Cutting device for rock wool board

A cutting device and rock wool board technology, which is applied in metal processing and other directions, can solve the problems of inability to collect and clean dust and debris in time, poor fixing effect and precision, and irregularity in the incision of rock wool board. The effect of dust speed and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

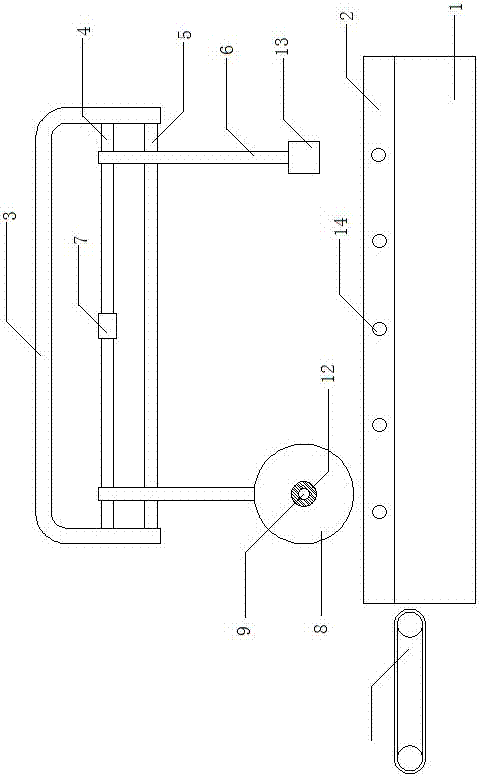

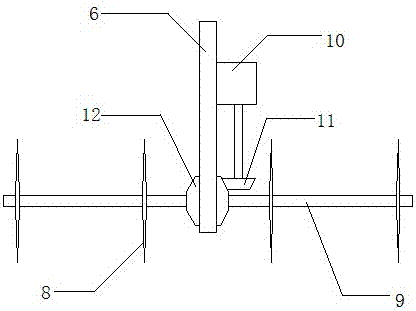

[0021] Such as figure 1 Shown is a schematic structural view of the present invention, which is a cutting device for rock wool boards, including a cutting base 1, a cutting knife holder, a cutting part and a pushing part.

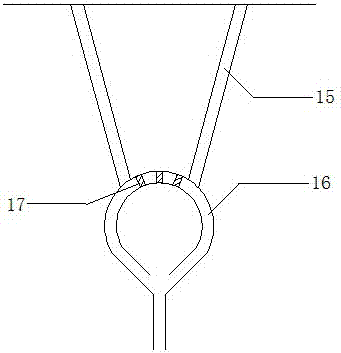

[0022] The surface of the cutting base 1 is provided with a cutting groove 2; the cutting groove 2 communicates with one side of the cutting base 1 to form a push port; the lower part of the cutting base 1 located on one side of the push port is also equipped with a feeding device 18; The feeding device 18 is a feeding pulley; the inner both sides of the cutting groove 2 are uniformly provided with dust suction holes 14; the dust suction holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com