is arranged in the middle part of the dial plate (26), and an air bag (27) is arranged at front side or rear side of the dial plate (26). The vacuum refreshing system adopts a motor-driven vacuum pump for air exhausting, the vacuumizing speed is rapid, the negative pressure is above 50Pa, in the operation and using process, the vessel condition can be monitored in a real-time way, and whether the vessel is leaked can be judged, so as to make corresponding display or control according to different conditions.

Owner:ニンボティーエルシーエレクトロニックインダストリーカンパニーリミテッド

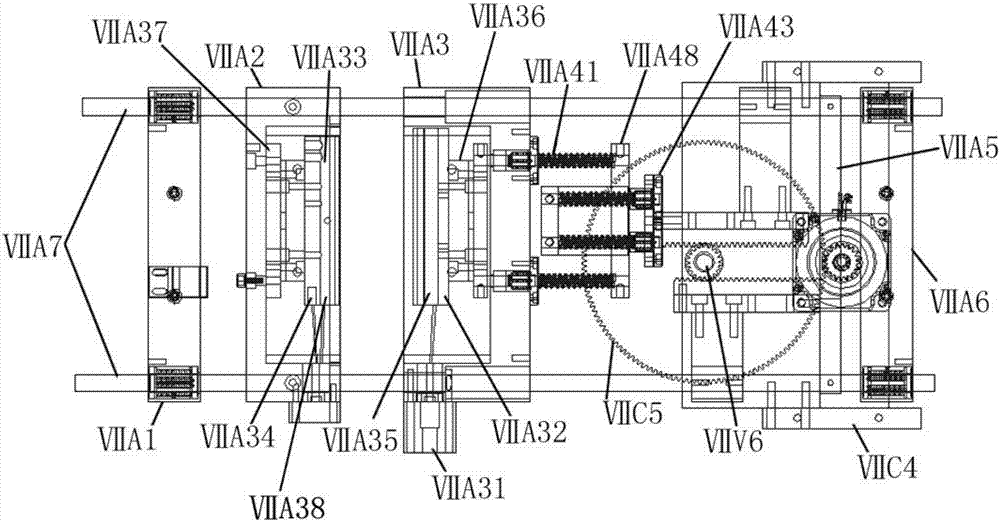

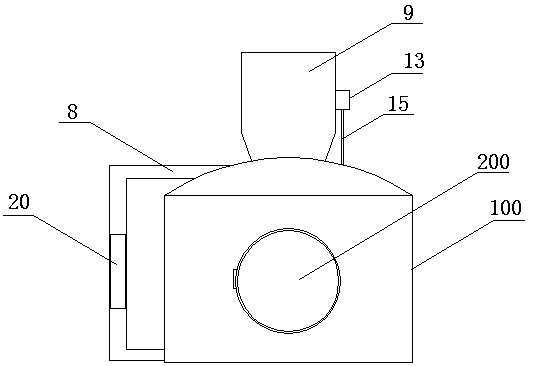

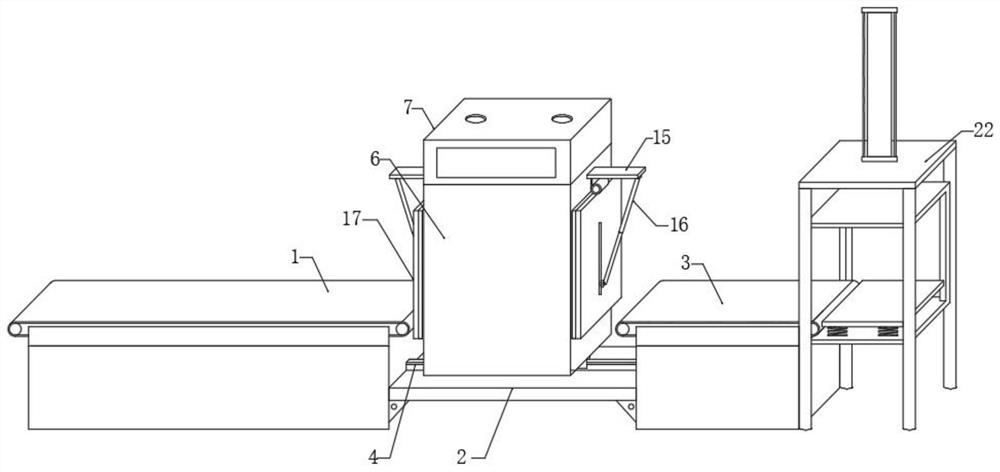

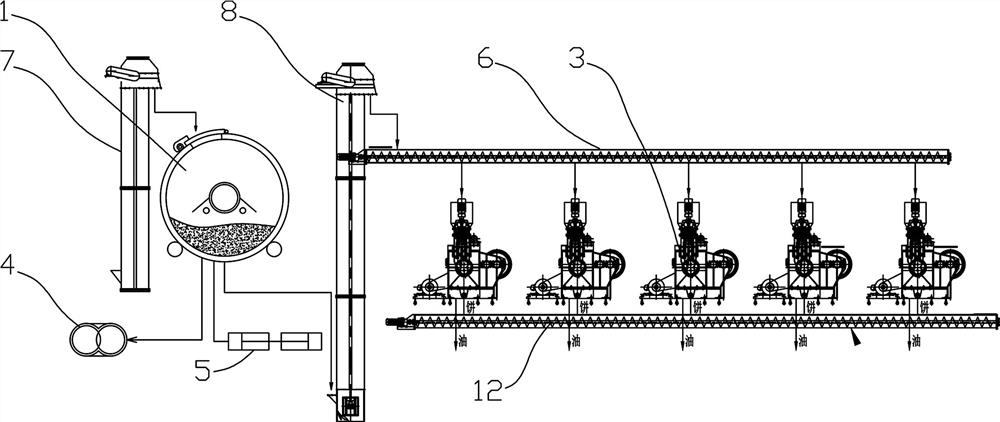

Pure electric reshaping and packaging machine and processing method thereof

ActiveCN106956824AFast packingNo less packagingPackaging under vacuum/special atmosphereFailure rateEstimated Weight

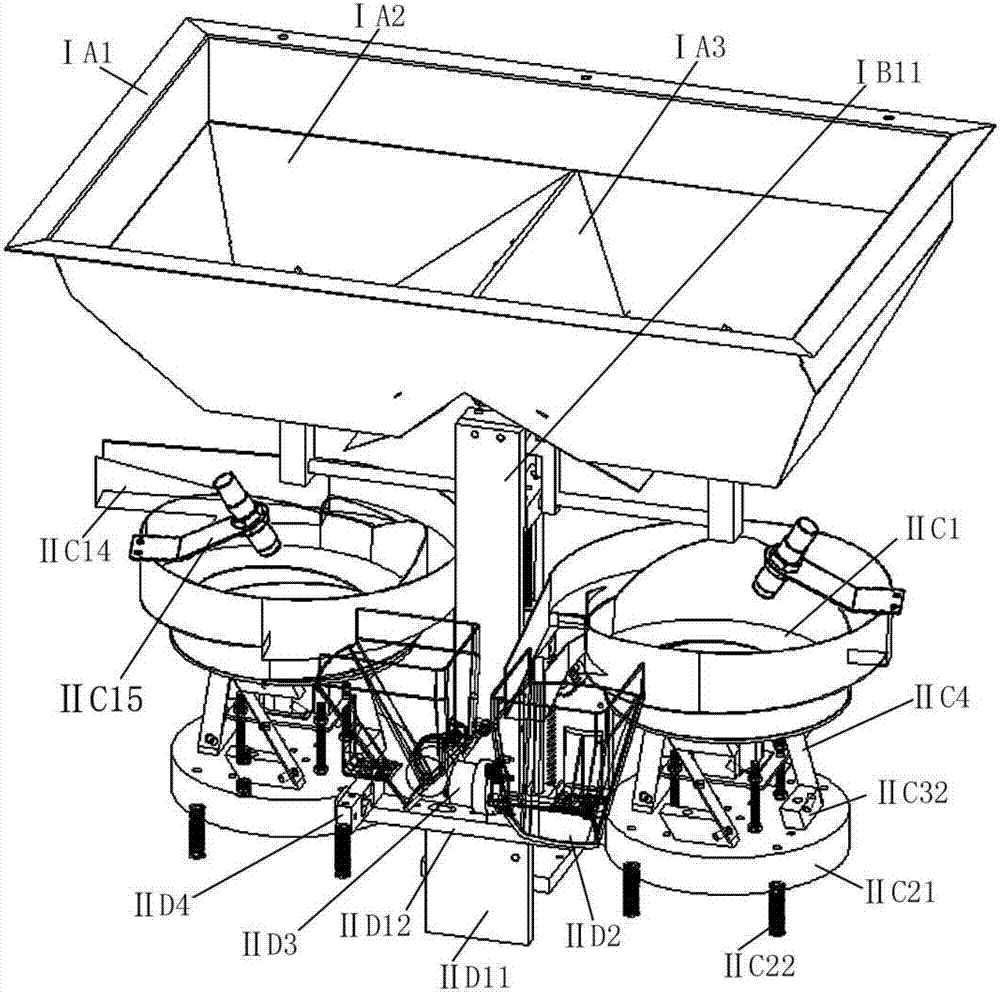

The invention discloses a pure electric reshaping and packaging machine and a processing method thereof. The processing method comprises the steps that tea leaves are poured into a cubic collecting hopper, the tea leaves in the cubic collecting hopper successively fall into a vibrating type feeding mechanism through dredging of a lifting type discharging dredging mechanism, the vibrating type feeding mechanism conveys the tea leaves to a weighing mechanism in a vibrating spiral feeding mode, and the weighing mechanism conveys the tea leaves reaching the estimated weight to a longitudinal guiding device; meanwhile, an outer bag is conveyed to the position under the longitudinal guiding device, a bag taking and coding device and the longitudinal guiding device cooperate with each other to open the outer bag, and the tea leaves are finally filled into the outer bag; an outward vacuumizing and bilateral heat sealing device and a bag reshaping device act simultaneously, the outward vacuumizing and bilateral heat sealing procedures are completed while the outer bag is reshaped, and the outer bag filled with the tea leaves is finally processed to be shaped. The pure electric reshaping and packaging machine and the processing method thereof have the advantages of being novel in structure, more stable in operation, low in failure rate, high in working efficiency, capable of saving energy and flexible and diverse in outer bag reshaping mode.

Owner:福建省安溪县兴安金属有限公司

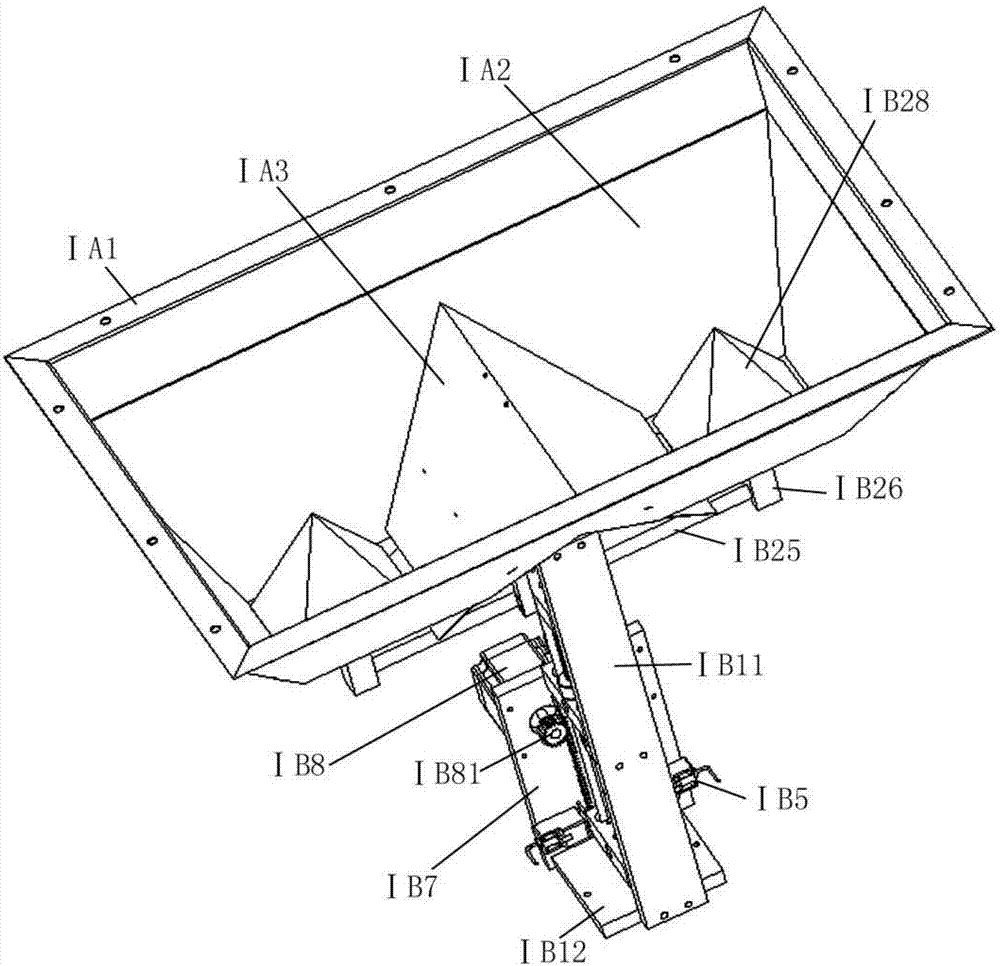

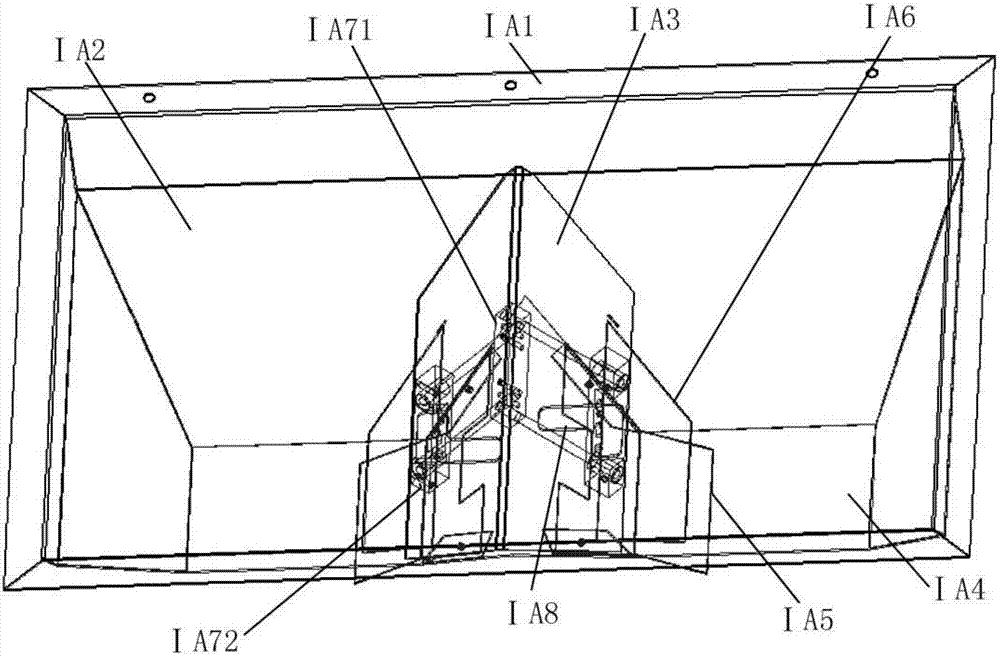

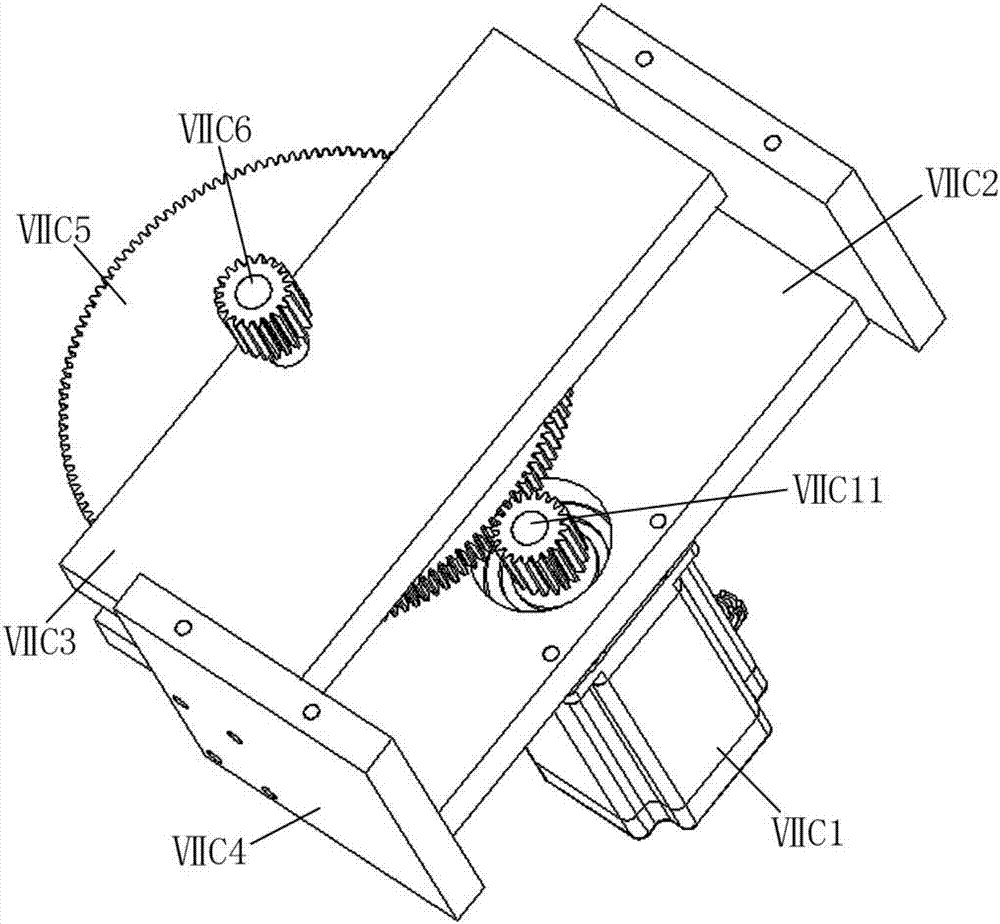

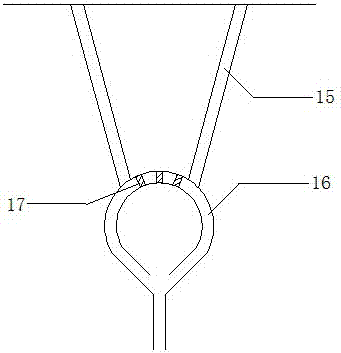

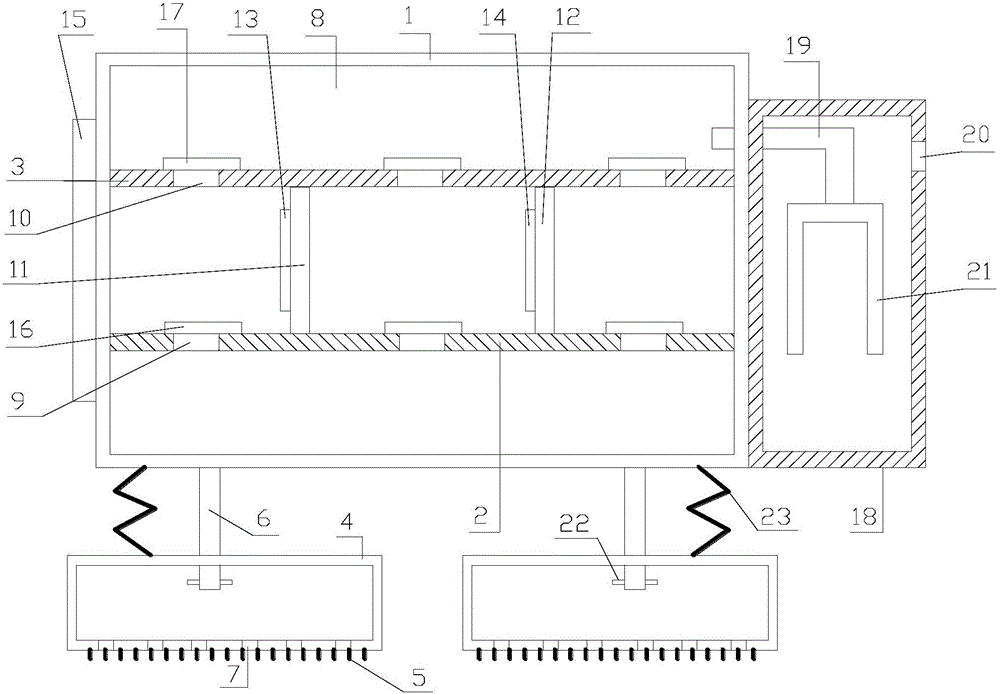

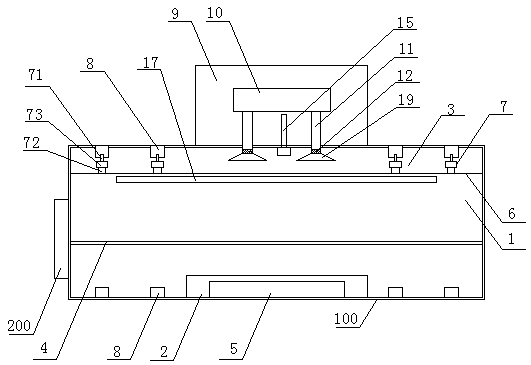

Vacuum sealing and shaping device of tea packing machine

InactiveCN108163255AReduce volumeCompact structurePackaging under vacuum/special atmospherePackaging automatic controlAgricultural engineeringPiston rod

The invention provides a vacuum sealing and shaping device of a tea packing machine. The vacuum sealing and shaping device comprises a machine frame, a sealing mechanism, an air extraction mechanism and a shaping mechanism, wherein the air extraction mechanism and the shaping mechanism are installed on the machine frame from top to bottom in sequence; and a material jacking mechanism is installedin the position, corresponding to the shaping mechanism, of the machine frame. The air extraction mechanism comprises a first horizontal air cylinder installed on the machine frame, a left shell connected with a piston rod of the first horizontal air cylinder, a right shell opposite to the left shell, a connection rod, a longitudinal installation plate and a second horizontal air cylinder installed on the machine frame from left to right in sequence, a piston rod of the second horizontal air cylinder sequentially penetrates through the longitudinal installation plate, the connection rod and the right shell, and the left shell and the right shell are provided with a first inwards concave cavity and a second inwards concave cavity correspondingly. The sealing mechanism comprises a third horizontal air cylinder installed on the longitudinal installation plate, a first sealing heat chuck and a second sealing heat chuck opposite to the first sealing heat chuck, the first sealing heat chuckis installed on the left shell and located in the first cavity, and a piston rod of the third horizontal air cylinder penetrates through the right shell and is connected with the second sealing heat chuck movably arranged in the second cavity.

Owner:福建元弘自动化科技有限公司

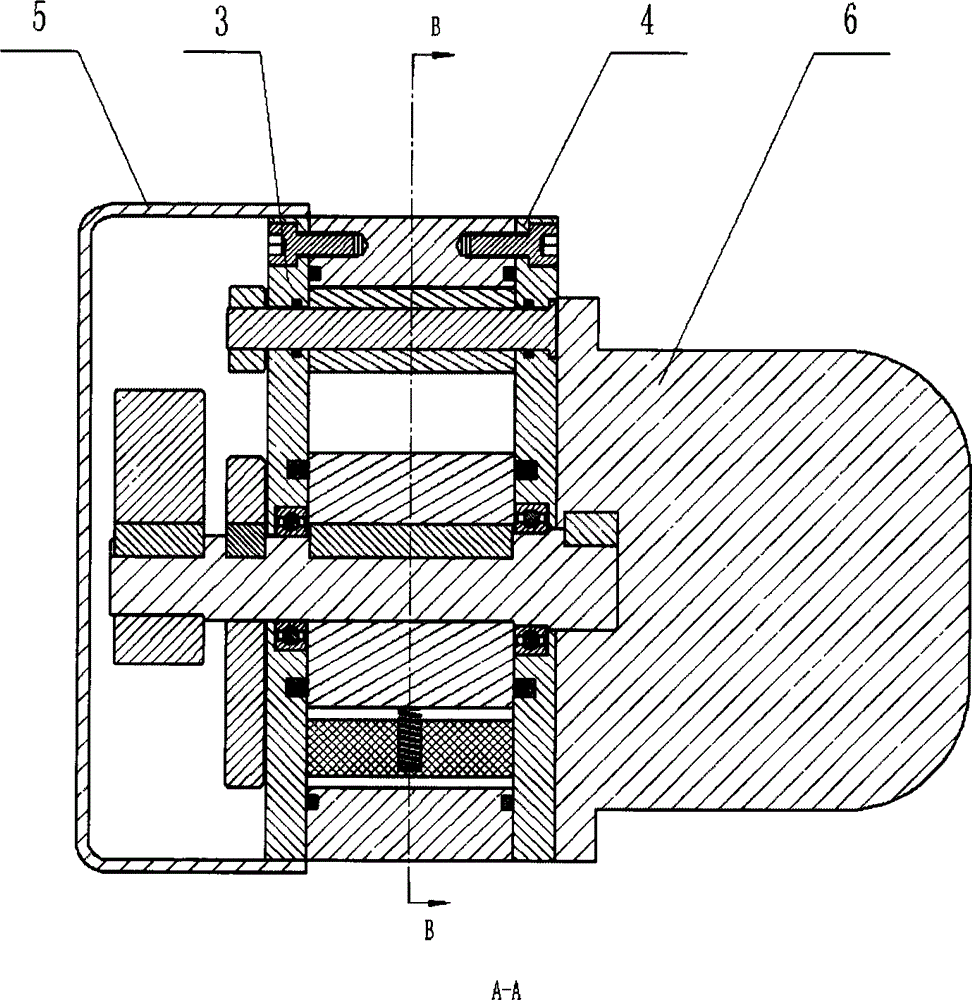

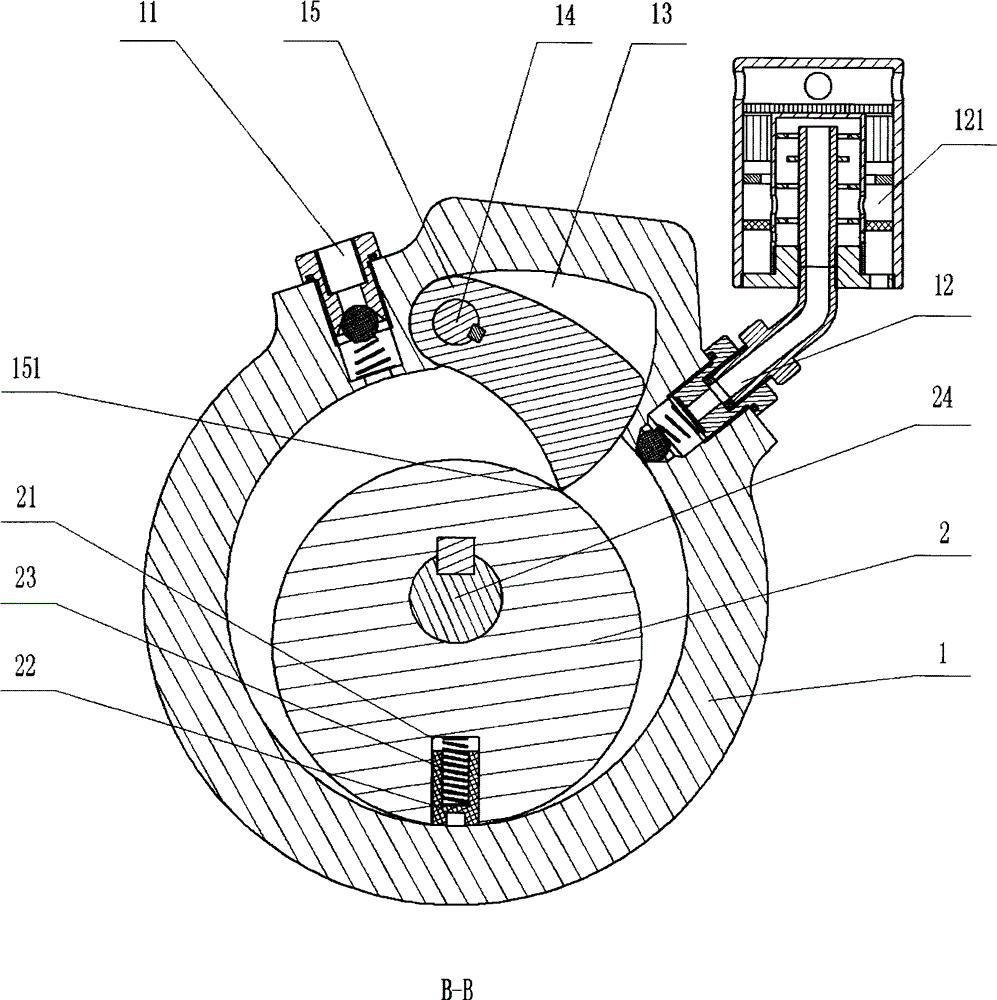

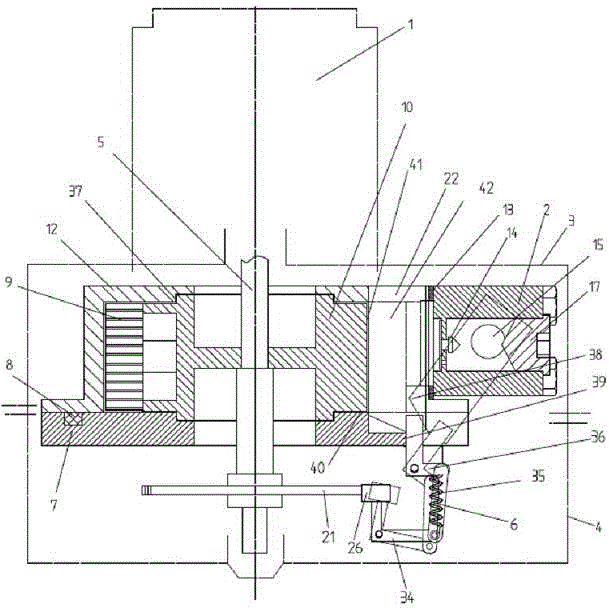

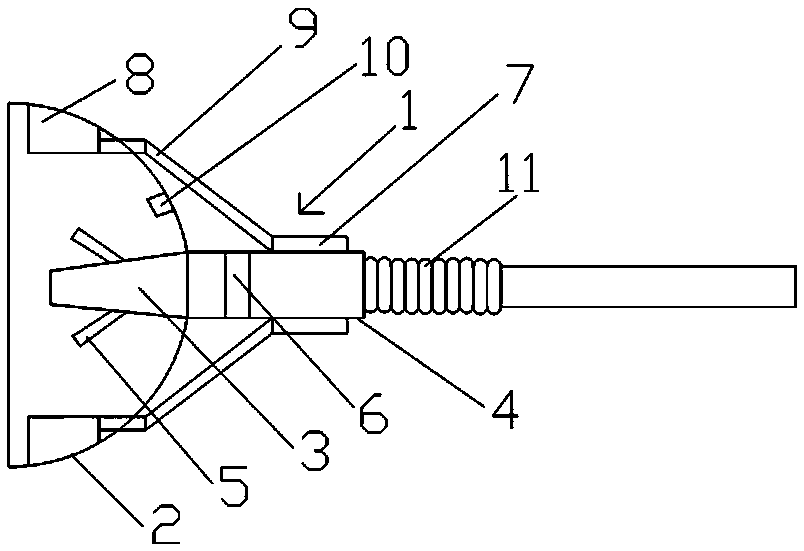

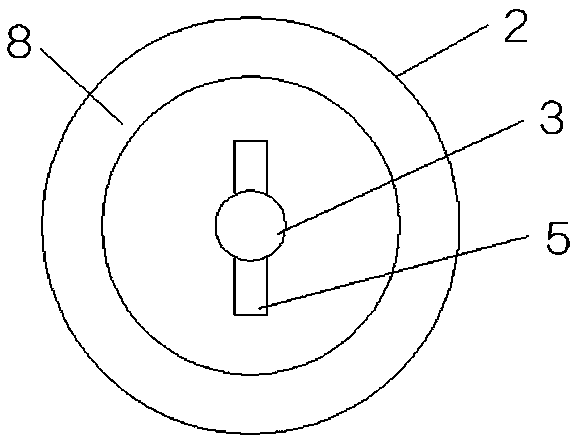

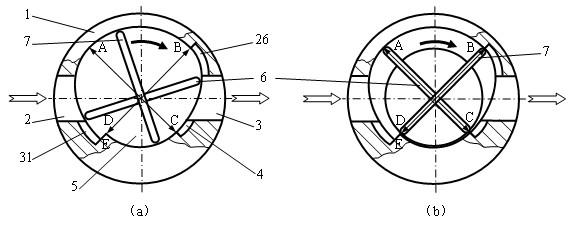

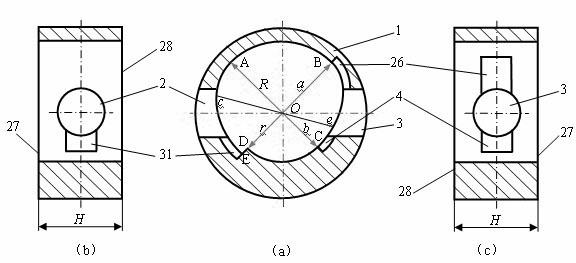

Single-stage rotary vane type vacuum pump

InactiveCN104131975AIncrease vacuumIncrease effective volumeRotary piston pumpsRotary piston liquid enginesSingle stageEngineering

A single-stage rotary vane type vacuum pump. The pump round face between a pump suction port and an exhaust port is provided with a groove; the groove is provided inside with a spacer; the lower right edge of the spacer contacts the outer circular surface of a rotor, and the left end of the spacer is connected with a small shaft; the left end of the small shaft is connected with a rotating arm arranged on the outer side of a left pump cover; the rotor is an eccentric one, a rotary vane is arranged at the maximum eccentric radius, and one end of the rotary vane is in contact with the inner circular surface of the pump body; the rotating shaft of the rotor is in coaxial arrangement with the inner circle of the pump body, and the left end of the rotating shaft is respectively connected with a control handwheel arranged on the outer side of the left pump cover and a rotor balance block; and the control handwheel is provided with a lug boss, the lug boss controls a spiral arm to drive the pacer to return to the groove instantly at each rotation, without touching the rotary vane. The single-stage rotary vane type vacuum pump with rotor provided with only a piece of the rotary vane has significant characteristics of large effective volume for vacuum suction, good sealing performance of rotary vane, high degree of vacuum for the container, and high speed.

Owner:NANTONG GUANGXING PNEUMATIC EQUIP

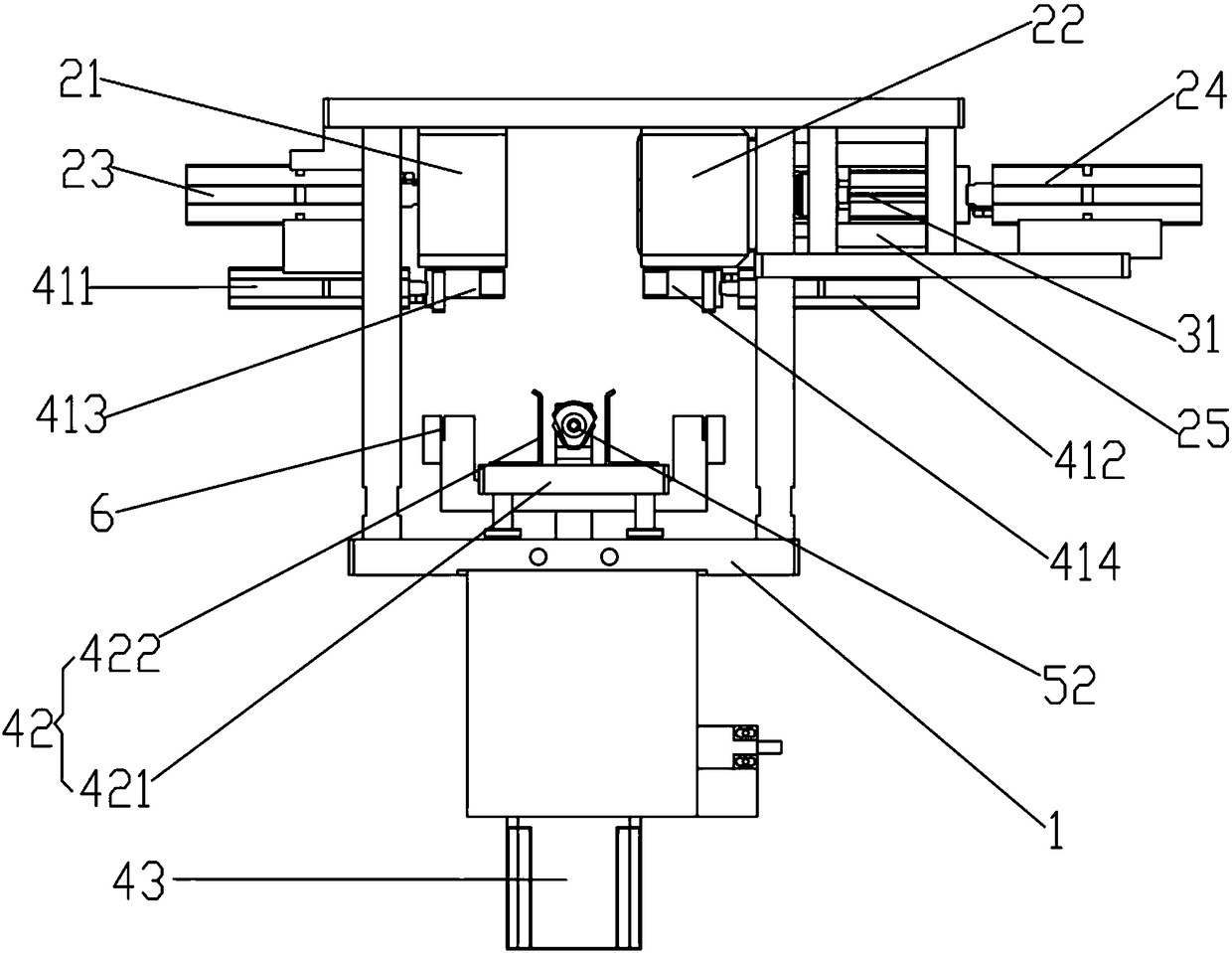

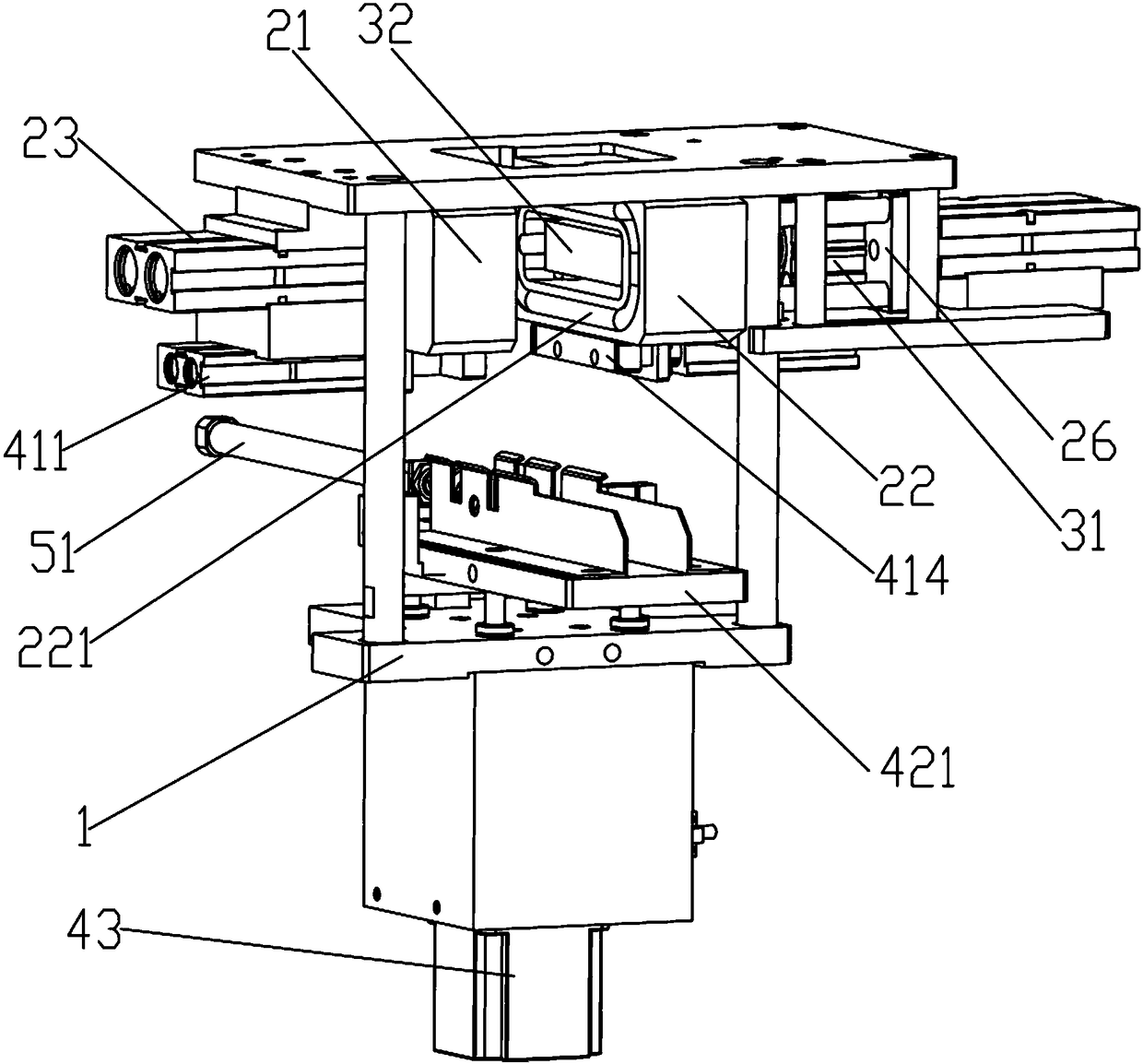

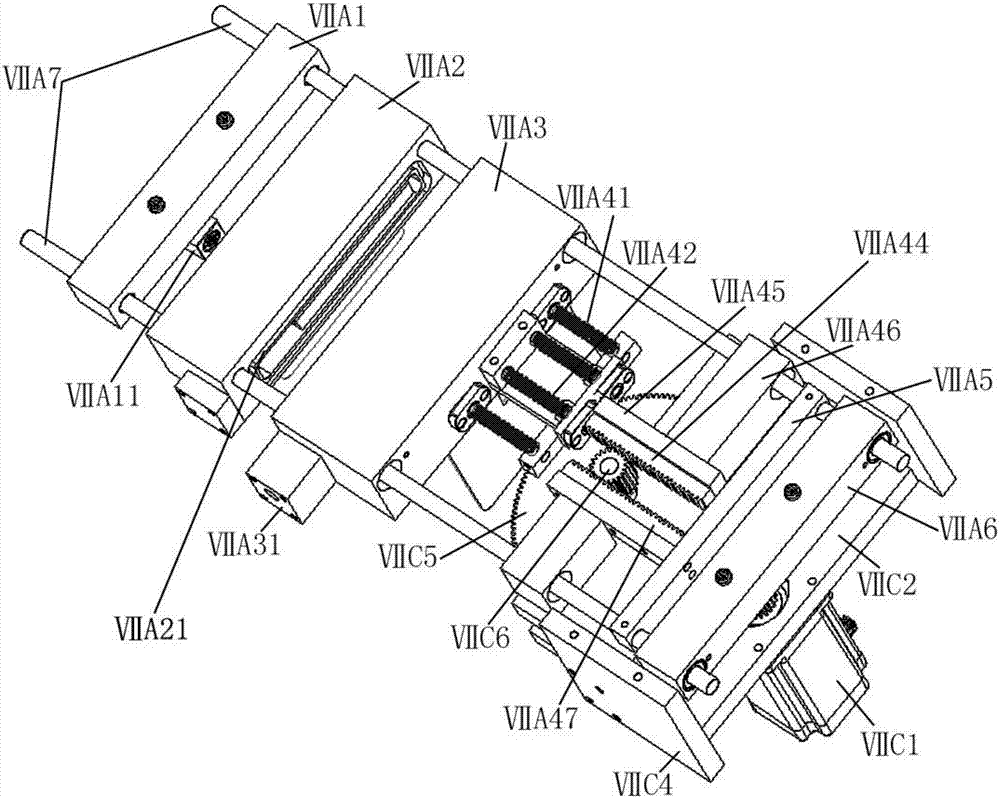

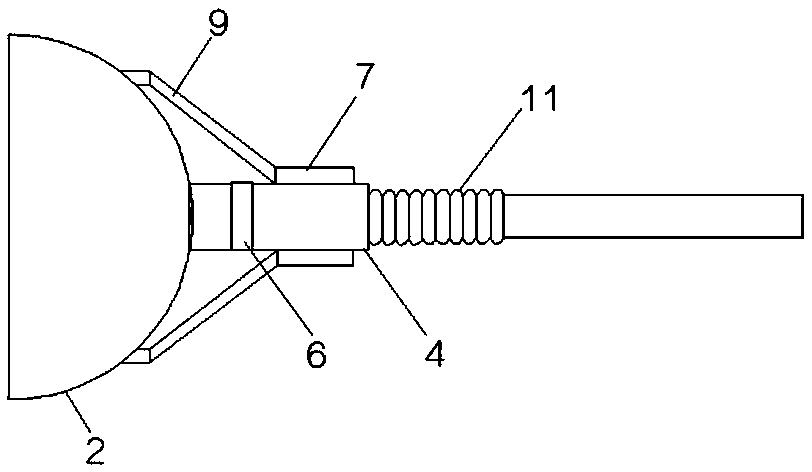

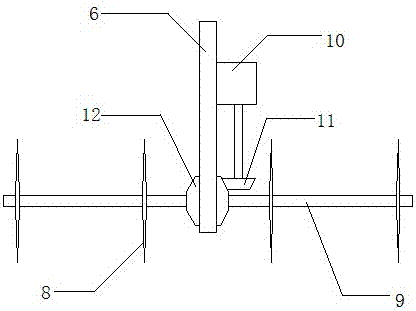

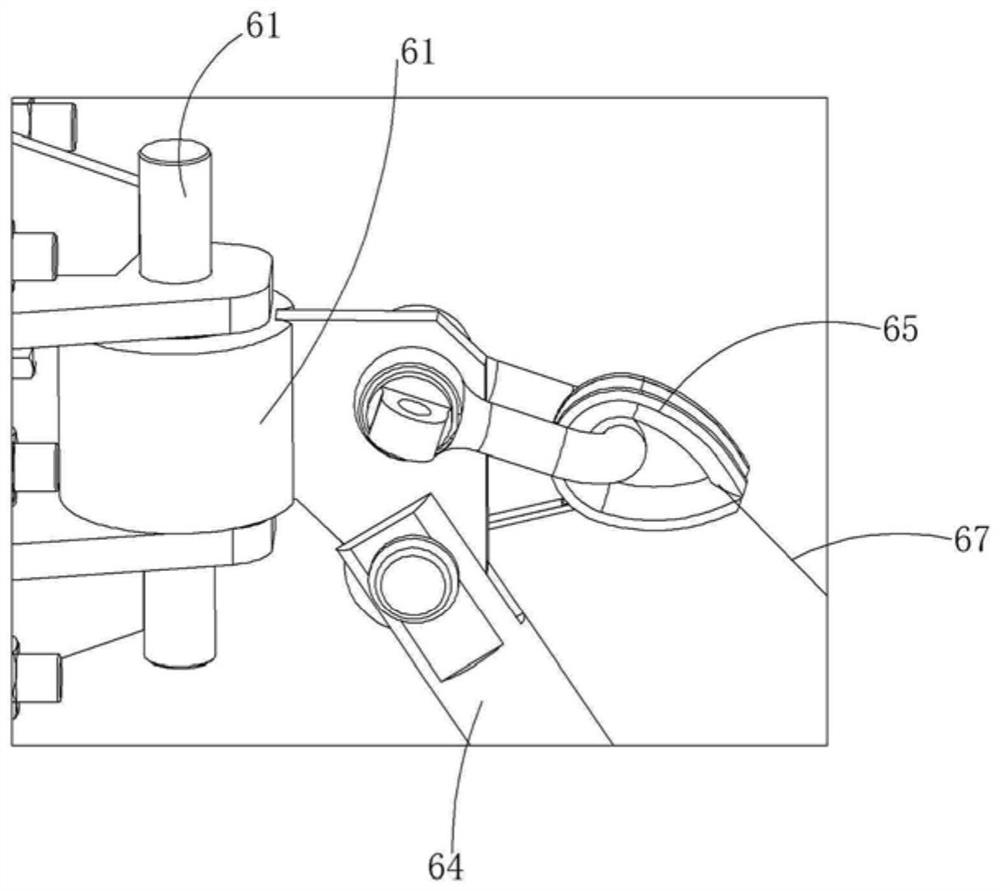

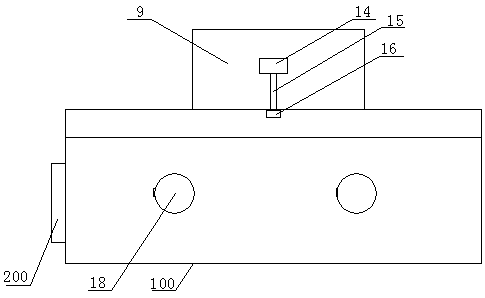

Outward vacuumizing and bilateral heat sealing device for pure electric reshaping and packaging machine

ActiveCN106956800ANovel structureFast vacuumingPackaging by pressurising/gasifyingWrapper twisting/gatheringSolenoid valveEngineering

The invention discloses an outward vacuumizing and bilateral heat sealing device for a pure electric reshaping and packaging machine. A vacuum chamber vacuumizing port of a right vacuum chamber silica gel fixing module arranged in a bilateral sealing mechanism communicates with a vacuum pump arranged in an outward vacuumizing mechanism, the vacuum pump controls whether an outward vacuumizing vacuum chamber is vacuumized or not through switch switching of a vacuumizing solenoid valve, and a driving mechanism is arranged under the right side of the bilateral sealing mechanism. The device has the advantages that the structure is novel, the vacuumizing speed is high, assembly and maintenance are easy and convenient, energy is saved, and bilateral sealing is more practical.

Owner:福建省安溪县兴安金属有限公司

Power-driven vacuum pump for car braking system

The invention relates to a power-driven vacuum pump for a car braking system, and belongs to the field of car braking. The power-driven vacuum pump comprises a motor, and a lower shell and an upper shell body are internally provided with a pump body assembly, a one-way valve assembly, a cam and a connecting rod assembly; and single blades are adopted for rotating at a high speed in an annular cavity and are matched with the cam, an air blocking sheet and the one-way valve to move to form a vacuum cavity. The inner wall of an annular cavity formed by the blade and a blocking sheet rotor and the inner wall of an annular cavity formed by the blade, an upper cover plate and a lower cover plate are in clearance fit, friction cannot be generated, heat cannot be generated, long-time running can be achieved, the reliability is improved, and noise is reduced; and air pumping and air discharging are carried out at the same time, the vacuumizing rate is high, air leakage is reduced, and the final vacuum degree of the vacuum pump can be improved.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

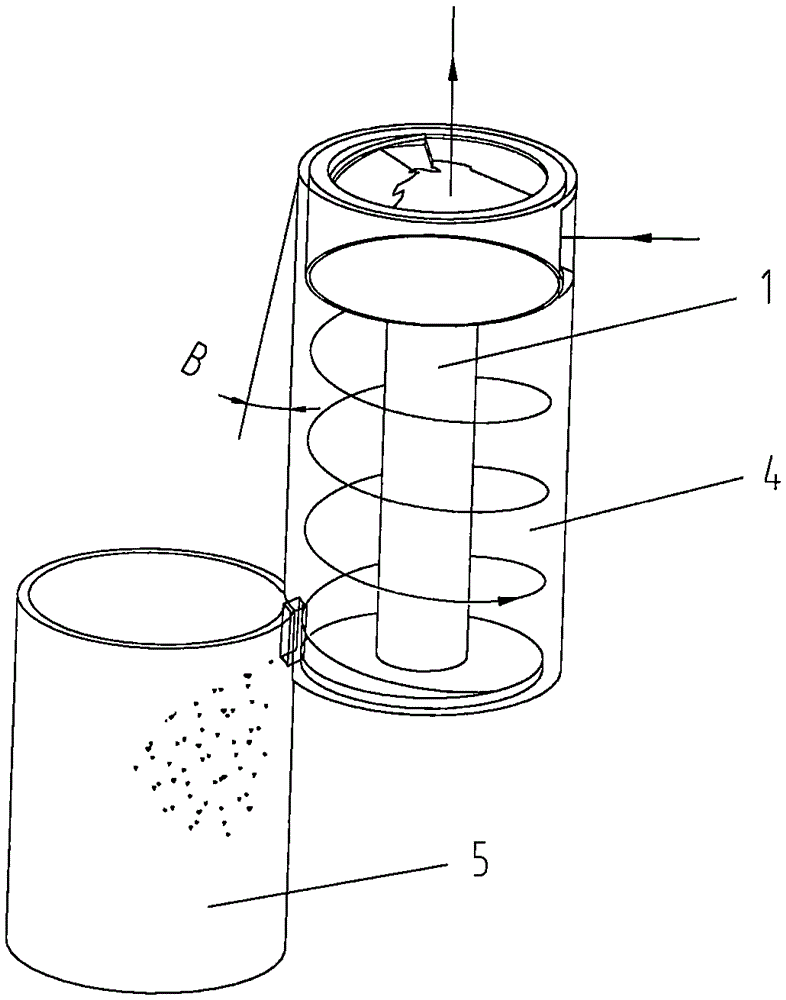

Dust collector used for airflow micronizer

PendingCN108144380AInhibited DiffusionFast vacuumingDispersed particle filtrationDirt cleaningEngineeringDust collector

The invention discloses a dust collector used for an airflow micronizer. The dust collector comprises a dust collection mechanism and a dust cover which are in fixed connection, wherein the dust collection mechanism comprises a dust suction pipe, a pipe body and an air outlet unit; the side surface of the dust suction pipe is provided with an auxiliary dust suction pipe; the interior of the pipe body is provided with a filter screen; the air outlet unit is arranged at the side surface of the pipe body and is fixedly connected with the pipe body; the interior of the dust cover is provided withan air outlet; an air outlet pipe is arranged on the air outlet; the air outlet pipe and the air outlet unit are in fixed connection; the interior of the dust cover is provided with a dust detector; and the upper end of the pipe body is provided with a telescopic pipe. The dust collector used for the airflow micronizer provided by the invention is insusceptible to causing dust diffusion, can adjust the distance of dust collection according to actual situations, and has good dust collection effect.

Owner:ZHENGZHOU LION TIGER ABRASIVE MATERIALS & ABRASIVE TOOLS CO LTD

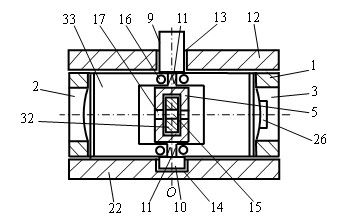

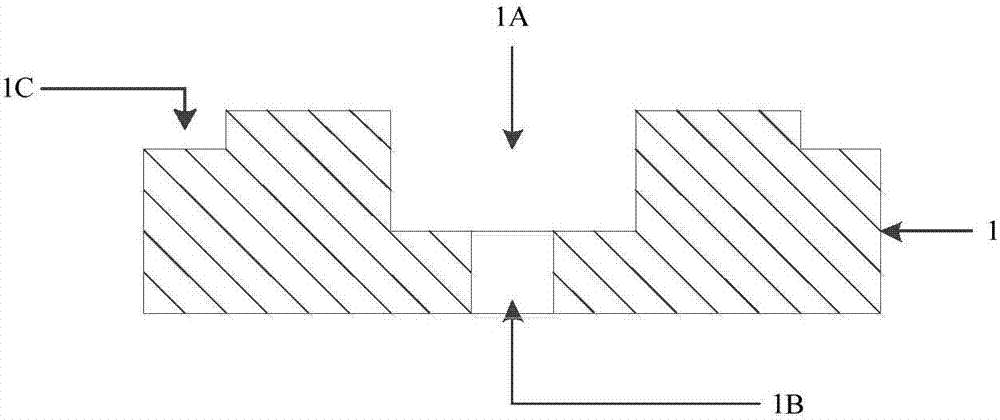

Vacuum pump with special-shaped cavity

InactiveCN102678553AReduce in quantitySimple structureRotary piston pumpsRotary piston liquid enginesDrive shaftSlide plate

The invention discloses a vacuum pump with a special-shaped cavity; the vacuum pump comprises a stator and a rotor; wherein the stator is a cylinder body provided with a special-shaped cylindrical-surface inner cavity, an inlet and an outlet; the special-shaped cylindrical-surface inner cavity is formed by two arc surfaces and two non-arc surfaces; the rotor is formed by a rotor body and two pairs of combination slide plates; the rotor body is a circular cylinder body provided with a transmission shaft, a centering shaft and a crossed guide groove; the two pairs of combination slide plates are vertically arranged in the guide groove; a cover plate is a flat plate provided with a bearing hole; the two end faces of the stator are matched with the cover plate to form into a sealing cavity; the rotor is matched with the bearing hole on the cover plate by the transmission shaft and the centering shaft; the external drive couple drives the rotor to rotate by the transmission shaft. When the rotor rotates, the combined arc surface of the special-shaped cylindrical-surface inner cavity matches with the rotor to control the two pairs of combination slide plates to slide alternatively to intake air through the inlet and press air out through the outlet, thereby forming negative pressure in the inlet area.

Owner:NINGBO YINZHOU FUCHUN PRECISION CASTING

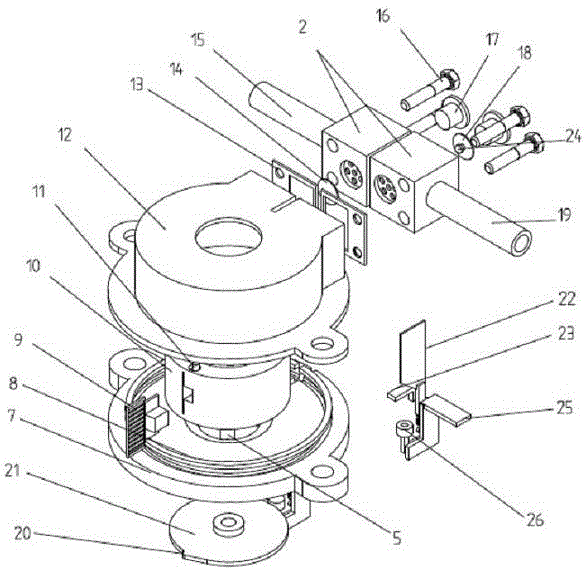

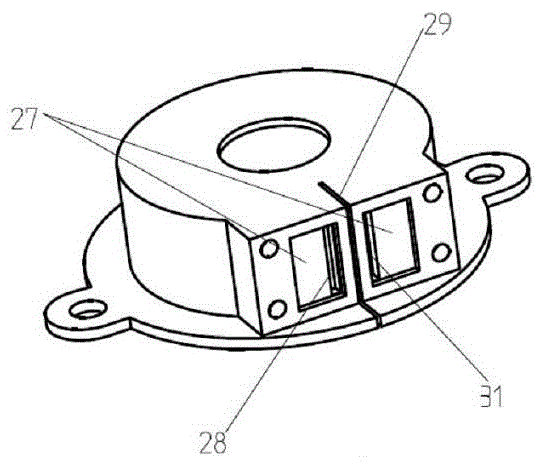

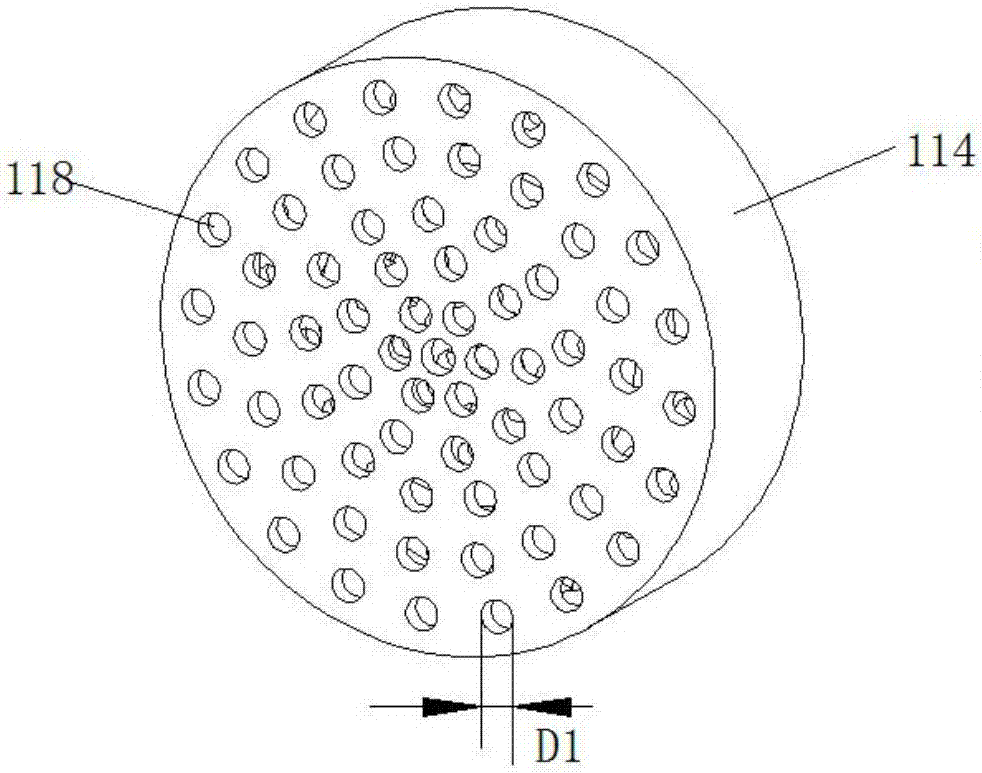

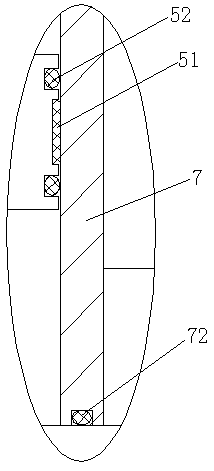

Microcircuit internal atmosphere detection test clamp

ActiveCN107389867AReduce cavity volumeReduce the amount of gasGas analyser construction detailsEngineeringAtmosphere

The invention discloses a microcircuit internal atmosphere detection test clamp and relates to the field of reliability and environment tests of electronic products. The clamp comprises a primary clamp body, a secondary clamp body and a cover body, wherein an inwards concave press cavity is formed in the central position of one end of the primary clamp body and used for accommodating the secondary clamp body, a through connecting channel is formed in the press cavity and used for accommodating a to-be-tested device, a yield part is arranged on the peripheral edge, located on the same side of an opening part of the press cavity, of the primary clamp body and used for mounting a seal ring, and the cover body covers the opening of the press cavity and the seal ring. The clamp provides a new thought for accommodating of the to-be-tested device, that is, the connecting channel with the diameter slightly larger than that of the to-be-tested device is designed, the to-be-tested device is put in the connecting channel, the sealing property of the clamp and protection of the to-be-tested device are greatly improved, besides, the matched secondary clamp body is designed, can fix the to-be-tested device and can greatly reduce vacant space in the clamp, and influence of the atmosphere of the clamp on the detection result is further reduced.

Owner:NO 24 RES INST OF CETC

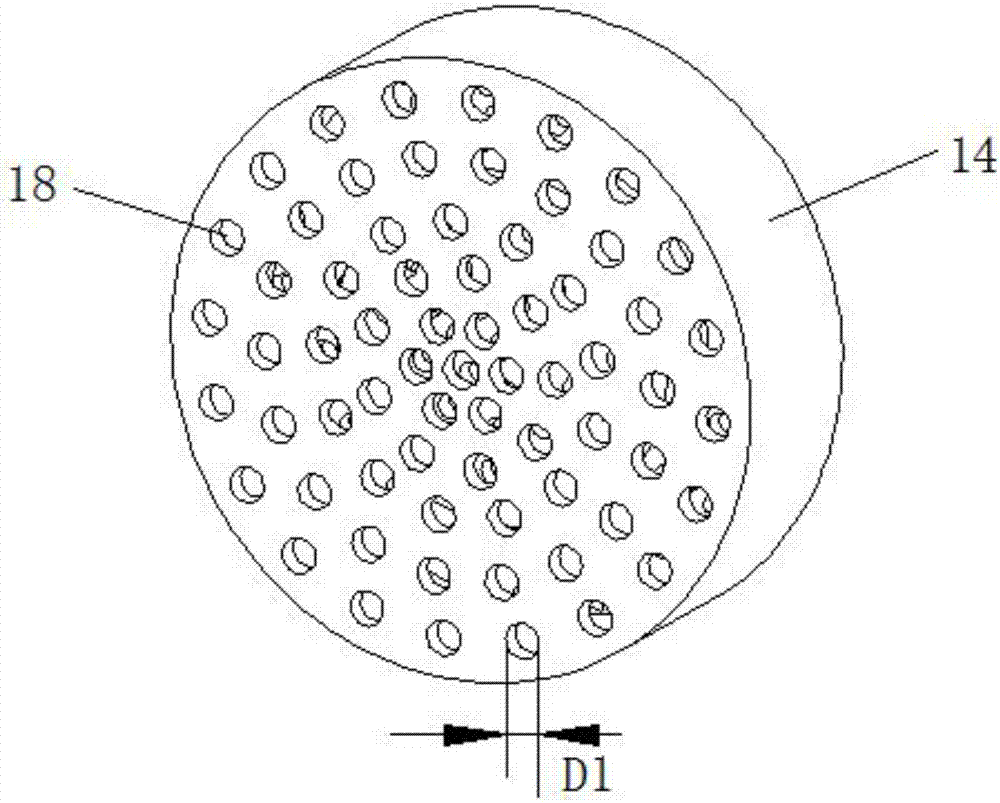

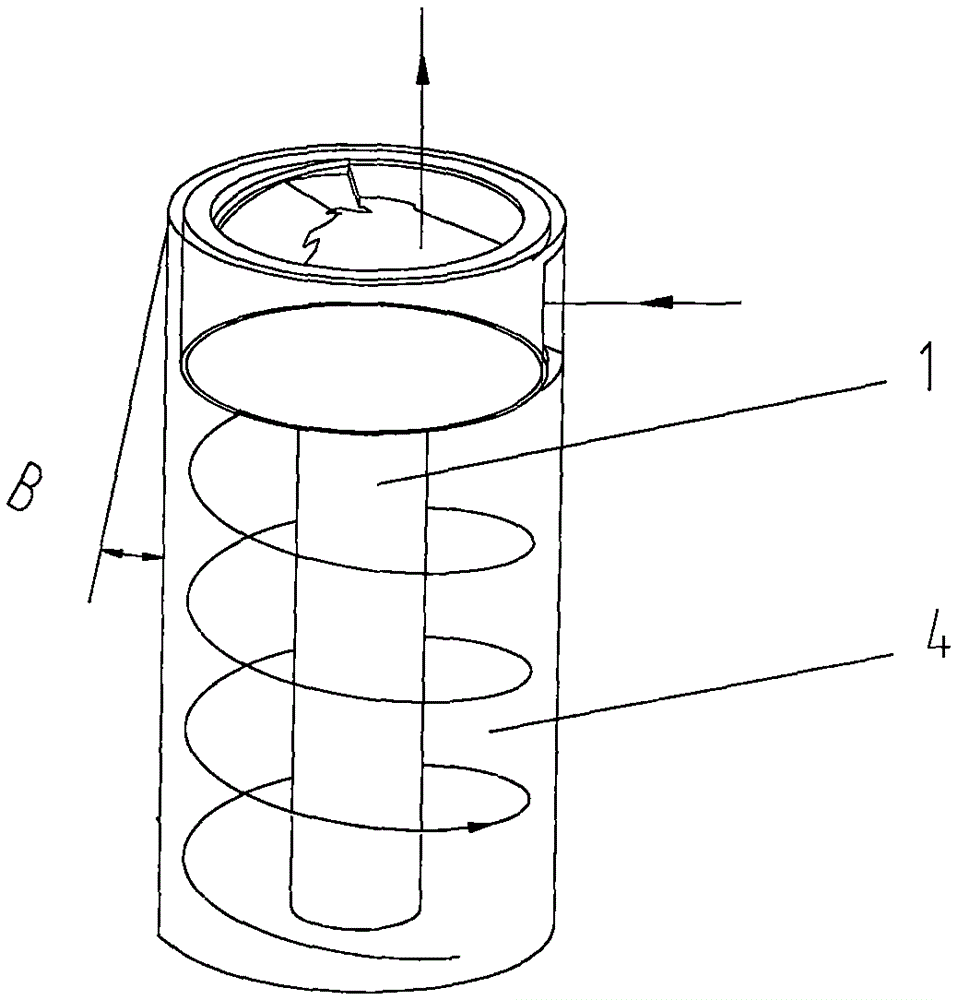

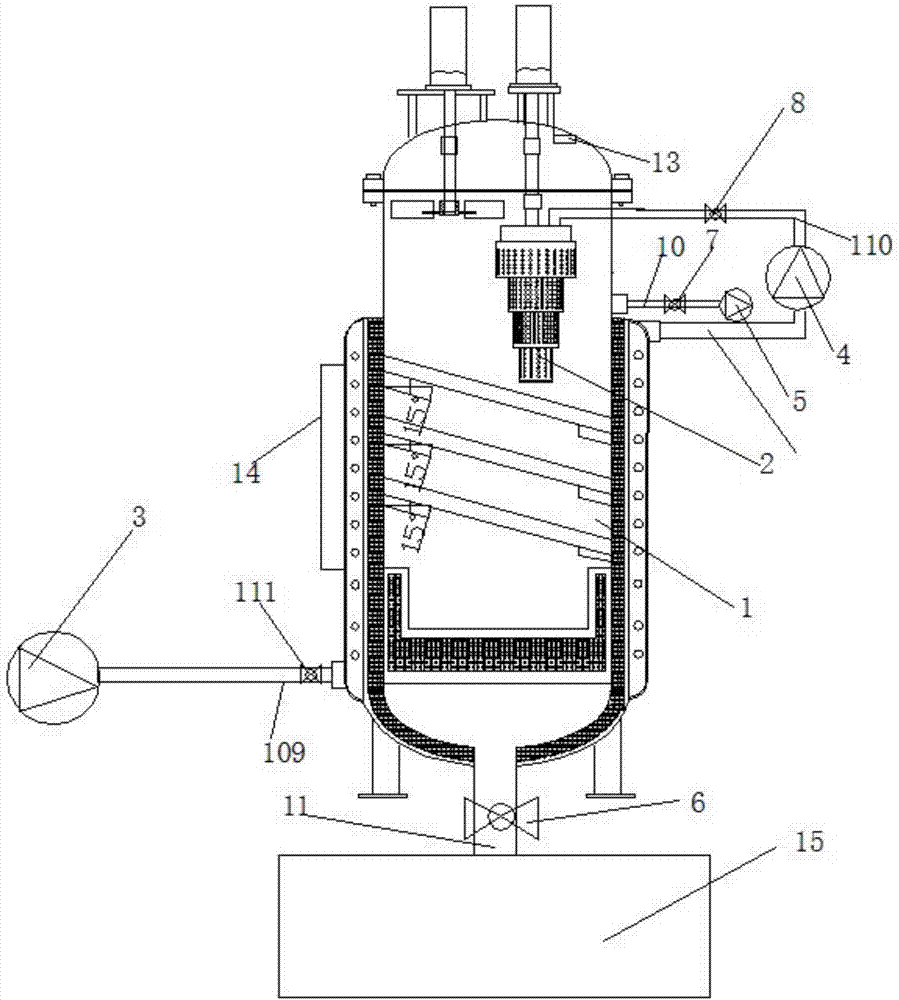

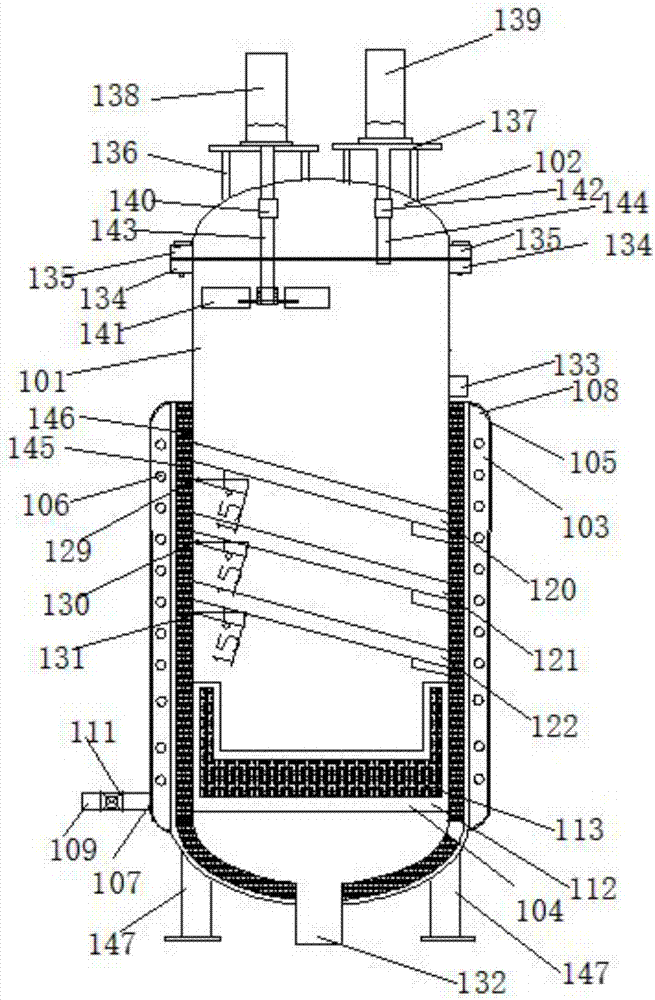

Vacuum tank used for vacuum oil purifier

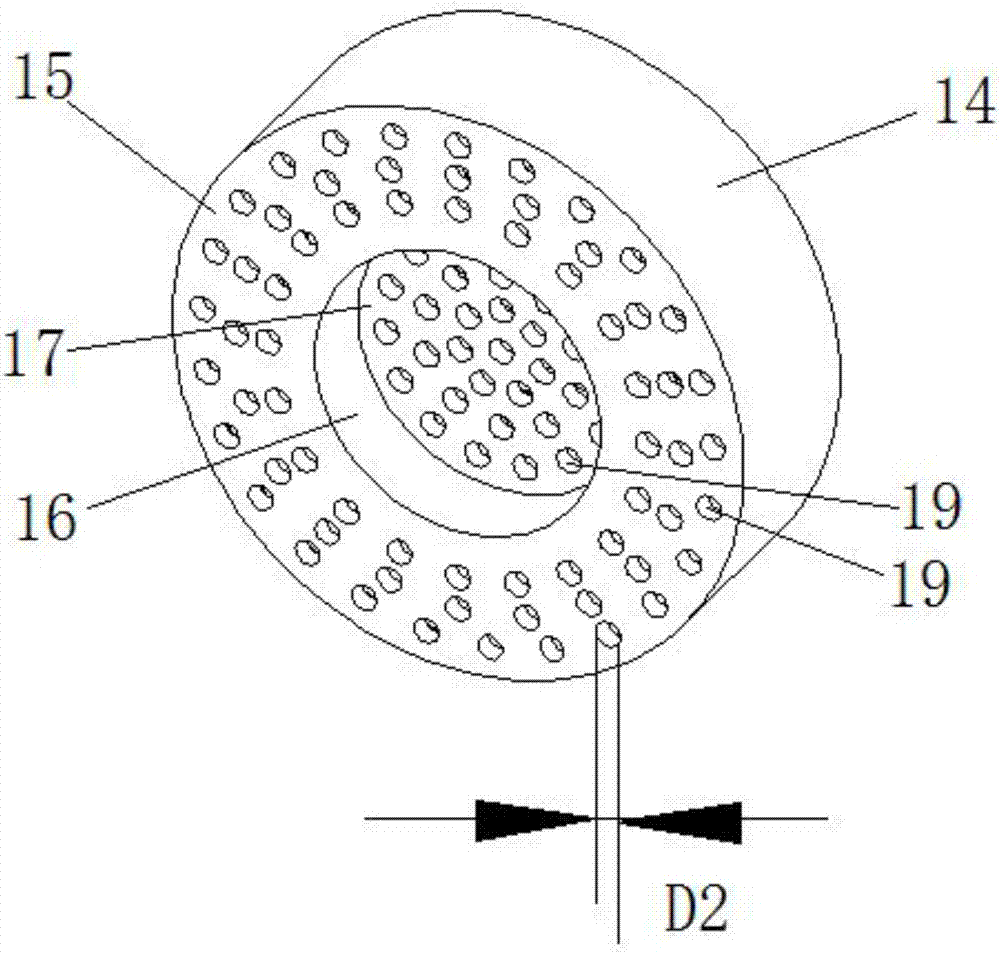

InactiveCN107158746AImprove work efficiencyImprove the efficiency of separation and dehydrationIon-exchange process apparatusIon-exchanger regenerationVacuum pumpingUnsaturated hydrocarbon

The invention relates to a vacuum tank used for a vacuum oil purifier. According to the invention, a blower fan is arranged in the vacuum tank, axial flowing of air in the vacuum tank is enhanced, work efficiency of the vacuum tank is increased, vacuum-pumping speed is accelerated; three layers of filtering structures with different structures are arranged in the vacuum tank, water evaporation is accelerated; an oil film formation area is enhanced, vacuum separating and dehydrating efficiency is increased; by arranging an adsorption purifying apparatus below a mesh plate, the strong adsorption capability of an adsorbent on acidic component, resin, asphaltene and unsaturated hydrocarbon in waste oil is used for adsorption, the first aperture diameter is less than the second aperture diameter, so that in equal time, the inflow amount of the waste oil is greater than the efflux amount, full contact of the waste oil and the adsorbent is guaranteed, and the purifying effect is increased.

Owner:镇江市长江机电设备厂有限公司

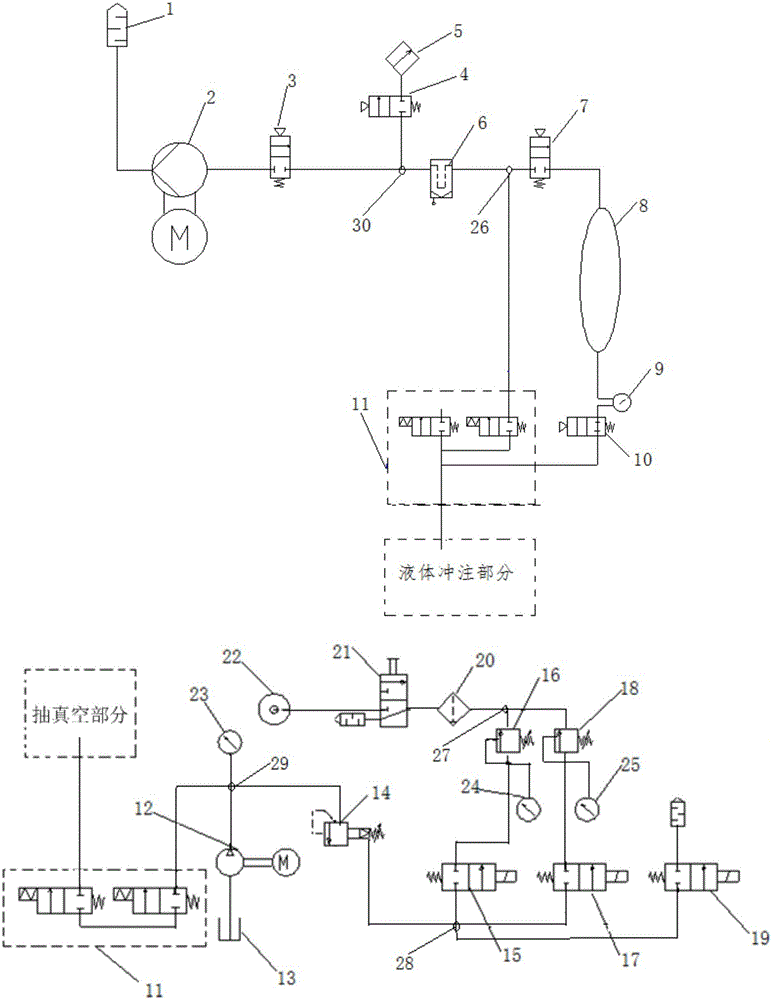

Liquid filling equipment

InactiveCN106564847AImprove dosing efficiencyFast vacuumingLiquid transferring devicesSolenoid valveEngineering

The invention provides liquid filling equipment. The liquid filling equipment comprises a vacuumizing part, a filling part and a filling gun head. The vacuumizing part comprises a vacuum pump, a vacuum tank, a vacuum pump on / off control valve, a first vacuum tank connection / disconnection control valve and a second vacuum tank connection / disconnection control valve. The filing part comprises a filling pump, a pilot type overflow valve, an air source, a first solenoid valve, a second solenoid valve, a first remote pressure regulating valve and a second remote pressure regulating valve. By the adoption of the liquid filling equipment, the liquid filling time of vehicles can be shortened, and the filling efficiency of the vehicles is improved.

Owner:CHERY AUTOMOBILE CO LTD

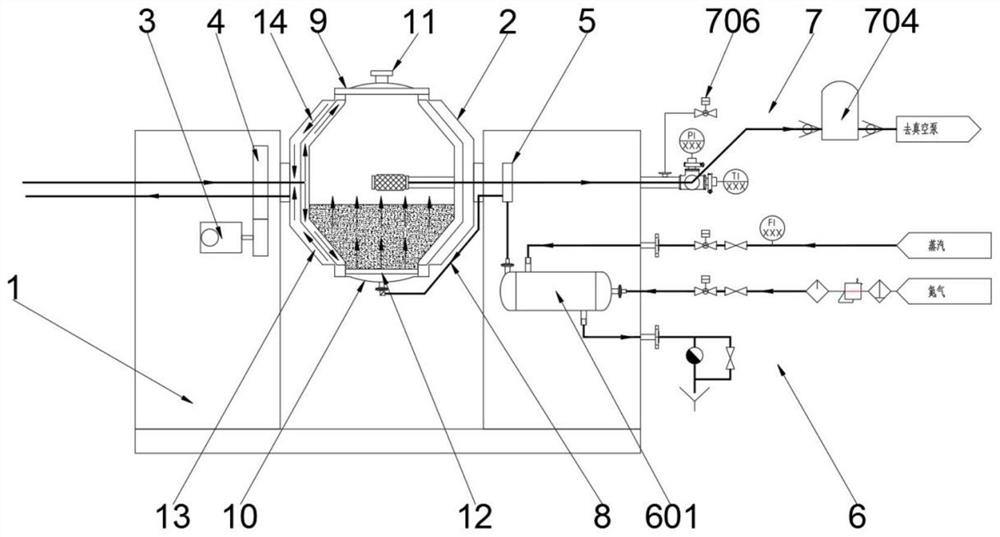

Pulsating replacement type novel vacuum dryer device

ActiveCN111637690AAvoid pollutionImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsThermodynamicsWater vapor

The invention discloses a pulsating replacement type novel vacuum dryer device and belongs to the technical field of material drying. According to the pulsating replacement type novel vacuum dryer device, a rotary tank body is subjected to hanging supporting through a rack, the end, connected with the rack, of the rotary tank body is provided with a rotary air guide device, the rotary air guide device is connected with the rotary tank body and an air supply mechanism, and the end, close to the rotary air guide device, of the rotary tank body is further provided with an air exhausting mechanismused for air exhausting vacuumizing. The pulsating replacement type novel vacuum dryer device is scientific and reasonable and safe and convenient to use, the inner portion of the rotary tank body isheated by utilizing a first clamping sleeve cavity and a heat source, indirect heating is realized, material pollution is avoided, in the material drying process, one path of inert gases heated by aheater is additionally arranged to perform convection current contact with materials inside the tank body through a pulse gas filter plate, heat exchanging is realized, meanwhile, the gases after theheat exchanging are discharged out through the air exhausting mechanism, the heated inert gases are taken as carriers of water vapor discharging after the material drying, and the material drying efficiency is improved.

Owner:CHANGZHOU AOKAI DRYING EQUIP

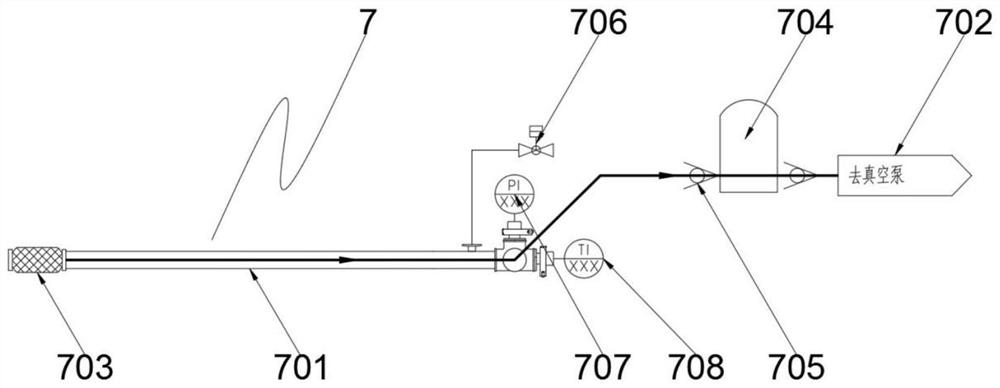

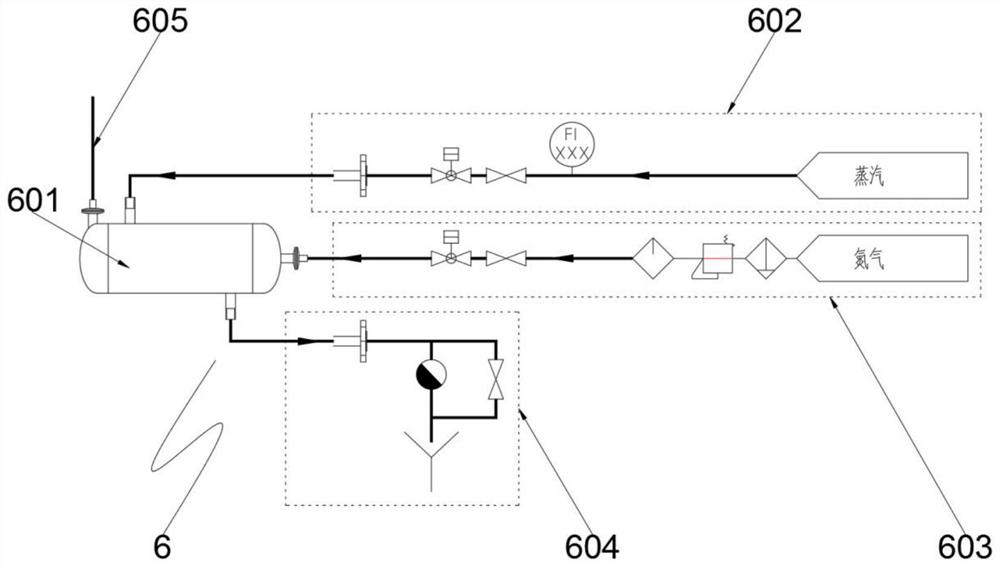

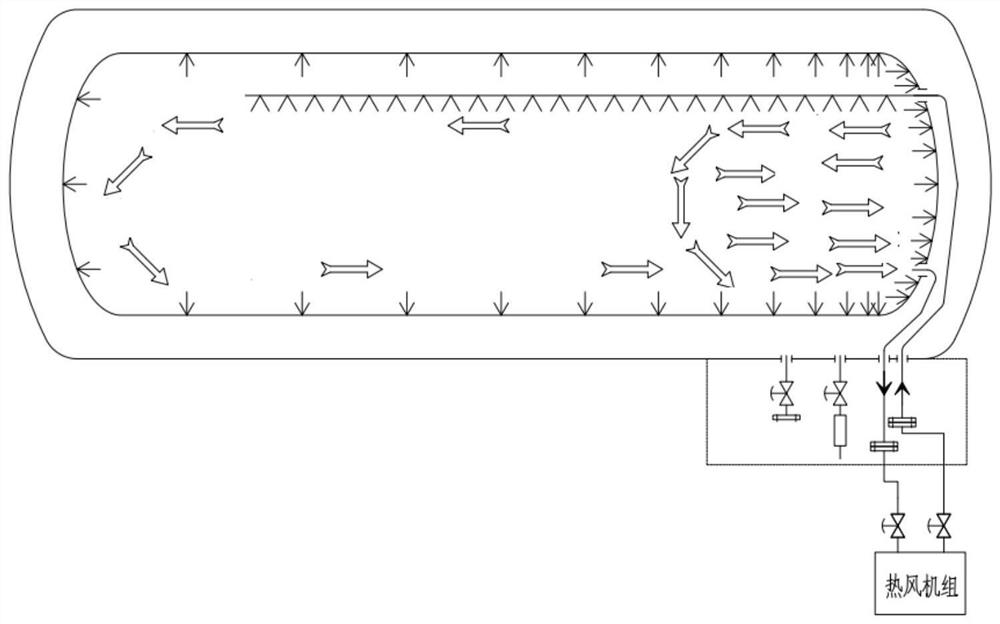

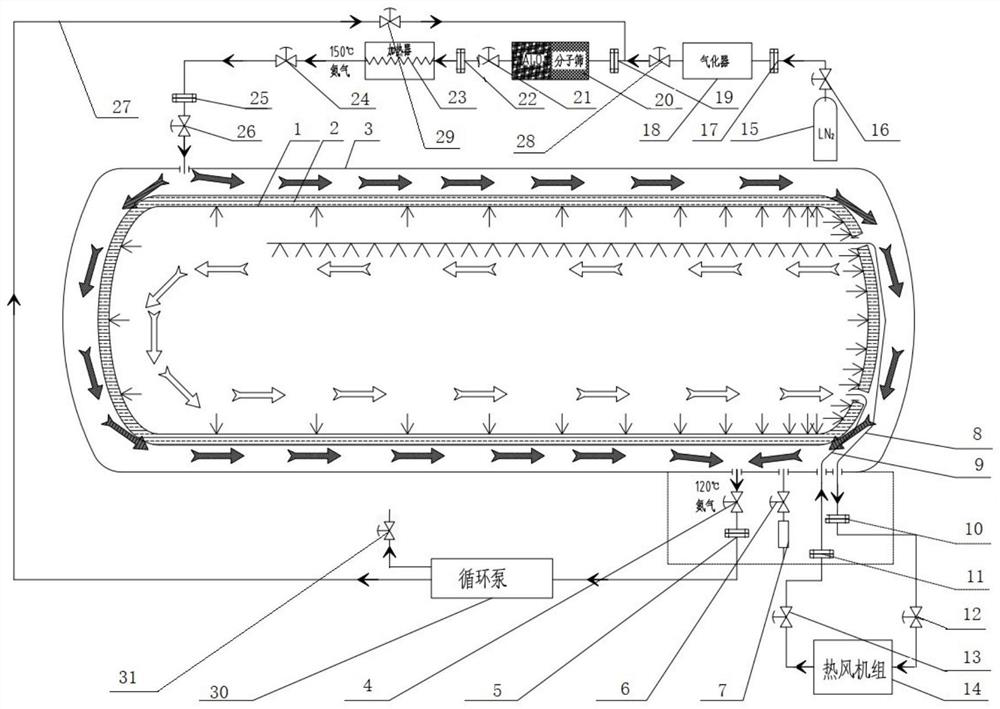

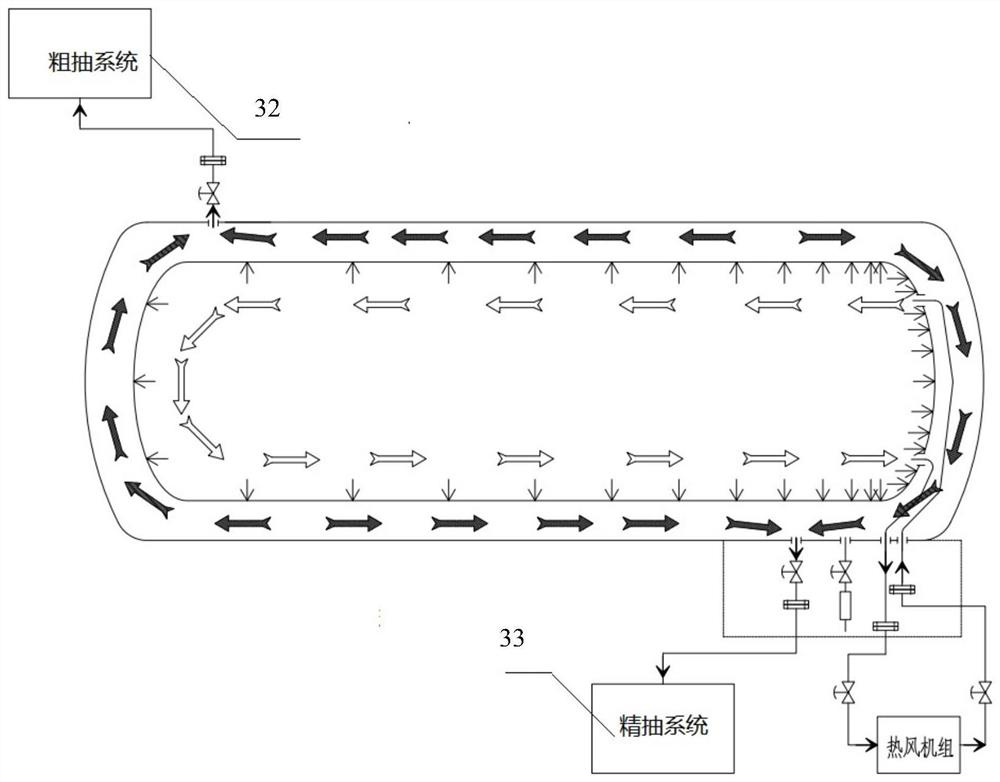

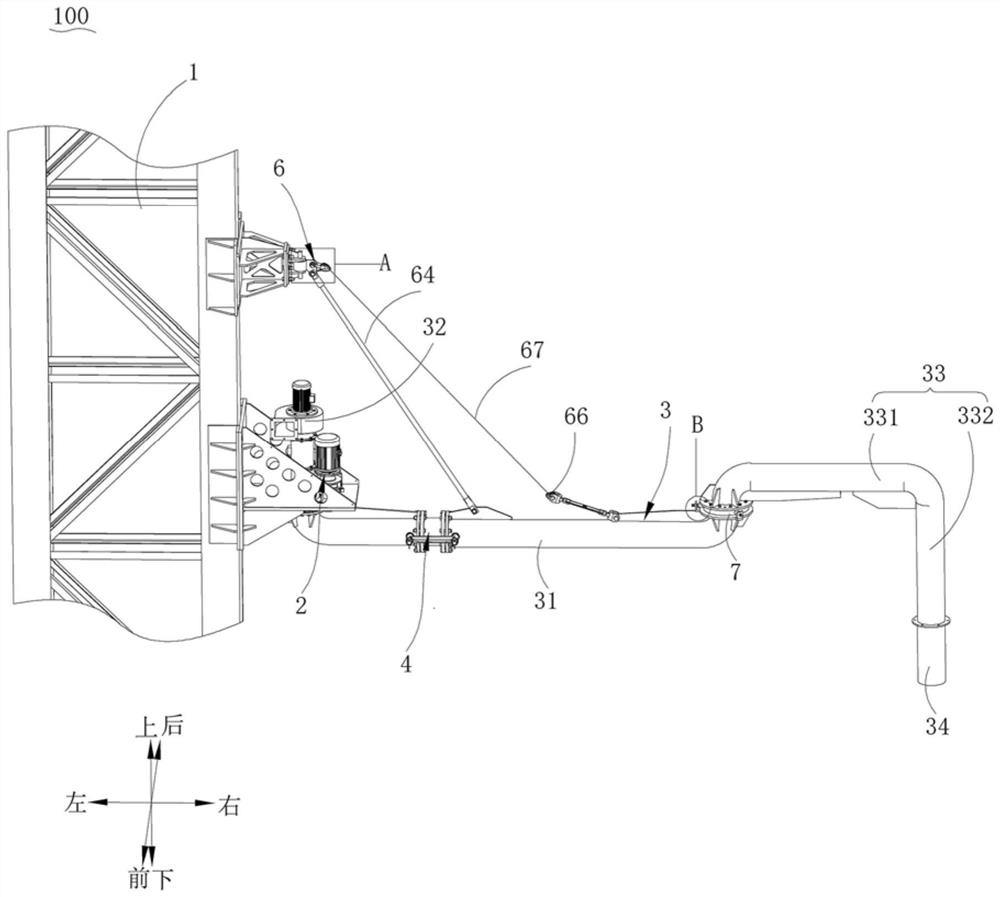

Frozen liquefied gas tank container vacuum-pumping system and method

ActiveCN112303476AHeating fastEmission reductionVessel wallsRotary piston pumpsVacuum pumpingSolid particle

The invention discloses a frozen liquefied gas tank container vacuum-pumping system and method. Through an inner tank body heating module and an interlayer hot nitrogen circulation heating module, continuous circulation heating is conducted, then nitrogen replacement is conducted, an inner barrel circulation heating system works continuously, then two or more rough vacuum-pumping units are used for rough vacuum pumping, after the vacuum degree reaches 0.5 Pa, nitrogen replacement is completed three times, and after rough vacuum pumping reaches about 1 Pa, fine vacuum pumping is conducted; andafter the vacuum degree is pumped to 10<-2> Pa, internal circulation heating is stopped, meanwhile, the vacuum degree is sealed for cooling, and then the vacuum degree is detected. The interlayer hotnitrogen circulation heating module is introduced, the interlayer space can be directly heated in the circulation process, most of moisture and small solid particles which are easily brought out are brought out through circulation while the interlayer space is rapidly heated, the vacuum pumping speed is increased in principle, energy consumption needed by the vacuum pumping procedure is reduced, and the vacuum pumping efficiency is improved, so that the cost of the whole production process is reduced, and carbon dioxide emission is reduced.

Owner:山东中车同力钢构有限公司

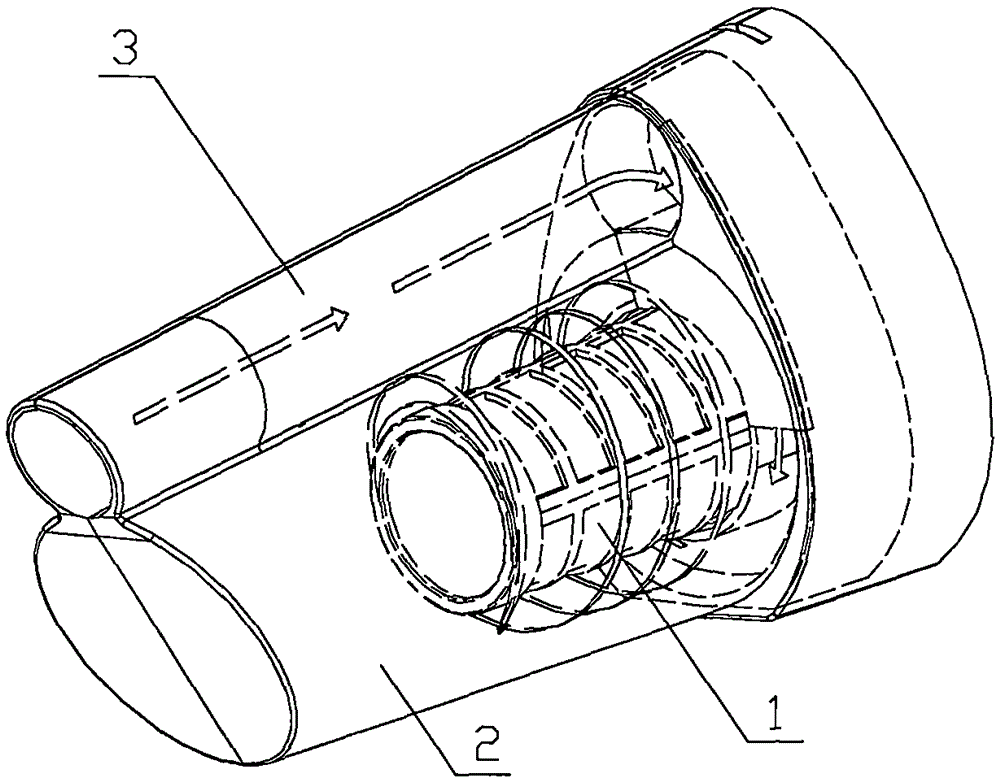

Filtering device

ActiveCN105457426AReduce volumeGuaranteed service lifeCombination devicesSuction filtersCycloneInlet channel

The invention discloses a filtering device. The filtering device comprises a power component, a cyclone working cavity, a spiral air inlet channel arranged at the bottom of the cyclone working cavity as well as a filter arranged inside the cyclone working cavity, wherein an air flow enters the filter and then flows to the power component, one end of the filter is mounted at the bottom of the cyclone working cavity, and the other end is propped against the top of the cyclone working cavity. Compared with the prior art, the filtering device has the advantages that the size of the cyclone working cavity is smaller, the filter produces negative pressure more quickly, dust can be collected into the cyclone working cavity at the moment that the filtering device is started, the dust collection speed is high, and the working efficiency is high.

Owner:胡国海

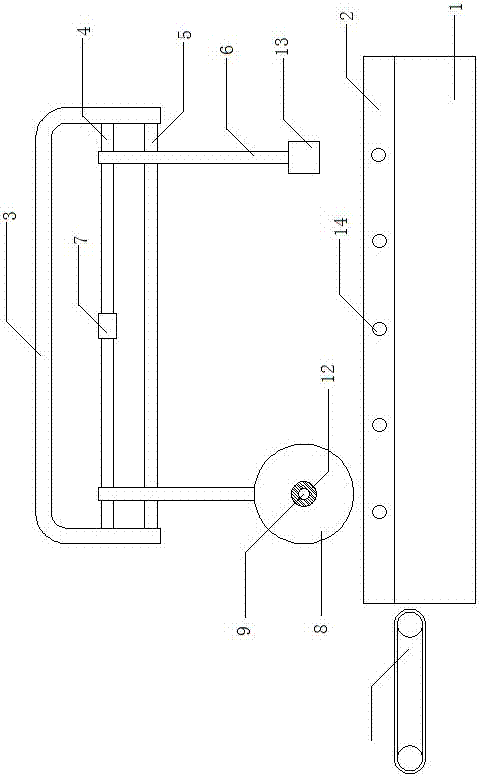

Cutting device for rock wool board

ActiveCN107053299AFast vacuumingImprove absorption rateMetal working apparatusMating connectionEngineering

The invention provides a cutting device for a rock wool board. The cutting device for the rock wool board comprises a cutting base, a cutter rack, a cutting portion and a push portion. A cutting groove is formed in the surface of the cutting base and communicates with one side of the cutting base to form a push opening. The cutter rack comprises a mounting support, a lead screw, a sliding rod and mounting rods, wherein the mounting support is a U-shaped support with an opening being downward; the lead screw is mounted in the middle of the mounting support, and the sliding rod is mounted at the bottom of the mounting support; a lead screw nut is arranged in the middle of the lead screw in a matching mode; screw threads of the two sides of the lead screw nut are opposite; and the top ends of the mounting rods are matched and connected with the lead screw, the bottom ends of the mounting rods are arranged on the surface of the sliding rod in a sleeving mode, and then the mounting rods are arranged vertically and downwards. The cutting portion and the push portion are mounted at the bottoms of the two mounting rods correspondingly. By means of the cutting device for the rock wool board, pushing, cutting and collecting of the rock wool board can be achieved according to the specific size requirements, the cutting efficiency is high, the sucking rate of dust and chippings generated during cutting is high, the cutting environment is kept to be tidy and clean, and the cutting device for the rock wool board is novel in structure and convenient to use.

Owner:安徽瑞联节能科技股份有限公司

Blackboard eraser capable of reducing dust pollution

InactiveCN105799396AHigh frequency of current changeRapid changeBoard cleaning devicesBristleEngineering

The invention discloses a blackboard eraser capable of reducing dust pollution. The blackboard eraser comprises a shell, bristle mechanisms, a first splitter plate, a second splitter plate and a dust suction mechanism. A containing space is arranged in the shell. Each bristle mechanism comprises a mounting plate, bristles and a connecting pipe, wherein the mounting plate is arranged below the shell, a containing cavity is formed in the mounting plate, a plurality of dust suction holes are formed in the bottom wall of the mounting plate and communicate with the containing cavity, and the bristles are mounted on the bottom wall of the mounting plate. The first splitter plate and the second splitter plate are arranged in the containing space of the shell and divide the containing space into a first web cavity, a second web cavity and a third web cavity from top to bottom. The first end of each connecting pipe communicates with the containing cavity in the corresponding mounting plate, and the second end of each connecting pipe communicates with the third web cavity. A first air inlet hole, a second air inlet hole and a third air inlet hole are sequentially formed in the first splitter plate. According to the blackboard eraser, dust can be prevented from flying, the content of chalk dust in air is reduced, the teaching environment is beautified, and environment pollution is reduced.

Owner:宿州学院

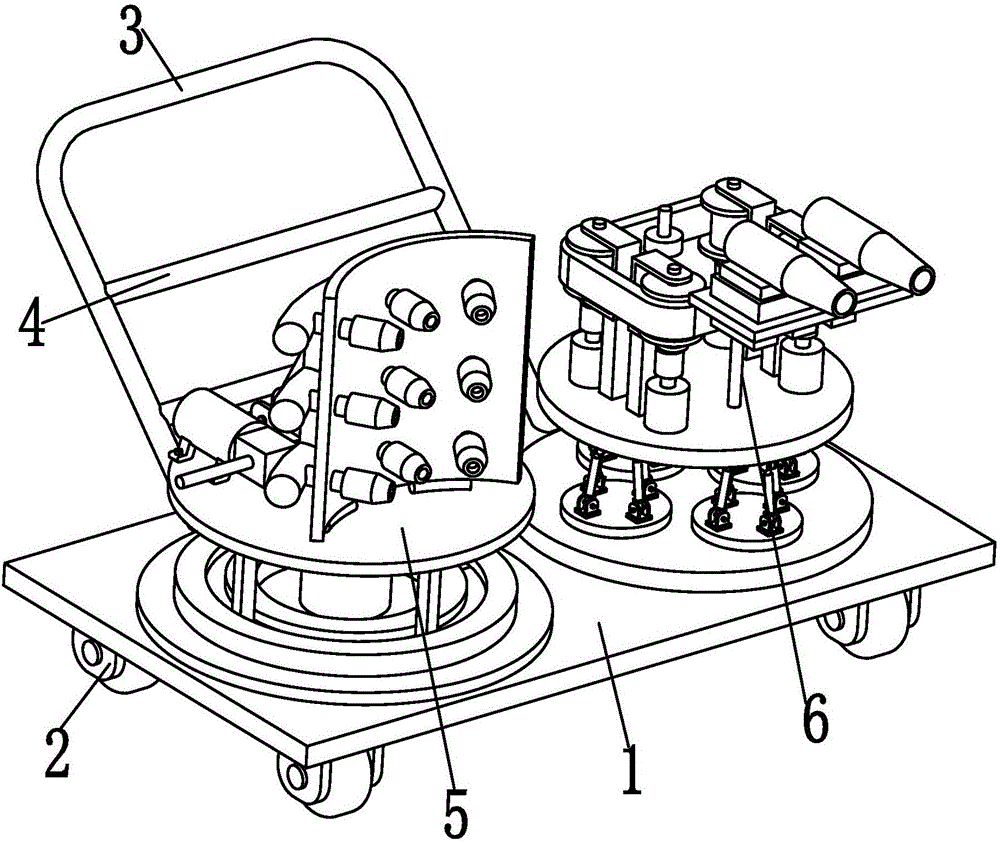

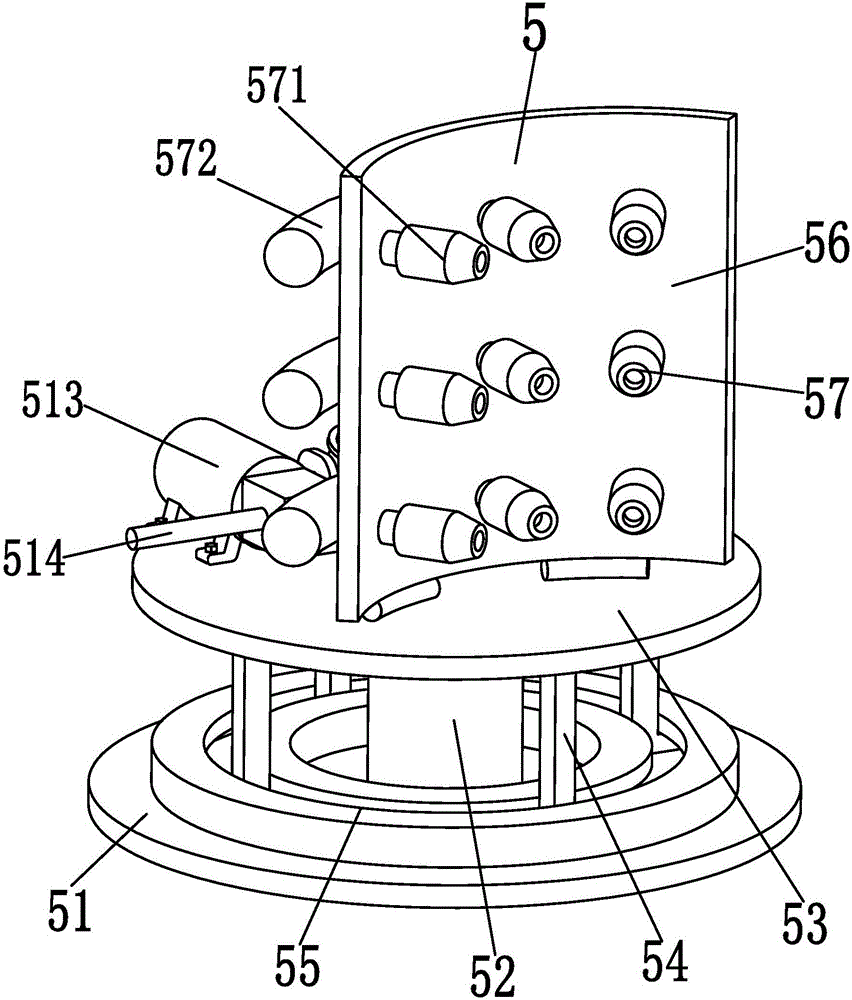

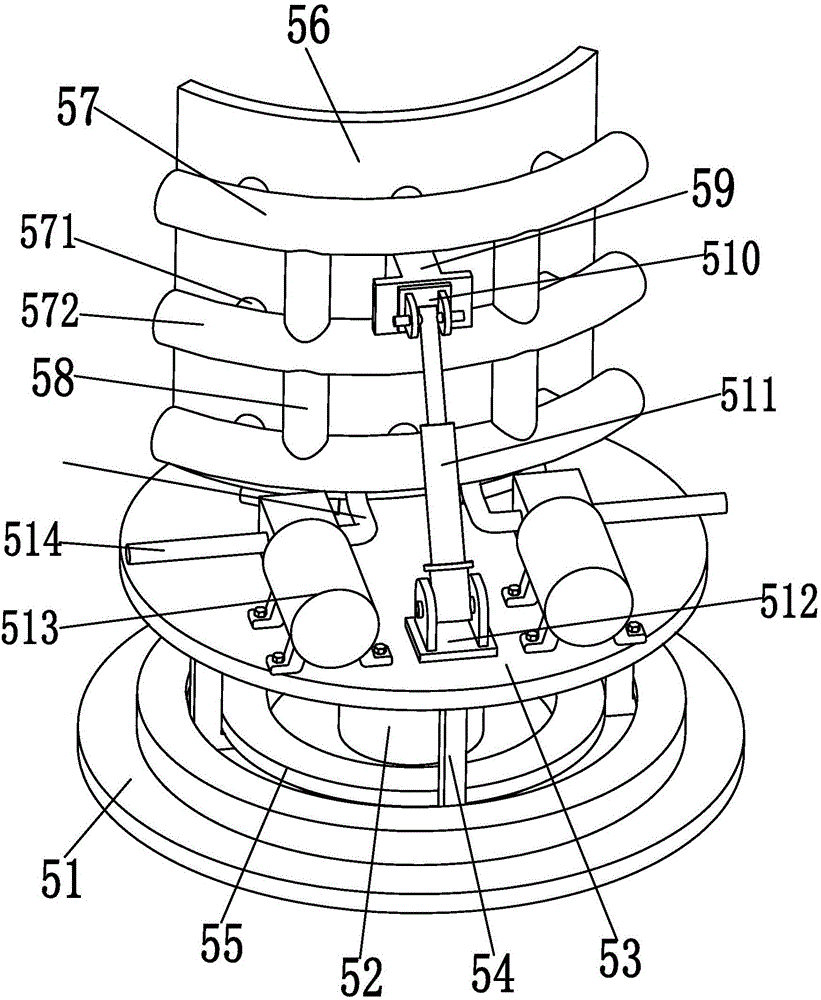

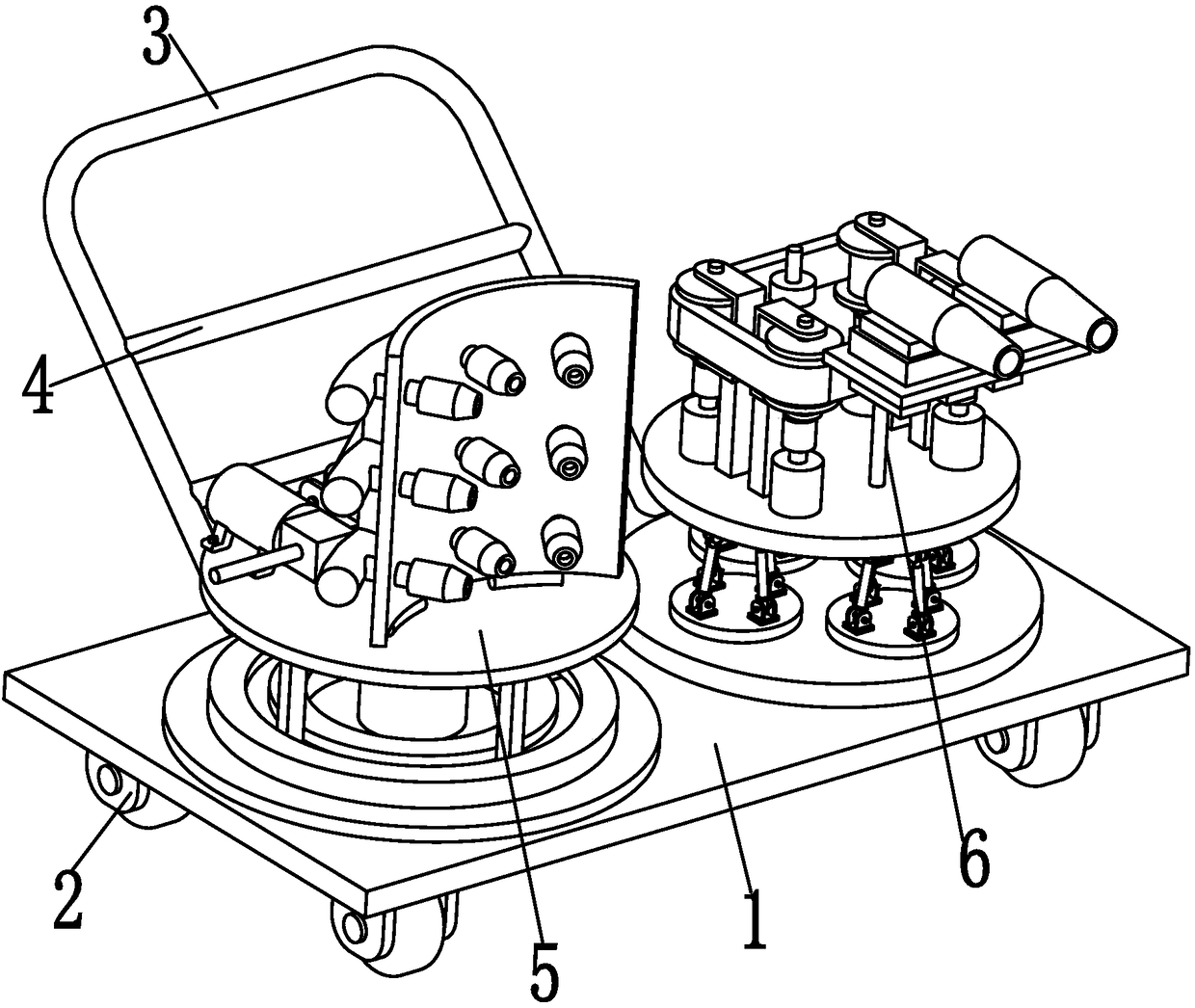

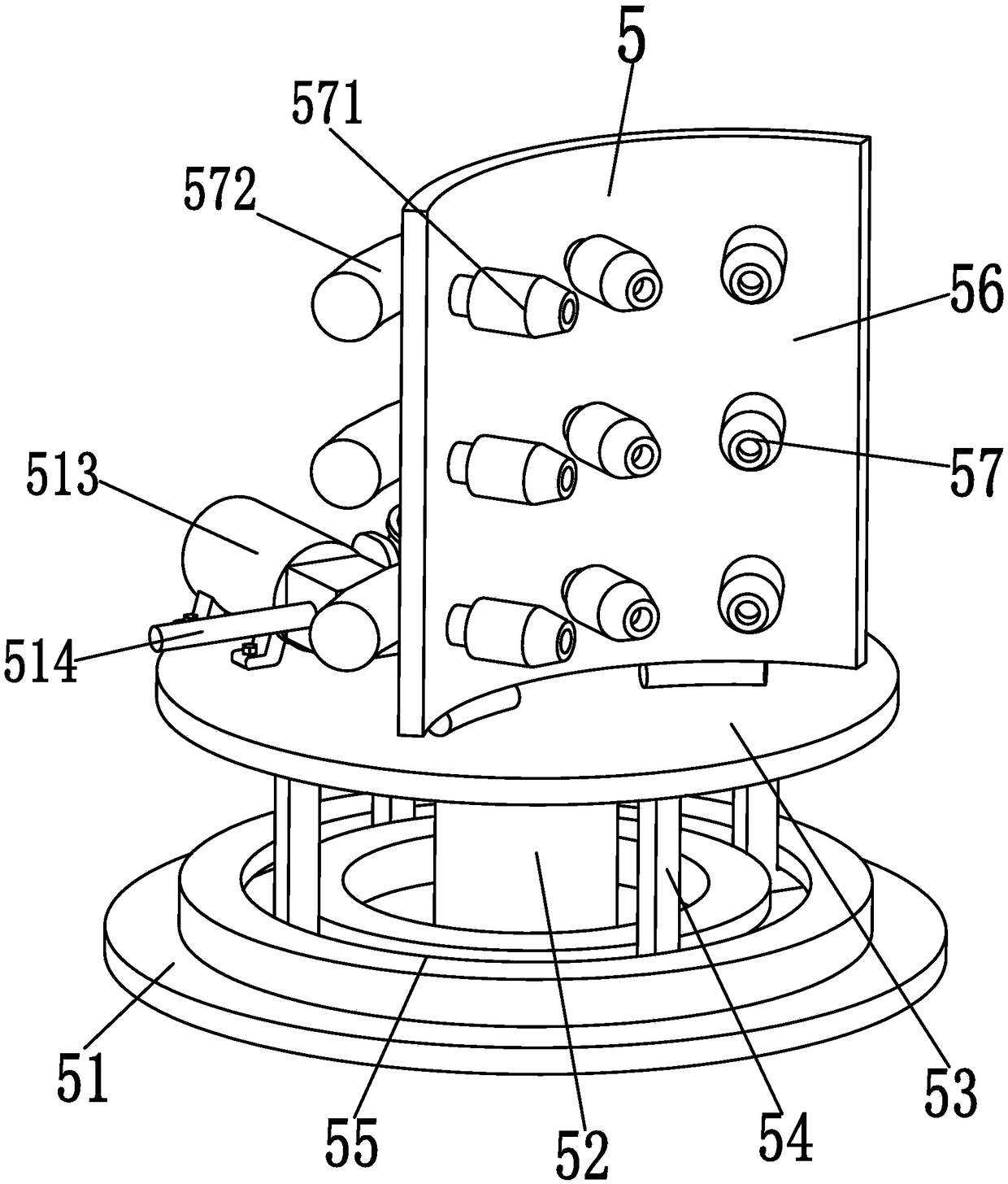

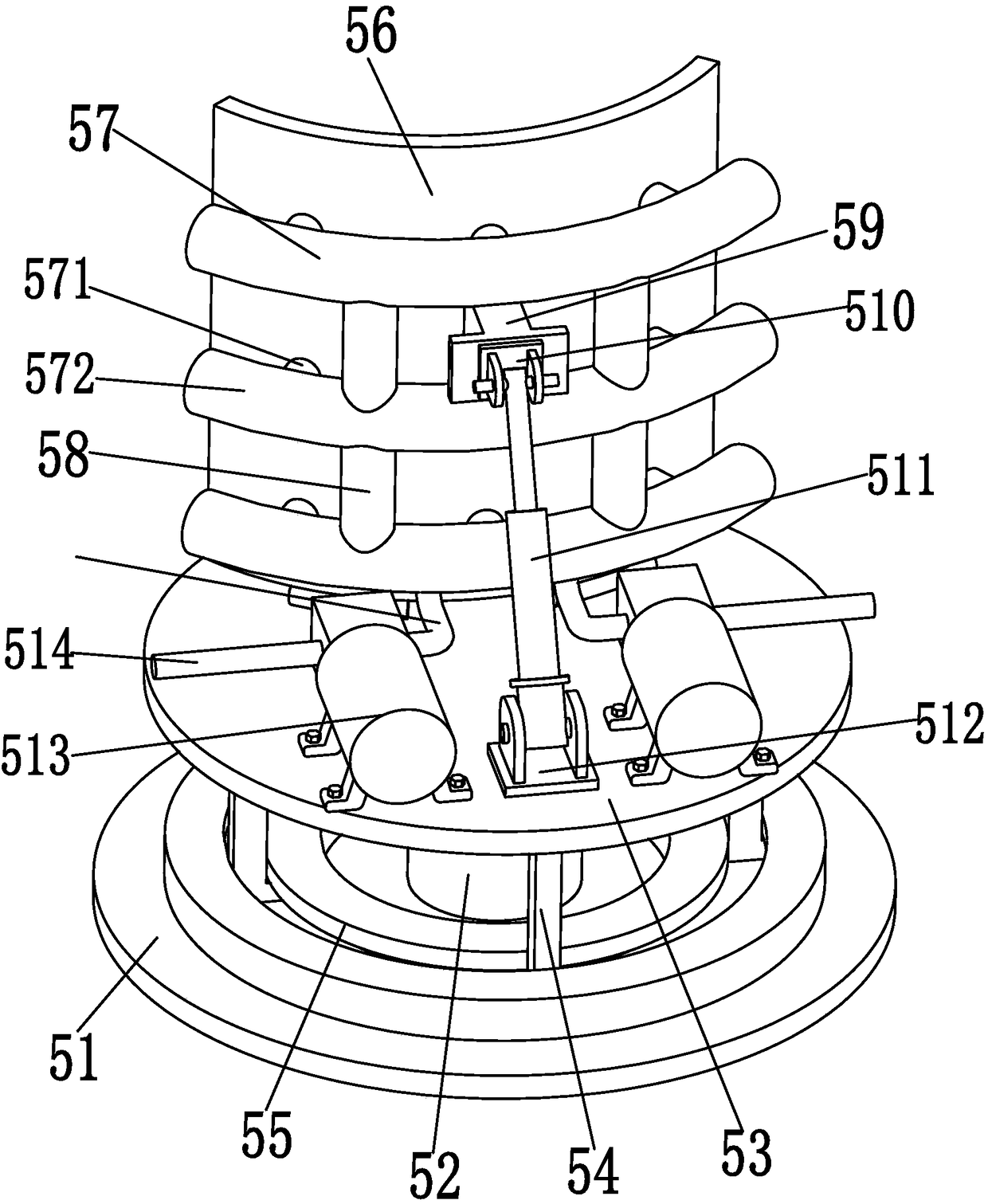

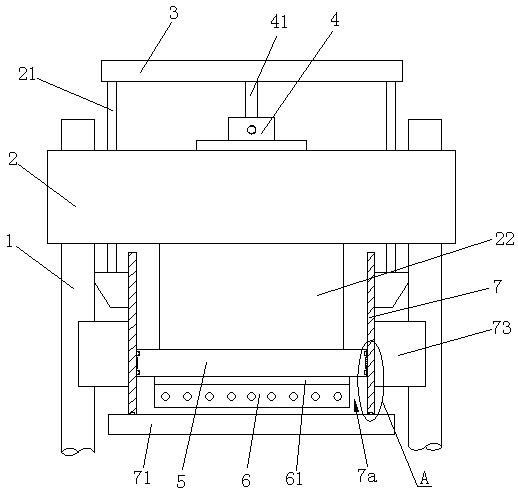

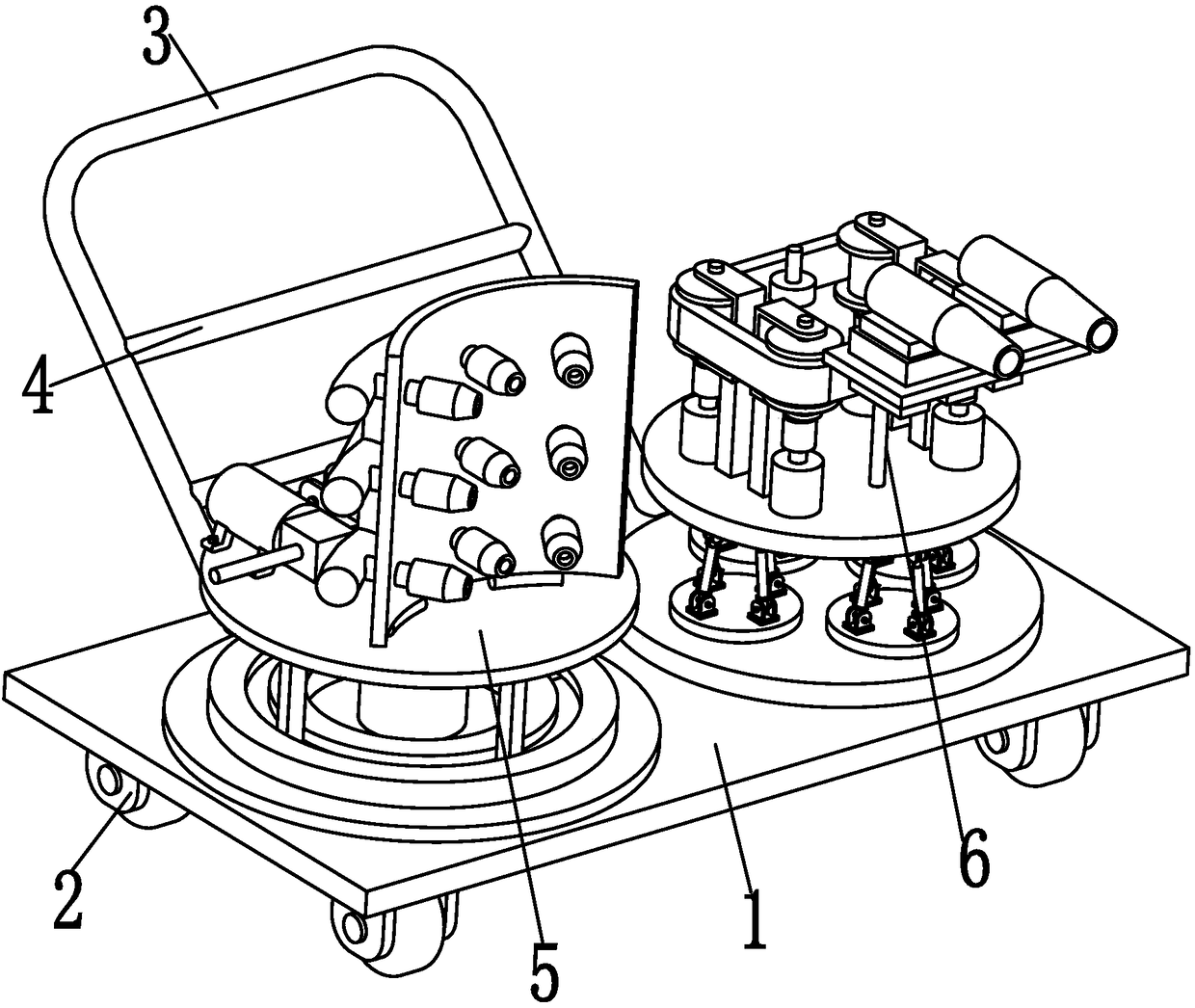

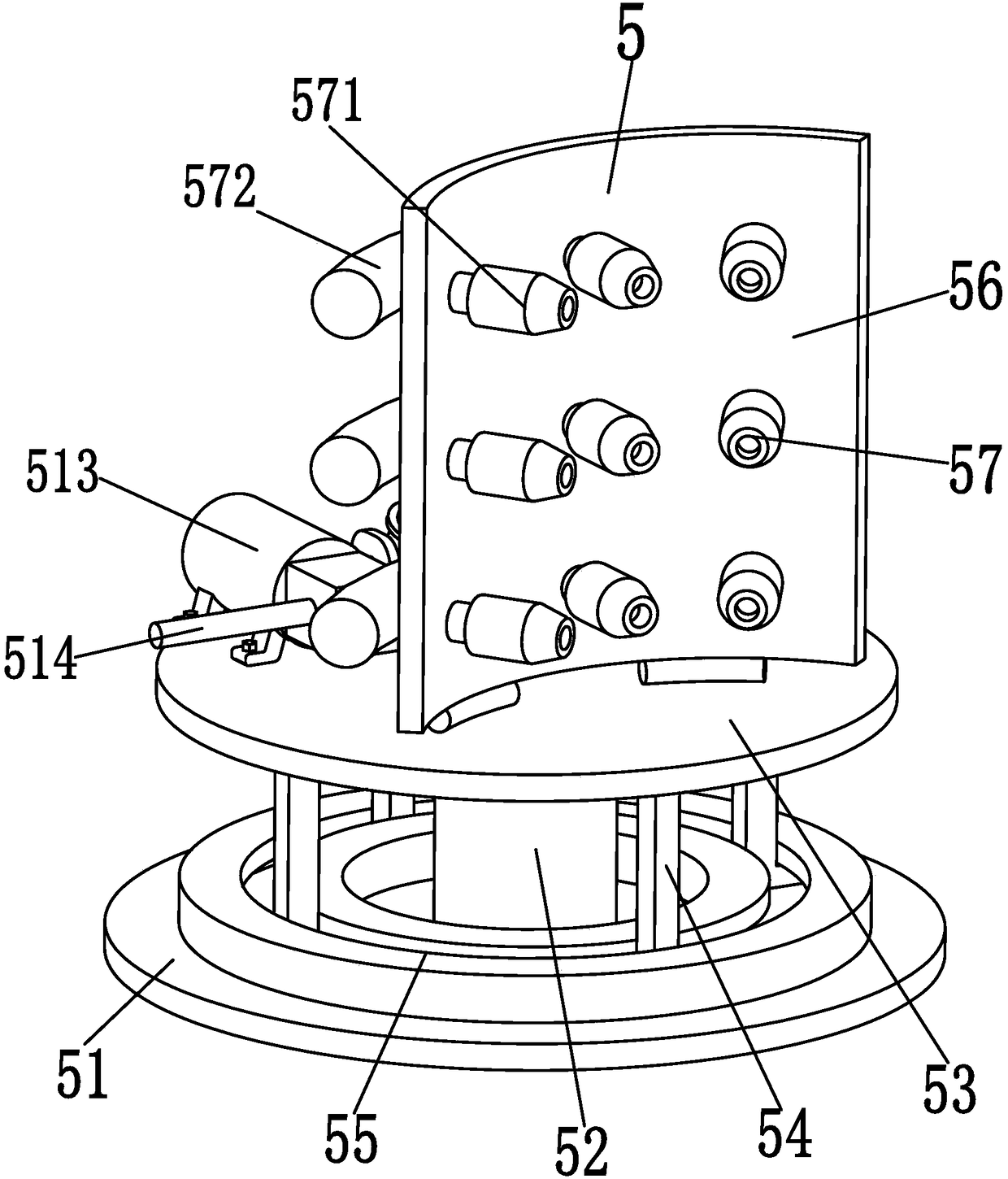

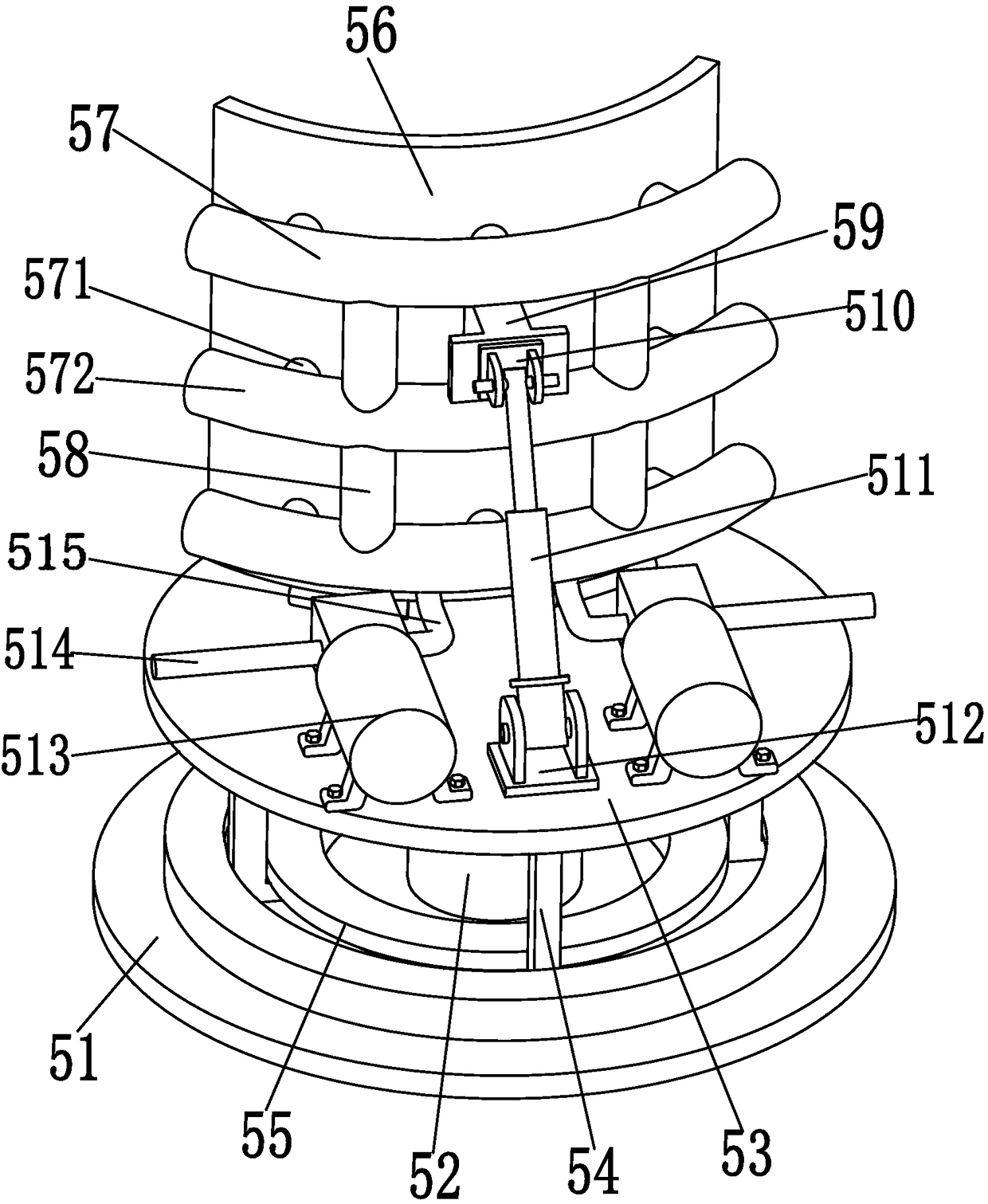

Spraying dust-collecting robot for down-the-hole drill drilling

ActiveCN106285494ARealize the function of spray dust suppressionImprove the effect of dust suppressionEarth drilling toolsConstructionsEngineeringAutomation

The invention relates to a spraying dust-collecting robot for down-the-hole drill drilling. The spraying dust-collecting robot comprises a base plate. Four universal wheels are symmetrically installed at the lower end face of the base plate; a handrail is arranged at the back side of the upper end face of the base plate; two transverse rods are arranged on the handrail; and a worker assisted by the four universal wheels drives the spraying dust-collecting robot to move to a down-the-hole drill rock drilling position through the handrail. A spraying device is installed at the left side of the upper end face of the base plate and can achieve a spraying dust-reducing function when a down-the-hole drill conducts rock drilling; and a dust-collecting device is installed at the right side of the upper end face of the base plate and can achieve an automatic dust-collecting function when the down-the-hole drill conducts rock drilling. The spraying dust-collecting robot for down-the-hole drill drilling can simultaneously achieve the spraying dust-reducing and automatic dust-collecting functions when the down-the-hole drill conducts rock drilling, and has the advantages that no manual spraying adjusting operation is needed, spraying angles can be automatically adjusted, operation is easy, the automation degree is high, the spraying effect is good, a movable dust-collecting mode is adopted, the dust-collecting direction is adjustable, dust collecting is fast, and the dust-collecting effect is good.

Owner:临沂恩科开发建设有限公司

Spray atomization system for vacuum oil purifier

ActiveCN107149793AImprove work efficiencyEnhanced Axial FlowIon-exchange process apparatusIon-exchanger regenerationSorbentEvaporation

The invention relates to a spray atomization system for a vacuum oil purifier. A fan is arranged in a vacuum tank, so the axial flow of air in the vacuum tank is enhanced; three layers of different filter structures are arranged in the vacuum tank, so the evaporation of water is accelerated, and the forming area of an oil film is increased; an adsorbing purification device is arranged under a mesh plate, impurities in waste oil are adsorbed by utilizing an adsorbing agent, and full contact between the waste oil and the adsorbing agent is ensured due to the fact that the diameter of a first small hole is smaller than that of a second small hole; four spray boxes are arranged in a spray device, each spray box is provided with a spray area, and when a sprayer rotates to work, a great amount of oil liquid and water will be sprayed at different positions and at different speeds, thereby facilitating rapid evaporation of the water, and improving the spray efficiency; the four spray boxes are arranged longitudinally, so the mounting size of the spray device is reduced, and the intelligence of the spray atomization system is realized by means of a PLC, an external liquid level meter and a pressure sensor.

Owner:镇江市长江机电设备厂有限公司

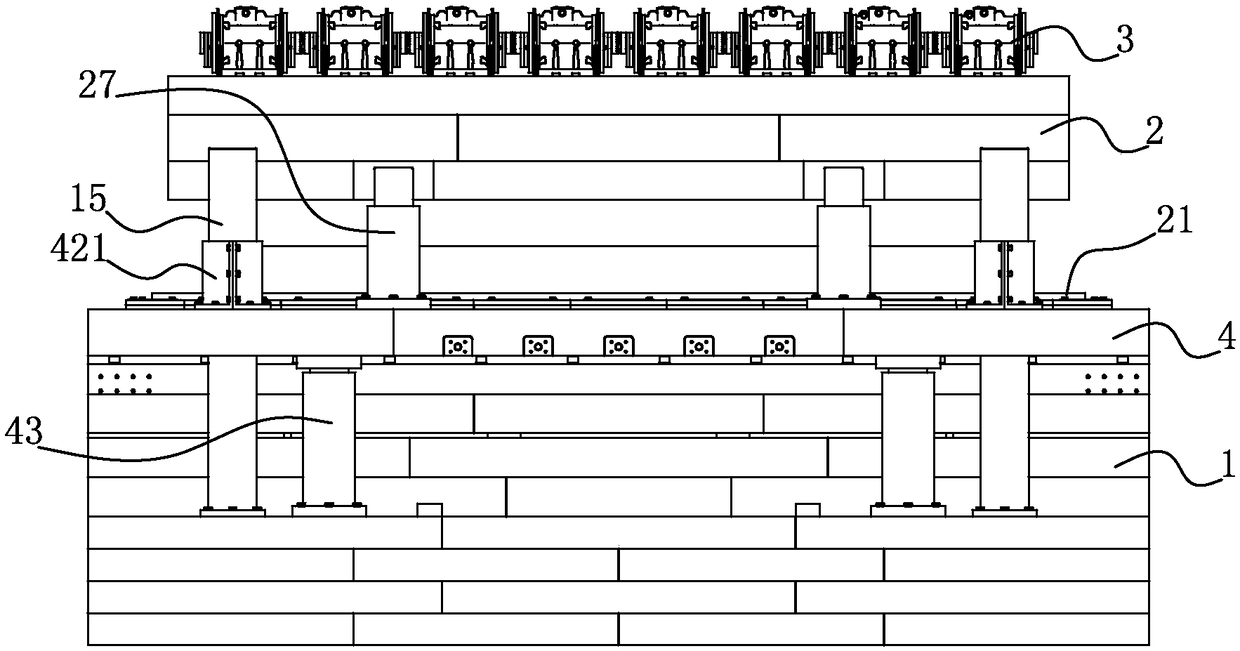

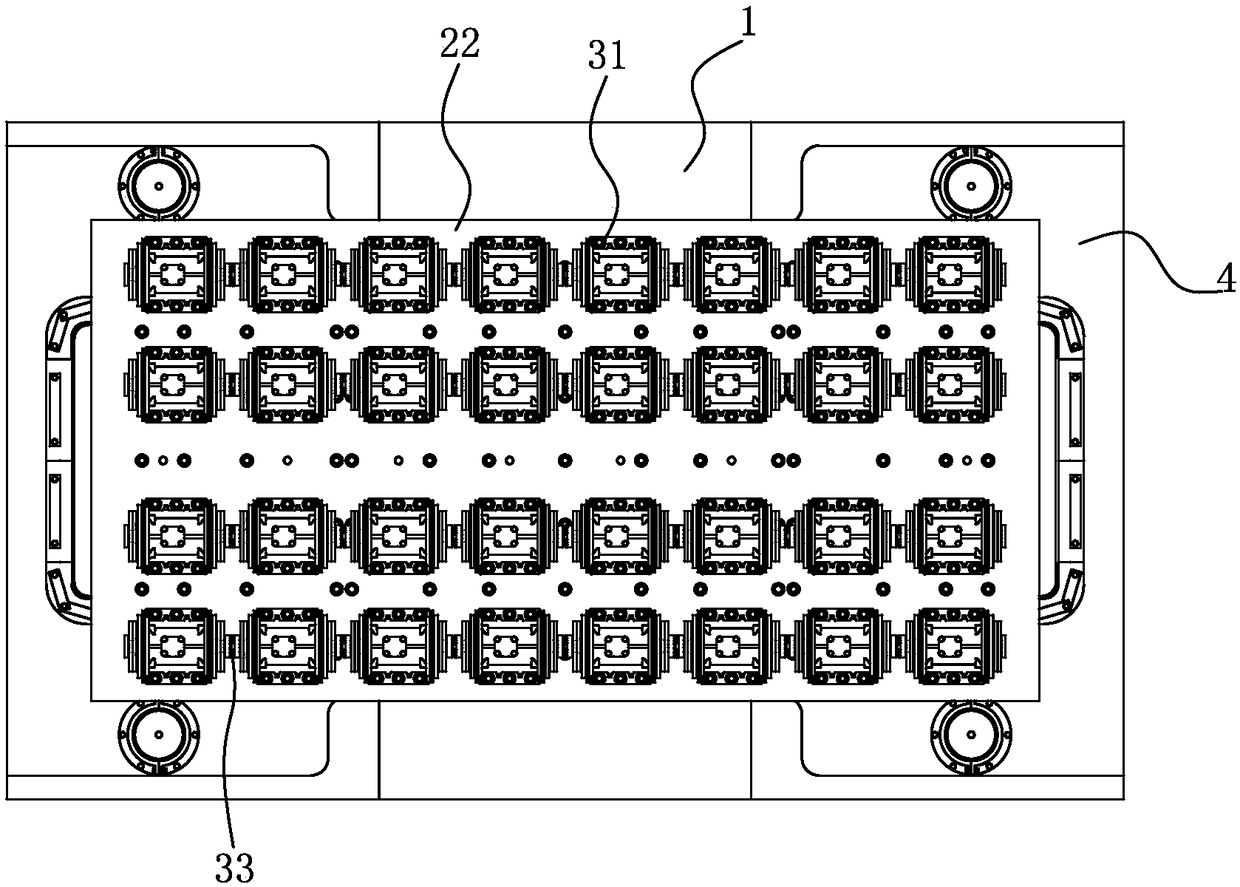

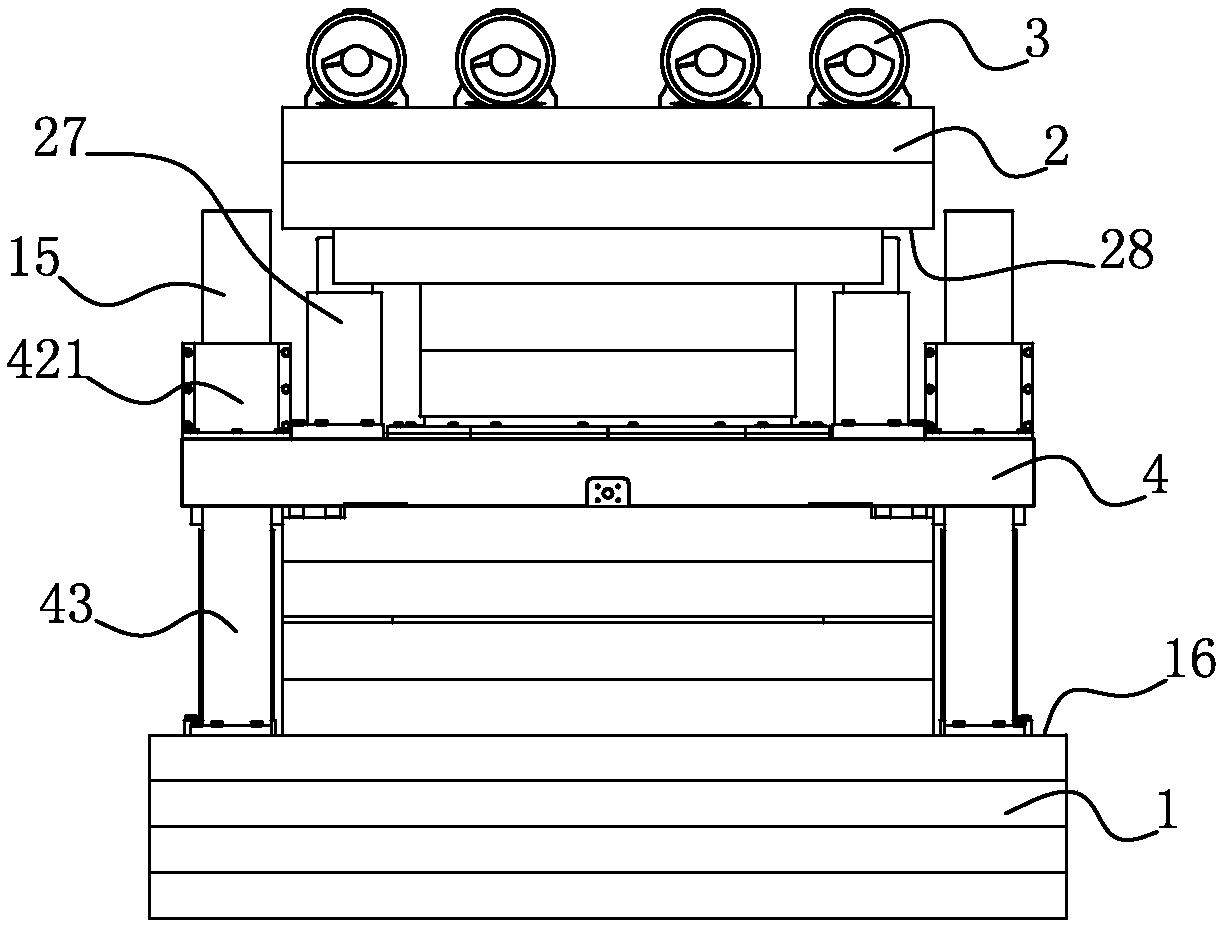

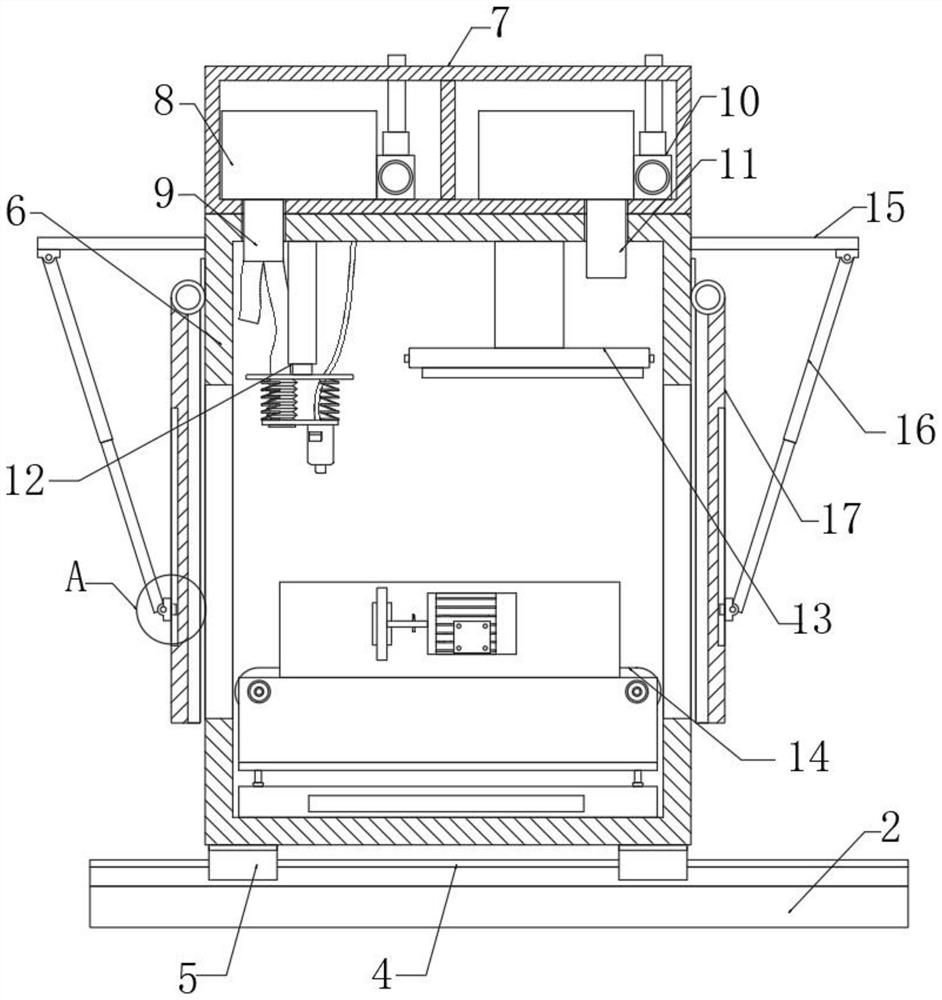

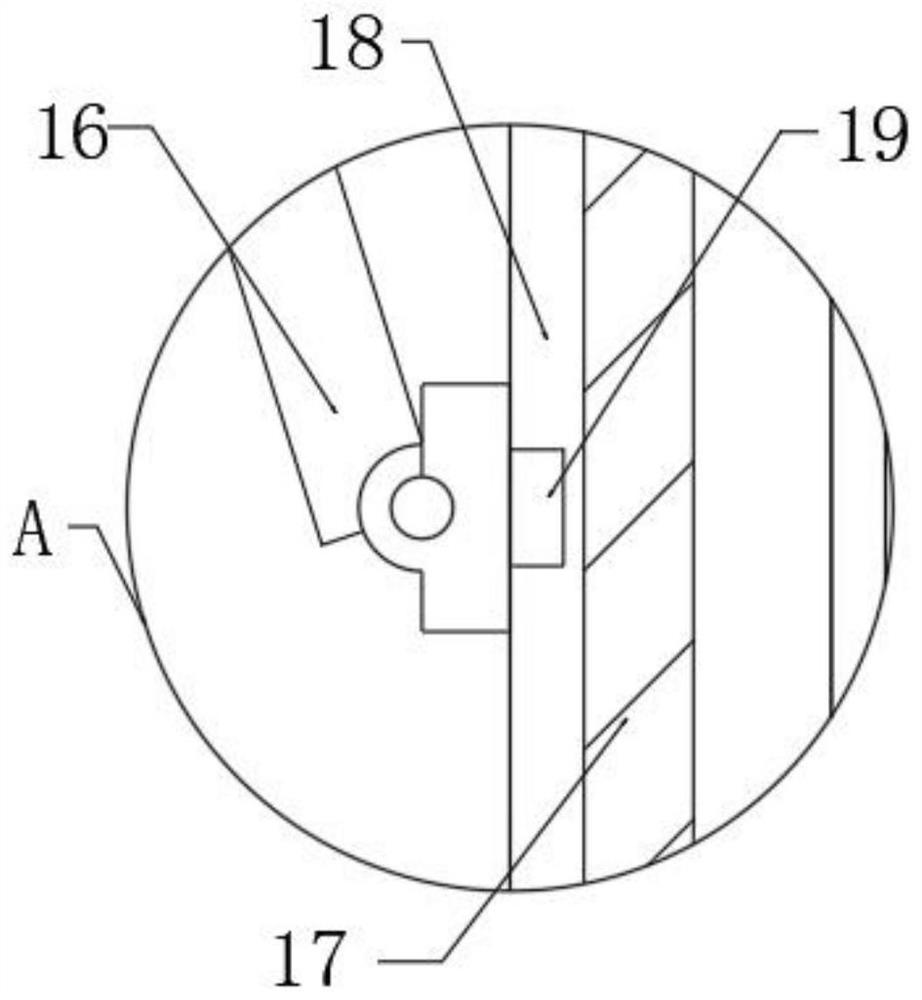

Forming machine for manufacturing vacuum stone

The invention discloses a forming machine for manufacturing a vacuum stone. The forming machine comprises a base, a heavy hammer and drivers, wherein the heavy hammer is installed on the base, and thedrivers are used for driving the heavy hammer; the base is provided with a material carrying area, the heavy hammer is used for beating the material carrying area, and a hammer plate is arranged at the bottom of the heavy hammer, and a material carrying belt is arranged on the base; the forming machine is further comprises a template, a hollow out part is formed in the middle of the template, thehammer plate is located in the hollowed out part, a multilayer lip-shape sealing rings are arranged at the top of a mold frame, and the lip-shape sealing rings abut against the side wall of the hammer plate; and an annular sealing ring is arranged at the bottom of the mold frame, the annular sealing ring abuts against the material carrying belt, the mold frame, the hammer plate and the material carrying belt form a vacuum cavity for wrapping materials, and a vacuum air suction channel is formed in the mold frame. According to the forming machine, a sealing structure is arranged at a vacuum stone material mixing position, only a vacuum stone mixing material is subjected to vacuum treatment, the vacuumizing speed is higher, and the sealing structure is simpler.

Owner:ANHUI UISTONE GREEN MATERIAL HI TEC CO LTD

Automatic device for prevention and treatment of dust in quarry drilling perforation operation

InactiveCN108104864ARealize the function of spray dust suppressionImprove the effect of dust suppressionEarth drilling toolsConstructionsEngineeringMaterial Perforation

The invention relates to an automatic device for prevention and treatment of dust in a quarry drilling perforation operation. The automatic device comprises a bottom plate, four universal wheels are symmetrically installed on the lower end surface of the bottom plate, an armrest is arranged on the back side of the upper end face of the bottom plate, two crossbars are arranged on the armrest, and astaff moves the automatic device through the armrest with the assistance of four universal wheels to the perforation position of the drilling perforation of a down-the-hole drill; the left side of the upper end surface of the bottom plate is provided with a spraying device, and the spraying device can realize the spraying and dust-removing function during the drilling perforation of the down-the-hole drill; and the right side of the upper end surface of the bottom plate is provided with a dust suction device which can realize the automatic dust-suction function during the drilling perforationof the down-the-hole drill. The automatic device can simultaneously realize the function of spraying and dust removing and the function of automatic dust suction during the drilling perforation of the down-the-hole drill, and has the advantages of no manual adjustment of spray operation, automatic adjustment of spray angle, simple and convenient operation, high degree of automation, good sprayingeffect, vacuuming by means of activities, adjustable dust-suction direction, high dust-suction speed, and good vacuum effect.

Owner:潘春燕

A high-efficiency vacuum pumping mechanism for a vulcanizing machine

Disclosed is an efficient vacuum pumping mechanism of a vulcanizing machine. The efficient vacuum pumping mechanism of the vulcanizing machine comprises a top base, wherein the top base is assembled on supporting columns. Connecting columns are arranged on the top base in a penetrating mode, and a fixed plate is fixedly arranged at the upper ends of the connecting columns. A vacuum cover oil cylinder is arranged above the top base, and the upper end of a piston rod of the vacuum cover oil cylinder is fixedly connected with the top base. A fixed base is arranged at the bottom of the top base, and a piston plate is arranged at the lower end of the fixed base. A heating disc is fixedly arranged on the piston plate, and a vacuum cover frame is arranged below the top base. A sliding plate is arranged at the bottom of the vacuum cover frame, the lower ends of the connecting columns are connected with the vacuum cover frame, and the periphery of the piston plate and the vacuum cover frame are in sealing fit. When the vacuum cover frame descends and is combined with the sliding plate to achieve die assembly, a vacuum chamber is formed in the vacuum cover frame and located between the piston plate and the sliding plate, and the heating disc is located in the vacuum chamber. The vacuum chamber is connected with a vacuum pumping circuit, and the vacuum pumping circuit mainly comprises a vacuum pump and a vacuum storage barrel, wherein the vacuum chamber and the vacuum storage barrel can conduct air convection. The efficient vacuum pumping mechanism of the vulcanizing machine has the advantages that the structure is simple, and the vacuum pumping efficiency can be effectively improved.

Owner:DONGYUNINGBOHYDRAULIC MACHINE INDAL

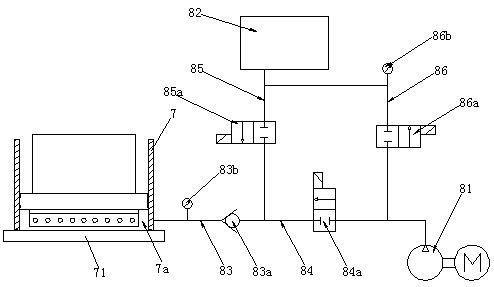

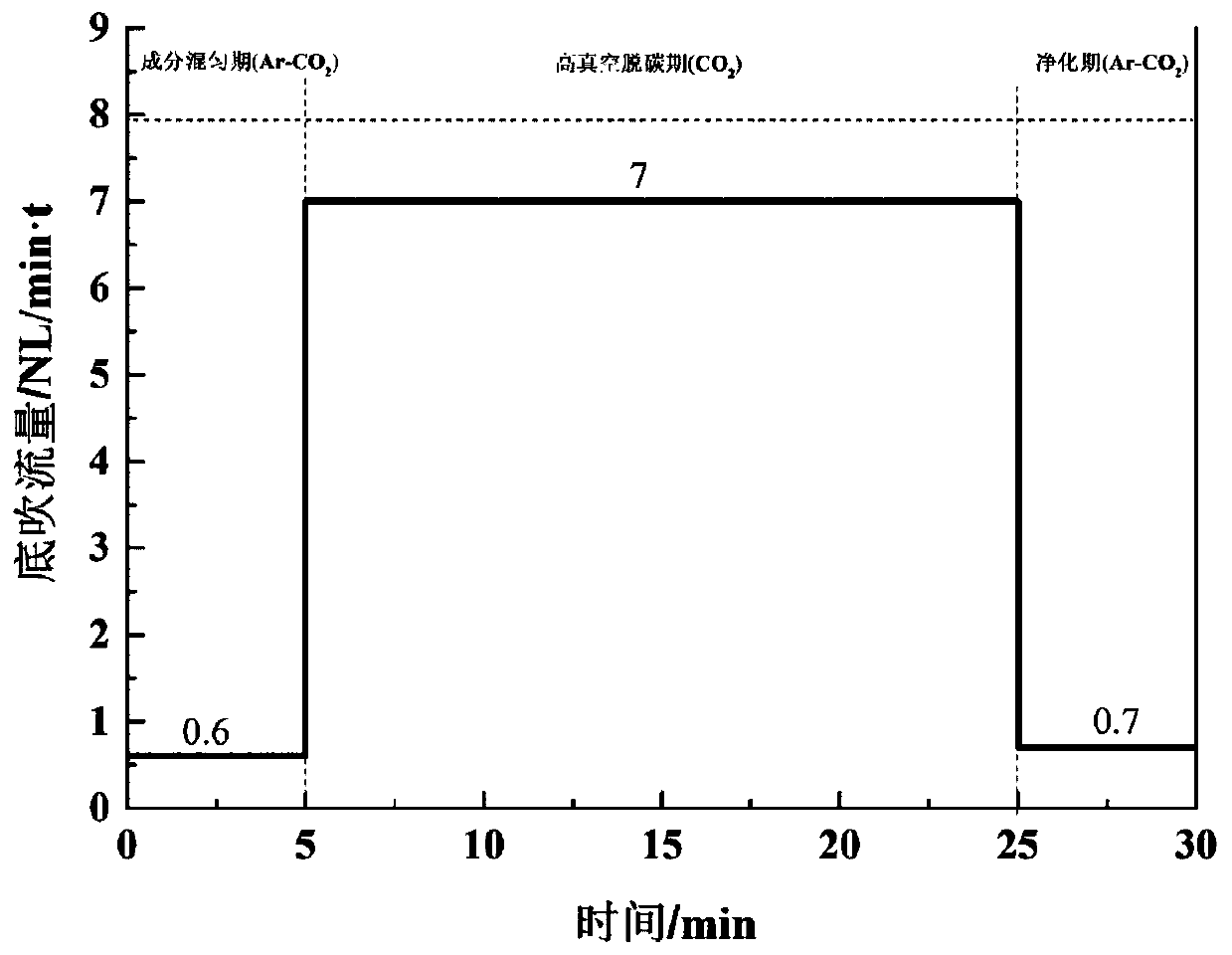

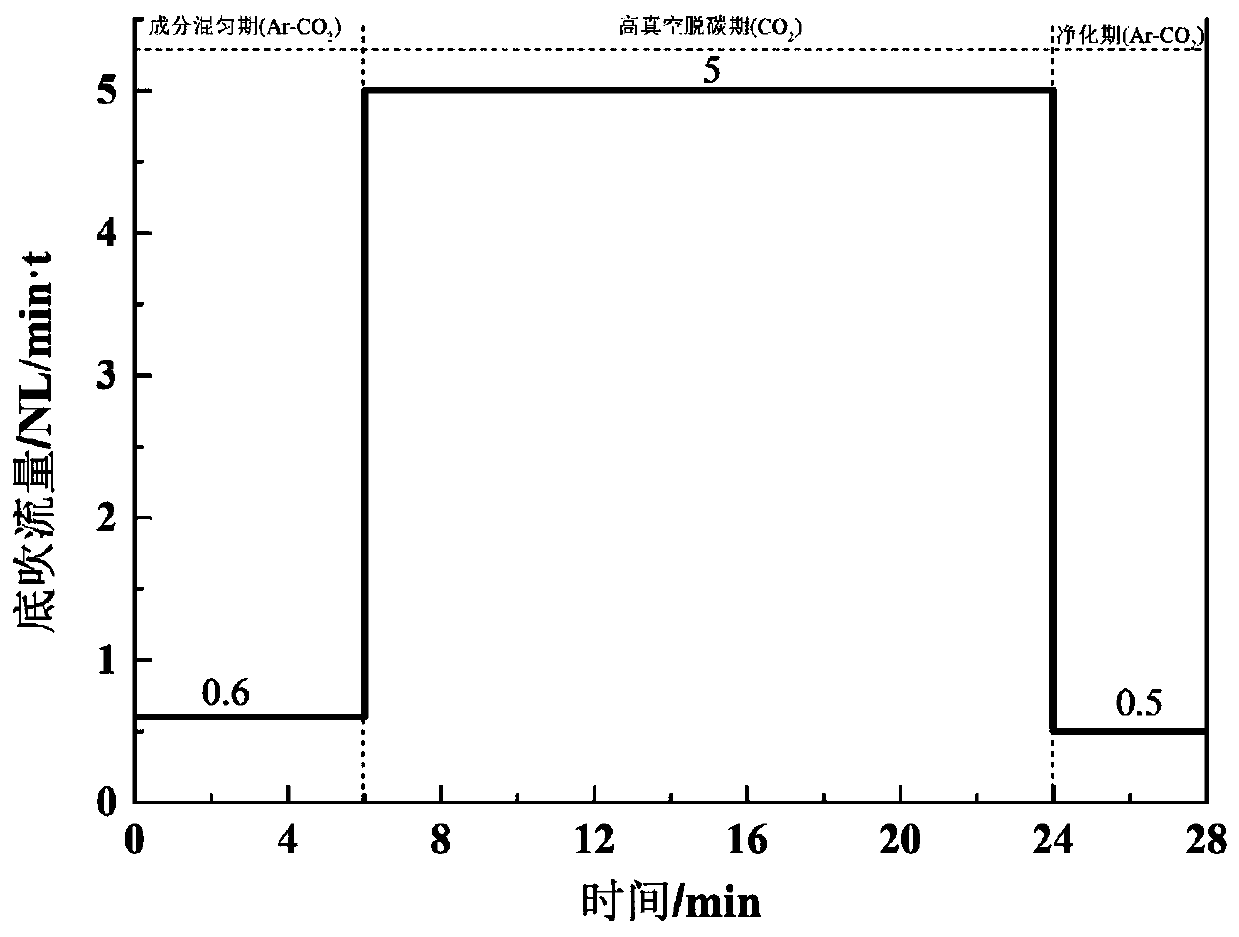

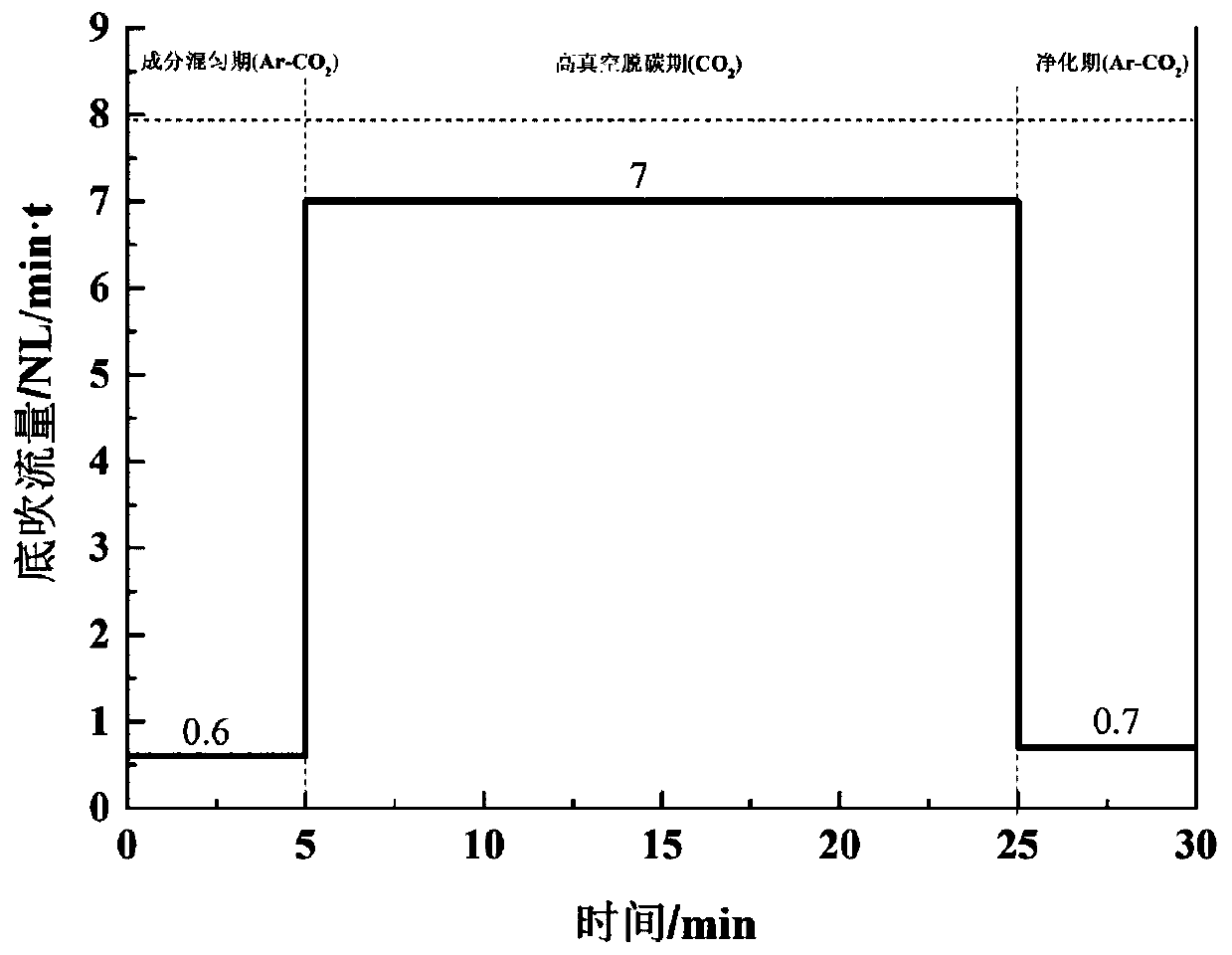

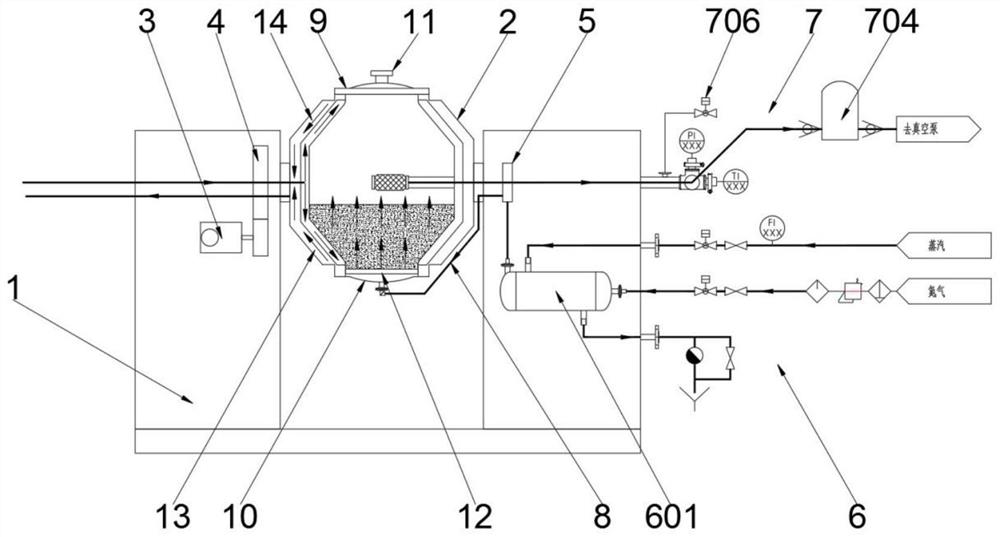

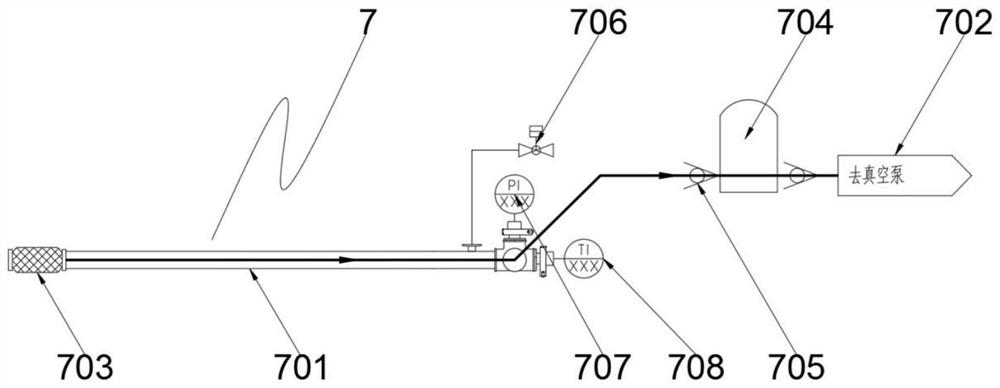

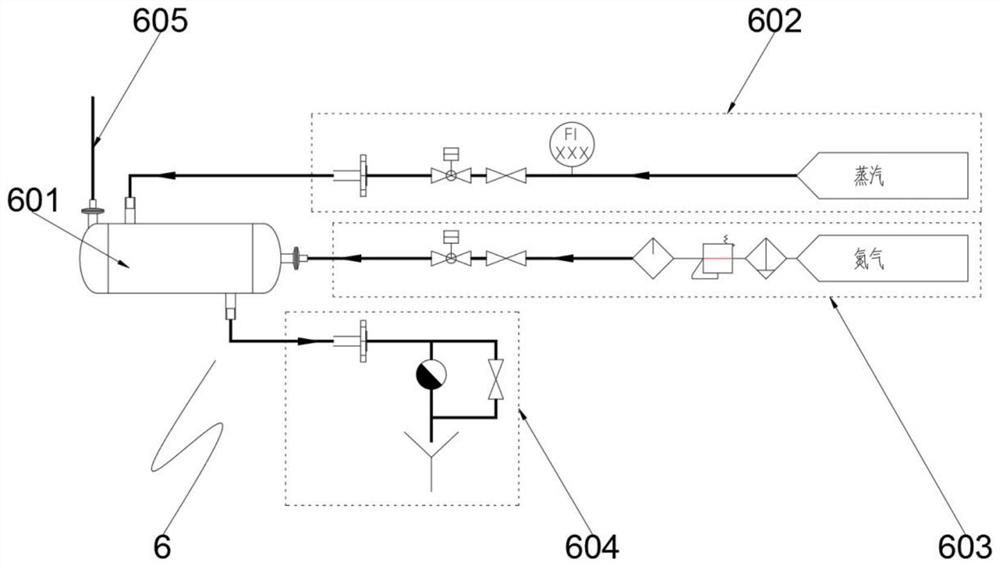

A method for denitrification in vd furnace using CO2 steelmaking

The invention relates to the technical field of the steelmaking industry, in particular to a method for steelmaking and denitrification of a VD furnace through CO2. The method for steelmaking and denitrification of the VD furnace through CO2 is suitable for the VD refinement of 30-350 t of steel ladles. According to the refinement process, bottom blowing of CO2 or CO2-Ar is performed through the steel ladles; different bottom blowing modes are adopted in all stages, the small-flow gas mixing bottom blowing is adopted in the liquid steel composition even-mixing stage, and liquid steel oxidationis prevented and the vacuumizing speed is increased; the high-flow bottom blowing of pure CO2 is adopted in the high vacuum decarburization stage, decarburization of CO2 is promoted, and then deep denitrification is achieved and dehydrogenation is enhanced; normal operation of a bottom blowing component is ensured by switching bottom blowing of Ar and high-pressure spraying and blowing in the bottom blowing repetition stage; and in the liquid steel purifying stage, bottom soft blowing of CO2-Ar mixed gas is performed, rapid flotation of nonmetal inclusions is promoted, and at the same time, CO2 gas is the main part of blowing, heat impact on a bottom blowing nozzle is reduced, the bottom blowing service life is prolonged, and finally low-cost smelting of low-nitrogen steel through the VDfurnace is achieved.

Owner:UNIV OF SCI & TECH BEIJING

A pulsating displacement vacuum dryer device

ActiveCN111637690BAvoid pollutionImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsThermodynamicsWater vapor

The invention discloses a pulsating displacement vacuum dryer device, which belongs to the technical field of material drying. The rotary tank body is supported in the air by a frame, and a rotary air guiding device is arranged at one end of the rotary tank body connected to the frame , the rotary air guide device is connected to the rotary tank body and the air supply mechanism, and the end of the rotary tank body close to the rotary air guide device is also provided with an exhaust mechanism for exhausting and vacuuming. The invention is scientific and reasonable, safe and convenient to use , using the cavity of the first jacket and the heat source to heat the inside of the rotary tank to realize indirect heating and avoid polluting the material. The materials in the tank are in convective contact to realize heat exchange. At the same time, the gas after heat exchange is discharged through the exhaust mechanism, and the heated inert gas is used as the carrier for the water vapor discharge after the material is dried, so as to improve the drying efficiency of the material.

Owner:CHANGZHOU AOKAI DRYING EQUIP

Simple and general automatic negative pressure lamination type vacuum OCA laminating machine

InactiveCN106313856AEasy to operateStepless adjustment of fitting pressureLaminationLamination apparatusRubber ringBaseboard

A simple and general automatic negative pressure lamination type vacuum OCA laminating machine is characterized in that a frame is arranged, the lower portion of the frame is provided with a baseboard, the upper portion of the frame is provided with a transparent cover plate, the baseboard is provided with an isobaric hole, the frame body is arranged between the baseboard and the transparent cover plate, the frame is provided with an air extraction valve and a stitching valve, a vacuum meter is arranged between the air extraction valve and the switching valve, a vacuum machine is connected to a position beside the air extraction valve, and the frame is provided with an upper seal rubber ring and a lower seal stitching rubber. The machine is simple to operate, allows a product to be taken out through two valves and three actions comprising air extraction, switching and venting, realizes visual operation, allows the laminating pressure to be momentarily steplessly adjusted in the laminating process, and allows the laminating effect to be visual.

Owner:尤德宏

Dust suction device and dust removal equipment

PendingCN112264420AExtended service lifeReduce maintenance costsDirt cleaningFixed frameDust control

The invention discloses a dust suction device and dust removal equipment. The dust suction device comprises a fixed frame, a driving assembly, a dust suction assembly and a supporting assembly. The driving assembly is mounted on the fixed frame. The dust suction assembly comprises a first rotating arm and an induced draft fan installed on the fixed frame, an air inlet of the first rotating arm communicates with outside air, an air outlet of the first rotating arm communicates with an air inlet of the induced draft fan, the first rotating arm is connected with the driving assembly, and the driving assembly is used for driving the first rotating arm to rotate relative to the fixed frame. The supporting assembly is installed on the fixed frame and connected with the first rotating arm so as to support the first rotating arm. The first rotating arm can rapidly suck dust under the action of the induced draft fan, the dust suction speed is increased, meanwhile, the dust suction range of thefirst rotating arm can completely cover a whole welding workshop, fixed-point dust suction can be conducted only on the position where dust needs to be sucked, the dust suction efficiency is improved,and meanwhile the operation cost can be saved.

Owner:WELLDONE ENVIRONMENTAL PROTECTION EQUIP CHANGSHA

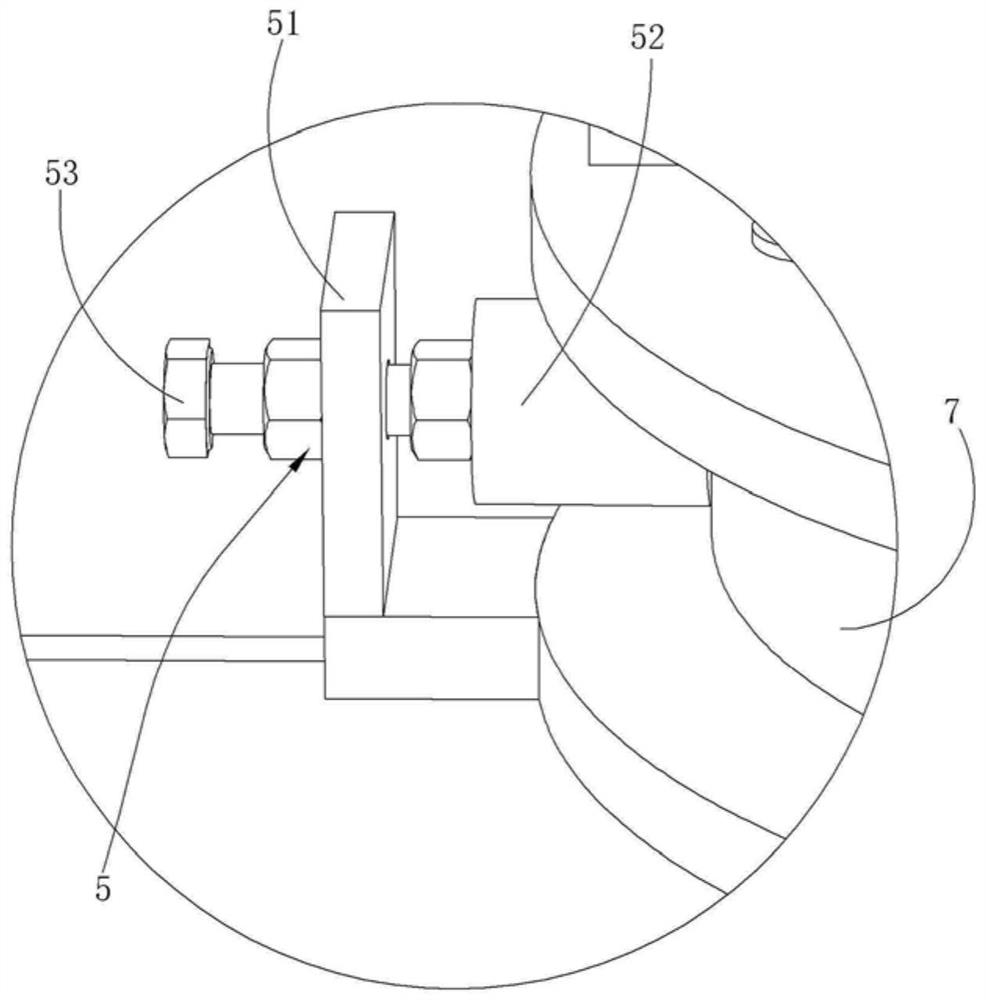

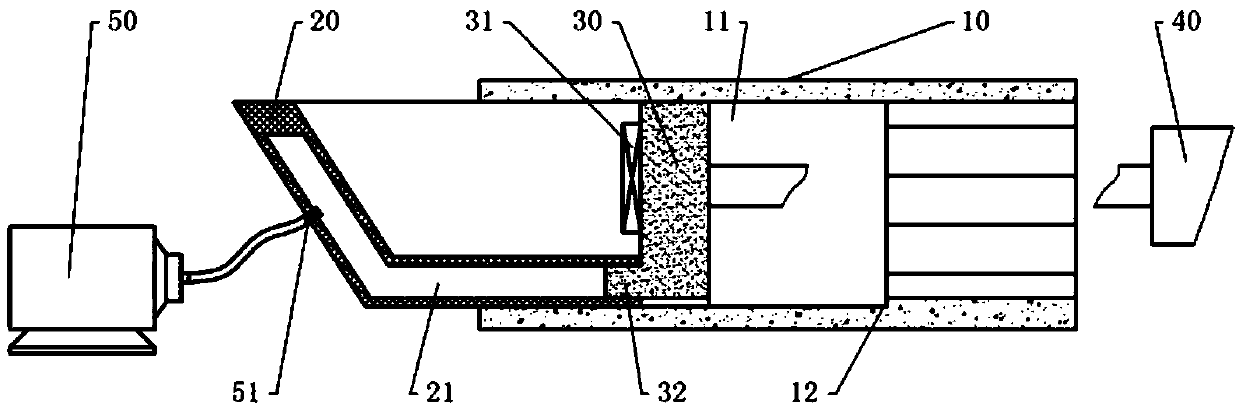

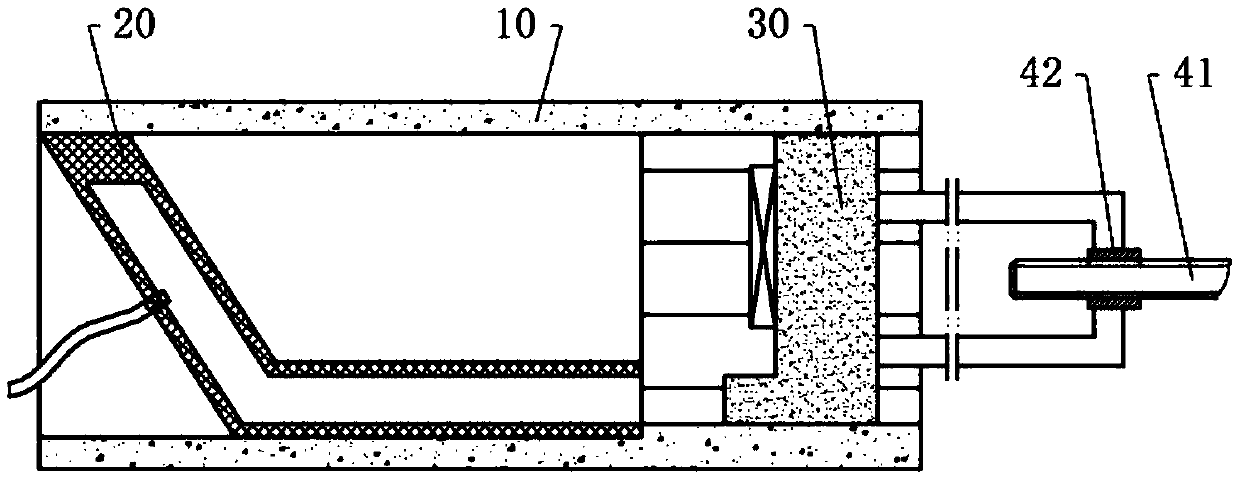

Radiant annealing method for camera bracket

ActiveCN108148958BShort working hoursFast vacuumingFurnace typesHeat treatment furnacesStopped workEngineering

The invention relates to the technical field of camera machining and particularly discloses a bright annealing method of a camera support. The bright annealing method of the camera support comprises the steps that (1) vacuumizing treatment is conducted on a vacuum cavity, a feeding groove is pushed out by a drawing mechanism from an opening at the left end of the heating cavity, and workpieces arefed into the feeding groove from a top opening of the feeding groove; (2) a plug block is pulled by the drawing mechanism to slide in the heating cavity, the plug block is pulled to the right end ofa furnace body, and after a vacuum pump stops work, a heater is connected with a power source; (3) the temperature of the heating cavity is raised to 410-450 DEG C, and the temperature is kept for 5-6hours; (4) after the temperature of the heating cavity is raised to 600-650 DEG C and kept for 1-1.5 hours, the heater is switched off; (5) after the temperature in the heating cavity is lowered to below 50 DEG C, the feeding groove is pushed out from the opening at the left end of the heating cavity, and the workpieces are taken out from the feeding groove. By the adoption of the bright annealing method of the camera support, a device can rapidly conduct vacuumizing on the heating cavity, and it is avoided that when the heating cavity is opened, air flushes into the heating cavity and damages the heater.

Owner:李倩楠

Vacuum high temperature brazing furnace with rapid cooling

InactiveCN108788360ARapid coolingImprove cooling effectMetal working apparatusSoldering auxillary devicesHeat conductingMetallurgy

The invention discloses a vacuum high temperature brazing furnace with rapid cooling. The vacuum high temperature brazing furnace with rapid cooling comprises a furnace body, a sealing door is arranged on one side of furnace body, and the furnace body is internally provided with a brazing chamber, a heating chamber and a cooling circulation chamber. The brazing chamber is internally provided witha brazing platform, a heating chamber with an open upper end is arranged under the brazing platform, the cooling circulation chamber is arranged above the brazing platform, and the cooling circulationchamber is internally provided with two or more groups of semiconductor cooling components. Cold conducting fins are connected with a grid plate, heat conducting fins are connected to one ends of circulation pipes, and the other ends of the circulation pipes are connected with the bottom of the brazing chamber in a communicating mode. A vacuum chamber is arranged above the furnace body. Accordingto the vacuum high temperature brazing furnace with rapid cooling, temperature and noise are reduced effectively, noise is reduced, and the working environment is improved; and meanwhile, recycling of heat in the high temperature brazing furnace is realized.

Owner:滁州华海中谊工业炉有限公司

A kind of vacuum packaging equipment for water-based varnish

ActiveCN113968376BFast vacuumingSpraying speed is fastFinal product manufacturePackaging by pressurising/gasifyingCircular discEngineering

The invention discloses a vacuum packaging equipment for water-based varnish, comprising: a conveyor belt; a carrier plate installed on one side of the conveyor belt; the other end of the carrier plate is mounted with a conveyor belt 2; Electric slide rails are fixed. In the present invention, an irregular disc is used to repeatedly squeeze the impact head to telescopically move, and while loading materials, the impact head can hit the surface of the loading bucket, so that the bubbles of the materials loaded inside are hit and discharged, and the existing loading is changed. The method causes the material to be mixed with a certain amount of air bubbles, and the situation that the loading barrel cannot be completely vacuumed occurs. The lower plate can move up and down, which can not only drive the filling head to enter the bottom of the inner cavity of the loading barrel, and then fill the material from bottom to top. The method replaces the direct filling method from the top in the past, which can prevent the residual air from being encapsulated at the bottom by the paint liquid, resulting in poor vacuum in the tank, changing the situation that the existing irrigation head is easy to collide with the barrel wall to generate air bubbles. .

Owner:江西辙炜新材料科技有限公司

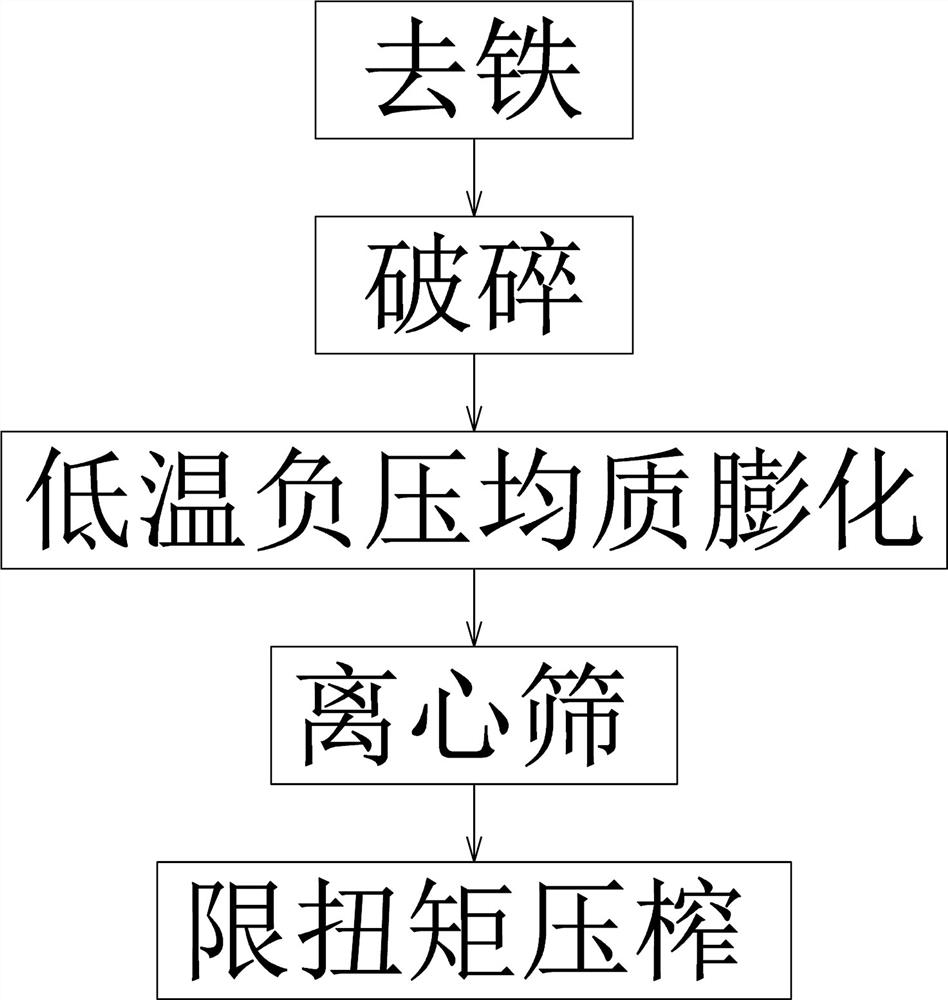

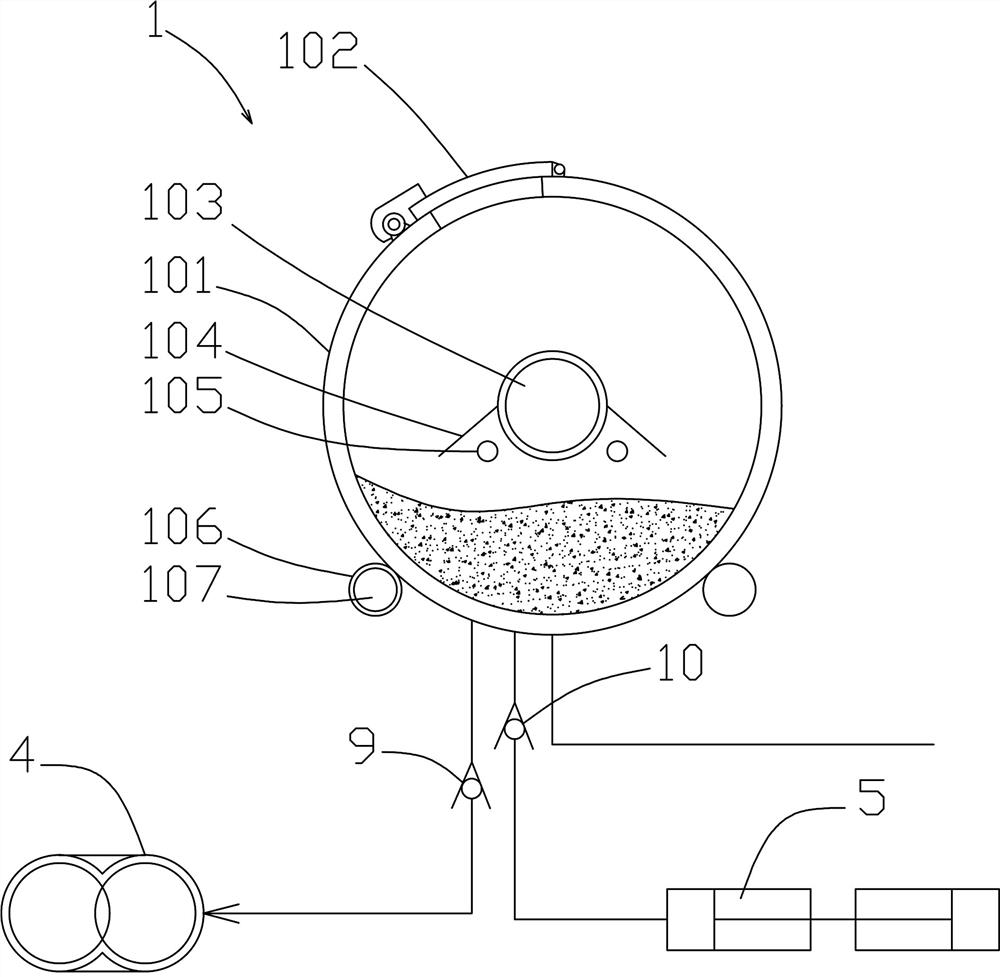

Flavored oil production method

PendingCN114643735AAccelerateImprove market reputation and sales revenueRotary centrifugesFatty-oils/fats productionEdible oilEngineering

The invention provides a production method of a flavor oil material, and relates to the field of edible oil pressing processes, and the production method comprises the following steps: carrying out low-temperature negative-pressure homogeneous puffing on the oil material; the heating mode of the oil is microwave heating; the heating temperature of the oil material is 80-99 DEG C; the negative pressure ranges from-0.098 Mpa to-0.6 Mpa; carrying out segmented filtration or squeezing on the puffed oil; the finished product oil rich in flavor substances is obtained through the steps. By adopting a low-temperature negative-pressure homogeneous puffing scheme, the oil yield is prevented from being influenced by excessive puffing, and the loss of flavor substances in the finished product oil due to too high temperature is also avoided.

Owner:TIANXING GRAIN & OIL MACHINERY EQUIP ANLU CITY

A spray vacuum robot for down-the-hole drilling rig drilling

ActiveCN106285494BRealize the function of spray dust suppressionImprove the effect of dust suppressionEarth drilling toolsConstructionsEngineeringDrilling machines

The invention relates to a spraying dust-collecting robot for down-the-hole drill drilling. The spraying dust-collecting robot comprises a base plate. Four universal wheels are symmetrically installed at the lower end face of the base plate; a handrail is arranged at the back side of the upper end face of the base plate; two transverse rods are arranged on the handrail; and a worker assisted by the four universal wheels drives the spraying dust-collecting robot to move to a down-the-hole drill rock drilling position through the handrail. A spraying device is installed at the left side of the upper end face of the base plate and can achieve a spraying dust-reducing function when a down-the-hole drill conducts rock drilling; and a dust-collecting device is installed at the right side of the upper end face of the base plate and can achieve an automatic dust-collecting function when the down-the-hole drill conducts rock drilling. The spraying dust-collecting robot for down-the-hole drill drilling can simultaneously achieve the spraying dust-reducing and automatic dust-collecting functions when the down-the-hole drill conducts rock drilling, and has the advantages that no manual spraying adjusting operation is needed, spraying angles can be automatically adjusted, operation is easy, the automation degree is high, the spraying effect is good, a movable dust-collecting mode is adopted, the dust-collecting direction is adjustable, dust collecting is fast, and the dust-collecting effect is good.

Owner:XUANHUA TAIYE DIVING HOLE MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com