A pulsating displacement vacuum dryer device

A vacuum dryer and vacuum pumping technology, which is applied in non-progressive dryers, drying gas arrangement, dryers, etc., can solve the problem that water vapor cannot be discharged well, materials are dry and heated unevenly, and gas supply methods are uneven. Correctness and other issues to achieve the effect of shortening the start-up time, uniform distribution, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

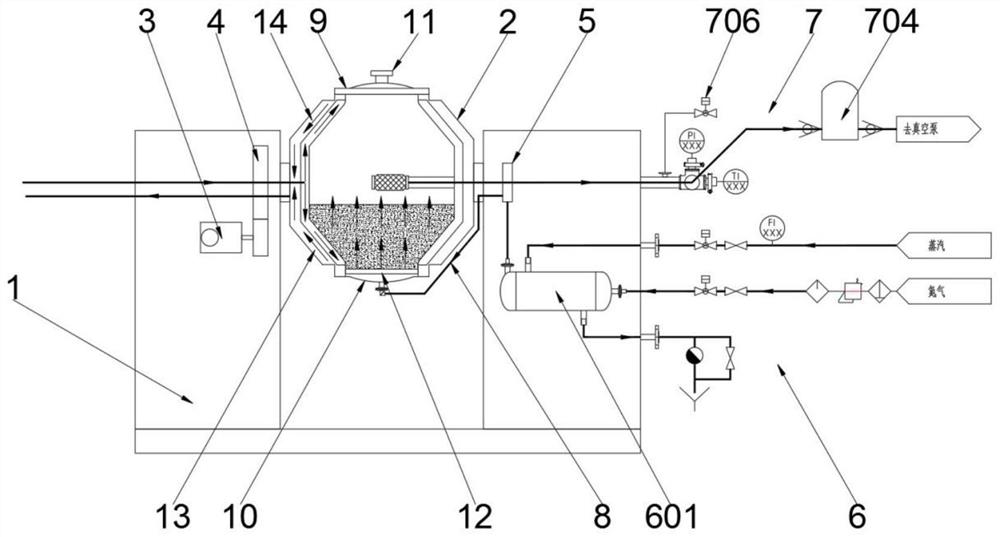

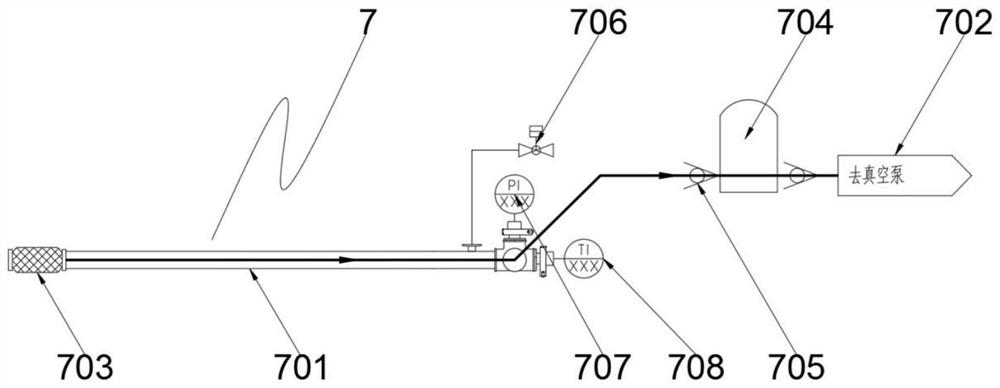

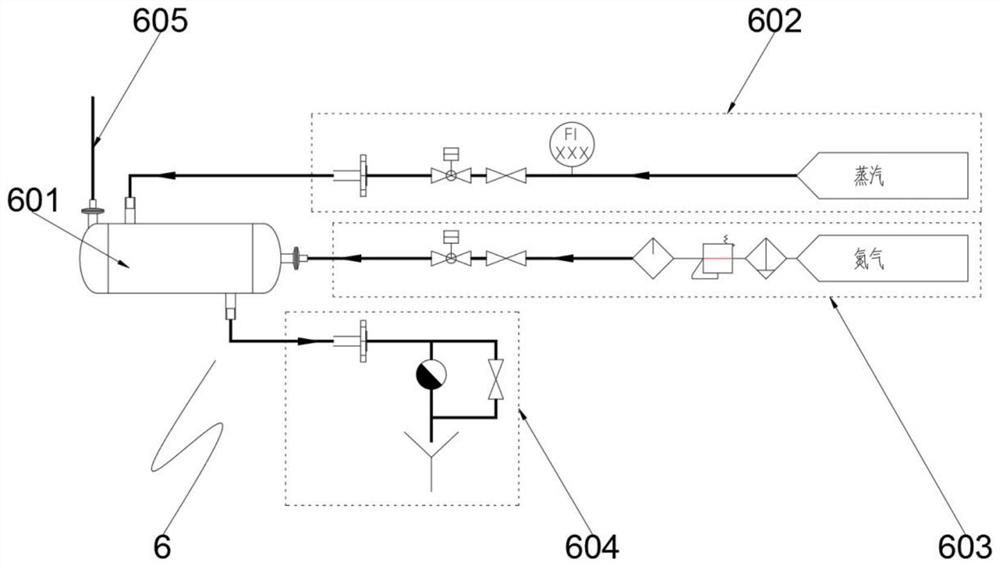

[0058] Example: such as Figure 1-8 As shown, a pulsating displacement vacuum dryer device includes a frame 1, a rotary tank body 2, a rotary air guiding device 5, an air supply mechanism 6, an exhaust mechanism 7 and a control system;

[0059] The rotary tank body 2 is supported in the air by the frame 1, and one end of the rotary tank body 2 connected to the frame 1 drives the rotary tank body 2 to rotate through the transmission motor 3, and the rotation speed of the rotary tank body 2 is reduced by the reducer 4, and the reducer 4 Mesh connection with the output gear of the transmission motor 3, the reducer 4 is used to reduce the speed of the rotary tank 2, so as to ensure that the materials inside the rotary tank 2 will not be unable to turn over by themselves due to centrifugal movement, which will affect the drying effect of the materials , the rotational speed of the rotary tank body 2 is less than 10r / min, the other end of the rotary tank body 2 connected to the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com