Coating material for preventing submersed nozzle from nodulation and preparation method thereof

A technology for nozzle nodule and coating material, which is used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of nodule blockage, easy baking and oxidation of immersed nozzles, etc., to reduce raw material costs and prevent oxidation. Good performance and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

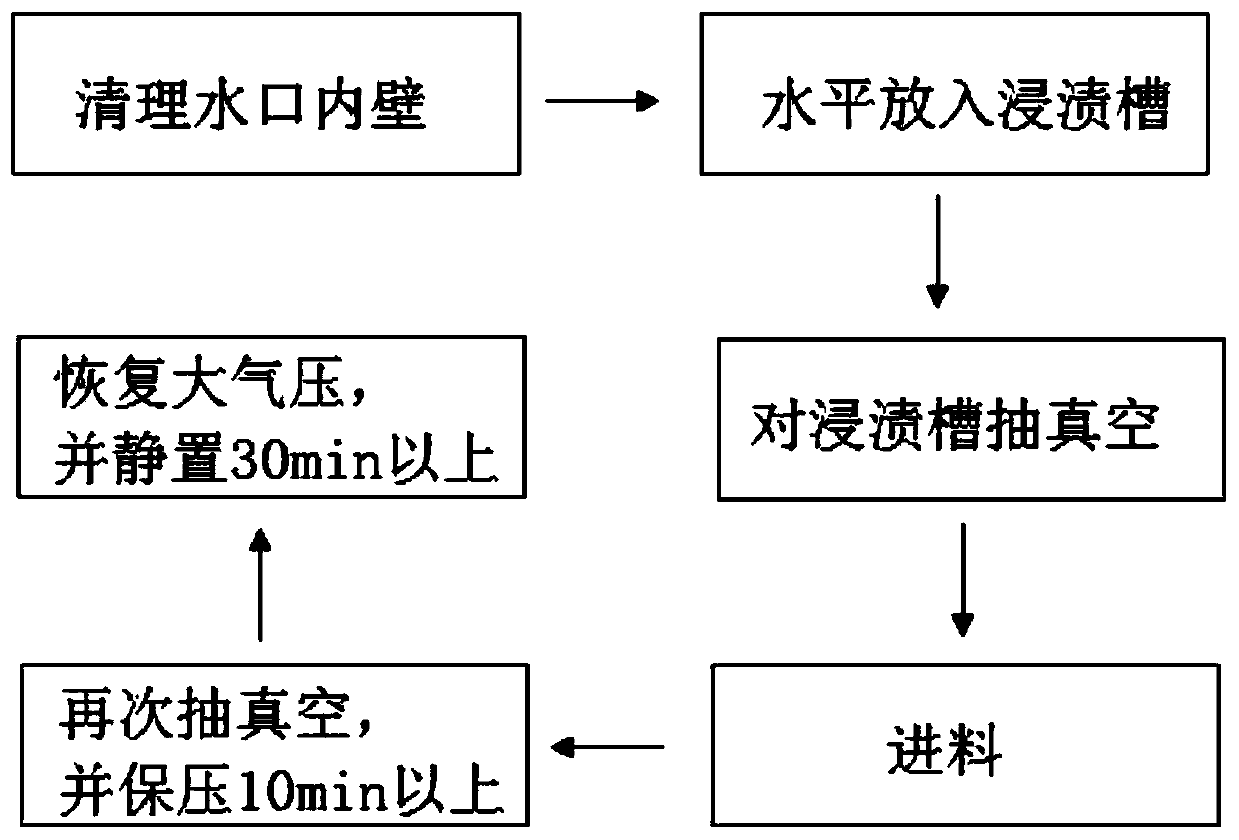

Method used

Image

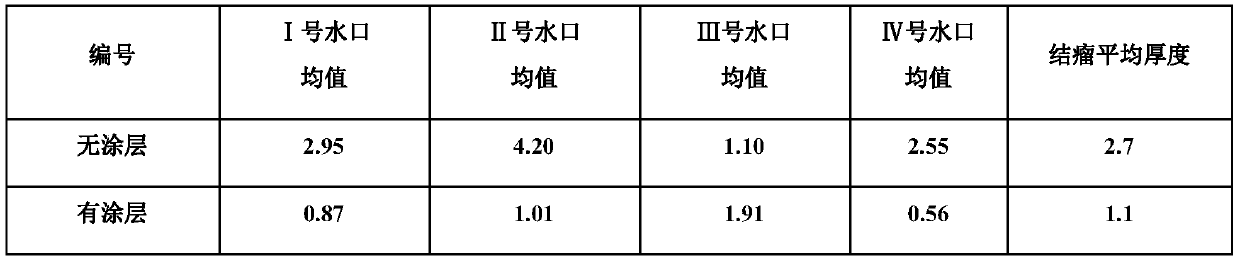

Examples

Embodiment 1

[0041] A coating material for preventing nodulation of submerged nozzles in this embodiment, its raw materials include the following components by weight: mullite fine powder: 20, corundum fine powder: 15, Guangxi white mud: 4, activated alumina Micropowder: 7, Aluminum Dihydrogen Phosphate: 5, Flux: 8, Antioxidant: 2, Dispersant: 0.3. The coating material is mainly made of mullite fine powder, corundum fine powder, Guangxi white mud, quartz powder, activated alumina fine powder, etc., using aluminum dihydrogen phosphate as a binder, and adding flux, dispersant and anti- Oxidizing agent, the prepared coating has good adhesion and oxidation resistance. As the raw material part uses mullite fine powder, the properties of mullite are stable, and its melting point is 1850°C, which can not only reduce the raw material cost of the overall coating material, but also improve the thermal shock stability and high temperature performance of the submerged nozzle coating .

[0042] The f...

Embodiment 2

[0055] A coating material for preventing nodulation at the submerged nozzle of this embodiment is basically the same as that of Embodiment 1, the difference is: mullite fine powder 24, corundum fine powder 20, Guangxi white mud 8, active oxidation Aluminum fine powder 17, dihydrogen phosphate 7, waste glass powder 7.5, potassium feldspar 1.5, boron frit 1, aluminum powder 1, silicon powder 3, silicon carbide 6, carboxymethyl cellulose 2.

[0056] The preparation method of a coating for preventing nodules at the submerged nozzle of this embodiment is basically the same as that of Embodiment 1, except that in the mixing step: mullite fine powder, corundum fine powder, Guangxi White mud, activated alumina micropowder, flux, dispersant, and antioxidant are placed in water at a temperature of 70°C and mixed evenly, then aluminum dihydrogen phosphate is added, and then stirred for 5 minutes with a mixer. The slurry was obtained after ball milling for 3 h. The prepared coating is im...

Embodiment 3

[0060] A coating material for preventing nodules in the submerged nozzle of this embodiment is basically the same as that of Embodiment 1, the difference is: mullite fine powder 56, corundum fine powder 23, Guangxi white clay 8, active Alumina fine powder 18, aluminum dihydrogen phosphate 5, waste glass powder 6, potassium feldspar 2, boron frit 1, aluminum powder 0.5, silicon powder 1.5, silicon nitride fine powder 1.5, hydroxyethyl cellulose 1.

[0061] The preparation method of a coating for preventing nodules at the submerged nozzle of this embodiment is basically the same as that of Example 1, the difference being that in the mixing step: mullite fine powder, corundum fine powder, Guangxi White mud, activated alumina micropowder, fluxing agent, dispersant, and antioxidant are placed in water at a temperature of 60°C and mixed evenly, then aluminum dihydrogen phosphate is added, and then stirred with a mixer for 10 minutes, and the mixture is obtained after stirring evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com