Flavored oil production method

A production method and technology for oilseeds, which are applied in the production of fat/fat, fat production, centrifuges, etc., can solve problems such as affecting the flavor of oilseeds, reducing oil yield, increasing oil content of oil residues, etc., so as to improve market reputation and sales. Revenue, effect of increased speed

Pending Publication Date: 2022-06-21

TIANXING GRAIN & OIL MACHINERY EQUIP ANLU CITY

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Excessive puffing will increase the specific surface area of the oil, increase the combined area with the oil, increase the oil content of the oil residue, and reduce the oil yield

Moreover, in the state of high-pressure pressing, the taste of some unfavorable substances is also easy to enter the oil, affecting the flavor of the oil, such as the bitterness in the walnut coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

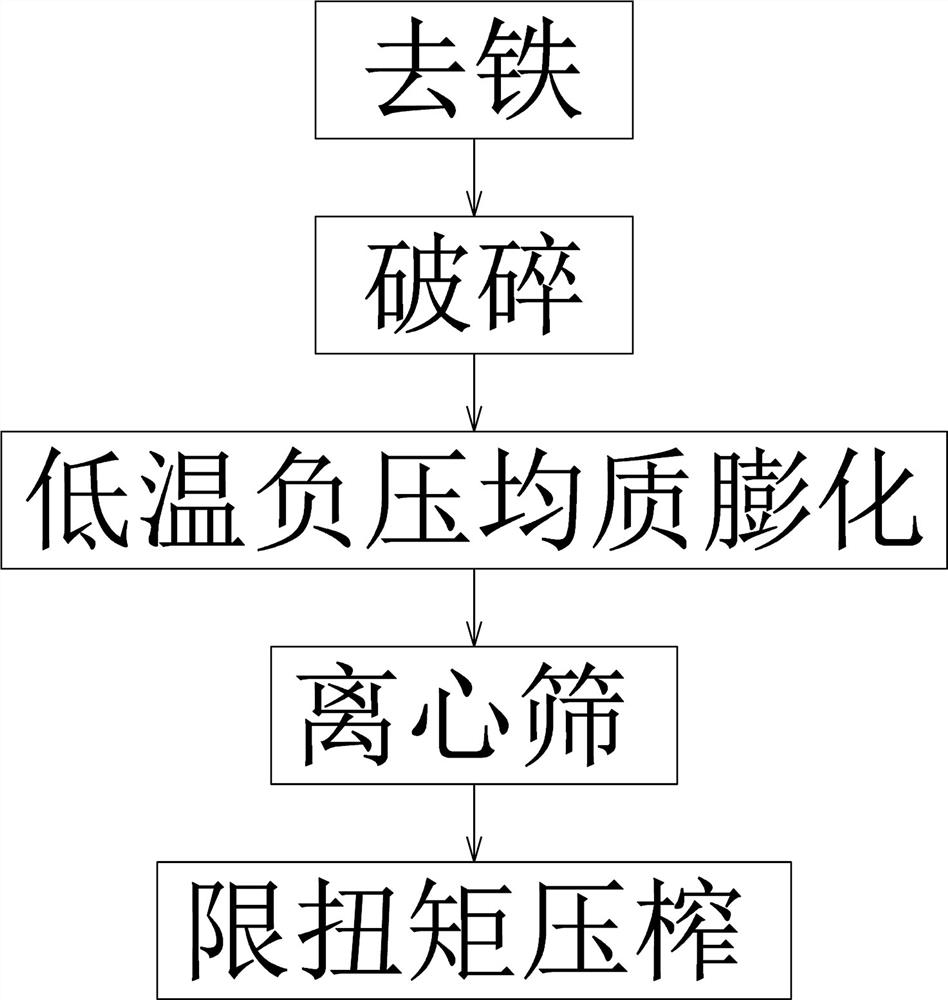

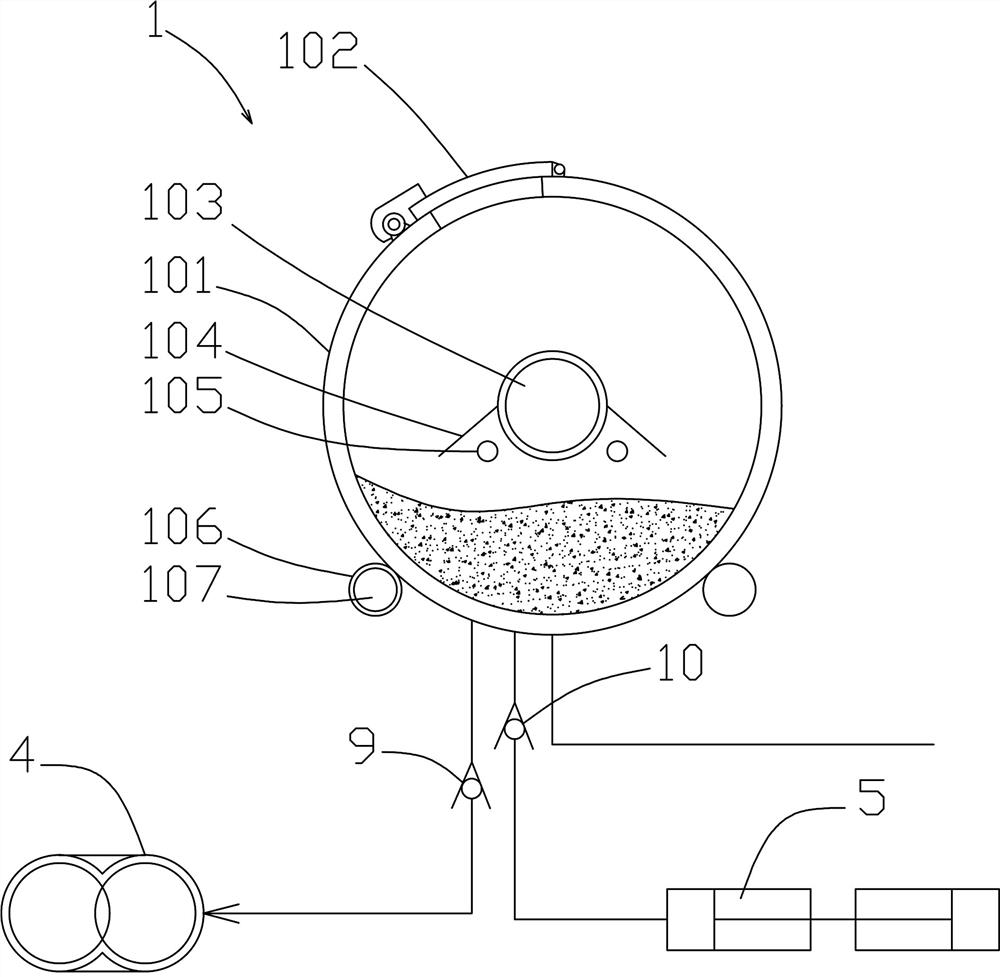

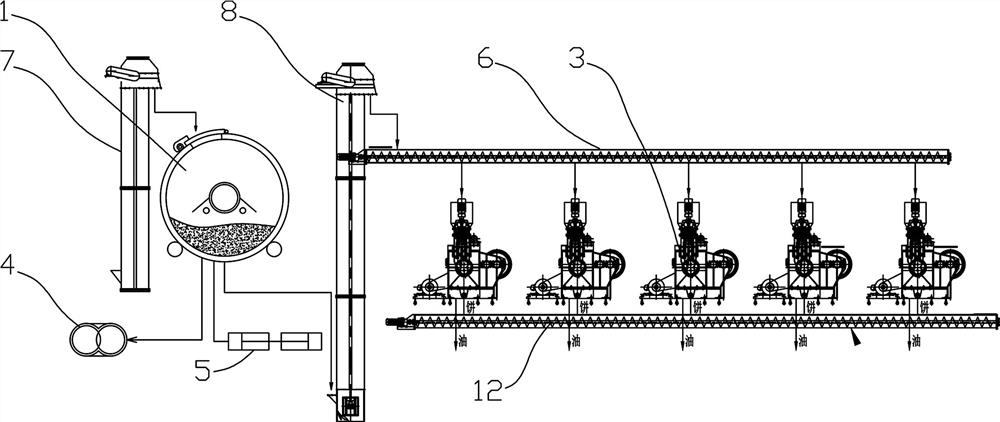

The invention provides a production method of a flavor oil material, and relates to the field of edible oil pressing processes, and the production method comprises the following steps: carrying out low-temperature negative-pressure homogeneous puffing on the oil material; the heating mode of the oil is microwave heating; the heating temperature of the oil material is 80-99 DEG C; the negative pressure ranges from-0.098 Mpa to-0.6 Mpa; carrying out segmented filtration or squeezing on the puffed oil; the finished product oil rich in flavor substances is obtained through the steps. By adopting a low-temperature negative-pressure homogeneous puffing scheme, the oil yield is prevented from being influenced by excessive puffing, and the loss of flavor substances in the finished product oil due to too high temperature is also avoided.

Description

Technical field [0001] The present invention involves the field of edible oil pressing technology, especially a flavor oil production method. Background technique [0002] Existing oil production lines are generally used in soybean, cottonseed, rapeseed, sunflower seeds, peanuts, sesame, walnuts and other high oil -containing plant oil. Generally, the production process is to remove iron → softened → rolled → steaming and stir -fry→ squeeze → filter.You can usually smell a strong fragrance at the production site, especially in sesame oil production technology.During this process, the flavor and material loss in the oil is large. When the user eats refined oil, the flavor in the oil has been lost, which makes the flavor of the refined oil insufficient and affects the quality of the finished dishes. [0003] In the existing technologies, there is also a process route that uses puffed pressure.Among them, the steps of patch → molding → pressing can increase the oil output rate, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B30B9/16B04B1/00B04B7/16C11B1/02C11B1/08

CPCB30B9/16B04B1/00B04B7/16C11B1/02C11B1/08Y02W30/74

Inventor 刘桂子叶平雷鑫周智勇黄德龙

Owner TIANXING GRAIN & OIL MACHINERY EQUIP ANLU CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com