Patents

Literature

97results about How to "Improve anti-oxidation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gypsum mold formula for casting magnesium alloy and preparation method thereof

The invention discloses a gypsum mold formula for casting a magnesium alloy and a preparation method thereof, relating to preparation of a gypsum mold for casting a magnesium alloy. The gypsum mold formula comprises an additive component consisting of four basic components, including alpha-semihydrated gypsum, quartz powder, bauxite and magnesium sulfate as well as seven substances such as trisodium orthophosphate, barium chloride, a water reducing agent and the like. The invention further discloses a preparation method for the gypsum mold formula. Due to the adoption of scale graphite, oxidation of the magnesium alloy is effectively prevented; the water reducing agent is added into the formula, so that the fluidity of gypsum slurry is improved, the water consumption is lowered by 30 percent simultaneously, and the gypsum mold strength and drying efficiency are increased; the linear shrinkage of the gypsum mold can be remarkably lowered by using the gypsum mold formula together with barium chloride and urea; moreover, a solvent component consisting of tap water is adopted, so that the problems of high water consumption, poor fluidity, low strength, large size deformation, difficulty in breaking and the like existing in an ordinary gypsum mold are solved; and meanwhile, the problems of oxidization and combustion of the magnesium alloy are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

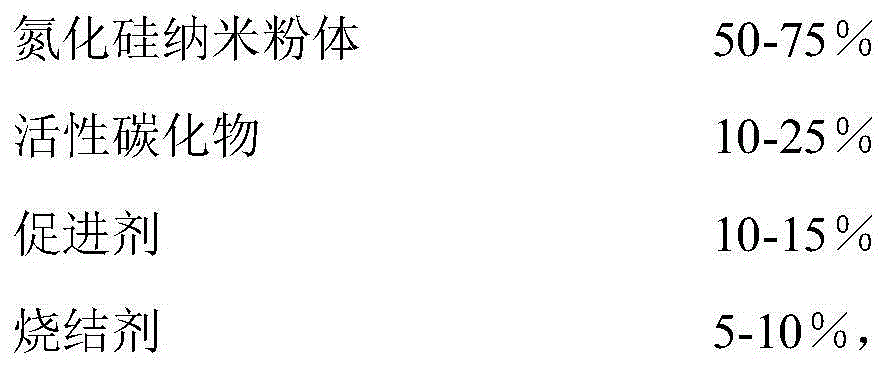

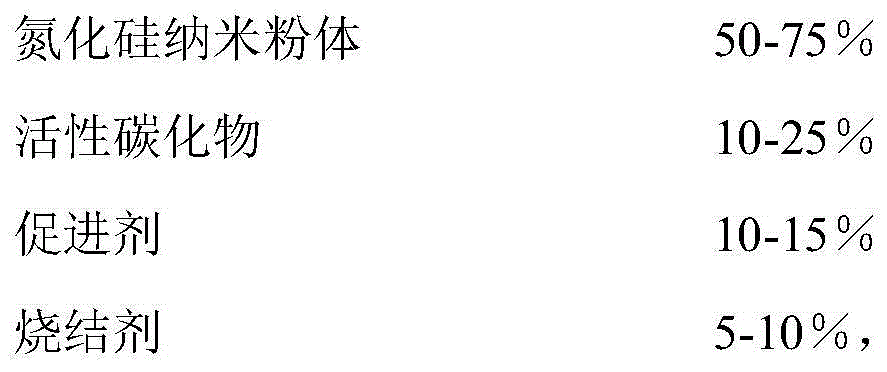

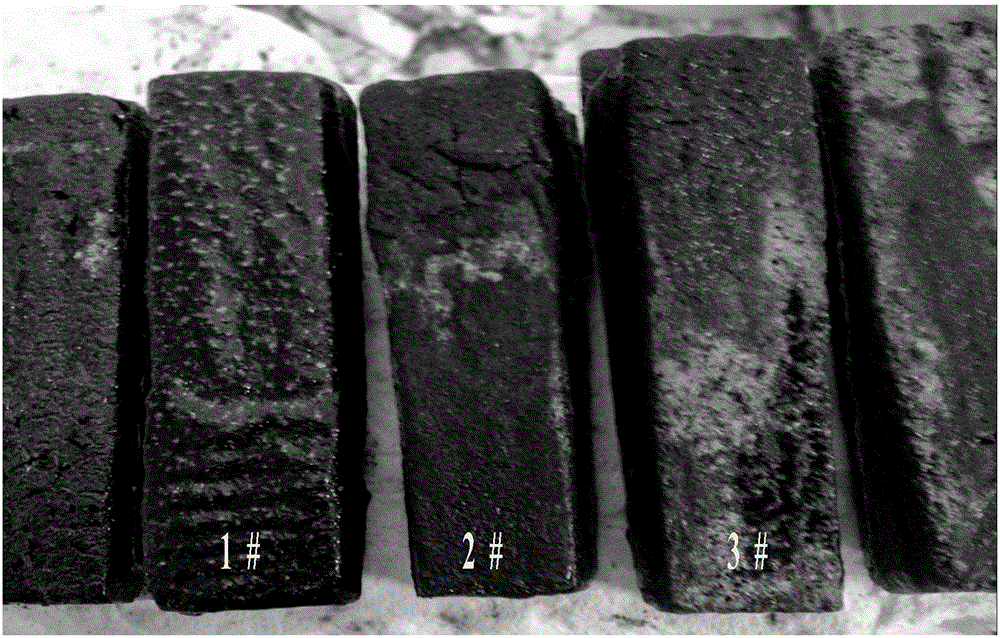

Nanometer mixed powder, high-temperature antioxidant coating and application of nanometer mixed powder and high-temperature antioxidant coating

ActiveCN104692822AImprove thermal stabilityExcellent resistance to crack susceptibilityCarbideOxidation resistant

The invention discloses nanometer mixed powder, a high-temperature antioxidant coating and application of the nanometer mixed powder and the high-temperature antioxidant coating, and belongs to the technical field of steel heat treatment antioxidant protection. The high-temperature antioxidant coating comprises the nanometer mixed powder, and the nanometer mixed powder comprises, by weight, 50%-75% of silicon nitride nano-powder, 10%-25% of active carbide, 10%-15% of an accelerant and 5%-10% of an agglutinant, wherein the active carbide is selected from SiC powder, B4C powder and Al4C3 powder, the accelerant comprises SiO2, Al2O3 and K2O+Na2O, and the agglutinant comprises Fe3O4. By means of the high-temperature antioxidant coating, steel metal has the good antioxidant performance during high-temperature heat treatment, the application scope is wider, and the pollution to the environment is small, and the cost is low.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL

High-temperature anti-oxidation coating for steel billet of plain carbon steel and preparation method of high-temperature anti-oxidation coating

InactiveCN104497653APlay a protective effectHigh applicable temperatureCoatingsCellulosePolyvinyl alcohol

The invention relates to a high-temperature anti-oxidation coating for a steel billet of plain carbon steel and a preparation method of the high-temperature anti-oxidation coating. The technical scheme is as follows: a component A and a component B which are sub-packaged are mixed according to the mass ratio of (0.8-2):1 and are mechanically stirred when the high-temperature anti-oxidation coating is used, wherein the component A is prepared from the chemical components in percentage by mass: 20-35% of alumina powder, 20-30% of silicon dioxide powder, 15-25% of magnesia powder, 5-15% of calcium oxide powder, 5-10% of zirconium dioxide powder, 2-5% of sodium carbonate powder, 2-5% of potassium carbonate powder, 2-5% of iron oxide powder and 1-5% of aluminum powder; and the component B is prepared from the chemical components in percentage by mass: 1-5% of (CH2O)n, 4-10% of (C12H22O11)n, 5-15% of (C6H10O5)n, 0.5-2% of polyvinyl alcohol, 0.1-1% of sodium carboxymethylcellulose, 0.1-0.8% of hydroxyethyl cellulose and the balance of water. The high-temperature anti-oxidation coating has the characteristics of good anti-oxidation effect, high applicable temperature, self-falling capacity, safety, environment friendliness and low cost.

Owner:苏州赛格瑞新材料有限公司

Anti-oxidation coating for carbon anodes in aluminum electrolysis

The invention relates to a technology for preventing high-temperature oxidation of carbon anodes during aluminum electrolysis production, specifically to an anti-oxidation coating for carbon anodes in aluminum electrolysis. The coating comprises, by weight, 30-40% of alumina powder, 10-20% of sodium fluoride, 10-20% of aluminium fluoride, 1.0-5.0% of a complex anti-oxidant, 10-15% of a binder, 2-5% of a suspending agent and the rest of a solvent. The high-temperature anti-oxidation coating can effectively raise oxidation resistance of carbon anodes at high temperature, has an effect of resisting corrosion of cryolite slag to the coating, effectively reduces carbon anode consumption in aluminum electrolysis production, prolongs service life of carbon anodes, saves consumption cost of carbon anodes, decreases discharge of gas generated by high-temperature oxidation-combustion of carbon anodes, and obviously improves the working environment.

Owner:SHENYANG RES INST OF FOUNDRY

Soaking treatment method for oil repellency and antioxidation of copper net or foamy copper

InactiveCN103103513APrevent oxidation and discolorationEfficient removalMetallic material coating processesWater bathsAlcohol

The invention discloses a soaking treatment method for oil repellency and antioxidation of a copper net or foamy copper. The soaking treatment method comprises the following steps of: soaking the copper net or the foamy copper in a mixed solution including the components of 1.0mol / L-2.0mol / L of hydrochloric acid, 2g / L-5g / L of a surfactant, 1g / L-3g / L of fluorosilane and alcohol in concentration, wherein the water-bath heating temperature is 30 DEG C to 90 DEG C, the soaking time is 5 minutes to 30 minutes; washing the soaked and treated copper net or foamy copper by deionized water, and putting the washed copper net or foamy copper to an oven for curing for 0.5 hour to 1.5 hours under the temperature of 150 DEG C to 250 DEG C; and taking out the cured copper net or foamy copper to obtain the bright oil-repellent anti-oxidant copper net or foamy copper. The soaking treatment method disclosed by the invention can be used for effectively preventing the formation of an oxide layer.

Owner:SOUTHEAST UNIV

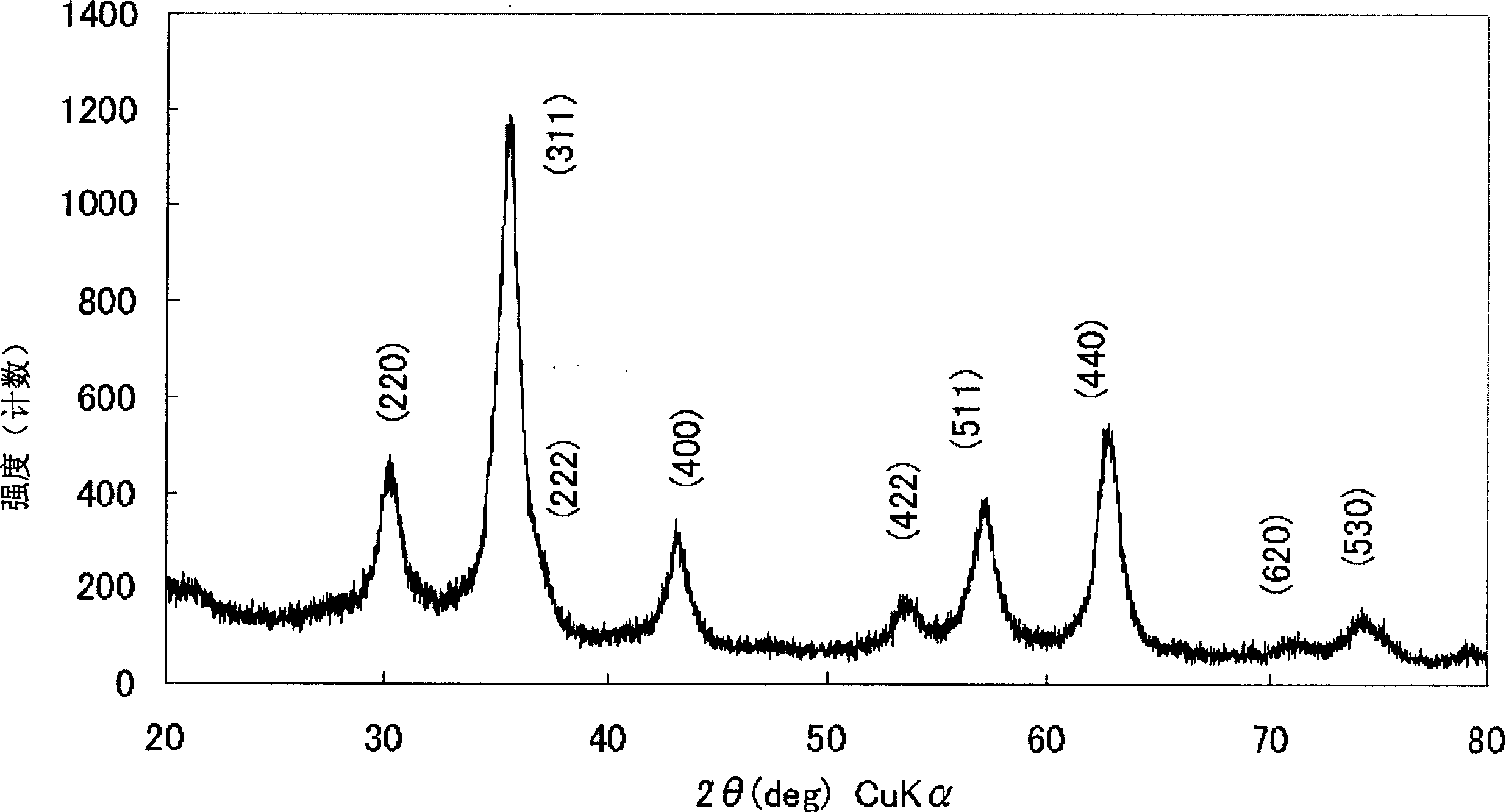

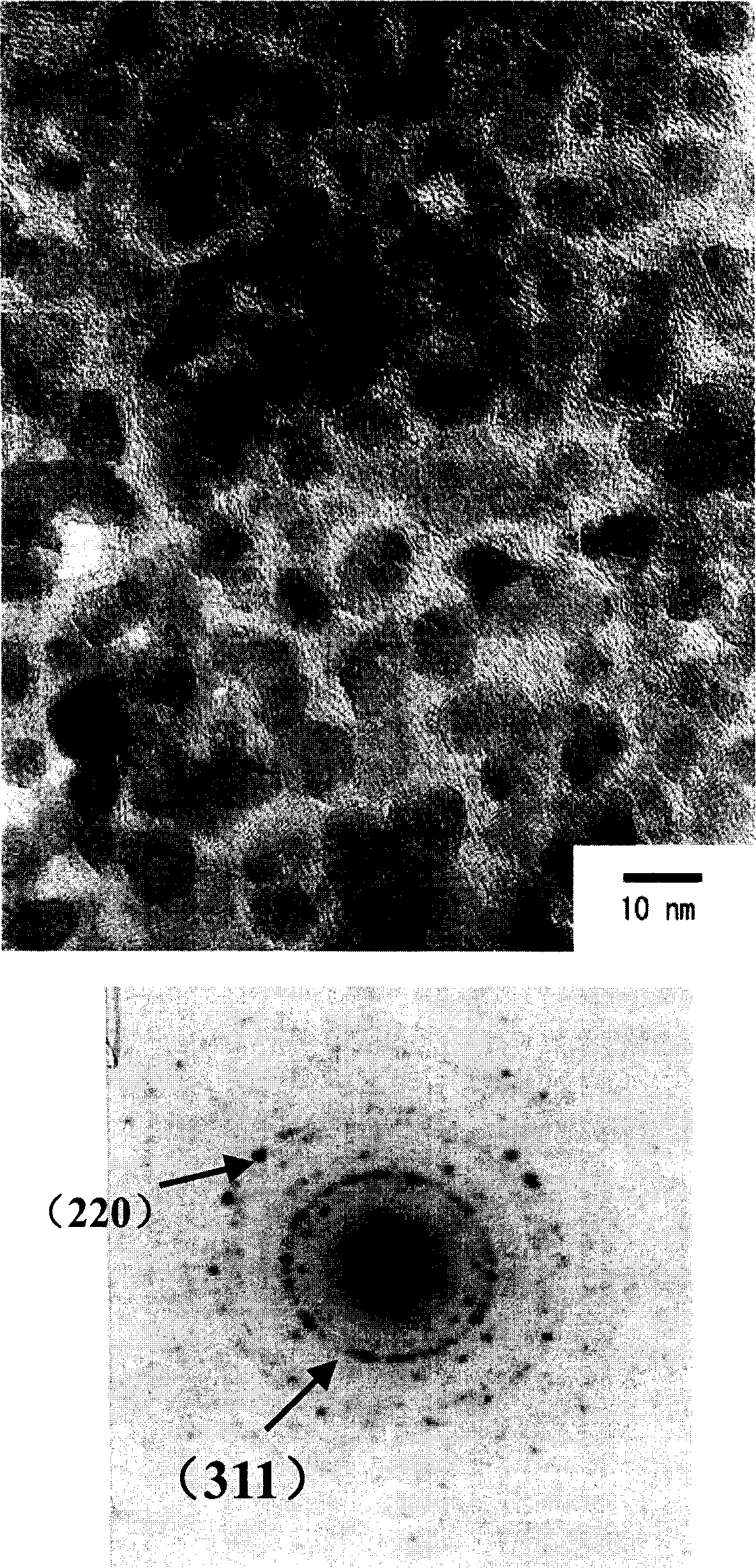

Ferrimagnetism fluid

InactiveCN1797624AImprove flow characteristicsExcellent magnetic propertiesMagnetic liquidsInductances/transformers/magnets manufactureIron saltsManganese

The method includes following steps: using chemical coprecipitation method to prepare mixed liquor of ammonia (or sodium hydroxide), bivalent iron salt (manganese, nickel, cobalt etc.) and tervalent iron salt; dropping the mixed liquor to ion exchange water, and keeping pH of solution at 7; mixing round the solution to generate suspending liquid of ferrite; using ultrasonic to coat a layer of surface active agent on surfaces of fine grains evenly; finally, using ultrasonic to disperse fine grains on solvent evenly.

Owner:巨东英 +1

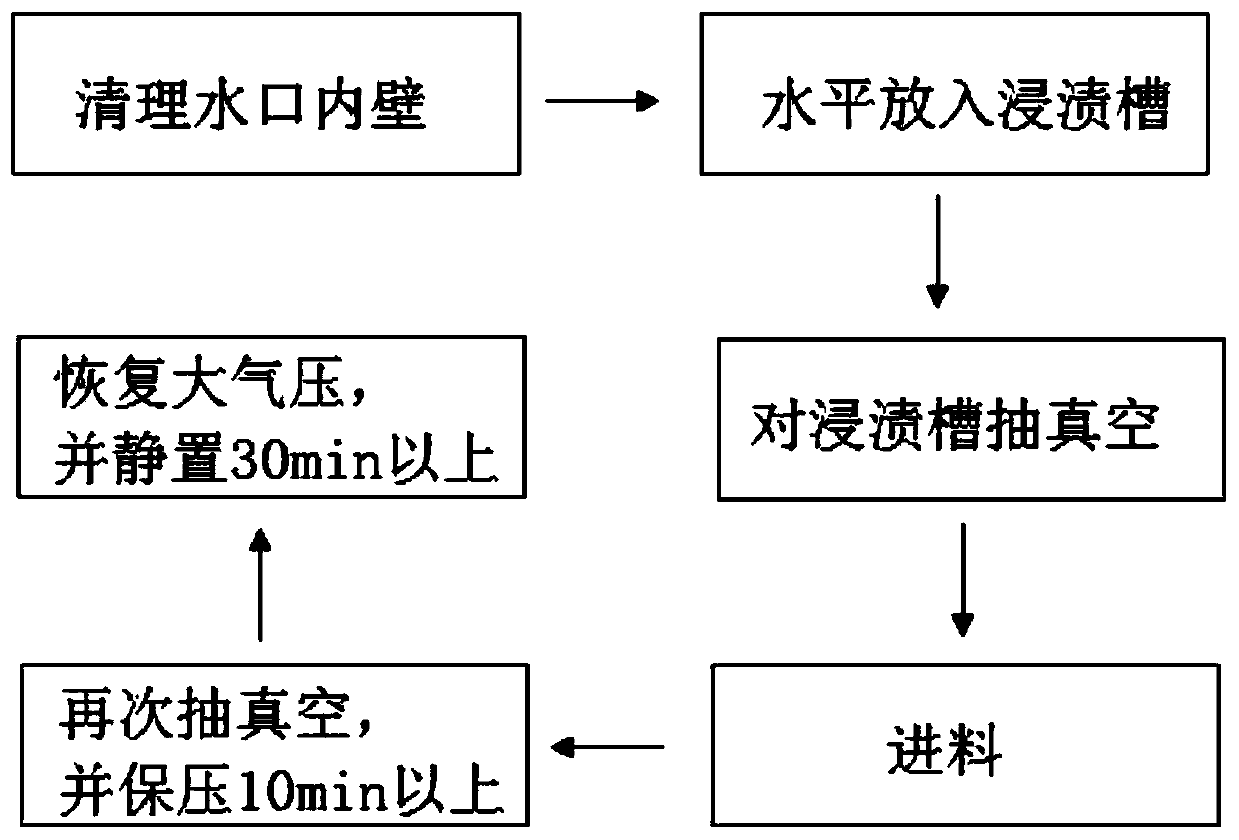

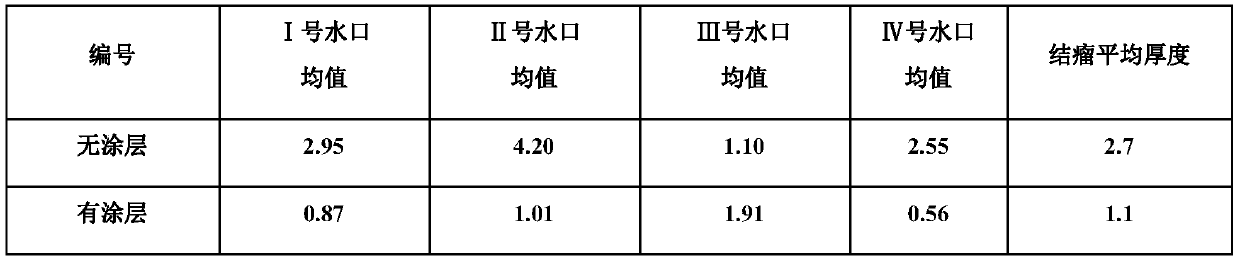

Coating material for preventing submersed nozzle from nodulation and preparation method thereof

ActiveCN110922214AGood adhesion performanceGood oxidation resistanceMelt-holding vesselsPhosphoric acidOxide

The invention discloses a coating material for preventing a submersed nozzle from nodulation and a preparation method thereof, and belongs to the technical field of coating materials of submersed nozzles. The coating material comprises the following components in parts by weight: 20-56 parts of mullite fine powder, 15-23 parts of corundum fine powder, 4-8 parts of Guangxi white mud, 7-18 parts ofactivated aluminum oxide micro powder, 5-8 parts of aluminum dihydrogen phosphate, 8-12 parts of a fluxing agent, 2-11 parts of an antioxidant and 0.3-2.0 parts of a dispersing agent. The invention aims to solve the problems that in the prior art, a submersed nozzle is easy to bake and oxidize, and nodules are generated to block the submersed nozzle. According to the coating material for preventing the submersed nozzle from nodulation and the preparation method thereof, the purposes of preventing the submersed nozzle from being baked and oxidized and preventing air from entering molten steel through the nozzle in the using process can be achieved, and the submersed nozzle is prevented from blocking caused by nodulation.

Owner:MAANSHAN IRON AND STEEL COMPANY

Anti-oxidation processing method of copper wire

ActiveCN103643187AReduce oxidationDoes not affect weldabilityLiquid surface applicatorsCoatingsCopper wireWire drawing

The invention provides an anti-oxidation processing method of a copper wire, which comprises the steps of smelting, wire drawing and annealing. The processing method provided by the invention realizes stable anti-oxidation effect and uniform lamination; the obtained copper wire has good electrical conductivity and is easy to weld and not easily oxidized; and the method can be widely applied to the processing of a copper wire.

Owner:浙江佳博科技股份有限公司

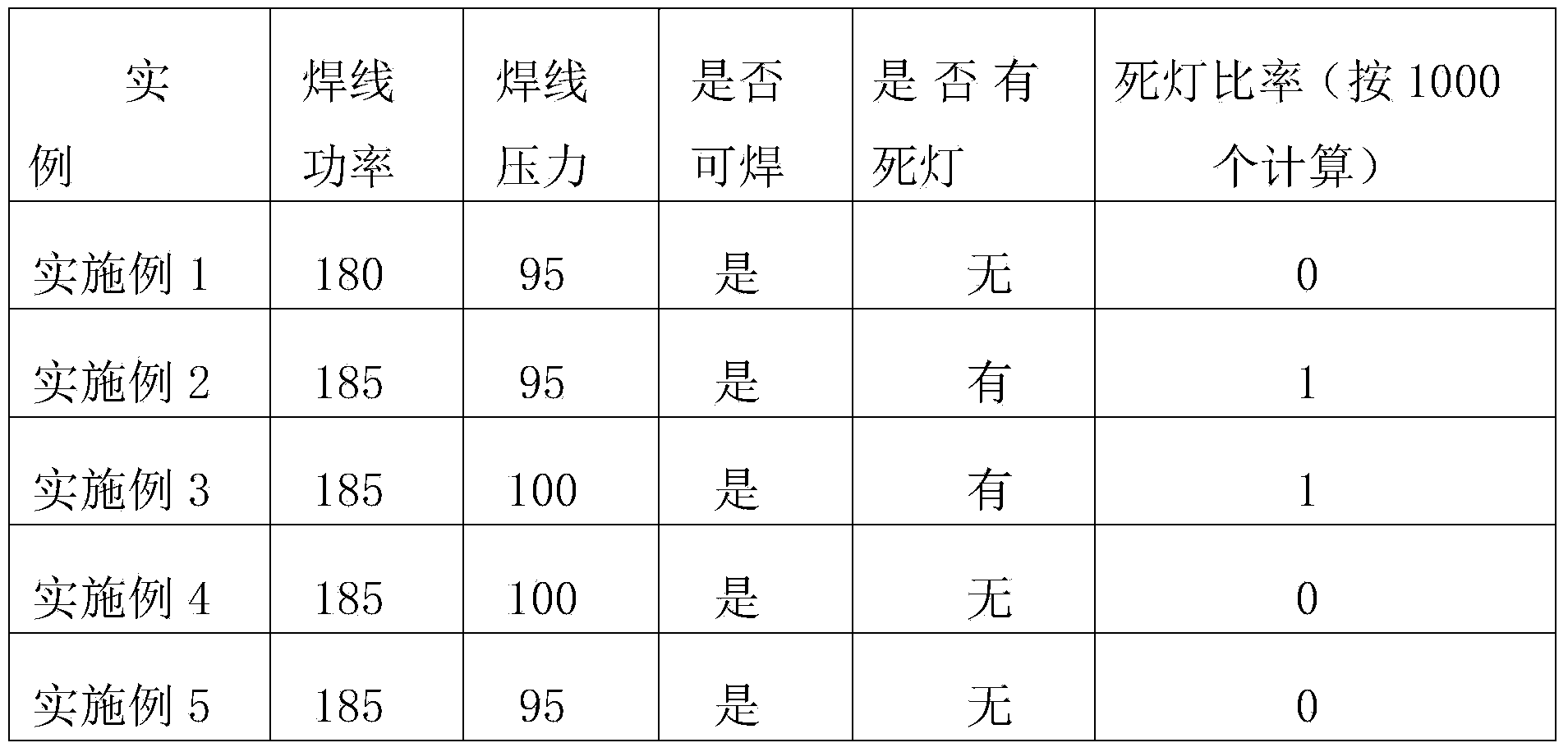

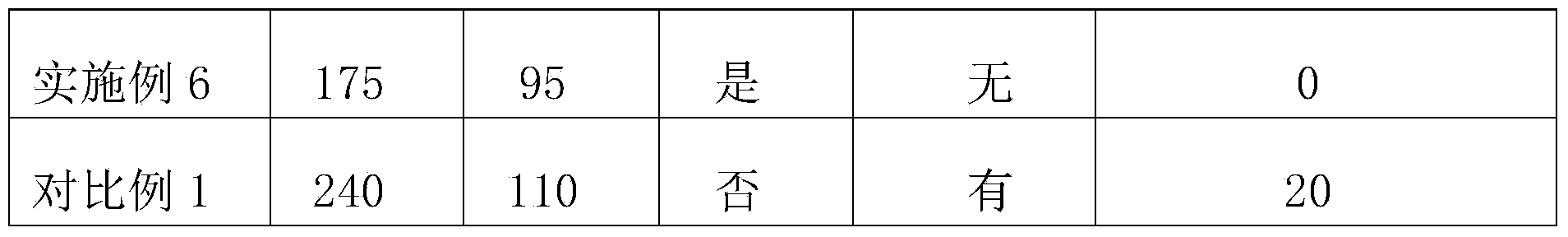

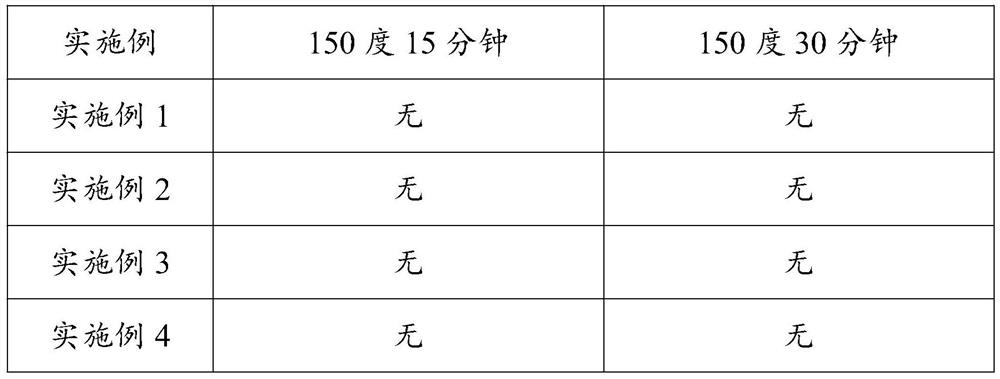

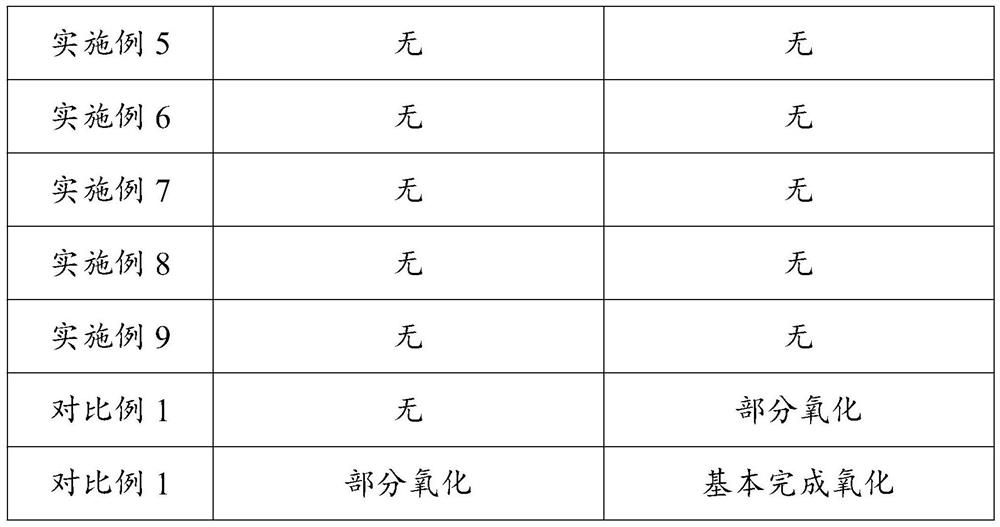

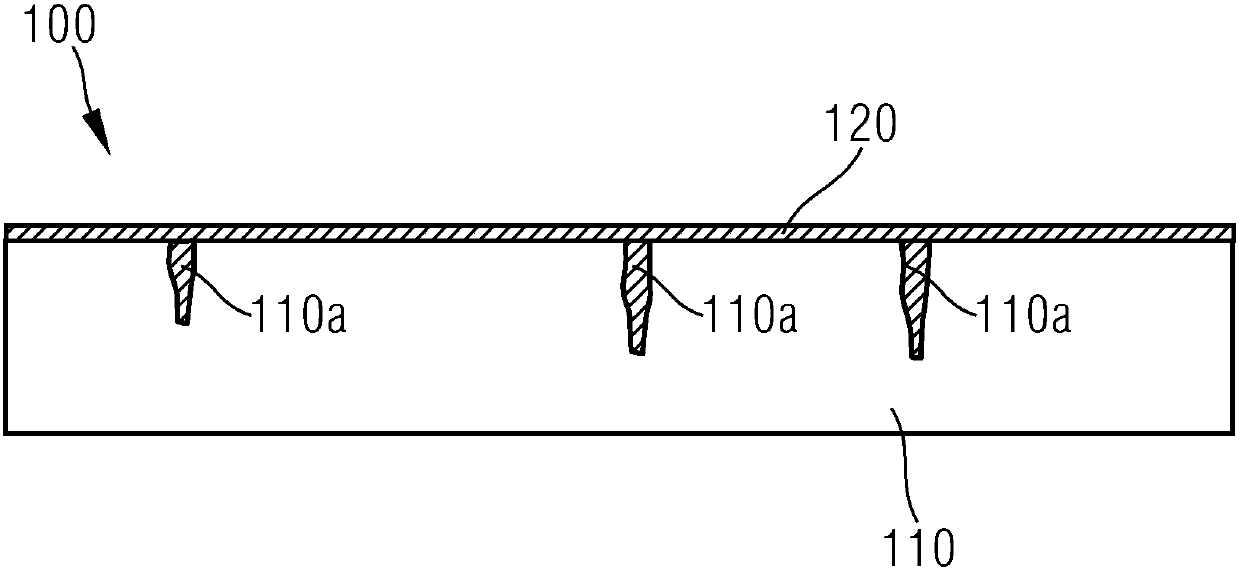

Quantum dot optical thin film without barrier film and preparation method thereof

The invention relates to a quantum dot optical thin film without a barrier film and a preparation method thereof. The quantum dot optical thin film comprises a body which prepared by curing a quantumdot colloid solution to form a film. The quantum dot colloid solution comprises, by weight, 0.5 part of a quantum dot solution and a resin solution, wherein the quantum dot solution has a concentration of 15 mg / L; the resin solution comprises, by weight, 10 parts of organic resin, 100 to 400 parts of a diluent and 0.1 part of an auxiliary agent; and the above components are mixed in proportion toprepare the quantum dot colloid solution which is then naturally dried in the air for film formation. According to the quantum dot optical thin film of the invention, quantum dots are wrapped by organic resin in virtue of the film forming property of the organic resin, and supporting with a substrate and protection via a barrier film are not needed; after the quantum dot optical thin film is formed after curing, the quantum dot optical thin film can be directly used and has excellent water and oxidation resistance and improved light transmittance; and the preparation method is simplified and material cost is reduced.

Owner:HUIZHOU KINGBALI TECH

Method for preparing steel ladle or tundish covering agent by using boron slurry

The invention relates to the technical field of steel metallurgy, and particularly relates to a method for preparing a steel ladle or a tundish covering agent by using boron slurry. The method comprises the steps of: dehydrating and drying the boron slurry in a gas furnace; converting Fe2O3 in the boron slurry into magnetic Fe3O4; reducing MnO into Mn; removing the Mn through magnetic separation; and adding a pre-melted mixture of CaO and Al2O3 so as to obtain a molten steel covering agent serving as a steel ladle or a tundish, or adding a small number of carbon materials for controlling the melting speed and the melting performance so as to obtain the covering agent. According to the method, waste boron slurry resources can be reused; the method has the advantages of being simple in preparation process, low in machining cost, eliminating harm of the boron slurry and reducing discharging of metallurgical waste; furthermore, the covering agent prepared by the method has high surface activity, good impurity absorption performance, good expandability and good effects of preventing molten steel from sucking air and being oxidized and preserving heat, has remarkable economic and social benefits and is deserved to popularization.

Owner:JIANGSU UNIV

Liquid oxidation-proof slag formation-resistant additive for lead-free solder and preparation method thereof

InactiveCN1962158AReduce lossesReduce formationWelding/cutting media/materialsSoldering mediaLiquid stateCrucible

The invention relates to a liquid leadless solder anti-oxidization anti-slag additive, and relative production, wherein it comprises Sn at 90-93% and P at 10-7%. The production comprises adding tin into pot to be fused, and cutting the left fine tin rod into sheet tin bars, coiling it into ball shape and compressing into cake; then adding phosphor powder uniformly into stainless steel mixing cylinder, sealing cover and emerging into the liquid fused liquid of pot; lifting the cylinder up and down, until the material is fused and flowed into the pot, cooling it into particles. The invention has better oxidation resistance, while the slag rate can be reduced 40-60%.

Owner:张海鹏

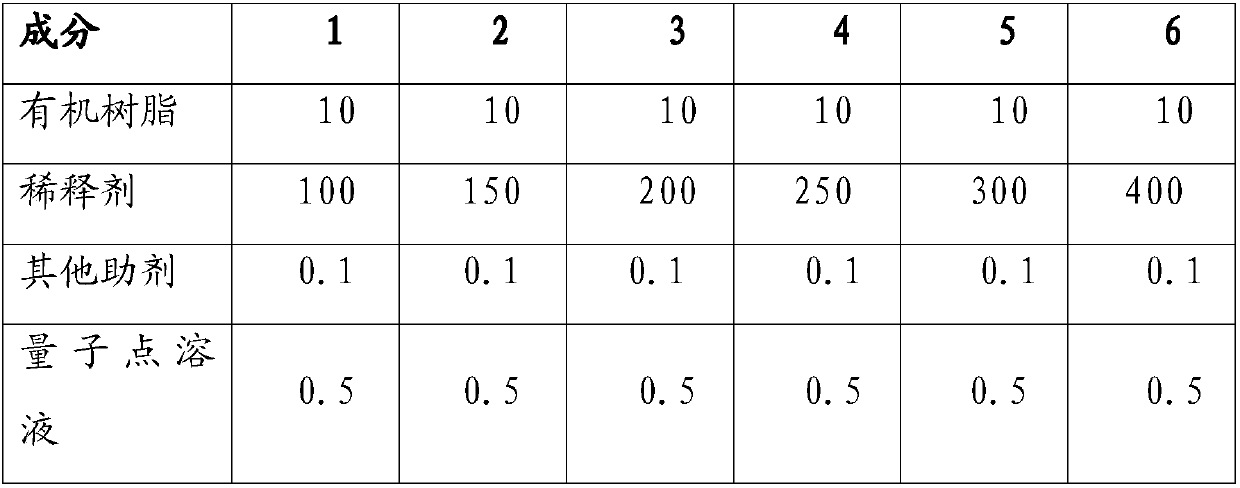

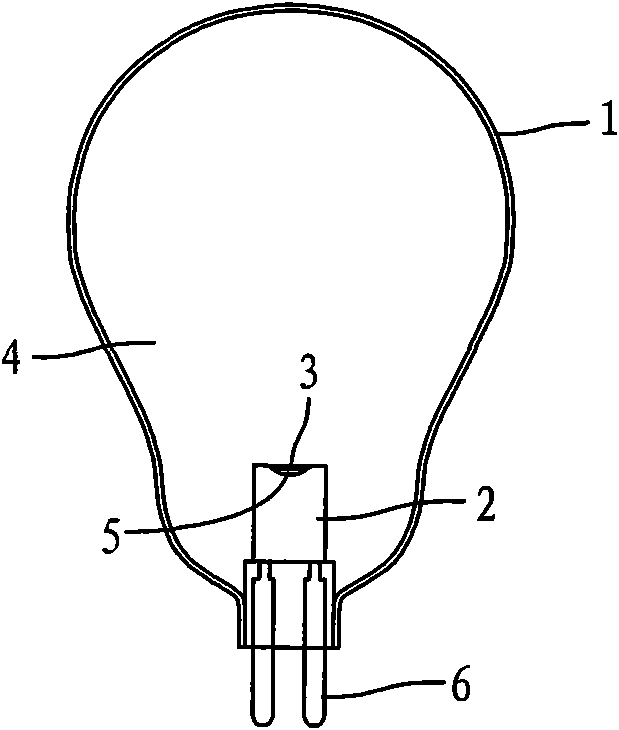

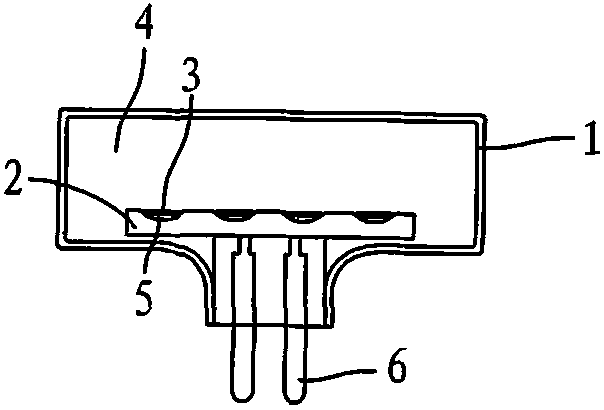

Packaging structure of luminous semiconductor chip and packaging method thereof

InactiveCN101975340AImprove cooling environmentNormal working temperaturePoint-like light sourceElectric circuit arrangementsEpoxySemiconductor chip

The invention discloses a packaging structure of a luminous semiconductor chip and a packaging method thereof. The packaging structure of the luminous semiconductor chip comprises the luminous semiconductor chip and a lampshade, wherein the luminous semiconductor chip is fixed on the bracket of the luminous semiconductor chip; the lampshade and the bracket of the luminous semiconductor chip are fixedly connected and form a sealed cavity; and the luminous semiconductor chip is positioned in the cavity. The lampshade and the bracket of the luminous semiconductor chip of the invention form the sealed cavity to isolate the luminous semiconductor chip from outside and oxygen, so that the luminous semiconductor chip has less possibility of being affected with damp and oxidized, and the packaging structure can be in nude packing without encapsulation by epoxy resin, thus the luminous semiconductor chip can radiate the heat from each direction so as to greatly improve the heat dissipation environment of the luminous semiconductor chip, and the luminous semiconductor chip has normal working temperature without a radiator. Thus, the packaging structure has low manufacture cost, is favourable for popularizing and using products, has simple packaging technology and is favourable for the mass production of the product.

Owner:敬俊

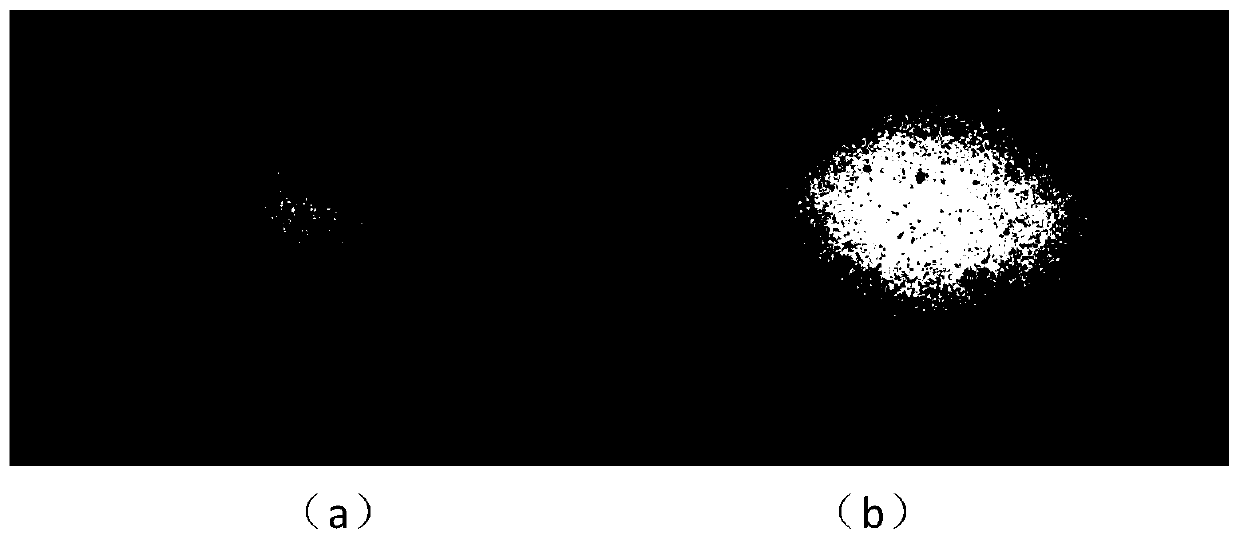

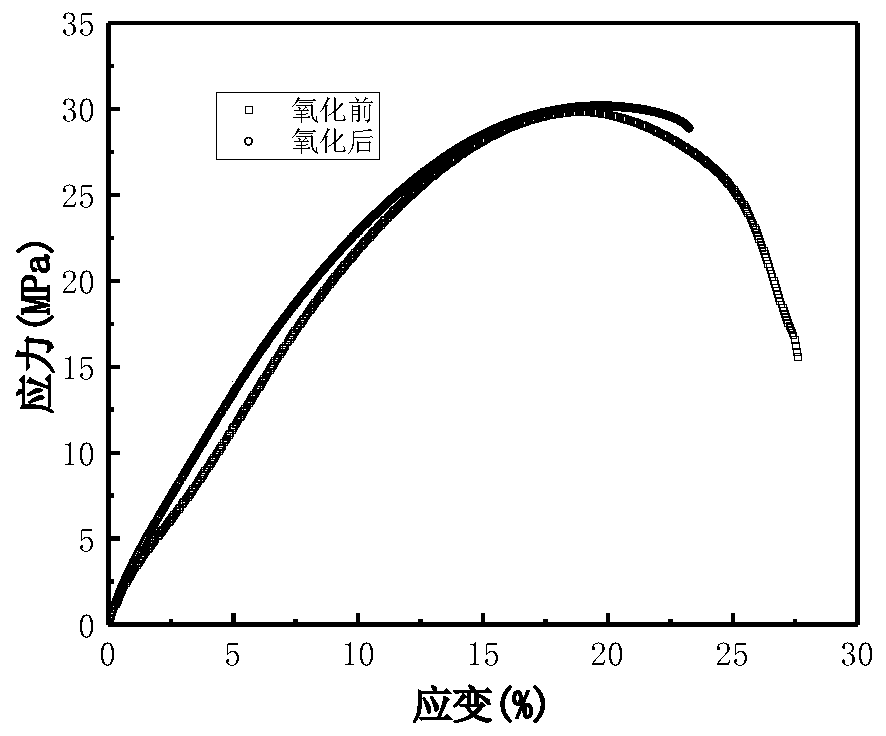

Bionic antioxidant polypropylene material and preparation method thereof

The invention discloses a bionic antioxidant polypropylene material and a preparation method thereof. The preparation method comprises the following steps: preparing polydopamine particles by taking dopamine as a raw material, or preparing black pigment particles by taking tyrosine as a raw material, mixing the black pigment particles or the polydopamine particles with polypropylene according to aratio of 0.1: (100-10), dropwise adding 0.1% of paraffin, and stirring for 5-10 minutes in an electric stirrer at a high speed; adding an obtained mixture to an extruder, controlling the temperatureof the extruder to be 160-180 DEG C, 170-190 DEG C and 180-200 DEG C, the ultrasonic frequency to be 10-20 kHz, the ultrasonic frequency is 0-400 W, extruding and granulating to obtain the bionic antioxidant polypropylene resin, and further processing and molding the granules to obtain required bionic polypropylene films, sheets, pipes or fibers and other materials.

Owner:YICHUN UNIVERSITY

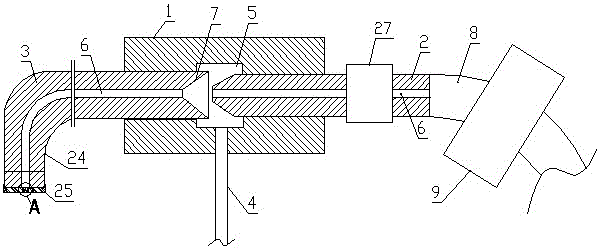

Novel aluminum steel continuous casting tundish covering agent and application thereof

The invention relates to a novel aluminum steel continuous casting tundish covering agent and the application thereof and belongs to the technical field of steel continuous casting. The tundish covering agent comprises components, by mass, 26-35% of CaO, 26-13% of SiO, 22-32% of Al2O3, 5-12% of MgO, 8-15% of (Na2O+Li2O) and 2-8% of B2O3. The tundish covering agent has the low viscosity of 0.5-1.2 Pa.s at the temperature of 1300 DEG C and has the low melting temperature of 1180 DEG C-1300 DEG C, can effectively absorb impurities in aluminum steel, improve the cleanness of molten steel in a tundish, well prevent the molten steel from being oxidized for the second time, and improve the quality of a casting blank, and has the advantages of being good in heat preserving property and the like. The designed covering agent can be well applied to the aluminum steel continuous casting process with the Al mass percentage within the range of 0.3-3%.

Owner:CENT SOUTH UNIV

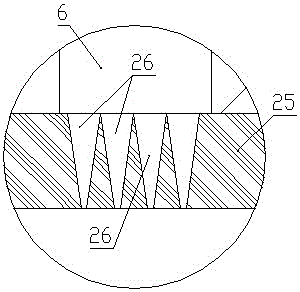

Stretch bender oil mist sprayer

ActiveCN104984847AAvoid scratchesAdjust the degree of extrusionLiquid spraying apparatusSprayerAlloy

The invention discloses a stretch bender oil mist sprayer comprising a housing; the housing is connected with an air inlet pipe, an air outlet pipe and an oil inlet pipe; a buffer cavity is arranged in the housing; a soft pipe connected with the rear end of the air inlet pipe is provided with a pressure controller; the pressure controller comprises an upper seat and a lower seat; the top of upper seat is provided with a motor; the lower seat is connected with a fixed block; the fixed block is connected with a globe bearing; the globe bearing is connected with a sleeve pipe in a slide manner; an inner wall of the sleeve pipe is screwed with an output shaft of the motor; a spring slot is arranged in the globe bearing; a pressure spring is arranged in the spring slot, and presses against a steel ball; slide friction force between a sleeve pipe outer wall and the steel ball is bigger than a rotary friction force between the output shaft and the sleeve pipe when the output shaft of the positive-negative rotation motor rotates in the sleeve pipe; the bottom surface of the upper seat and the top surface of the lower seat are provided with corresponding arc slots clamped on the soft pipe. The stretch bender oil mist sprayer can spray on the surface of aluminum and aluminum alloy belt material so as to form a protection oil film, thus effectively preventing product oxidation, and scratches between layers in the product transport process can be prevented.

Owner:登电集团铝加工有限公司

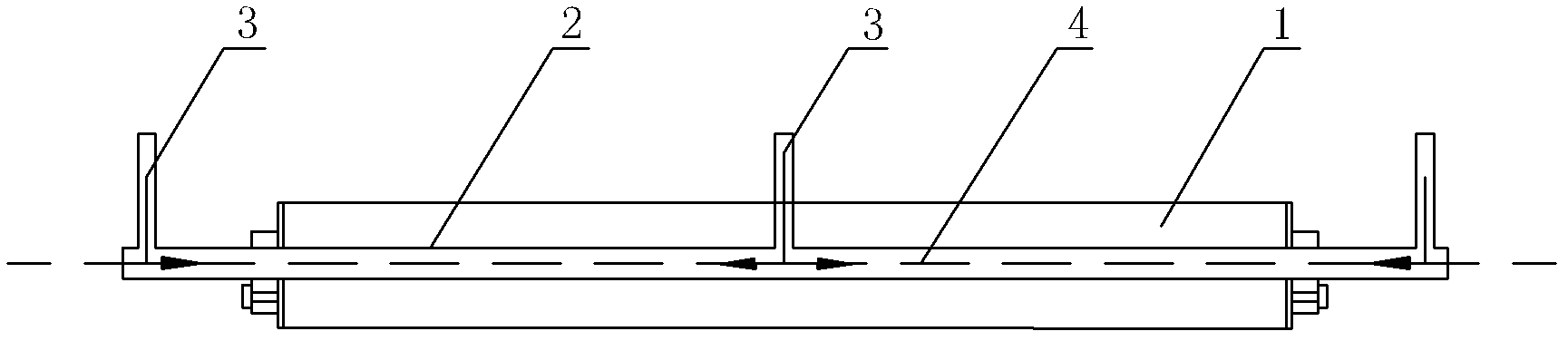

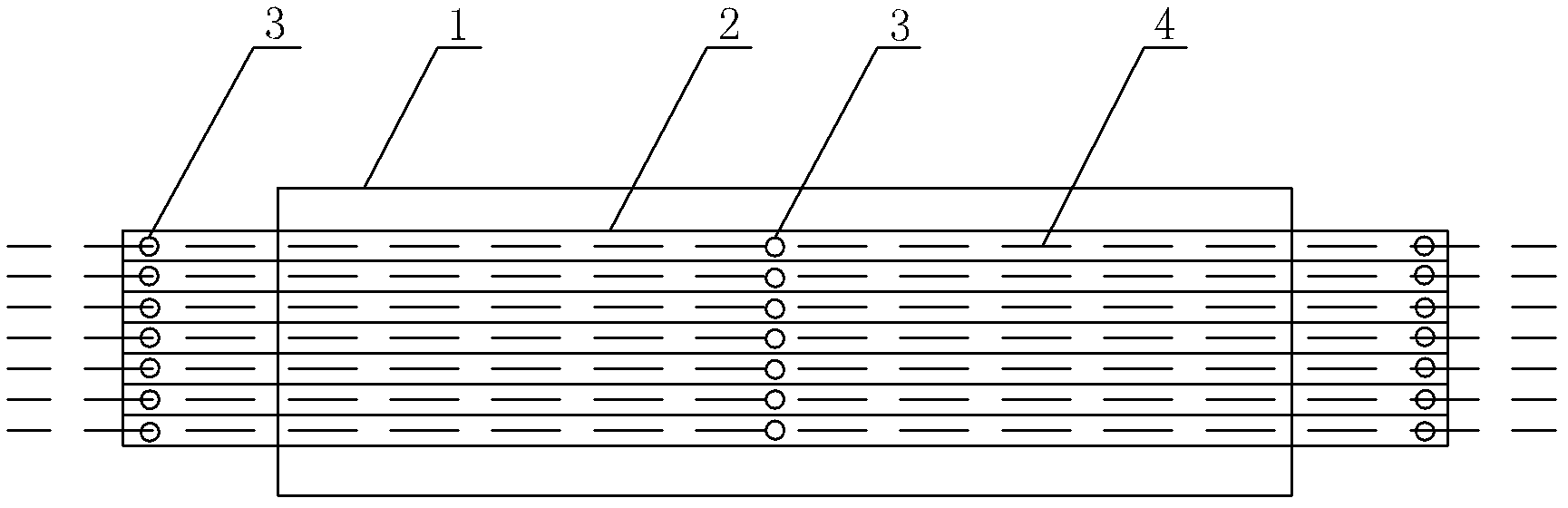

Method for preventing enameled wires from being oxidized and device for implementing method

The invention relates to a method for preventing enameled wires from being oxidized. The method includes performing annealing treatment for copper wires via annealing pipelines; filling steam to the middle of each annealing pipeline via two ends of the annealing pipeline; and simultaneously filling steam into the two ends of each annealing pipeline from the middle of the annealing pipeline. A device for implementing the method for preventing the enameled wires from being oxidized comprises an annealing furnace and the annealing pipelines penetrating through the annealing furnace, steam pipelines are connected to the two ends of each annealing pipeline, and a steam pipeline is connected to the middle of each annealing pipeline. The method and the device have the advantages that the method includes filling the steam from two sides and the middle of each annealing pipeline, so that the steam in the annealing pipelines cannot flow to the outside, the steam utilization rate is increased, and electricity and energy are saved; and the oxidation prevention performance is good, and the quality of each enameled wire can be improved.

Owner:WUJIANG SHENZHOU MACHINERY

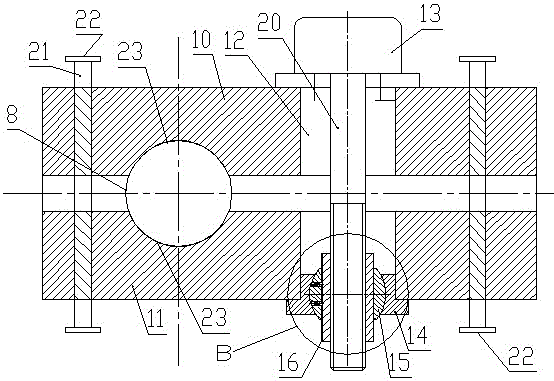

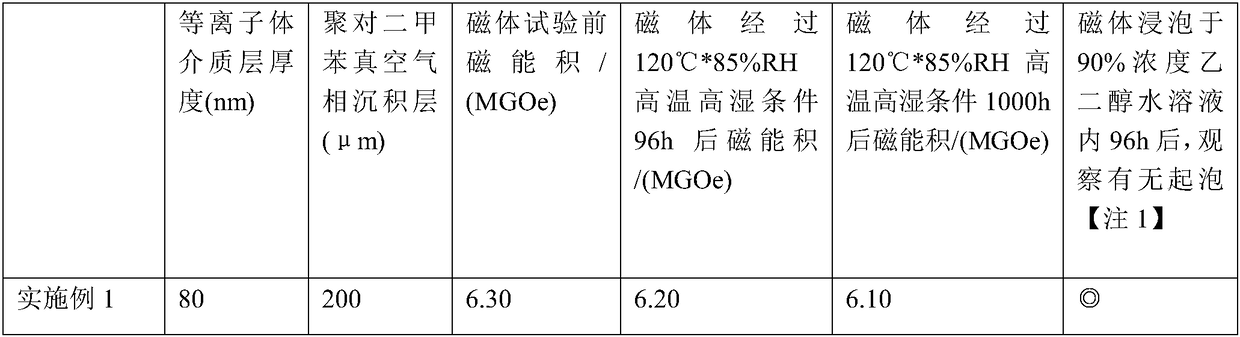

Magnet for micro-electronic water pump rotor and preparation method thereof

InactiveCN108231321AReduce volumeImprove work efficiencyPermanent magnetsMagnetic circuit characterised by magnetic materialsSolventNeodymium iron boron

The invention discloses a magnet for a micro-electronic water pump rotor. The magnet comprises a magnet body, and the magnet body is injection molding polyphenylene sulfide PPS-neodymium iron boron magnet; a low-temperature plasma dielectric layer is formed on the outer surface of the magnet body through plasma surface modification treatment, a poly-p-xylene vacuum gas phase deposition layer is formed outside the low-temperature plasma dielectric layer of the magnet body through a vacuum gas phase deposition method. The invention further discloses a preparation method of the magnet for the micro-electronic water pump rotor. The magnet for the micro-electronic water pump rotor is more excellent in acid-base resistance, solvent resistance, oxidation resistance and magnetic performance, smallin size, low in mass, high in working efficiency, and capable of meeting the requirement for the severe working environment of a micro-electronic water pump.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Anti-oxidation method for forging double-drive-axle triple gear

ActiveCN103495691APrevent oxidationReasonable workmanshipMetal-working apparatusWheelsGear wheelGas heating

The invention discloses an anti-oxidation method for forging a double-drive-axle triple gear. The anti-oxidation method comprises the steps of feeding, intermediate frequency furnace heating, die preheating, die lubricant spraying, blank making die cavity feeding, blank making and forming, pre-forging die cavity material taking, forging, material taking, die lubricating, stacking, water soaking, steel shot casting, shot blasting, descaling, intermediate frequency protecting gas heating, precision forging shaping die cavity feeding, and isothermal normalizing. The anti-oxidation method for forging the double-drive-axle triple gear can be used for preventing forging piece oxidation in the process of forging the triple gear. The anti-oxidation method for forging the double-drive-axle triple gear has the advantages of being reasonable in technology, convenient to achieve and good in anti-oxidation effect. The anti-oxidation method for forging the double-drive-axle triple gear is suitable for being used as a method for preventing oxidation of metal parts.

Owner:兴城市粉末冶金有限公司

Fusible chaplet for thin-walled iron casting, application method and combined core

PendingCN109277538AImprove mechanical propertiesImprove fusion effectFoundry mouldsFoundry coresRound barThin walled

A fusible chaplet for a thin-walled iron casting comprises an inner copper body and an outer tin layer wrapping the exterior of the copper body. The inner copper body is made of copper, and the outertin layer is made of tin; the inner copper body comprises a binding post, and an upper supporting seat and a lower supporting seat which are vertically connected to the two ends of the binding post; acombined core comprises an upper water jacket core, round bar cores and chaplets, and one upper water jacket core is provided; a plurality of round bar cores and chaplets are provided, and the roundbar cores correspond to the chaplets one by one; the top surface of the upper water jacket core is provided with a plurality of core units arranged continuously, and one round bar core is arranged above each core unit correspondingly; and one chaplet is arranged between each round bar core and each core unit. According to the design, not only can the more complete fusion between the chaplets and the casting be ensured, but also impurities are not introduced; and the anti-oxidation effect is better.

Owner:DONGFENG COMML VEHICLE CO LTD

Anti-oxidation method for superfine copper powder

The invention provides an anti-oxidation method for superfine copper powder. The superfine copper powder produced with the pure water washing electrolytic method meets requirements; one or two of benzene propane nitrile triazole, methyl benzene propane nitrile triazole and citric acid is / are utilized for preparing first antioxidant; ascorbic acid or glucose is utilized for preparing second antioxidant; the first antioxidant is poured into washed copper powder to a scale for soaking, and the second antioxidant is added for soaking; and then filtering, drying and sieving are performed to accomplish the anti-oxidation treatment on the superfine copper powder. Aiming at the superfine copper powder produced with the electrolytic method, the anti-oxidation method for superfine copper powder enables the oxidation of the copper powder in the drying process to be prevented, the excellent performance of the superfine copper powder is maintained, and under the pressure of 2MPa, the measured resistivity of the copper powder is 3.0*10<-6>-4.0*10<-6> ohmm, and the oxygen content is 0.10-0.20%. The anti-oxidation method for the superfine copper powder is suitable for the industries of electrical carbon, powder metallurgy parts, diamond tools and the like.

Owner:JINCHUAN GROUP LIMITED

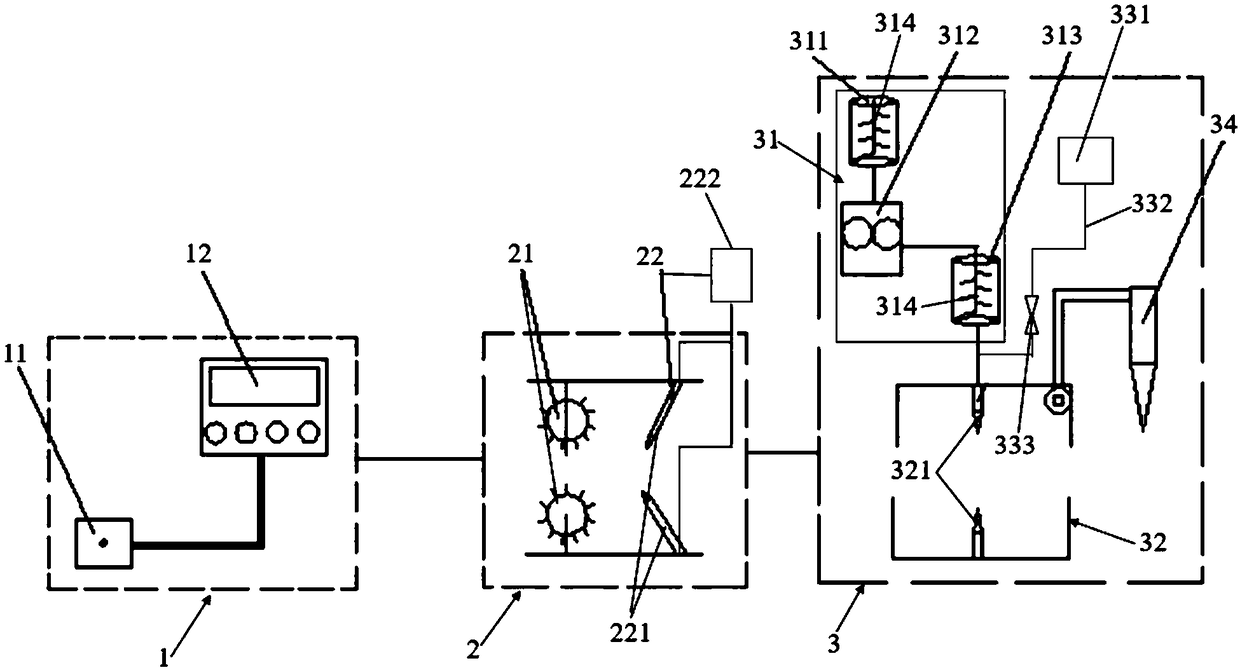

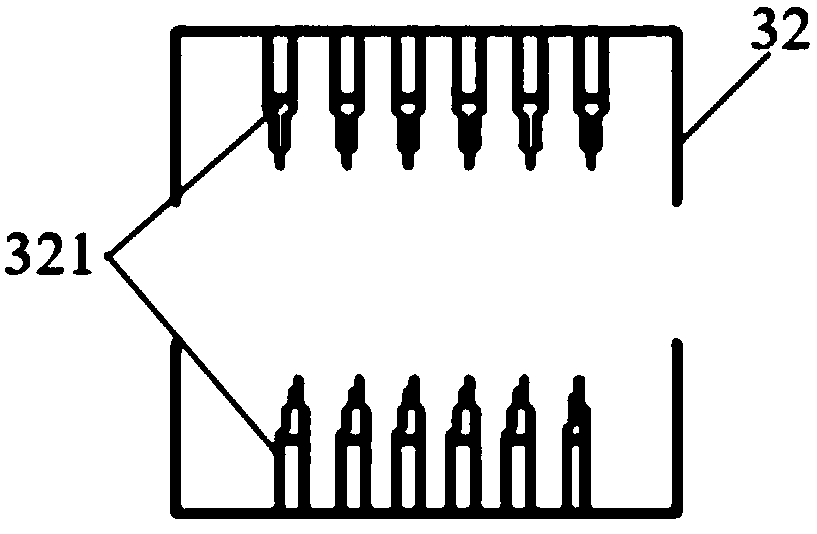

Online spraying device for steel billet anti-oxidation coating and online spraying method thereof

PendingCN109201399AEasy to useImprove adhesionGrinding machinesSpray boothsHeating furnaceOperating time

The invention discloses an online spraying device for steel billet anti-oxidation coating. The online spraying device comprises a steel billet information detecting system, a steel billet pretreatmentsystem for treating the surface of the steel billet, a spraying system and a conveying roller. The steel billet enters a heating furnace sequentially through the steel billet information detecting system, the steel billet pretreatment system and the spraying system along with the conveying roller. The steel billet information detecting system includes an inductive probe for detecting the surfacetemperature and length of the steel billet and a central processor. The inductive probe is connected with the central processor. The steel billet pretreatment system and the spraying system are connected with the central processor. The inductive probe detects the surface temperature and length of the steel billet, when the temperature is higher than 600 DEG C, the central processor will not make any instructions, and when the temperature is not higher than 600 DEG C, the central processor will calculate the opening time and operating time after the opening of the steel billet pretreatment system and the spraying system and instruct the same to enter a state ready to operate. The invention further discloses an online spraying method for steel billet anti-oxidation coating.

Owner:MAANSHAN IRON & STEEL CO LTD

Cutting fluid for after-cutting processing of neodymium iron boron

InactiveCN102766519AExcellent anti-rust and anti-oxidation effectLow costLubricant compositionChemistryKetone

The invention discloses a cutting fluid for after-cutting processing of neodymium iron boron. The cutting fluid comprises the following components, by weight: 5-7% of ethylenediamine, 14-16% of isopropanol amine, 8-10% of oleic acid, 1-3% of sebacic acid, 3-5% of water-soluble phosphate, 4-6% of polyether, 12-14% of methyl benzotriazole, 0.5-0.7% of TX-10, 6-8% of polyvinyl alcohol, 0.1-0.3% of 5-chlorine-2-methyl-4-isothiazolin-3-one, 0.5-0.7% of emulsified oil, 3-5% of isopropyl alcohol and the balance of water.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Electrolytic copper foil antioxidant

PendingCN112095109AUnlimited temperature rangePrevent oxidationElectroforming processesElectrolysisMetallurgy

The invention relates to an electrolytic copper foil antioxidant. The electrolytic copper foil antioxidant comprises the following components, by mass, 0.1-10 parts of carboxylic acid, 0.1-5 parts ofinorganic salt or a silane coupling agent, 0.1-10 parts of a surfactant mixture and 0.1-10 parts of a film-forming agent. The surfactant mixture comprises at least one surfactant having an HLB value less than 14 and at least one surfactant having an HLB value greater than 14. According to the provided electrolytic copper foil antioxidant, the antioxidant does not contain heavy metals, does not need to be electrified and does not need to be washed with water, is safe and environment-friendly, and is a new generation of electrolytic copper foil antioxidant.

Owner:HUBEI ENG UNIV

Aluminum alloy mirror surface anodic oxidation method

InactiveCN110965099AEasy to useQuality improvementSurface reaction electrolytic coatingElectrolytic agentMegasonic cleaning

The invention discloses an aluminum alloy mirror surface anodic oxidation method, which comprises the following steps: S1, cleaning: placing the aluminum alloy in an ultrasonic cleaning machine, and degreasing and cleaning the aluminum alloy by a degreasing agent solution; S2, acid pickling: immersing the aluminum alloy in an acid solution to remove an oxide film layer on the surface of the aluminum alloy, after a period of time, performing neutralization treatment on the the aluminum alloy in an alkaline solution, and finally rinsing the the aluminum alloy with deionized water to remove the residual alkaline solution; S3, anodic oxidation: immersing the aluminum alloy in an electrolyte, and turning on a power supply to carry out an anodic oxidation treatment. According to the invention, through a reasonable surface treatment on the aluminum alloy before the anodic oxidation and a hole sealing treatment by a specific hole sealing agent after the anodic oxidation, the quality of an oxide film formed on the surface of the aluminum alloy is greatly improved, and the formed oxide film has good wear-resistant and anti-oxidation effects, so that the service performance of the aluminum alloy is effectively improved.

Owner:苏州市科渠金属制品有限公司

Method for manufacturing copper-magnesium alloy stranded wire for cold tinned railway

The invention relates to the field of stranded wires for railways, in particular to a method for manufacturing a copper-magnesium alloy stranded wire for a cold tinned railway.The method comprises the following steps that 1, a copper-magnesium alloy rod is connected, extruded and drawn to form a copper-magnesium alloy single-wire blank; 2, the copper-magnesium alloy single-wire blank is subjected to surface treatment; 3, the copper-magnesium alloy single-wire blank treated with surface treatment fluid is subjected to blowing and washing many times; 4, the copper-magnesium alloy single-wire blank obtained in the step 3 is subjected to acid pickling; 5, the copper-magnesium alloy single-wire blank subjected to acid pickling is blow-dried and placed in an electroplate liquid tank for electrotinning; 6, the copper-magnesium alloy single-wire blank is drawn many times through a drawbench, and copper-magnesium alloy single wires of the specified size are manufactured; 7, the copper-magnesium alloy single wires are stranded into the copper-magnesium alloy stranded wire.The production process is simple, the process operation reliability is high, the tinning effect is good, and high corrosion resistance is achieved.

Owner:CHANGZHOU YITENG ELECTRICAL

Processing technology of coaxial cable

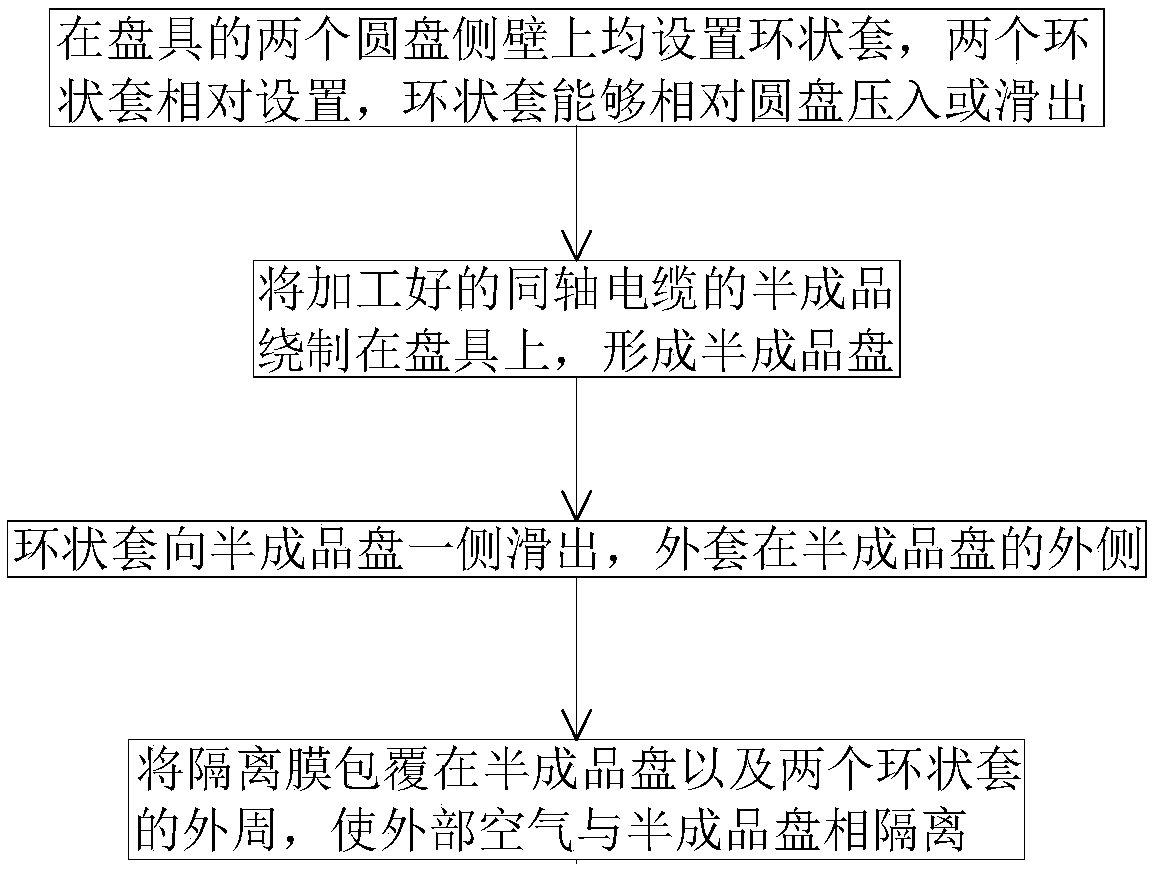

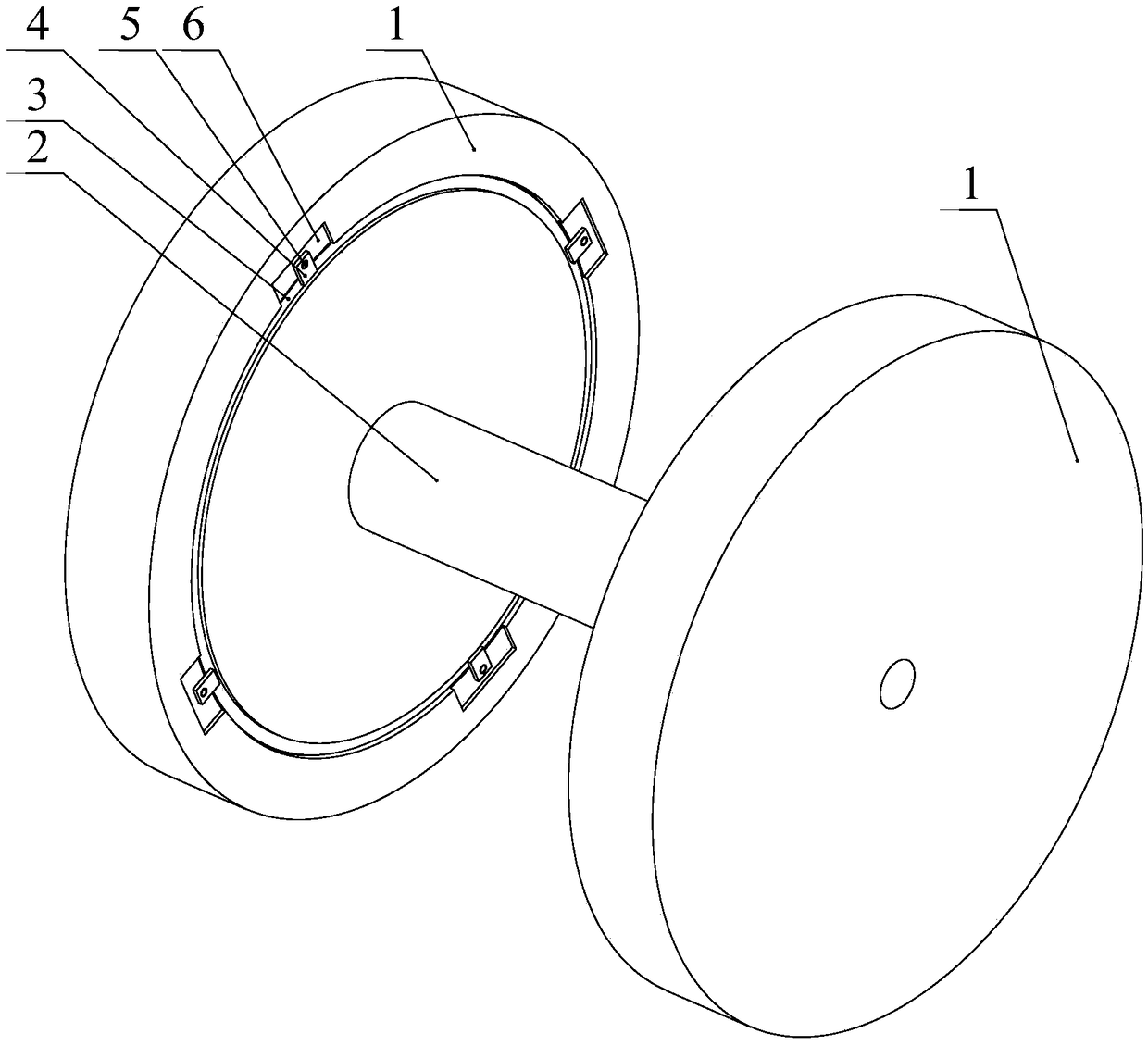

ActiveCN107799239BEffective isolationAvoid enteringManufacturing co-axial cablesCircular discCoaxial cable

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

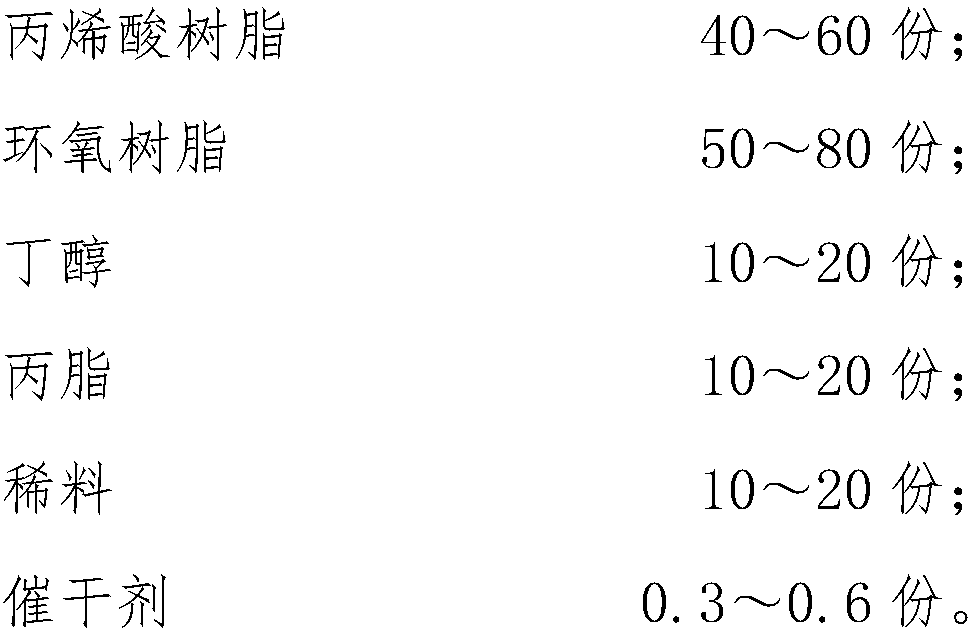

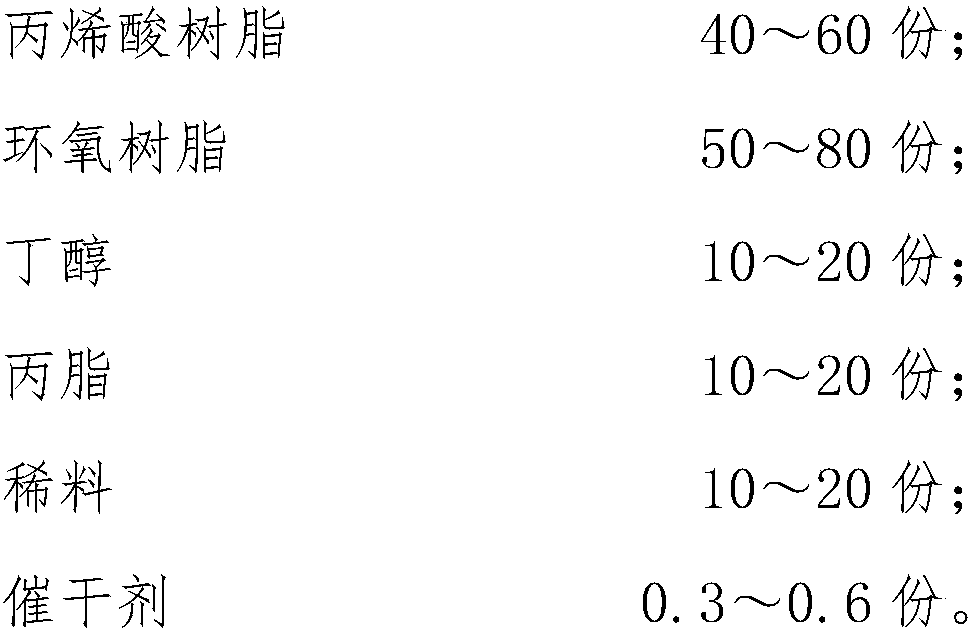

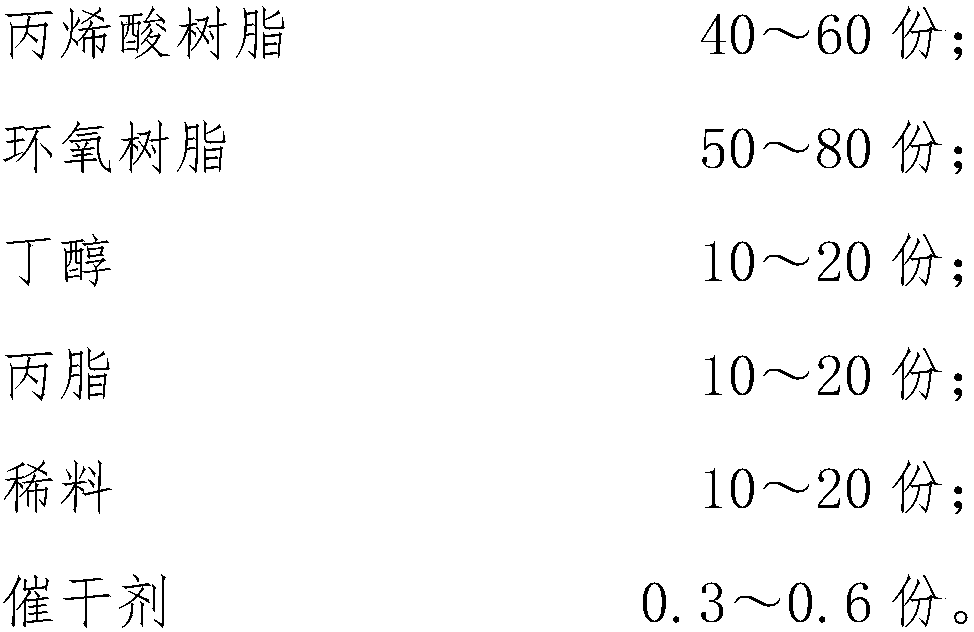

Special protective paint for expressway crash barrier, and preparation method thereof

PendingCN111349373AEasy to processExtended service lifeFireproof paintsAnti-corrosive paintsEpoxyAcrylic resin

The invention provides a special protective paint for an expressway crash barrier, and a preparation method of the special protective paint. The protective paint consists of the following components in parts by weight: 40-60 parts of an acrylic resin, 50-80 parts of an epoxy resin, 10-20 parts of butanol, 10-20 parts of propyl ester, 10-20 parts of a thinner and 0.3-0.6 part of a drier. The preparation method comprises: placing the components into a reaction kettle, carrying out stirring treatment for 1 h at a rotating speed of 280-530 r / min, then adding a dispersing agent and a defoaming agent into the mixture obtained in the step 1, and carrying out stirring treatment again for 1.5 h at a rotating speed of 400-600 r / min to finally obtain a finished product. According to the invention, after being used, the protective paint has strong adhesive force, high-temperature resistance, water resistance, salt mist resistance, oil resistance and corrosion resistance; the protective paint is simple to process; and when the protective paint is used for spraying maintenance of an expressway crash barrier, the crash barrier can keep the complete use function, the service life of the expresswaycrash barrier is prolonged, normal passing of vehicles is not hindered, and the maintenance cost can be greatly reduced.

Owner:袁洪声

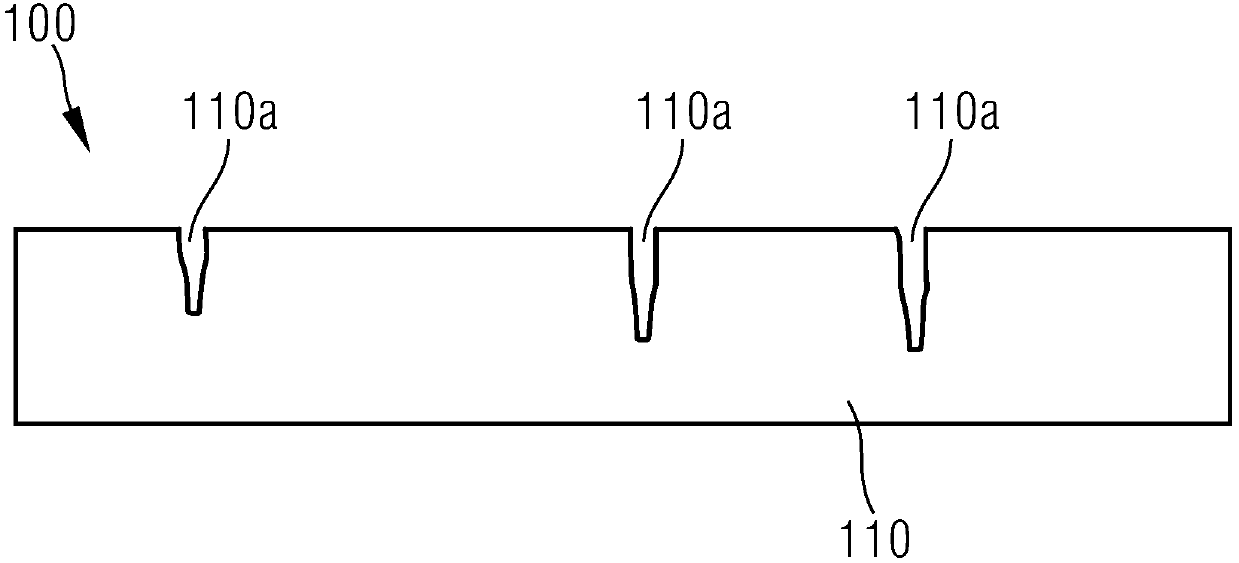

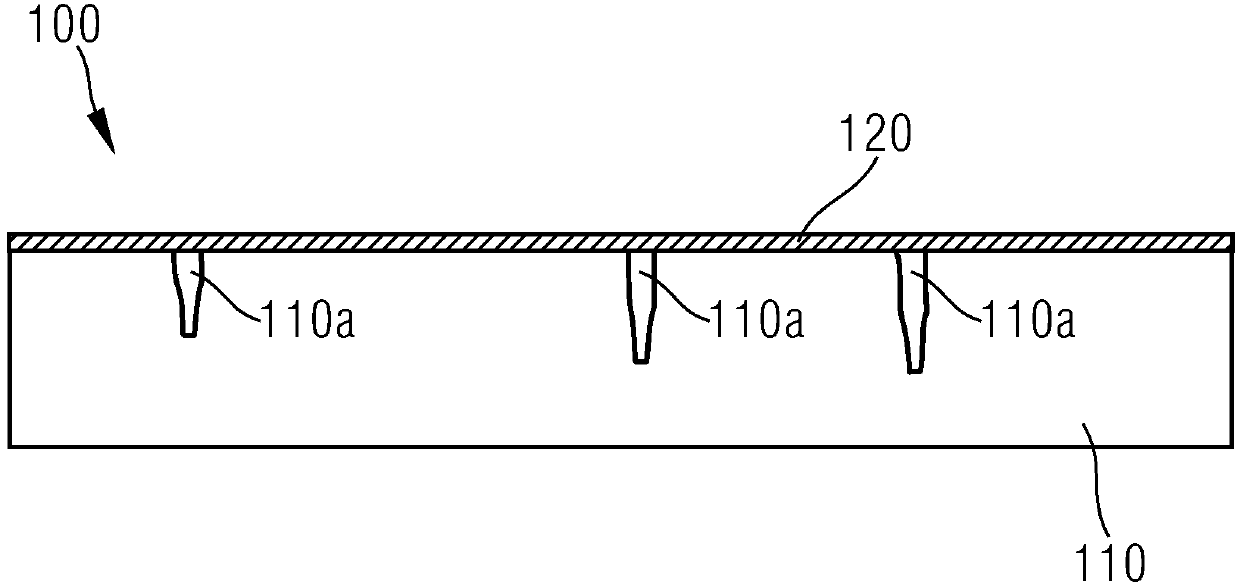

Method for improving quality of inner surface of 3D printed part

ActiveCN110193602ADoes not affect the internal structureDoes not affect accuracyAdditive manufacturing apparatusIncreasing energy efficiency3d printChemical plating

The invention provides a method for improving the quality of the inner surface of a 3D printed part. The method comprises the following steps that chemical plating is conducted on a printed part by utilizing a first material so as to deposit a first material layer on the surface of the printed part; and the printed part is placed into a vacuum furnace for heat treatment. According to the method, surface voids and tiny pits of the surface of the printed part with an internal groove structure can be filled with materials, the roughness of the inner surface and the outer surface of the printed part is reduced, and the surface quality of the inner surface and the outer surface of the printed part is improved; and in addition, due to the fact that the thickness of the first material layer usedfor coating a substrate of the printed part is smaller than 5 microns, the internal structure accuracy, the shape accuracy or the size accuracy of the printed part cannot be influenced.

Owner:SIEMENS AG

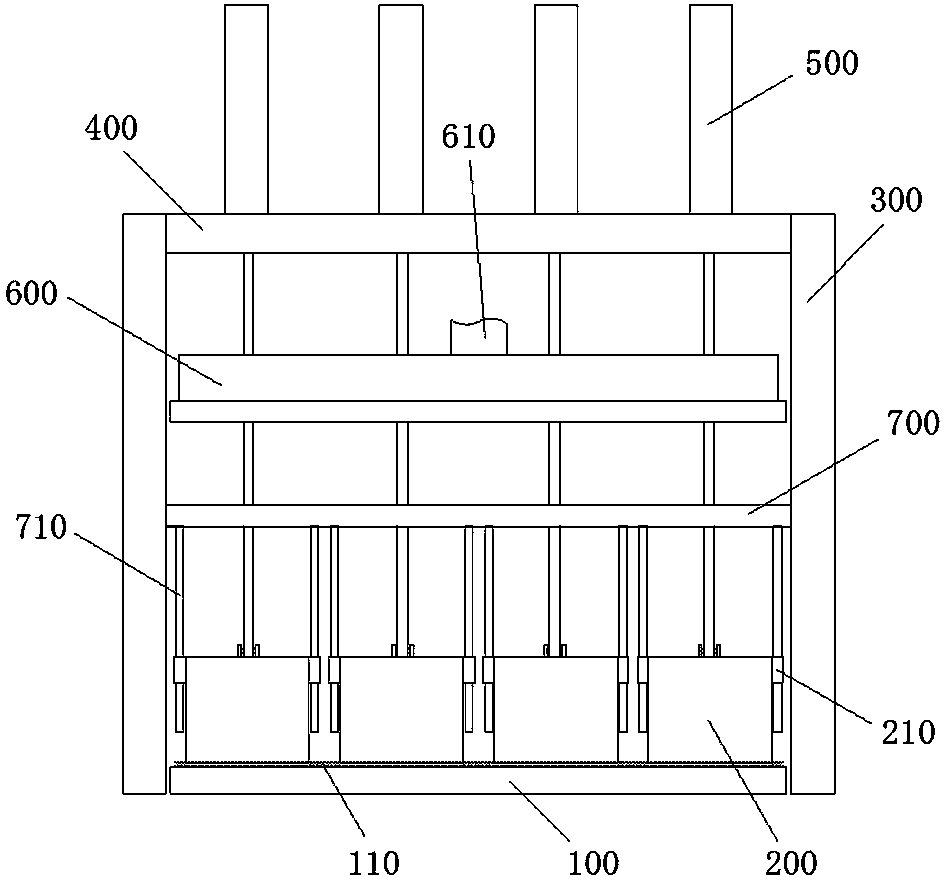

Casting anti-oxidation device and method

The invention relates to a casting anti-oxidation device and method. The casting anti-oxidation device comprises a sand tank located on the lower portion and filled with sand, a plurality of cover bodies covering the sand and capable of being lifted upwards are arranged above the sand tank, the cover bodies are arranged linearly in the length direction of the sand tank, supports are erected at thetwo ends of the sand tank, and a first cross beam is transversely arranged between the upper ends of the two supports; and air cylinders corresponding to the cover bodies one to one are arranged on the first cross beam, and the driving ends of telescopic rods of the air cylinders are connected with the cover bodies. According to the casting anti-oxidation device, operation is easy, using is convenient, it can be ensured that a casting is cooled in an oxygen-free environment, the surface of the casting is prevented from being oxidized, the anti-oxidation effect is good, the casting surface quality is improved, and the service life of the casting is prolonged.

Owner:福建立松金属工业有限公司

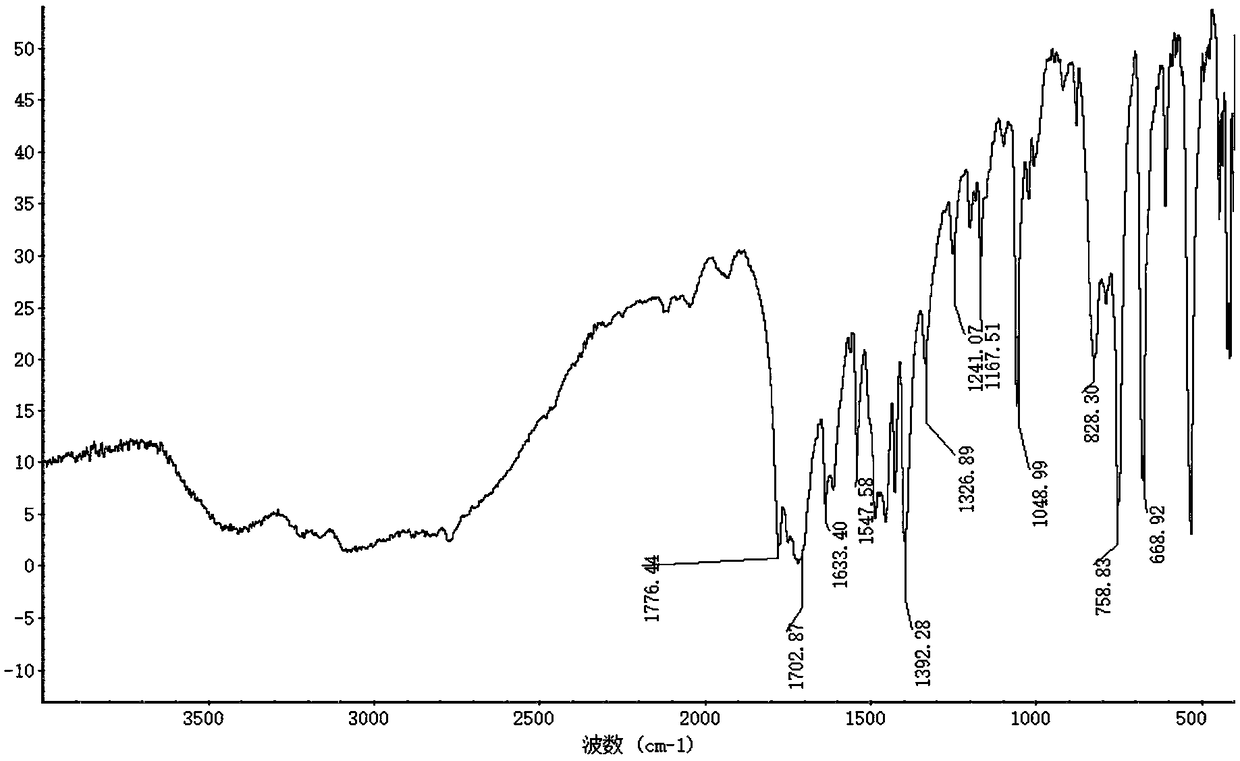

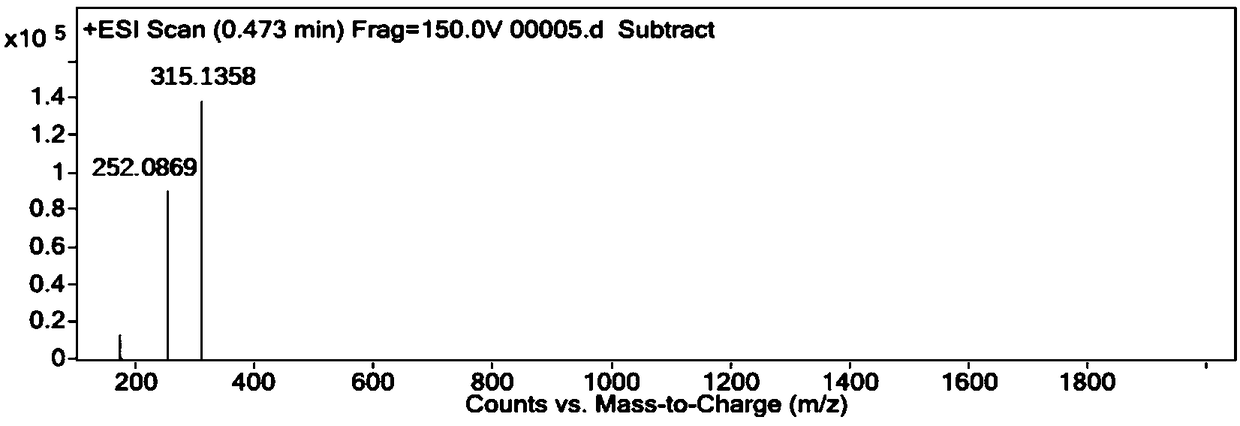

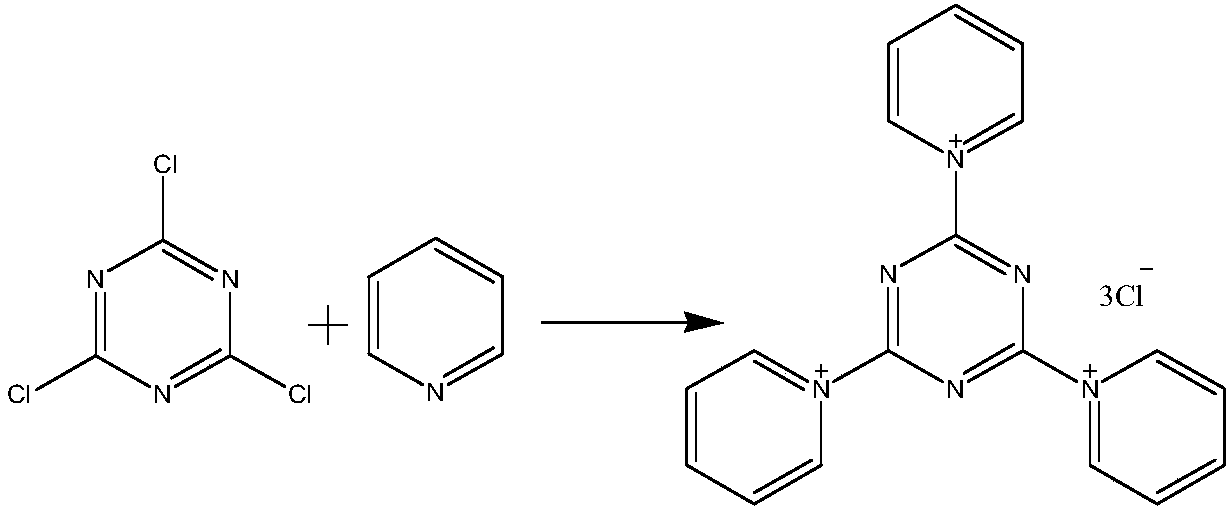

Polyheterocyclic cyanuric chloride antioxidant corrosion inhibitor as well as preparation method and application thereof

InactiveCN109020956AReduce corrosionImprove adsorption capacityOrganic chemistryDrilling compositionSolubilityOrganic solvent

The invention discloses a polyheterocyclic cyanuric chloride antioxidant corrosion inhibitor as well as a preparation method and application thereof. The preparation method of the antioxidant corrosion inhibitor comprises the following steps: dissolving cyanuric chloride in an organic solvent to obtain a solution A, adding an organic amine into the organic solvent to obtain a solution B, adding the solution B into the solution A at 0-5 DEG C, and stirring for carrying out a reaction for 2-3h; then, heating up to 30-45 DEG C, carrying out a reaction for 4-6h, then heating up to 70-80 DEG C andcarrying out a reaction for 8-12h; cooling to the room temperature, filtering, washing, and drying to obtain the antioxidant corrosion inhibitor. The corrosion inhibitor has good corrosion inhibitionproperty at the high temperature; when being used an antioxidant corrosion inhibitor for a gas-injection well, the polyheterocyclic cyanuric chloride antioxidant corrosion inhibitor has good dissolubility in highly mineralized formation brines, and has an obvious inhibiting effect on oxygen corrosion of carbon steel of the gas-injection well.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com