Patents

Literature

42results about How to "Large layer thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

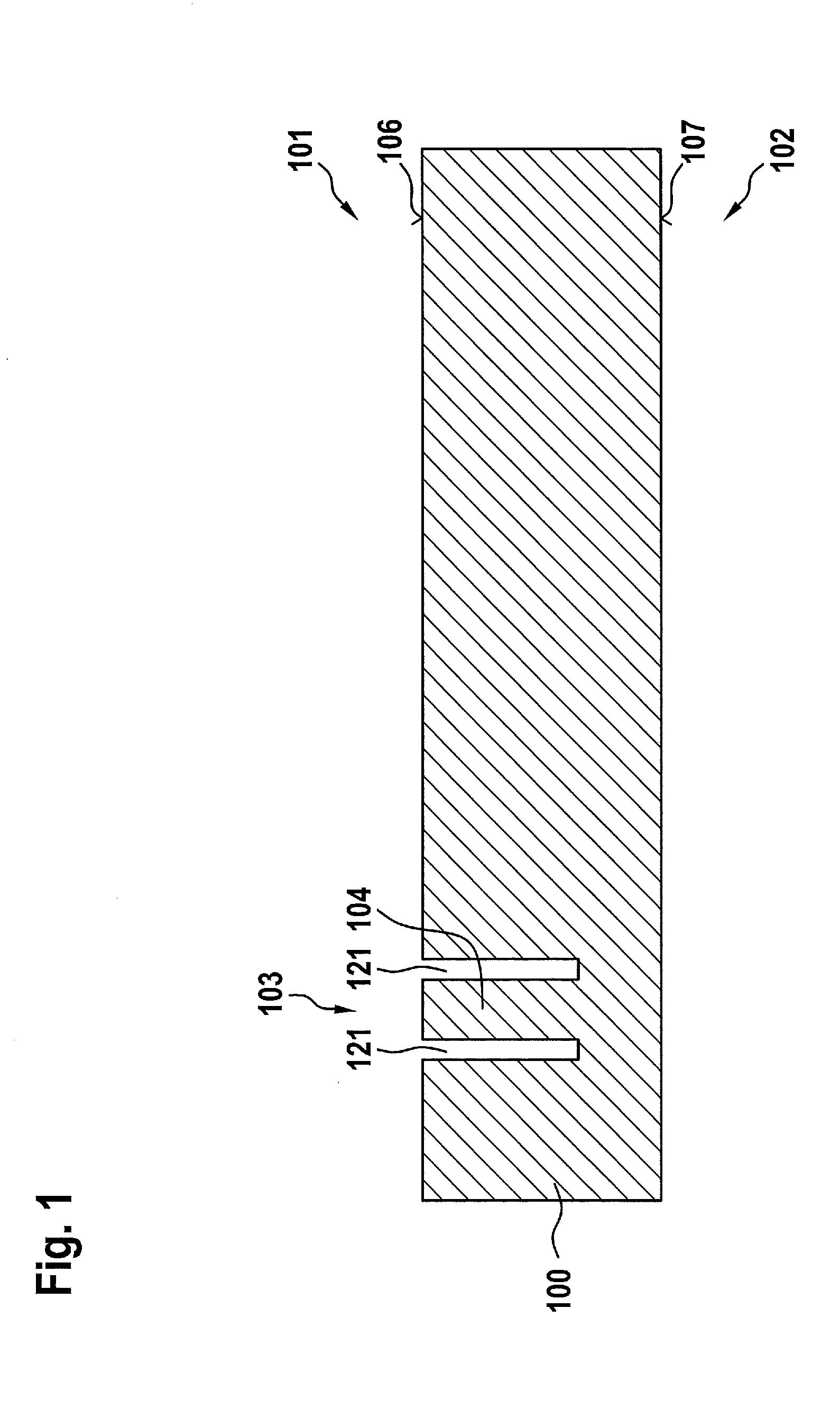

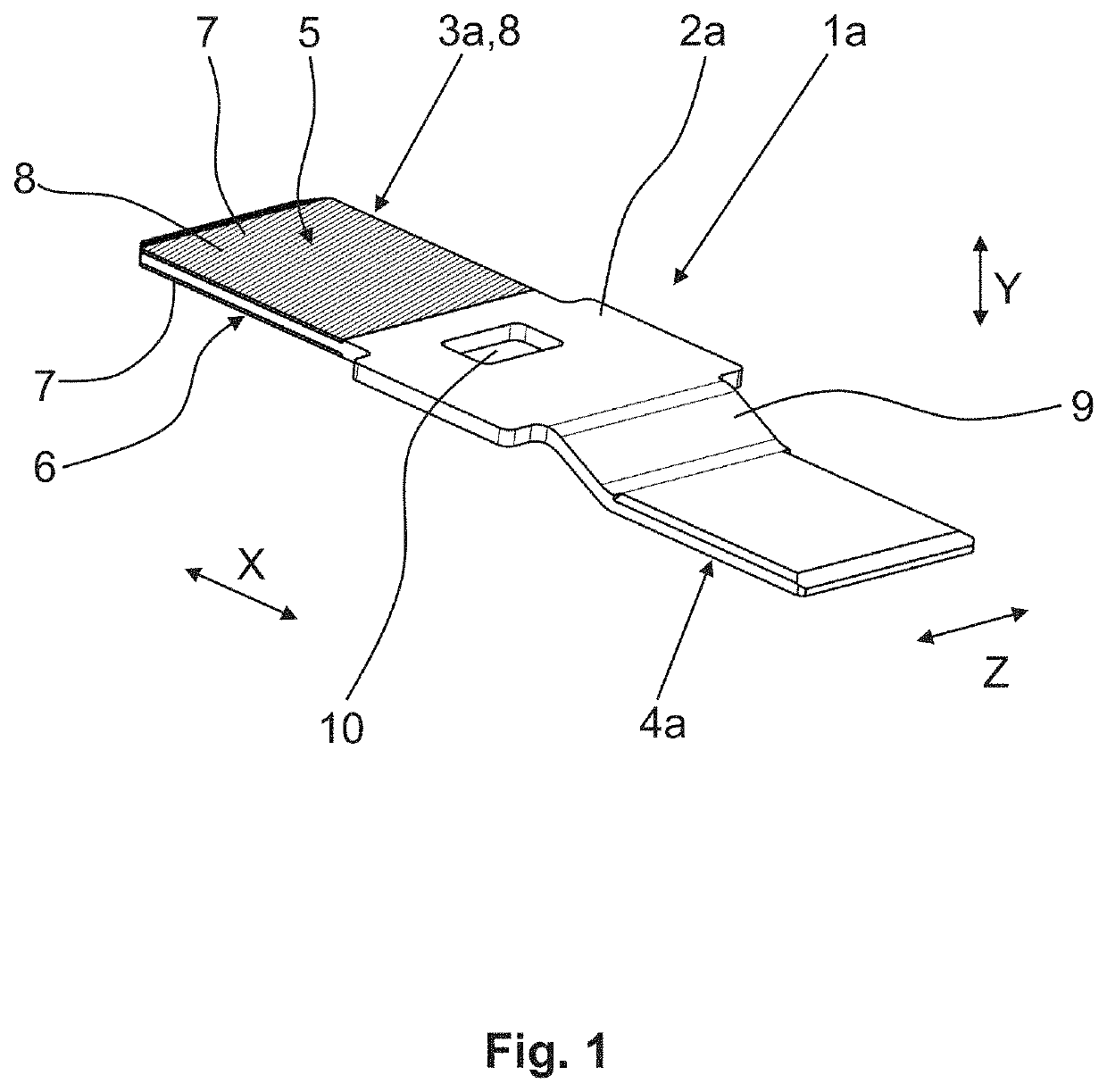

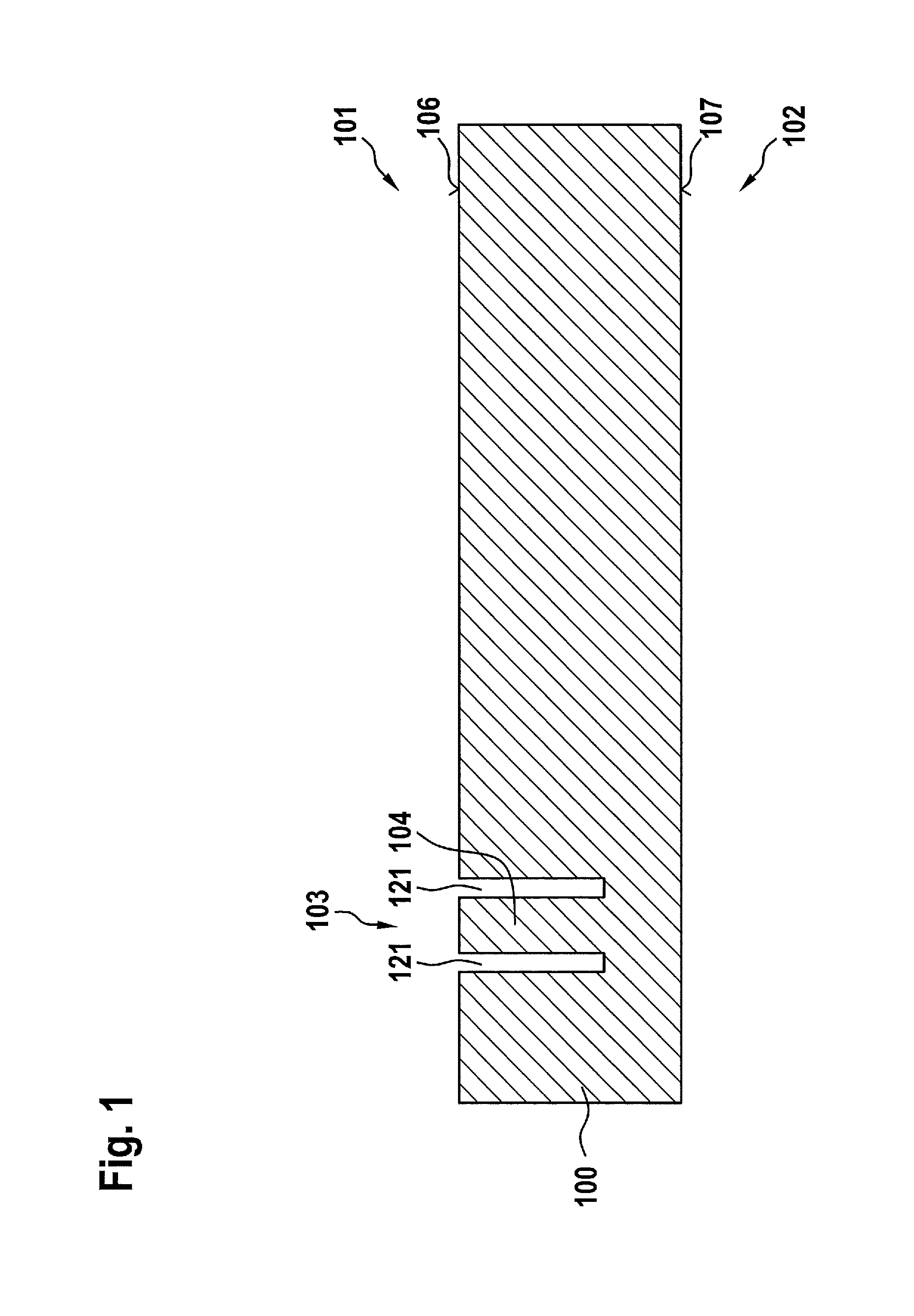

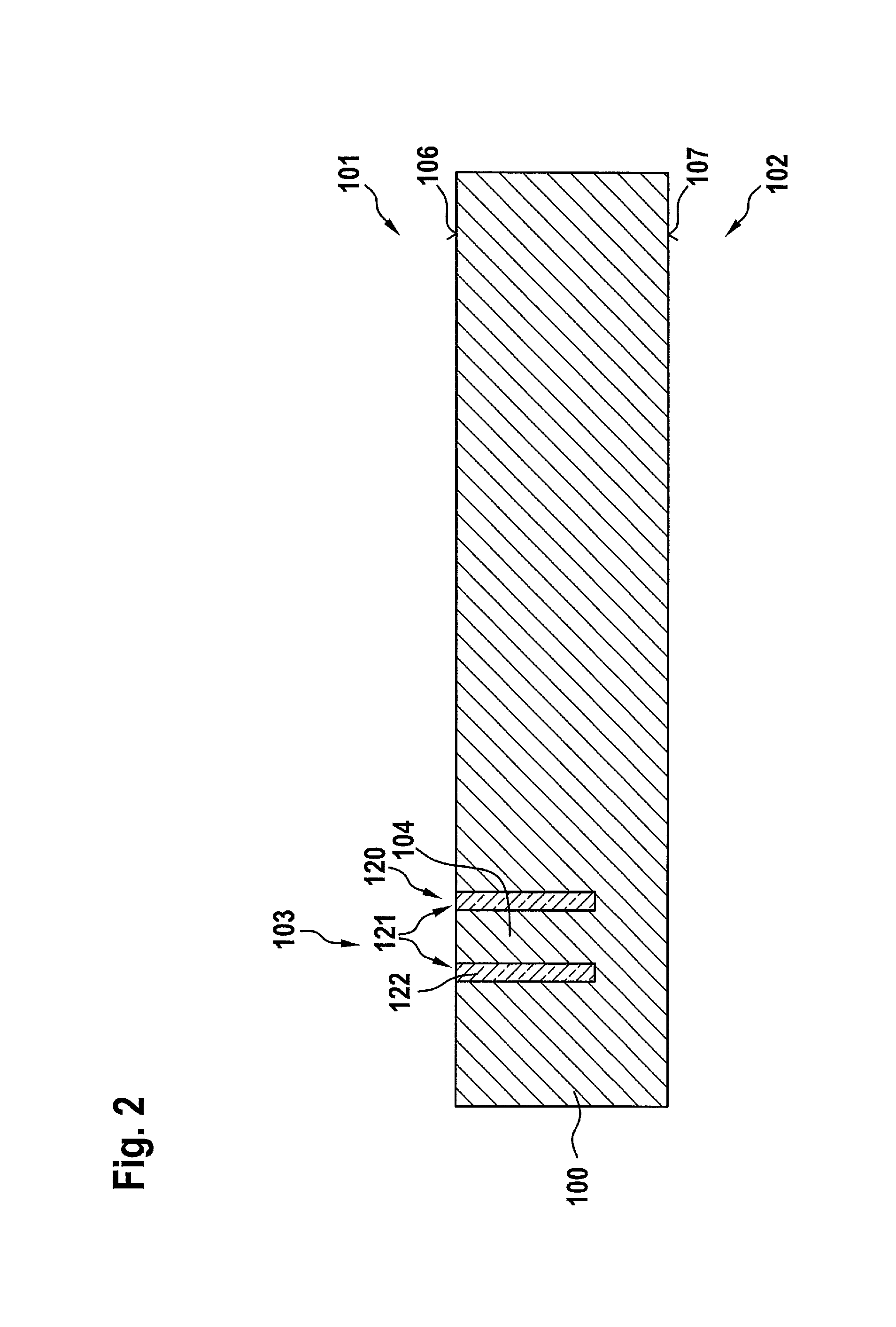

Analytical test element with a capillary channel

InactiveUS7008799B1Large layer thicknessReliable exclusionBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteCapillary channel

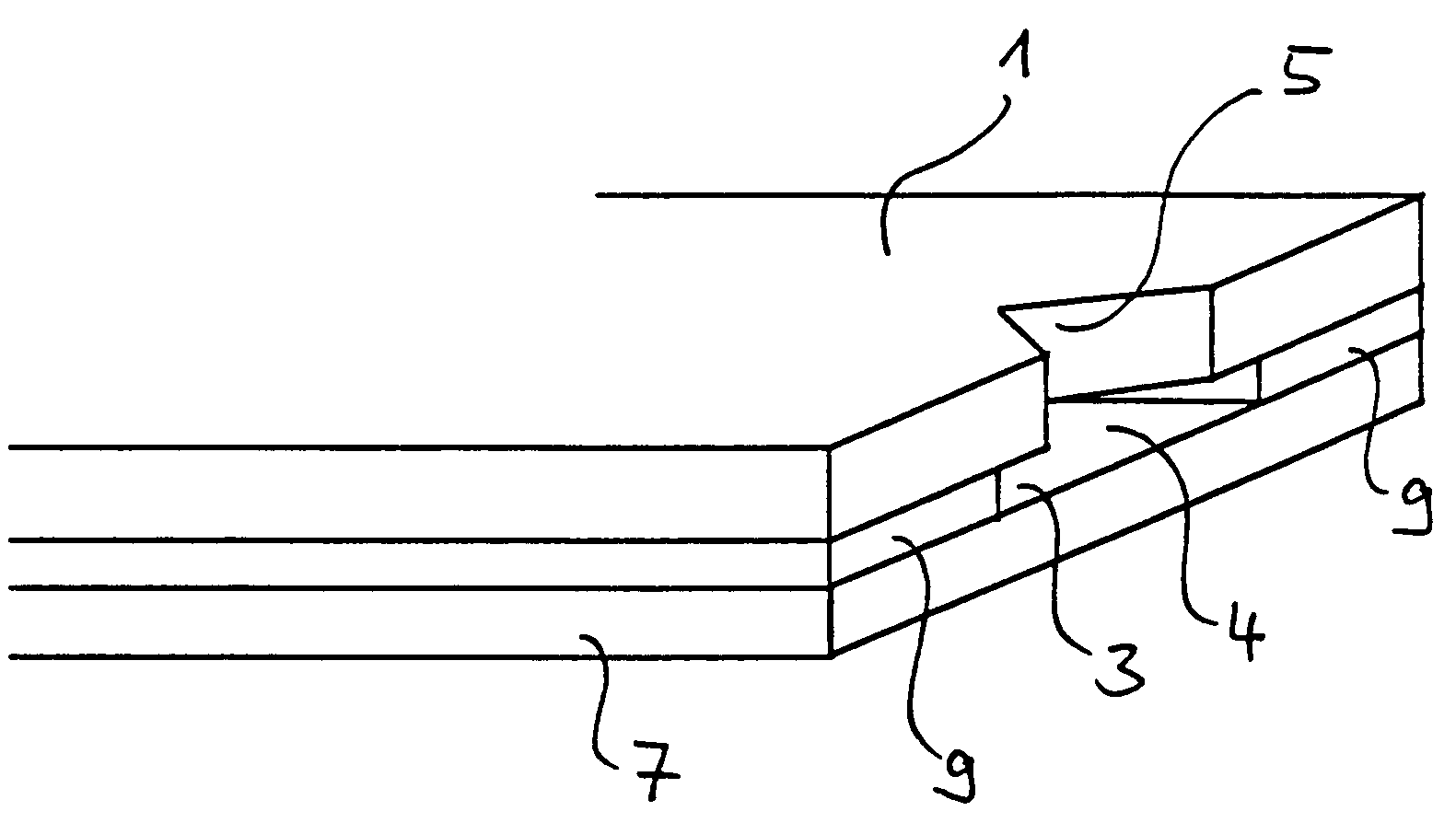

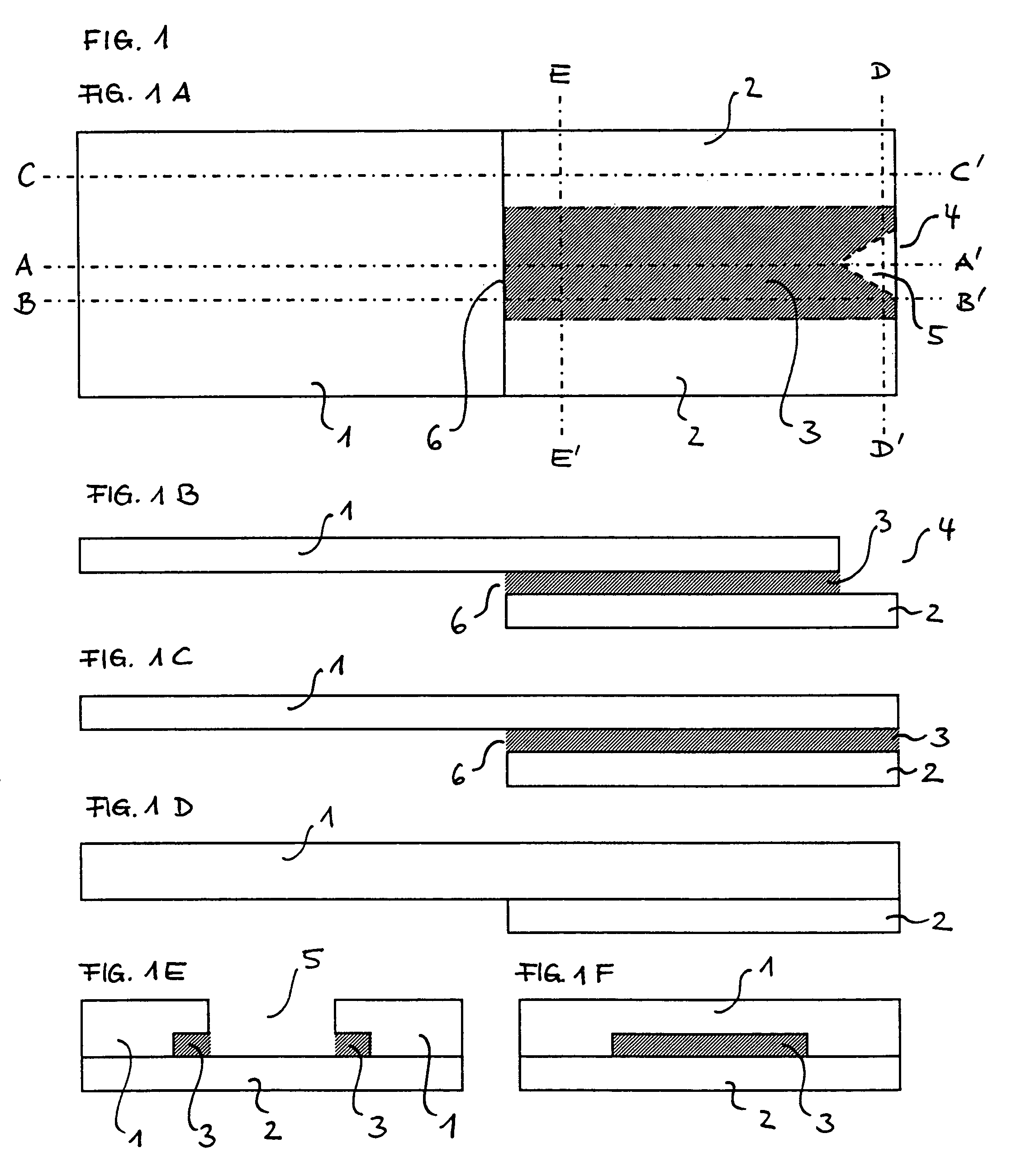

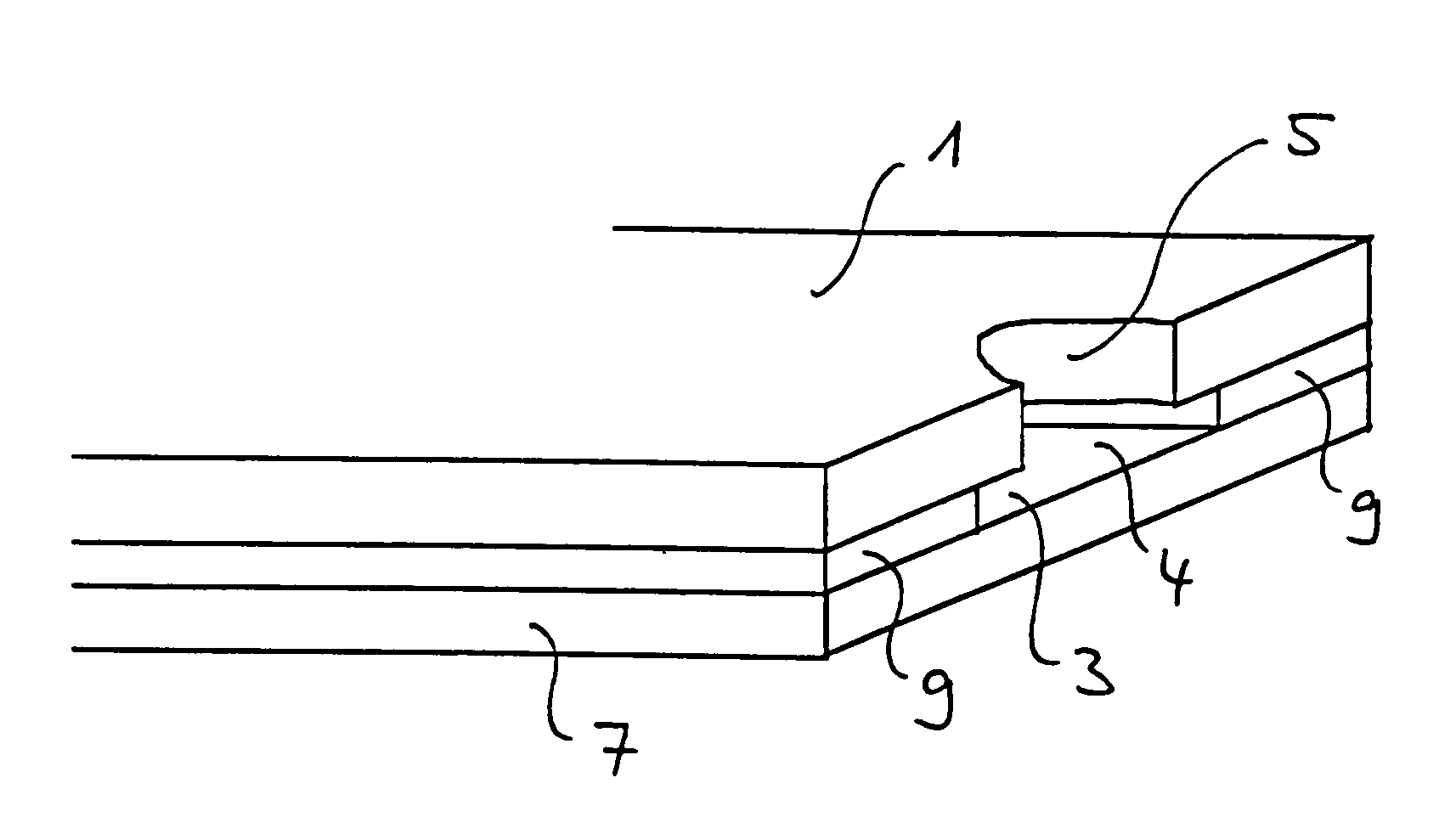

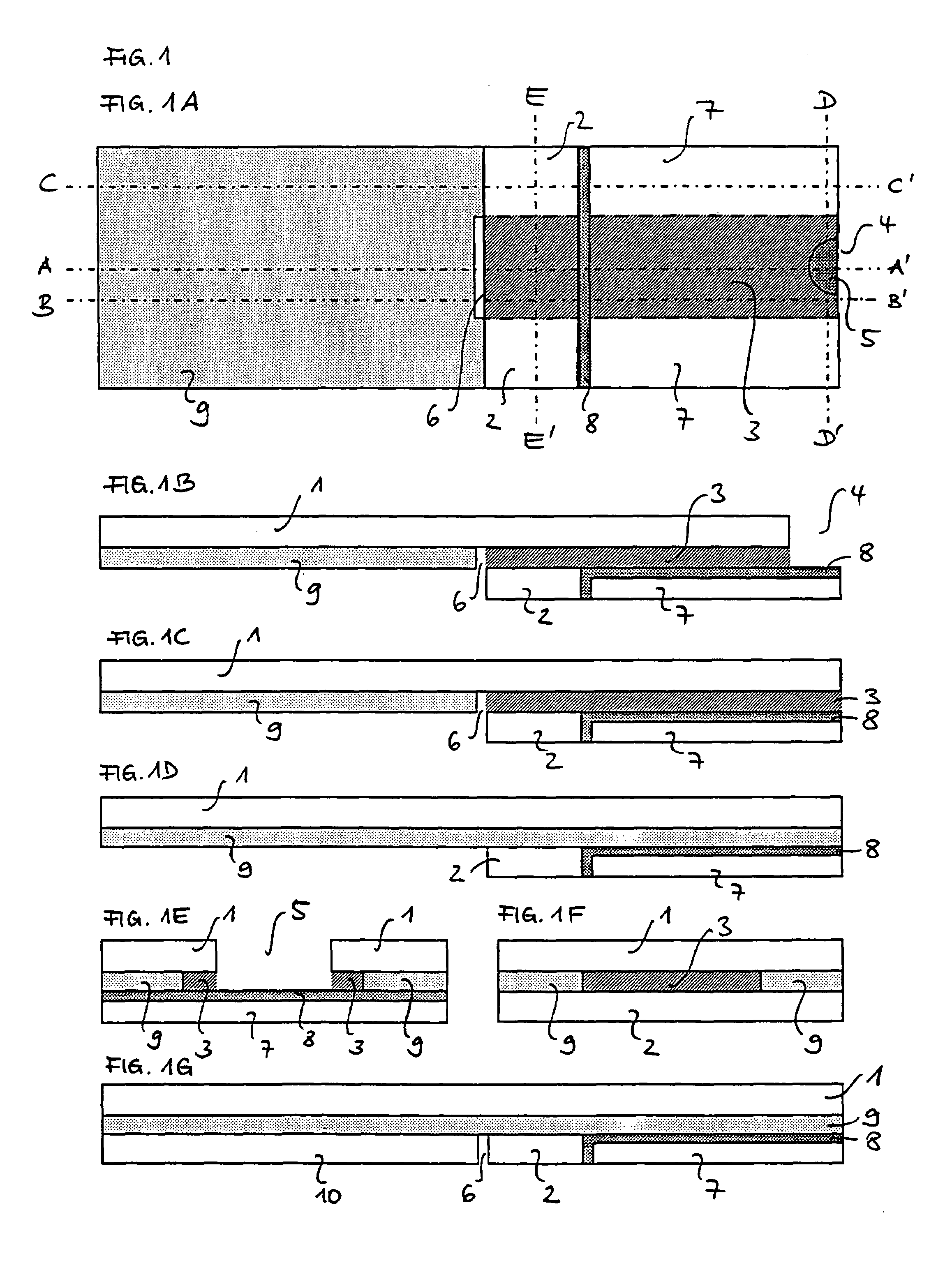

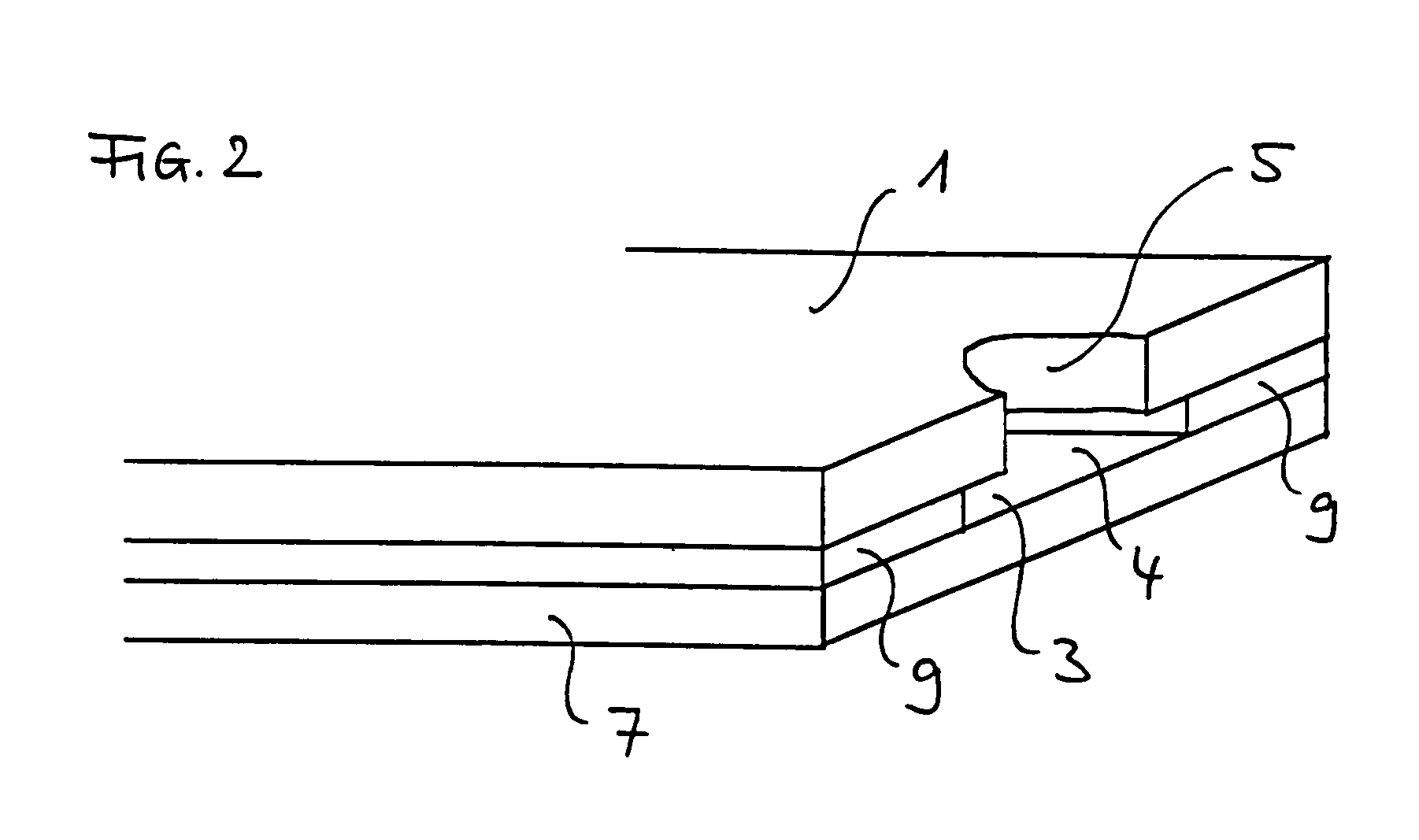

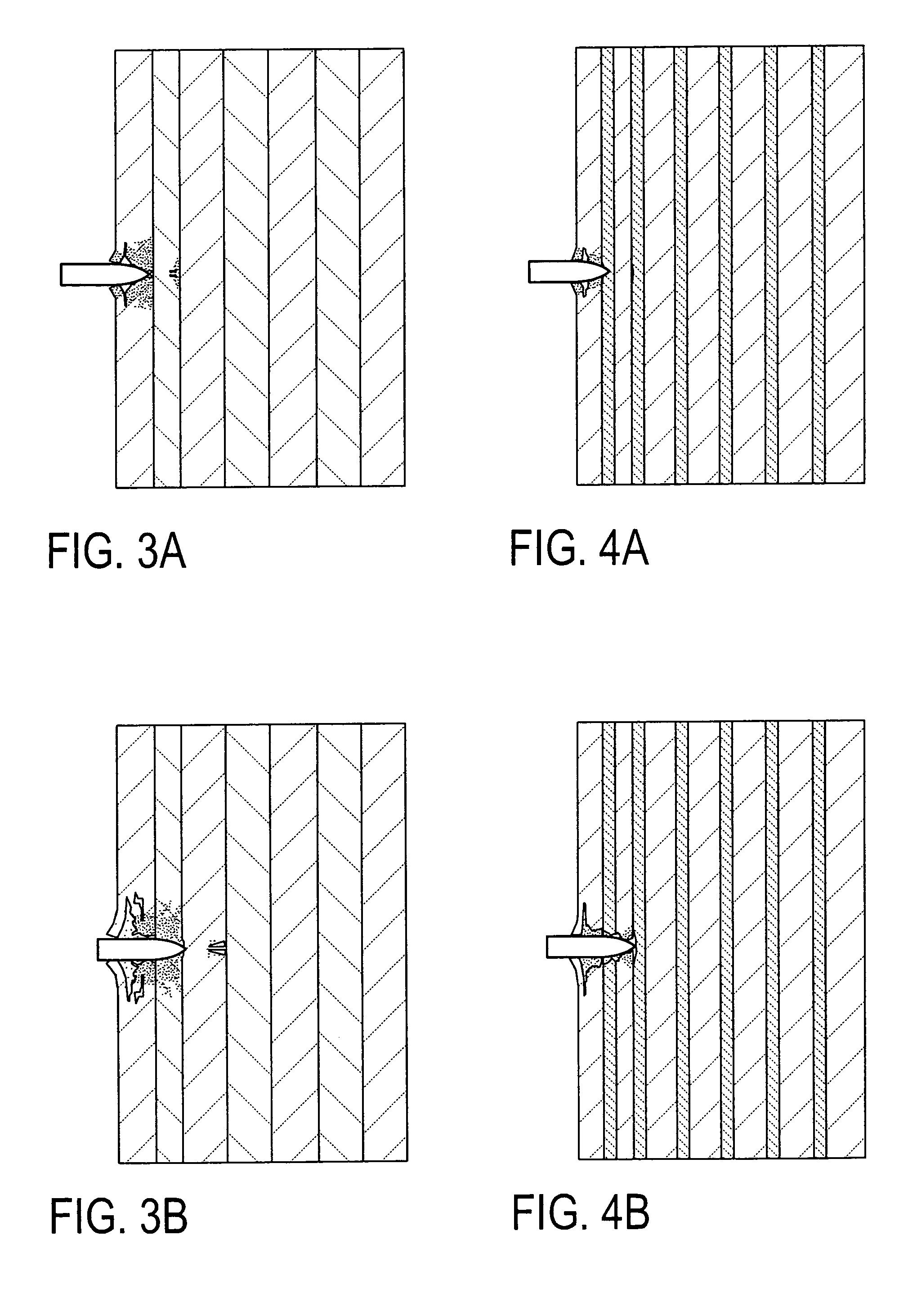

The invention concerns an analytical test element for the determination of an analyte in a liquid containing an inert carrier, a detection element and a channel capable of capillary liquid transport which has a sample application opening at one end and a vent opening at the other end of the channel capable of capillary liquid transport, wherein the channel capable of capillary liquid transport is formed at least partially by the carrier and the detection element and extends in the direction of capillary transport from the sample application opening at least to the edge of the detection test element that is nearest to the vent opening and wherein a notch is located in one of the surfaces forming the channel capable of capillary liquid transport at the edge of the test element forming the sample application opening so that one side of the edge of the test element forming the sample application opening is at least partially discontinuous and the surface opposite to the notch is exposed. It also concerns the use of the said analytical test element for the determination of an analyte in a liquid as well as a method for the determination of an analyte in a liquid sample with the aid of the said analytical test element.

Owner:ROCHE DIAGNOSTICS GMBH

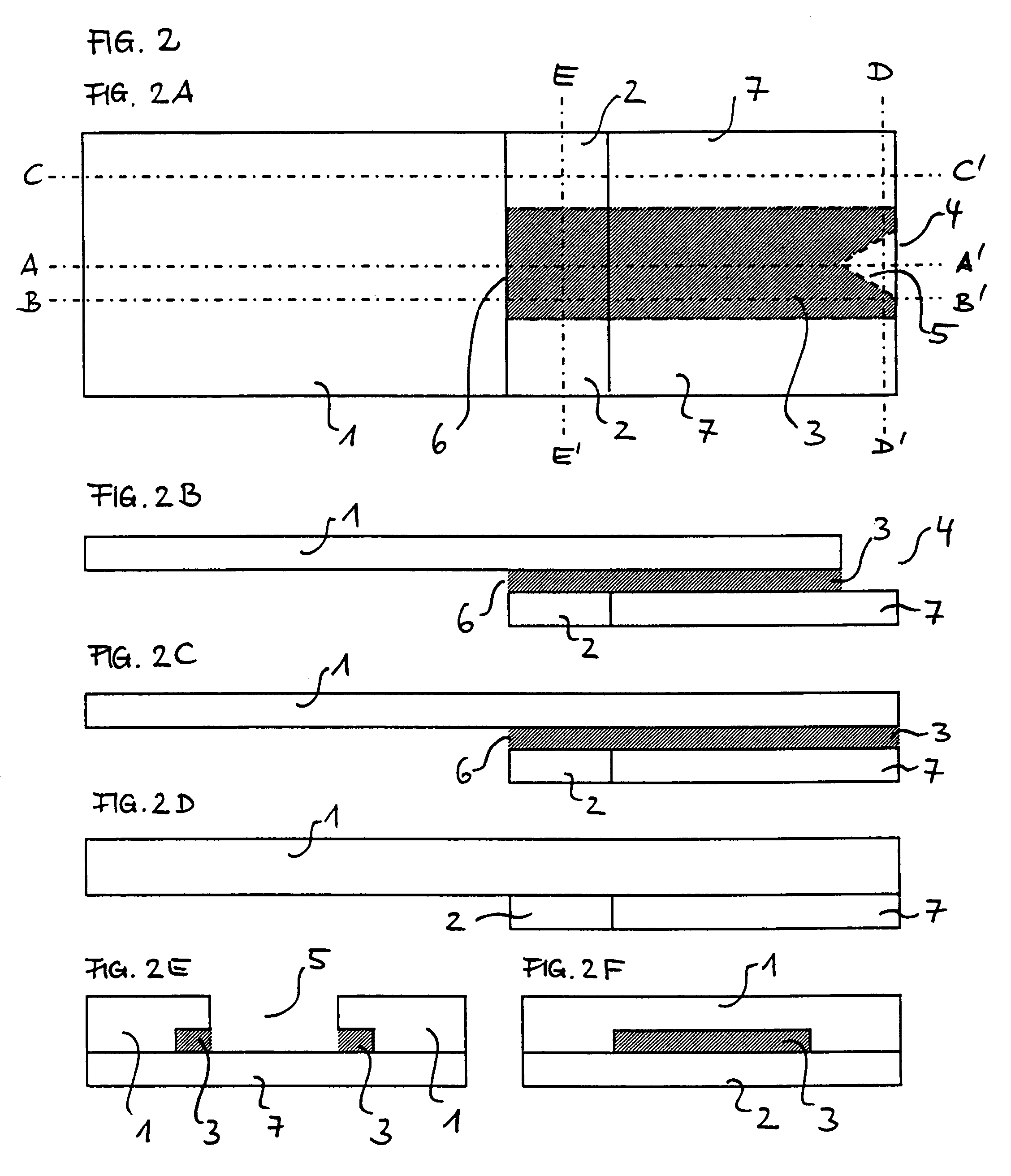

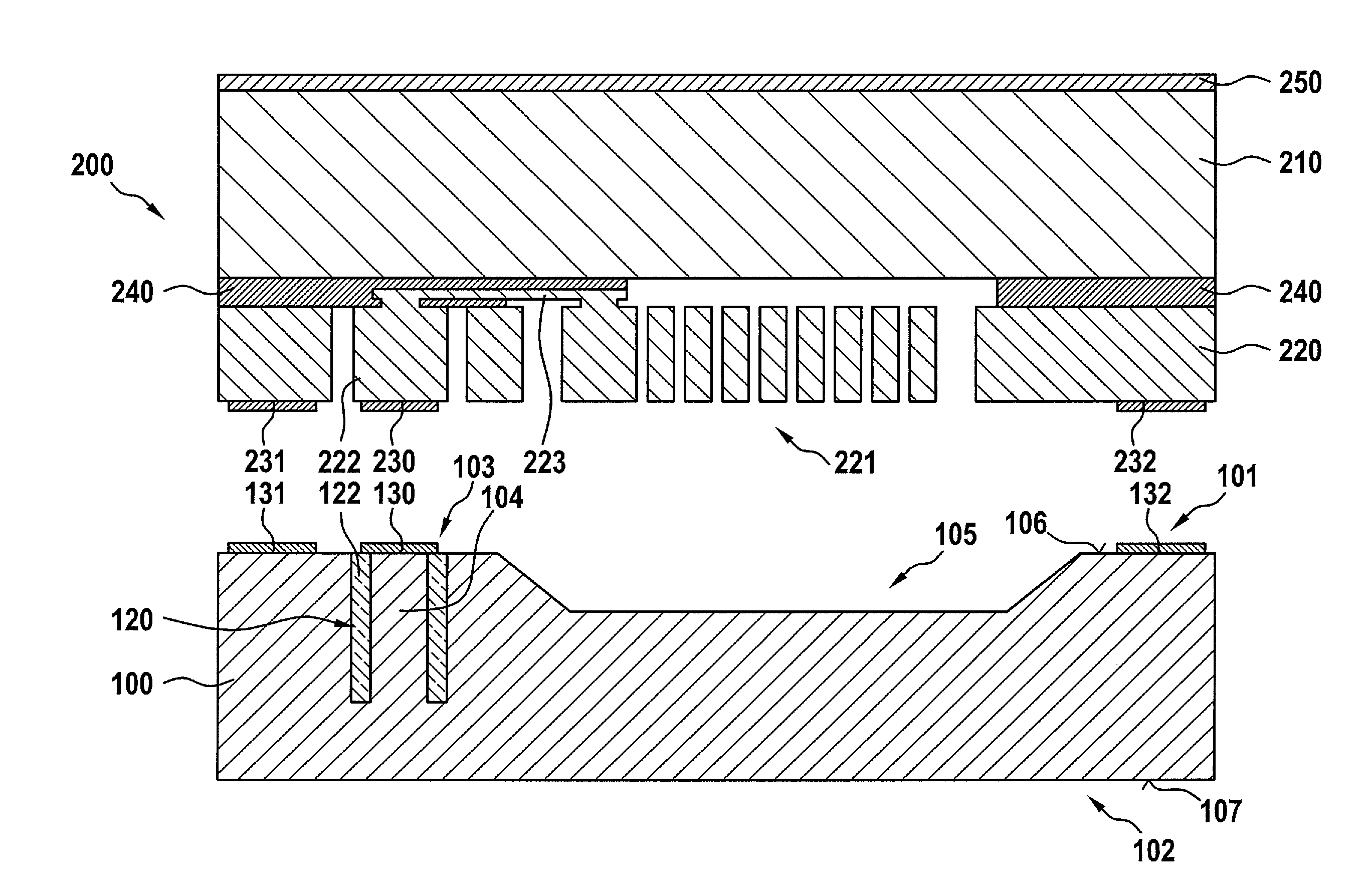

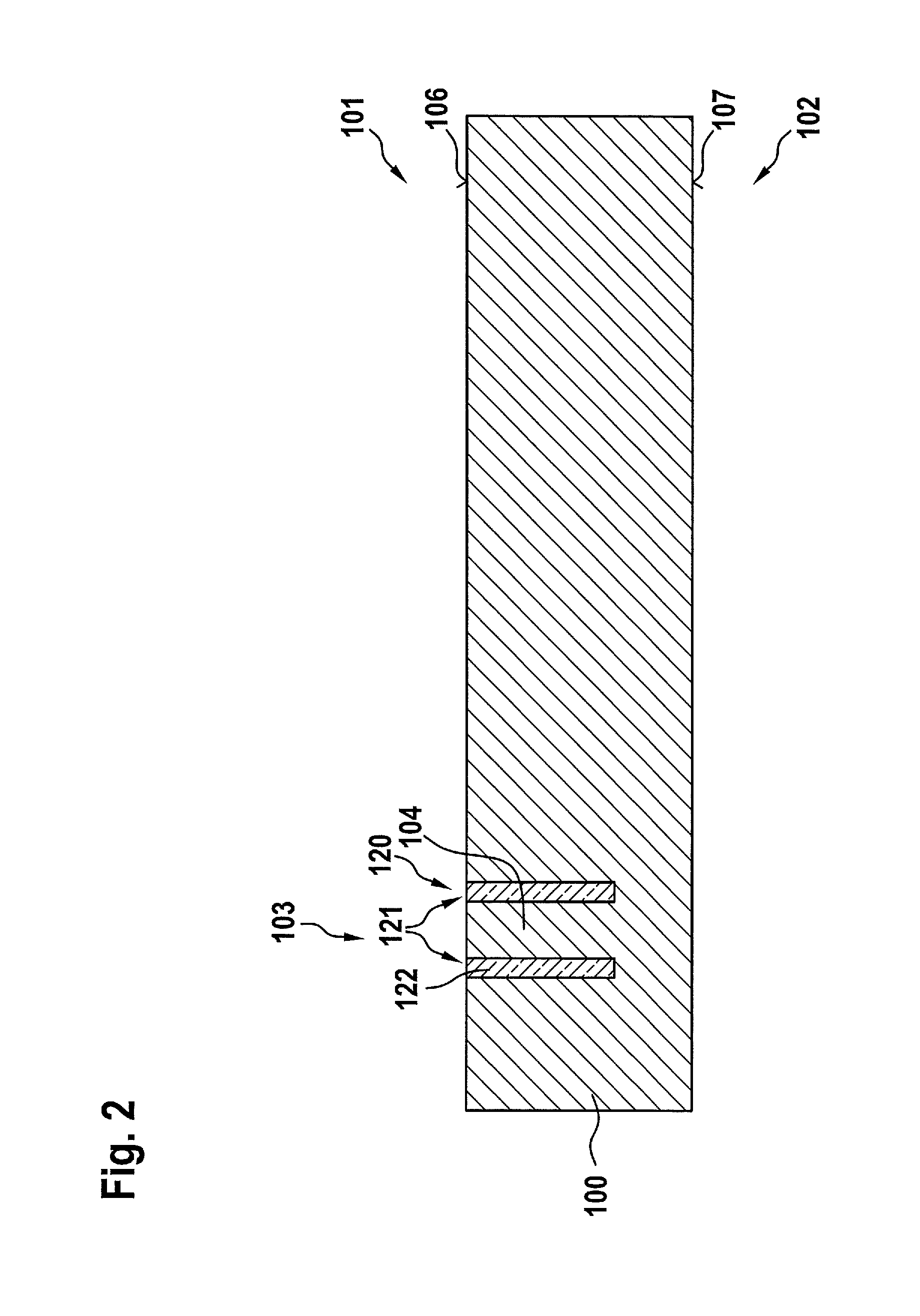

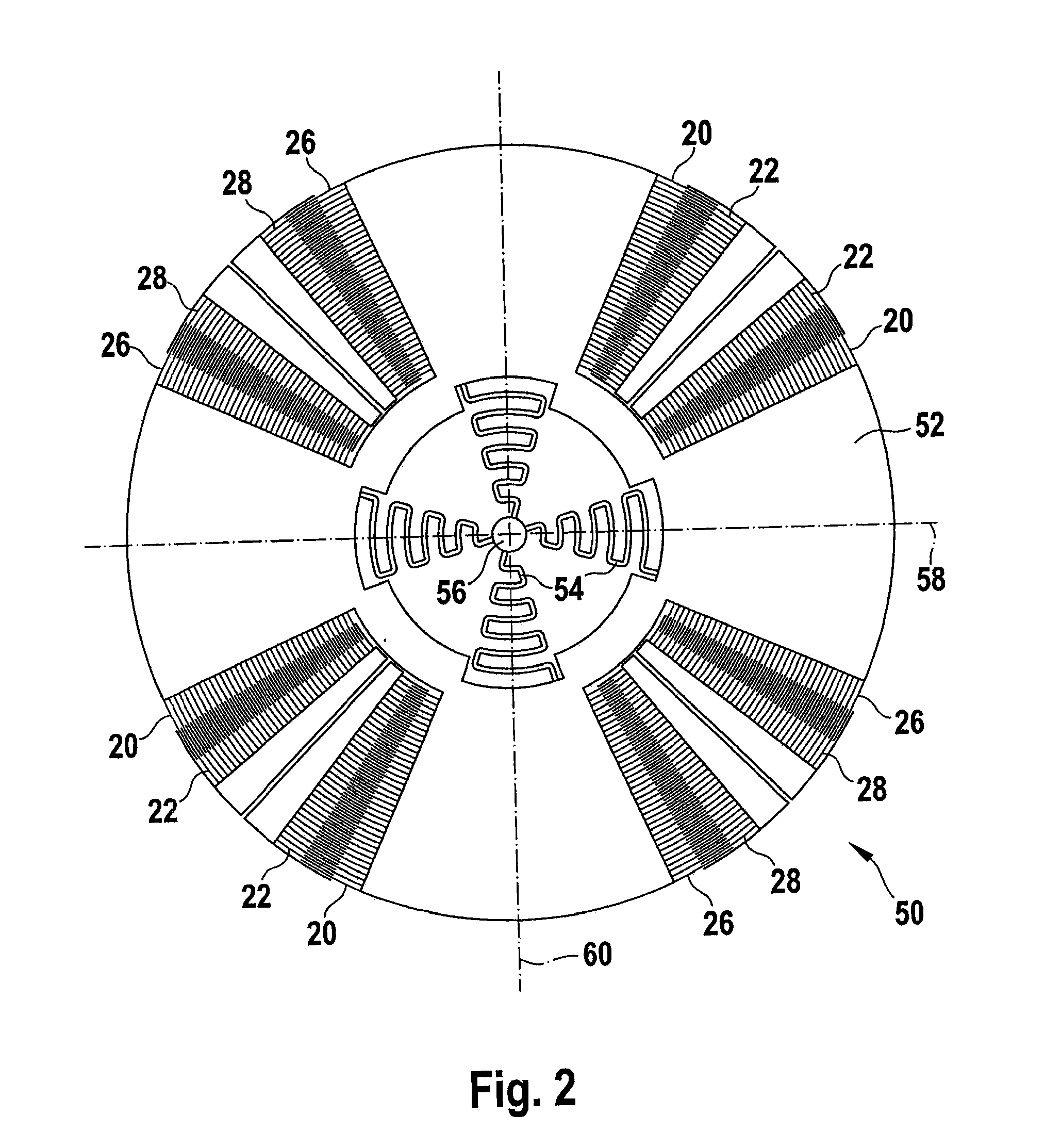

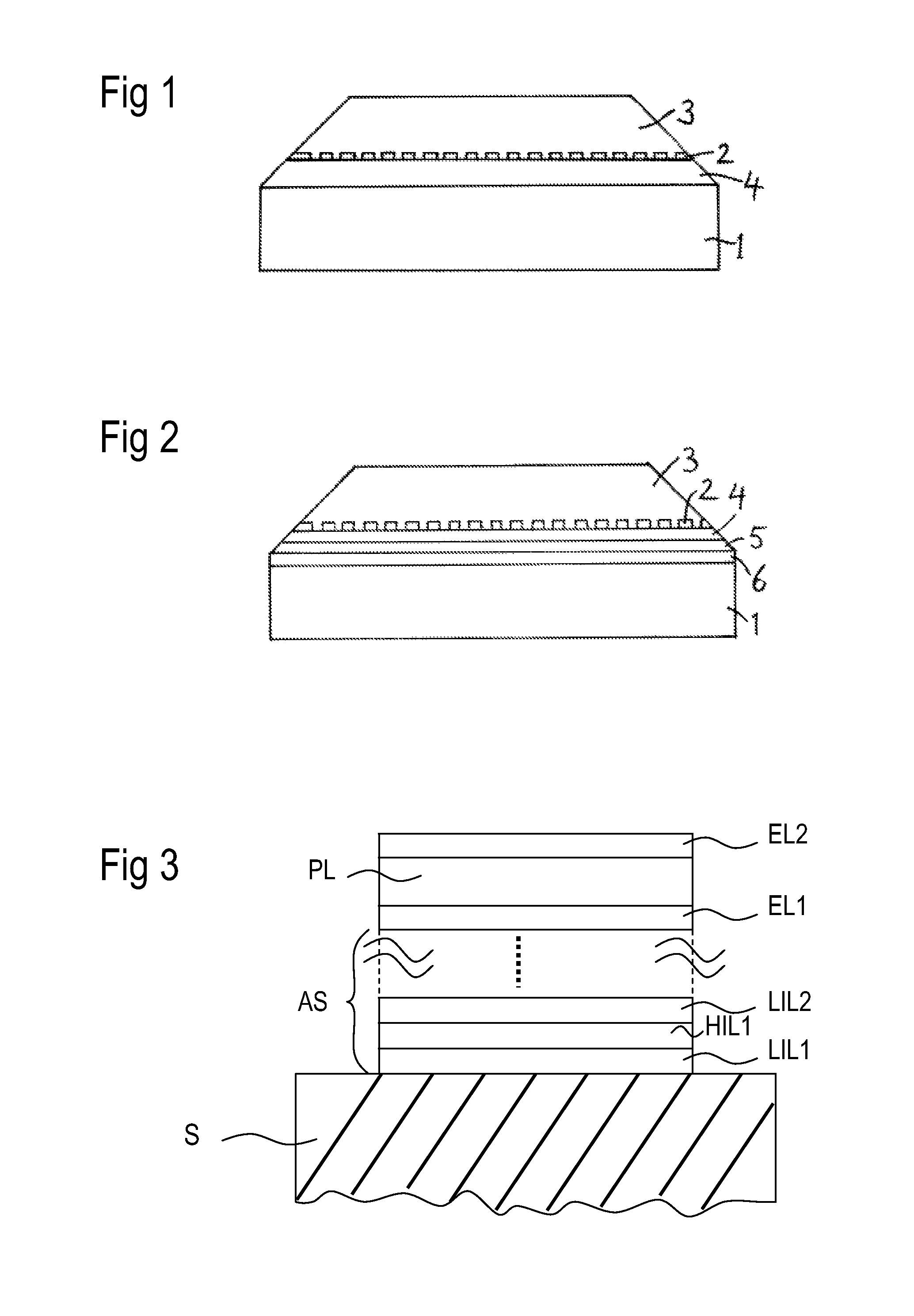

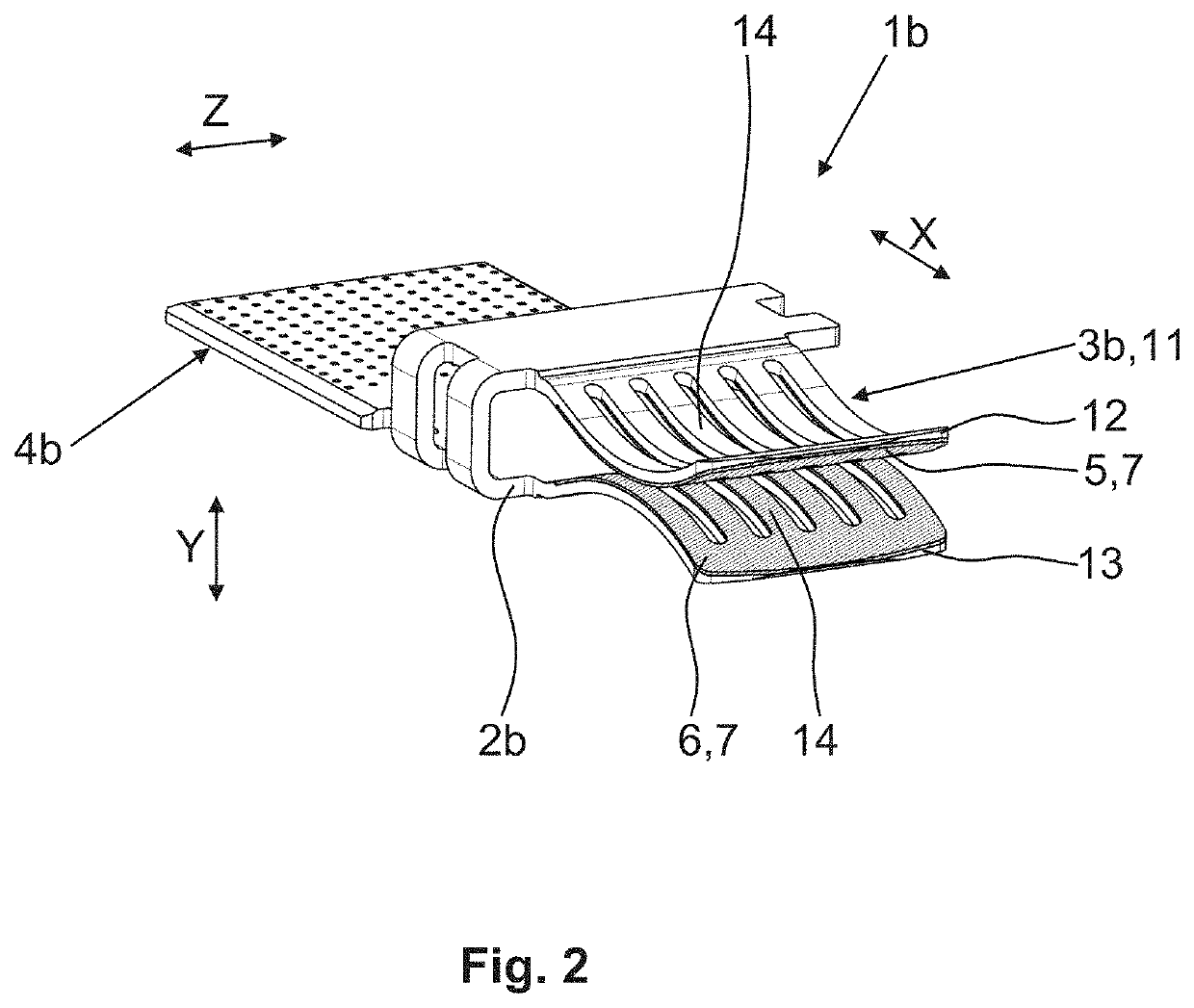

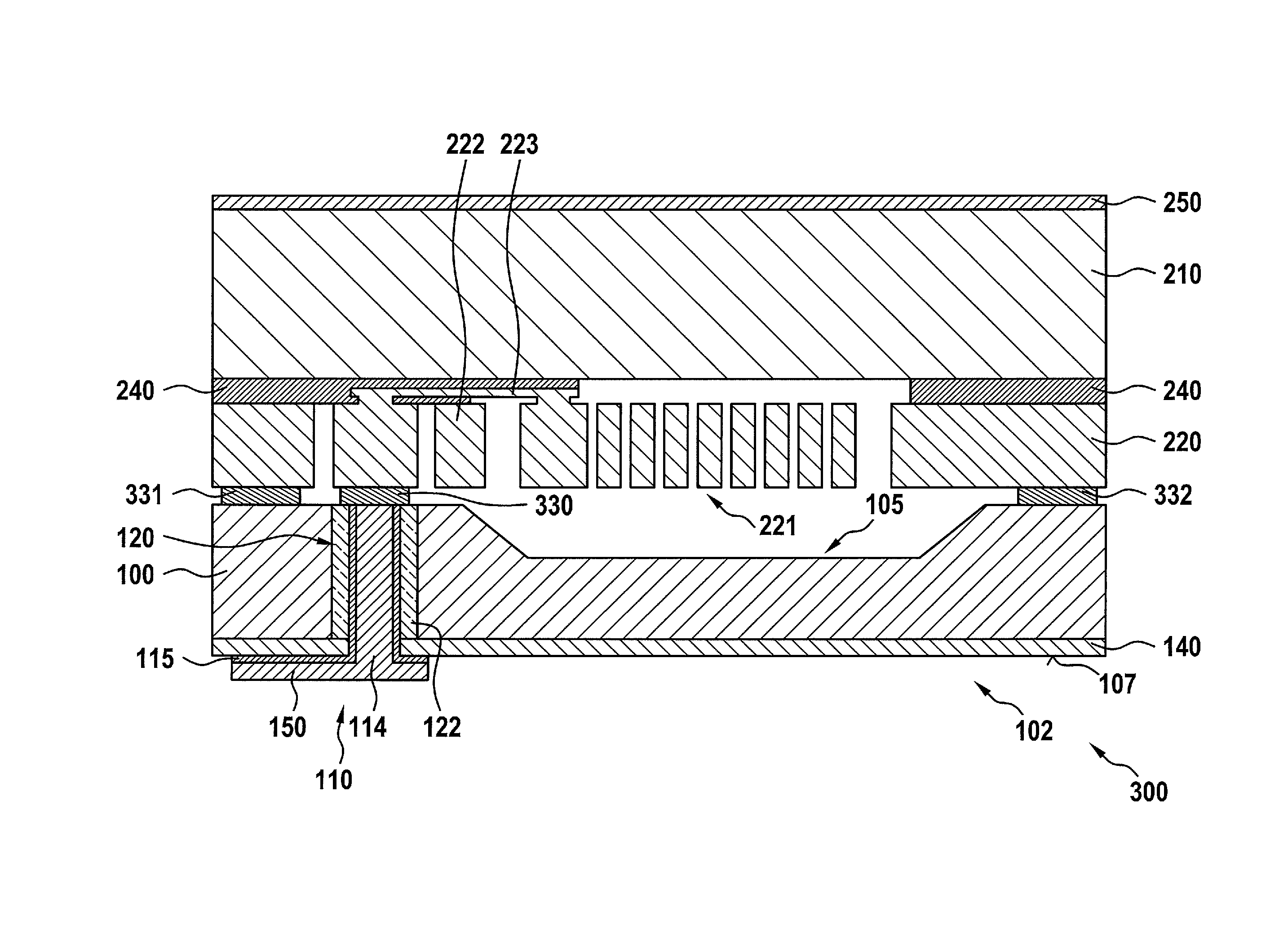

Capillary active test element having an intermediate layer situated between the support and the covering

InactiveUS7238534B1Large layer thicknessAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorTest elementBiomedical engineering

The invention concerns a device for withdrawing samples of liquid samples for analytical elements. The capillary-device channel is essentially formed by a carrier, a cover and optionally an intermediate layer between the cover and carrier. A notch is located in one of the surfaces forming the channel capable of capillary liquid transport at the edge of the test element forming the sample application opening so that one side of the edge of the test element forming the sample application opening is at least partially discontinuous and the surface opposite to the notch is exposed. It also concerns a method for withdrawing a liquid sample into an analytical element with the aid of a device according to the invention.

Owner:ROCHE DIAGNOSTICS GMBH

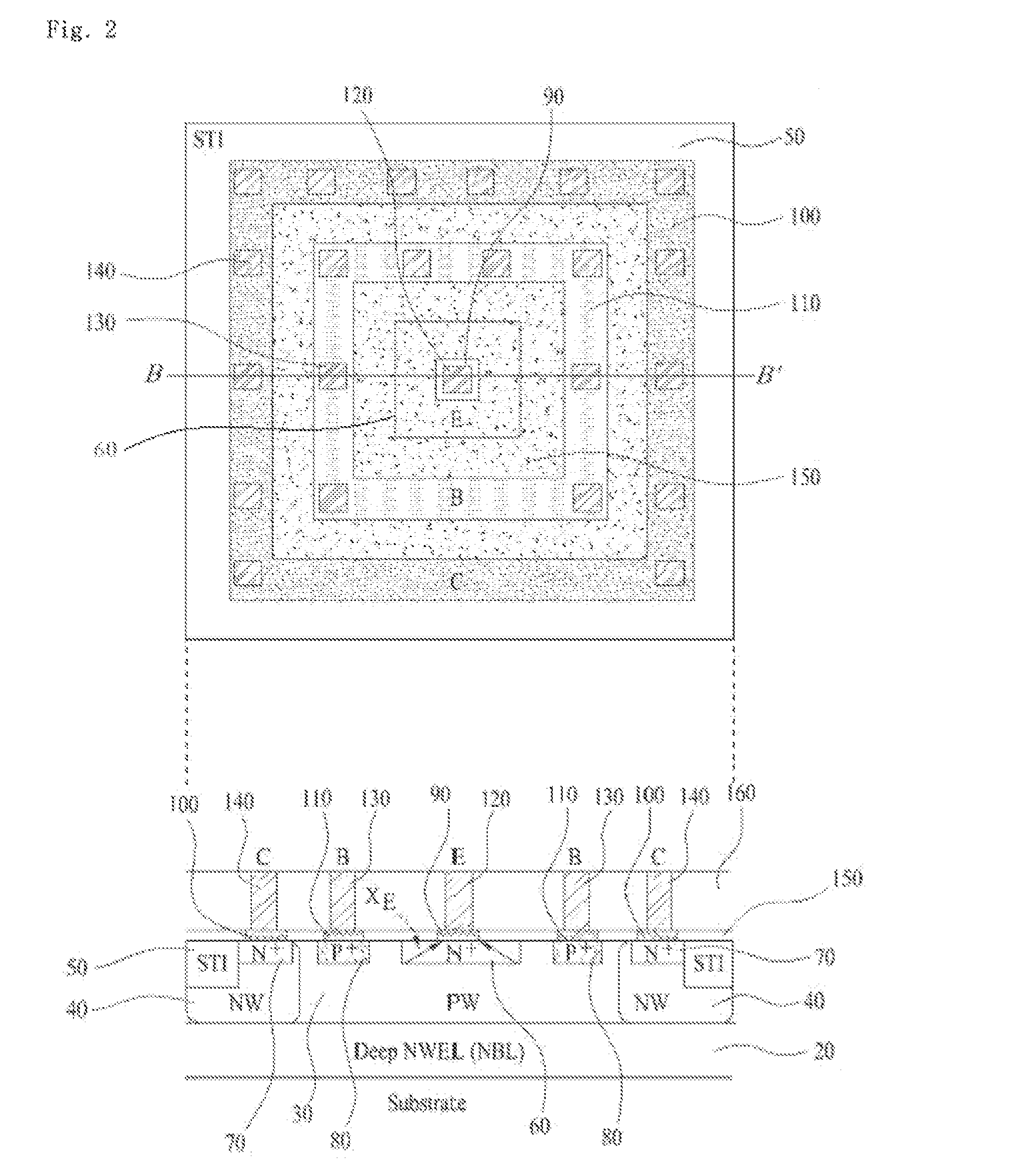

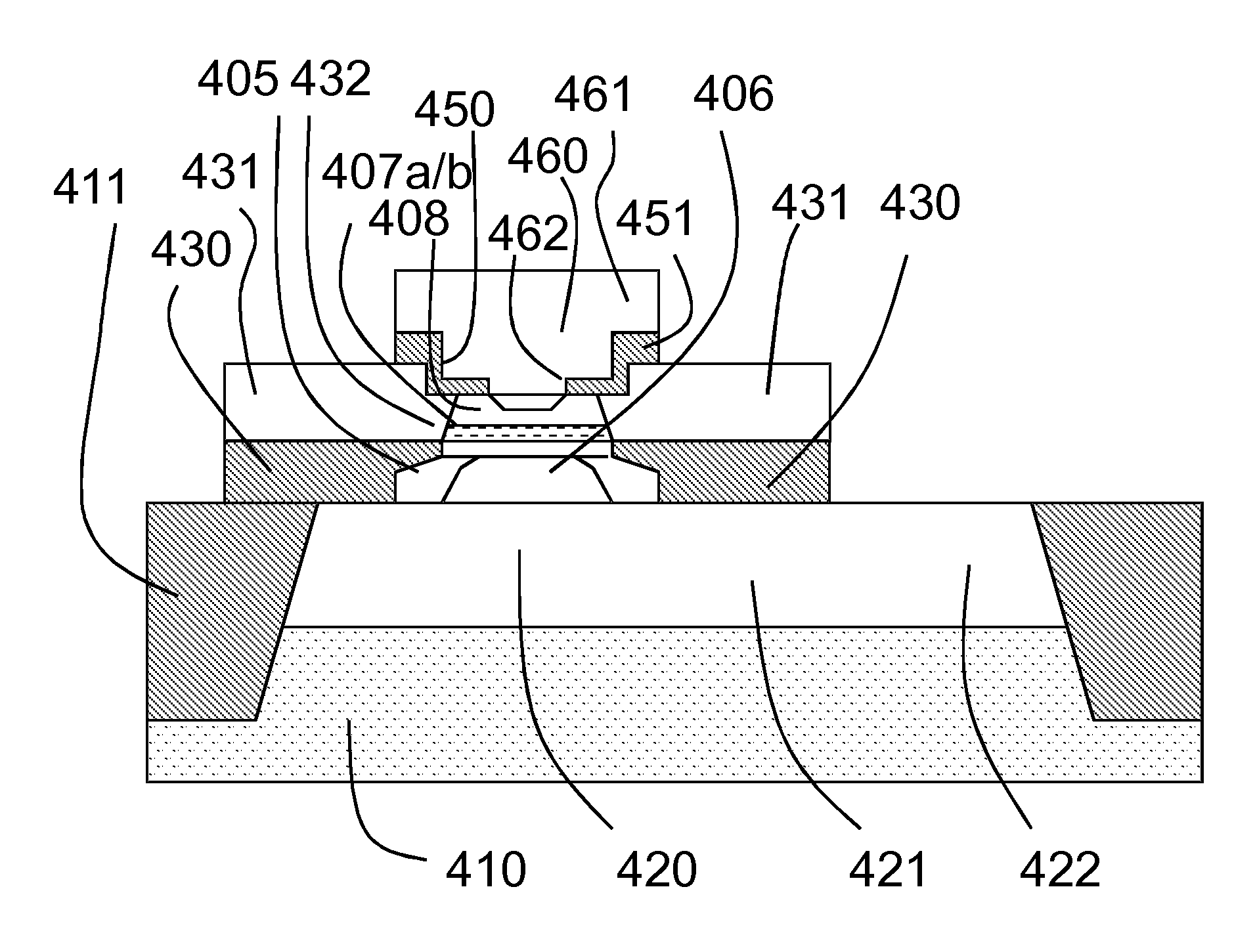

Bipolar Junction Transistor Based on CMOS Technology

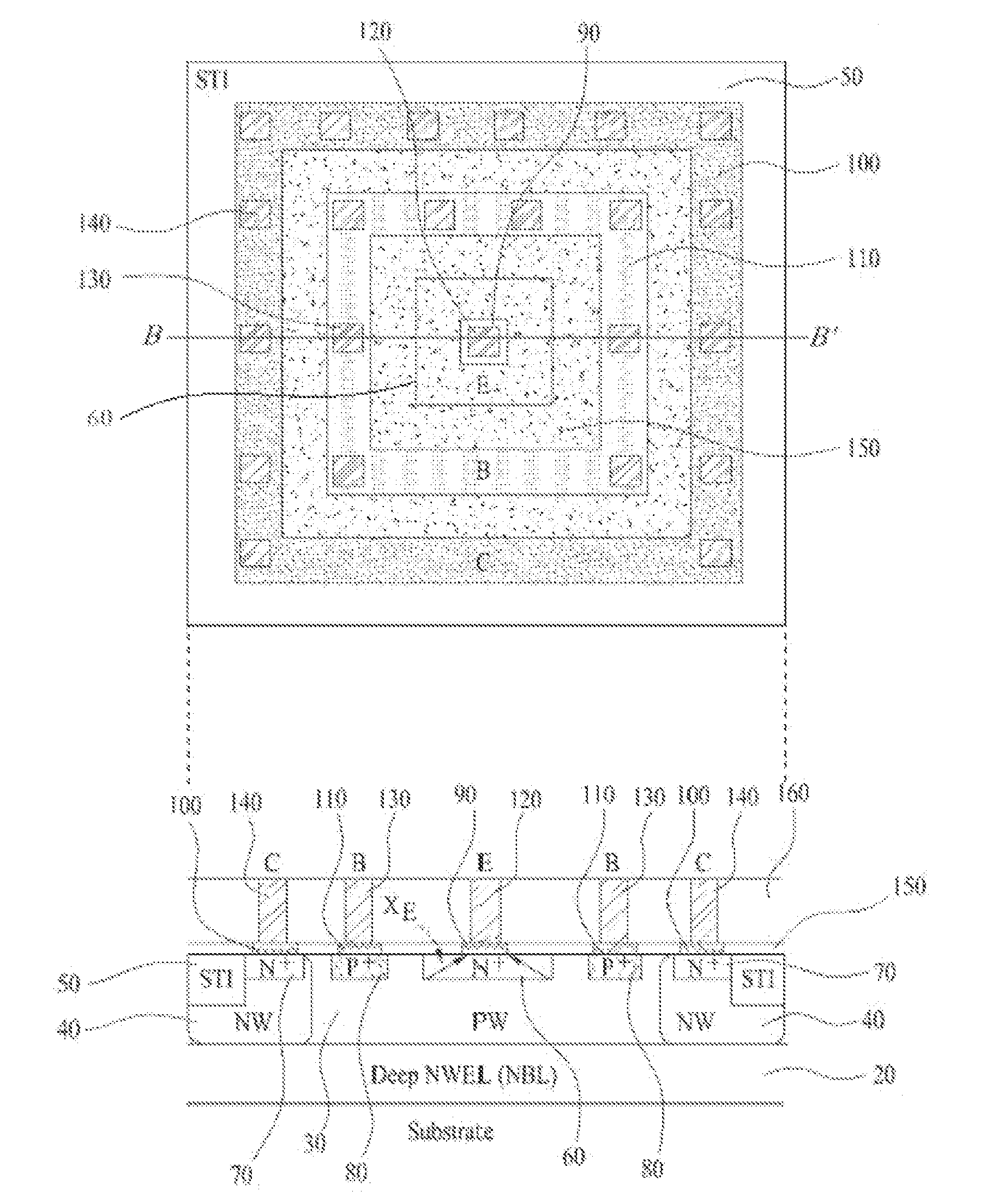

InactiveUS20120032303A1Increase currentHigh base resistanceTransistorSemiconductor/solid-state device manufacturingCMOSEngineering

The present invention relates to semiconductor technologies, and more particularly to a bipolar junction transistor (BJT) in a CMOS base technology and methods of forming the same. The BJT includes a semiconductor substrate having an emitter region, a base having a first contact, and a collector having a second contact and a well plug; a first silicide film on the first contact; a second silicide film on the second contact; a first silicide blocking layer on or over the semiconductor substrate between the first and second silicide films, and a second silicide blocking layer on the semiconductor substrate between the first silicide film and the emitter region.

Owner:DONGBU HITEK CO LTD

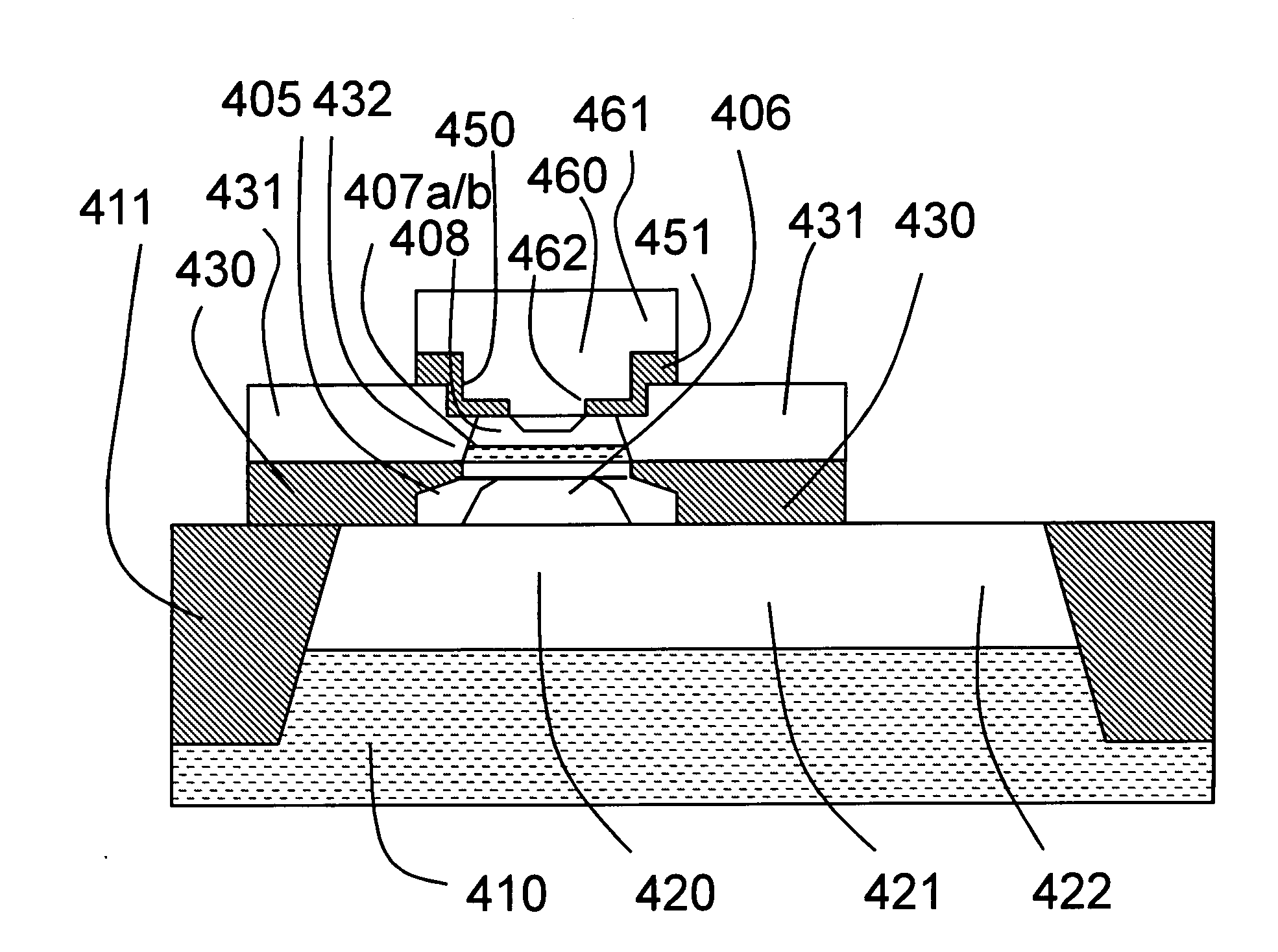

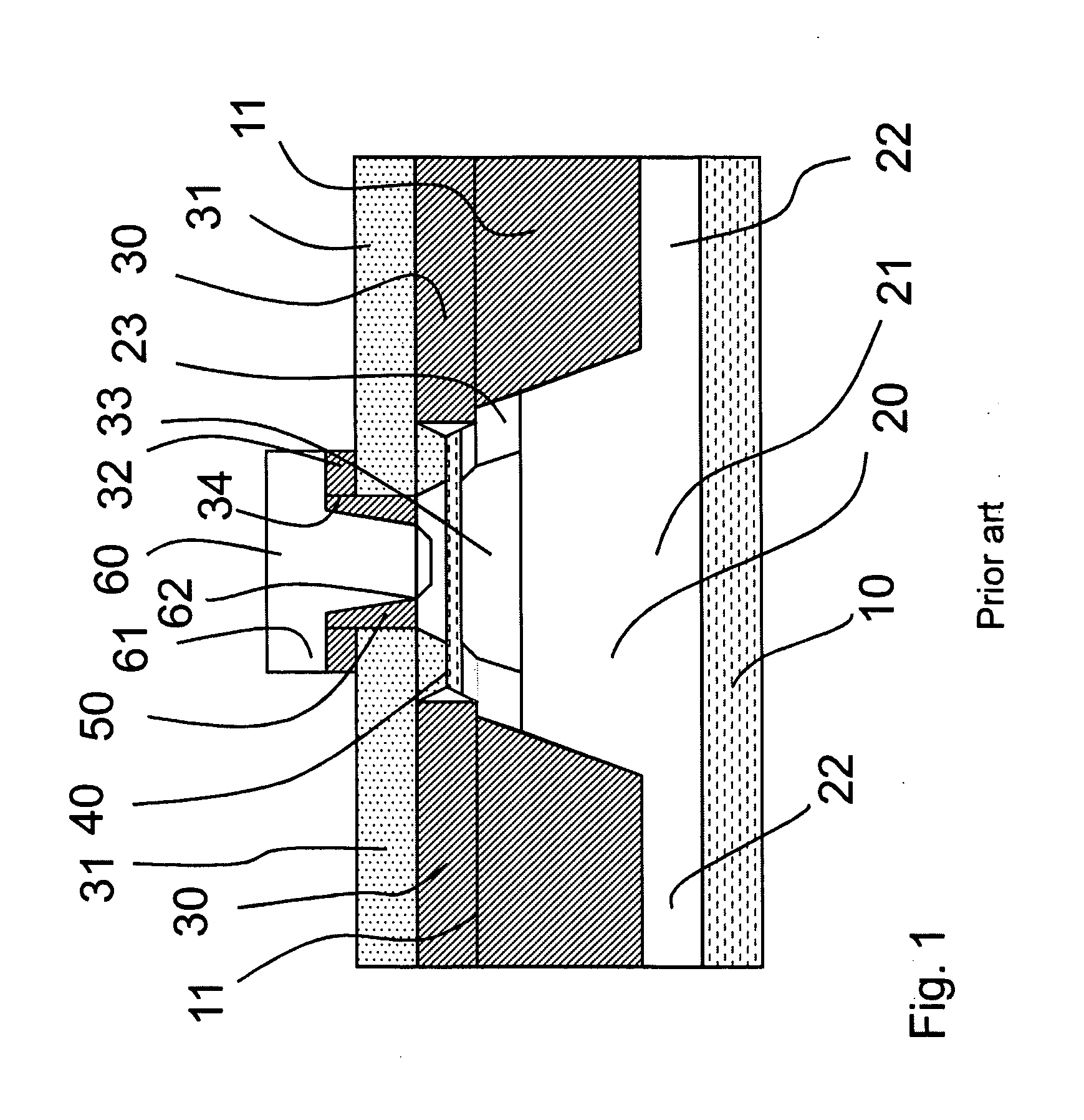

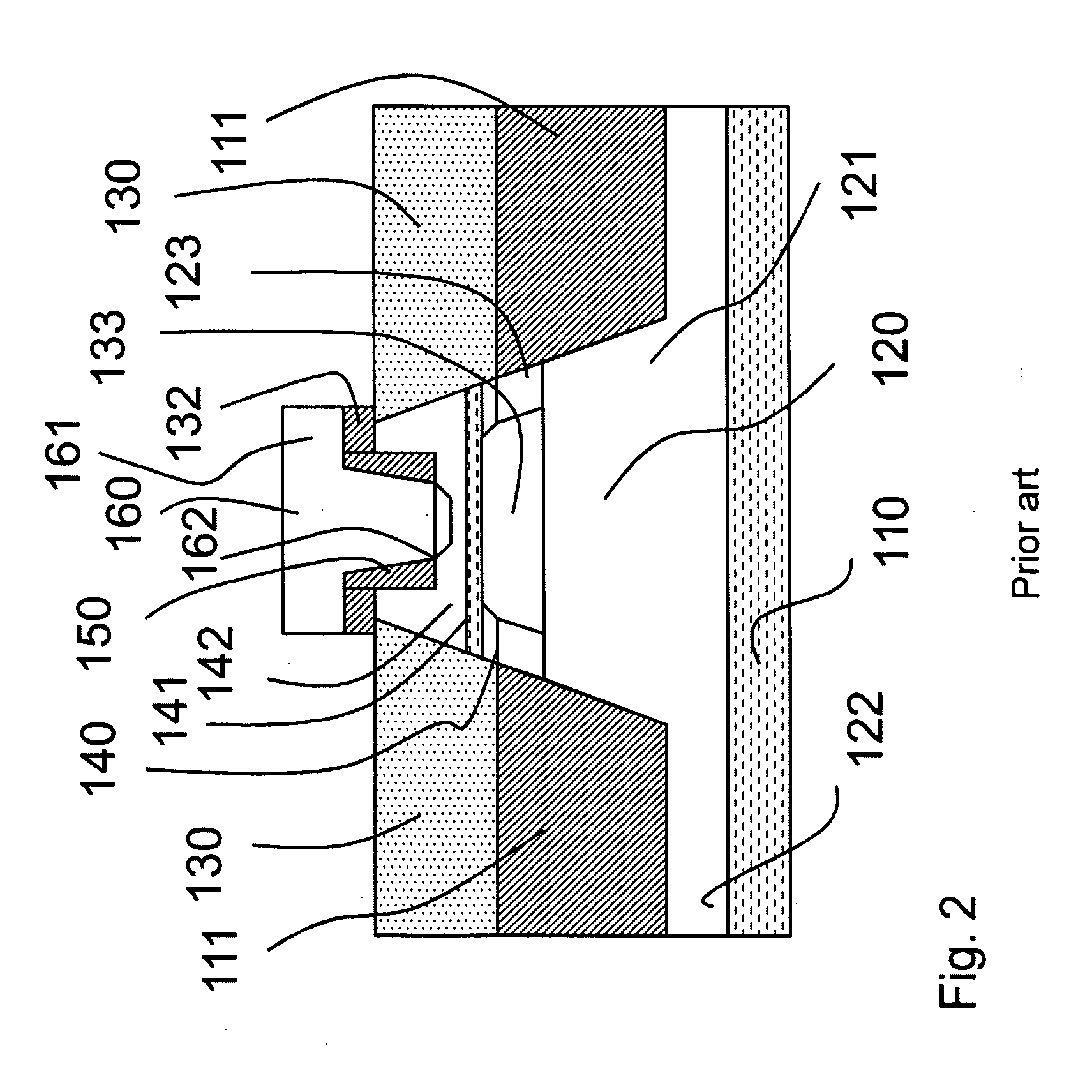

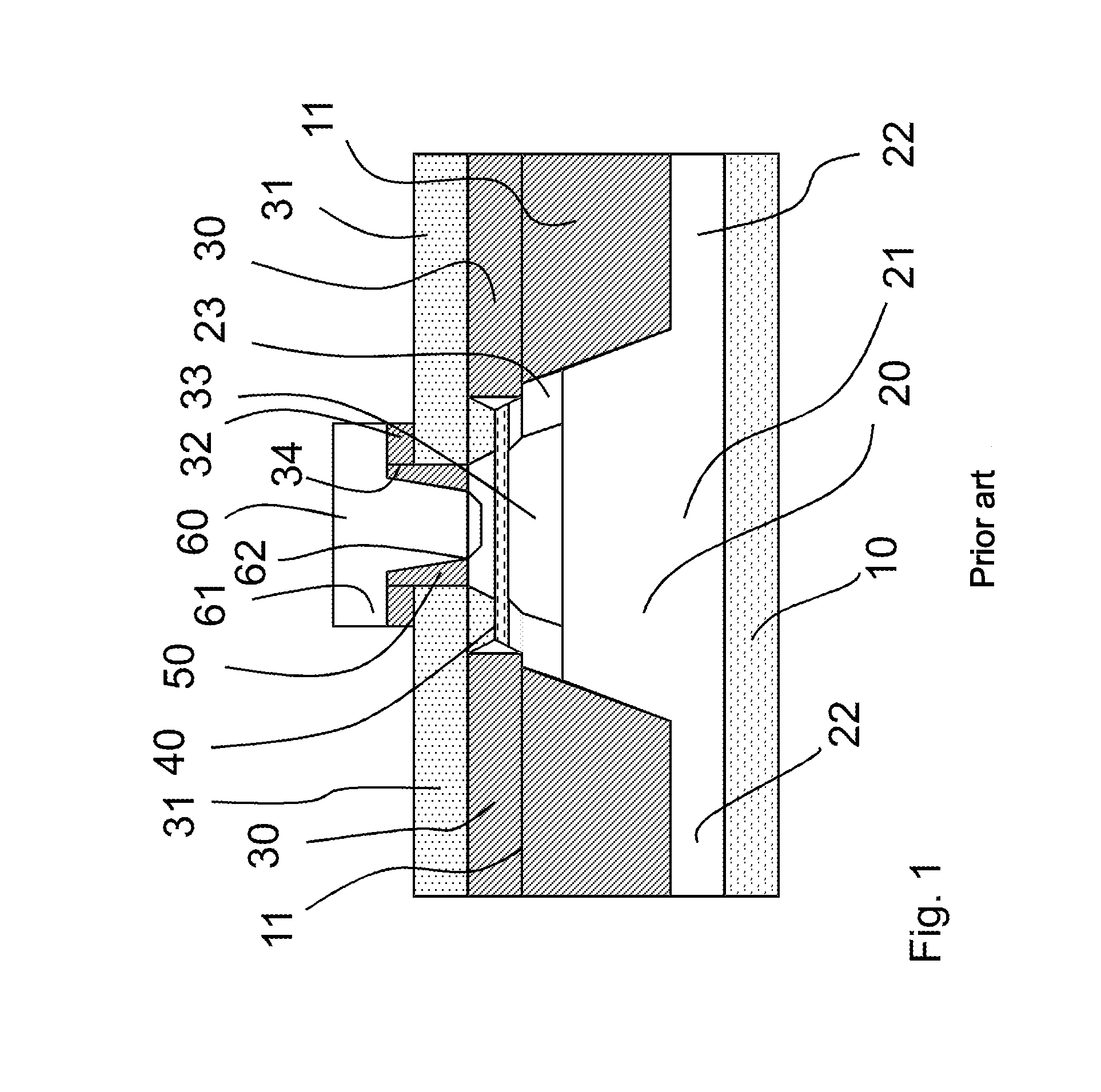

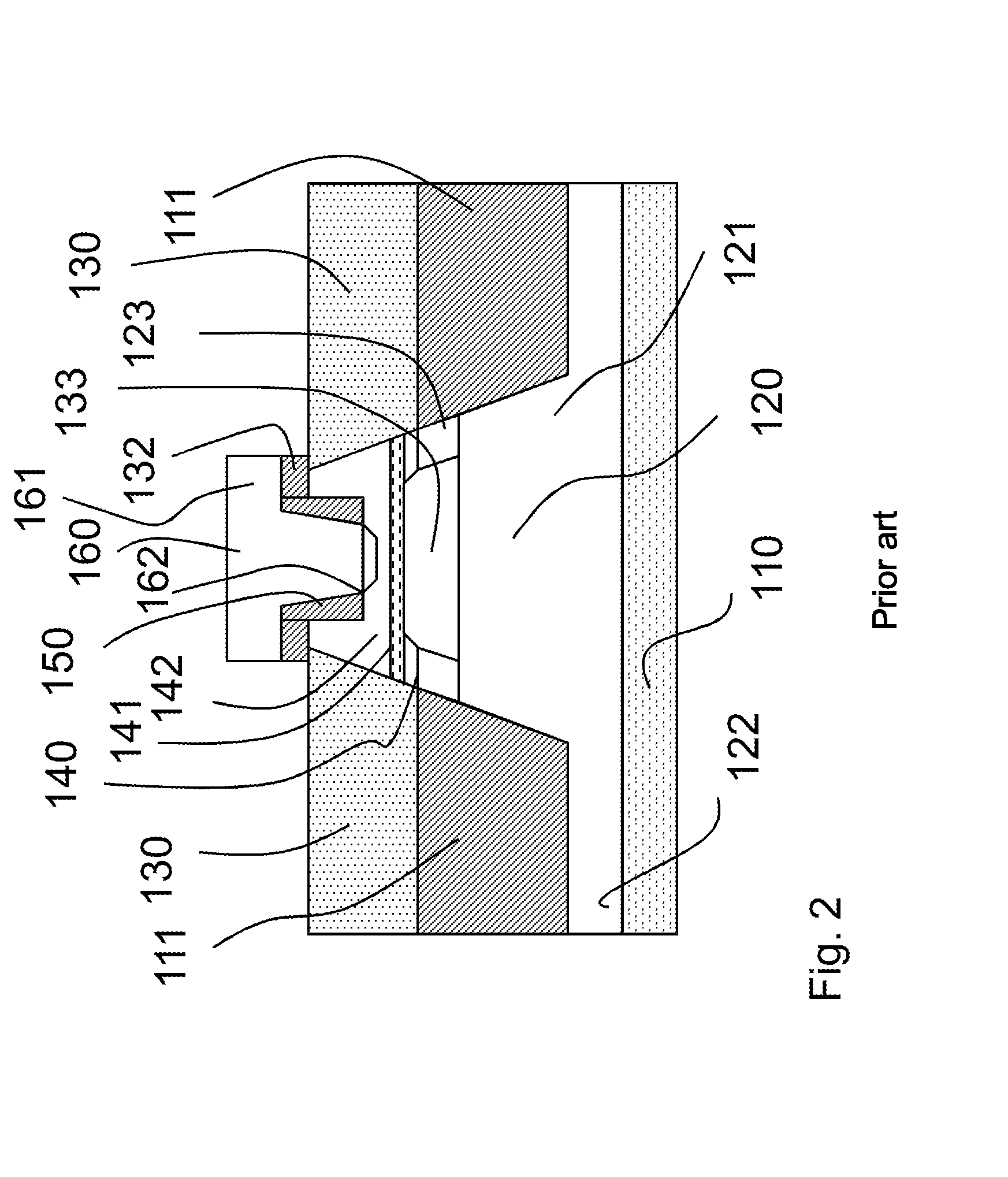

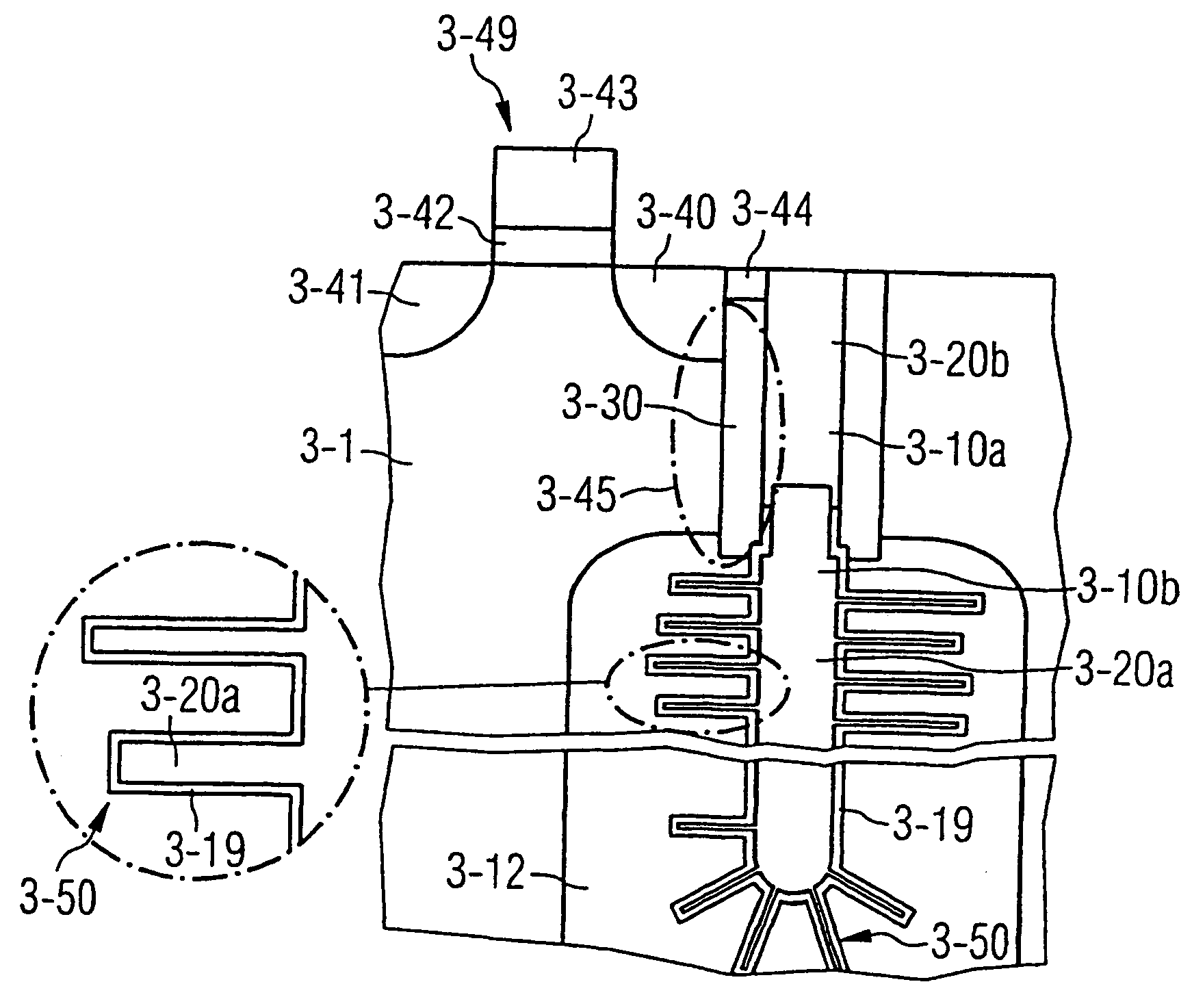

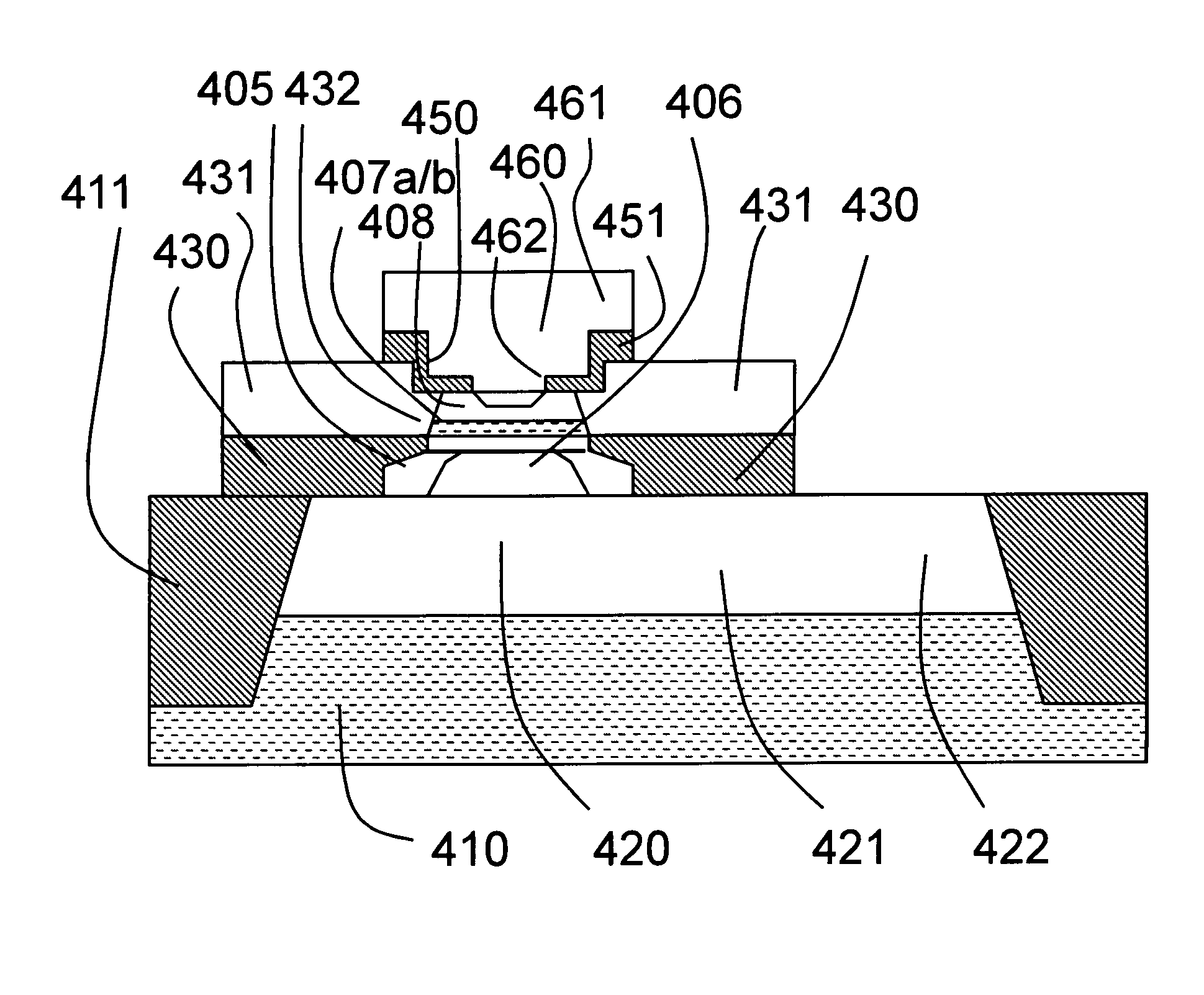

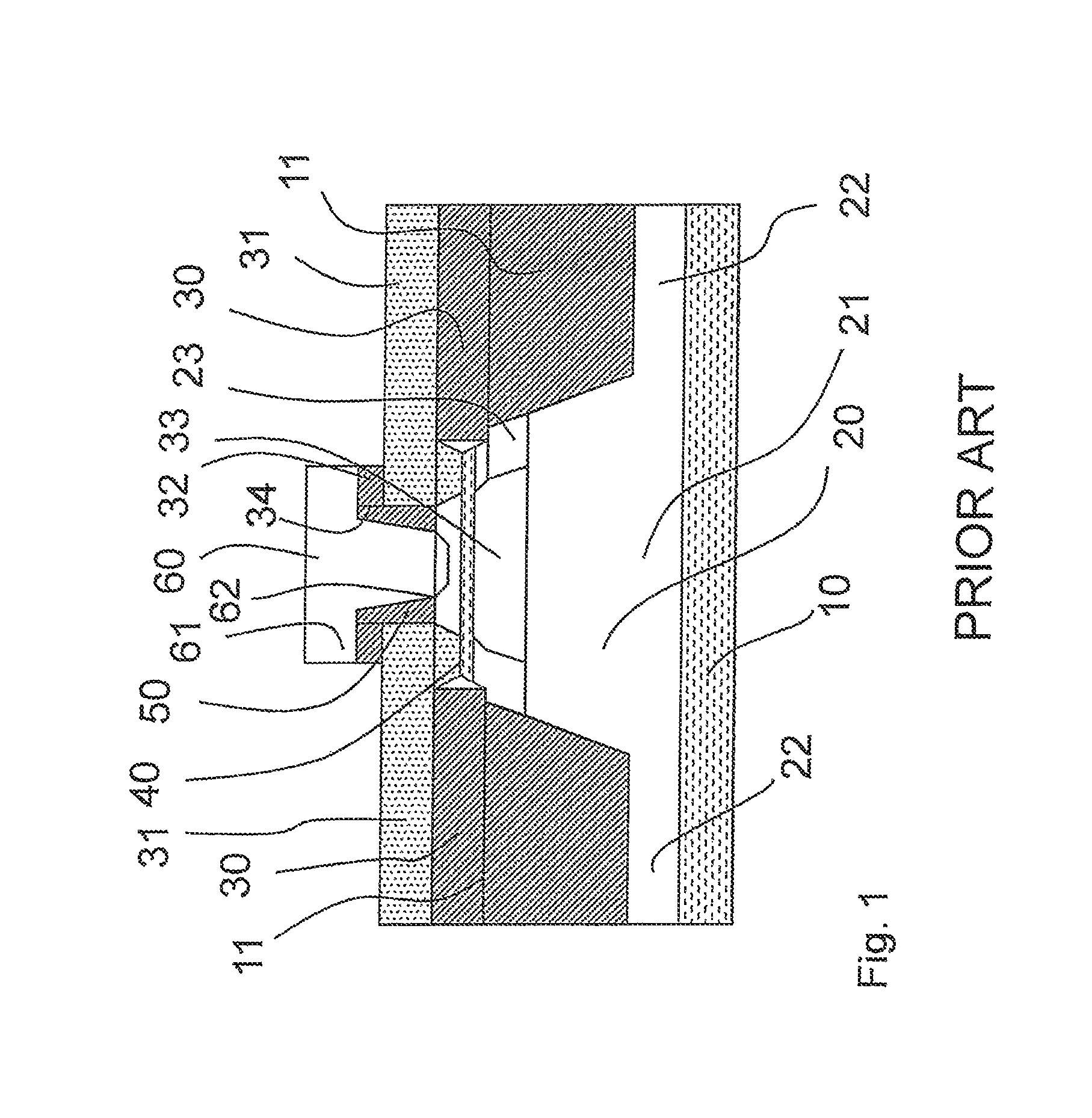

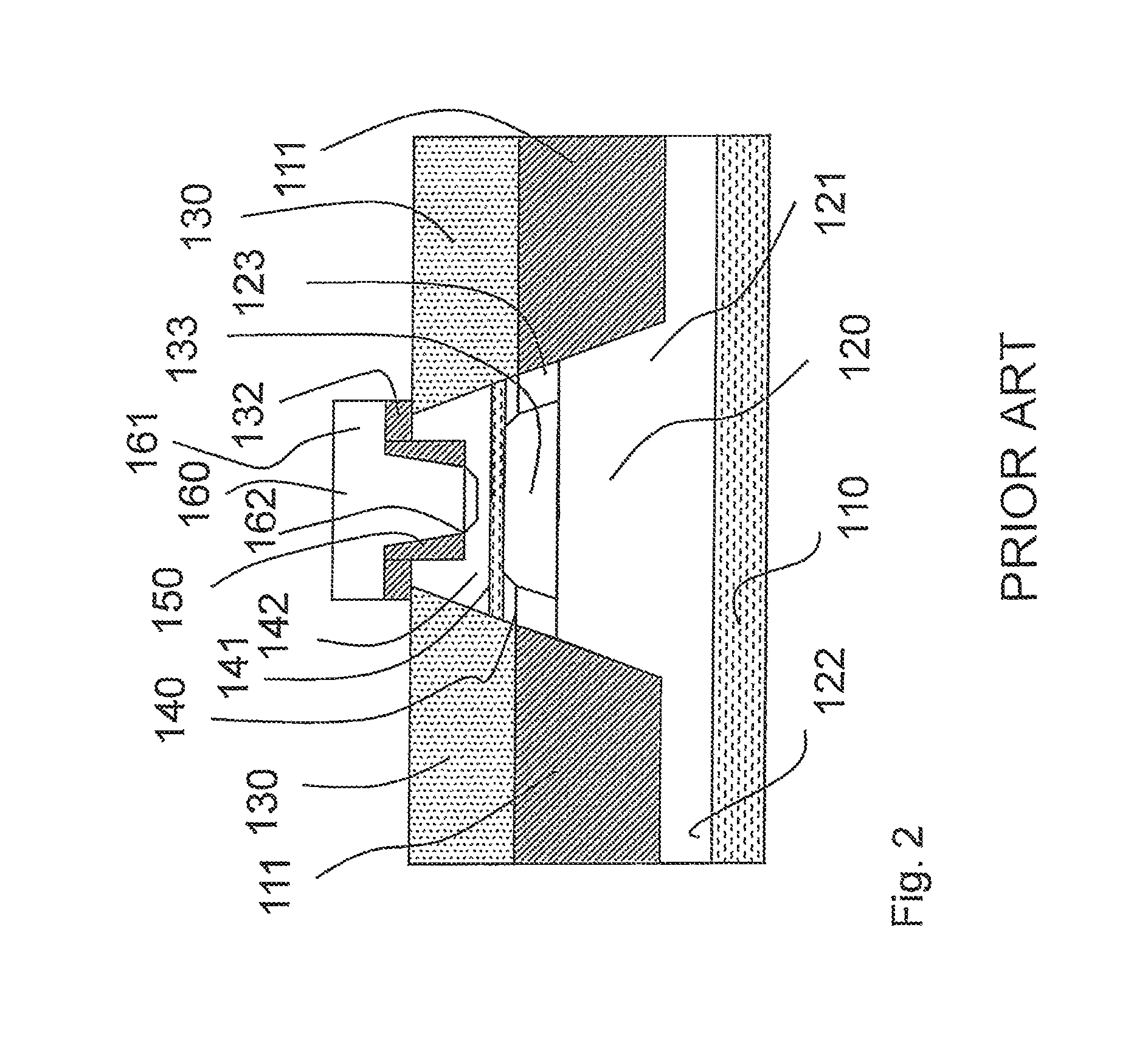

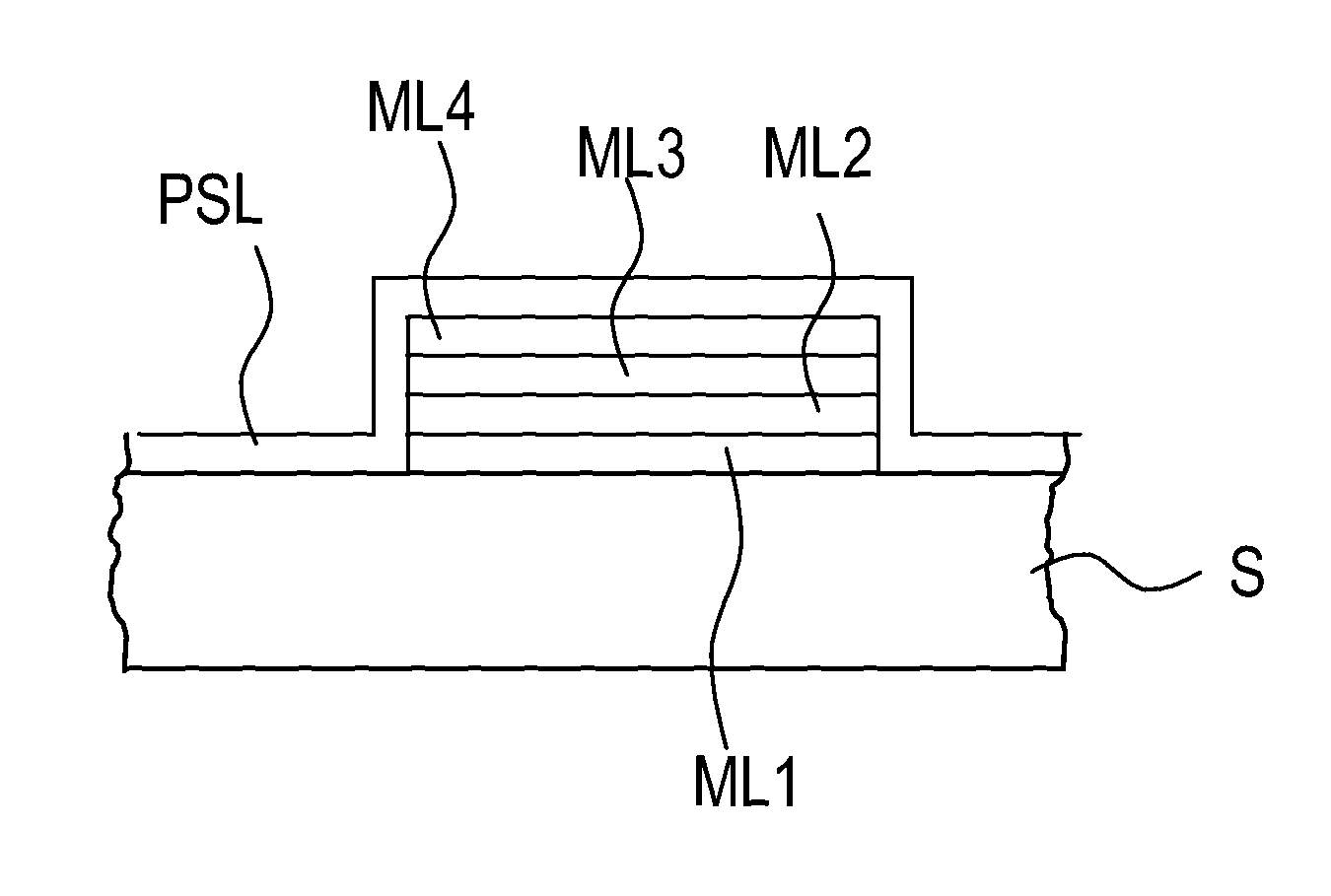

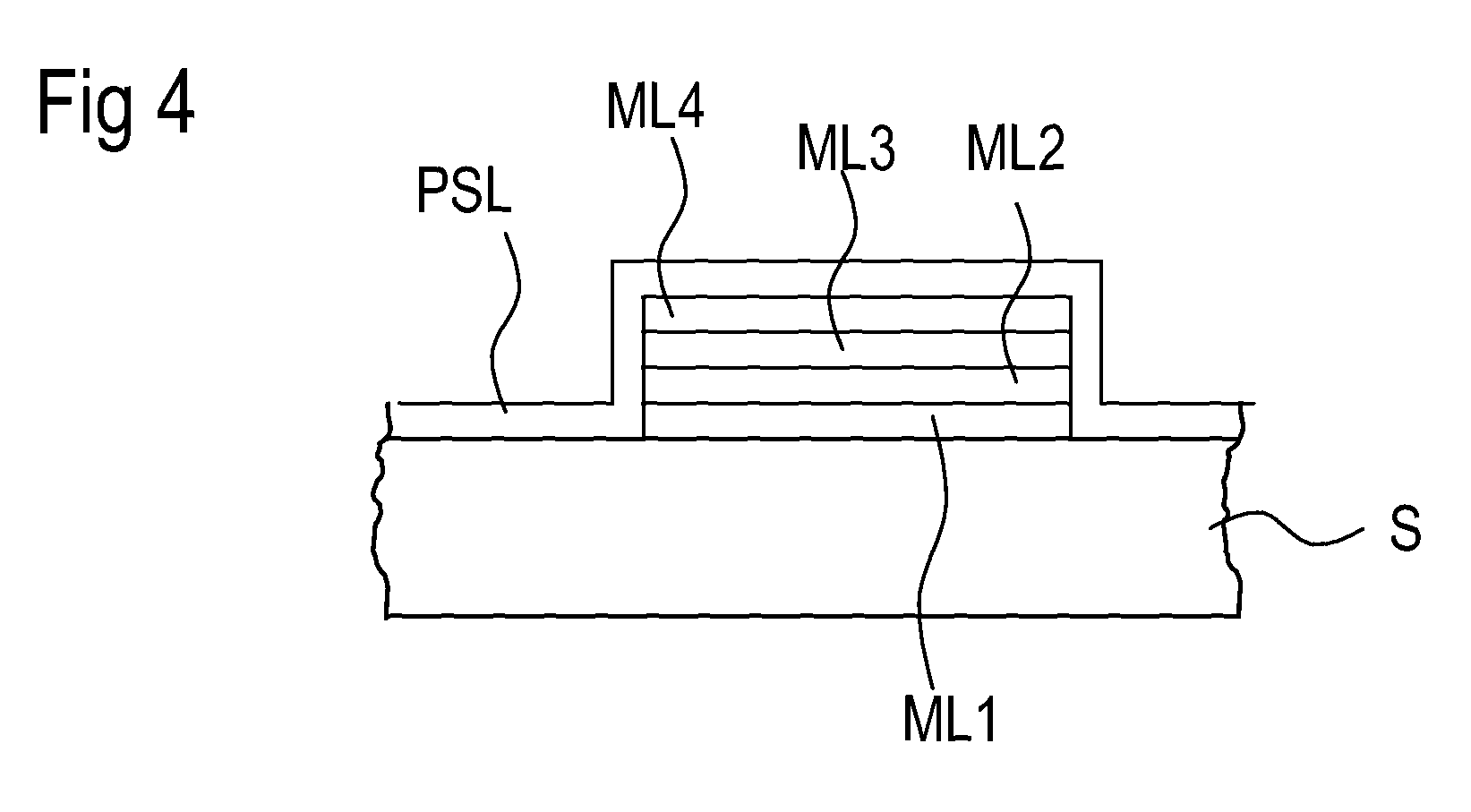

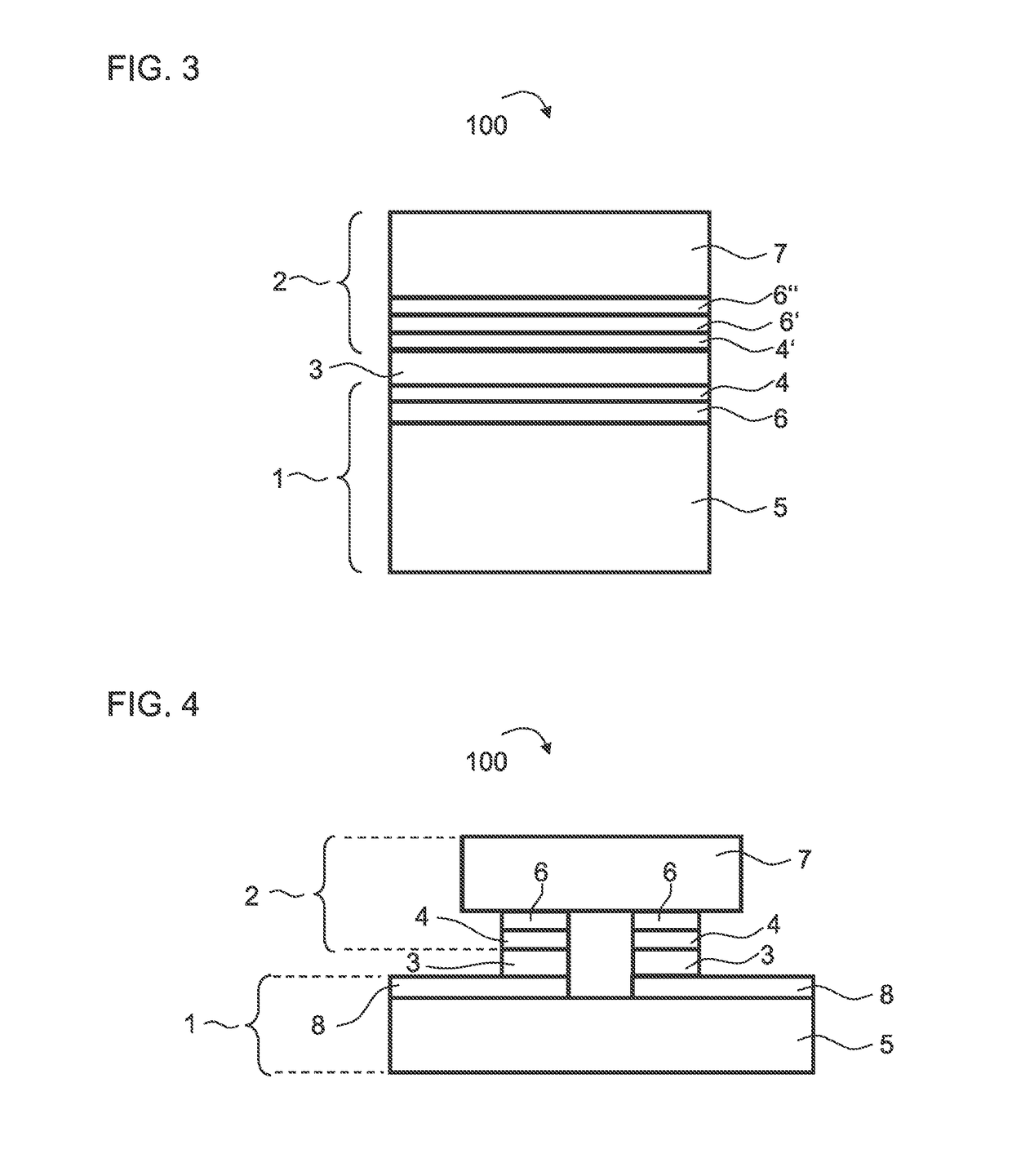

Bipolar transistor having self-adjusted emitter contact

ActiveUS20120001192A1Good high-frequency characteristicReduce resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesChemical compositionSemiconductor materials

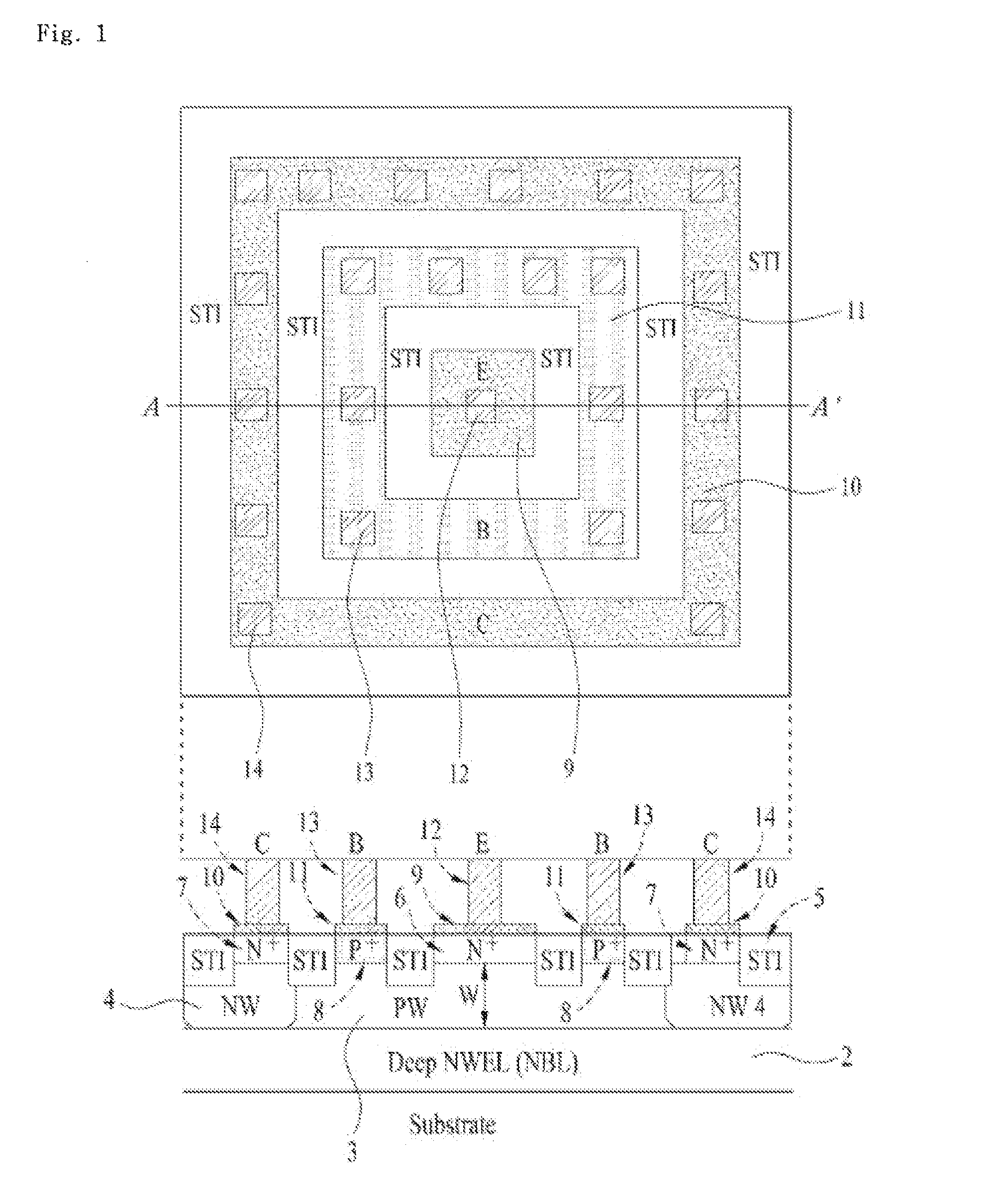

A semiconductor device, comprising a substrate layer made of a semiconductor material of a first conductivity type and having a first insulation region, and a vertical bipolar transistor having a first vertical portion of a collector made of monocrystalline semiconductor material of a second conductivity type and disposed in an opening of the first insulation region, a second insulation region lying partly on the first vertical portion of the collector and partly on the first insulation region and having an opening in the region of the collector, in which opening a second vertical portion of the collector made of monocrystalline material is disposed, said portion including an inner region of the second conductivity type, a base made of monocrystalline semiconductor material of the first conductivity type, a base connection region surrounding the base in the lateral direction, a T-shaped emitter made of semiconductor material of the second conductivity type and overlapping the base connection region, wherein the base connection region, aside from a seeding layer adjacent the substrate or a metallization layer adjacent a base contact, consists of a semiconductor material which differs in its chemical composition from the semiconductor material of the collector, the base and the emitter and in which the majority charge carriers of the first conductivity type have greater mobility compared thereto.

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE

Modification of surfaces in order to increase the surface tension

InactiveUS7025836B1Large layer thicknessImprove adhesionLiquid surface applicatorsOxide/hydroxide preparationWater vaporAlloy

A process is provided for the production of a surface coating as well as the use of surface coatings to increase the surface tension of objects. The surface coating is obtained by depositing a layer of at least one element that can be oxidized with water or an alloy that can be oxidized with water. Subsequently, the deposited layer is subjected to boiling water or water vapor. The element is generally derived from the following group of elements: Al, Si, Ti, V, Cr, Mn, Fe, Co, Ni, Zn, Ga, Ge, Zr, Nb, Cd, In, Sn, Sb.

Owner:ROCHE DIAGNOSTICS GMBH

Method for fabricating a bipolar transistor having self-aligned emitter contact

ActiveUS20150140771A1Good high-frequency characteristicReduce resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesChemical compositionSemiconductor materials

A method of producing a semiconductor device, comprising a substrate layer made of a semiconductor material of a first conductivity type and having a first insulation region, and a vertical bipolar transistor having a first vertical portion of a collector made of monocrystalline semiconductor material of a second conductivity type and disposed in an opening of the first insulation region, a second insulation region lying partly on the first vertical portion of the collector and partly on the first insulation region and having an opening in the region of the collector, in which opening a second vertical portion of the collector made of monocrystalline material is disposed, the portion including an inner region of the second conductivity type, a base made of monocrystalline semiconductor material of the first conductivity type, a base connection region surrounding the base in the lateral direction, a T-shaped emitter made of semiconductor material of the second conductivity type and overlapping the base connection region, wherein the base connection region, aside from a seeding layer adjacent the substrate or a metallization layer adjacent a base contact, consists of a semiconductor material which differs in its chemical composition from the semiconductor material of the collector, the base and the emitter and in which the majority charge carriers of the first conductivity type have greater mobility compared thereto.

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE

Aluminium oxide-based metallisation barrier

InactiveUS20130341769A1Large layer thicknessMaintain good propertiesSemiconductor/solid-state device detailsSolid-state devicesDiffusion barrierMetal

Owner:MERCK PATENT GMBH

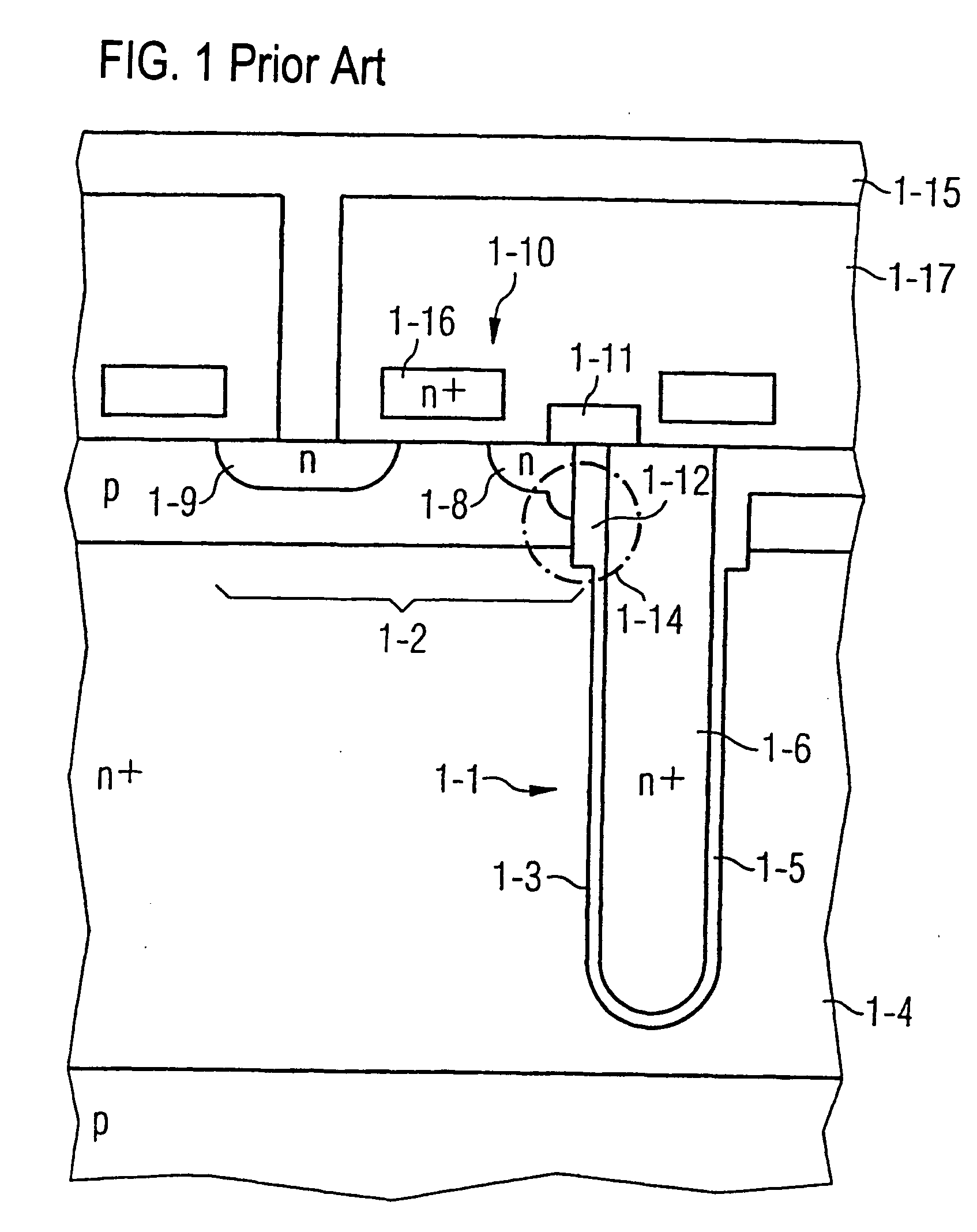

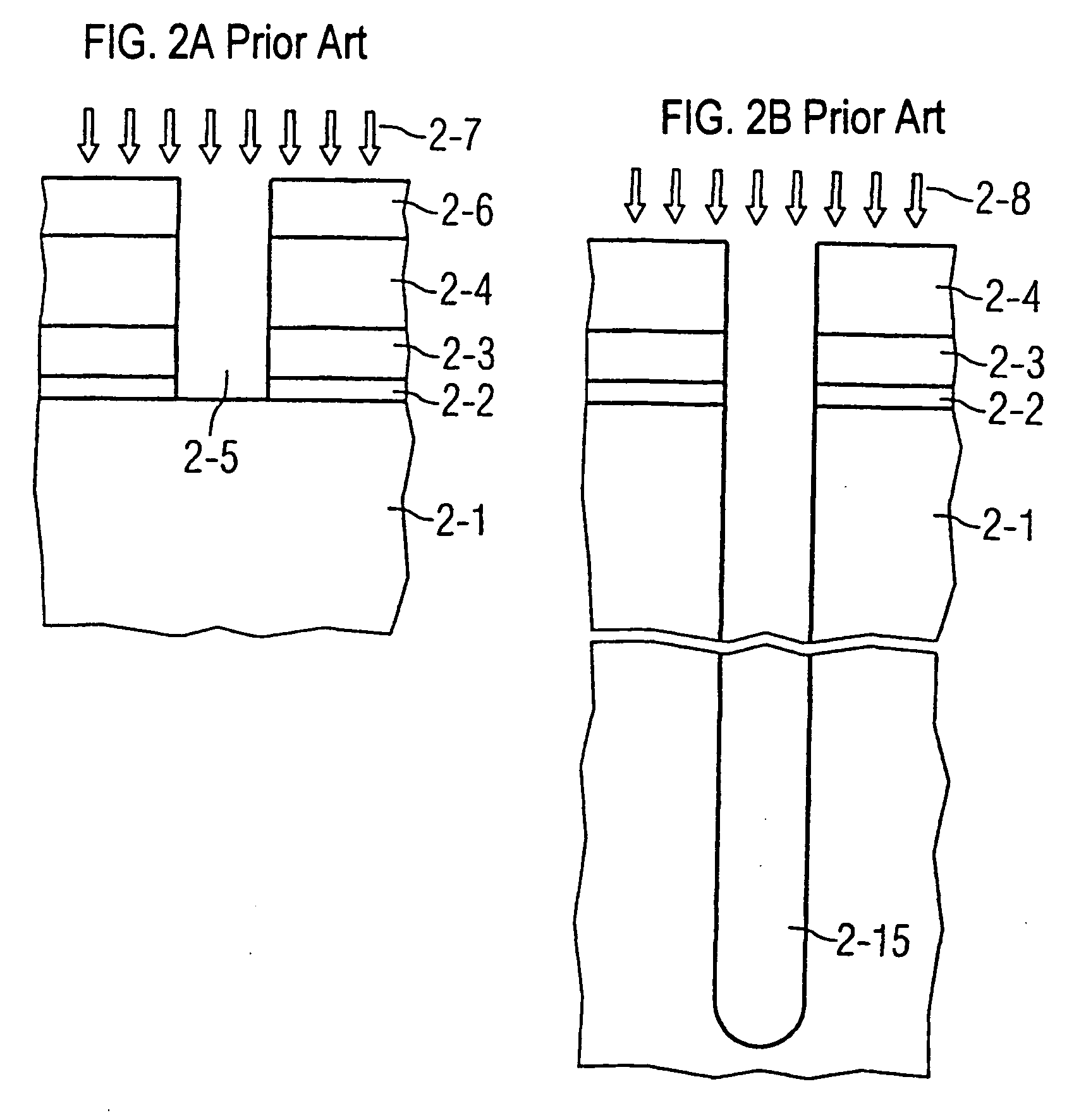

Method for fabricating trench capacitors for integrated semiconductor memories

InactiveUS20050118775A1Offset shrinkageLarge layer thicknessTransistorSolid-state devicesCapacitorSemiconductor

In a method for fabricating trench capacitors, in particular for memory cells having at least one selection transistor for integrated semiconductor memories, a trench for the trench capacitor is formed. The trench has a lower trench region, in which the capacitor is disposed, and an upper trench region, in which an electrically conductive connection from an electrode of the capacitor to a diffusion zone of the selection transistor is disposed. The method reduces the number of process steps for the fabrication of memory cells and enables fabrication of buried collars in the storage capacitors with an insulation quality as required for the fabrication of very large-scale integrated memory cells (<300 nm trench diameter).

Owner:POLARIS INNOVATIONS LTD

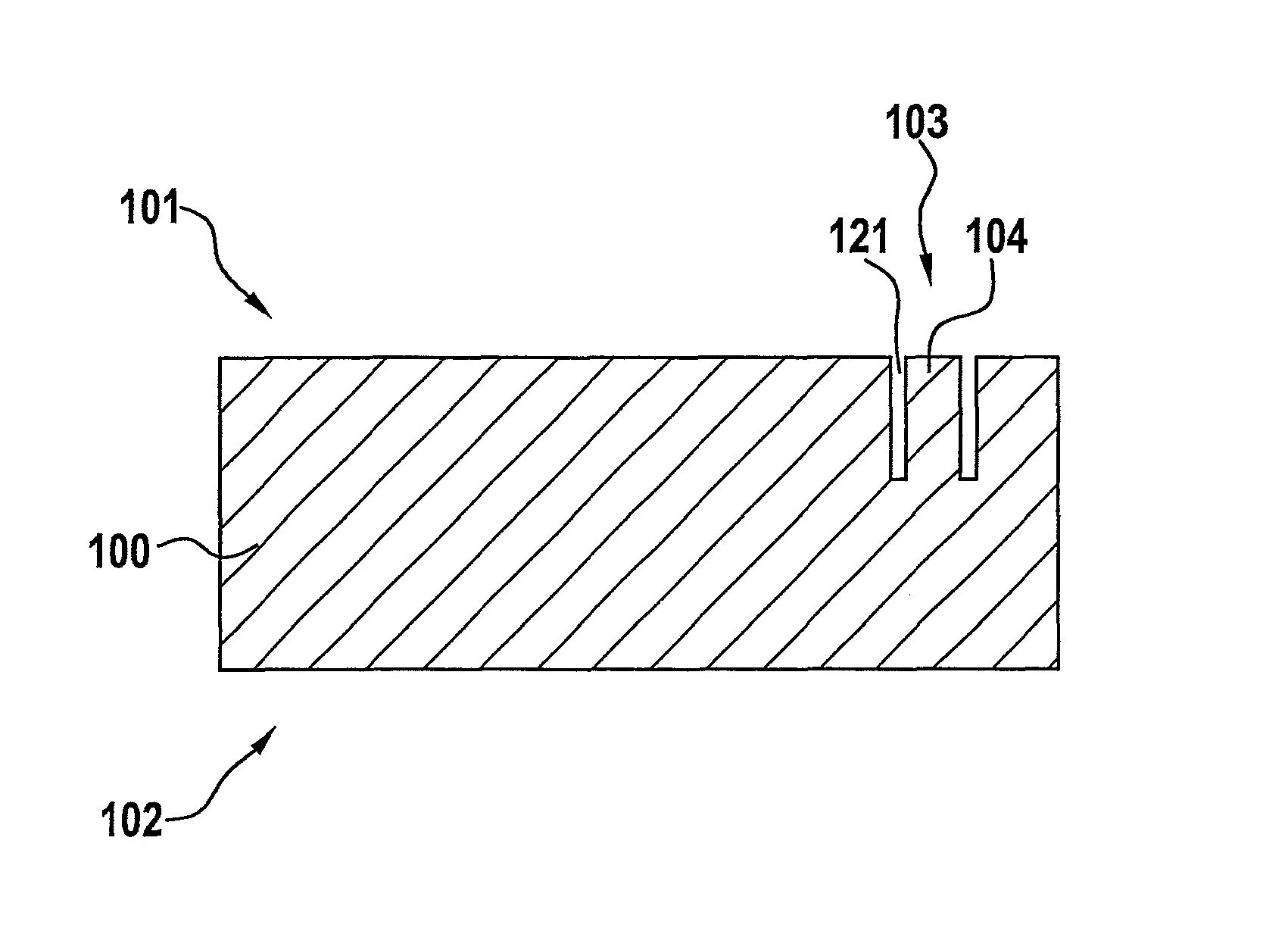

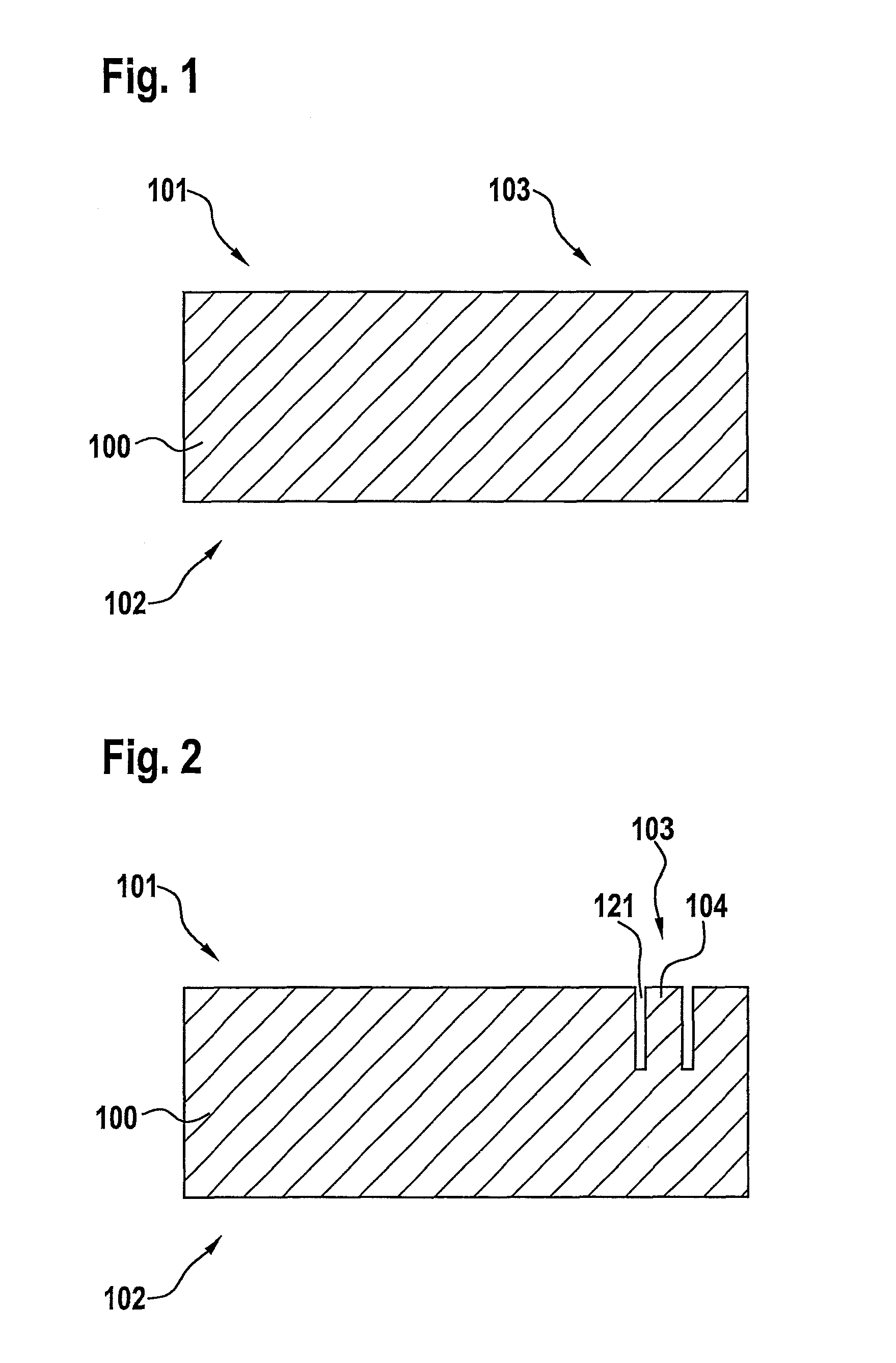

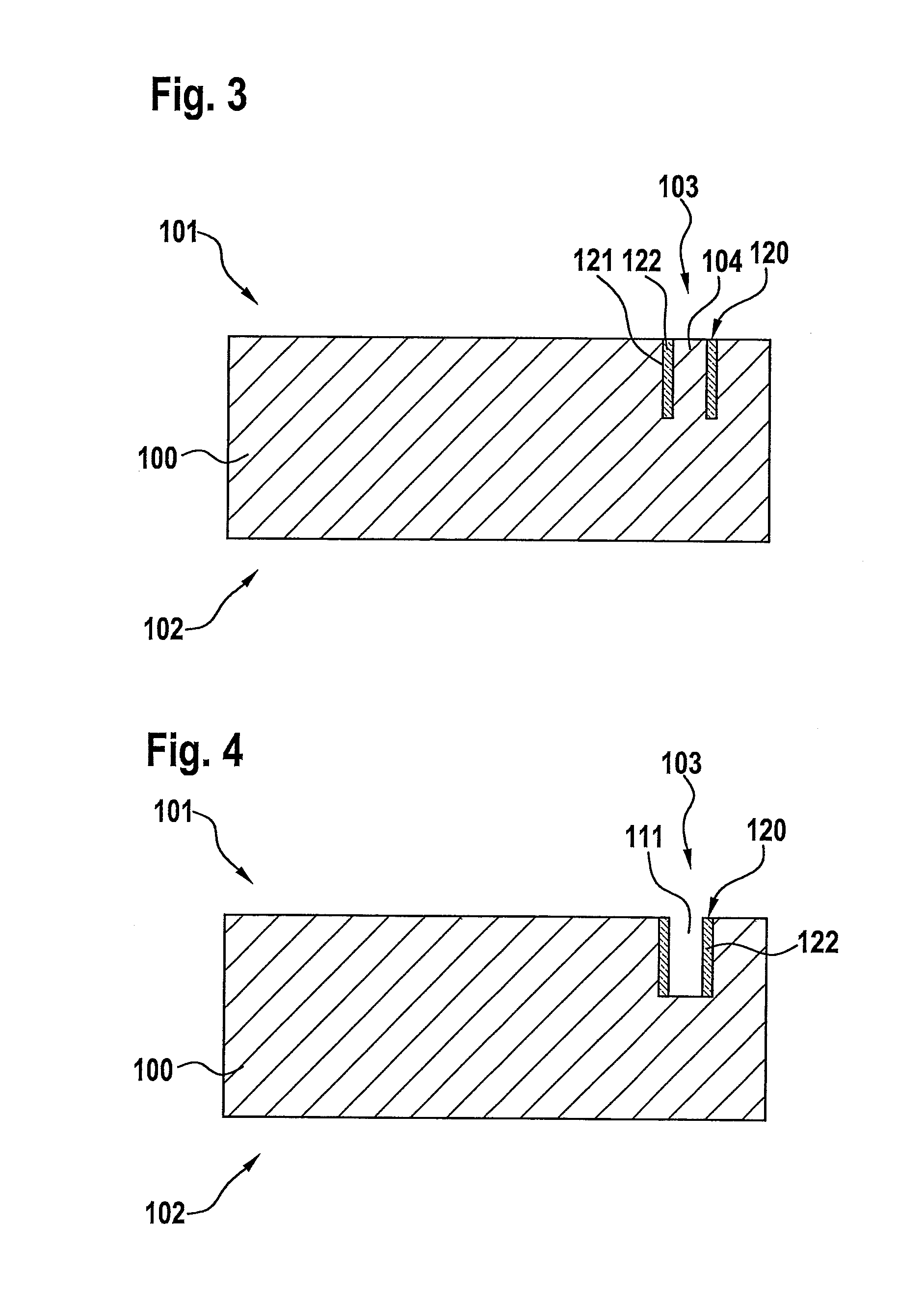

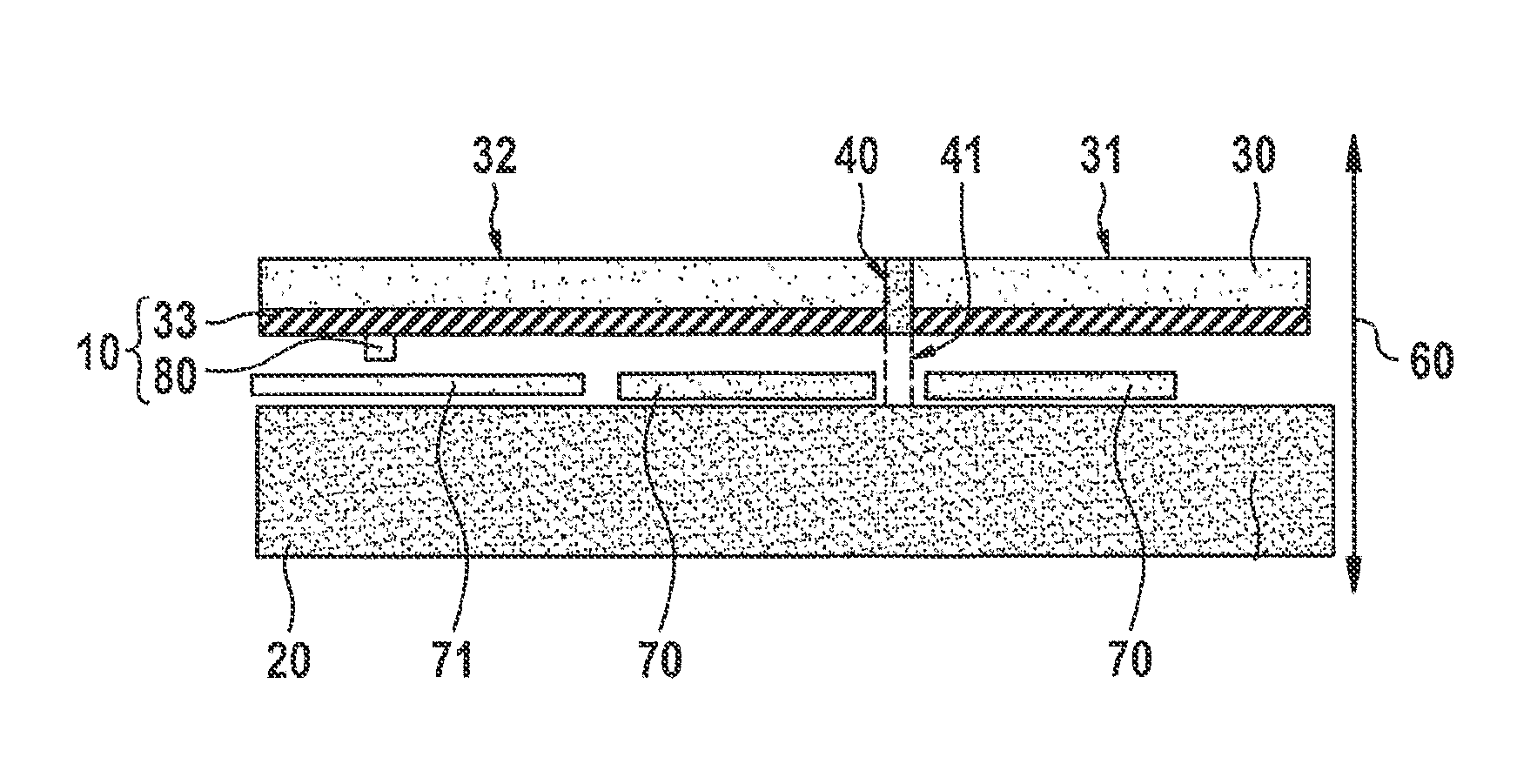

Method for manufacturing a component having an electrical through-connection

ActiveUS20130341738A1Efficient productionReduced base areaDecorative surface effectsSemiconductor/solid-state device manufacturingElectricityEngineering

A method for manufacturing a component having an electrical through-connection includes: providing a semiconductor substrate having a front side and a back side opposite from the front side; producing, on the front side of the semiconductor substrate, an insulating trench which annularly surrounds a contact area; introducing an insulating material into the insulating trench; producing a contact hole on the front side of the semiconductor substrate by removing the semiconductor material surrounded by the insulating trench in the contact area; and depositing a metallic material in the contact hole.

Owner:ROBERT BOSCH GMBH

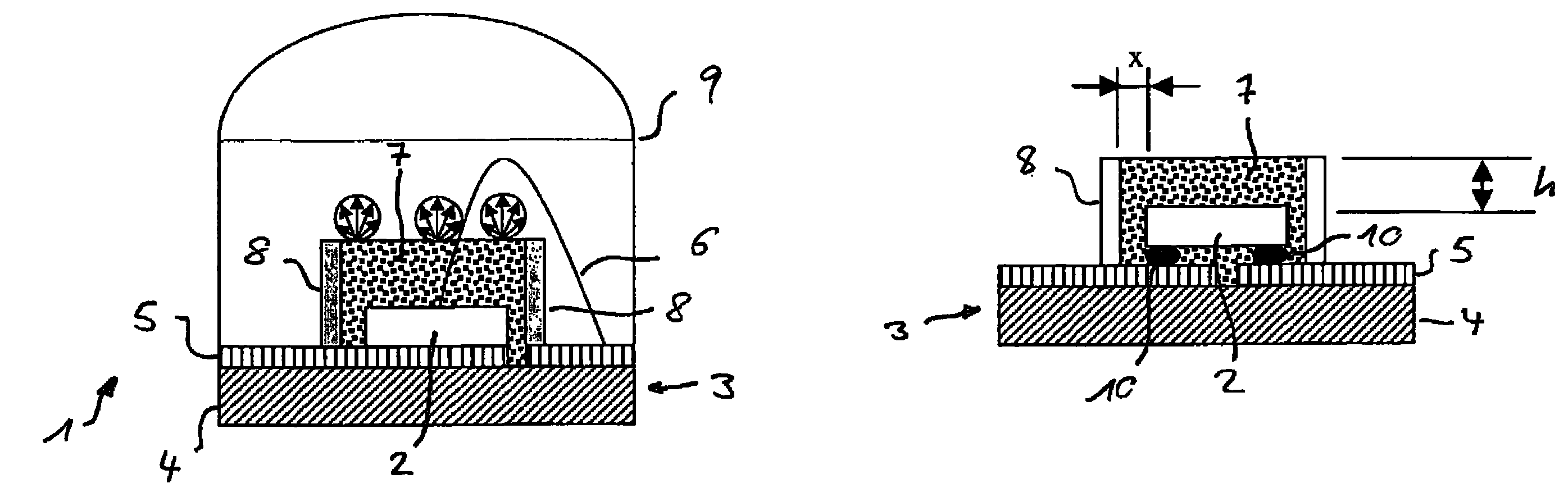

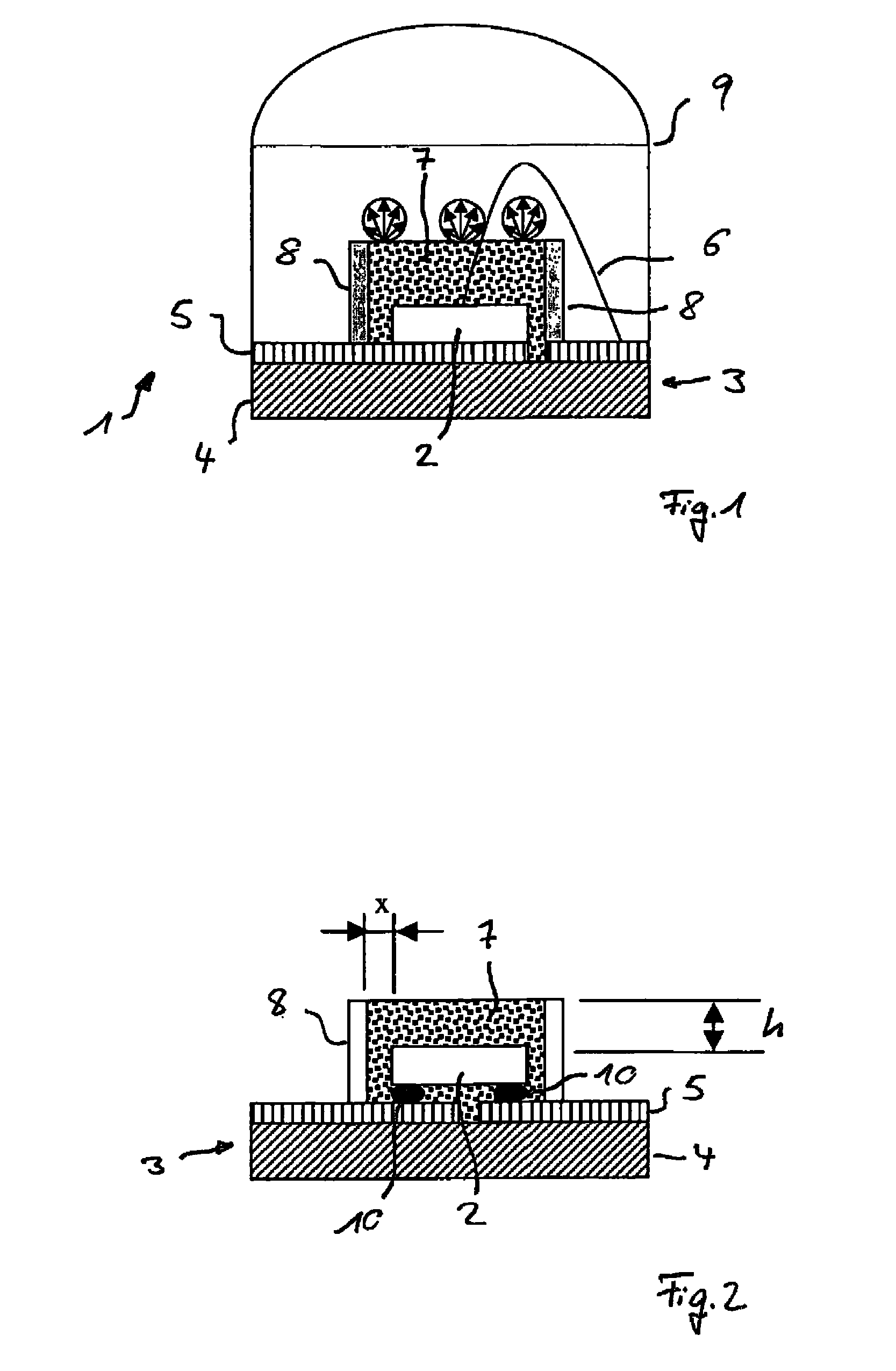

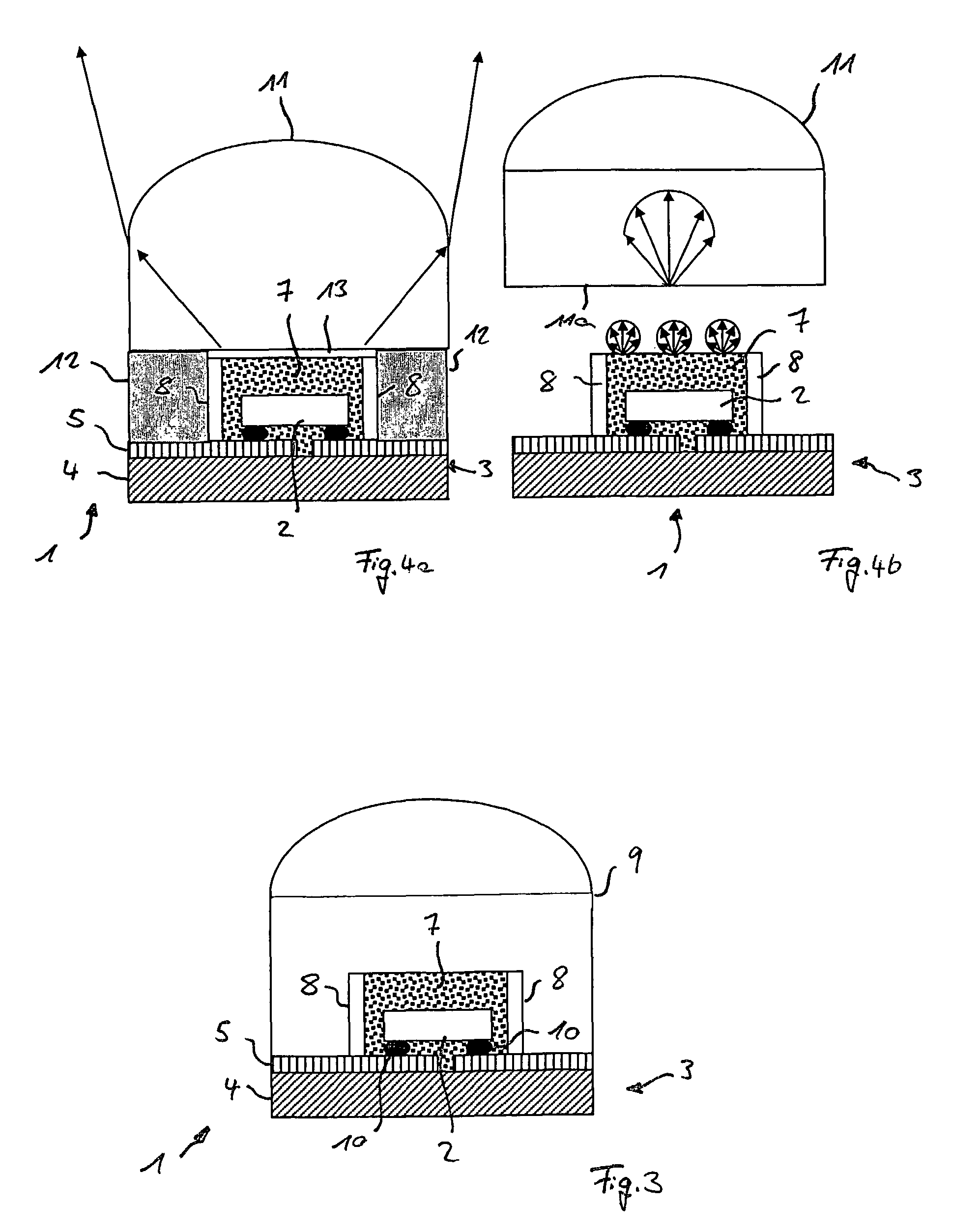

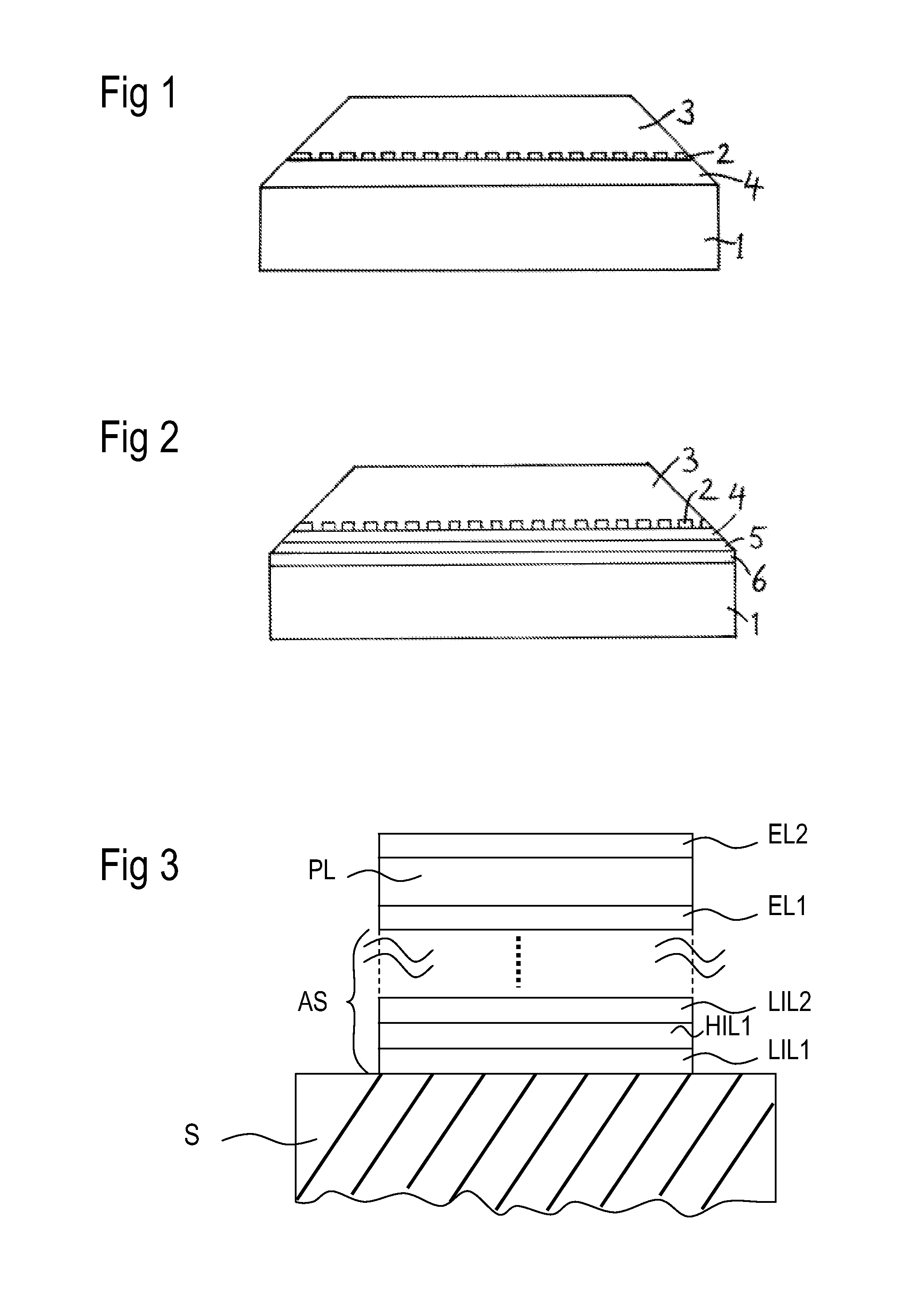

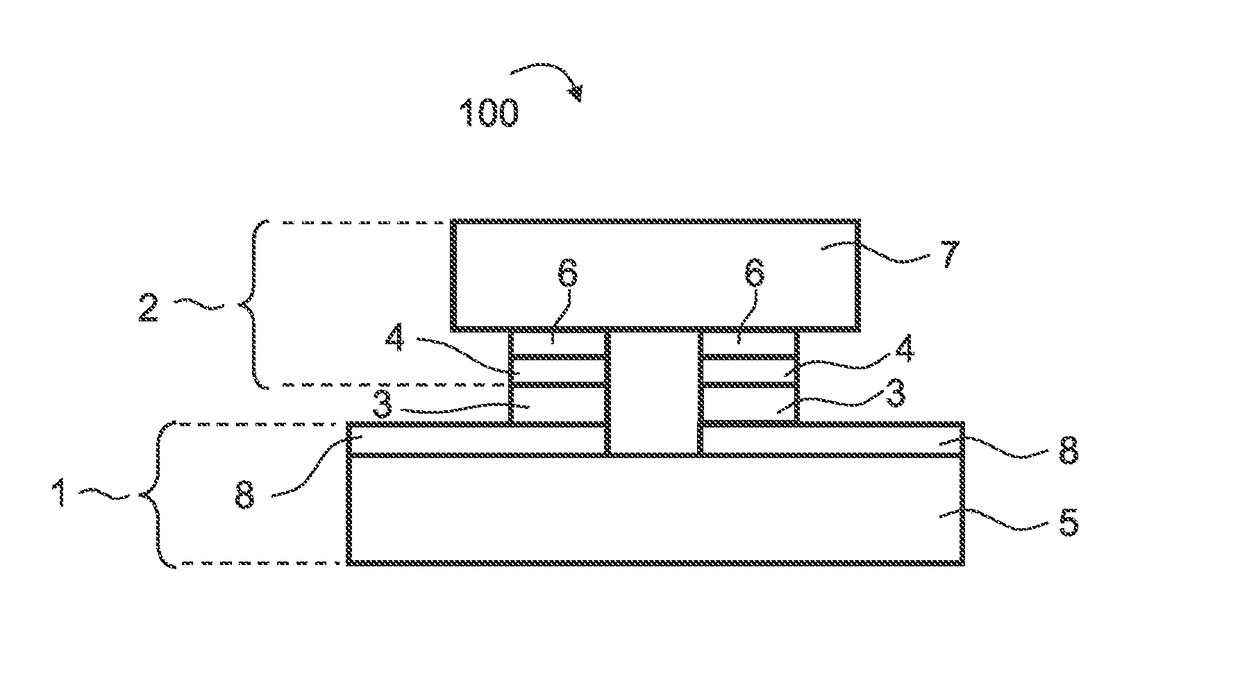

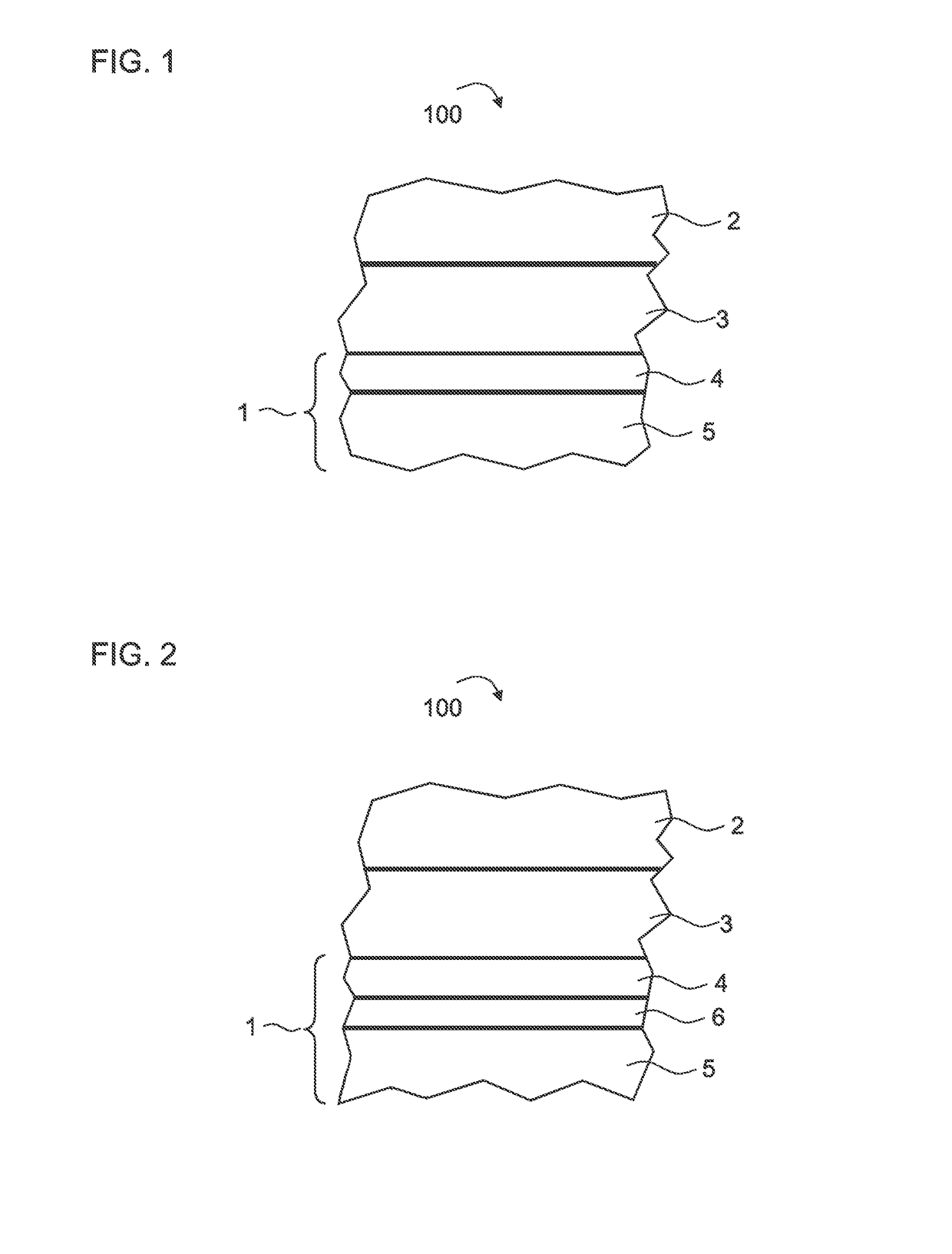

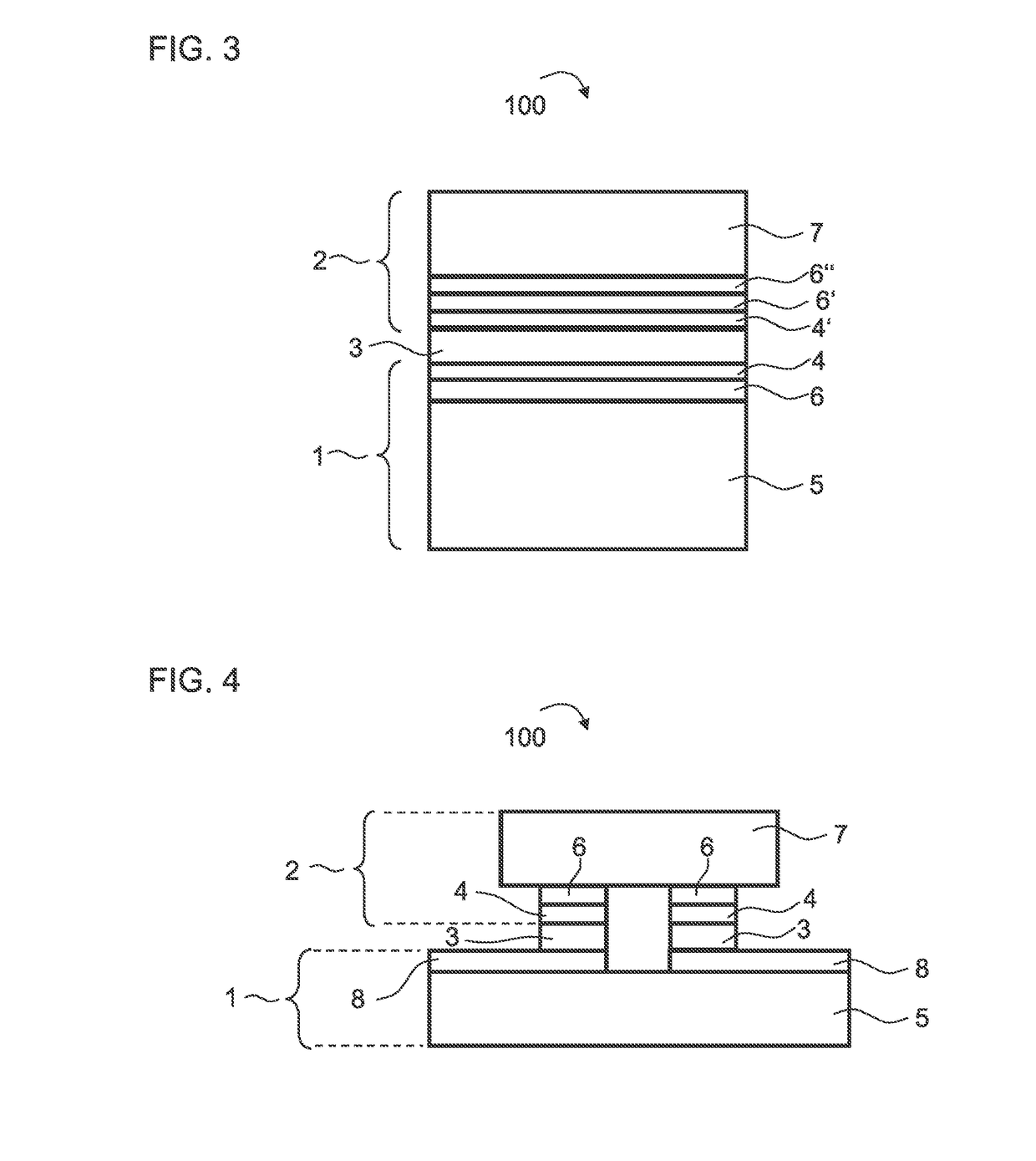

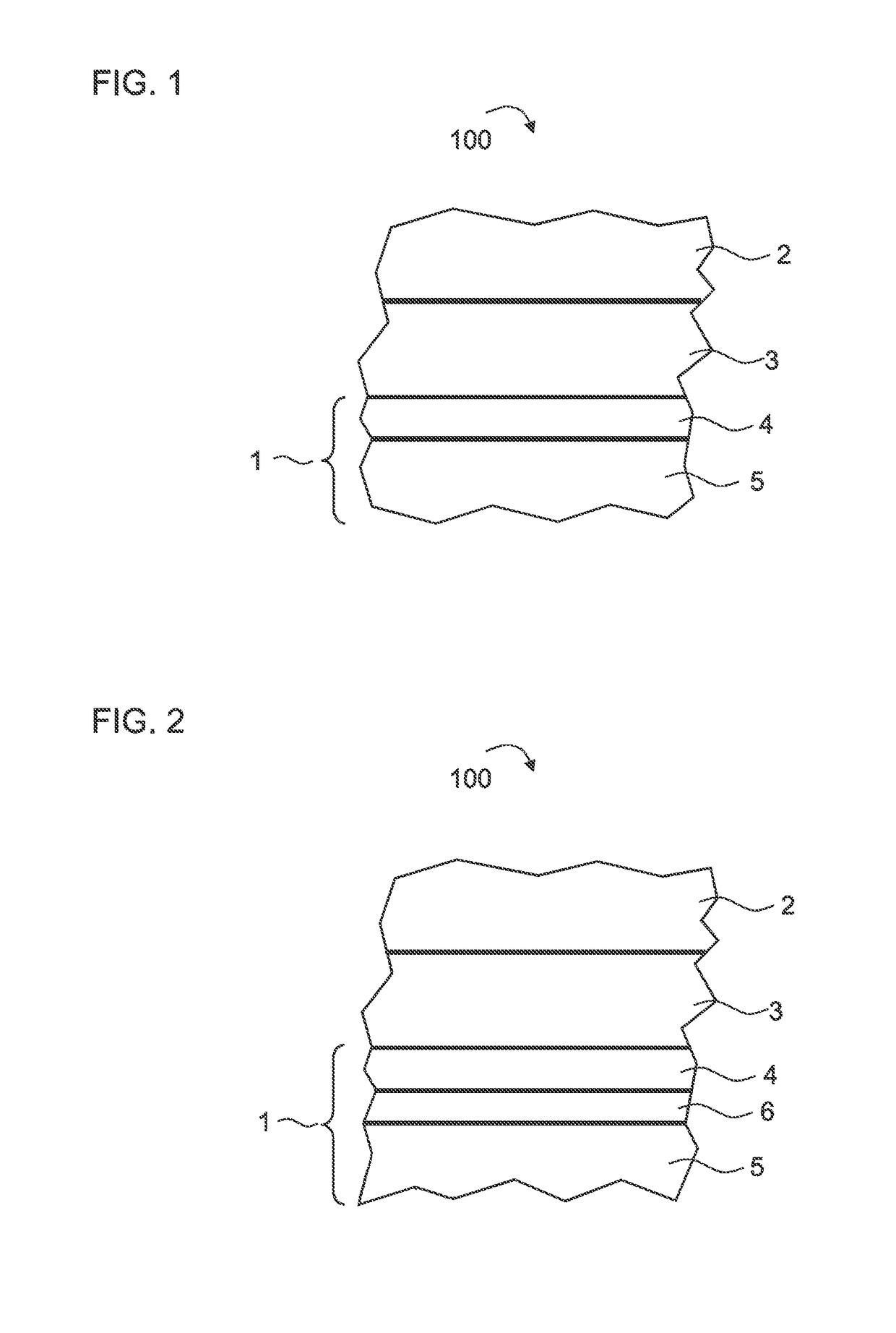

Light-emitting diode arrangement comprising a color-converting material

InactiveUS7777236B2Avoid disadvantagesDescribed in connectionSolid-state devicesSemiconductor devicesWavelengthLength wave

With a light-emitting diode arrangement (1) having a light-emitting diode chip (2) arranged on a base (3), and colour conversion material (7) surrounding the light-emitting diode chip (2), which material is constituted to convert at least a part of the light emitted by the light-emitting diode chip (2) into light of another wavelength, the colour conversion material (7) is surrounded to the side by a reflector (8), the lateral distance (x) of the light-emitting diode chip (2) to the reflector (8) amounting to at most 0.5 mm.

Owner:TRIDONIC OPTOELECTRONICS GMBH

Method for manufacturing a component having an electrical through-connection

ActiveUS20140027927A1Avoids entrainmentAvoids metal entrainmentSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveElectricity

A method for manufacturing a component having an electrical through-connection is described. The method includes the following steps: providing a semiconductor substrate having a front side and a back side opposite from the front side, producing an insulating trench, which annularly surrounds a contact area, on the front side of the semiconductor substrate, filling the insulating trench with an insulating material, producing an electrical contact structure on the front side of the semiconductor substrate by depositing an electrically conductive material in the contact area, removing the semiconductor material remaining in the contact area on the back side of the semiconductor substrate in order to produce a contact hole which opens up the bottom side of the contact structure, and depositing a metallic material in the contact hole in order to electrically connect the electrical contact structure to the back side of the semiconductor substrate.

Owner:ROBERT BOSCH GMBH

Bipolar transistor having self-adjusted emitter contact

ActiveUS8933537B2Good high-frequency characteristicReduce resistanceTransistorSolid-state devicesChemical compositionSemiconductor materials

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE

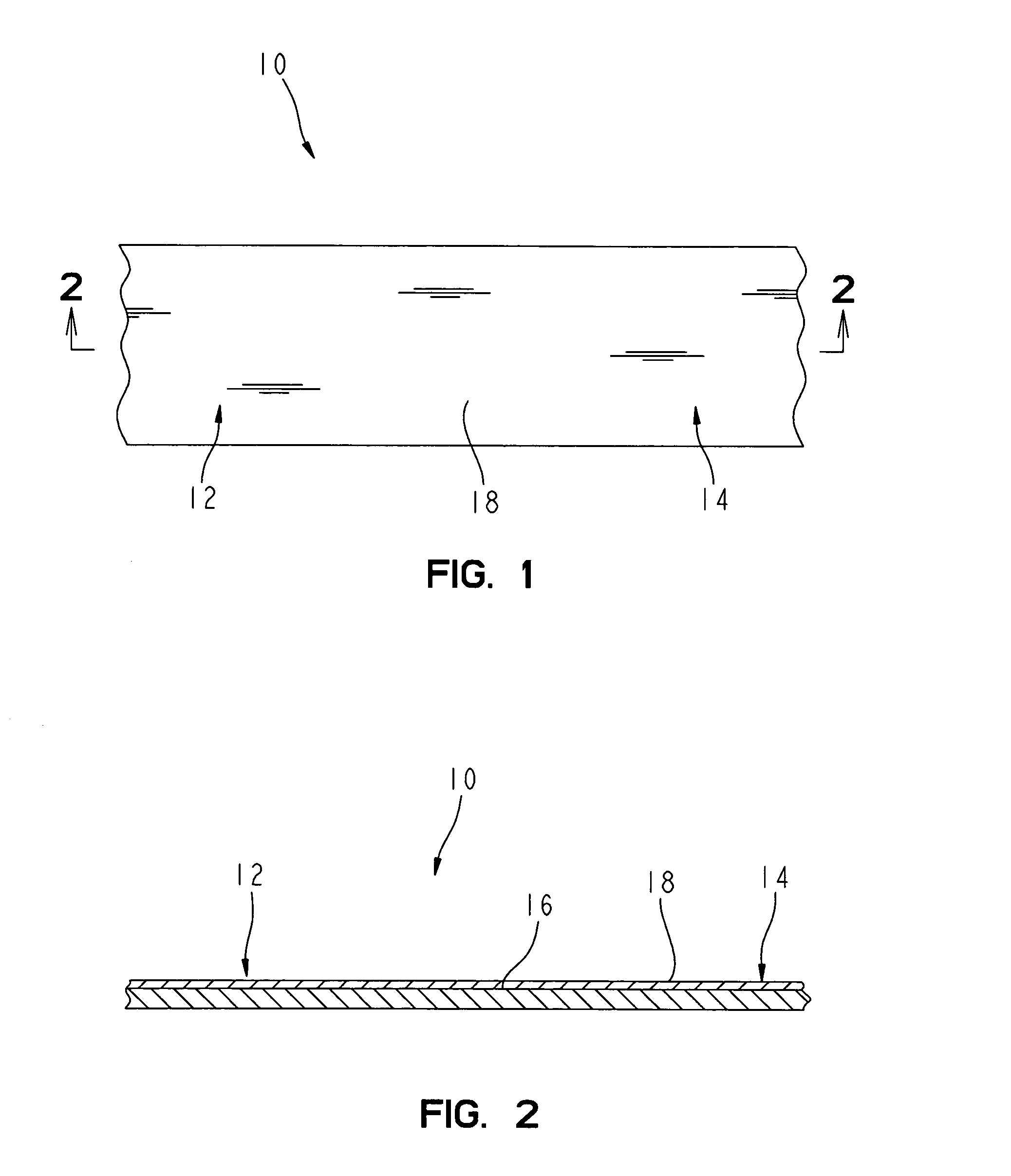

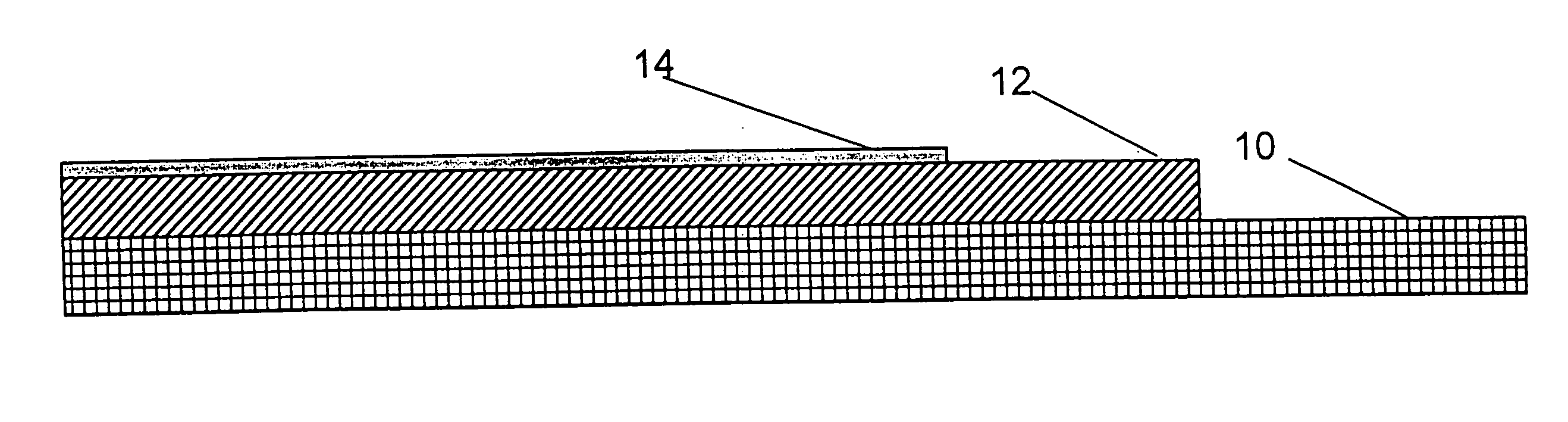

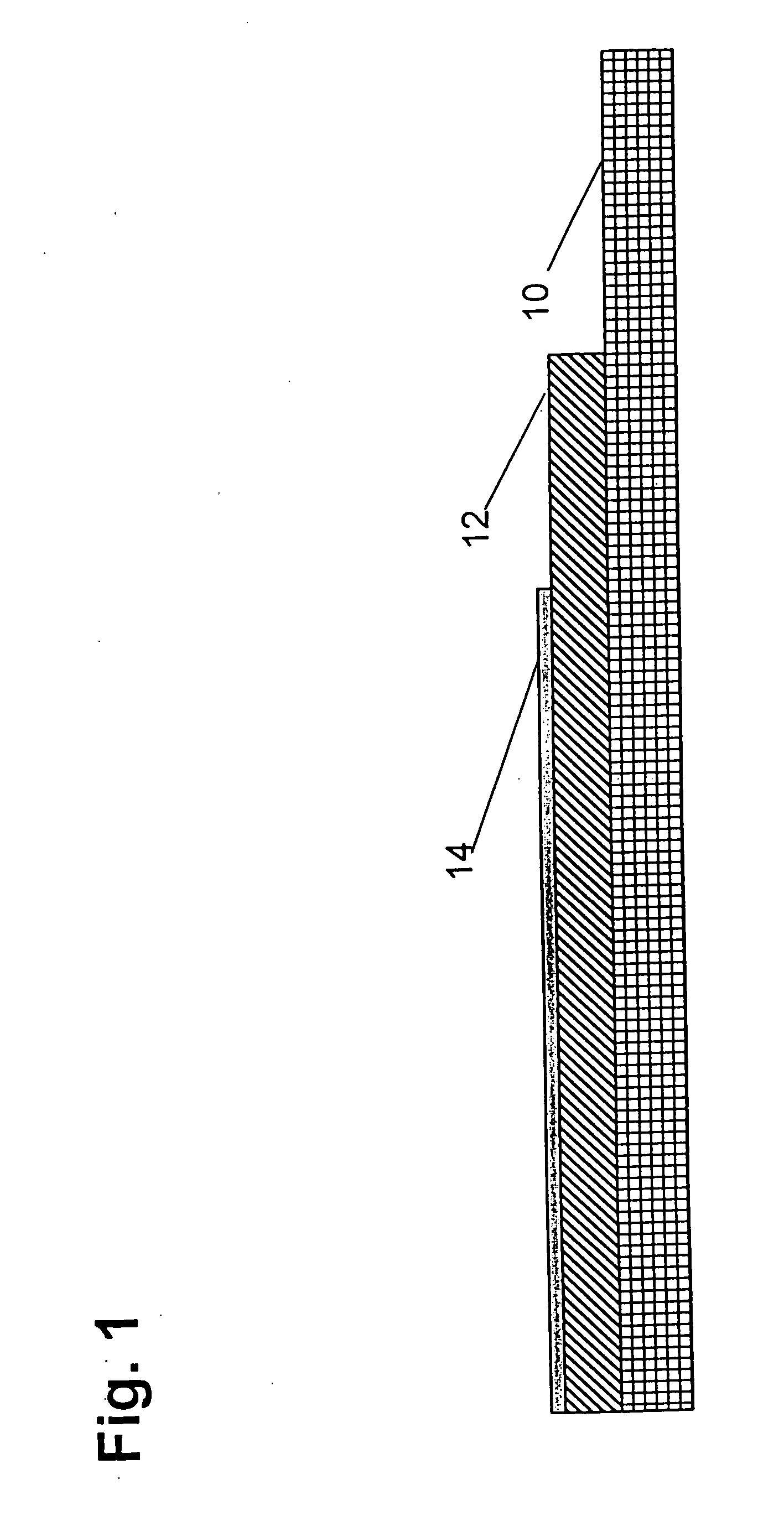

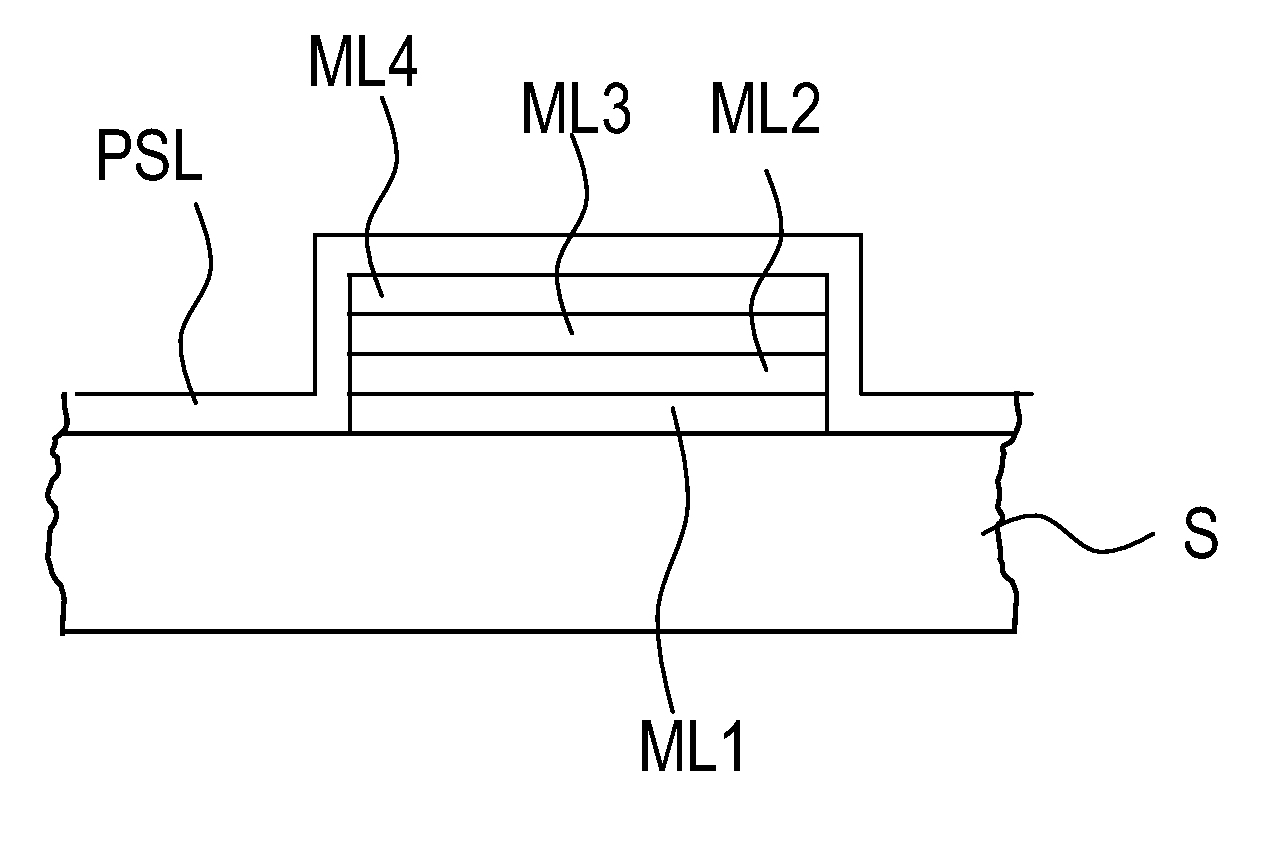

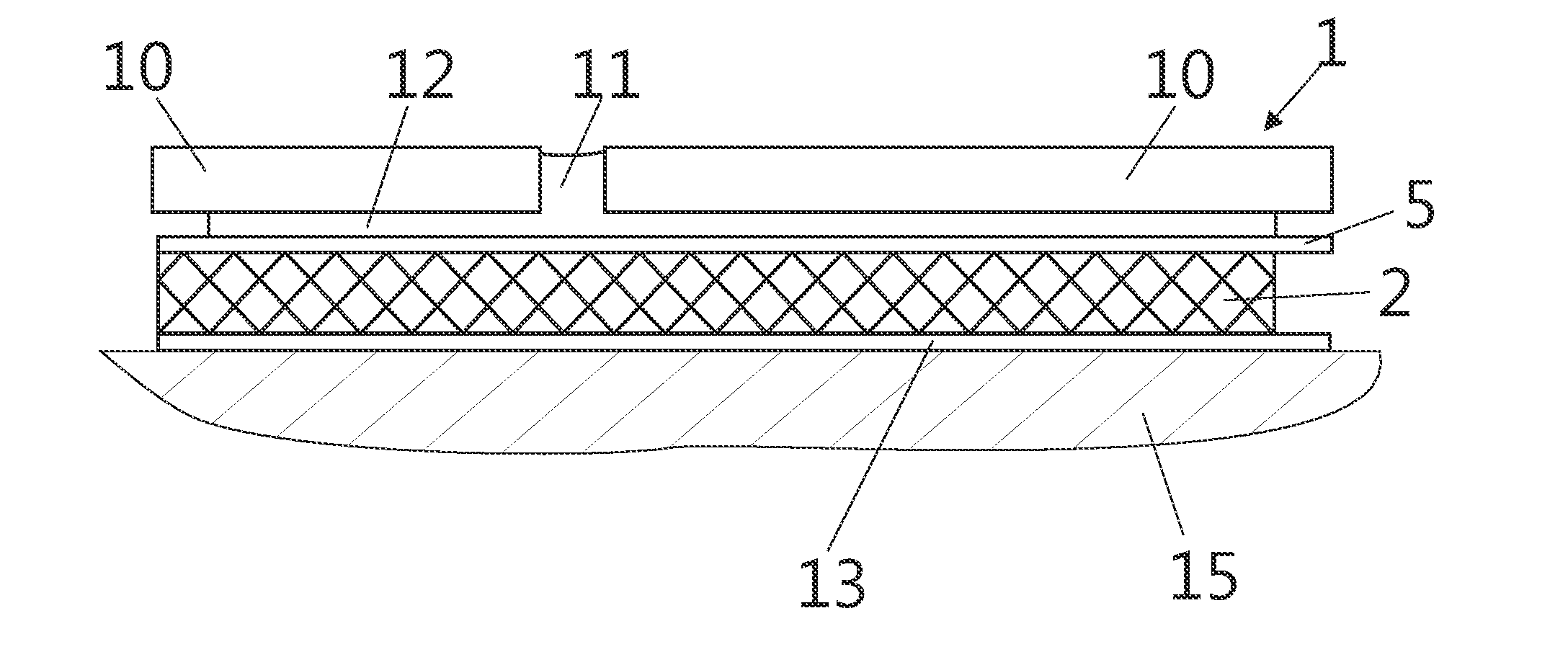

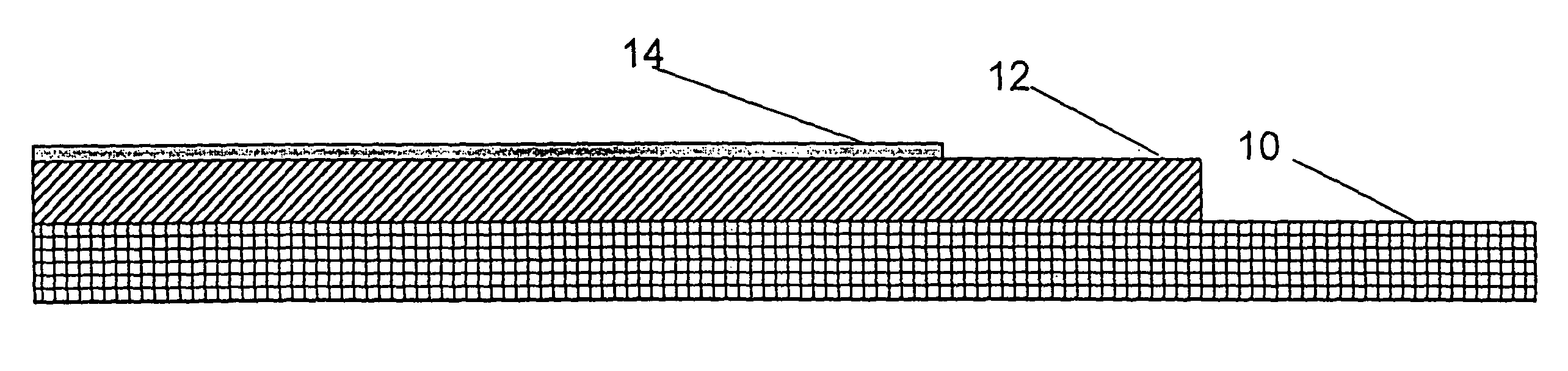

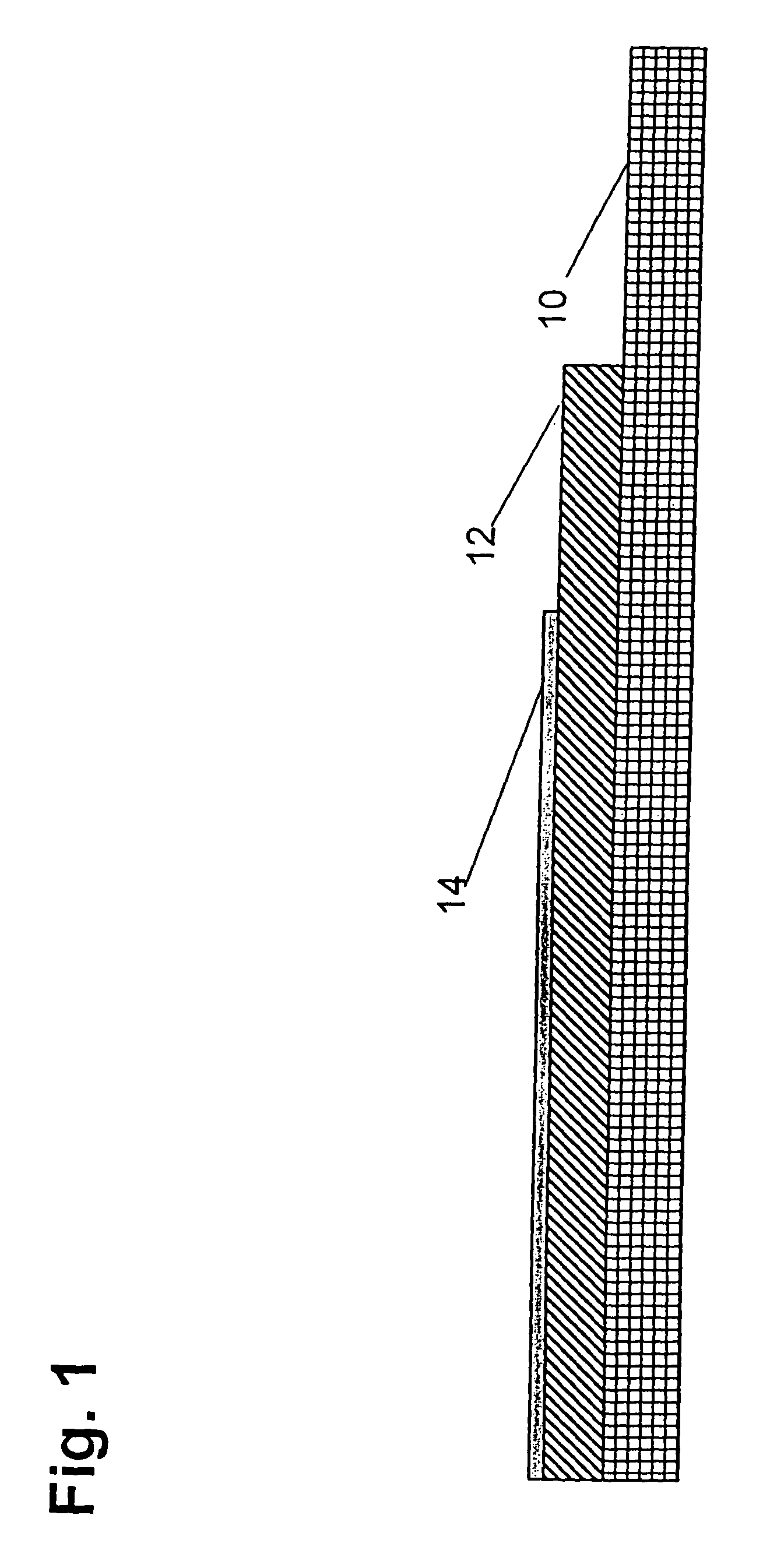

Sheet-or web-like, decorative coating film and method for producing the same

ActiveUS20060240247A1Great layer thicknessReduce product costSpecial paperDecorative surface effectsPaper sheetPolymer chemistry

A method for producing a sheet-like or web-like, decorative, scratch- and / or abrasion-resistant coating material, in particular a coating film, comprising the steps: coating a support layer (10) made of paper and / or plastic with a liquid or pasty base layer (12) which is free of organic solvents and comprises radiation-curing resins but no heat-curing resins and also an abrasive filler, preferably an inorganic filler, drying the support layer (10) coated with the base layer (12), in particular by supplying heat, applying a covering layer (14) to the dried, non-crosslinked base layer (12), said covering layer containing a radiation-curing resin and no abrasive fillers, and jointly curing and / or crosslinking the covering layer and also the radiation-curing resins in the base layer by irradiating the covering layer with UV and / or electron beams.

Owner:SURTECO DECOR

Attapulgite sewage treatment agent and preparation method thereof

InactiveCN106865655AGood dispersionGood suspensionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateAluminium chloride

The invention discloses an attapulgite sewage treatment agent and a preparation method thereof, and relates to the technical field of attapulgite processing. The attapulgite sewage treatment agent is prepared from the following raw materials in parts by weight: 150 to 200 parts of attapulgite, 200 to 250 parts of hollow glass beads, 80 to 100 parts of deionized water, 20 to 25 parts of a sulfuric acid solution, 20 to 25 parts of cross-linked rectorite, 2 to 5 parts of ferric trichloride, 2 to 5 parts of ferrous sulfate, 2 to 5 parts of magnesium sulfate, 2 to 5 parts of polyacrylamide, 2 to 5 parts of aluminium chloride, 2 to 5 parts of polyferric sulfate, 2 to 5 parts of sodium hydroxide, 2 to 5 parts of sodium benzoate, 2 to 5 parts of corn starch, 2 to 5 parts of straw, 1 to 3 parts of cottonseed shell residue, 1 to 3 parts of modified diatomite, 1 to 3 parts of citric acid, 1 to 3 parts of aids and a proper amount of water. The attapulgite serves as the raw material and is subjected to modification treatment, so high dispersibility, high suspension property and good adsorption effect are achieved.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

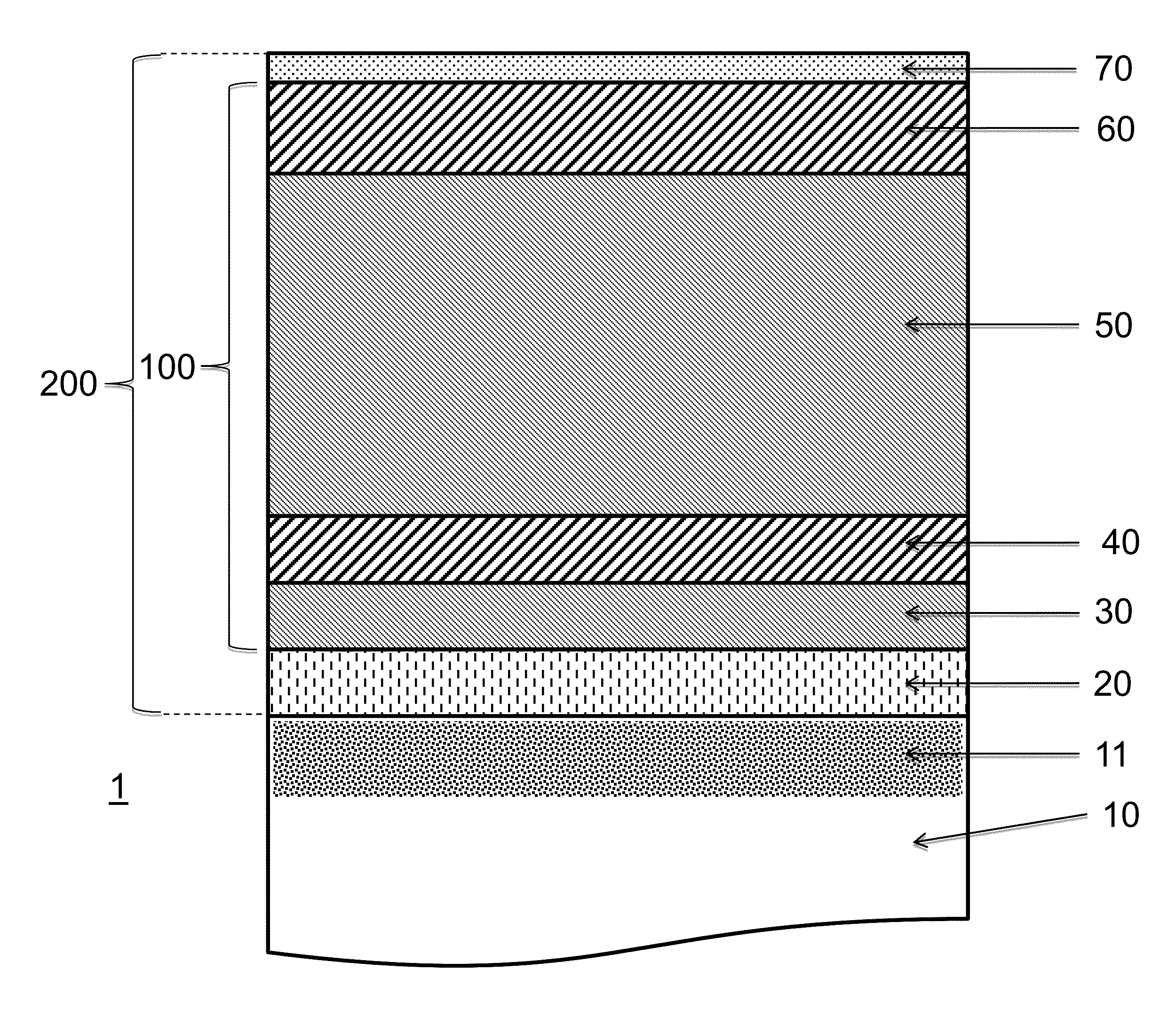

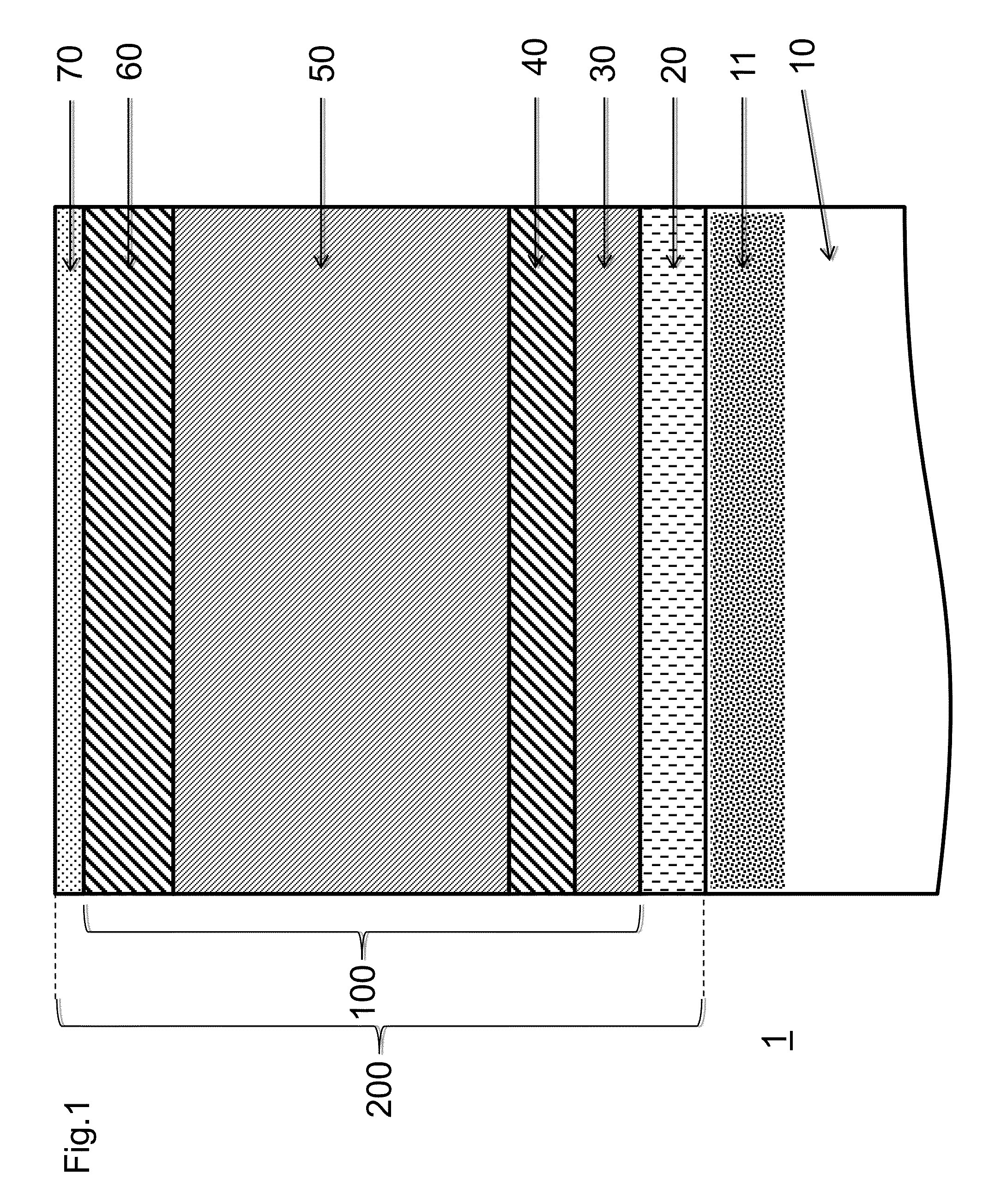

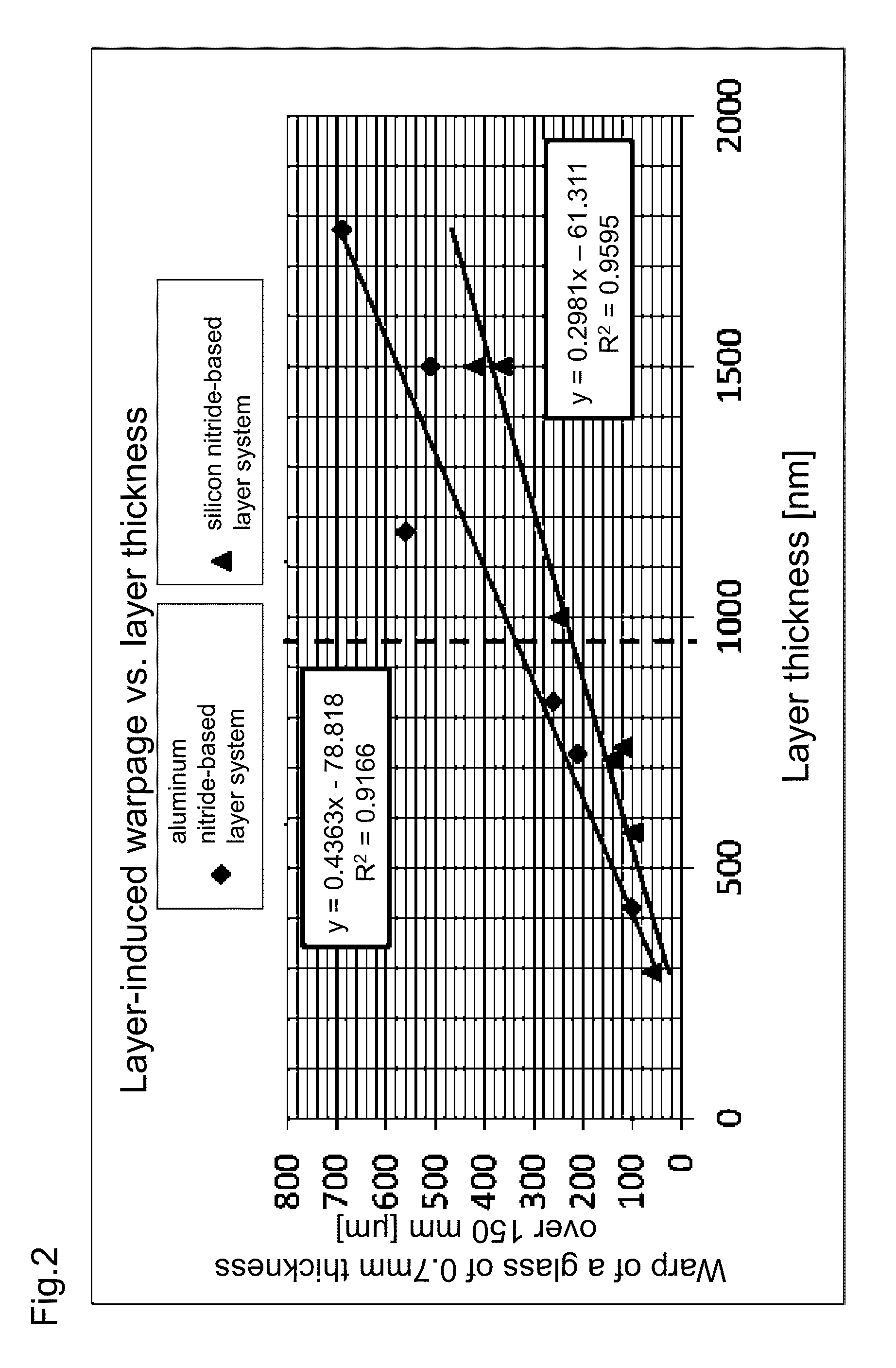

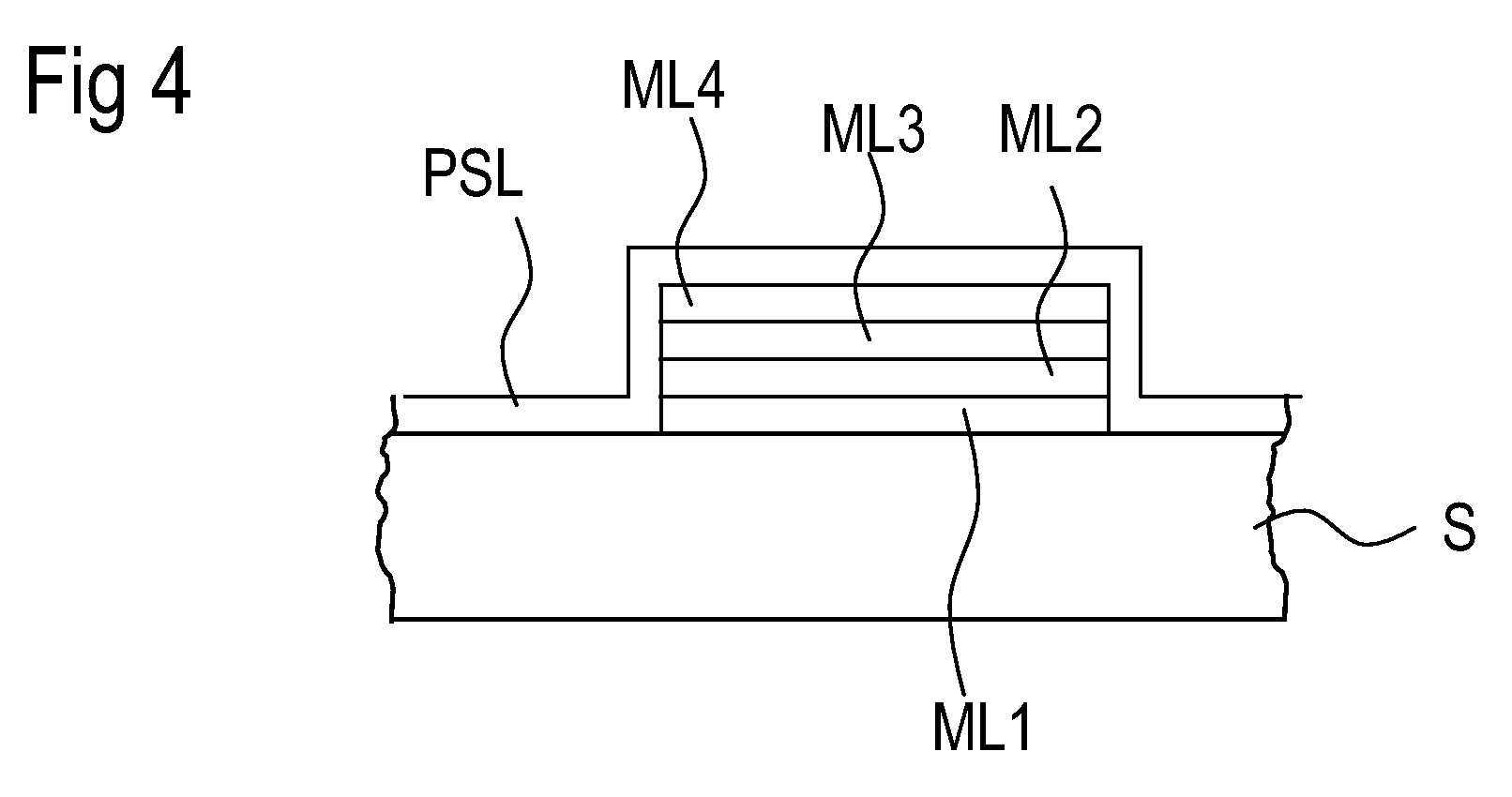

Scratch-resistant chemically tempered glass substrate and use thereof

InactiveUS20150353418A1Improve scratch resistanceReduces conspicuousnessLayered productsVacuum evaporation coatingAnti-reflective coatingRefractive index

An object of the disclosure is to provide a layer system for a chemically tempered glass substrate, which adheres particularly well to the glass substrate and provides an anti-reflective effect and particularly high scratch resistance. Accordingly, the invention provides a scratch-resistant chemically tempered glass element, comprising a chemically tempered glass substrate having a potassium-rich surface, and a layer system which comprises a plurality of successive layers including an oxygen-rich layer adjacent the potassium-rich surface of the glass substrate. The oxygen-rich layer comprises predominantly silicon oxide and / or aluminum oxide, and is an adhesion promoting layer for a nitridic hard material layer which is the lowermost part of a multi-layered, in particular four-layered, anti-reflective coating. The anti-reflective coating is composed of layers of different refractive indices, alternating higher refractive indices and lower refractive indices.

Owner:SCHOTT AG

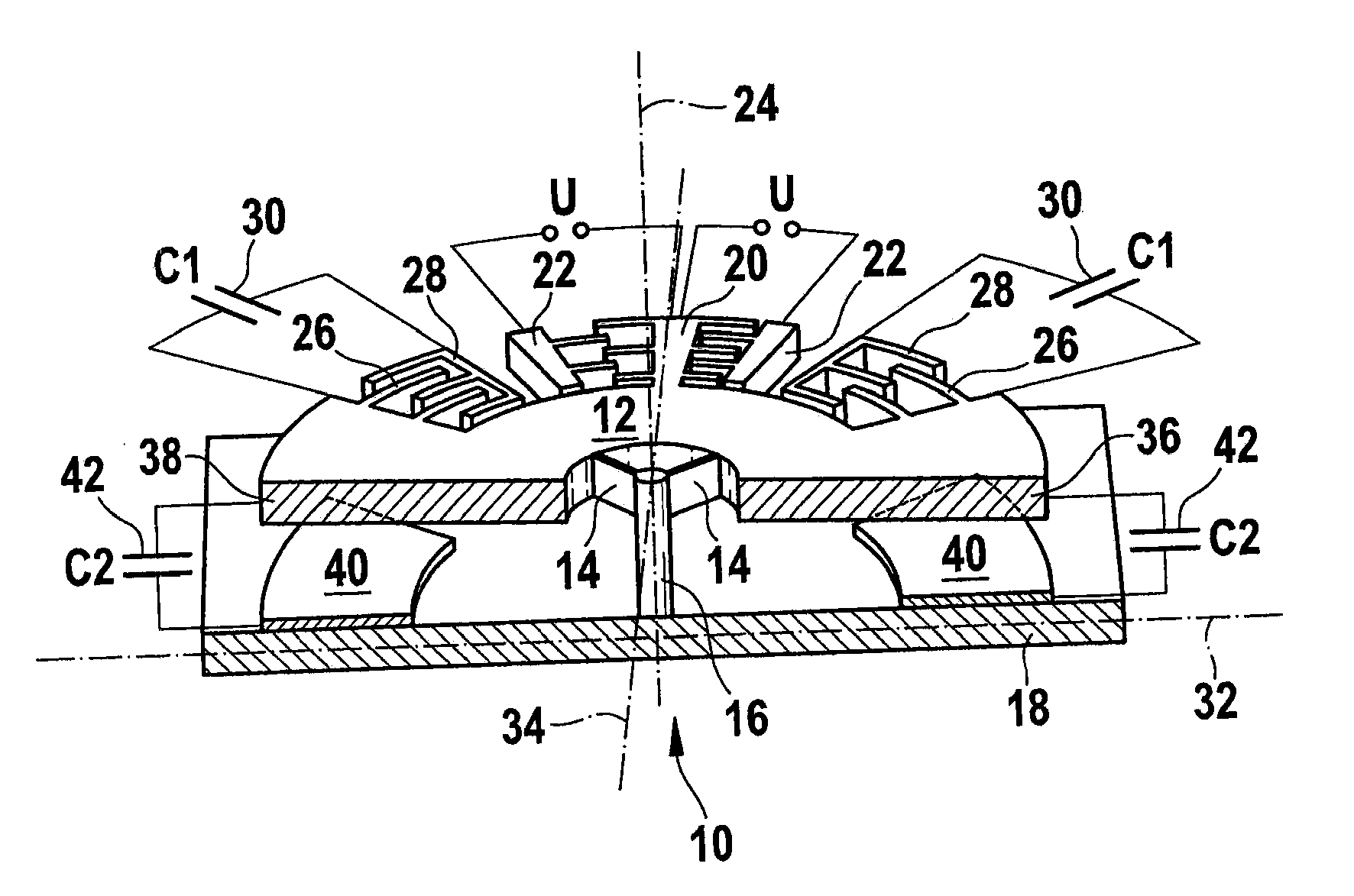

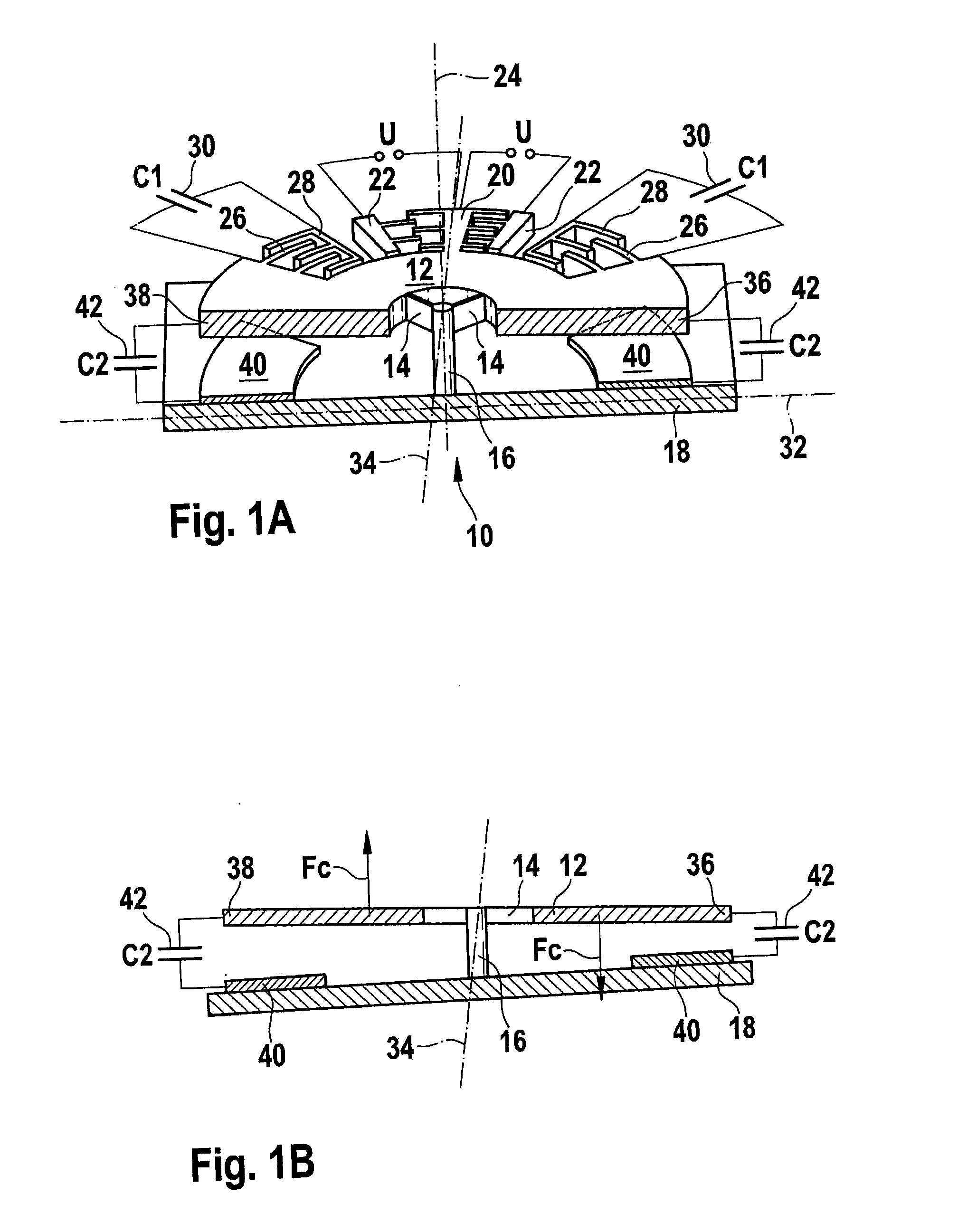

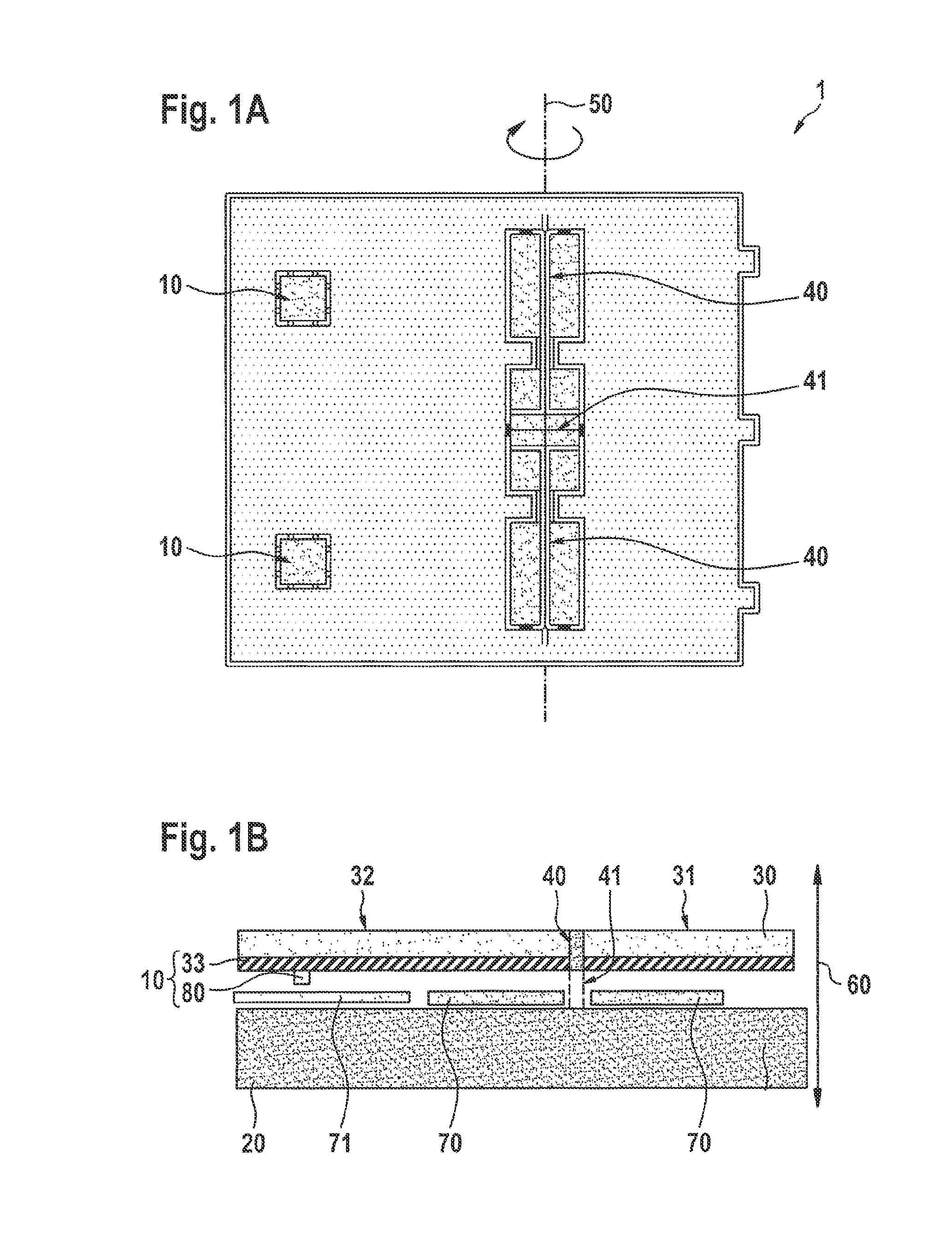

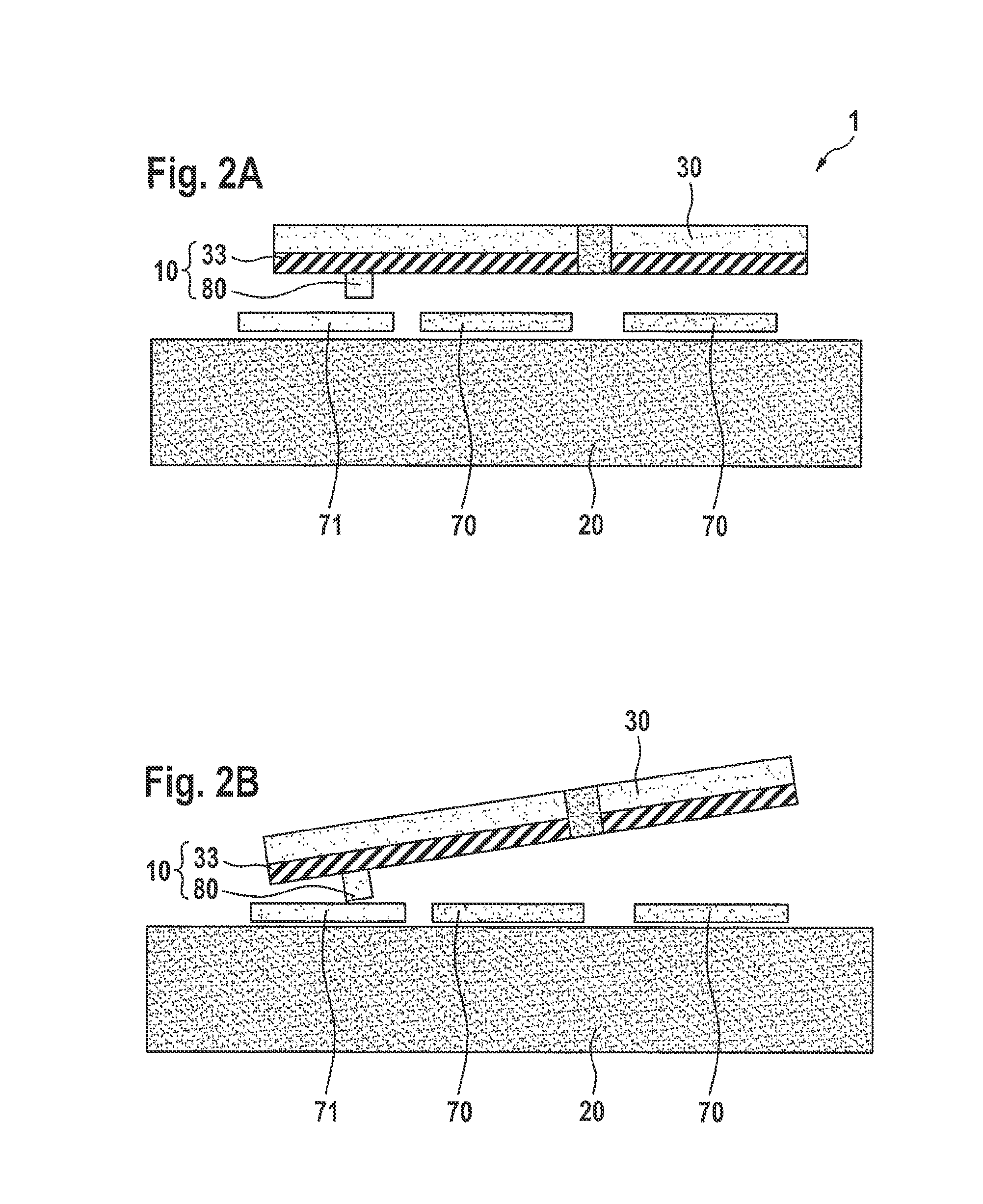

Manufacturing method for a rotation sensor device and rotation sensor device

ActiveUS20100058863A1Increases electrical sensitivitySuppress noiseAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSemiconductor materialsEngineering

A device and manufacturing method for a rotation sensor device includes a holding device, an oscillating mass, and a spring, via which the oscillating mass is connected to the holding device. The spring is designed so that the oscillating mass can be set into an oscillating movement around an oscillation axis with respect to the holding device with the aid of a drive. The steps include: producing a layer sequence having a first layer made of semiconductor material and / or metal and a second layer made of semiconductor material and / or a metal, a boundary surface of the first layer, at least partially being covered by an insulating layer; structuring the spring out of the first layer; and structuring at least one oscillating mass subunit of the oscillating mass, which can be set into the oscillating movement around the oscillation axis with the aid of the drive, out of the second layer.

Owner:ROBERT BOSCH GMBH

Microacoustic Component and Production Method

InactiveUS20120056507A1Large layer thicknessEliminate the problemPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesAtomic layer depositionMaterials science

The microacoustic component has a substrate that has at least one layer (composed of a dielectric or piezoelectric material, and a metallic strip structure. The layer is composed of a dielectric or piezoelectric material and / or the metallic strip structure have / has been produced or can be produced by the atomic layer deposition method.

Owner:SNAPTRACK

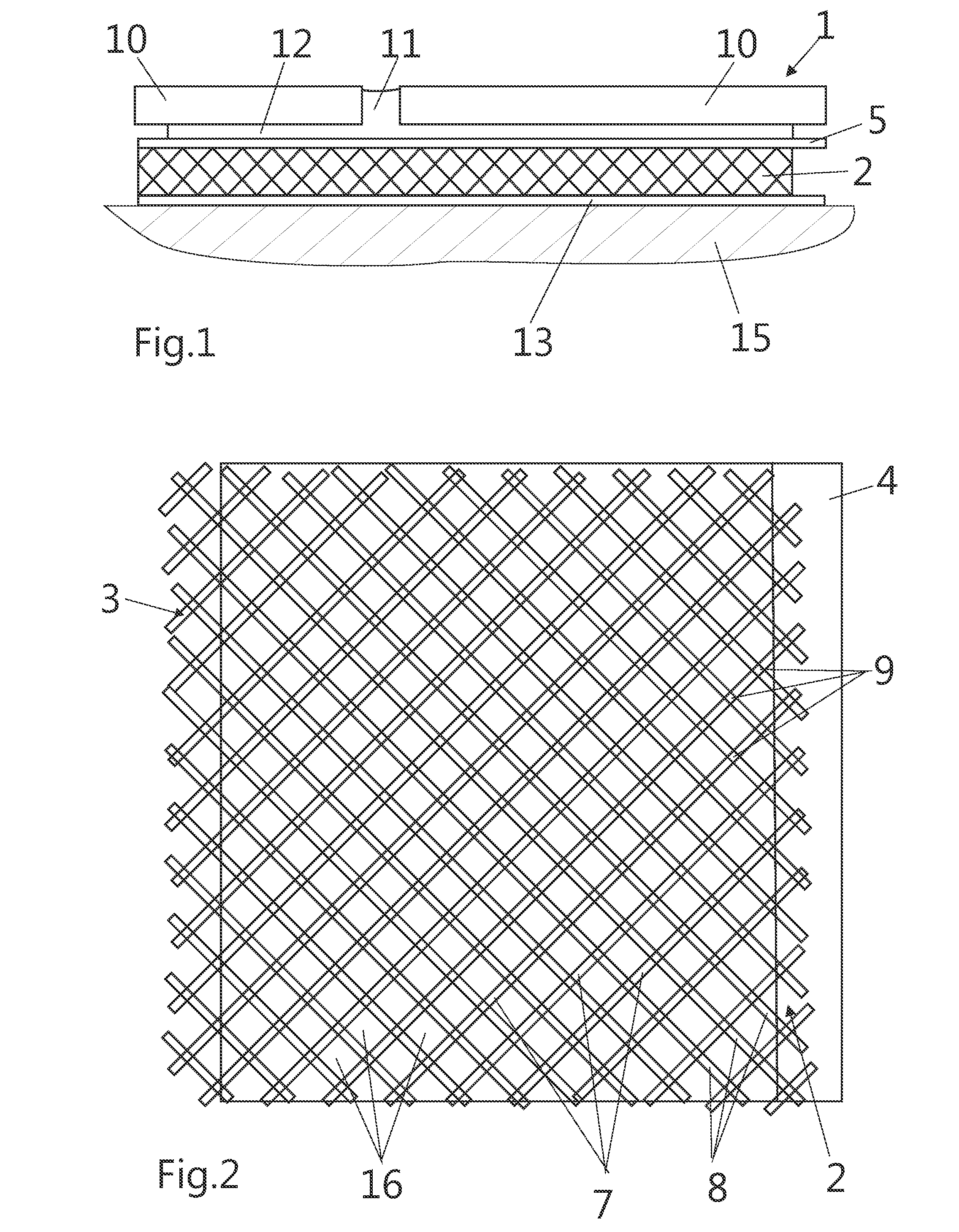

Combined decoupling and heating system

InactiveUS20150021315A1Reduce the numberReduce thicknessLighting and heating apparatusOhmic-resistance electrodesElectricityFiber

The invention relates to a combined decoupling and heating system, in particular for installing ceramic tiling using the thin bed method, having at least one anchoring layer formed from a structure element for a filler compound that is to be introduced in the area of the upper side of the decoupling and heating system and that is ductile during processing and hardens thereafter. The anchoring layer is formed at least in part of mechanically highly stressable reinforcement fibers made of a material that itself is electrically conducting or that has become electrically conductive through coatings and / or additives, whereby the reinforcement fibers can be heated up by conducting electrical current thus forming the heating layer of an electrically operable area heating system.

Owner:BLANKE

Flexible stop for an acceleration sensor

ActiveUS8952466B2Minimize impactMeet high requirementsAcceleration measurement using interia forcesPiezoelectric/electrostrictive devicesSeismic massClassical mechanics

A micromechanical acceleration sensor includes a seismic mass and a substrate that has a reference electrode. The seismic mass is deflectable in a direction perpendicular to the reference electrode, and the seismic mass has a flexible stop in the deflection direction. The flexible stop of the seismic mass includes an elastic layer.

Owner:ROBERT BOSCH GMBH

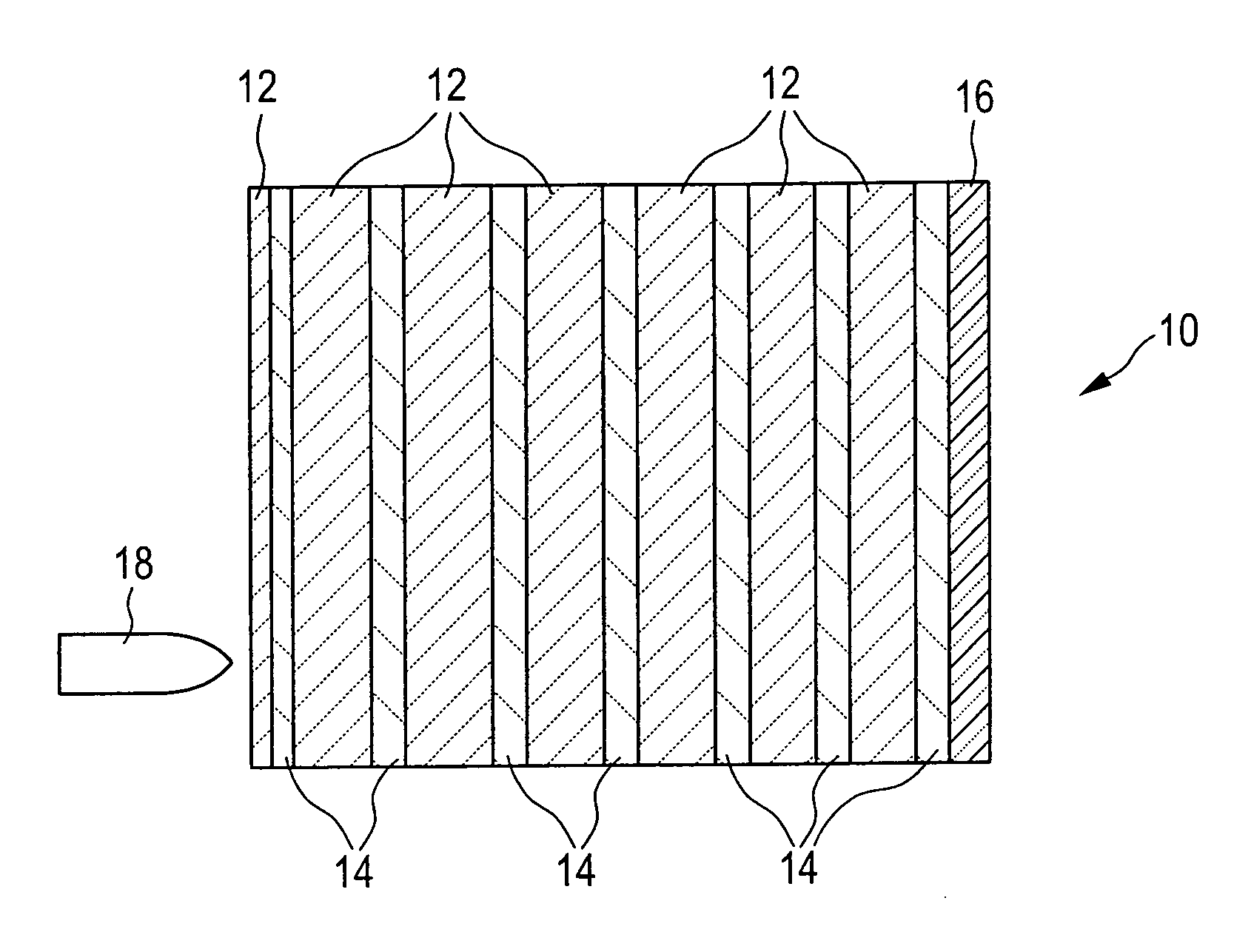

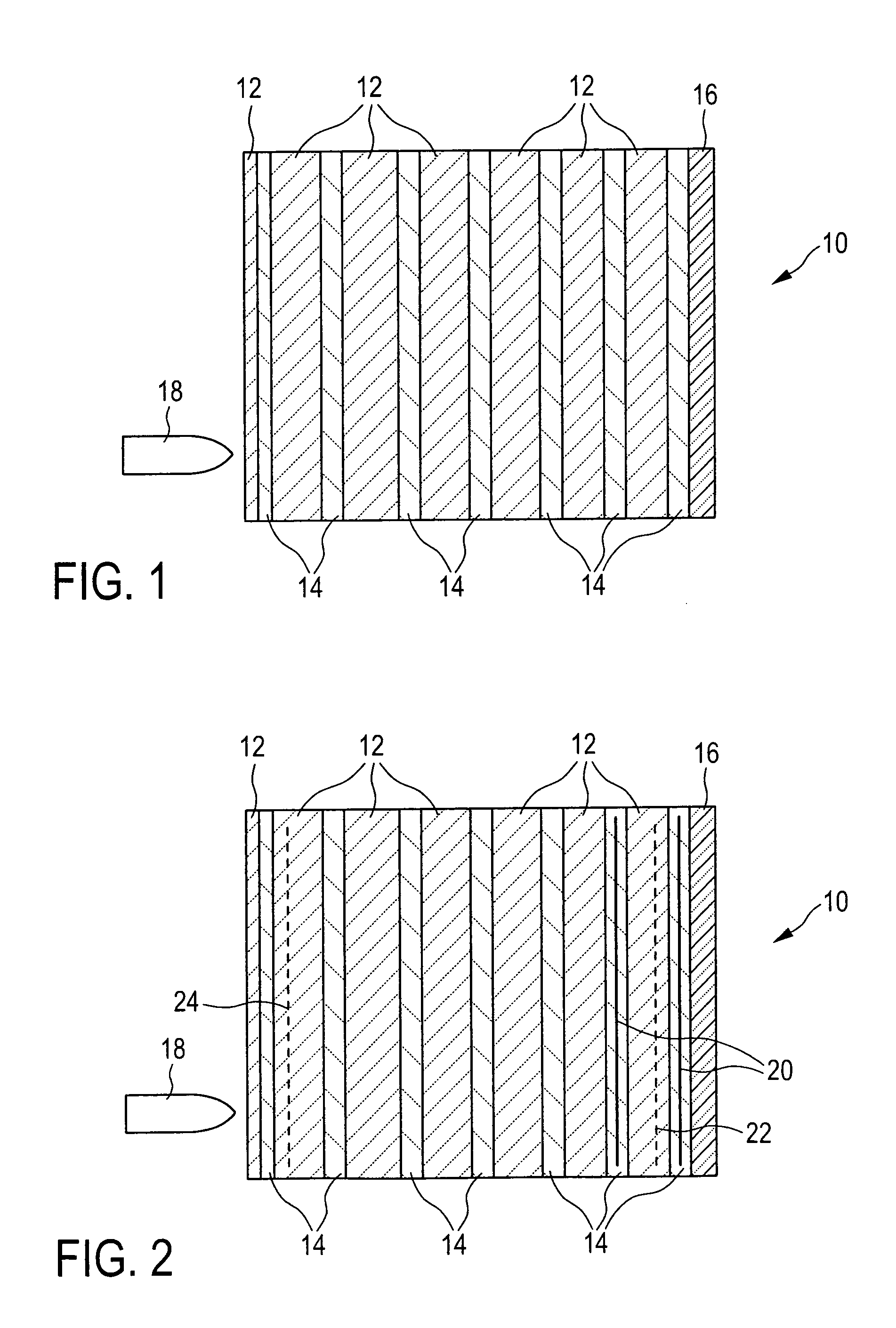

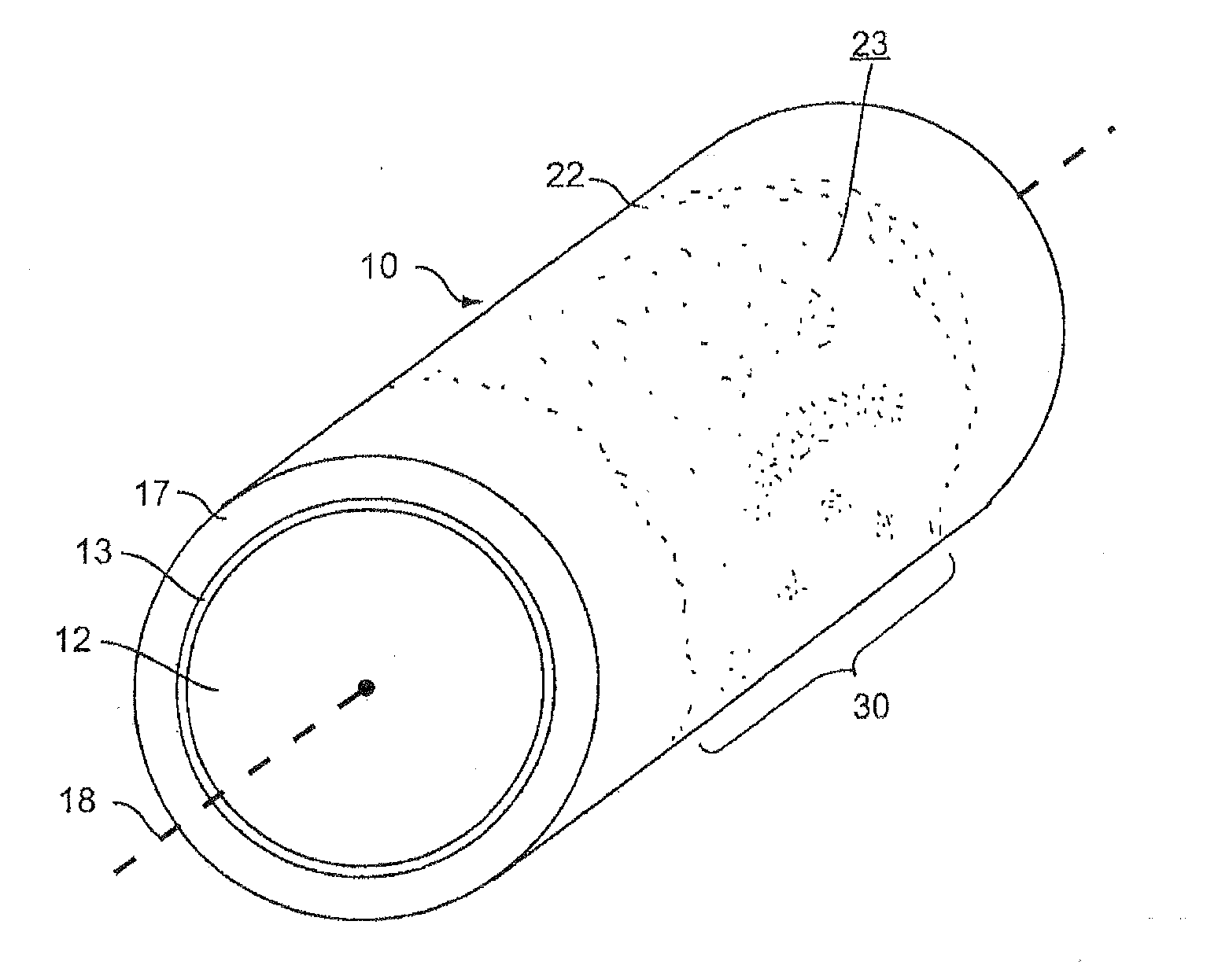

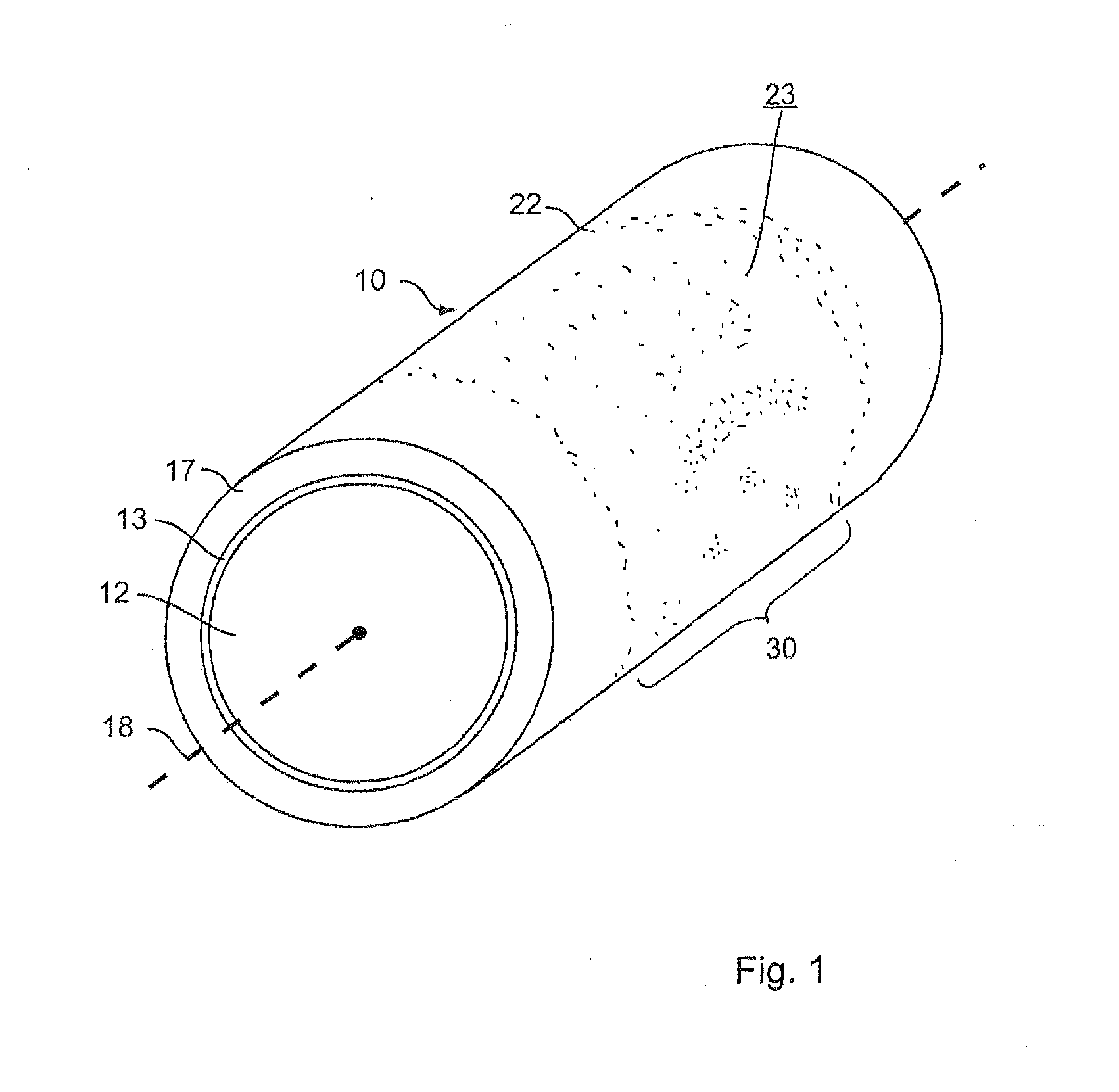

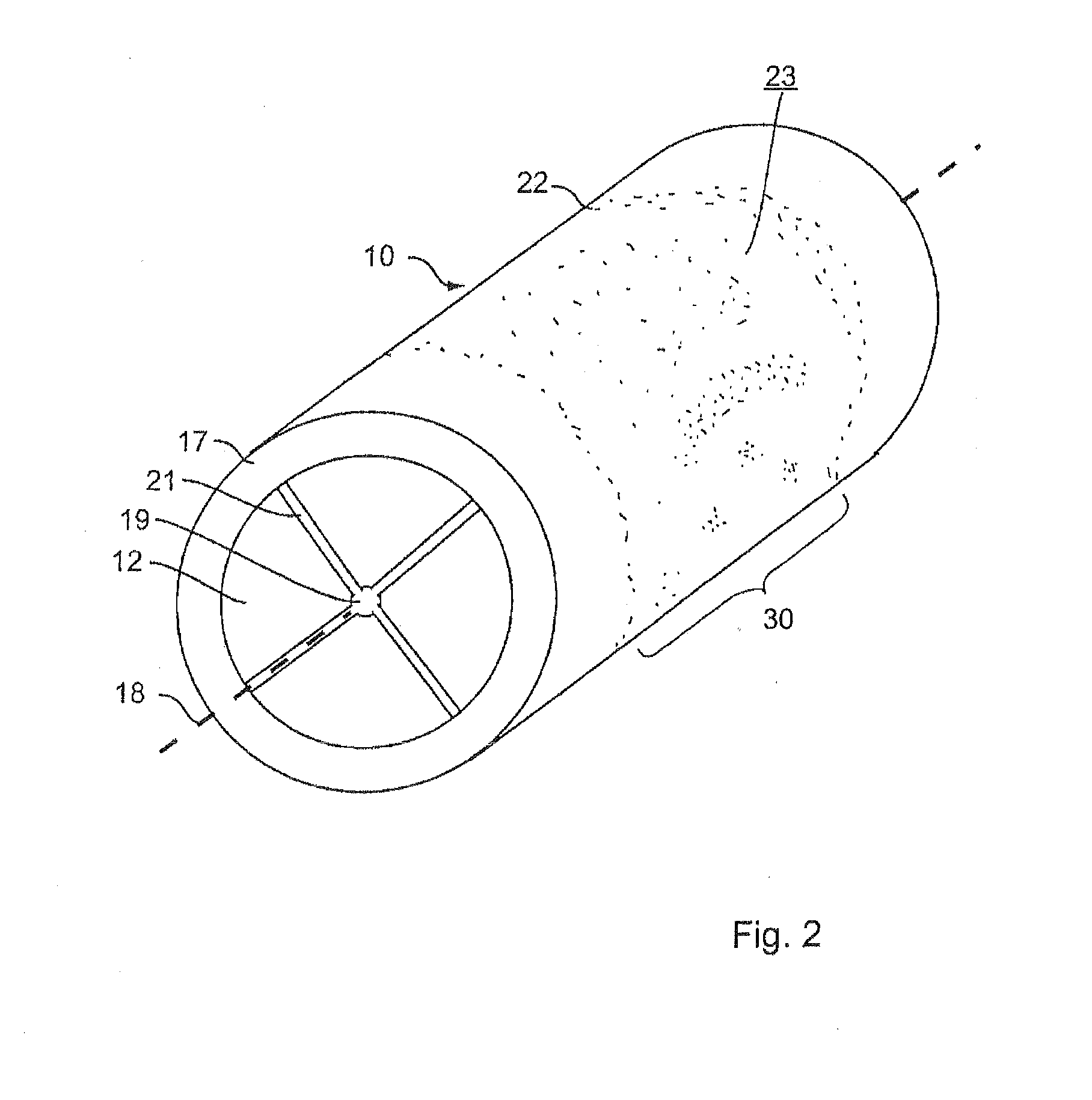

Bullet-resistant transparent laminate composite and protection arrangement having a bullet-resistant transparent laminate composite

InactiveUS8833233B2Improve ballistic performanceImprove the protective effectProtective equipmentSynthetic resin layered productsEngineeringLayer thickness

A bullet-resistant transparent laminate composite (10) has at least two plates (12) arranged one behind the other and at a spacing relative to each other in the direction of threat and comprising a transparent first material with a modulus of elasticity of at least about 1,500 N / mm2, and a respective intermediate layer (14) of a transparent second material with a lower modulus of elasticity than that of the first material between two adjacent plates (12). The layer thicknesses of the plates (12) and the intermediate layer or layers (14) are so selected that the overall layer structure of the layer composite (10) of plates and intermediate layer or layers has a modulus of elasticity which is at least about 10% lower in comparison with a block made exclusively from the first material and of the same overall thickness.

Owner:IABG LICHTENAU +2

Nickel-containing layer arrangement for intaglio printing

InactiveUS20110308958A1Easy to recycleLarge layer thicknessElectrolytic coatingsLayered productsMetallic NickelElectrical and Electronics engineering

A layer arrangement for a gravure cylinder including nickel in at least a first region through the entire thickness (d) thereof, with a mass fraction of at least 0.80, the arrangement being designed to permit an imaging by means of a laser in the first region and to serve as the outermost layer of the gravure cylinder for intaglio printing. A method for producing a layer arrangement for a printing form wherein the layer arrangement includes nickel in at least a first region through the entire thickness (d) thereof, with a mass fraction of at least 0.80 and at least in the radially external region has a solid lubricant component (X) has the following steps: the layer arrangement is produced on a cylinder core by galvanic coating and a printing image is generated on the layer arrangement for intaglio printing.

Owner:IPT INT PLATING TECH

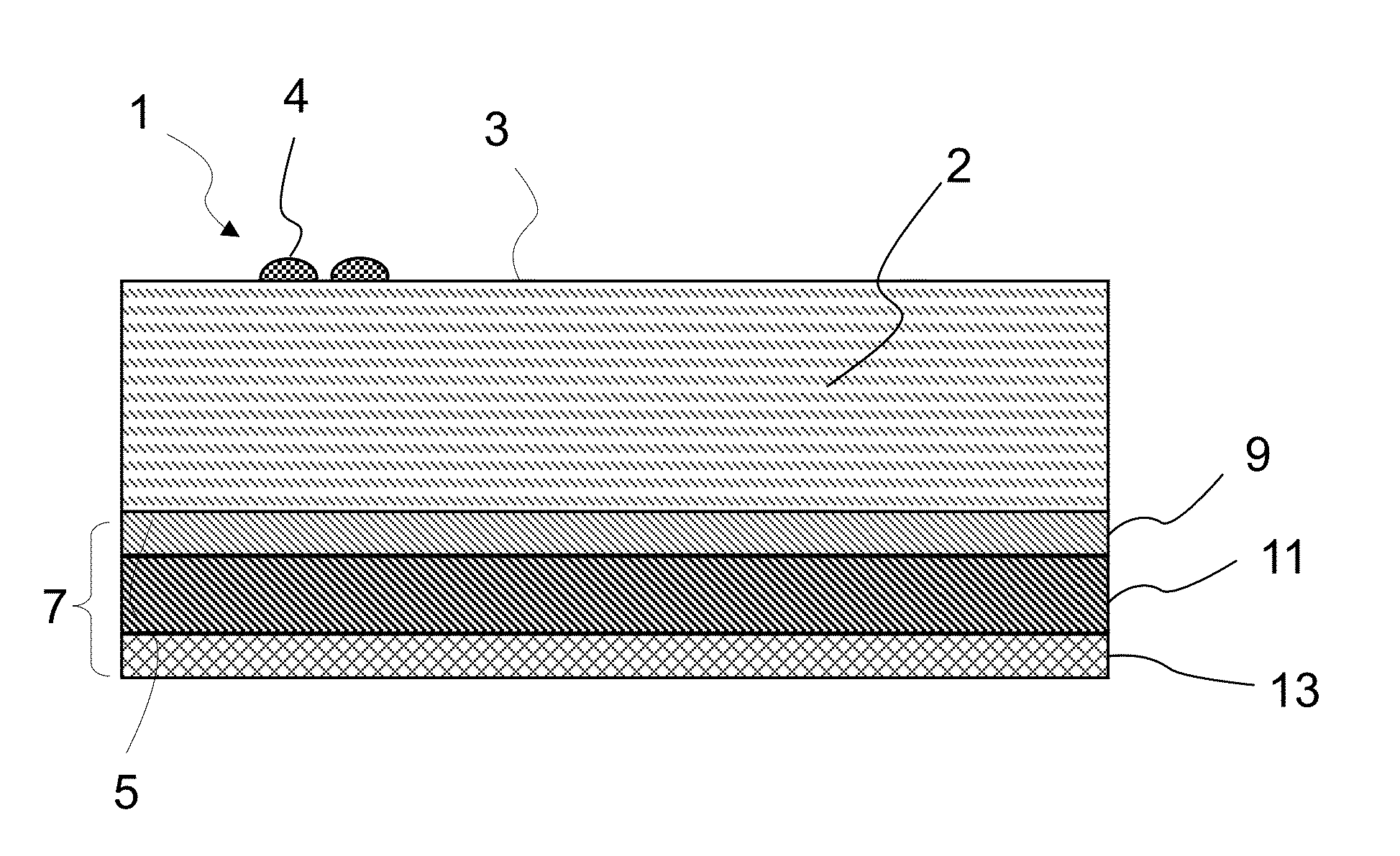

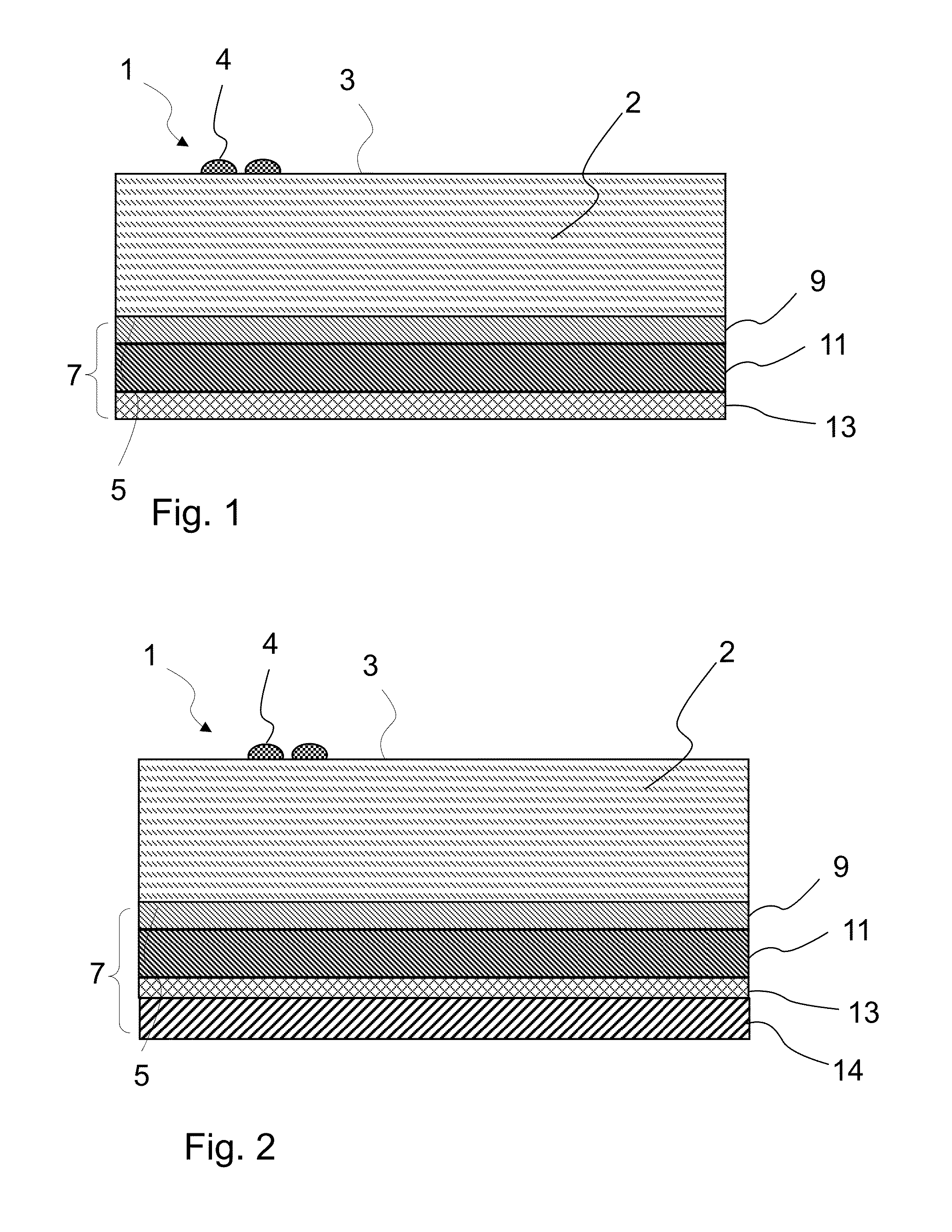

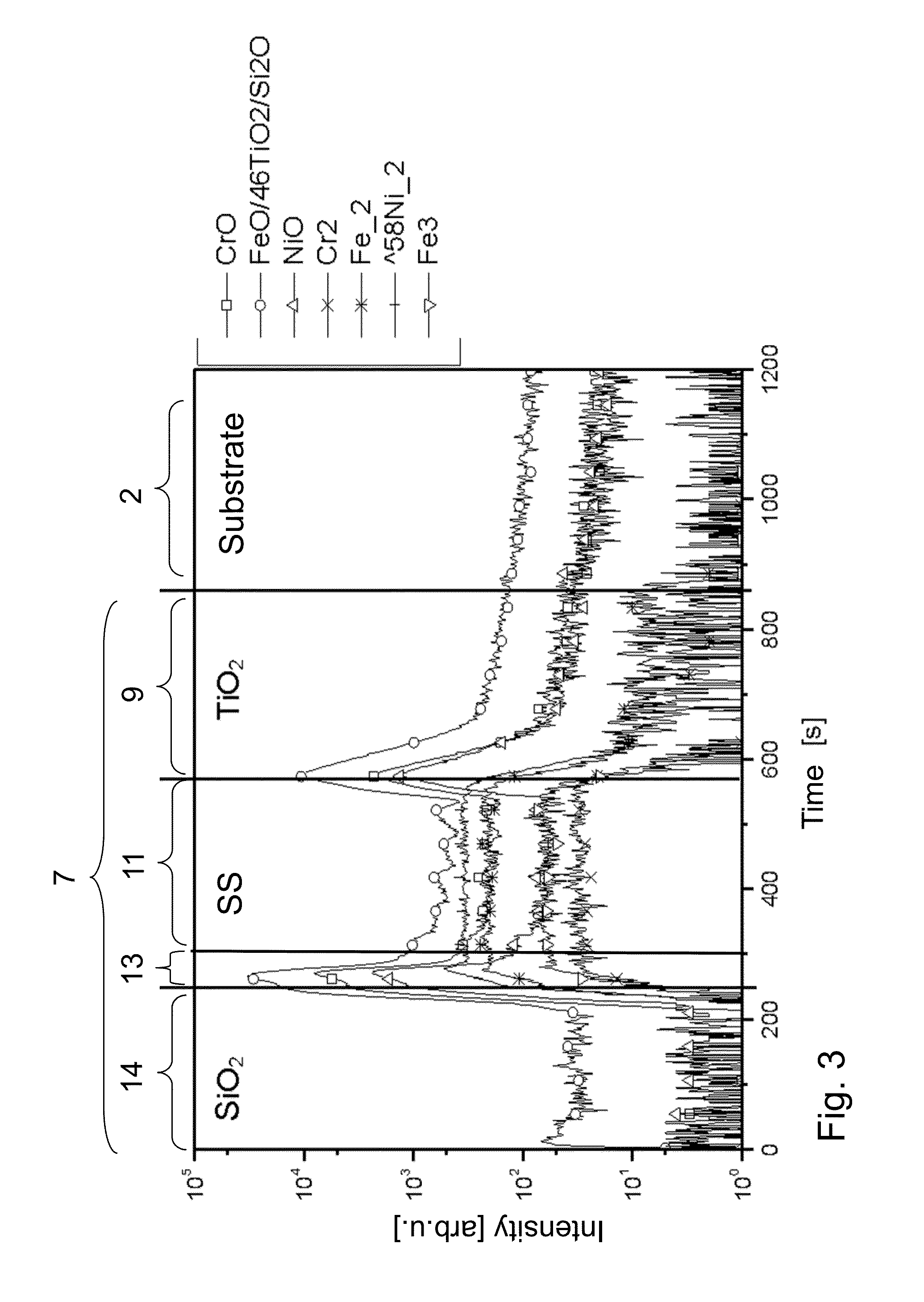

Coated glass ceramic plate

ActiveUS20140335349A1Easy to manufactureExcellent adhesion promoterVacuum evaporation coatingSputtering coatingAlloyOxygen

A coated glass ceramic cooking plate is provided, which has a multilayer coating on its lower surface. The multilayer coating includes a metallic layer of an alloy including components chromium, iron, nickel, and silicon. The silicon content of the alloy is at least 2 atomic percent. This metallic layer is covered by a barrier layer in form of an oxide of an alloy including components chromium, iron, nickel, and silicon, also with a silicon content of at least 2 atomic percent. The molar content of oxygen of the barrier layer is greater by at least a factor of 10 than that of the metallic layer.

Owner:SCHOTT AG

Method of producing a microacoustic component

InactiveUS8940359B2Large layer thicknessEliminate the problemPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAtomic layer depositionMaterials science

The microacoustic component has a substrate that has at least one layer (composed of a dielectric or piezoelectric material, and a metallic strip structure. The layer is composed of a dielectric or piezoelectric material and / or the metallic strip structure have / has been produced or can be produced by the atomic layer deposition method.

Owner:SNAPTRACK

Sheet-or web-like, decorative coating film and method for producing the same

InactiveUS7919144B2Damaging abrasion effects can be effectively preventedImprove adhesionSpecial paperDecorative surface effectsOrganic solventElectron

A method for producing a sheet-like or web-like, decorative, scratch- and / or abrasion-resistant coating material, in particular a coating film, comprising the steps:coating a support layer (10) made of paper and / or plastic with a liquid or pasty base layer (12) which is free of organic solvents and comprises radiation-curing resins but no heat-curing resins and also an abrasive filler, preferably an inorganic filler,drying the support layer (10) coated with the base layer (12), in particular by supplying heat,applying a covering layer (14) to the dried, non-crosslinked base layer (12), said covering layer containing a radiation-curing resin and no abrasive fillers, andjointly curing and / or crosslinking the covering layer and also the radiation-curing resins in the base layer by irradiating the covering layer with UV and / or electron beams.

Owner:SURTECO DECOR

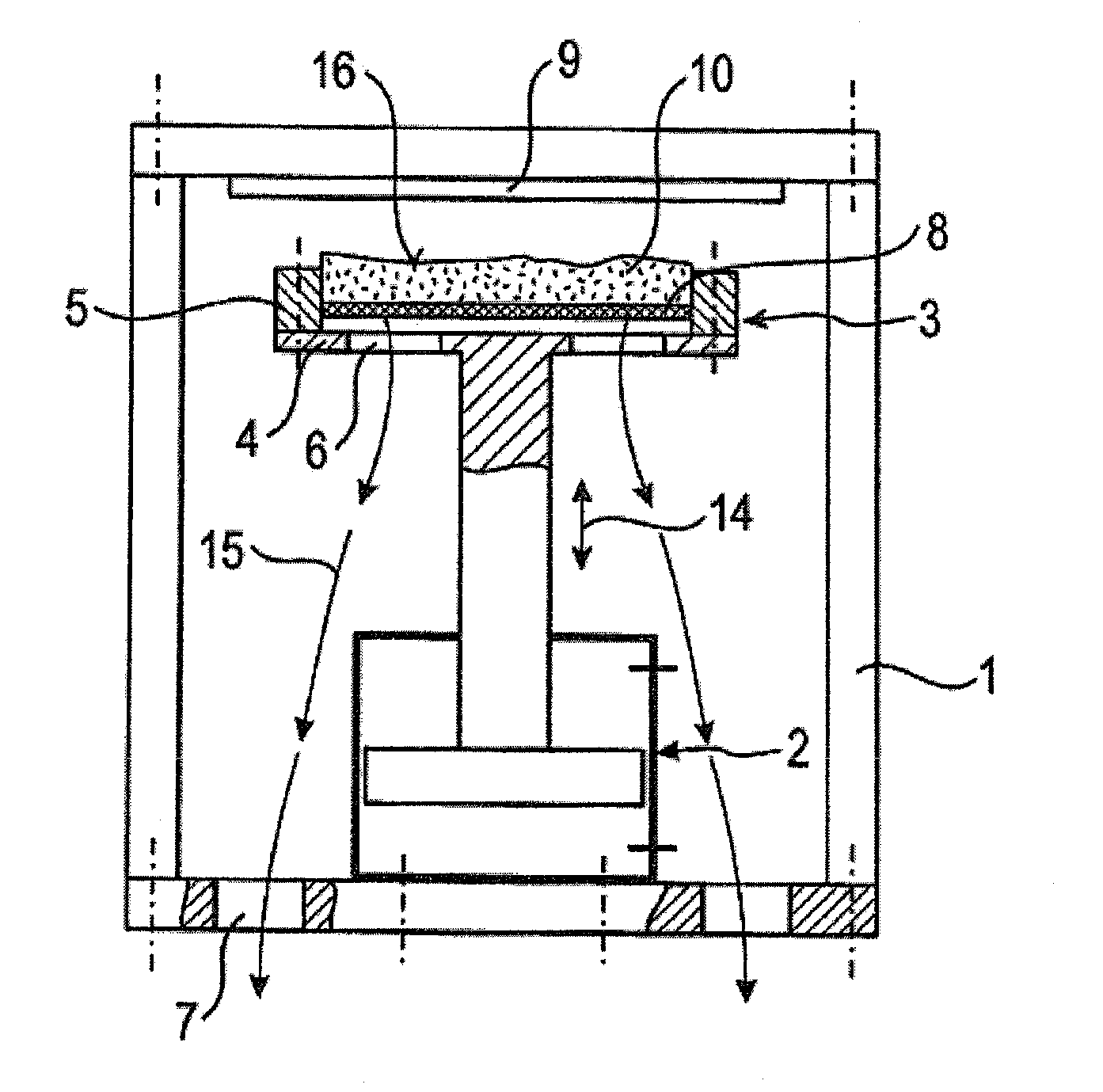

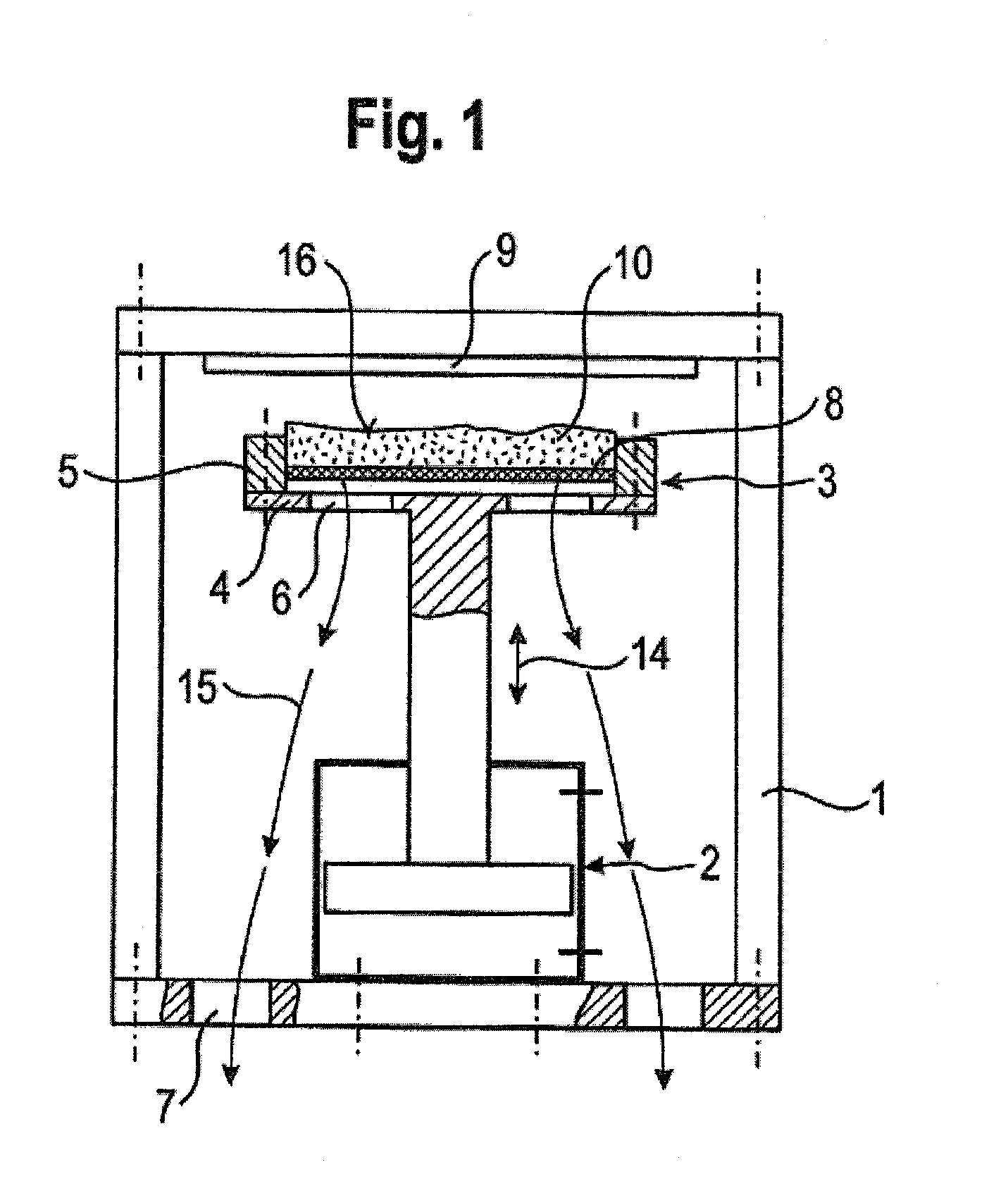

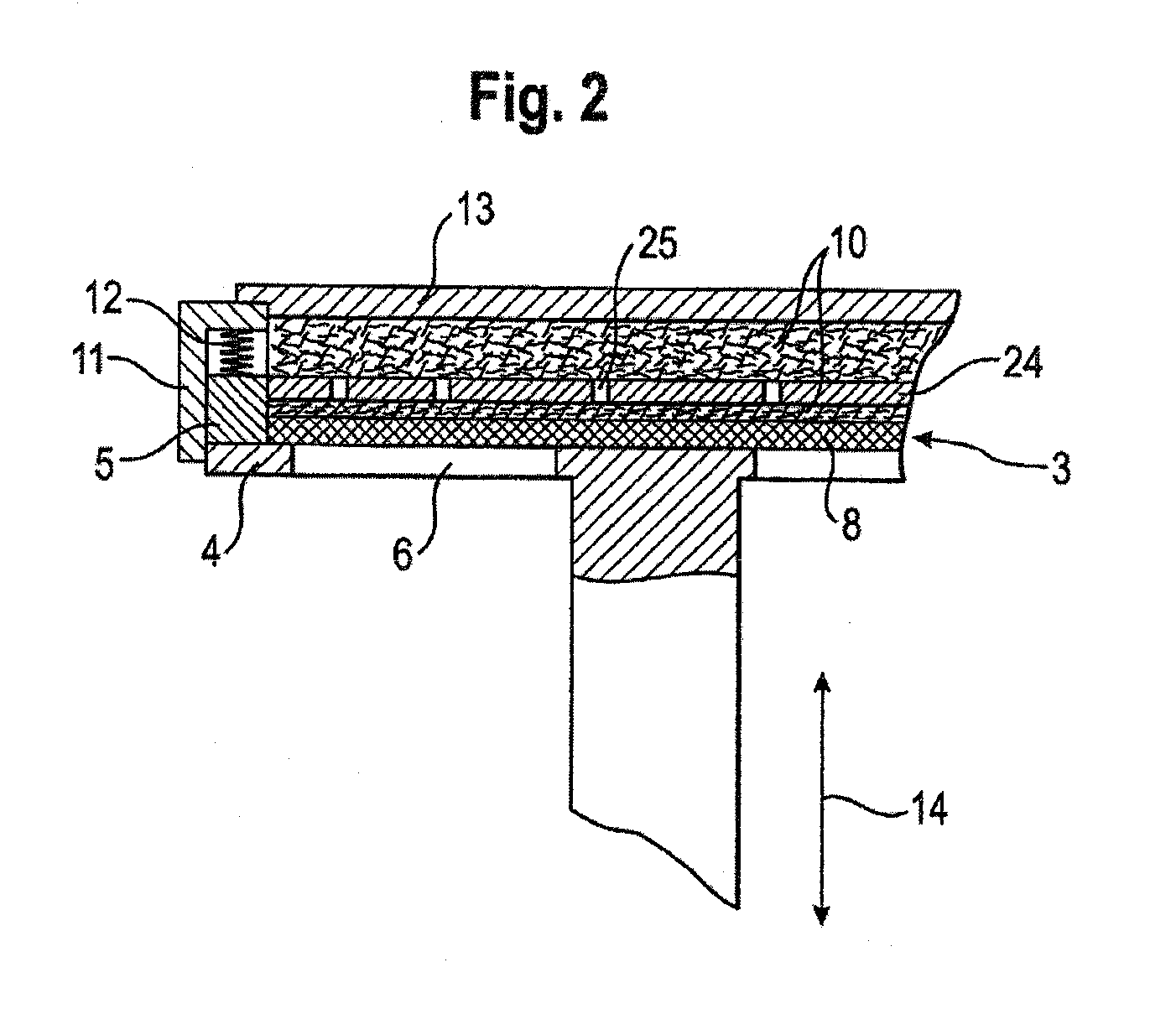

Method for separating grinding oil from grinding slurry; separating station for carrying out said method and plant according to said method

InactiveUS20120273429A1Improve heat utilizationClear conditioningCentrifugal force sediment separationWater/sewage treatment by magnetic/electric fieldsSheet steelHeating effect

The invention relates to a plant for separating grinding slurry originating from grinding machines into metal chips and grinding oil. According to the invention, a carrier bowl (3) in a frame (1) is filled with a divided volume of the grinding slurry (10). The carrier bowl (3) has a perforated plate (4) having an edge (5) as a floor and a sieve-like intermediate floor (8). By means of a lifting device (2), the carrier bowl (3) is moved to the effective region of an inductor plate (9) serving as a heater. The induction heat heats the ferromagnetic steel or iron particles present in the grinding slurry (10). Said heating effects a reduction in viscosity of the grinding oil in the grinding slurry (10), from which substantial portions flow downward through the openings (6) or (7). In certain cases, the effect can be improved by placing a steel plate on the free surface (16) of the grinding slurry layer (10).

Owner:ERWIN JUNKER MASCHNINENFAB

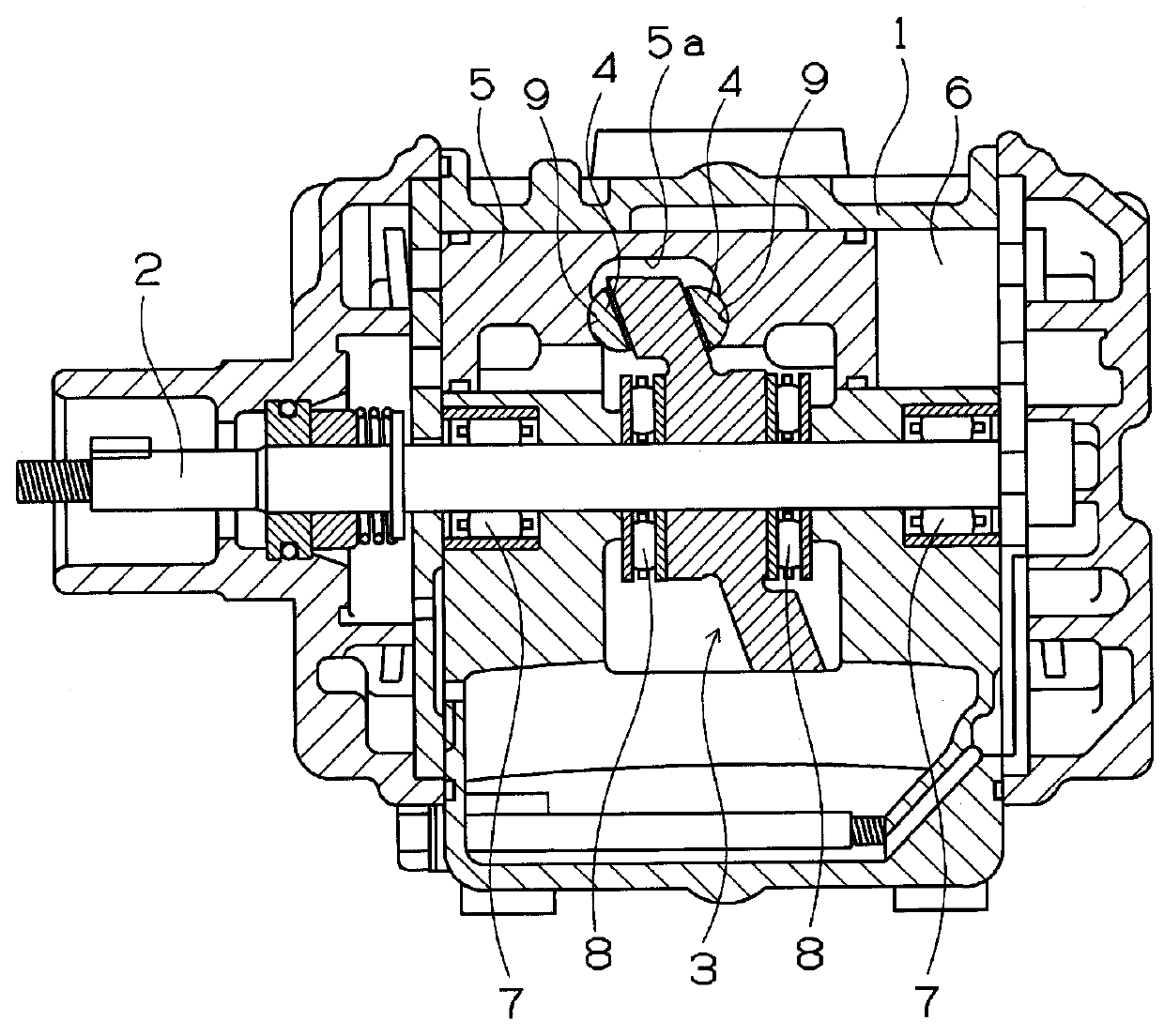

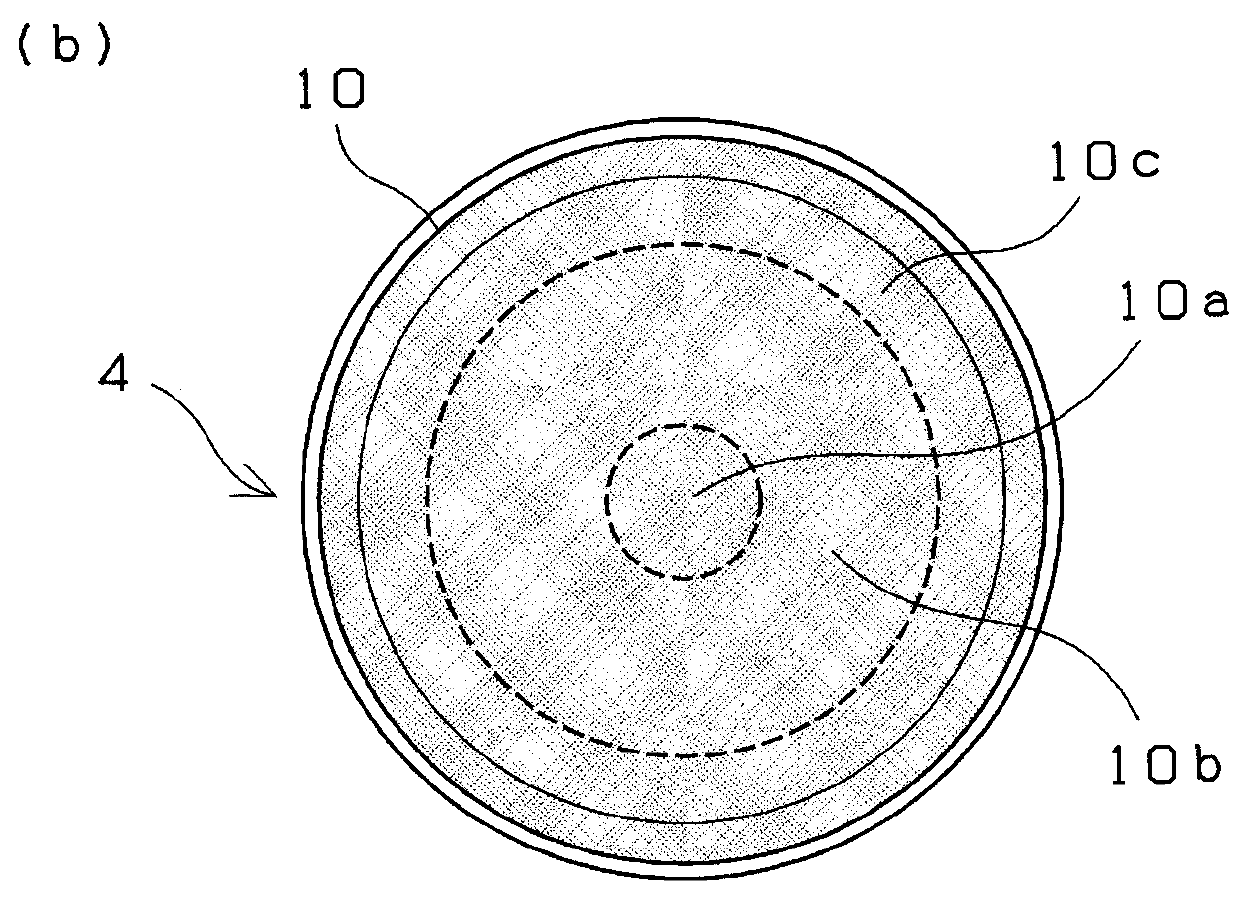

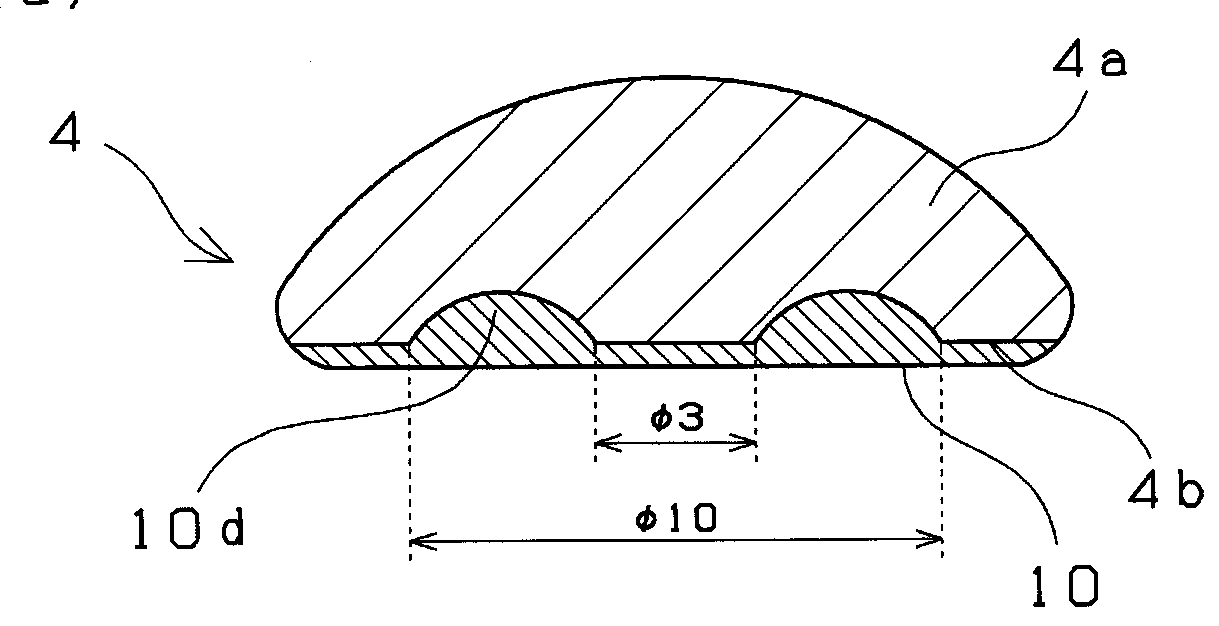

Semispherical shoe for swash plate compressor and swash plate compressor

InactiveUS20160053751A1Heat dissipationAvoid layeringFluid-pressure actuatorsEngine componentsStart timeLayer thickness

It is an object of the present invention to provide a semispherical shoe which can be prevented from being subjected to seizure even in a dry lubrication state in which there is no lubricating oil at the start time of an operation, does not deteriorate in its lubricating property owing to frictional heating, and ensures sufficient durability and a swash plate compressor in which a lubricating film is not formed on a sliding contact surface of a swash plate owing to the use of the semispherical shoe. A semispherical shoe (4) makes sliding contact with the swash plate of the swash plate compressor. A surface of a planar part (4b) which makes sliding contact with the swash plate consists of a resin layer (10). A surface of a spherical part (4b) consists of a base material of the semispherical shoe. In viewing the surface of the planar part divided into three parts consisting of a central part (10a), an outer edge part (10c), and an intermediate part (10b) interposed between the central part (10a) and the outer edge part (10c) in a direction vertical to the surface of the planar part, an annular belt portion (10d) whose layer thickness is larger than that of each of the central part (10a) and the outer edge part (10c) is formed inside the intermediate part (10a).

Owner:NTN CORP

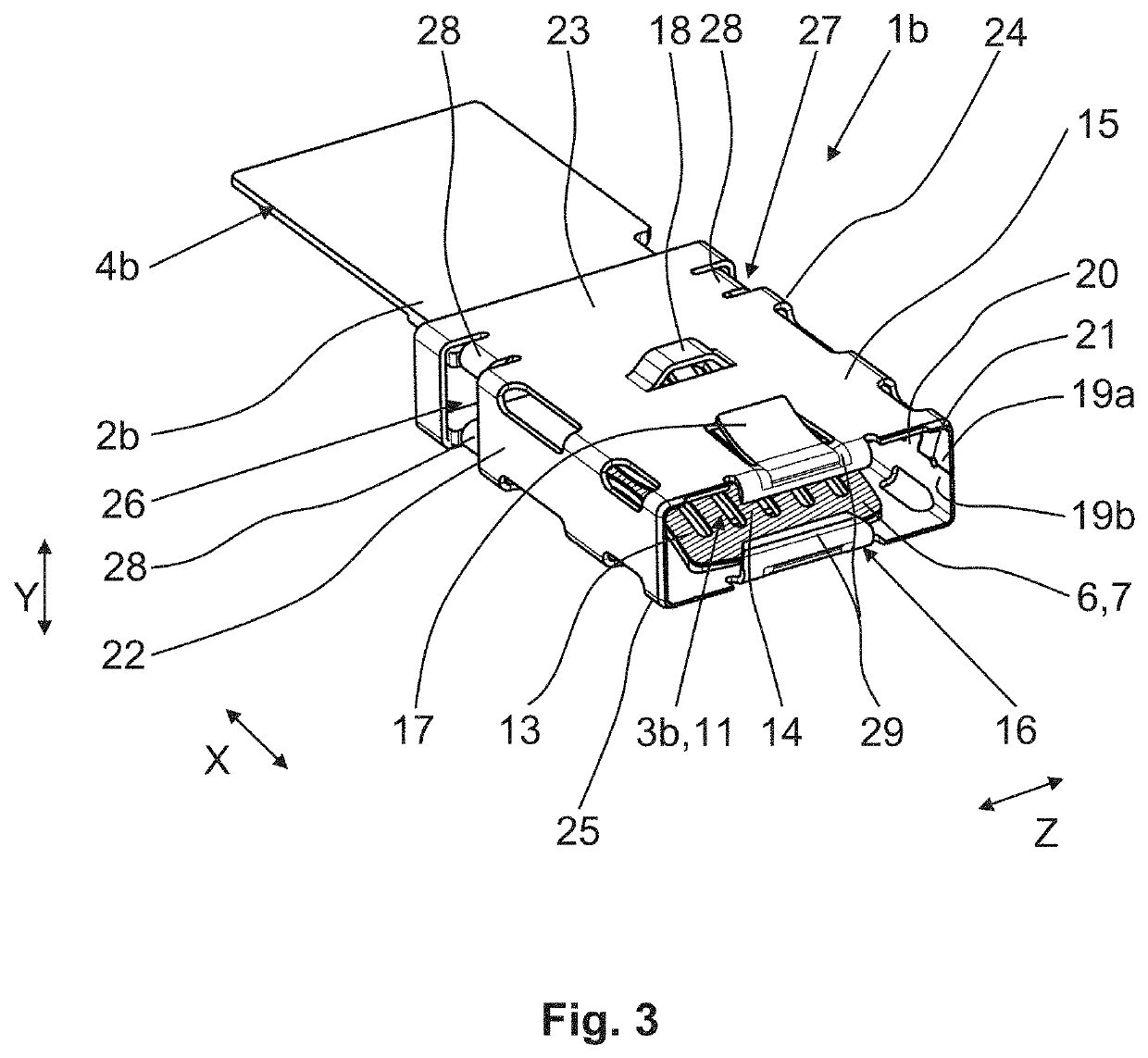

Electrical connector and method of making an electrical connector

ActiveUS20210281001A1Improve stabilityLarge layer thicknessContact member manufacturingAdditive manufacturing apparatusElectrical conductorElectrical connection

An electrical connector includes at least one base body with at least one contact portion and at least one connection portion. The connection portion is provided for fastening an electrical conductor. The base body is made of a first material, and a layer of a second material is arranged in a surface area of the contact portion. An electrical connector that ensures reliable electrical contacting even under heavy mechanical stresses is realized by applying the layer of the second material by means of roll cladding or an additive manufacturing process.

Owner:LEAR CORP

Method for manufacturing a component having an electrical through-connection

ActiveUS9034757B2Avoids metal entrainmentQuality improvementDecorative surface effectsSemiconductor/solid-state device detailsElectricitySemiconductor materials

A method for manufacturing a component having an electrical through-connection is described. The method includes the following steps: providing a semiconductor substrate having a front side and a back side opposite from the front side, producing an insulating trench, which annularly surrounds a contact area, on the front side of the semiconductor substrate, filling the insulating trench with an insulating material, producing an electrical contact structure on the front side of the semiconductor substrate by depositing an electrically conductive material in the contact area, removing the semiconductor material remaining in the contact area on the back side of the semiconductor substrate in order to produce a contact hole which opens up the bottom side of the contact structure, and depositing a metallic material in the contact hole in order to electrically connect the electrical contact structure to the back side of the semiconductor substrate.

Owner:ROBERT BOSCH GMBH

Electronic Device and Method for Producing an Electronic Device

ActiveUS20170271295A1Improve protectionLarge layer thicknessSemiconductor/solid-state device detailsSolid-state devicesContact layerElectronic equipment

An electronic device and a method for producing an electronic device are disclosed. In an embodiment the electronic device includes a first component and a second component and a sinter layer connecting the first component to the second component, the sinter layer comprising a first metal, wherein at least one of the components comprises at least one contact layer which is arranged in direct contact with the sinter layer, which comprises a second metal different from the first metal and which is free of gold.

Owner:OSRAM OLED

Electronic device and method for producing an electronic device

ActiveUS10147696B2Improve protectionLarge layer thicknessSemiconductor/solid-state device detailsSolid-state devicesContact layerMetal

An electronic device and a method for producing an electronic device are disclosed. In an embodiment the electronic device includes a first component and a second component and a sinter layer connecting the first component to the second component, the sinter layer comprising a first metal, wherein at least one of the components comprises at least one contact layer which is arranged in direct contact with the sinter layer, which comprises a second metal different from the first metal and which is free of gold.

Owner:OSRAM OLED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com