Single-stage rotary vane type vacuum pump

A rotary vane vacuum pump, single-stage technology, applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of small effective volume of vacuum suction, inconsistent contact sealing pressure, and different contact sealing effects , to achieve the effects of increased vacuuming speed, reliable contact and sealing, and high vacuuming degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

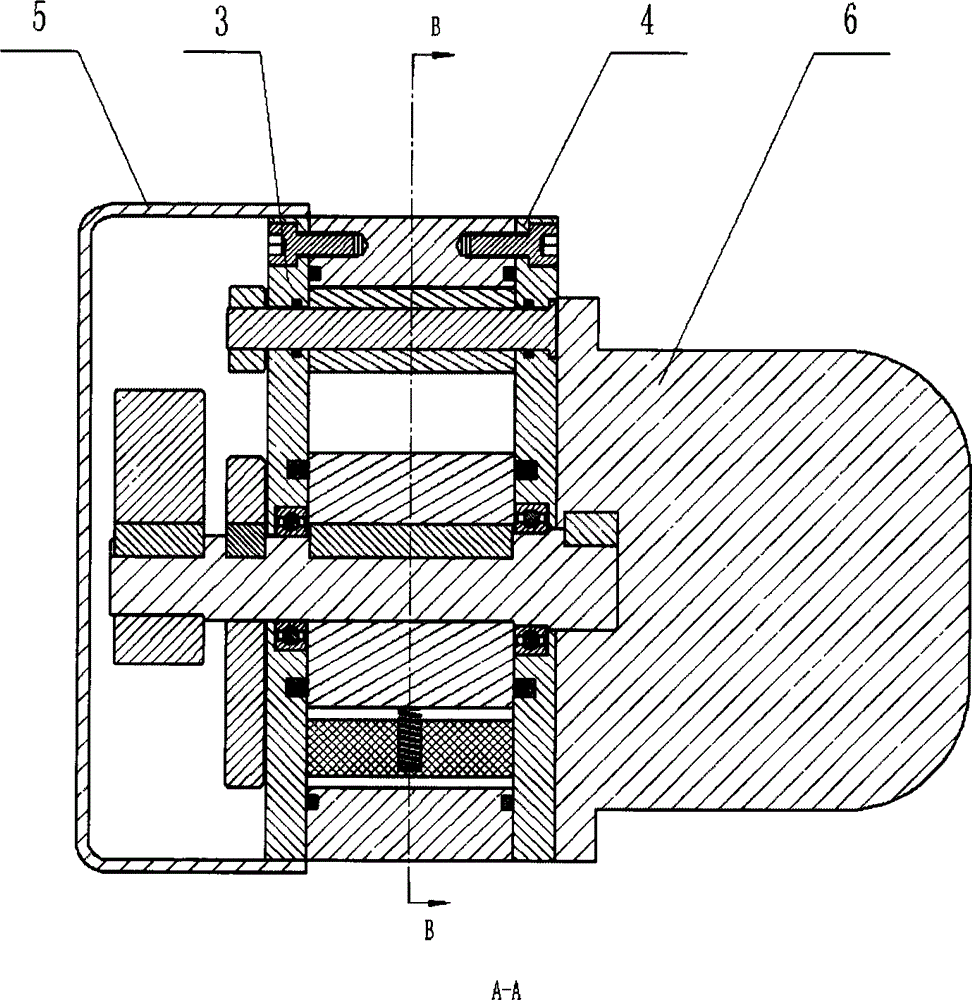

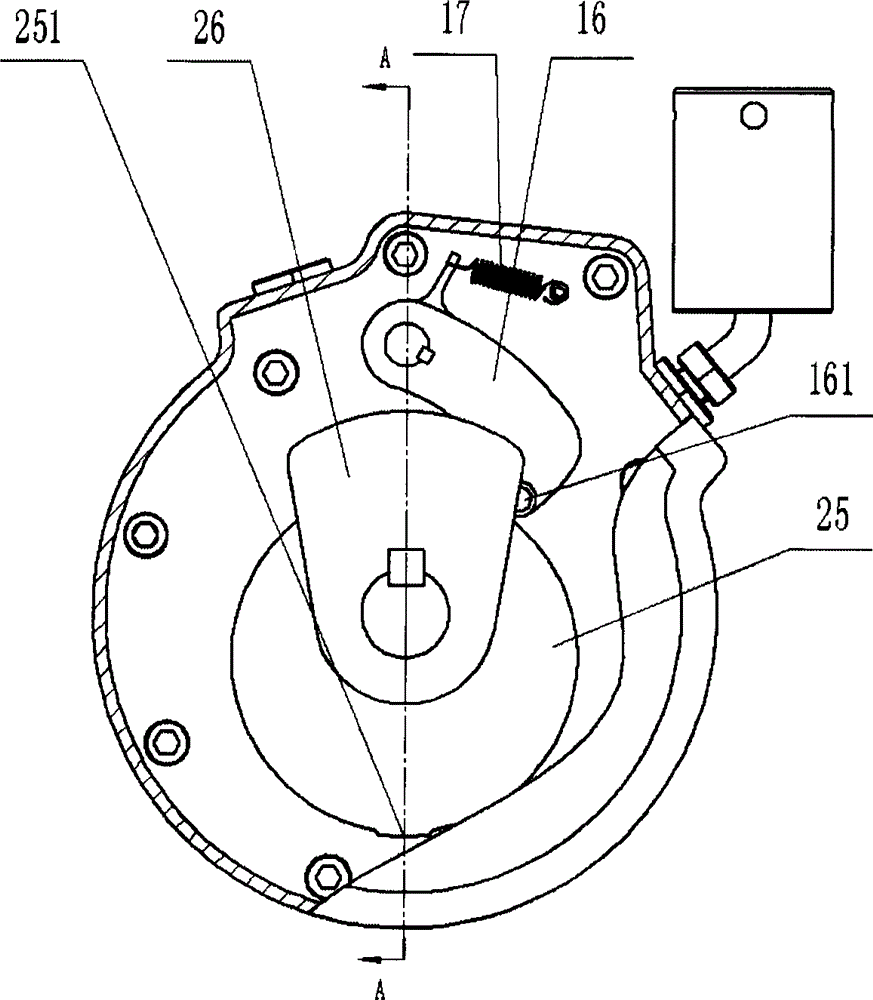

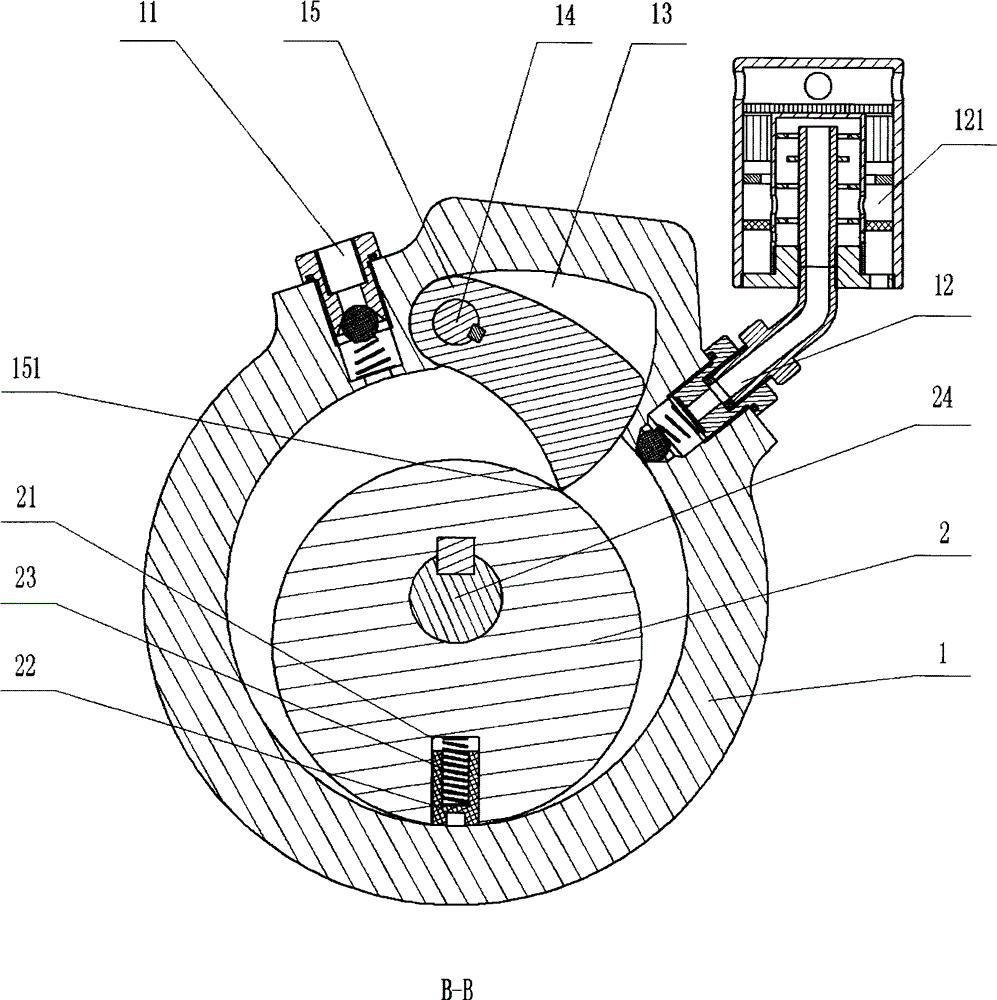

[0009] Such as figure 1 , figure 2 and image 3 In the shown embodiment, a single-stage rotary vane vacuum pump with only one rotary vane 22 provided on the rotor 2 is composed of a pump casing, a rotor 2 and a motor 6 . The pump casing includes a pump body 1 , a left pump cover 3 , a right pump cover 4 and a safety cover 5 . A vacuum suction port 11 and an exhaust port 12 are provided on the pump body 1 , and a gas-liquid separator 121 is provided on the exhaust port 12 . It is characterized in that: a groove 13 is provided on the inner circular surface of the pump body 1 between the suction port 11 and the exhaust port 12, and a spacer 15 is arranged in the groove 13, and the lower right side 151 of the spacer 15 is aligned with the The outer circular surface of the rotor 2 is in contact, the left end of the spacer 15 is connected with the rotatable small shaft 14 placed on the left pump cover 3 and the right pump cover 4, and the left end of the small shaft 14 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com