Patents

Literature

42results about How to "Offset shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

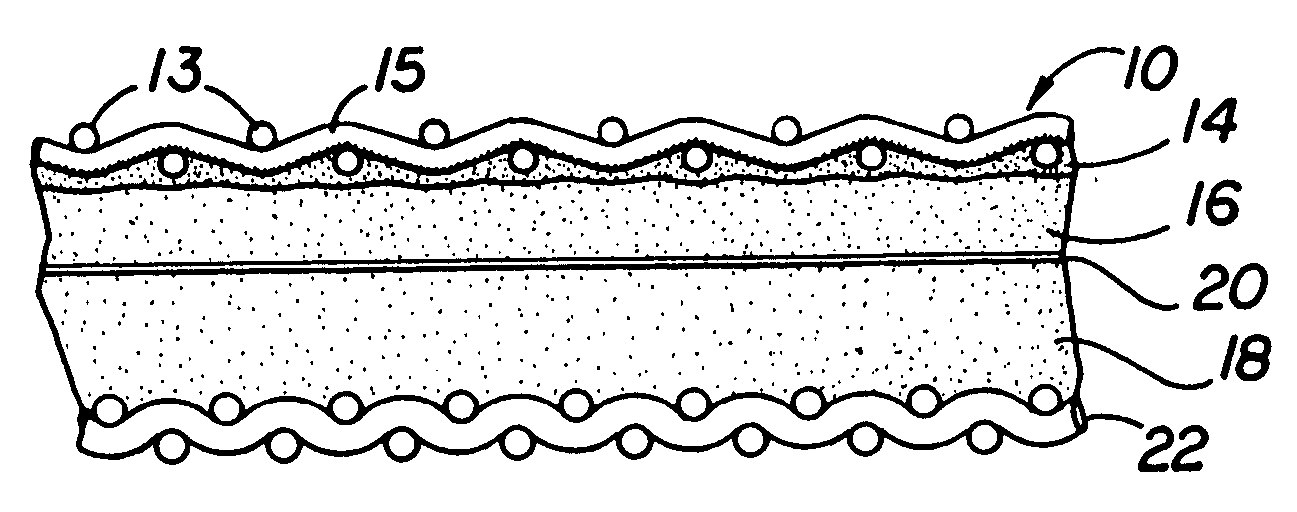

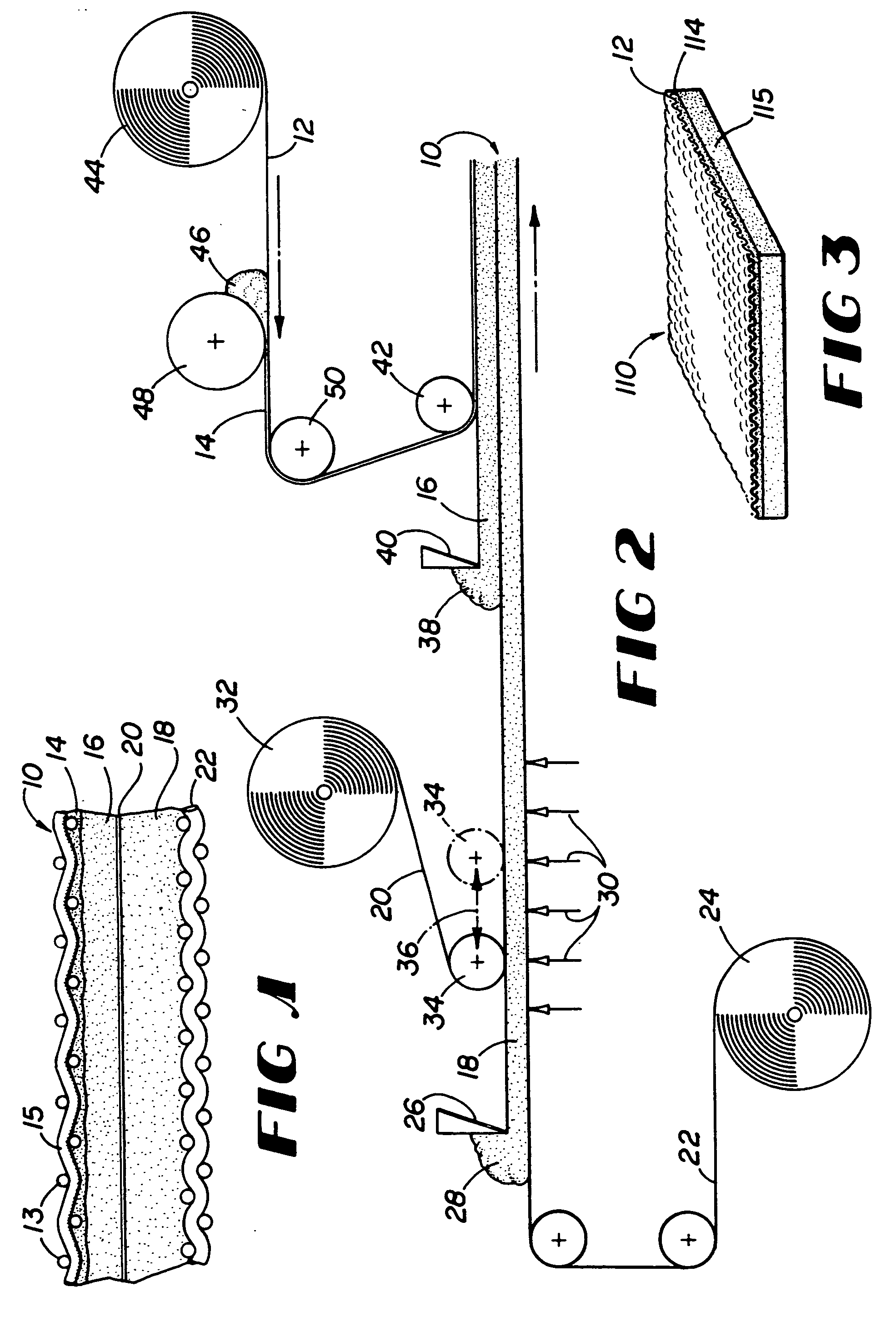

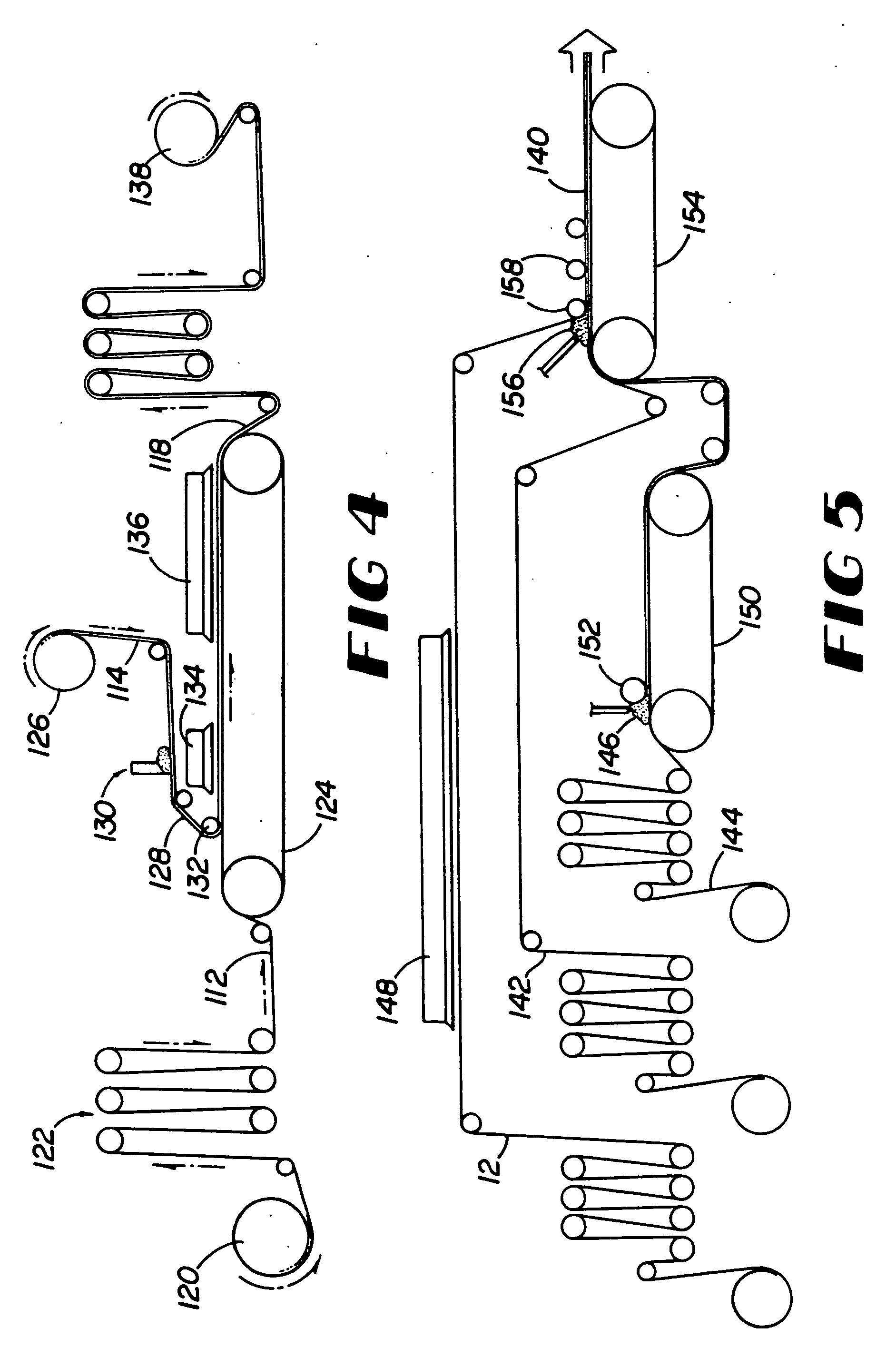

Floor covering with woven face

InactiveUS20040198120A1Increase rate of changeReduce the chance of changeSynthetic resin layered productsFloor coveringsYarnPolyester

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

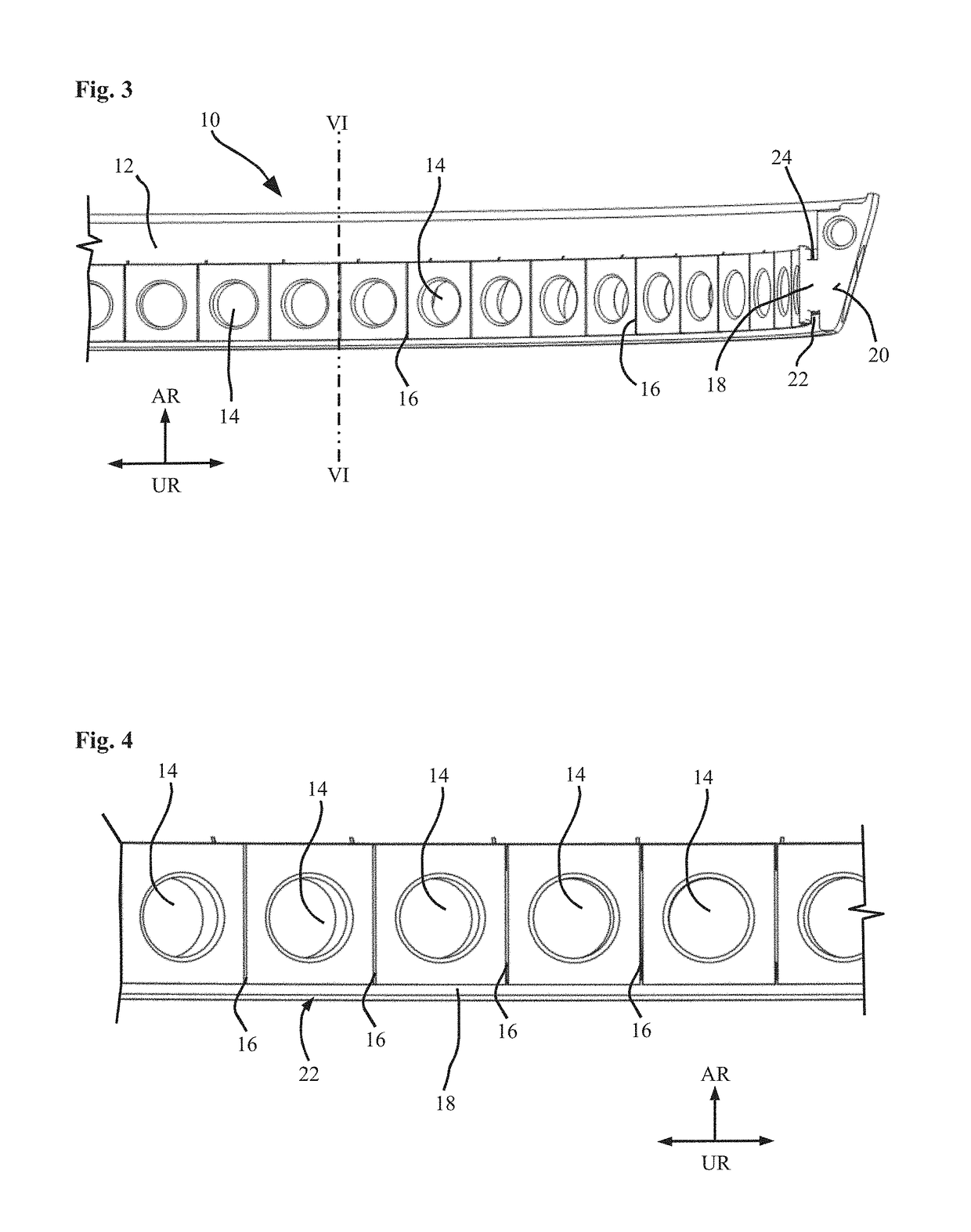

Corundum-mullite heat-insulating brick

The heat insulating corundum-mullite brick has the material composition comprising fused white corundum powder finer than 325 mesh 30-40 wt%, alpha-alumina powder finer than 325 mesh 20-30 wt%, gamma-alumina powder finer than 10 microns 20-30 wt%, sillimanite powder finer than 120 mesh 10-20 wt%, No. 1 Suzhou clay powder finer than 280 mesh 8-15 wt% and water 25-30 wt%, as well as foamed polystyrene balls of 0.5-2 mm size and saw dust in 0-0.5 mm size in certain amount. The heat insulating corundum-mullite brick has long service life, capacity of resisting high temperature up to 1700 deg.c, high resistance to various kinds one atmosphere, low heat conductivity, low heat capacity and excellent heat shock stability.

Owner:宜兴市中能耐火制品有限公司

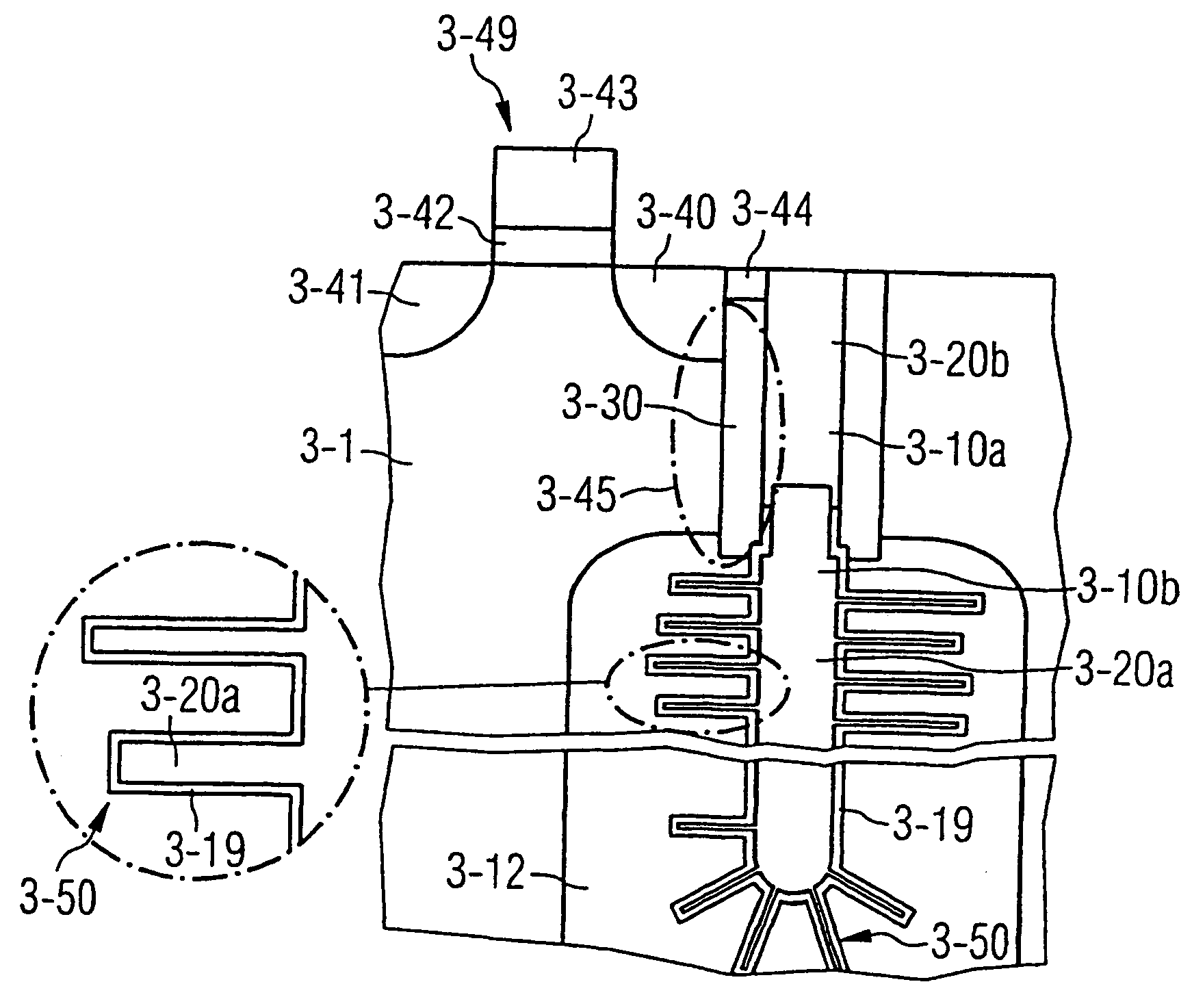

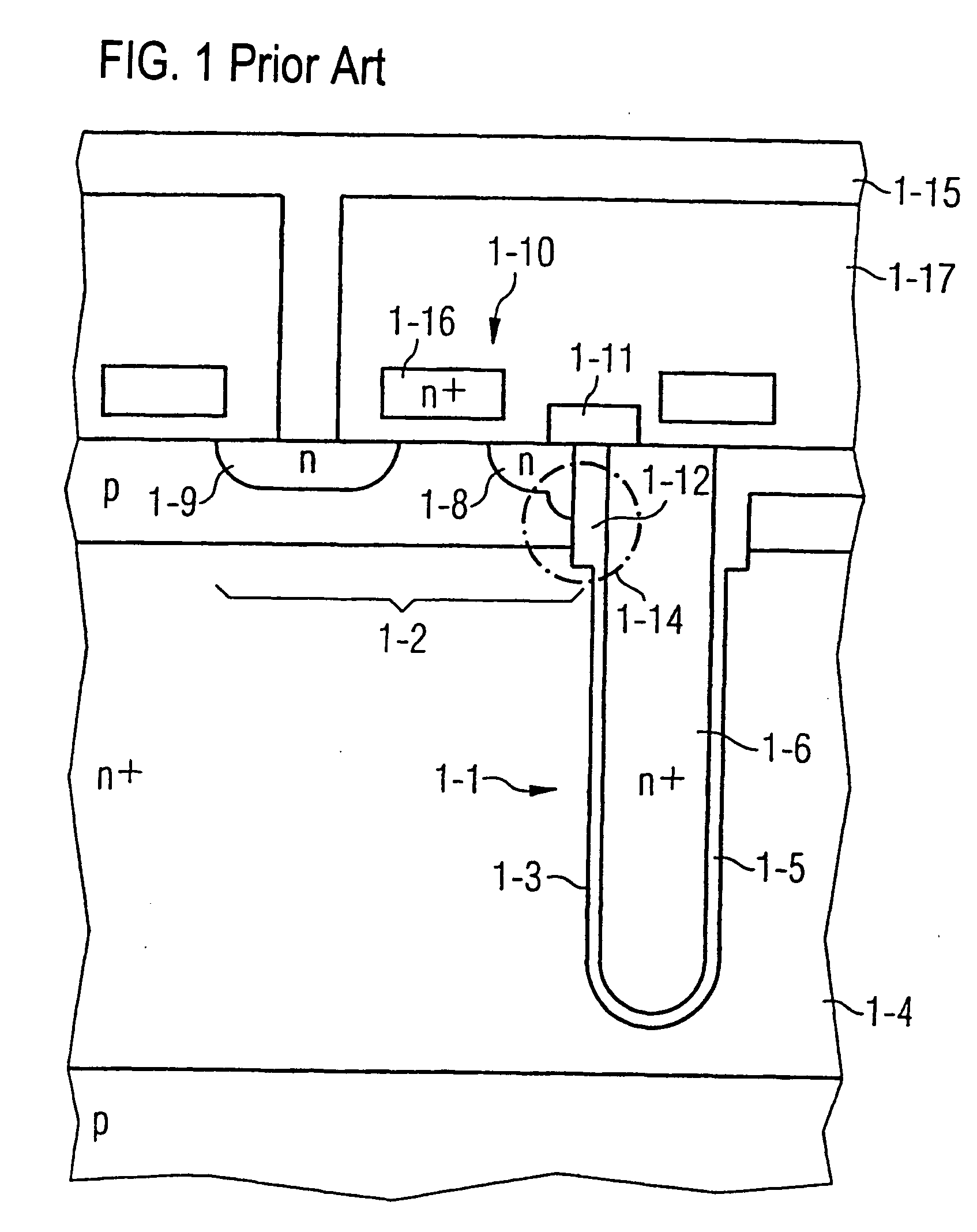

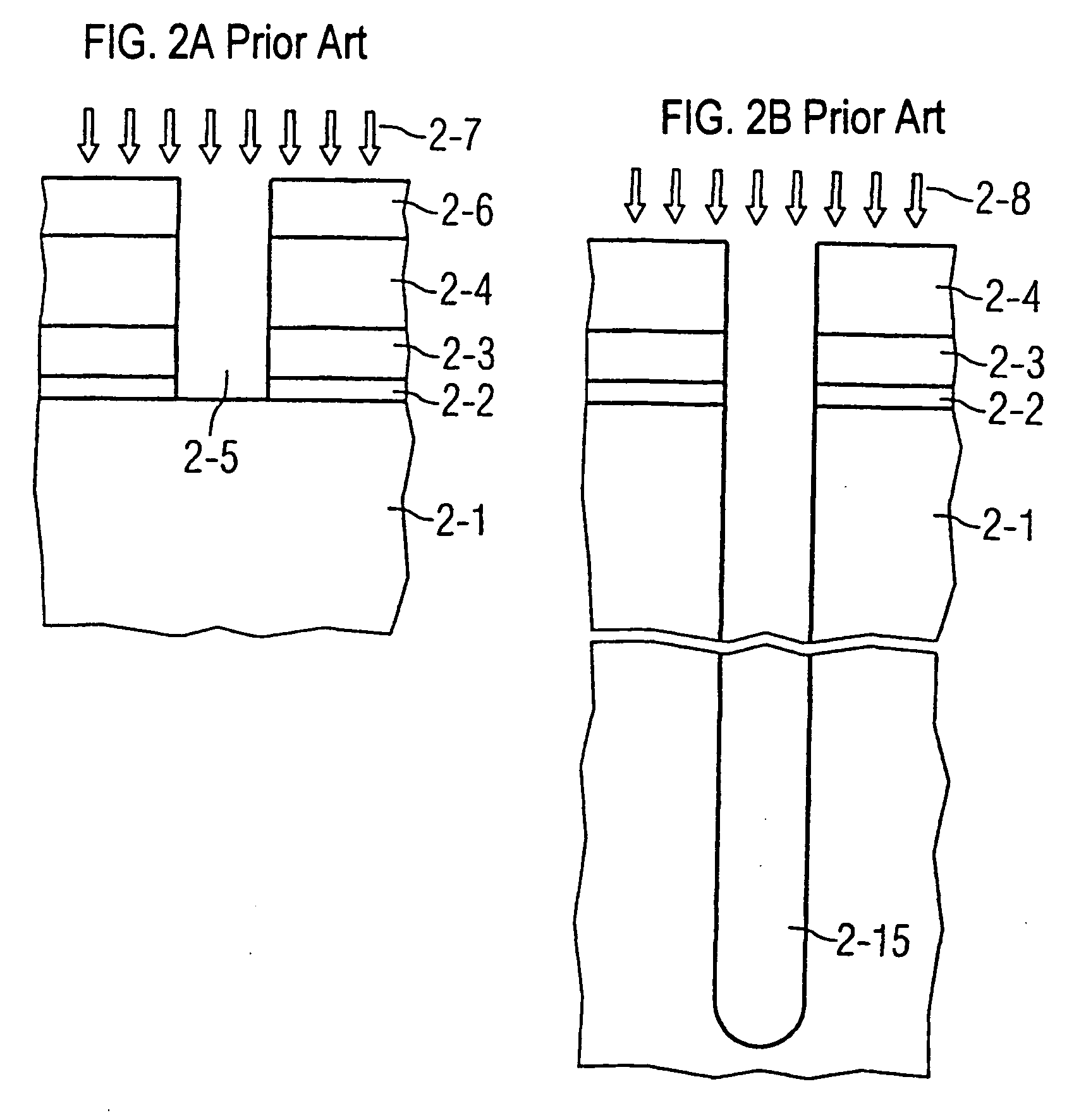

Method for fabricating trench capacitors for integrated semiconductor memories

InactiveUS20050118775A1Offset shrinkageLarge layer thicknessTransistorSolid-state devicesCapacitorSemiconductor

In a method for fabricating trench capacitors, in particular for memory cells having at least one selection transistor for integrated semiconductor memories, a trench for the trench capacitor is formed. The trench has a lower trench region, in which the capacitor is disposed, and an upper trench region, in which an electrically conductive connection from an electrode of the capacitor to a diffusion zone of the selection transistor is disposed. The method reduces the number of process steps for the fabrication of memory cells and enables fabrication of buried collars in the storage capacitors with an insulation quality as required for the fabrication of very large-scale integrated memory cells (<300 nm trench diameter).

Owner:POLARIS INNOVATIONS LTD

Method for preventing deformation of large-size thin-wall annular casting during welding process

ActiveCN102528218ANo mouth opening/neck deformationNo distortionWelding accessoriesLarge sizeMaterials science

The invention relates to a method for preventing deformation during a welding process, in particular to a method for preventing the deformation of a large-size thin-wall annular casting during the welding process. The method is characterized in that the method comprises the following steps of: preparation before welding: preparing a shim plate used for supporting at least five points of the casting so as to ensure that the casting is padded flatly and cannot be deformed by external forces during the welding, and an anti-deformation welding tooling, and then fixing the casting on the tooling; pre-heating before welding; selection of parameters of the welding process; and control of the welding process. The method provided by the invention is unique; the quality of the casting can be ensured; the production cycle can be shortened; the working efficiency can be improved; and the production cost can be saved.

Owner:KOCEL STEEL

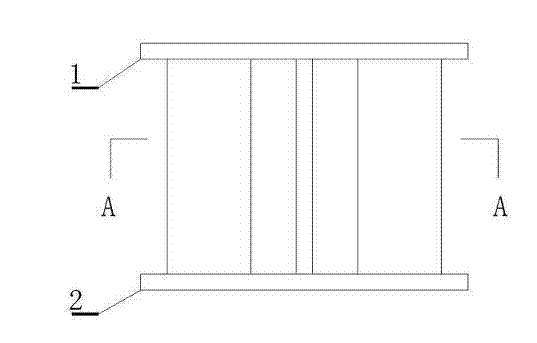

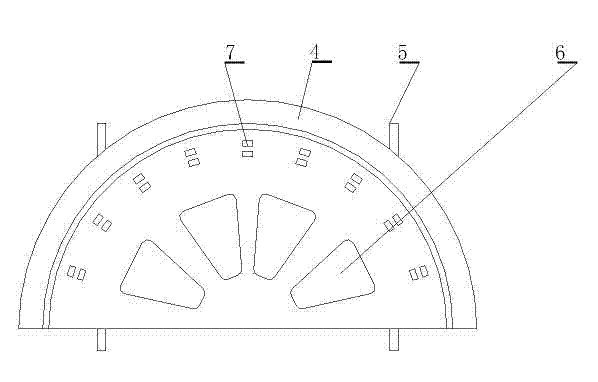

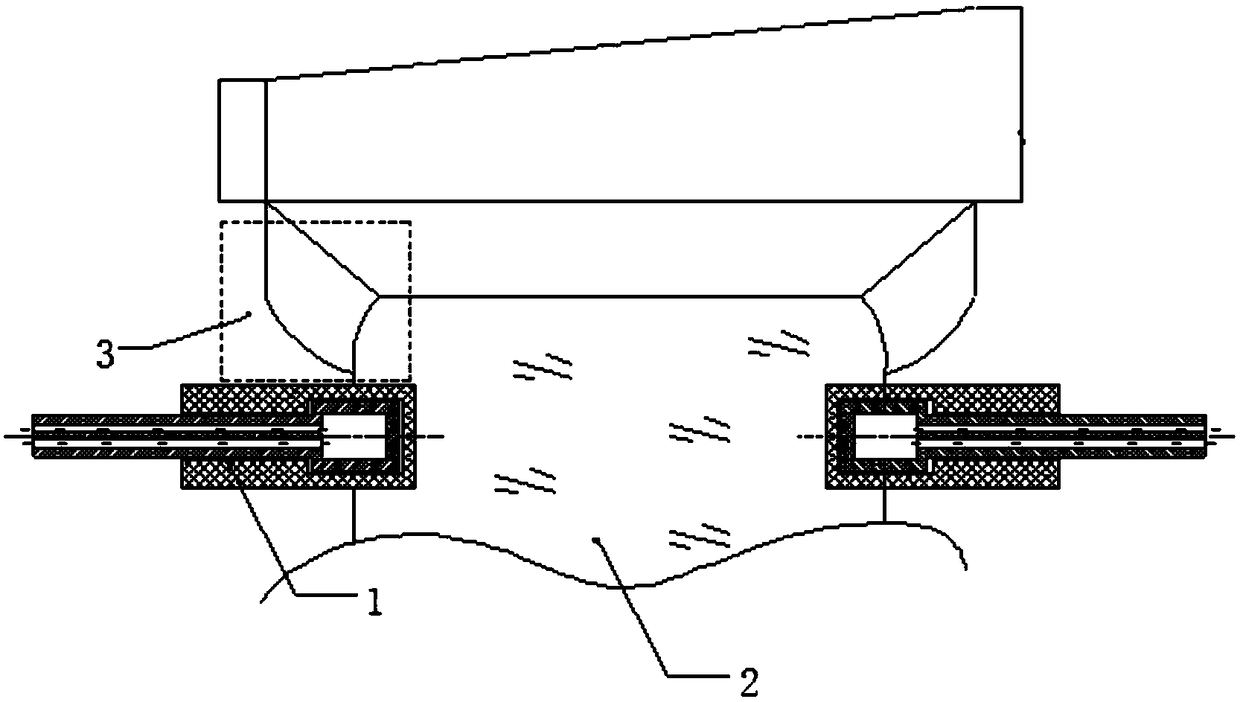

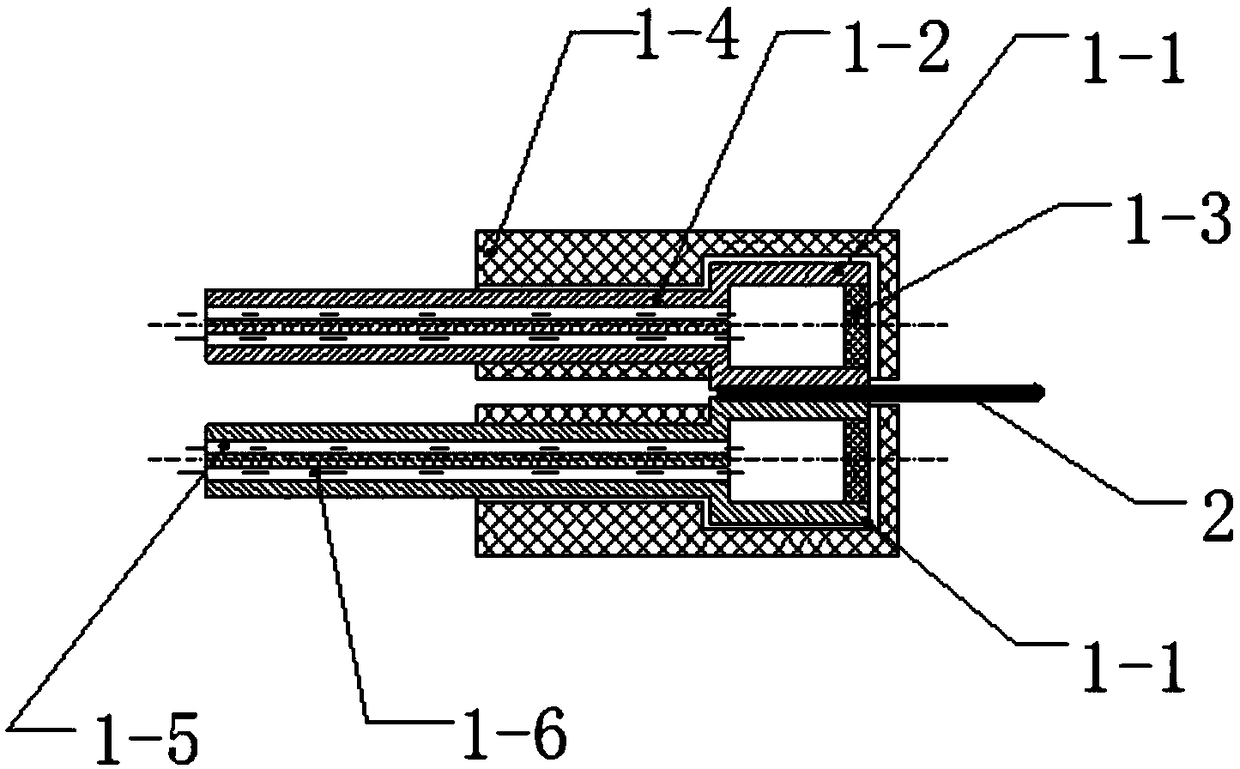

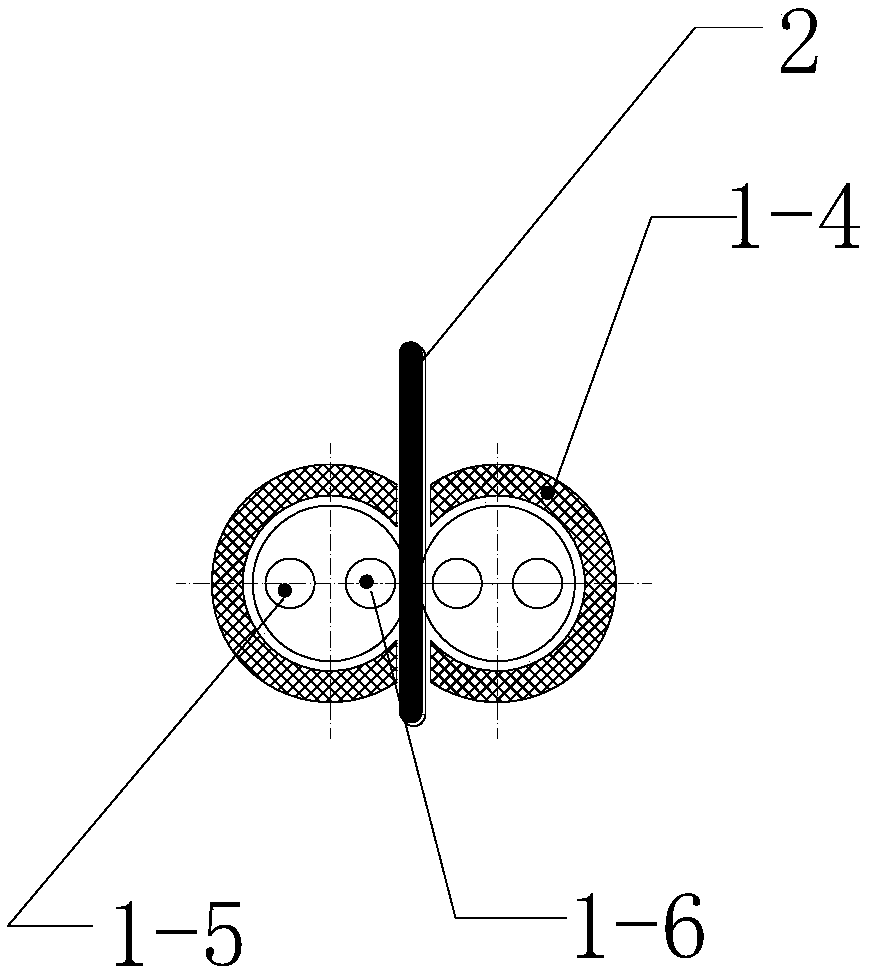

Width control system of overflow molding glass substrate

ActiveCN108996891AReduce the impactAvoid heat exchangeGlass forming apparatusControl systemEngineering

The invention provides a width control system of an overflow molding glass substrate. The width control system of the overflow molding glass substrate comprises two plate width control devices which have the same structure and are symmetrically arranged at the two ends of the glass substrate; the two plate width control devices are used for controlling the width of the glass substrate; each the plate width control device comprises two clamping rollers which rotate oppositely; the two clamping rollers are horizontally arranged on the positive and negative sides of the glass substrate; a connecting shaft is arranged on the end parts of the clamping rollers; the connecting shaft is connected with a driving device; a cooling channel for cooling the clamping rollers is arranged on the connecting shaft; the aim of controlling the width of the glass plate is fulfilled by rapidly cooling the glass side plates; and heat-insulating layers are arranged on the outer sides of the clamping rollers,so that influences on a temperature field of a drainage plate area can be reduced maximally.

Owner:IRICO DISPLAY DEVICES

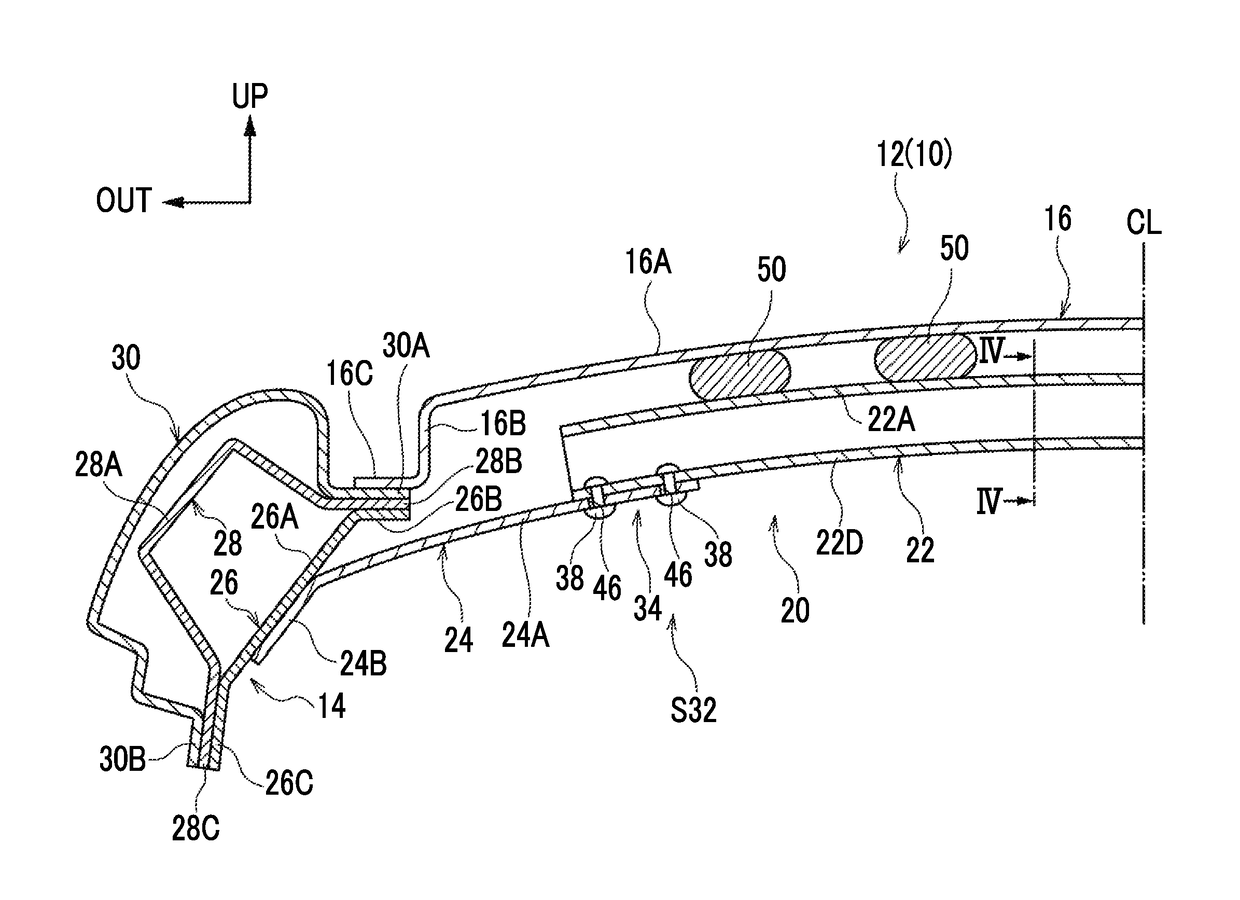

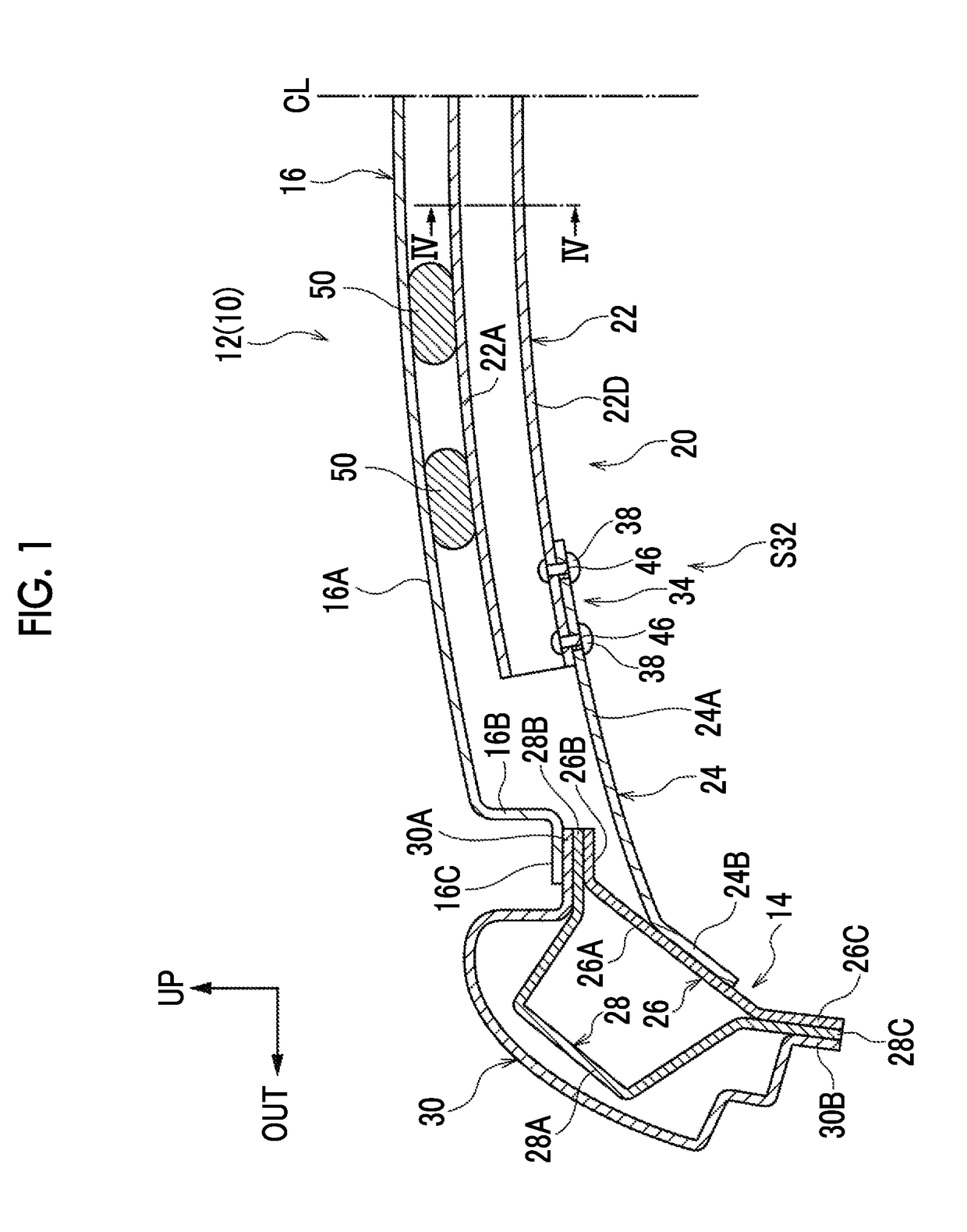

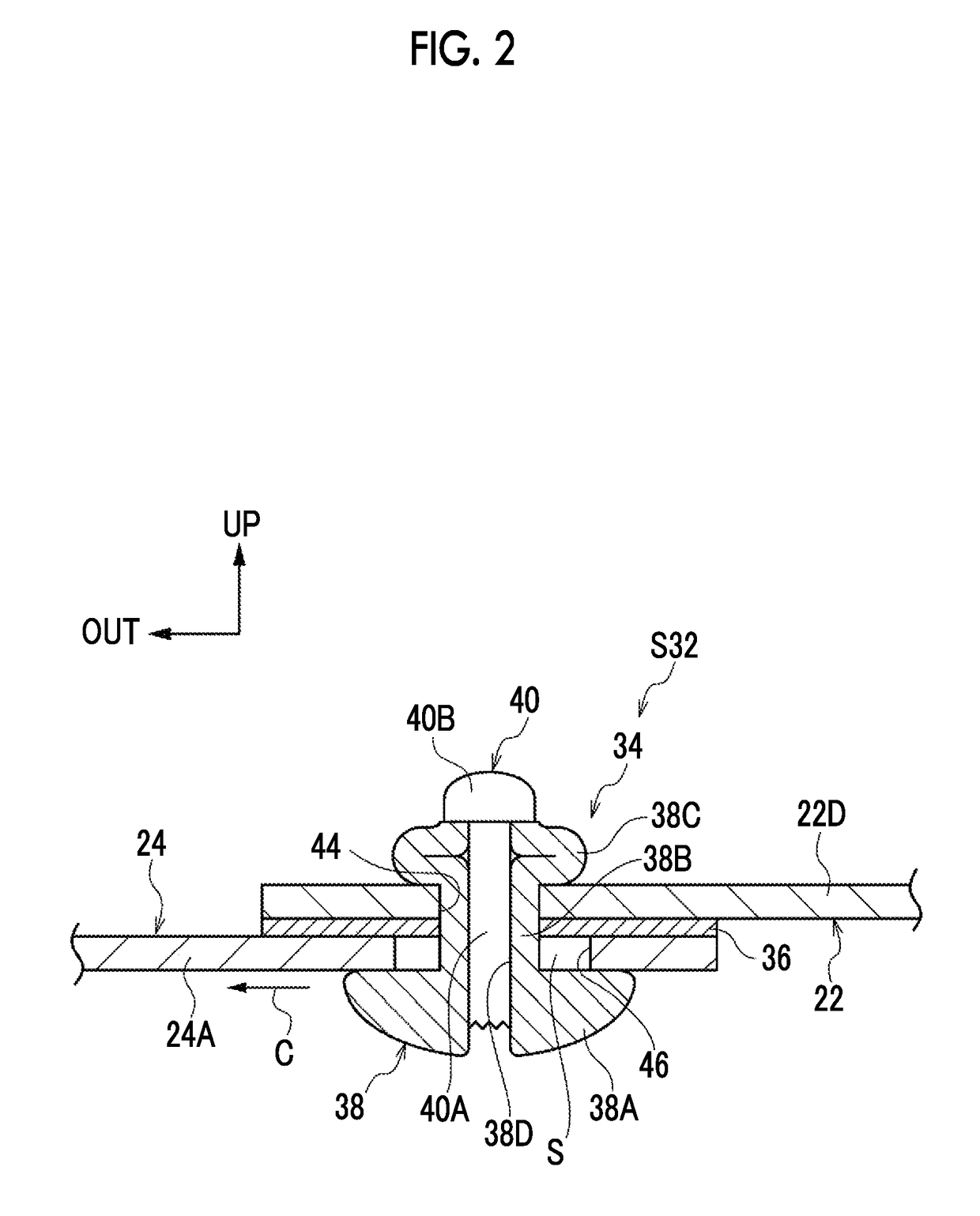

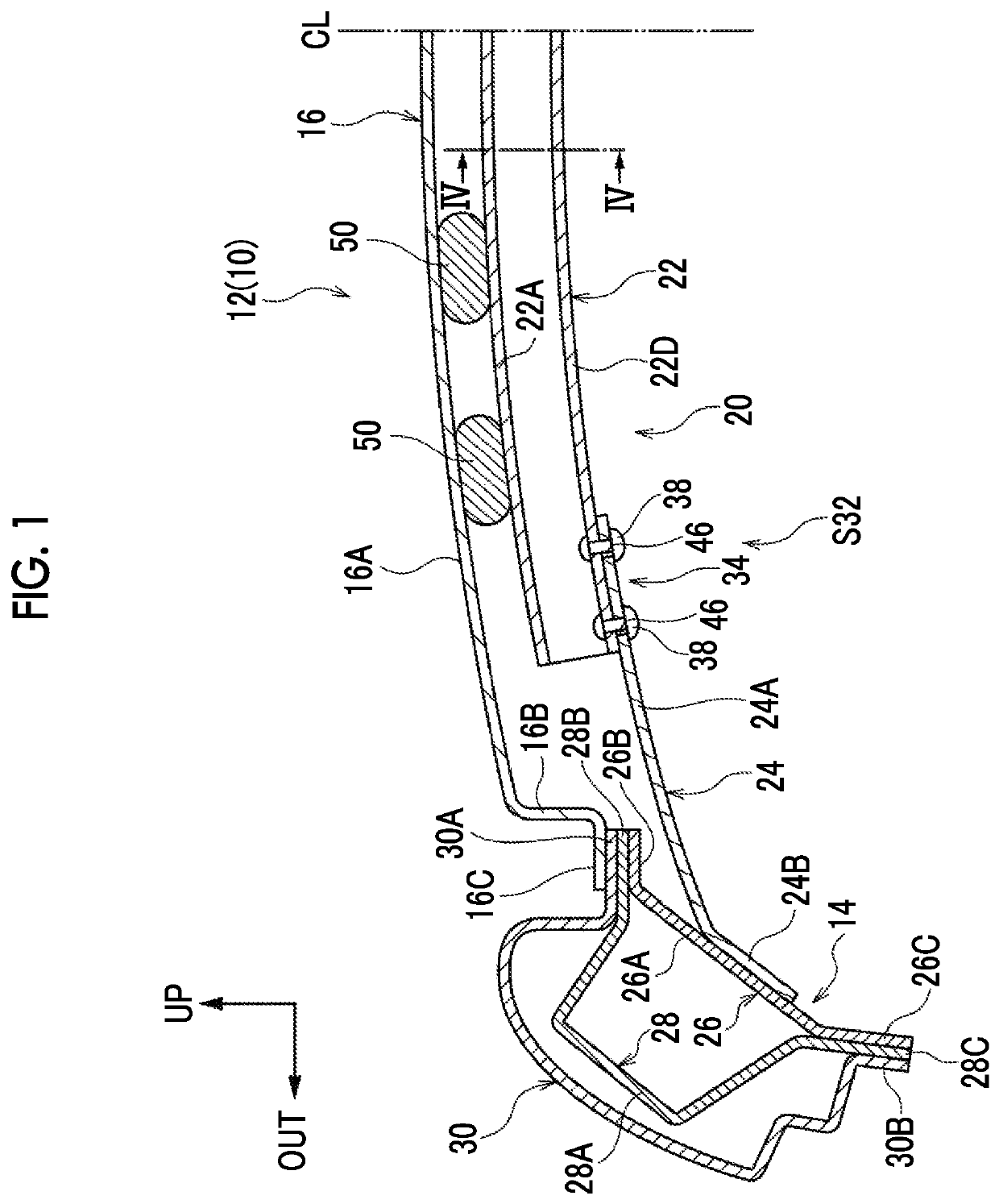

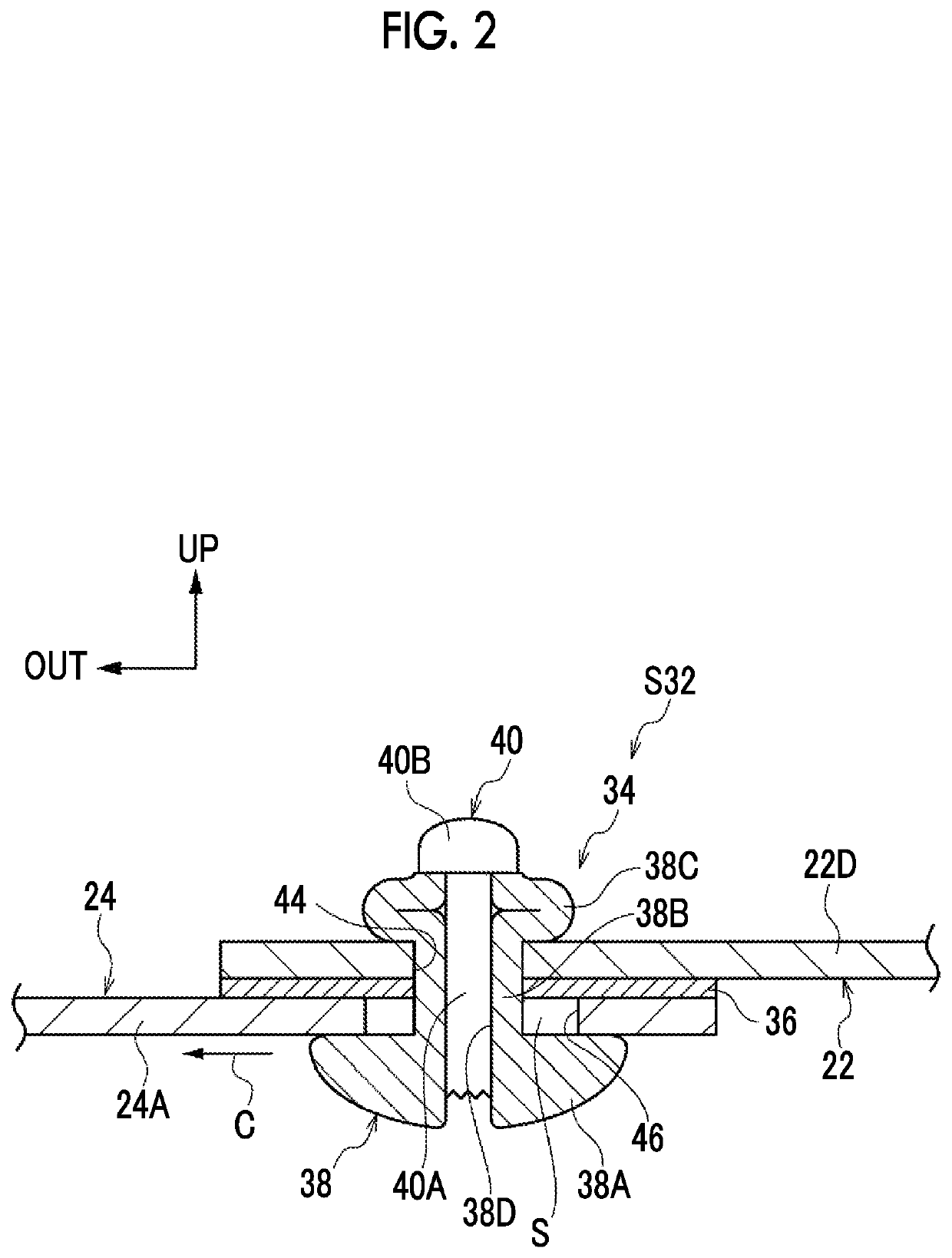

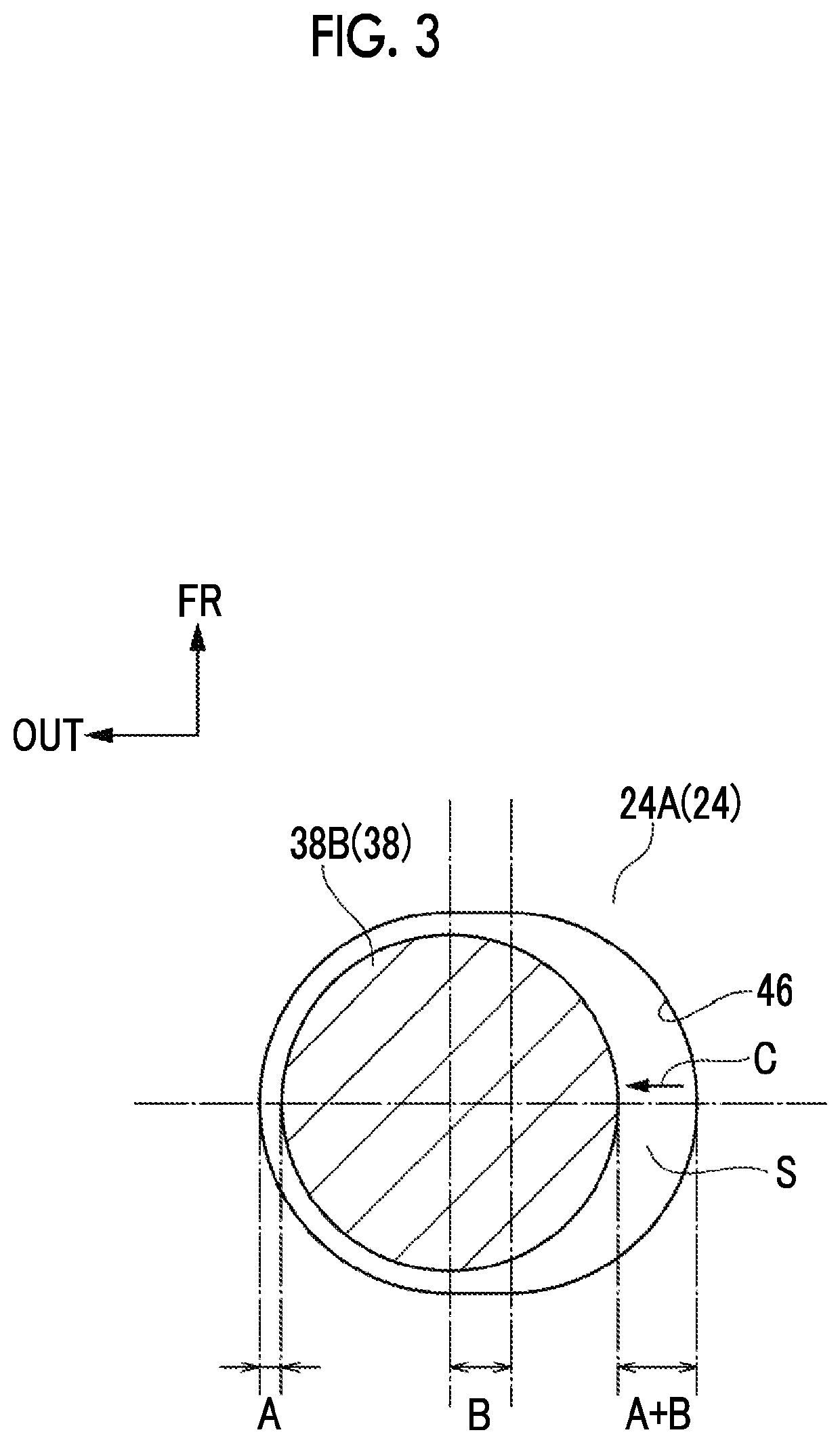

Vehicular panel structure

ActiveUS20180170451A1Improve body rigidityImprove rigiditySuperstructure subunitsSuperstructure connectionsFastenerEngineering

A vehicular panel structure includes a panel, a reinforcement disposed inward of the panel in a vehicle, and mastic that bonds the panel and the reinforcement to each other. The reinforcement is provided with a body portion constituting a middle portion in a longitudinal direction and having a linear expansion coefficient smaller than the linear expansion coefficient of the panel, a connection portion constituting an end portion in the longitudinal direction, and a joining portion allowing the body portion and the connection portion to be joined to each other by a thermosetting adhesive and a fastener. A long hole portion is disposed in the reinforcement and is formed in either the connection portion or the body portion. The fastener is inserted into the long hole portion.

Owner:TOYOTA JIDOSHA KK

Pin type porcelain insulator and preparation method thereof

InactiveCN111646777AAvoid agglomeration and condensationHigh breaking strengthAntifouling/underwater paintsPaints with biocidesFiberMetallurgy

The invention discloses a pin type porcelain insulator and a preparation method thereof and relates to the technical field of insulators; the pin-type porcelain insulator is prepared from the following raw materials in parts by weight: 16-24 parts of mullite12-20 parts of vermiculite, 12-18 parts of clay, 8-16 parts of zeolite powder, 10-18 parts of mica powder, 20-30 parts of allophane, 10-20 parts of medical stone, 2-6 parts of zircon sand, 4-10 parts of diatomite, 1-3 parts of sodium hexametaphosphate, 1-3 parts of nano silicon nitride, 1-5 parts of nano calcium carbonate, 0.8-1.4 parts ofsepiolite fiber, 0.4-1 part of lignin fiber, 1-5 parts of hexamethyldisilazane, 1-5 parts of dimethylformamide and 3-7 parts of vinyltriethoxysilane. The pin type porcelain insulator has the beneficial effects that the raw materials are reasonably matched, and a proper preparation method is adopted, so that the structural strength and breaking strength of the insulator are improved, and the service life of the insulator is prolonged.

Owner:萍乡欧姆绝缘子有限公司

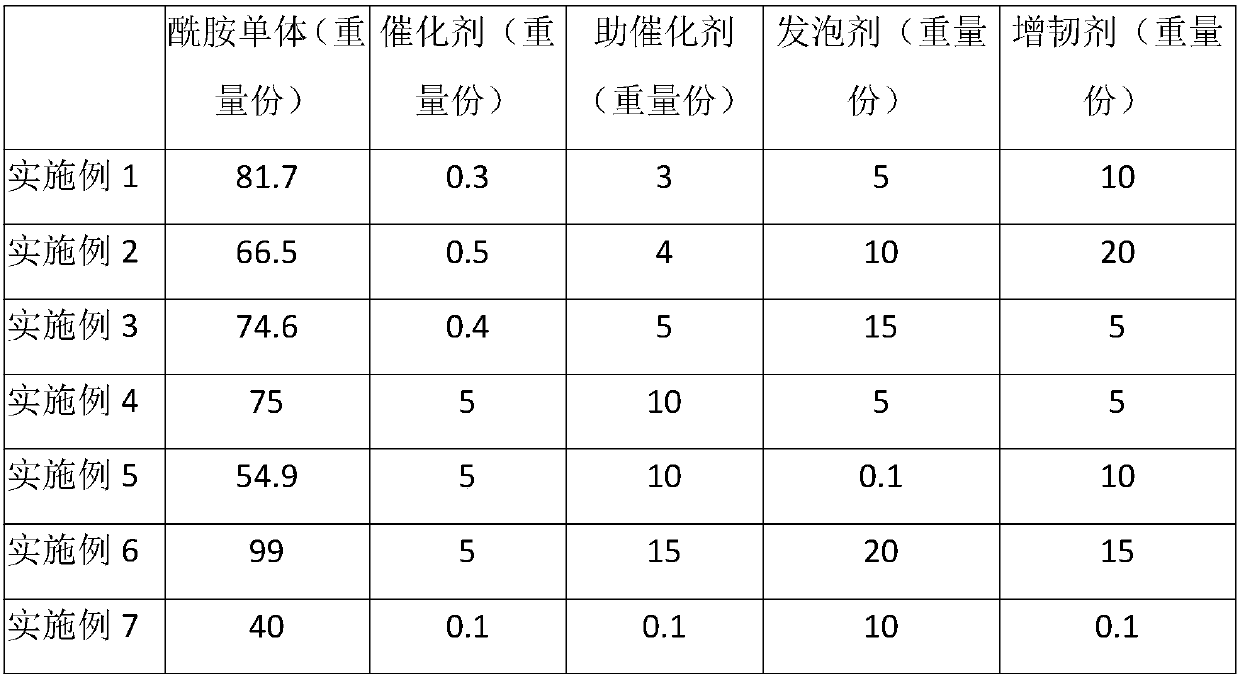

Lightweight foaming casting nylon material and its preparation method and application

The invention discloses a lightweight foaming casting nylon material, which is prepared from, by weight, 40-99.6 parts of amide monomer, 0.1-5 parts of catalyst, 0.1-15 parts of promoter, 0.1-20 partsof foaming agent, and 0.1-20 parts of flexibilizer. The lightweight foaming casting nylon material aims to solve the shortcomings of uncontrollable foaming and poor mechanical performance during theprocess of the existing foaming and casting production. By compounding the foaming agent with the flexibilizer and adjusting the MCPA6 formula technique, the foaming agent is foamed in a MCPA6 monomermelt, so as to further polymerize and shape. The lightweight foaming casting nylon material solves the problem of shaping and contraction of MCAP6. The invention further provides a preparation technique of the lightweight foaming casting nylon material; the foaming technique of the material is stable and the material is good in mechanical performance. The lightweight foaming casting nylon material can be widened to its application domain, and applied to lightweight, shock reduction and noise reduction of an automobile.

Owner:HUNAN UNIV OF TECH

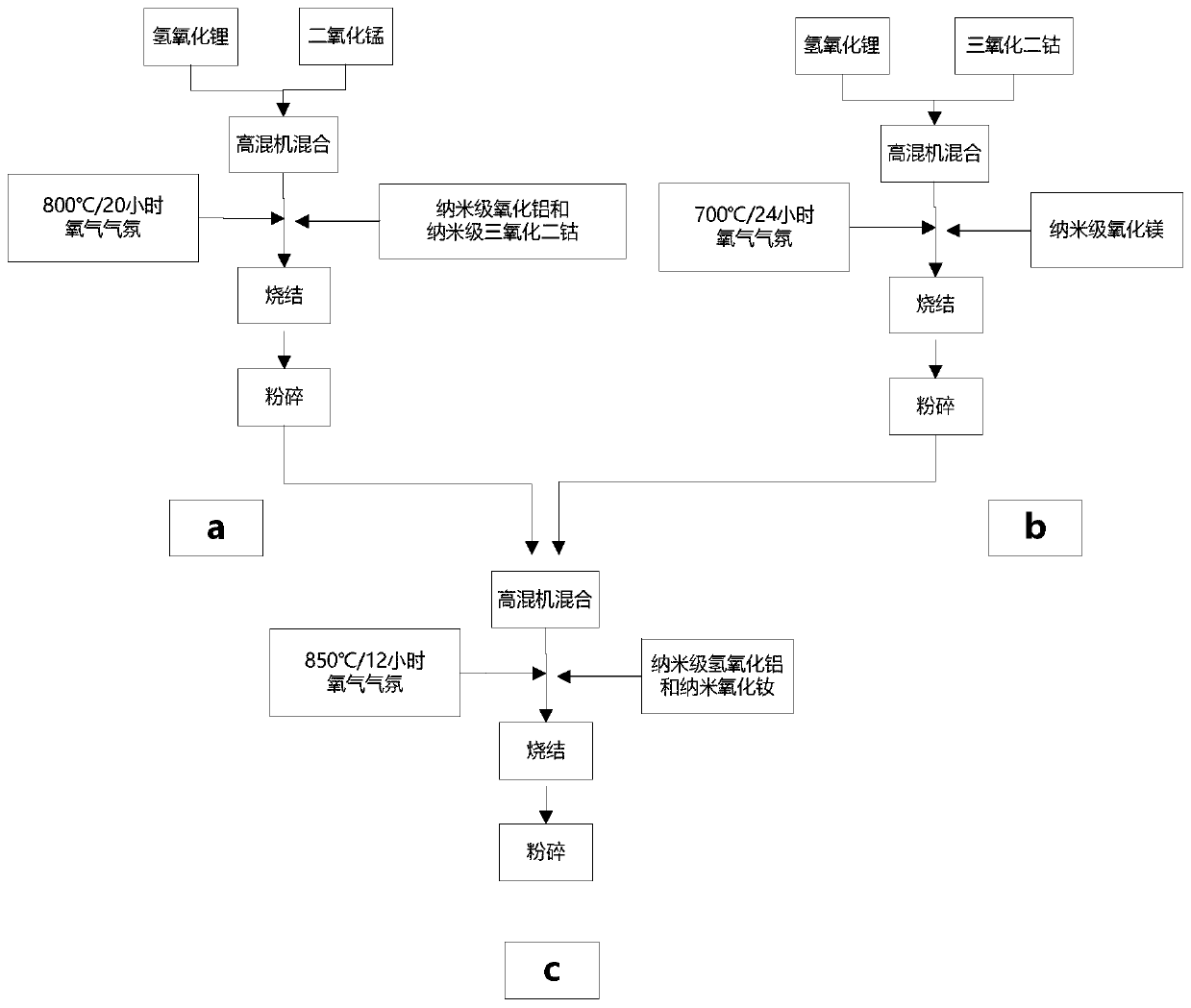

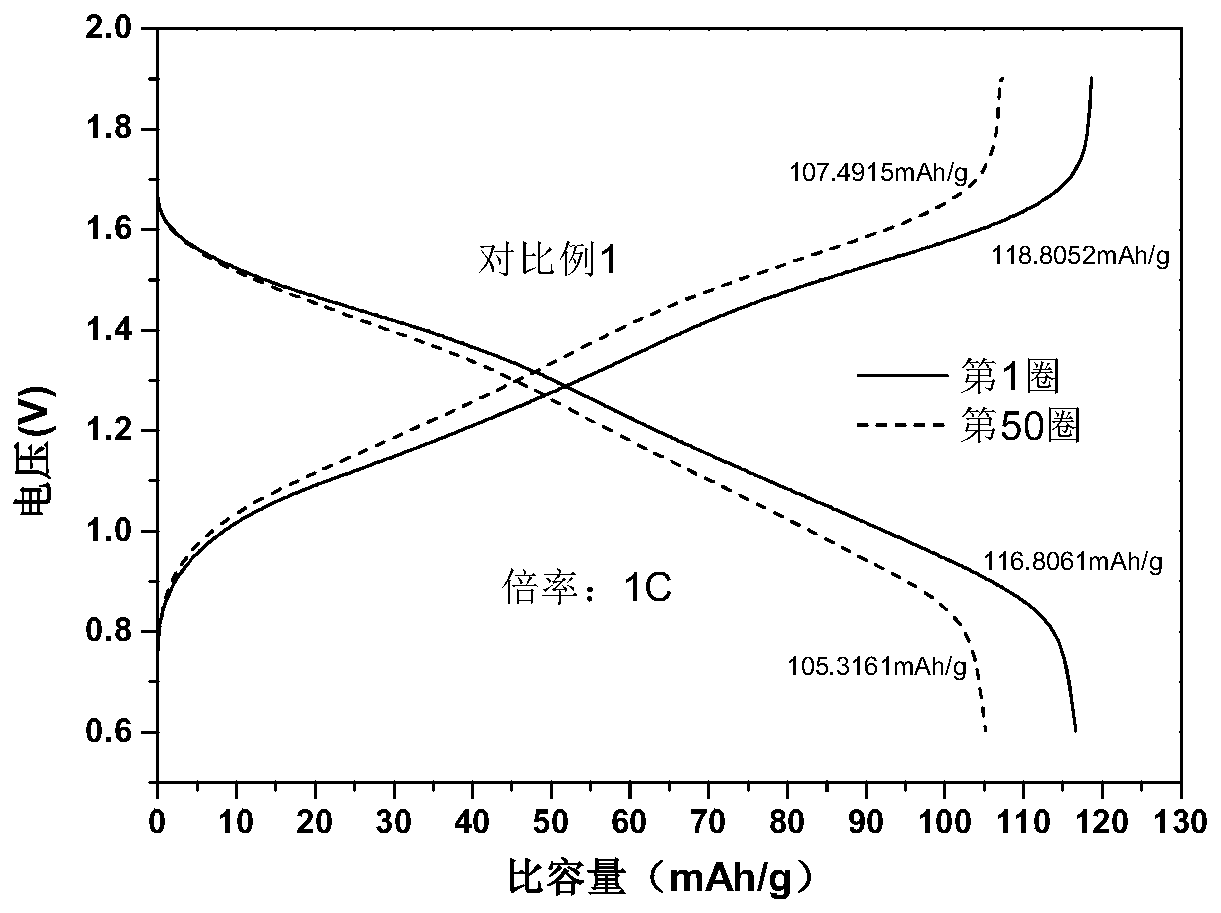

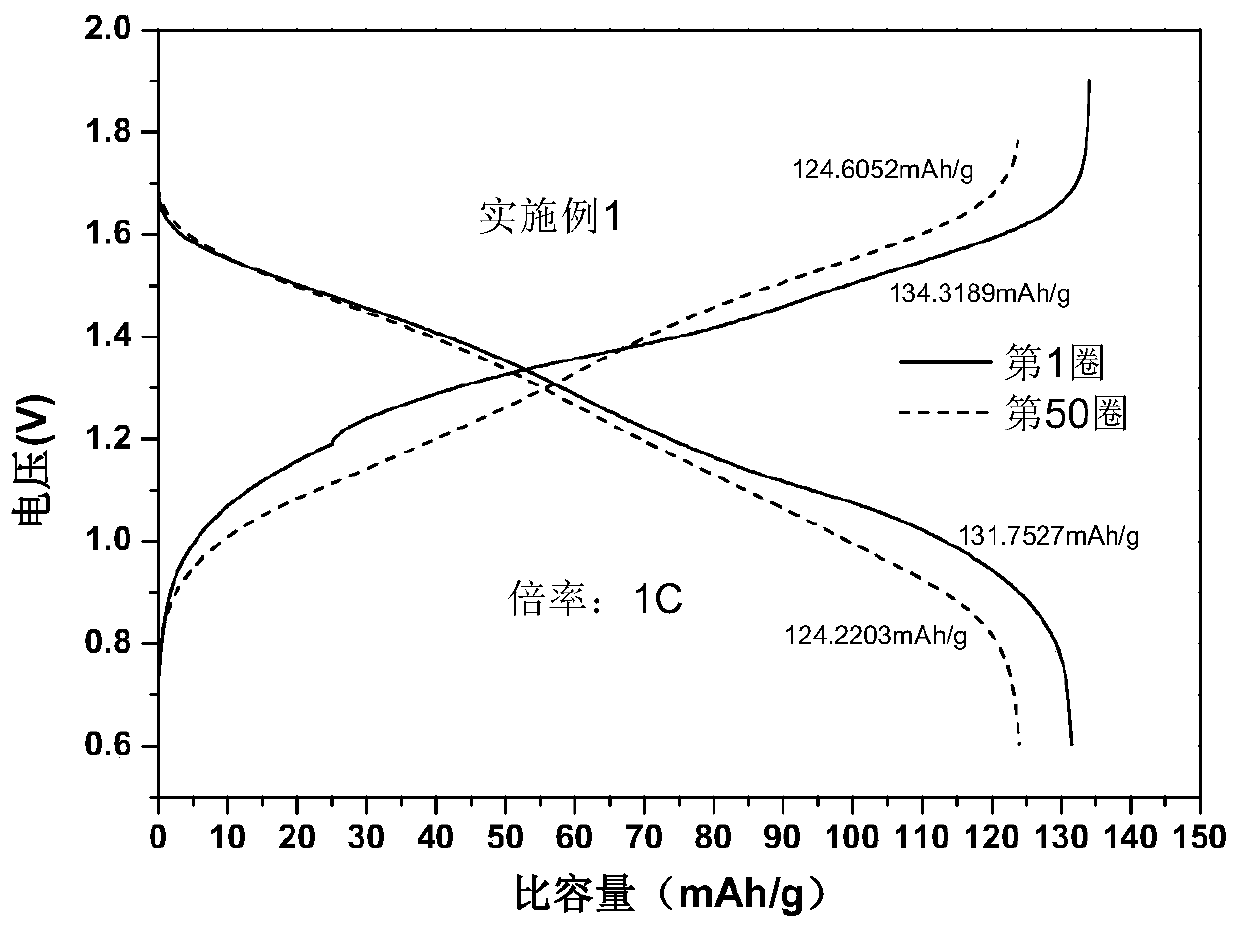

Composite positive electrode material, preparation method thereof and aqueous secondary battery

InactiveCN111477859AImprove cycle efficiencyReduce volumeSecondary cellsPositive electrodesElectrical batteryMaterials science

The invention discloses a composite positive electrode material capable of being used for a long-cycle lithium ion battery. The composite positive electrode material comprises modified lithium manganate and modified lithium cobalt oxide, and aluminum hydroxide and neodymium oxide which coat the surfaces of the modified lithium mangnate and the modified lithium cobalt oxide. Wherein the modified lithium manganate is doped with aluminum and cobalt elements; wherein the modified lithium cobalt oxide is doped with a magnesium element. The invention also discloses a preparation method of the composite positive electrode material and an aqueous secondary battery. According to the composite positive electrode material, the composite positive electrode material is synthesized by adopting a high-temperature solid-phase method, so that double modification of material doping and coating is realized, the technological process is greatly simplified, the compaction density of an electrode plate in the battery preparation process and the cycling stability in the battery cycling process are improved, and large-scale production is facilitated.

Owner:NINGBO FENGCHENG NANOTECHNOLOGY CO LTD

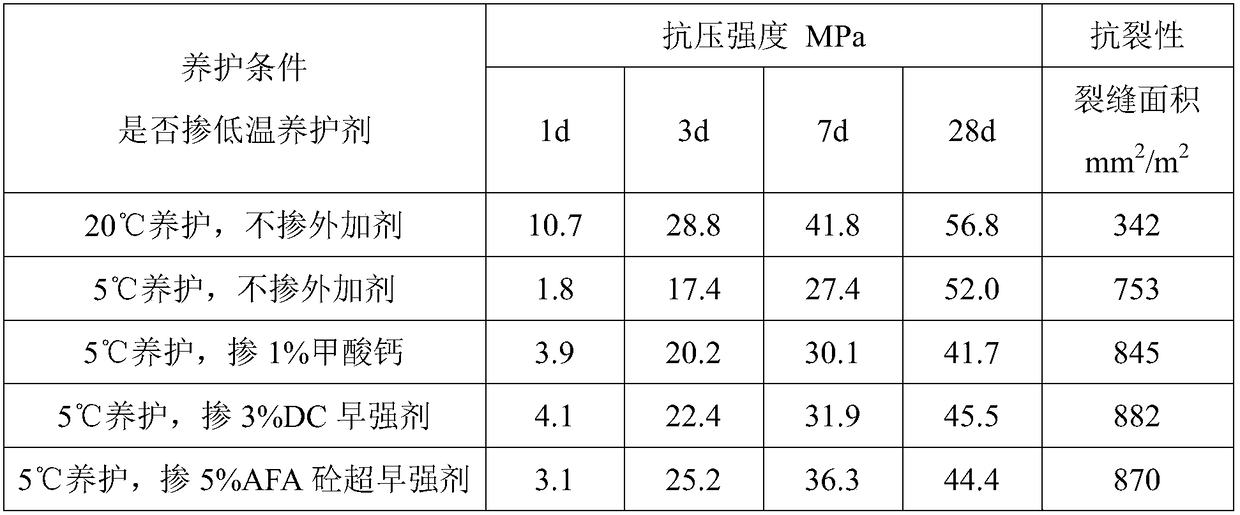

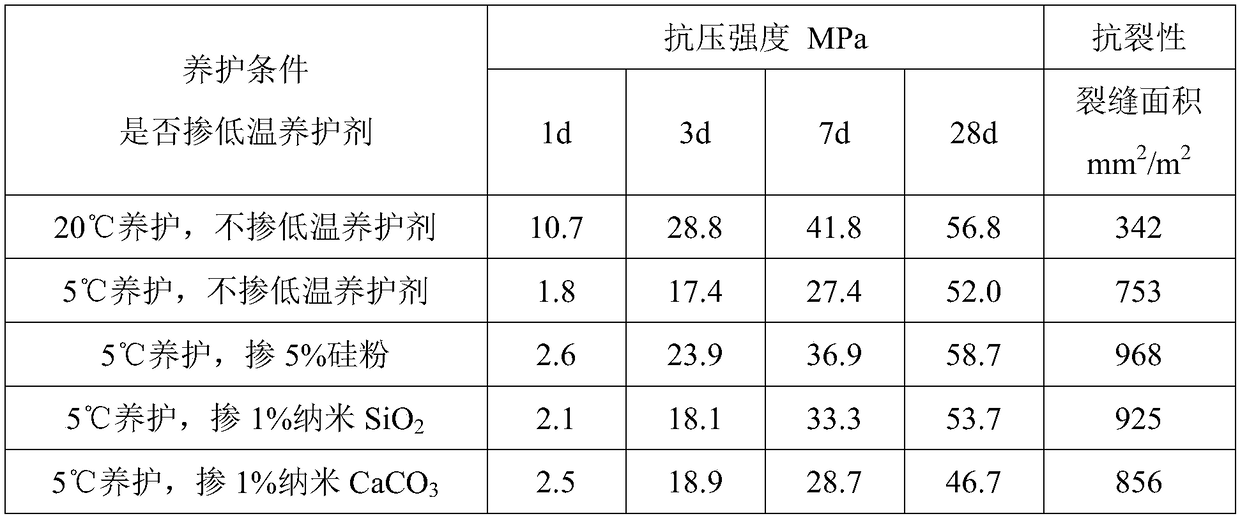

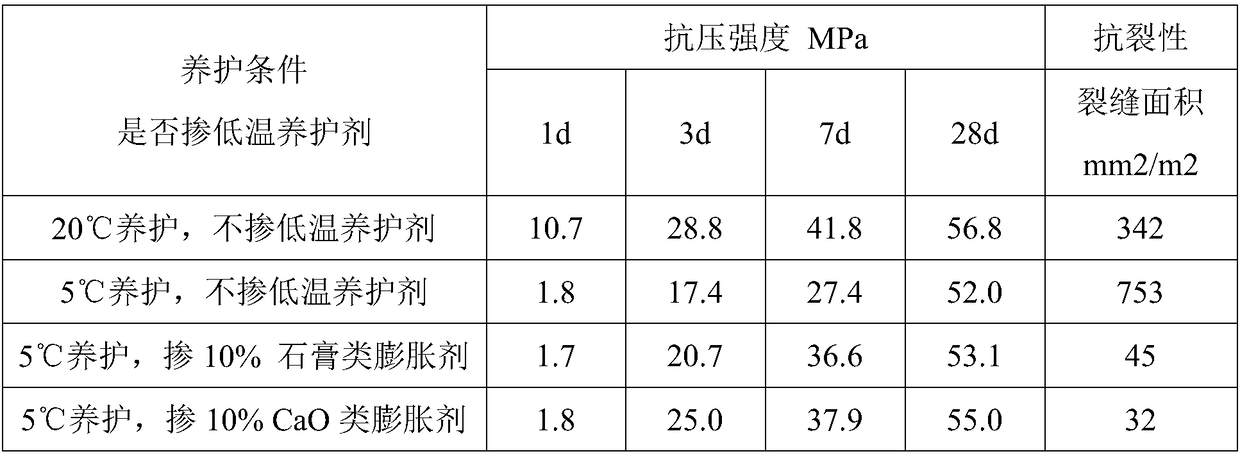

Concrete low-temperature curing agent

ActiveCN108191293AIncreased rate of strength developmentOffset shrinkageAlkaline earth metalLow temperature curing

The invention discloses a concrete low-temperature curing agent, which is prepared from the following ingredients in percentage by mass: 4 to 60 percent of cement hydration catalysis ingredients, 35 to 95 percent of anti-cracking ingredients and 0.3 to 10 percent of plastification ingredients, wherein the cement hydration catalysis ingredients are prepared from crystal nucleus and catalysts; the crystal nucleus is prepared by compounding one or several kinds of materials from nanometer silicon dioxide, nanometer calcium carbonate and nanometer aluminum oxide; the catalysts are prepared from one or several kinds of materials from lithium nitrate, ferric sulfate and alkali-earth metal halide. The concrete low-temperature curing agent does not contain chlorine or alkali; all ingredients are cooperated to achieve the effect of accelerating the hydration process of the concrete under the low-temperature condition; when the agent is added into the concrete at the mixing quantity of 5 to 10 percent, the intensity of the concrete in a low-temperature environment being 0 to 5 DEG C is not lower than the intensity of the concrete of the same mixture ratio under the standard curing conditionof 20 DEG C; the curing cost of the concrete at the low-temperature climate can be greatly reduced; meanwhile, no obvious influence exists on the work performance and deformation performance of the concrete.

Owner:NANJING HYDRAULIC RES INST

Preparation method of high temperature heat storage material

InactiveCN100427563CReduce dosageReduce production energy consumptionMachines/enginesHeat-exchange elementsHigh temperature storageKyanite

The invention relates to high temperature storage material manufacturing method. It includes selecting material, mixing, and preparing. It includes the following steps: using basalt as coarse aggregate, bauxite as fine aggregate, and aluminate cement as cementation agent; and adopting silicon micro-powder, activated alumina powder, natural graphite powder, and kyanite micro-powder as material; mixing them; adding 4-6% water; putting in steel mould and demoulding after 24 hours; setting in water at 20-25 centigrade degree for 72 hours; and baking at 100-120 centigrade degree for 24 hour. The formed material has high all round properties, and can avoid environmental pollution.

Owner:WUHAN UNIV OF TECH

Suspension insulator and preparation method thereof

InactiveCN111646779AImprove structural strengthExtended service lifeClaywaresPyrrolidinonesKaolin clay

The invention discloses a suspension insulator and relates to the technical field of insulators. The suspension insulator is prepared from the following raw materials in parts by weight: 22-30 parts of Kaolin, 16-24 parts of vermiculite, 10-18 parts of allophane, 0.5-1.5 part of sepiolite fiber, 0.5-1 parts of lignin fiber, 1-3 part of polypropylene fiber, 10-16 parts of natural zeolite powder, 12-20 parts of mica powder, 5-15 parts of barite powder, 20-30 parts of nacrite, 10-20 parts of bailai stone, 5-10 parts of zircon sand, 1-7 parts of polyvinylpyrrolidone, 1-3 parts of chromium sesquioxide, 1-3 parts of boron oxide, 1-3 parts of polyacrylic acid ethyl ester and 1-4 parts of vinyltriethoxysilane. The invention further discloses a preparation method of the insulator. The invention hasthe beneficial effects that the raw materials are reasonably matched, and a proper preparation method is adopted, so that the structural strength and breaking strength of the insulator are improved,and the service life of the insulator is prolonged.

Owner:萍乡欧姆绝缘子有限公司

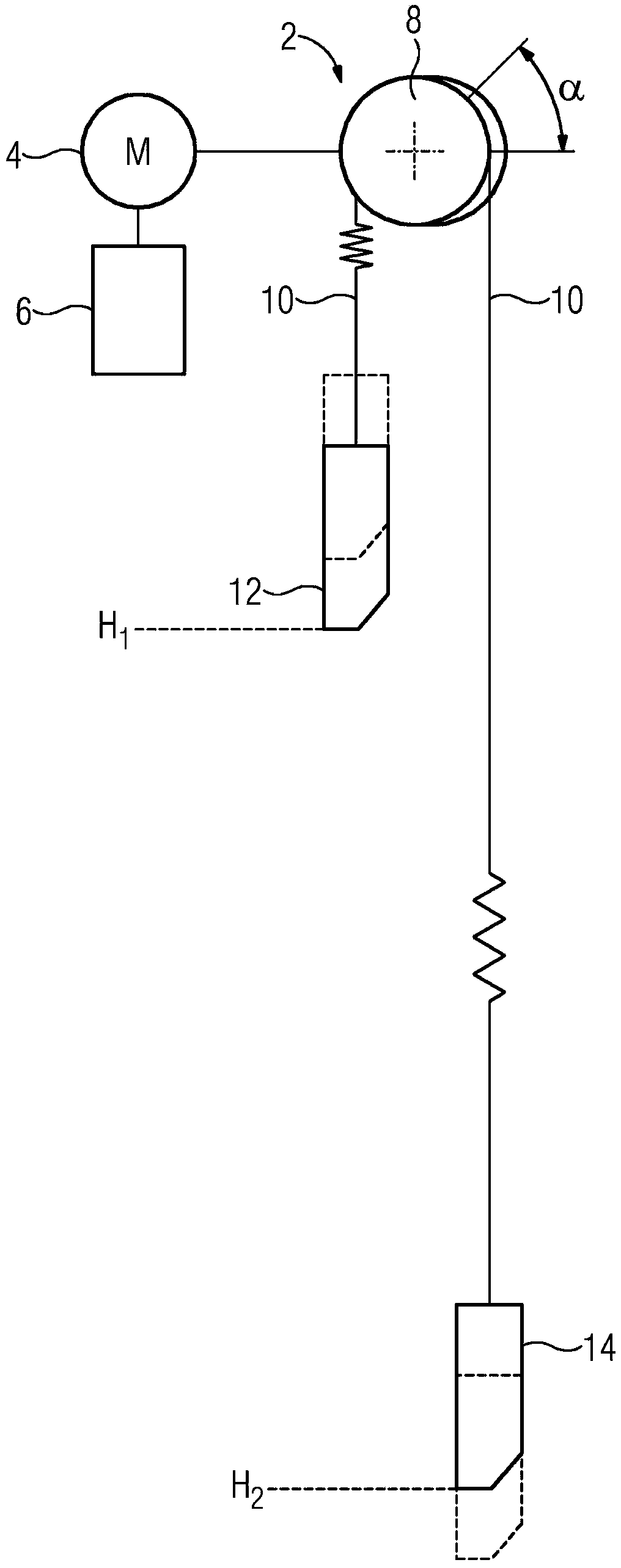

Method for driving and controlling hoist, hoist and control device for driving and controlling hoist driver

ActiveCN108290717BIncrease the lengthDoes not trigger vertical oscillationElevatorsMine liftsEngineeringCable carrier

The invention relates to a method for actuating a hoist (2), in particular for a shaft hoisting system, comprising a drive (4) having an associated control device (6), a cable carrier (8), at least one hoisting cable (10), and at least one hoist container (12, 14) for the vertical transport of transported material. The hoisting cable (10) elongates during loading of the hoist container (12, 14) due to the weight increase of the hoist container (12, 14). During unloading of the hoist container (12, 14), the hoisting cable (10) contracts again. In order to ensure height compensation during loading and unloading of the at least one hoist container, the drive (4) remains activated during loading or unloading and, to compensate for a change to the hoisting cable length, a rotation angle (α) of the cable carrier (8) is continually adjusted based on a predetermined rotation angle progression.

Owner:SIEMENS AG

Vehicular panel structure

ActiveUS11059524B2Suppression of distortionOffset shrinkageSuperstructure subunitsSuperstructure connectionsAdhesive cementLinear expansion coefficient

A vehicular panel structure includes a panel, a reinforcement disposed inward of the panel in a vehicle, and mastic that bonds the panel and the reinforcement to each other. The reinforcement is provided with a body portion constituting a middle portion in a longitudinal direction and having a linear expansion coefficient smaller than the linear expansion coefficient of the panel, a connection portion constituting an end portion in the longitudinal direction, and a joining portion allowing the body portion and the connection portion to be joined to each other by a thermosetting adhesive and a fastener. A long hole portion is disposed in the reinforcement and is formed in either the connection portion or the body portion. The fastener is inserted into the long hole portion.

Owner:TOYOTA JIDOSHA KK

High-strength fireproof heat-preserving castable

The invention discloses a high-strength fireproof heat-preserving castable. The castable is prepared from the following components in parts by weight: 50 to 55 parts of 1 to 8 mm light-weight konite, 5 to 10 parts of perlite raw ore, 10 to 25 parts of 1mm to 0mm light-weight Bonite, 5 to 10 parts of 200-mesh light-weight pyrophyllite powder, 5 to 10 parts of 325-mesh light-weight mullite fine powder, 5 to 10 parts of silica powder, 5 to 10 parts of Al2O3 micro powder with a particle size of 2 to 3 micrometers, 3 to 8 parts of aluminate cement, 5 to 10 parts of 0.25 to 1.5 mm glass beads, 0.31 part of sodium hexametaphosphate, and 0.3 part of explosion-proof fibers. The low heat-conduction fireproof energy-saving castable is obtained by virtue of the steps of stirring, uniformly mixing, oscillating molding, maintaining and baking and has the characteristics of light weight, high strength, low heat conduction coefficient, high temperature resistance, low water absorption rate and good compactness.

Owner:张静芬

Positioning element with recesses for a guide vane arrangement

ActiveUS20180058263A1Reduce the impactReduce impactEngine manufactureEngine fuctionsCouplingEngineering

The invention relates to a positioning element for a guide vane arrangement of a guide vane stage of a gas turbine, with at least one base section curved in the peripheral direction; a plurality of uptake openings arranged next to each other in the peripheral direction on the base section, whose aperture axis runs substantially in the radial direction and which are designed to take up a respective radially inner guide vane section; a coupling section provided on the base section, which is or can be coupled to a seal carrier of a seal arrangement. According to the invention, it is proposed that at least one recess is provided in the base section, which is arranged between two neighboring uptake openings and runs from inside to outside at least in the radial direction.

Owner:MTU AERO ENGINES GMBH

A kind of plastic for intermediate frequency furnace lining repair and its preparation method

The invention relates to a plastic material for repairing a medium-frequency furnace lining and a preparation method of the plastic material. According to the technical scheme, the preparation method comprises the following steps: taking 18 to 30 percent by weight of aluminum oxide powder, 10 to 20 percent by weight of kyanite, 2 to 7 percent by weight of chromium oxide powder and 2 to 5 percent by weight of a plasticizer as base materials, and taking 50 to 65 percent by weight of alumina particles as aggregates, wherein the sum of the base materials and the aggregates are raw materials; mixing the base materials for 1 to 1.5h, then adding the aggregates and the mixed base materials into a mixing and grinding machine, adding 3 to 5 percent by weight of phosphoric acid and 3 to 5 percent by weight of water, mixing and grinding, thus obtaining semi-dry paste; aging, adding the aged semi-dry paste into the mixing and grinding machine, additionally adding 2 to 3 percent by weight of phosphoric acid, 0.05 to 0.15 percent by weight of a corrosion inhibitor, 0.1 to 0.5 percent by weight of a moisturizing agent and 3 to 5 percent by weight of water, mixing and grinding, thus obtaining mixed paste, extruding and molding the mixed paste, thus obtaining the plastic material for repairing the medium-frequency furnace lining. The production cost is low, the prepared product is long in storage time, easy to construct and excellent in application performance.

Owner:LENGSHUIJIANG HUAKE PERFORMANCE MATERIALS

Ladle castable for smelting of high manganese steel, and preparation method of ladle castable

The invention relates to a ladle castable for smelting of high manganese steel, and a preparation method of the ladle castable. The ladle castable is characterized in that 43-68 wt% of microporous corundum particles and 10-27 wt% of magnesium aluminate spinel particles are taken as aggregate, 5-15 wt% of microporous corundum fine powder, 2-4 wt% of magnesium aluminate spinel micro-powder, 4-8 wt%of pseudo-boehmite, 2-4 wt% of rhop-Al2O3 fine powder, 0.1-1 wt% of monoclinic phase zirconia fine powder and 0.1-1.5 wt% of manganese powder are used as matrix, and the aggregate and the matrix are taken as raw materials; organic fibers with an amount being 0.04-0.08wt% of the weight of the raw materials, a polycarboxylic acid water reducer with an amount being 0.1-0.5wt% of the weight of the rawmaterials, maleic acid with an amount being 0.2-0.5wt% of the weight of the raw materials and a defoaming agent with an amount being 0.01-0.03wt% of the weight of the raw materials are taken as additives. The preparation method comprises the steps of mixing the matrix, the additives and water to obtain a premix; spreading the aggregate into a mould, then pouring the premix into the mould, molding, drying, and demoulding to obtain the ladle castable for the smelting of the high manganese steel. The ladle castable is high in strength, good in thermal shock resistance, scouring-resistant and excellent in steel slag erosion resistance, and can improve the quality of the high manganese steel.

Owner:WUHAN UNIV OF SCI & TECH

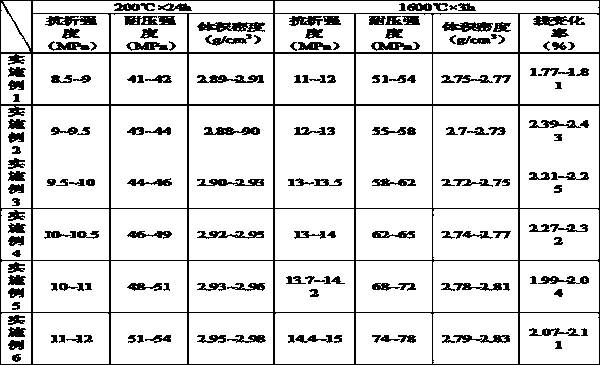

Multifunctional box culvert pipe gallery concrete and preparation method thereof

The invention discloses a multifunctional box culvert pipe gallery concrete and a preparation method thereof. The multifunctional box culvert pipe gallery concrete is prepared from, by weight, 20-25 parts of cement, 8-12 parts of sand, 9-18 parts of aggregate, 5-8 parts of microbeads, 8-15 parts of fly ash, 12-18 parts of zeolite, 4-6 parts of waterborne resin, 0.6-1.5 parts of an expanding agent,1-3 parts of composite fiber, 0.7-2 parts of a water reducing agent component and 12-20 parts of total water. The self-compacting and working performance of concrete can be obviously improved, meanwhile, the self-curing performance is achieved, and vertical cracking of a large-size, ultra-long and thin-wall concrete gallery body structure can be effectively reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

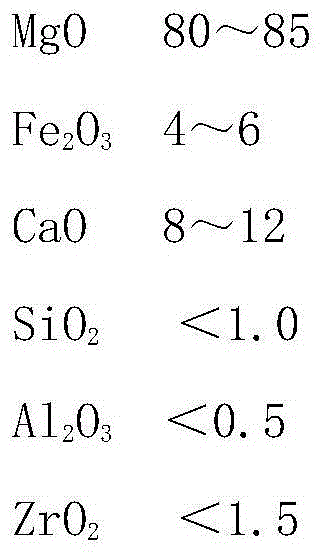

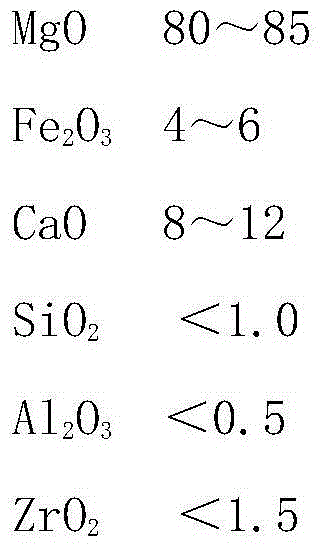

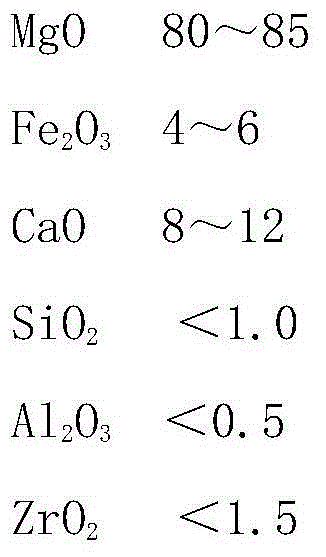

Preparation method of composite phase combined magnesium-base unshaped refractory material applied to bottom of electric furnace

The invention relates to a preparation method of a composite phase combined magnesium-base unshaped refractory material applied to the bottom of an electric furnace. The material is prepared from the following raw materials in parts by weight: 95-99 parts of a synthetic ball prepared from dolomite dust and iron oxide powder and 1-5 parts of desilicated zirconia, wherein the percentage of the dolomite dust MgO+CaO is larger than or equal to 80%; the percentage of the iron oxide powder Fe2O3 is larger than 98%; the percentage of the desilicated zirconia ZrO2 is larger than 98.5%; the preparation method comprises the following concrete steps: (1) preparing a dolomite dust-iron oxide powder synthetic ball by using the dolomite dust and the iron oxide powder; (2) processing the dolomite dust-iron oxide powder synthetic ball into fine powder with different particle sizes and mixing in proportion; (3) uniformly mixing and stirring the dolomite dust-iron oxide powder synthetic ball mixed powder and desilicated zirconia micro-powder of which the size is 325 meshes, and packaging a finished product in a bag. The preparation method disclosed by the invention has the advantages of improving the stability of material volume and preventing the problems of cracking, peeling and blocking of a steel discharging opening at the furnace body. By adding a special modifying agent desilicated zirconia and adopting a dolomite dust and iron oxide powder compounding technology, crystal type transformation, generated during material cooling, of the raw materials, is inhibited; surface pulverization of the furnace bottom is solved when the furnace is shut down; the service life of the material is further obviously prolonged.

Owner:海城市金福锋科技有限公司

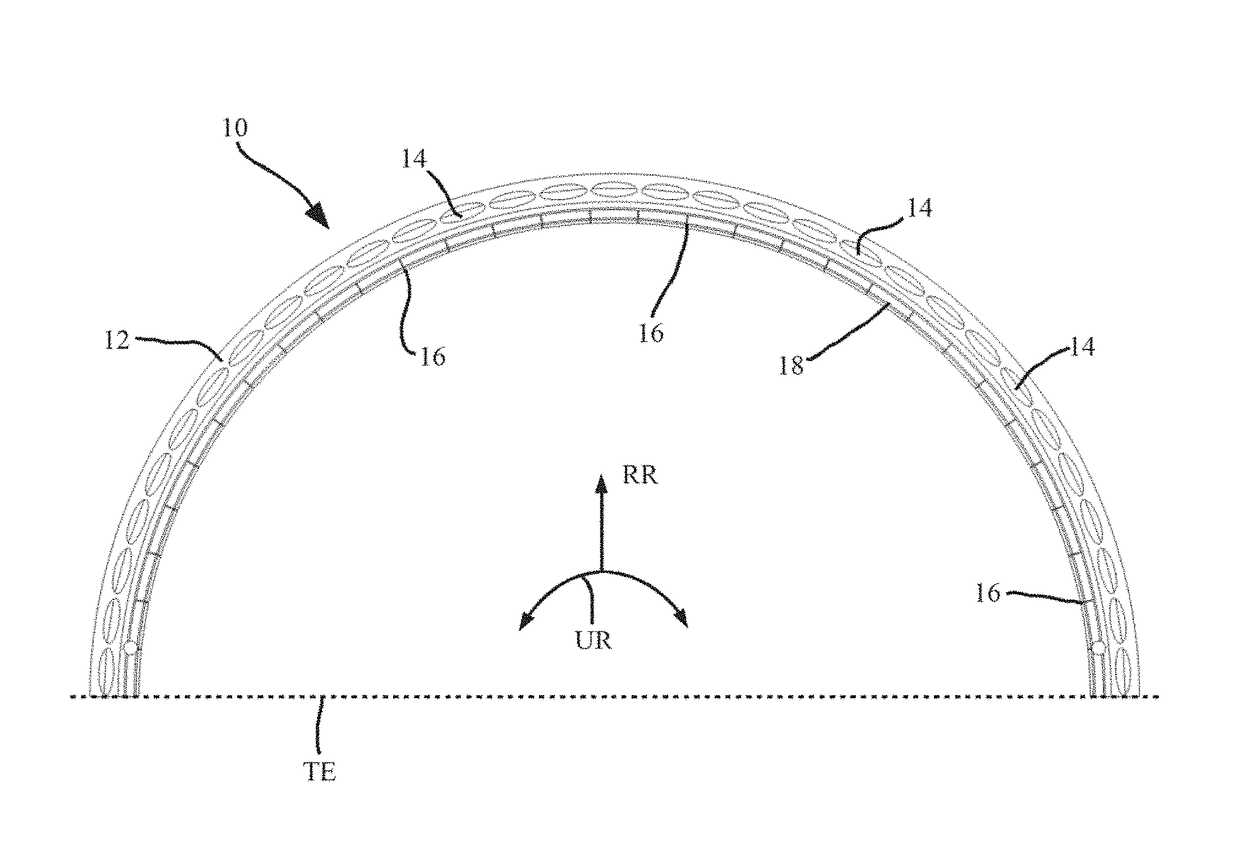

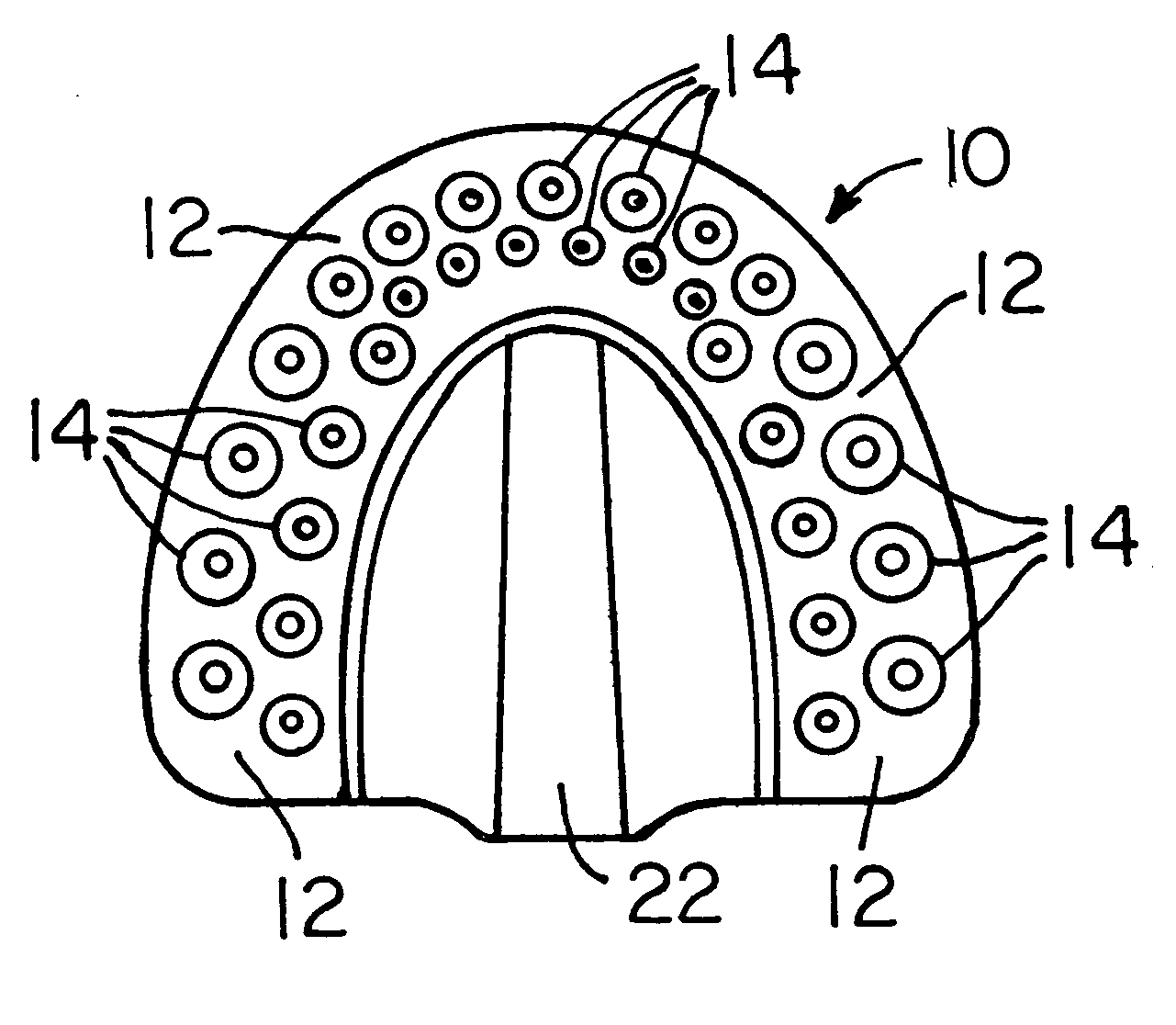

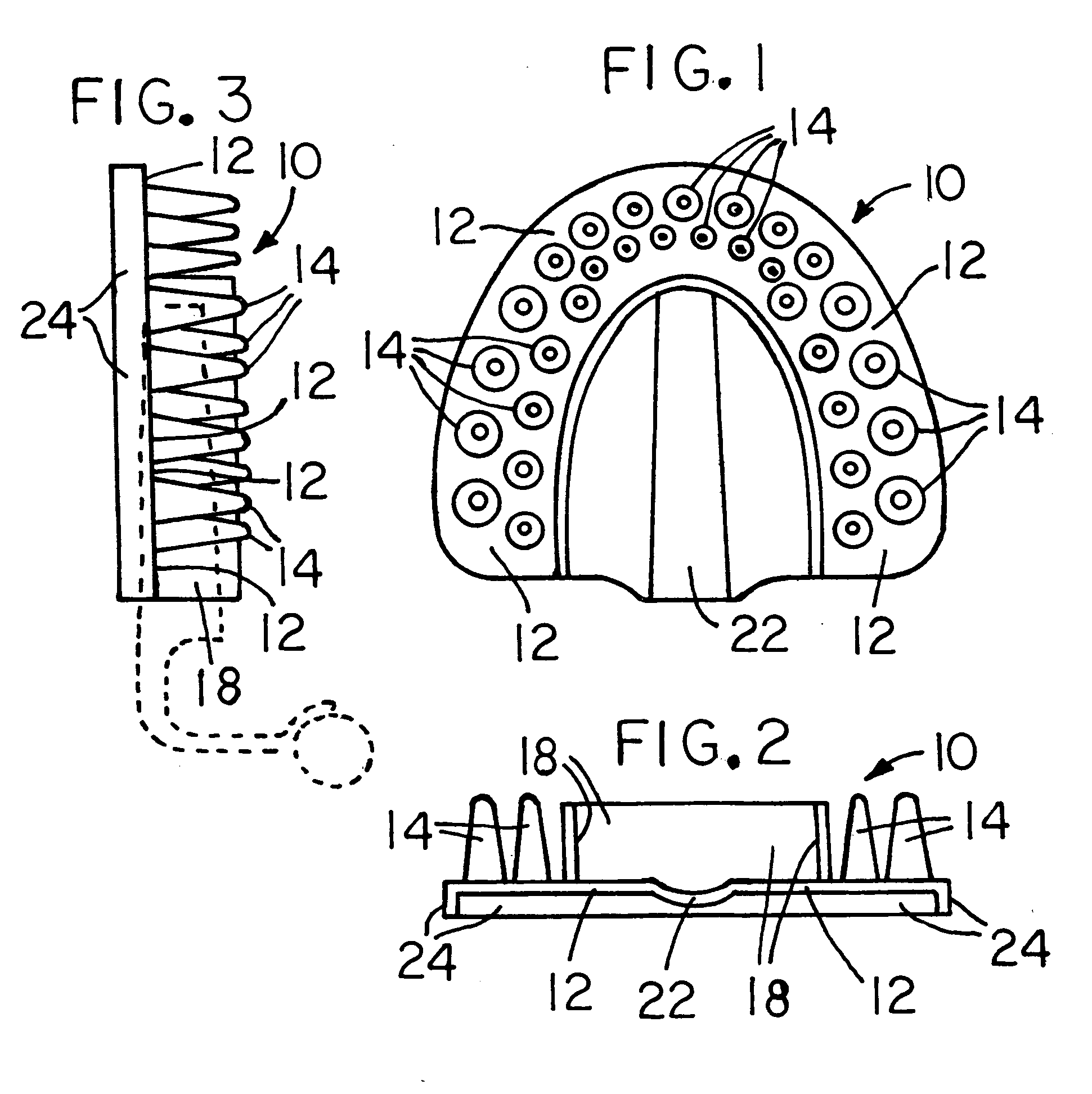

Dental model tray used in forming dental model

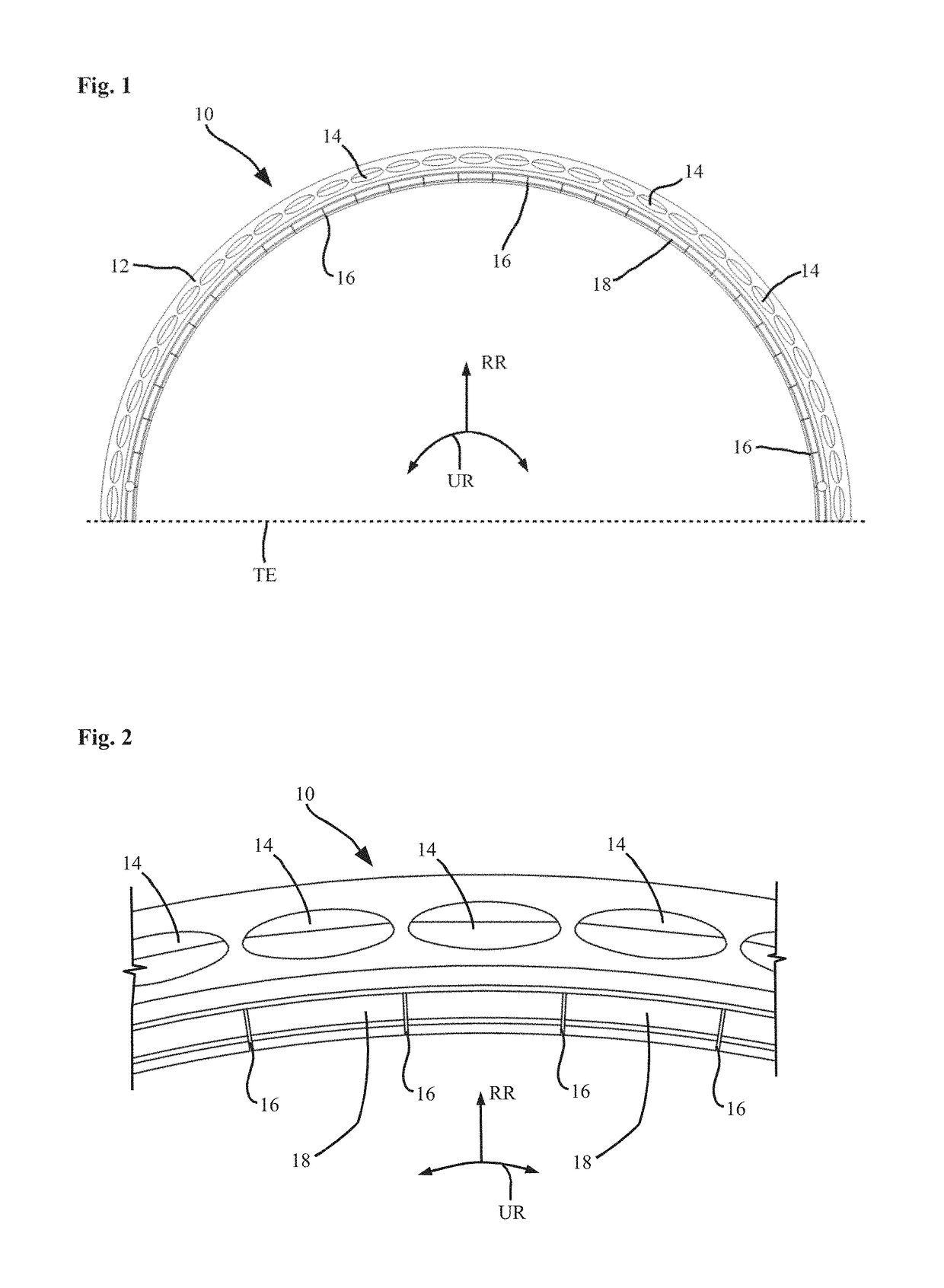

InactiveUS20050191595A1Easy to removeEasy to replaceImpression capsDental articulatorsEngineeringStructural engineering

Tray (10) for forming dental model comprises base wall (12) forming floor upon which dental casting material is poured. Spaced apart projections (14) extending upwardly from base wall (12). An upstanding axis of each projection (14) is substantially perpendicular to the upper face of the base wall (12). Projections (14) are arranged in two rows, with the projections (14) in one row being offset from corresponding projections (14) in the other row. Sidewalls of each projection (14) taper inwardly at an angle of between about 82 to 88 degrees with the upper face of the base wall (12). Each projection (14) has a thickness at its base of about 3 to 7 millimeters. The projections (14) are spaced from each other at their bases by a distance of from 0 to 5 millimeters.

Owner:GARLAND JAMES K

A kind of machine-pressed non-burning clay brick and preparation method thereof

The invention discloses a machine-pressed non-burning clay brick and a preparation method thereof, comprising the following components: hard clay, soft clay, quartz sand, pyrophyllite, dispersant, solid binder and liquid binder; Non-fired clay bricks can reach the normal temperature strength of fired clay bricks by drying at 120°C, without high temperature firing, low energy consumption, simple production process, high medium temperature strength, and small volume change at high temperature, which not only saves production The cost also reduces problems such as waste gas pollution caused by firing, omits the firing process of traditional clay bricks, and realizes energy saving and emission reduction of refractory clay bricks.

Owner:PUYANG REFRACTORIES GRP CO LTD +1

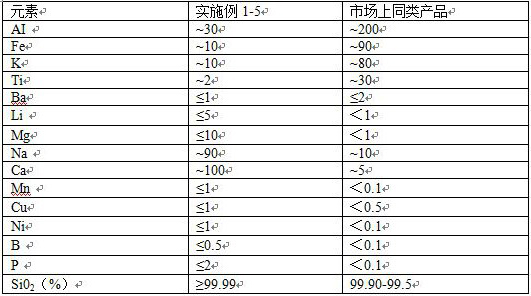

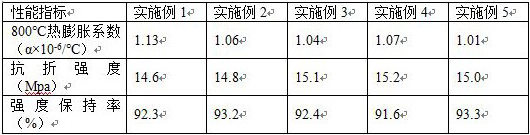

A kind of preparation technology of high refractory fused silica

A preparation process of high-refractory fused silica, comprising the following steps: (1) preparation of high-purity fused silica; (2) ingredients: the high-refractory fused silica, in parts by mass, mainly comprises the following components: 50-60 parts of high-purity fused silica powder, 40-50 parts of binder, 20-30 parts of cordierite, and 10-15 parts of sillimanite; batching is carried out according to the mass parts of each component in the formula; ( 3) Pretreatment: crushing, sieving and classifying high-purity fused silica powder, and wet ball milling, granulating, sieving, granulating and stale for binder, cordierite and sillimanite respectively; (4) mixing (5) molding; (6) drying; (7) firing. The preparation process of the high refractory fused silica of the present invention has the advantages of simple and efficient preparation process, reasonable formula design, high refractoriness and excellent thermal shock resistance, good chemical stability, small expansion coefficient, and thermal shock resistance. Low conductivity and broad application prospects.

Owner:徐州赛诺石英有限公司

High-performance cement-based material used for being poured into steel-concrete structure splicing joint

The invention discloses a high-performance cement-based material for being poured into a steel-concrete structure splicing joint. The high-performance cement-based material is characterized by comprising cement, a mineral admixture, yellow sand, an additive and water, In the volume of the cement-based material, the cement accounts for 778-924 Kg / m < 3 >, the mineral admixture accounts for 128-206 Kg / m < 3 >, the yellow sand accounts for 966-1090 Kg / m < 3 >, and the water accounts for 226-265 Kg / m < 3 >; and the additive accounts for 0.42%-0.55% of the mass of the cement. The cement-based material has the characteristics of small aggregate particle size, high flowability, capability of pouring special-shaped components or cavities, compact structure and no vibration.

Owner:SHAOXING SEIKO GREEN BUILDING INTEGRATED BUILDINGSYST IND

Corundum-mullite heat-insulating brick

The heat insulating corundum-mullite brick has the material composition comprising fused white corundum powder finer than 325 mesh 30-40 wt%, alpha-alumina powder finer than 325 mesh 20-30 wt%, gamma-alumina powder finer than 10 microns 20-30 wt%, sillimanite powder finer than 120 mesh 10-20 wt%, No. 1 Suzhou clay powder finer than 280 mesh 8-15 wt% and water 25-30 wt%, as well as foamed polystyrene balls of 0.5-2 mm size and saw dust in 0-0.5 mm size in certain amount. The heat insulating corundum-mullite brick has long service life, capacity of resisting high temperature up to 1700 deg.c, high resistance to various kinds one atmosphere, low heat conductivity, low heat capacity and excellent heat shock stability.

Owner:宜兴市中能耐火制品有限公司

Nanometer antirust coating for PVC pipe

InactiveCN108373662AReduce Shrinkage CrackingReduce dosageFireproof paintsAnti-corrosive paintsMicrometerCorrosion

The invention discloses a nanometer antirust coating for a PVC pipe. The nanometer antirust coating comprises, by weight, 20-30 parts of nanometer bentonite, 25-28 parts of nitrocellulose with particle sizes of 5-15 micrometers, 12-15 parts of medium sand, 2-4 parts of a filler, 0.5-0.8 parts of a high-efficiency water reducing agent, 2-4 parts of an Ag-Zn-containing inorganic antibacterial agent,4-6 parts of feldspar, 3-5 parts of an expansion agent, 3-6 parts of graphite powder and 2-4 parts of a rust inhibitor. The nanometer antirust coating can form a compact and hard coating on the surface of a PVC pipe and has high strength, high wear resistance, high temperature resistance, corrosion resistance and aging and warping resistance. The expansion agent can offset the shrinkage of the mortar and effectively reduce the shrinkage and cracking. The high-efficiency water reducer can reduce the use amount of water in the mortar, reduce the water-cement ratio, and reduce the shrinkage of the mortar during the setting process. The rust inhibitor improves the structural durability and helps to resist the corrosion of the steel bar in order to improve the sealing performance of a PVC pipeand effectively prolongs the service life of a PVC pipe.

Owner:青岛国福实业有限公司

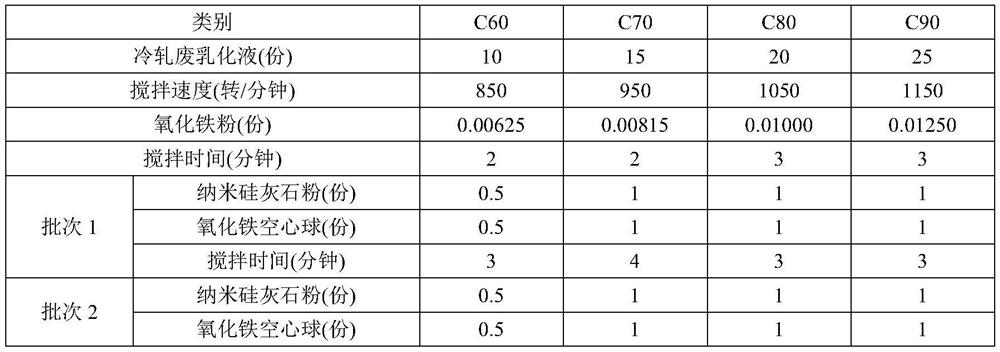

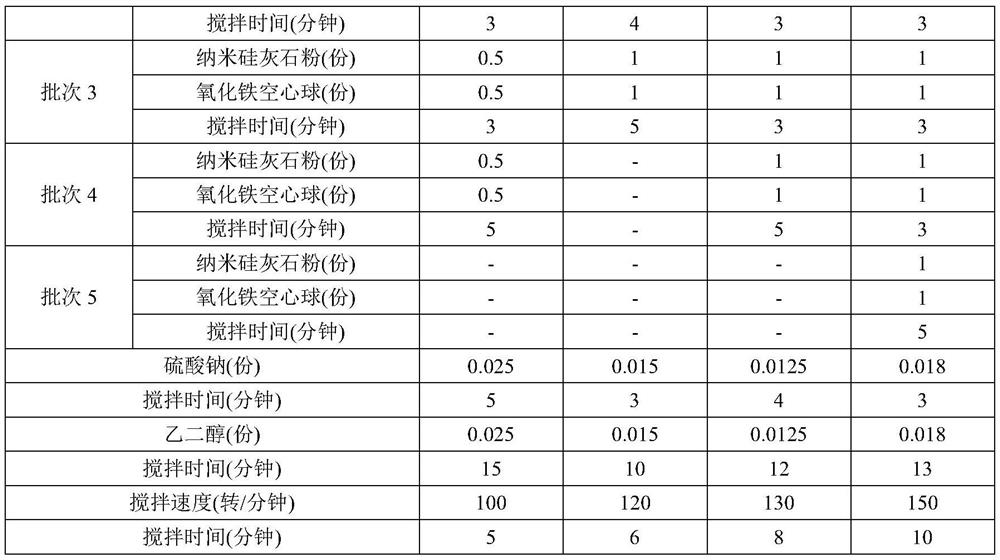

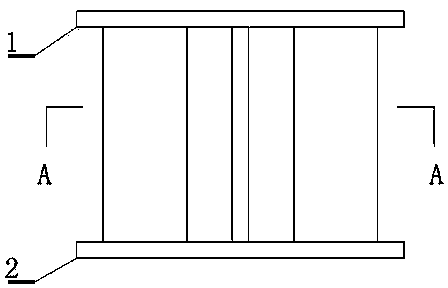

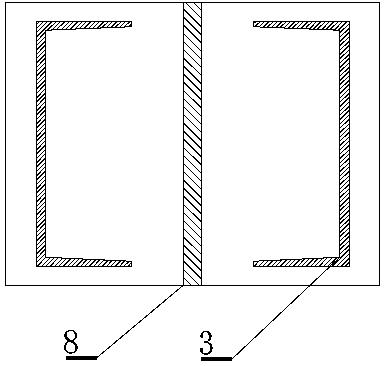

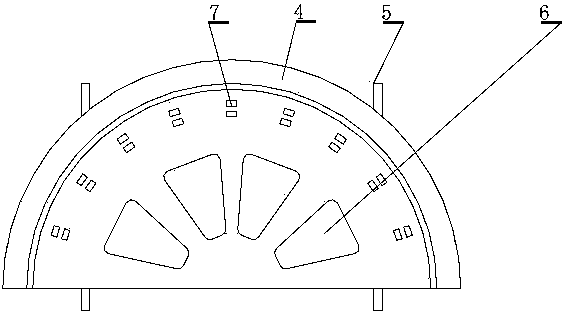

High-strength nano solid waste concrete prepared from iron oxide hollow spheres and method thereof

The invention provides high-strength nano solid waste concrete prepared from iron oxide hollow spheres and a method thereof, and the concrete comprises the following components: 100 parts of a cementing material, 155-196 parts of coarse aggregate, 132-282 parts of fine aggregate, 2.2-2.8 parts of a high efficiency water reducing agent, an admixture mainly composed of 2-5 parts of nanometer wollastonite powder, 2-5 parts of iron oxide hollow spheres, 1-4 parts of converter secondary dedusting ash, 10-25 parts of cold rolling waste emulsion, 0.0125-0.025 part of sodium sulfate, 0.00625-0.0125 part of iron oxide powder and 0.0125-0.025 part of ethylene glycol, and 29-32 parts of water. The preparation method comprises the following steps: mixing the coarse aggregate and the fine aggregate, adding the cementing material, conducting mixing, adding the high-efficiency water reducing agent and the make-up water, conducting mixing, conducting stirring, injecting the formed mixture into a concrete transport vehicle, and adding the converter digested secondary dedusting ash and the dispersed nanometer wollastonite powder before or simultaneously adding the water reducing agent and the make-up water. Dispersion of the nanometer material is promoted through the iron oxide hollow spheres, the strength of the nanometer solid waste concrete is improved, the mixing amount of metallurgical solid waste in the concrete is larger than or equal to 75%, and high-value utilization of the metallurgical solid waste is achieved.

Owner:ANGANG STEEL CO LTD

Preparation process of fused quartz with high fire resistance

The invention discloses a preparation process of high-fire-resistance fused quartz. The preparation process comprises the following steps: (1) preparing high-purity fused quartz; (2) burdening: on thebasis that the fused quartz with high fire resistance mainly comprises the following components in parts by mass: 50-60 parts of high-purity fused quartz powder, 40-50 parts of a binding agent, 20-30parts of cordierite and 10-15 parts of sillimanite, preparing the raw materials according to the mass parts of the components in the formula; (3) pretreatment: carrying out crushing, sieving and grading operations on the high-purity fused quartz powder, and respectively carrying out wet ball milling, granulation, sieving, granulation and aging on the binding agent, cordierite and sillimanite; (4)mixing the raw materials; (5) forming the semiproduct; (6) drying the semiproduct; and (7) firing the semiproduct. According to the preparation process of the high-fire-resistance fused quartz, the preparation process is simple and efficient, the formula design is reasonable, and the prepared fused quartz has high fire resistance, excellent thermal shock resistance, good chemical stability, smallexpansion coefficient, low thermal conductivity and wide application prospect.

Owner:徐州赛诺石英有限公司

Method for preventing deformation of large-size thin-wall annular casting during welding process

ActiveCN102528218BNo mouth opening/neck deformationNo distortionWelding accessoriesLarge sizeMaterials science

The invention relates to a method for preventing deformation during a welding process, in particular to a method for preventing the deformation of a large-size thin-wall annular casting during the welding process. The method is characterized in that the method comprises the following steps of: preparation before welding: preparing a shim plate used for supporting at least five points of the casting so as to ensure that the casting is padded flatly and cannot be deformed by external forces during the welding, and an anti-deformation welding tooling, and then fixing the casting on the tooling; pre-heating before welding; selection of parameters of the welding process; and control of the welding process. The method provided by the invention is unique; the quality of the casting can be ensured; the production cycle can be shortened; the working efficiency can be improved; and the production cost can be saved.

Owner:KOCEL STEEL

Micro-expansive cement prepared from fluidized bed combustion ash, and preparation method of cement

PendingCN113788634AOffset shrinkageReduced durabilityCement productionClinker (waste)Physical chemistry

The invention provides a micro-expansive cement prepared from fluidized bed combustion ash, and a preparation method of the cement. The micro-expansive cement comprises, by weight, 20-30% of fluidized bed combustion ash, 20-28% of clinker, 17-40% of slag, 20-25% of fly ash and a grinding aid, and the addition amount of the grinding aid is less than or equal to 0.5% of the total mass of the materials. The micro-expansive cement with stable performance is prepared by adjusting the matching proportion of the fluidized bed combustion ash, the clinker, the slag and the fly ash, and has the characteristics of high strength and small dry shrinkage coefficient. The preparation method of the micro-expansive cement effectively consumes the sulfur-fixing ash residues, is economical and energy-saving, not only improves the comprehensive utilization of the solid wastes, but also relieves the pressure of the environment, and accords with the green and environment-friendly concept.

Owner:长江三峡技术经济发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com