A high-efficiency vacuum pumping mechanism for a vulcanizing machine

A technology for vacuuming and vulcanizing machines, which is applied in the field of high-efficiency vacuuming mechanisms, which can solve the problems of large invalid space occupation, prolonged production time, and large occupied space, and achieve the effects of reducing vacuuming space, improving quality, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

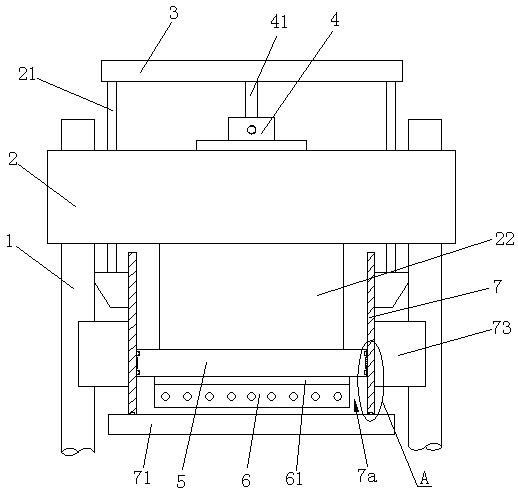

[0023] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

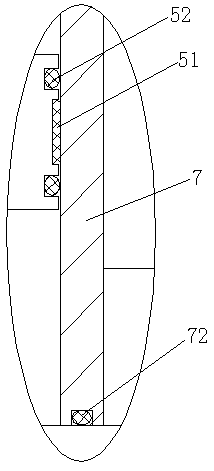

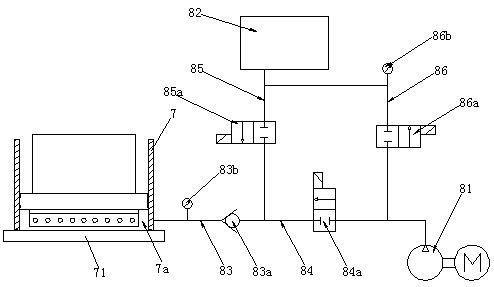

[0024] The reference signs are: pillar 1, top seat 2, coupling column 21, fixed seat 22, fixed plate 3, vacuum cover oil cylinder 4, piston rod 41, piston plate 5, wear-resistant sheet 51, first sealing strip 52, Hot plate 6, heat insulation plate 61, vacuum cover frame 7, vacuum chamber 7a, slide plate 71, second sealing strip 72, copper lining seat 73, vacuum pump 81, vacuum storage barrel 82, vacuum main pipe 83, check valve 83a, Main pipe vacuum gauge 83b, first branch pipe 84, first electromagnetic switch 84a, second branch pipe 85, second electromagnetic switch 85a, third branch pipe 86, third electromagnetic switch 86a, branch pipe vacuum gauge 86b.

[0025] Such as Figure 1 to Figure 3 as shown,

[0026] A high-efficiency vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com