Vacuum sealing and shaping device of tea packing machine

A technology of vacuum sealing and shaping device, used in packaging, packaging protection, transportation and packaging, etc., can solve the problems of complex equipment structure, slow vacuuming speed, increase packaging cost, etc., achieve simple equipment structure, fast vacuuming speed, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

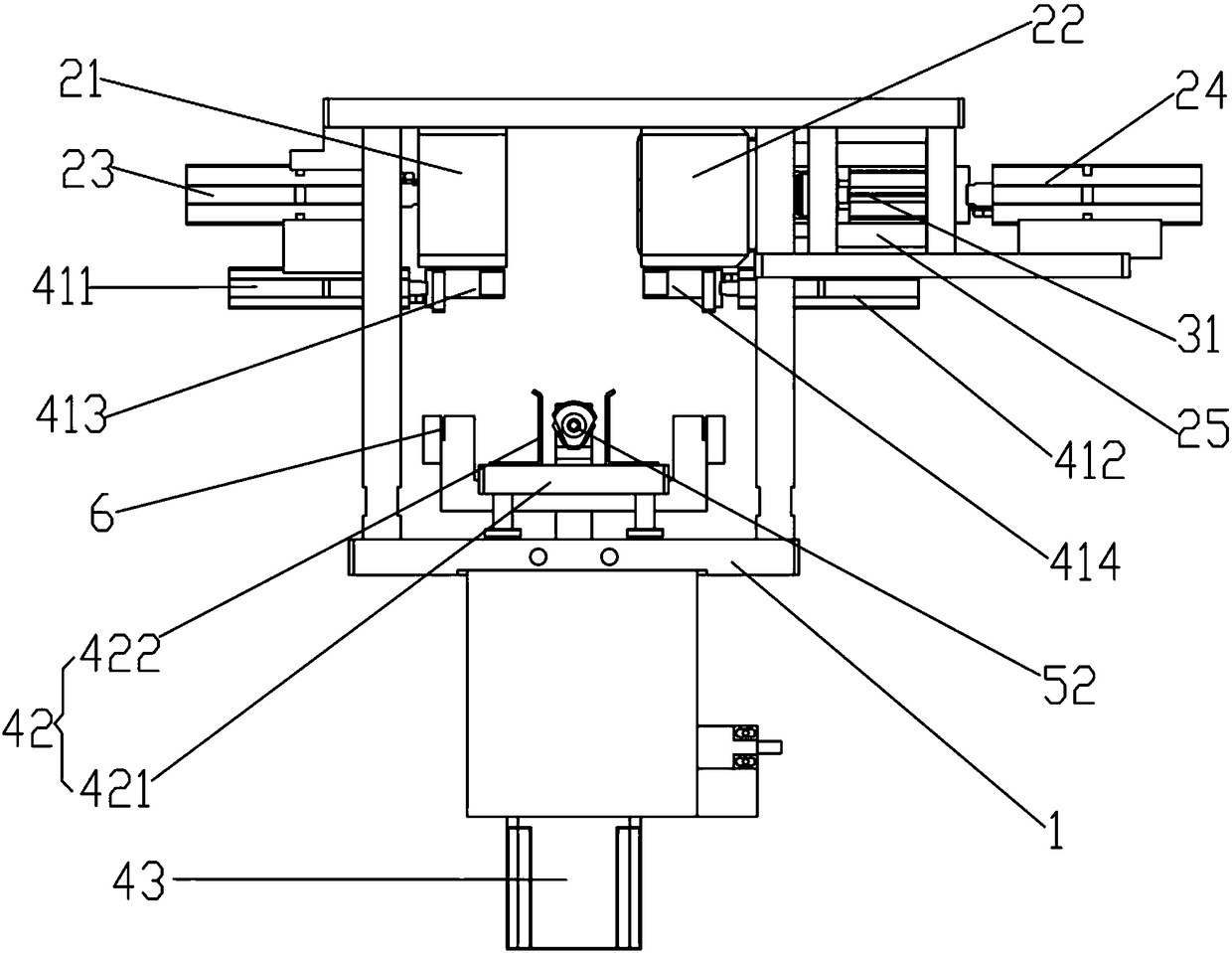

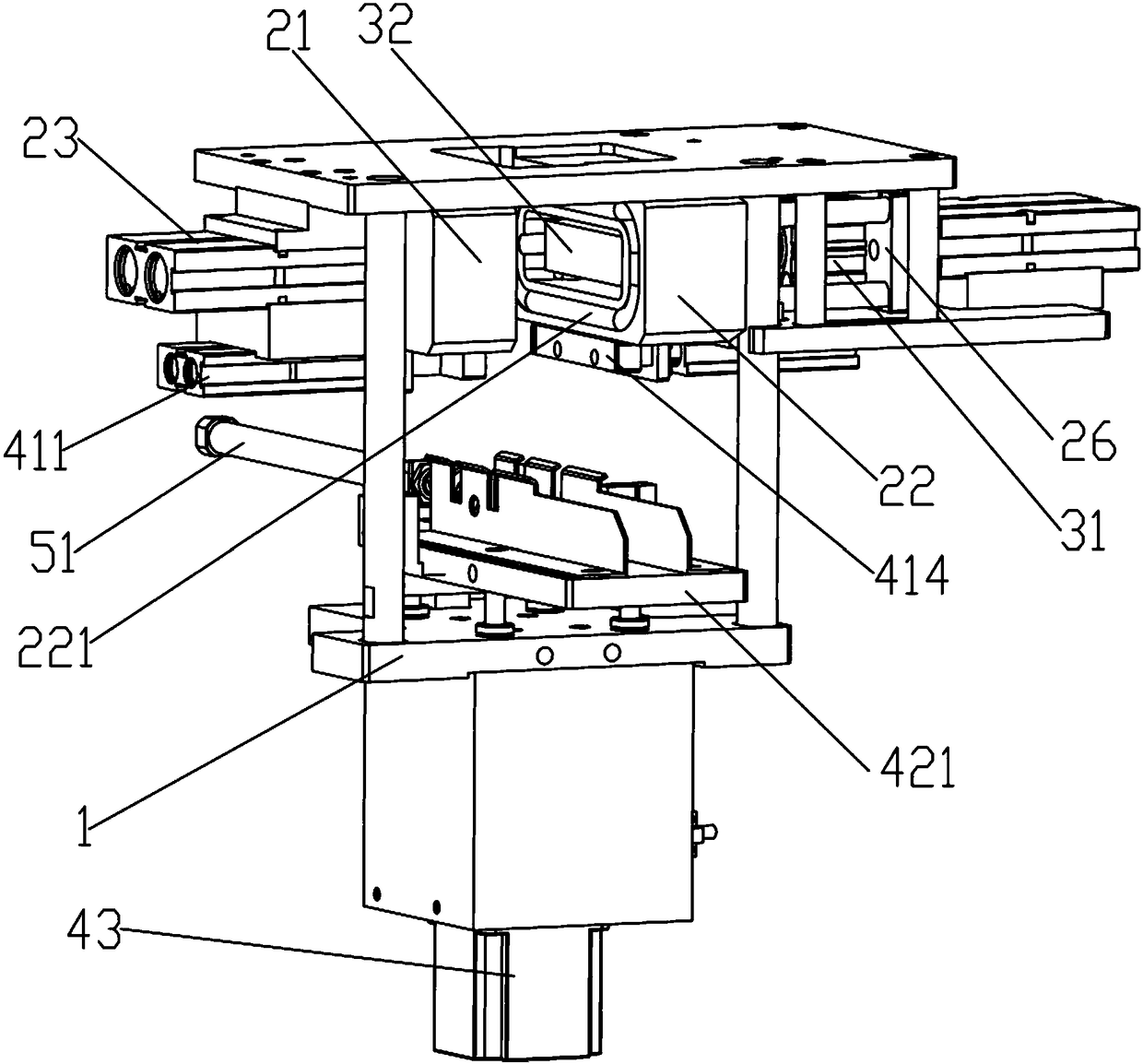

[0020] see Figures 1 to 2 , is a vacuum sealing and shaping device for a tea packaging machine as the best embodiment of the present invention, used for vacuum sealing and shaping the packaging bag filled with tea leaves, including a frame 1, an air pumping mechanism, and a sealing mechanism , a shaping mechanism and a material jacking mechanism, and the air pumping mechanism and the shaping mechanism are installed on the frame 1 sequentially from top to bottom, and the air pumping mechanism includes a left shell 21, a right shell 22, a first horizontal cylinder 23, a second Horizontal cylinder 24, connecting rod 25, longitudinal mounting plate 26, described left shell 21, right shell 22 are arranged oppositely, described first horizontal cylinder 23 is installed on the frame 1 and is positioned at the left side of left shell 21, and described second The piston rod of a horizontal cylinder 23 is connected with the left housing 21 and drives the left housing 21 to reciprocate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com