Processing technology of coaxial cable

A technology of coaxial cable and processing technology, which is applied in the field of coaxial cable processing technology, can solve the problems of unsatisfactory anti-oxidation effect and inability to fit the isolation film, etc., and achieve good anti-oxidation effect and the effect of isolating external air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

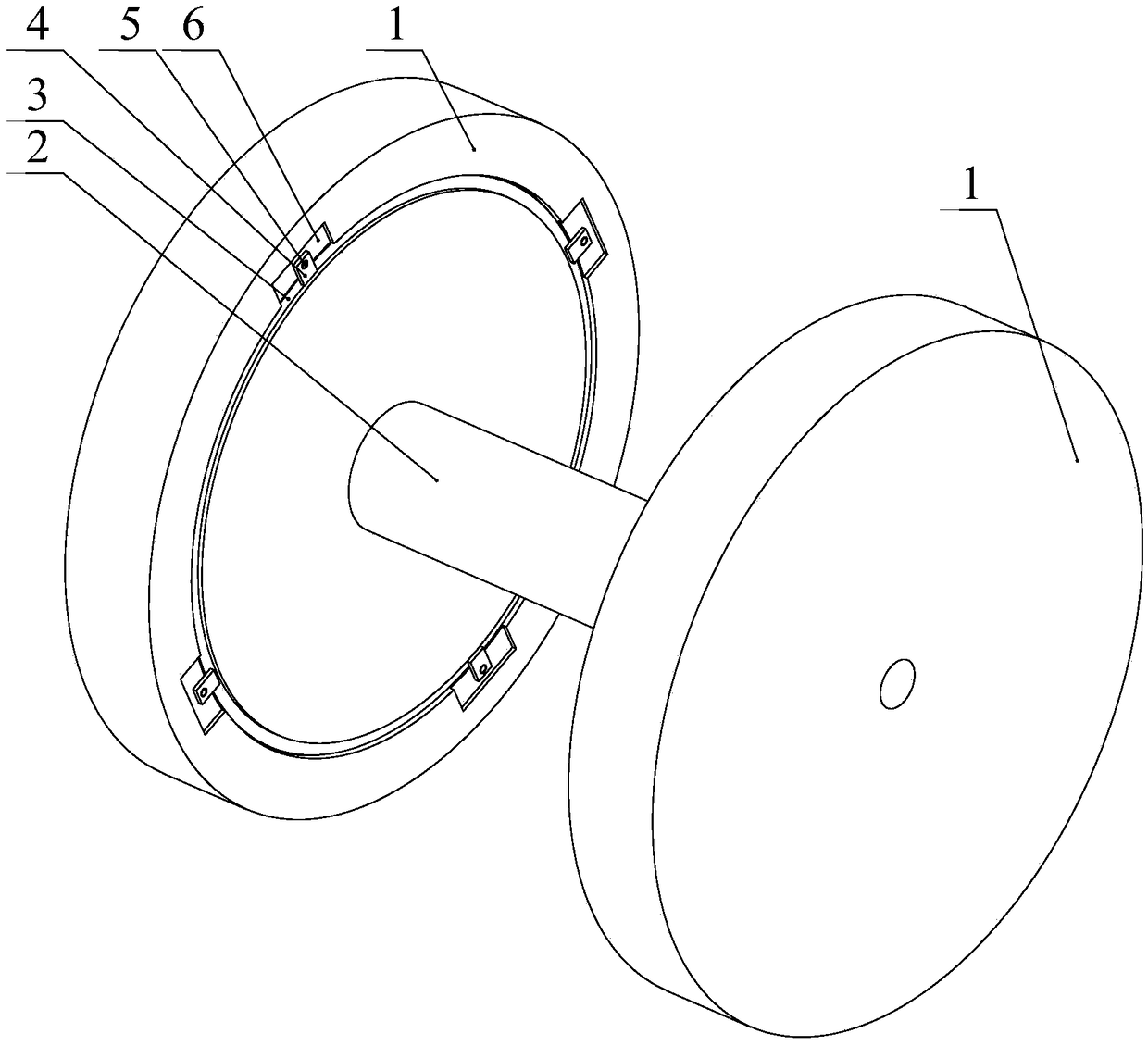

[0045] Below in conjunction with each accompanying drawing, the present invention is described in detail.

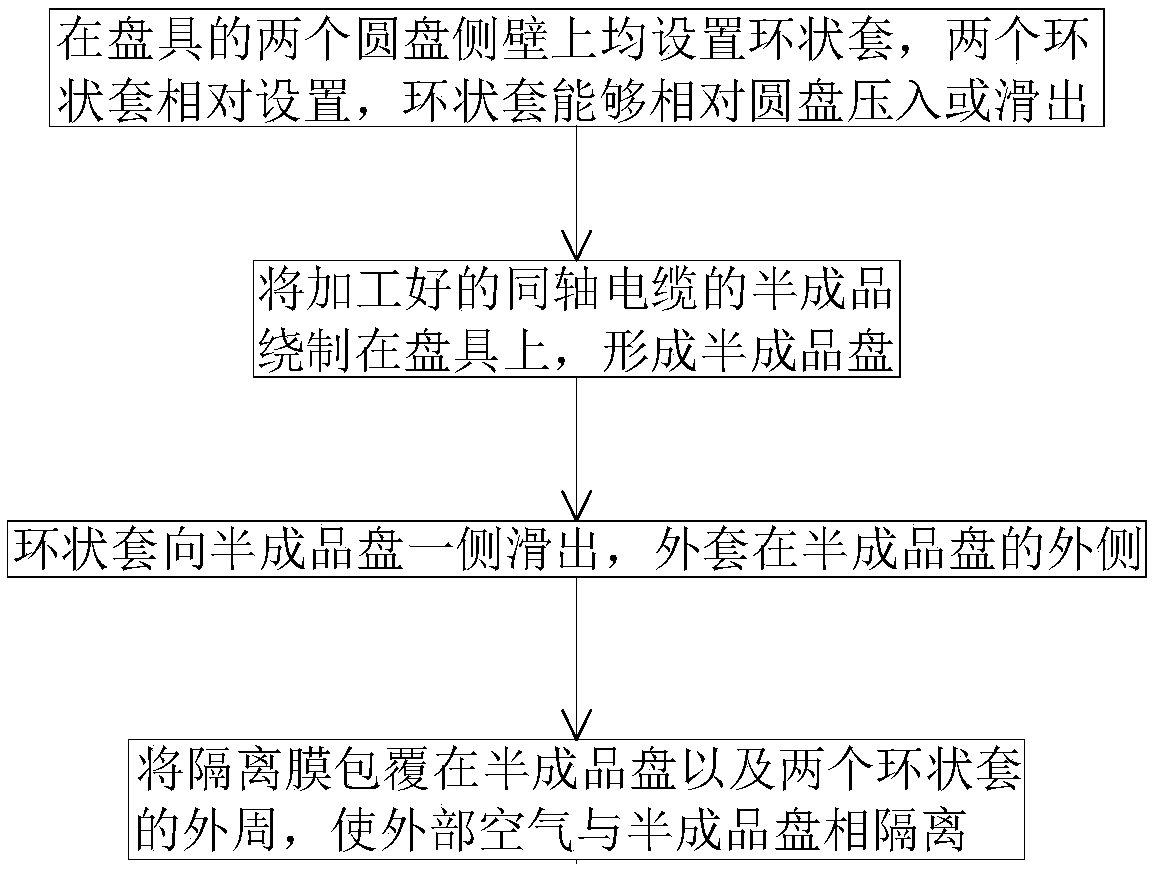

[0046] like figure 1 Shown, a kind of processing technology of coaxial cable comprises the following steps:

[0047] 1) Annular sleeves are arranged on the side walls of the two discs of the dish, and the two annular sleeves are arranged opposite to each other, and the annular sleeves can be pressed into or slid out relative to the disc;

[0048] 2) Winding the processed semi-finished coaxial cable on the plate to form a semi-finished plate;

[0049] 2) The annular sleeve slides out to one side of the semi-finished disk, and is covered on the outside of the semi-finished disk;

[0050] 3) Wrap the isolation film on the outer periphery of the semi-finished disk and the two annular sleeves, so as to isolate the external air from the semi-finished disk.

[0051] In this method, after the semi-finished product is rolled into a semi-finished disc, the annular sleeve can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com