Radiant annealing method for camera bracket

A camera and bright annealing technology, applied in furnaces, furnace types, heat treatment equipment, etc., can solve the problems of reduced work efficiency, internal impact of the furnace body, large air flow, etc., and achieve short working time, reduced impact, and small air flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

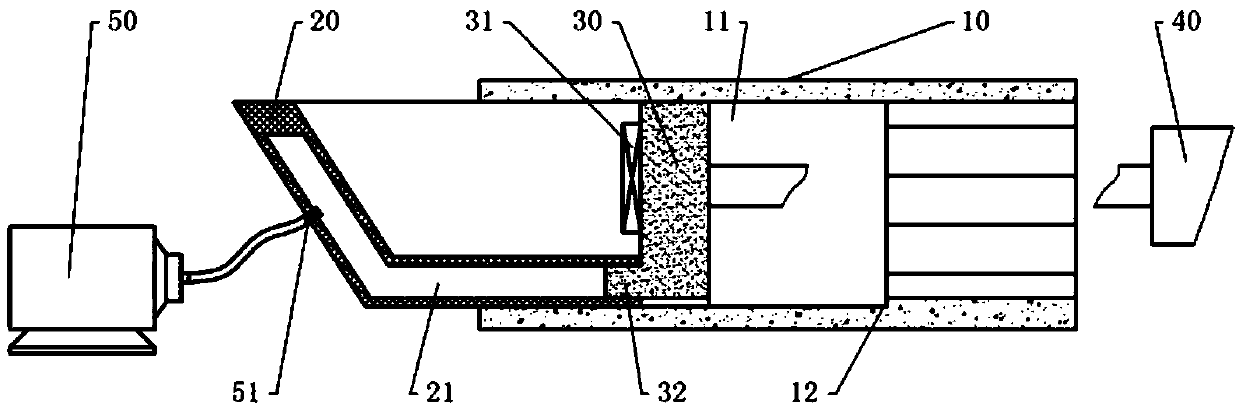

[0031] The method for bright annealing of the camera bracket in this embodiment uses a vacuum annealing furnace to perform bright annealing on the bracket. Such as figure 1As shown, the vacuum annealing furnace includes a furnace body 10, a feeding part and a traction part, and the feeding part and the traction part are arranged from left to right. The furnace body 10 is provided with a heating chamber 11 with openings at both ends. The feeding part includes a feeding tank 20 and a vacuum pump 50 , and the feeding tank 20 is arranged in the heating chamber 11 and is slidably connected with the furnace body 10 . The top and the right side opening of feed chute 20, when push feed chute 20 to the left, make the part of feed trough 20 slide out from heating cavity 11, then can pass the opening of feed chute 20 tops to feed chute 20 Insert the workpiece inside. A vacuum chamber 21 is provided in the side wall of the feed tank 20 , and a first notch is provided on the right side o...

Embodiment 2

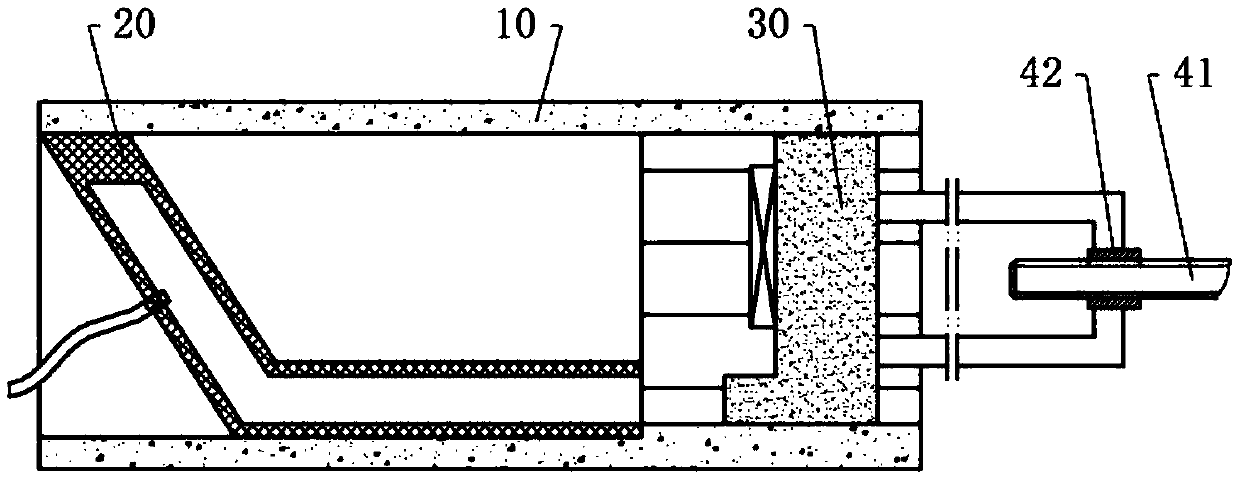

[0043] Such as figure 2 As shown, the difference between the second embodiment and the first embodiment is only that the traction mechanism in the second embodiment includes a servo motor, a lead screw 41 and a nut 42 matched with the lead screw 41, and the lead screw 41 passes through the output of the flange plate and the servo motor. The shaft is fixedly connected, and the nut 42 is fixed on the right side of the blocking block 30, so the blocking block 30 can be driven to slide left and right in the heating box through the forward and reverse rotation of the servo motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com