Patents

Literature

321results about How to "Improve ballistic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

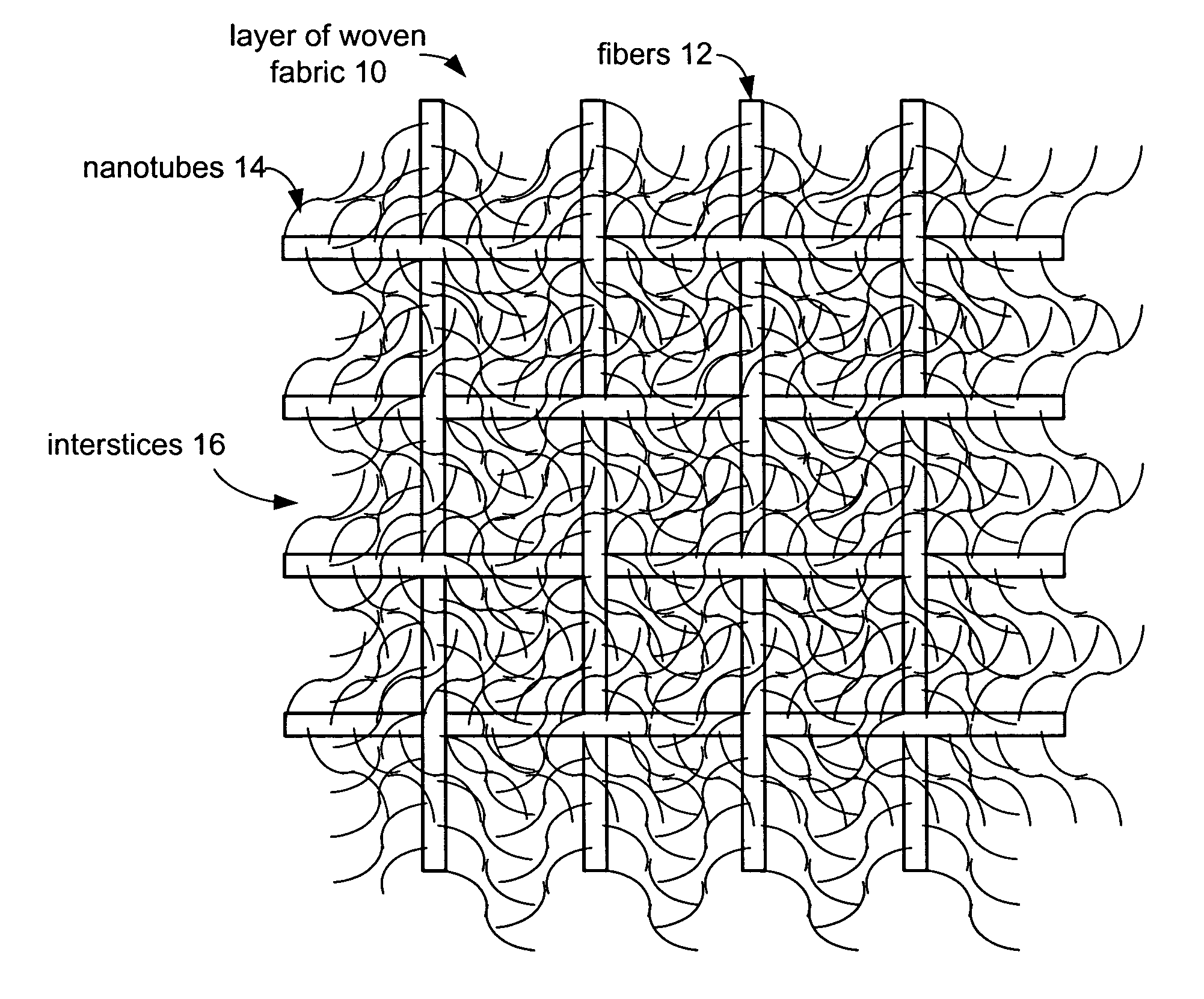

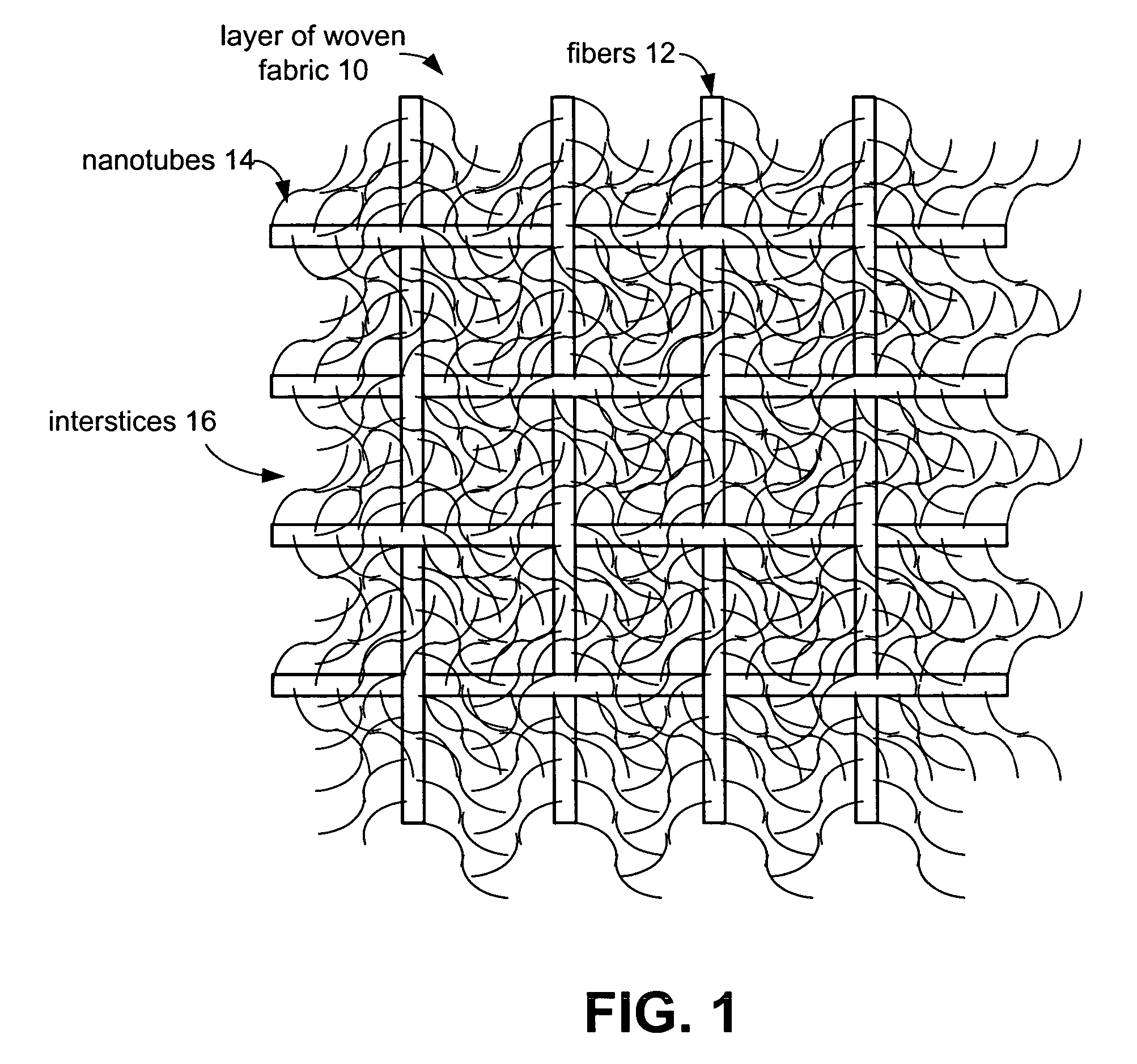

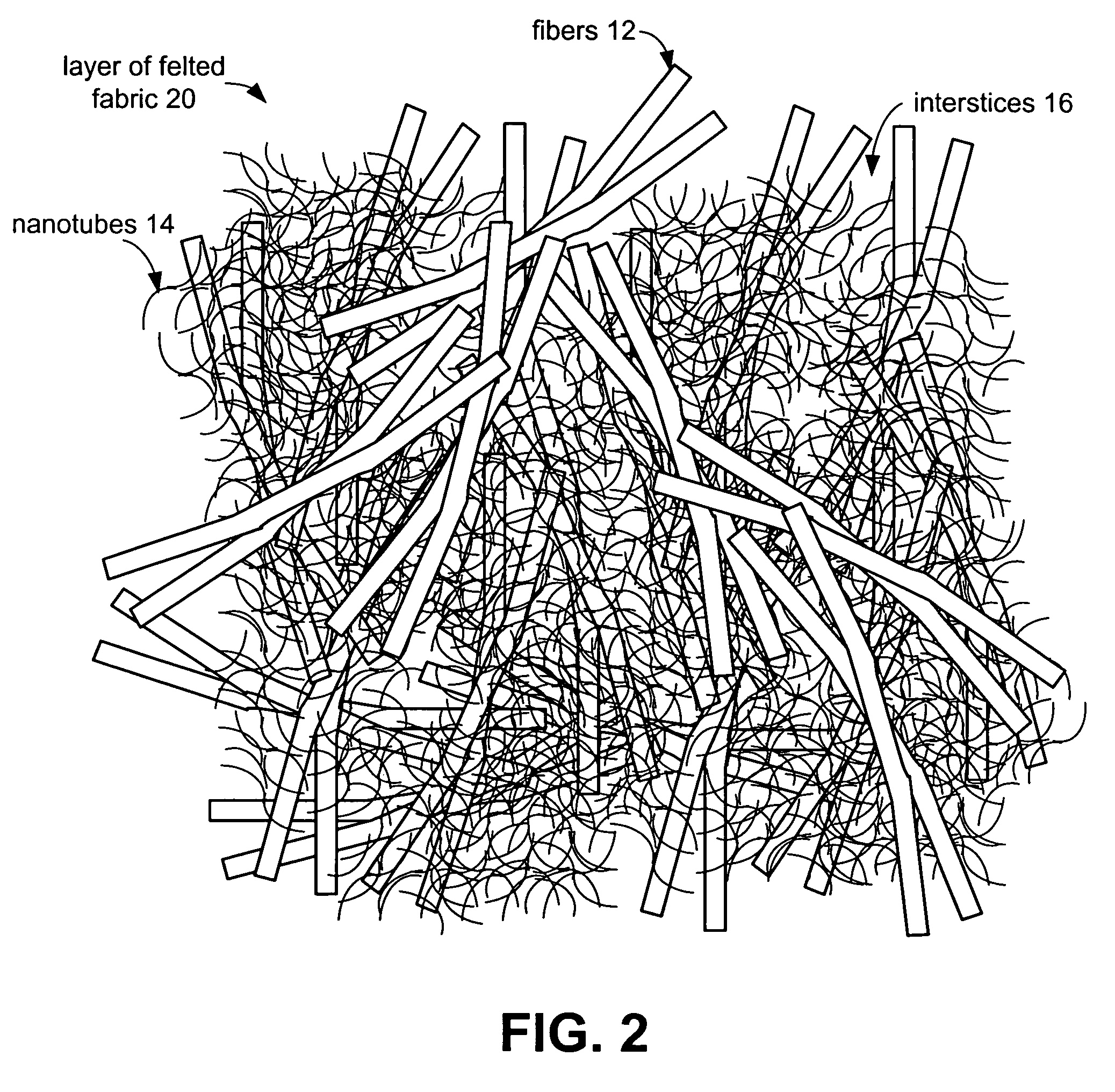

Ballistic fabrics with improved antiballistic properties

ActiveUS20060062944A1Good physical propertiesImprove propertiesMaterial nanotechnologyWarp knittingFiberYarn

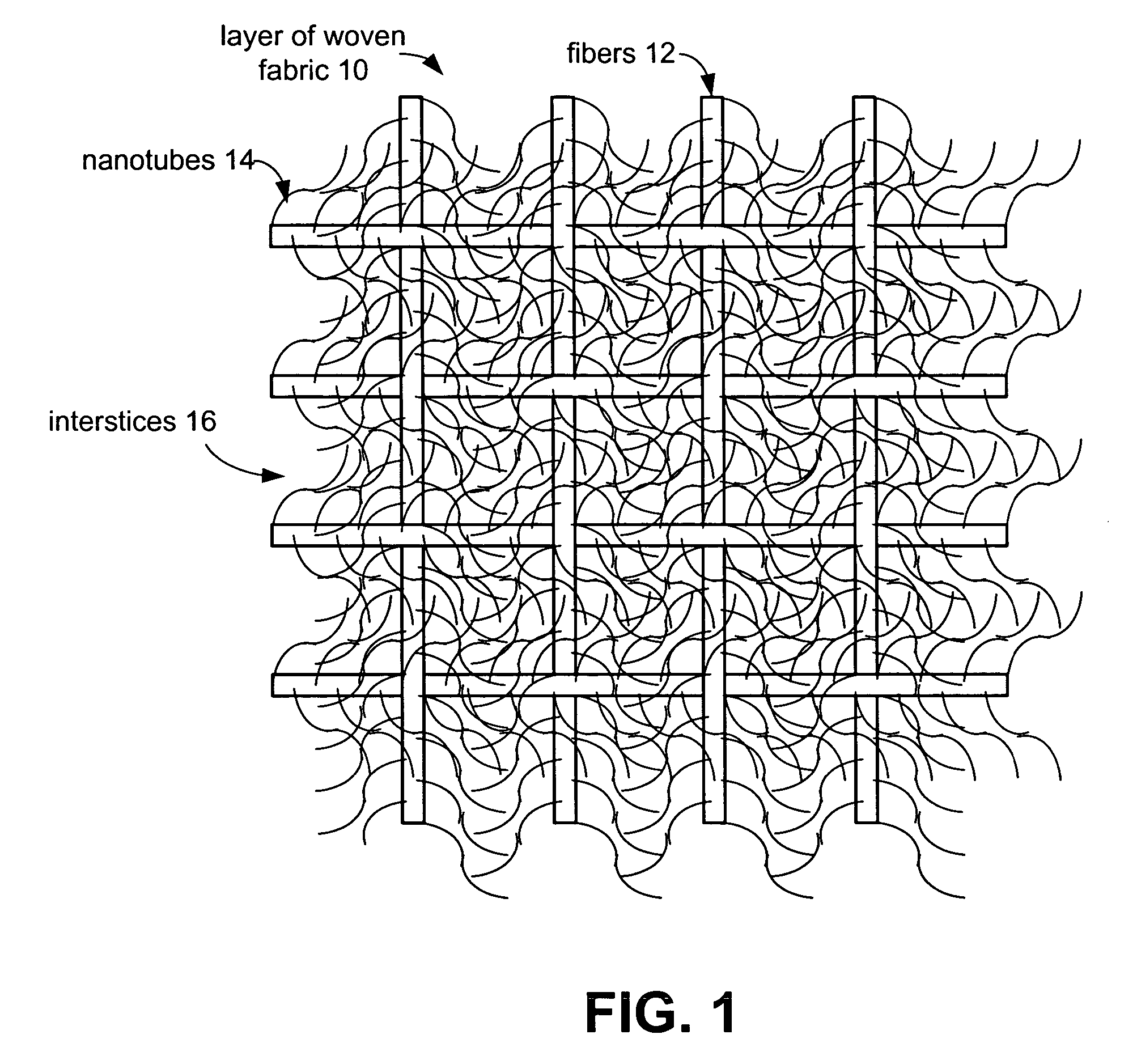

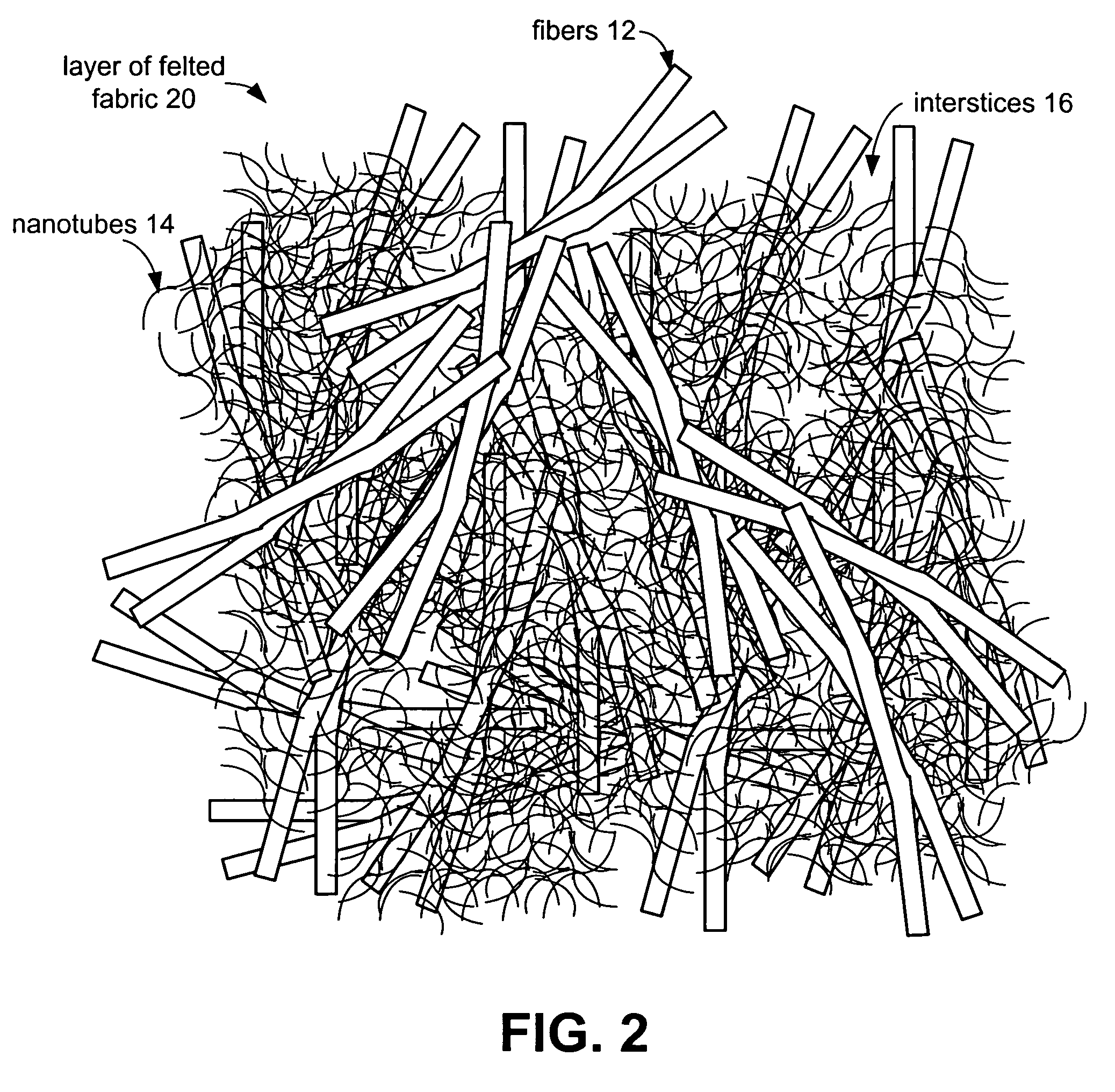

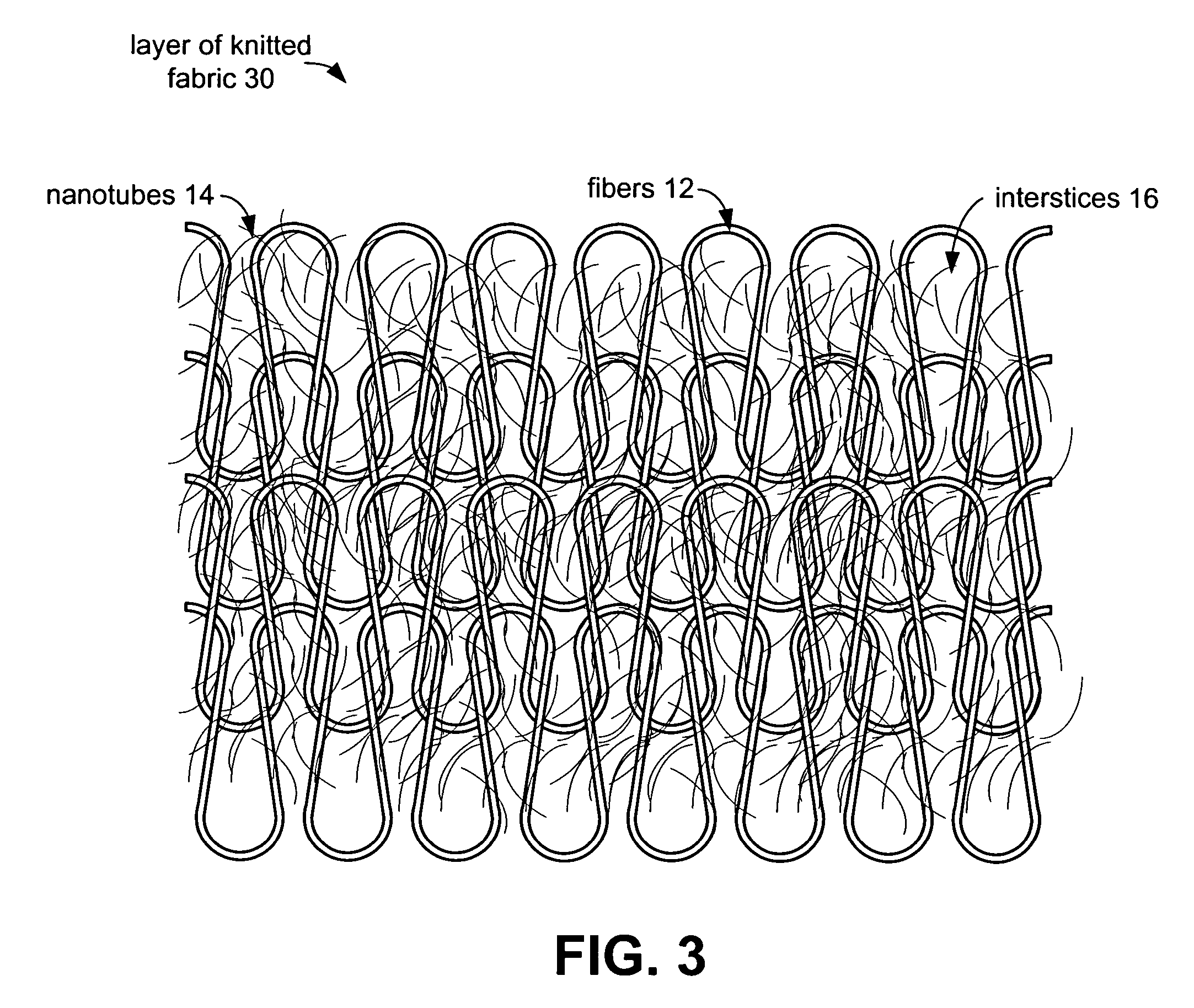

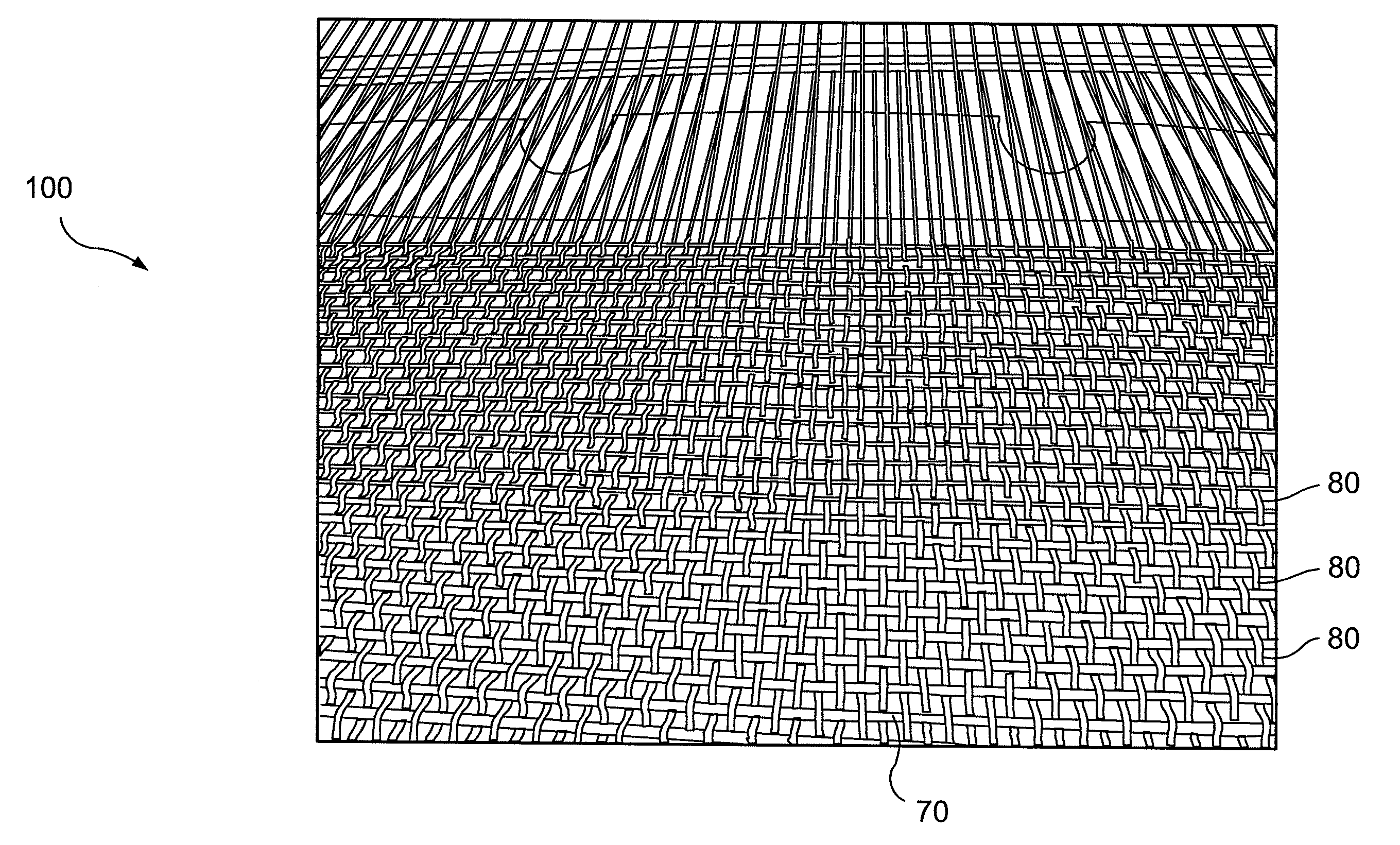

The present invention provides fabrics that have unique mechanical, chemical, electrical, and thermal properties. The fabrics comprise layers of woven, knit or felted fibers, yarns or tow. Interstitially synthesized nanotubes, such as single-walled or multi-walled carbon nanotubes, enhance the fabric's antiballistic properties. These nanotubes may also insulate, semi-conduct or super-conduct electrical charges, or provide enhanced thermal properties of these fabrics which can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

Processing of titanium-aluminum-vanadium alloys and products made thereby

InactiveUS20040221929A1Expensive to produceHigh energy input requirementMetal rolling arrangementsNitrogenTitanium

A method of forming an article from an alpha-beta titanium including, in weight percentages, from about 2.9 to about 5.0 aluminum, from about 2.0 to about 3.0 vanadium, from about 0.4 to about 2.0 iron, from about 0.2 to about 0.3 oxygen, from about 0.005 to about 0.3 carbon, from about 0.001 to about 0.02 nitrogen, and less than about 0.5 of other elements. The method comprises cold working the alpha-beta titanium alloy.

Owner:ATI PROPERTIES

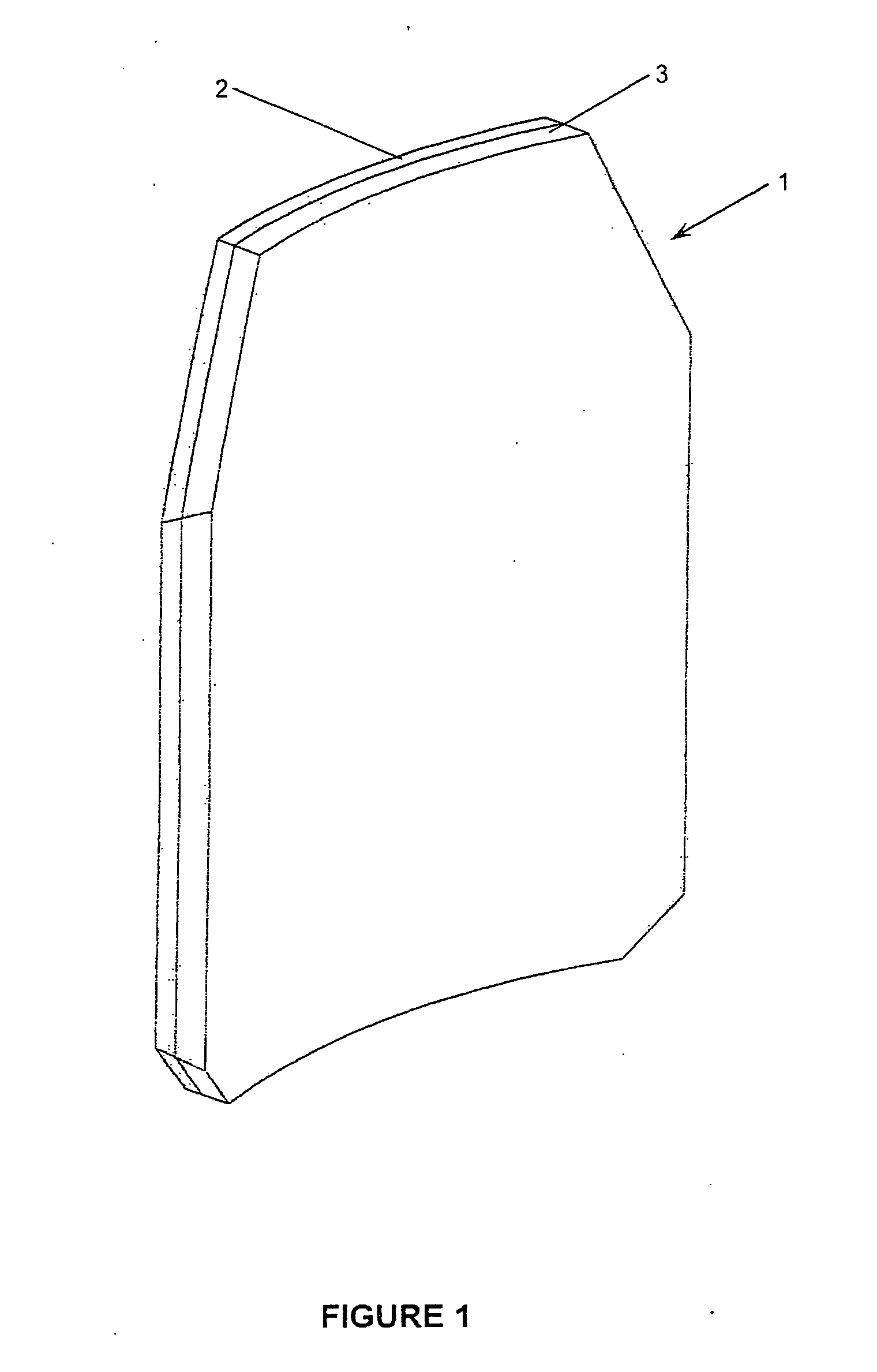

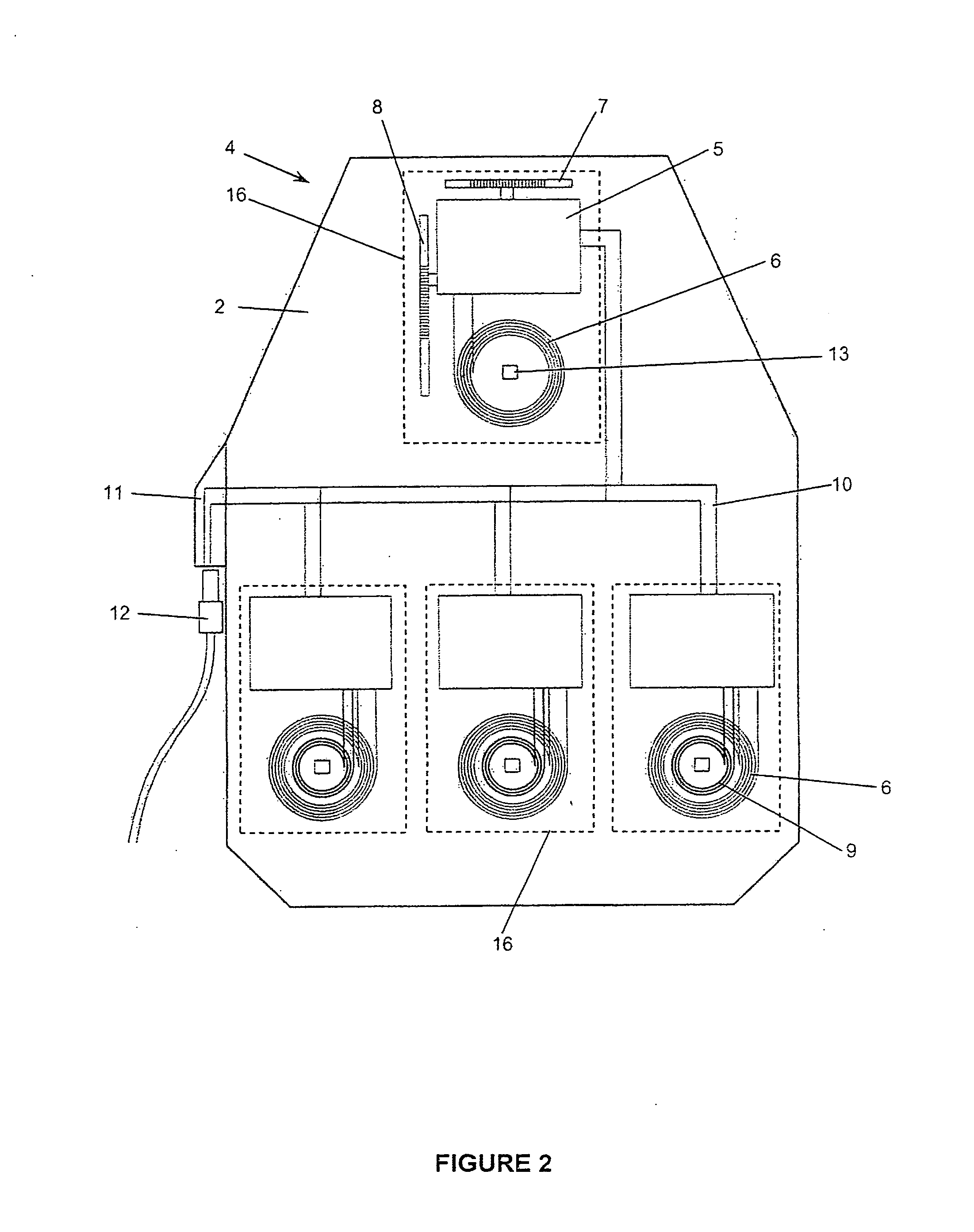

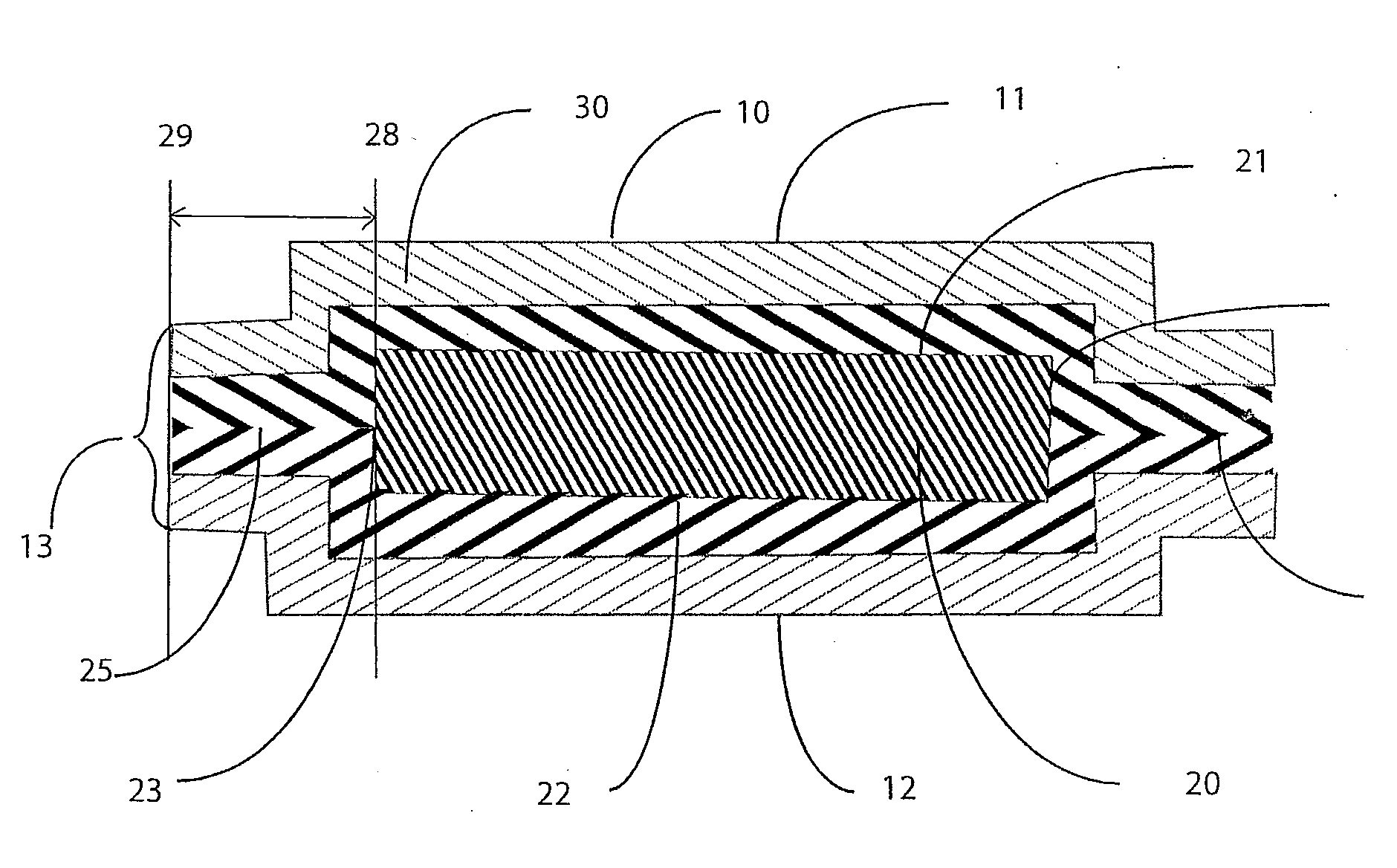

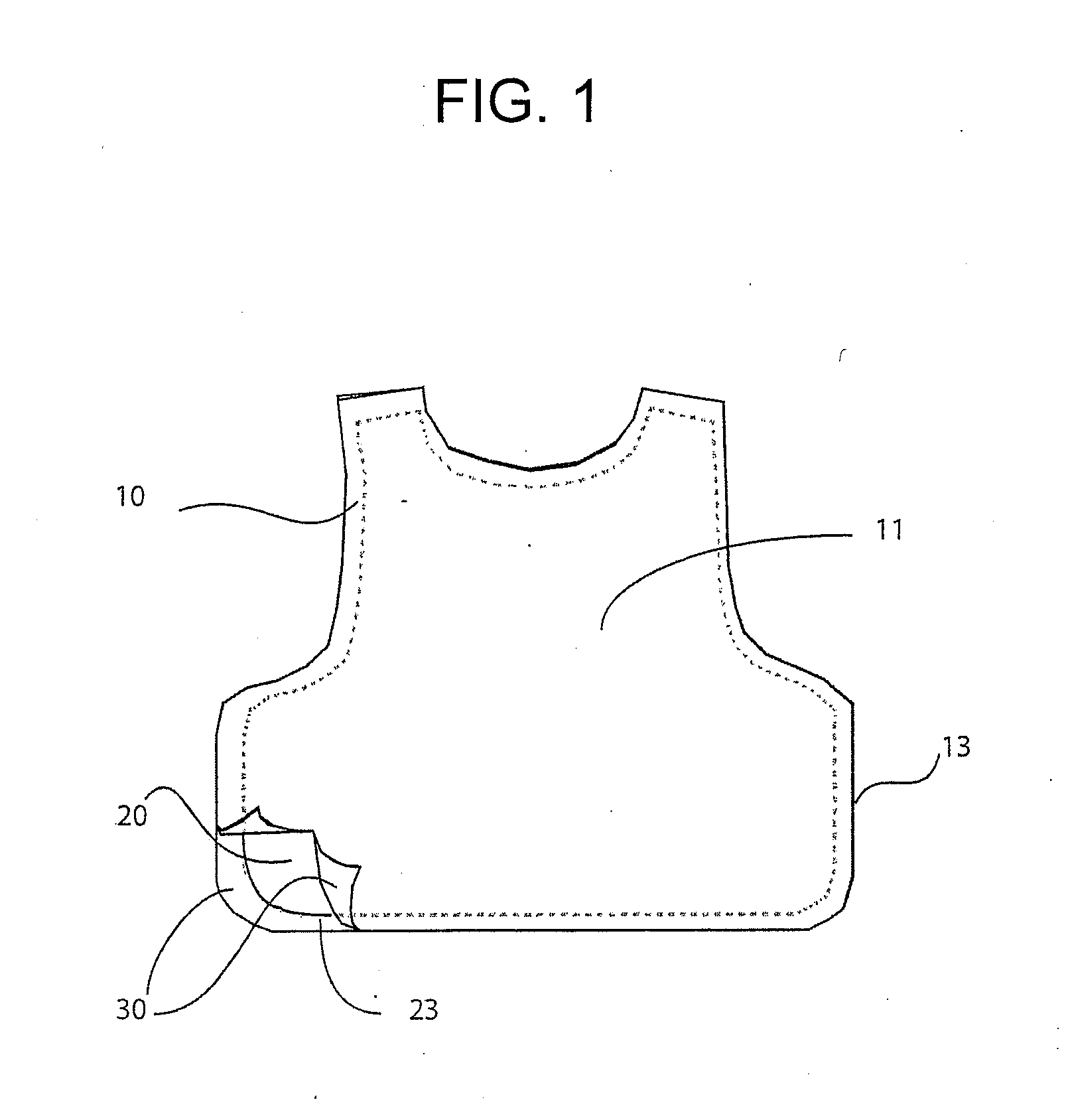

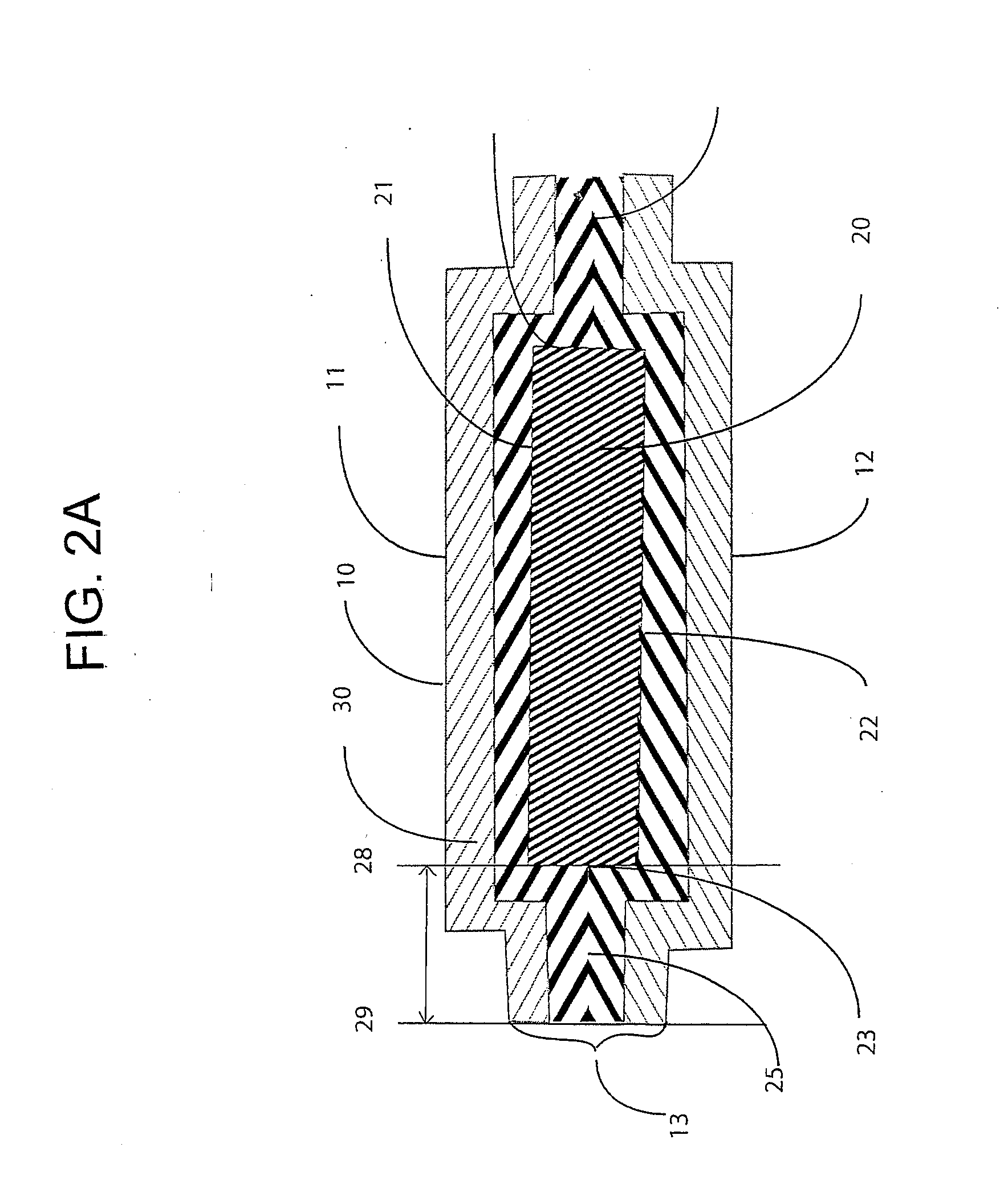

Inductive body armor

InactiveUS20120153740A1Excellent material penetration capabilityShort data exchangeNear-field transmissionArmourEngineeringHand held devices

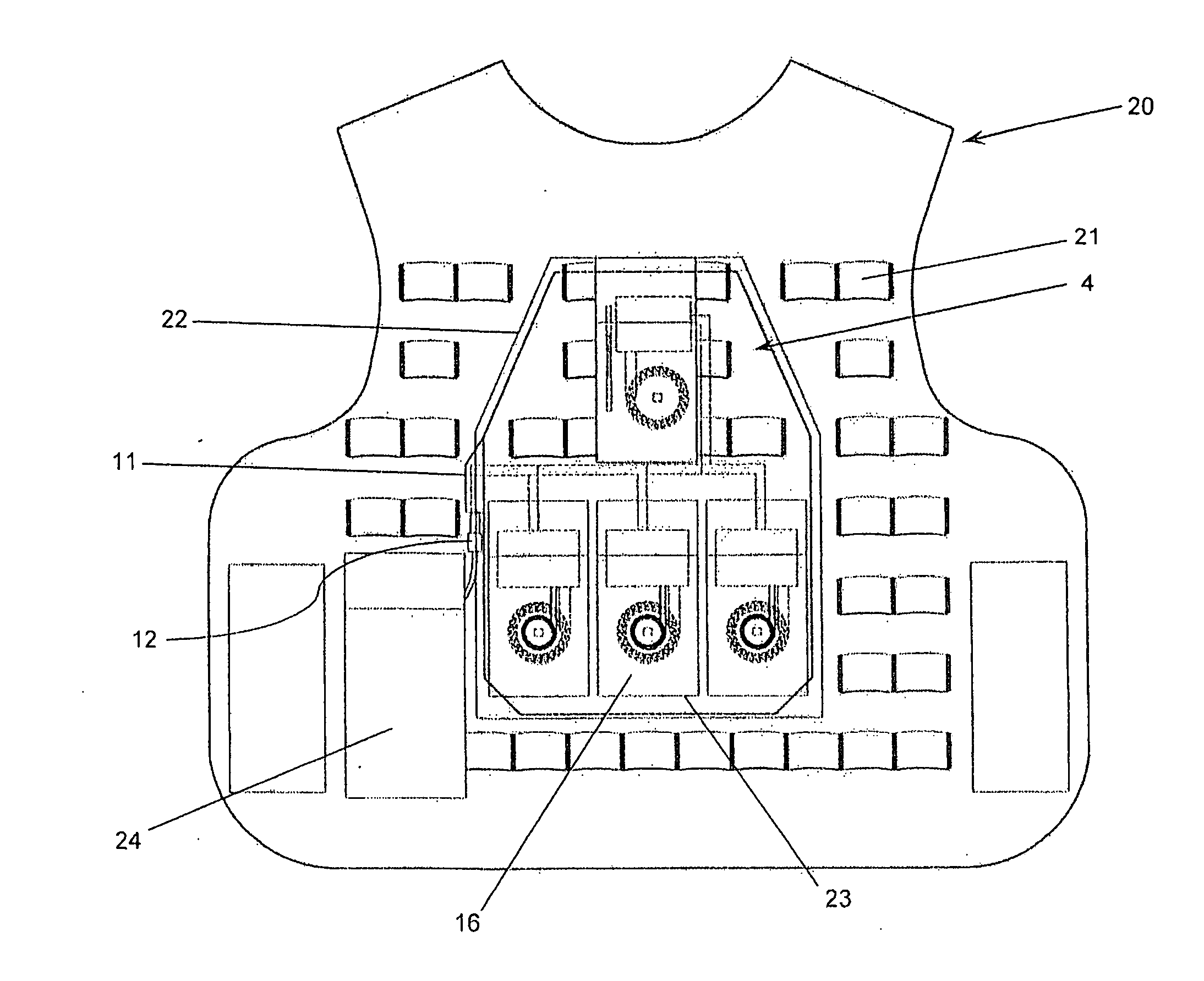

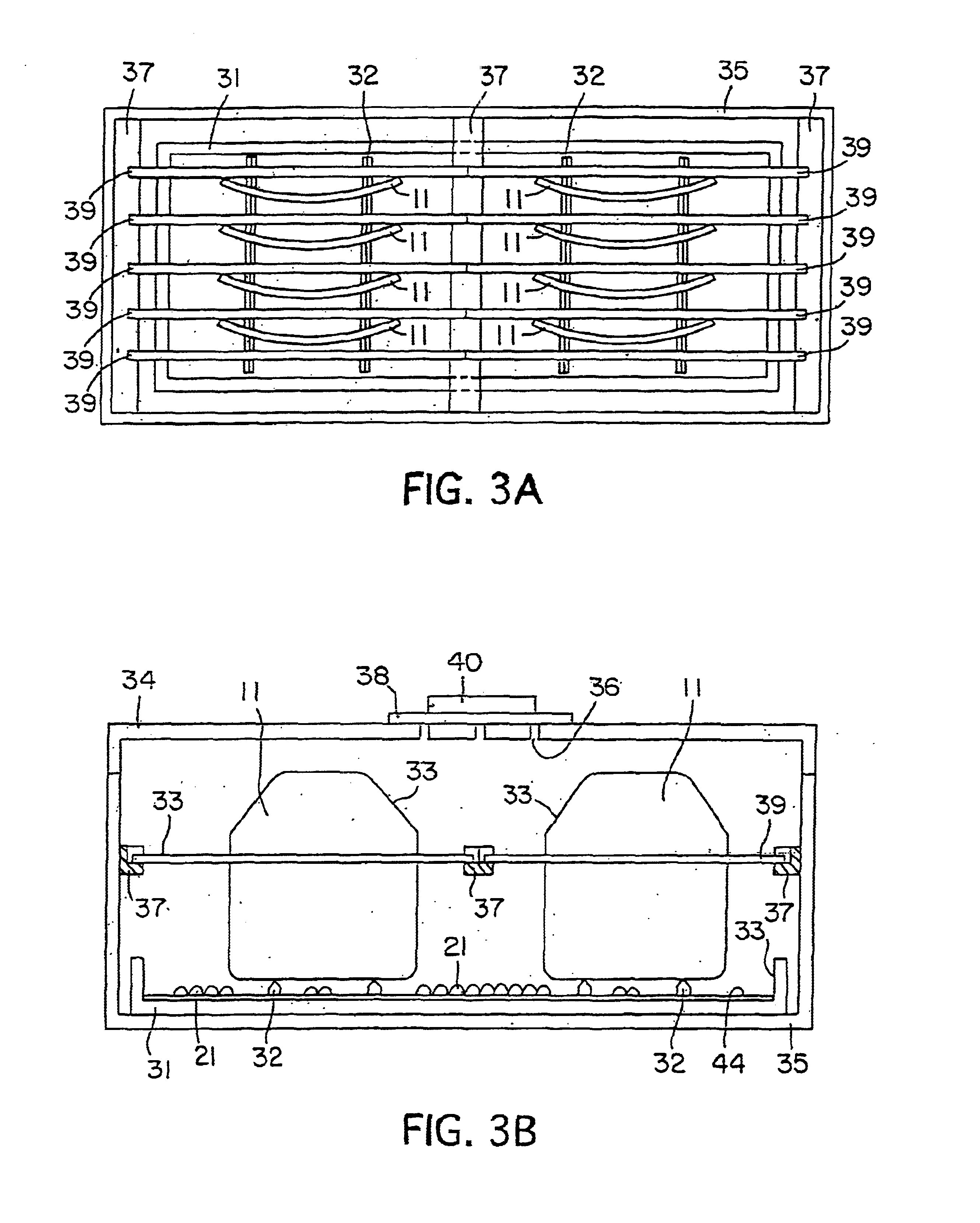

A system for the inductive transmission of power from a primary coil to a secondary coil and its associated secondary circuits, and for the inductive transmission of data between the primary and secondary coils includes a hard body-armor plate mountable in a tactical garment wherein at least one primary coil is embedded in the plate behind the plate's strike-face by a substantially uniform said first depth, and wherein the primary circuits of the primary coil are adapted to be electrically connected to a central power source carried on or in cooperation with said garment, and at least one device pocket is provided for an electronic hand-held device wherein said device pocket is mountable to an outer surface of said garment so as to be in an inductively coupling position aligned over said primary coil in said plate to thereby align said secondary coil of a hand-held device in the device pocket over and into inductively coupled registry with said primary coil in the plate.

Owner:CYNETIC DESIGNS

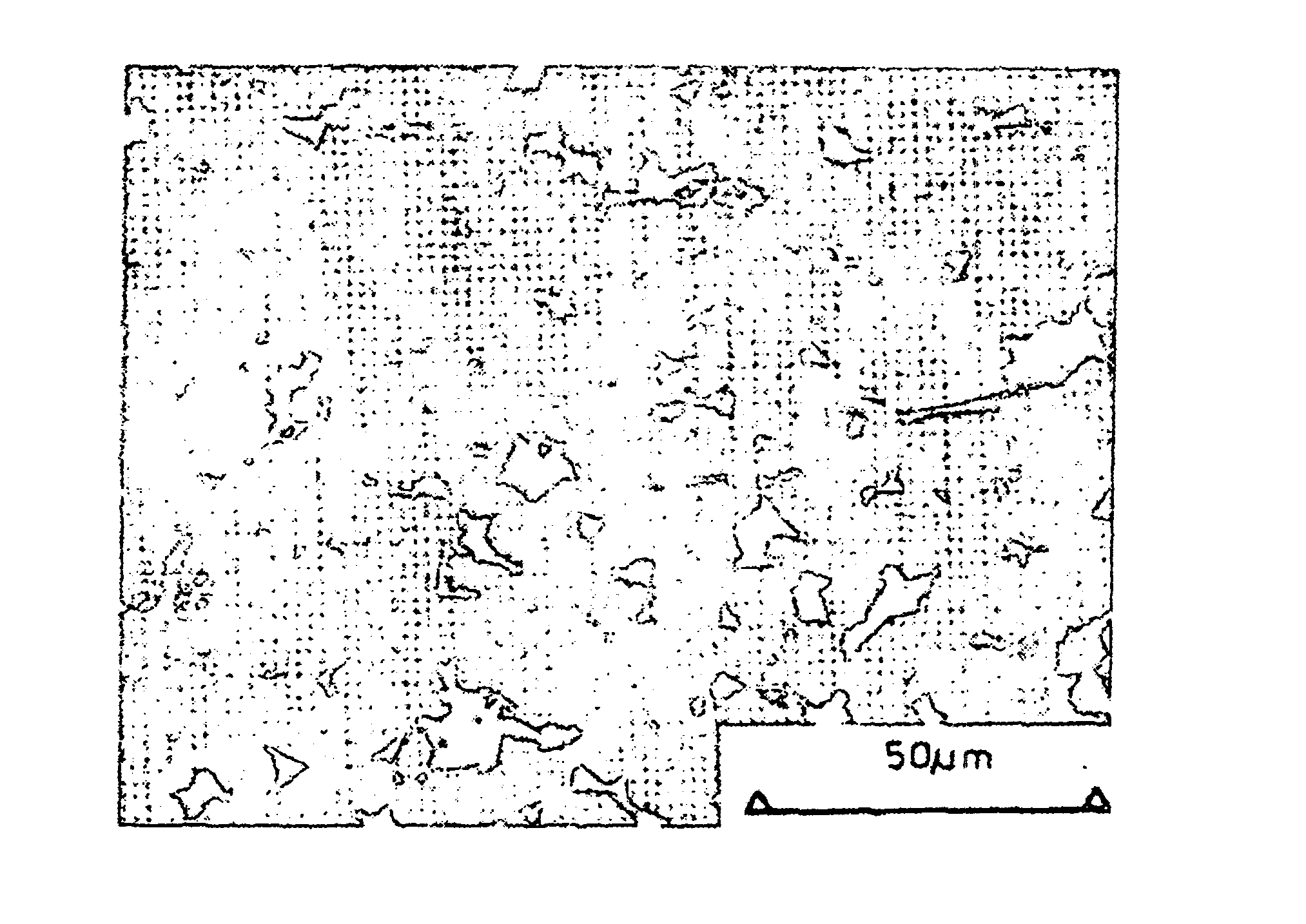

Ceramic-rich composite armor, and methods for making same

InactiveUS7104177B1Reduce manufacturing costHighly dimensionally accurate shaped articleCeramic layered productsArmour platesReaction bonded silicon carbideGrain growth

Silicon infiltration technology, e.g., siliconizing or reaction-bonding, is used to produce ceramic-rich composite bodies having utility as ballistic armor. In the main embodiment of the invention, the ballistic armor includes a reaction-bonded silicon carbide body (RBSC). Good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers, and by limiting the size of the morphological features making up the composite body. This control of “grain size” can be accomplished by controlling the size of the largest particles making up the porous mass to be infiltrated, but also of importance is controlling the processing conditions, particularly by controlling the factors that cause grain growth, coarsening of microstructure, and / or grain coalescence.

Owner:II VI DELAWARE INC

Energy absorbing device for ballistic body armor

InactiveUS6961957B2Improve safety and performanceReduce traumaPersonal protection gearArmour platesEnergy absorptionEngineering

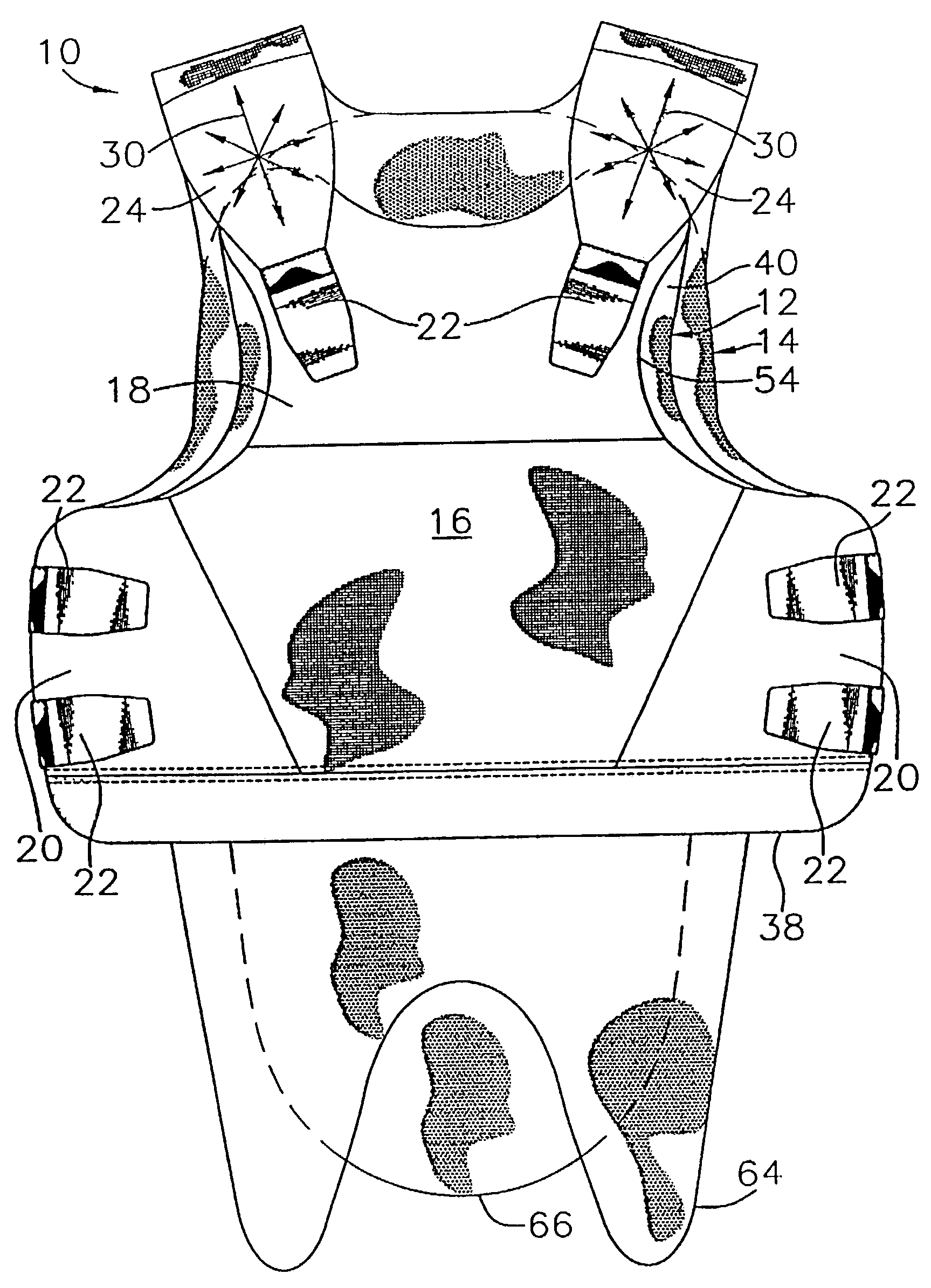

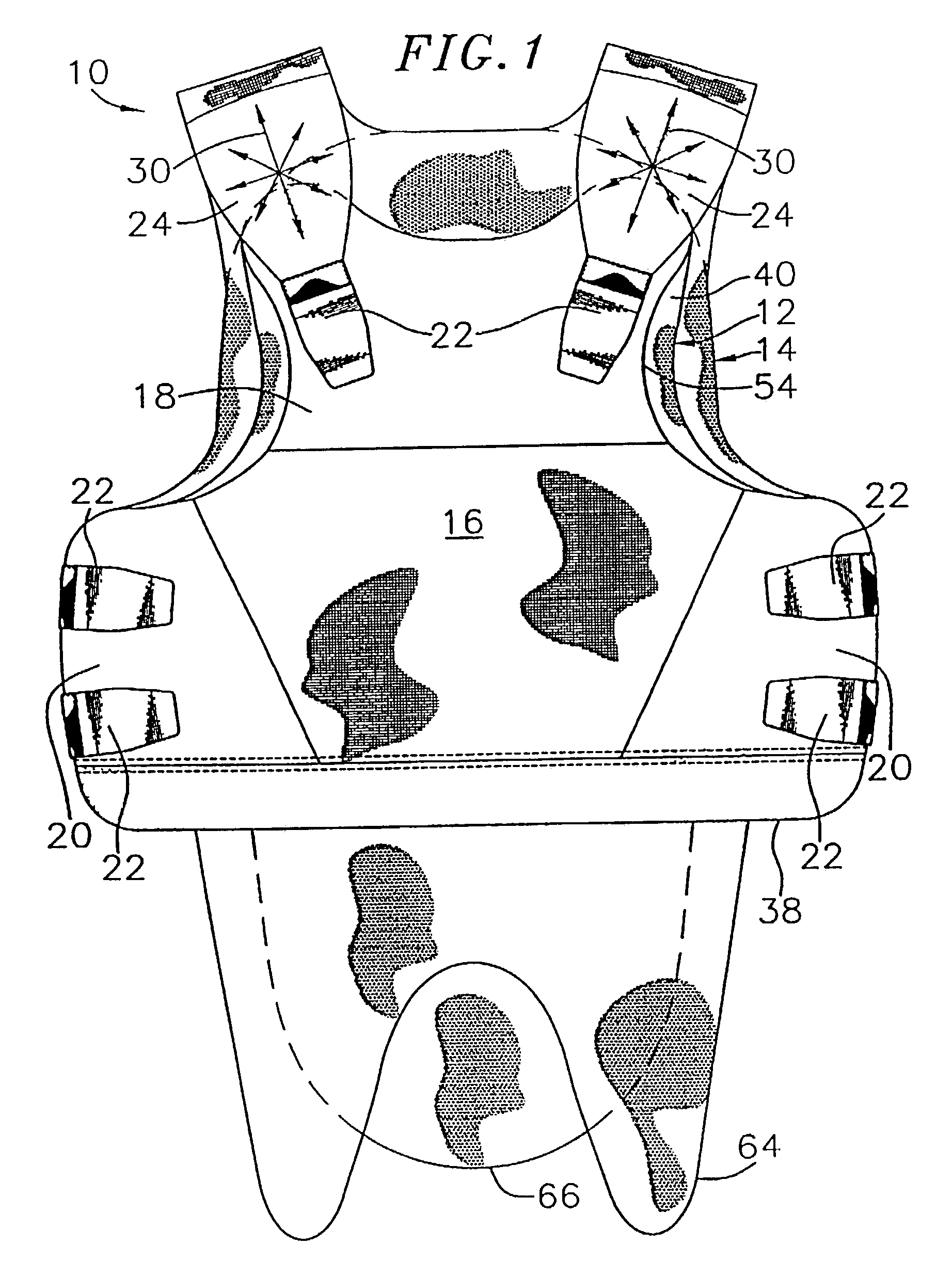

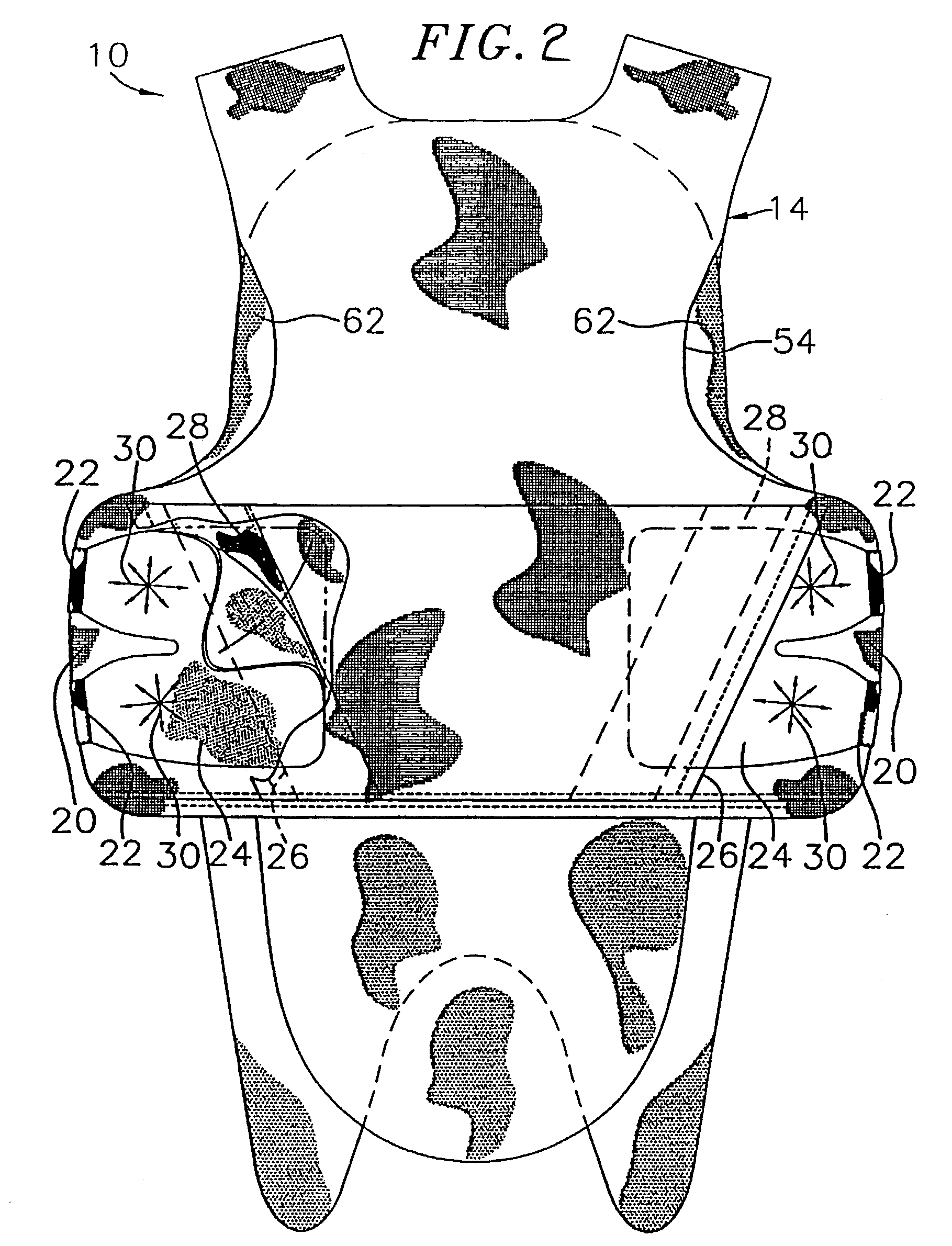

A ballistic vest having a front panel and a rear panel attached to each other by releasable connectors. The front and rear panel each have a ballistic package having a plurality of sheets of ballistic material and a semi-rigid frame structure attached to the layers of the ballistic material. The frame structure has a plurality of members defining openings in the frame structure wherein the frame structure absorbs energy from a projectile entering the sheets of ballistic material.

Owner:SAFARILAND

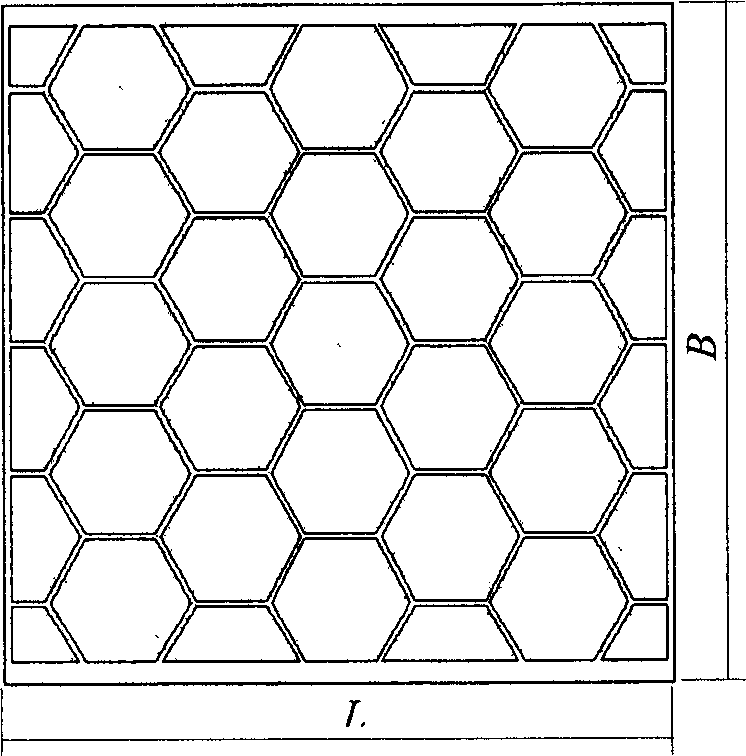

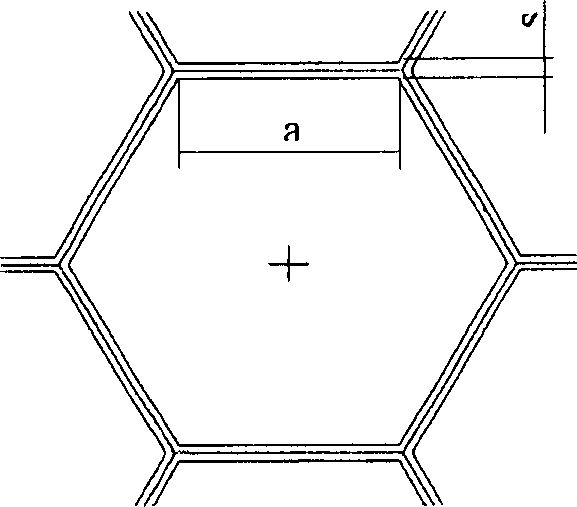

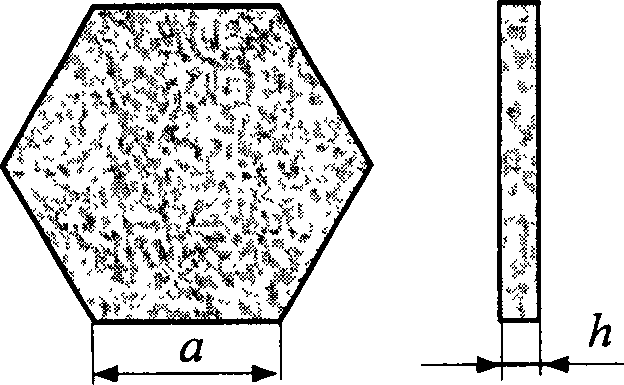

Composite bulletproof armour with steel honeycomb ceramic sandwich and manufacture thereof

In the invention, the composite bullet-proof armour plate consists of a metal panel, a honeycomb core board, a ceramic wafer core and a metal rear panel bonded with the metal brazing layer via the organic adhesive layer. The preparing method is that using the brozing and the line-cutting method are finished the honeycomb core board and the plain or curved ceramic wafer core, whose size must fit in that of the honeycomb hole of the honeycomb core board. The panel and the rear panel must be made of the bullet-proof steel plate through heat treating after cold rolling. The Ag72Cu metal brazing material and the epoxy resin group high strength structural sizing for connecting the interface are assembly welded.

Owner:UNIV OF SCI & TECH BEIJING

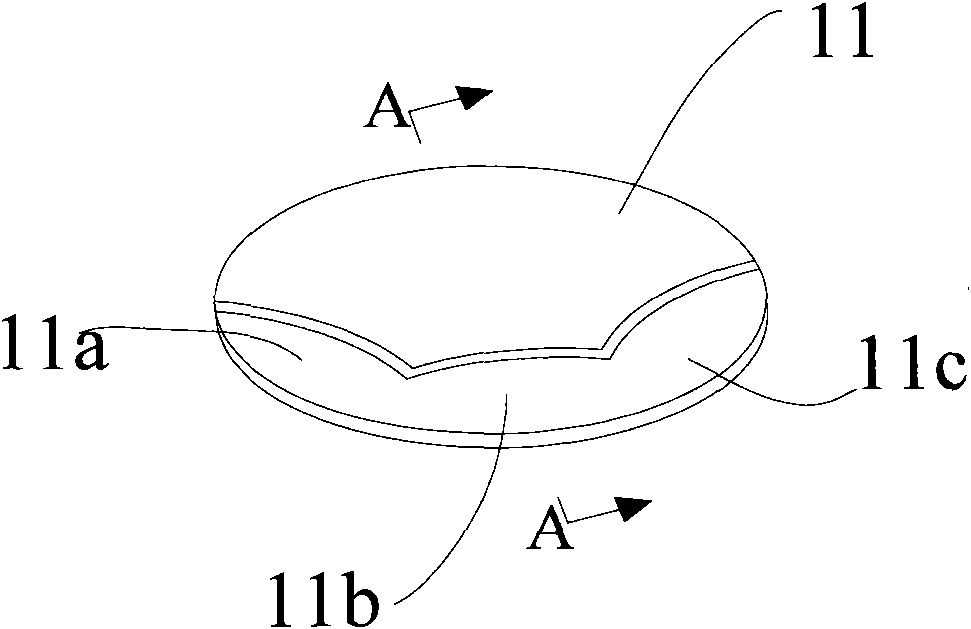

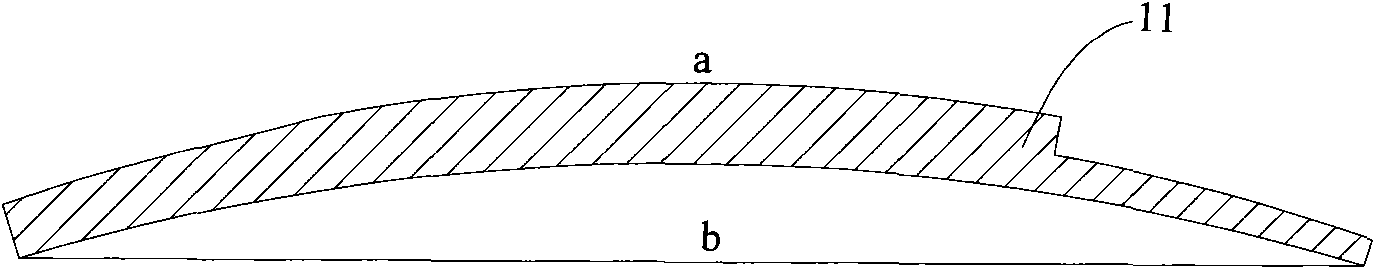

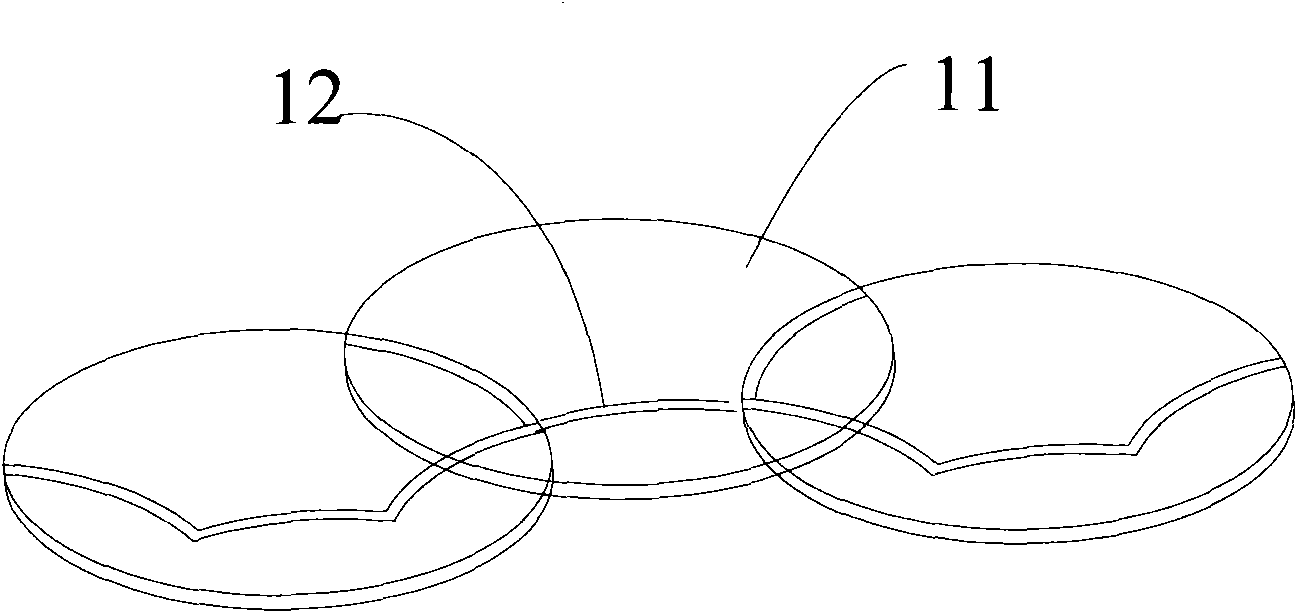

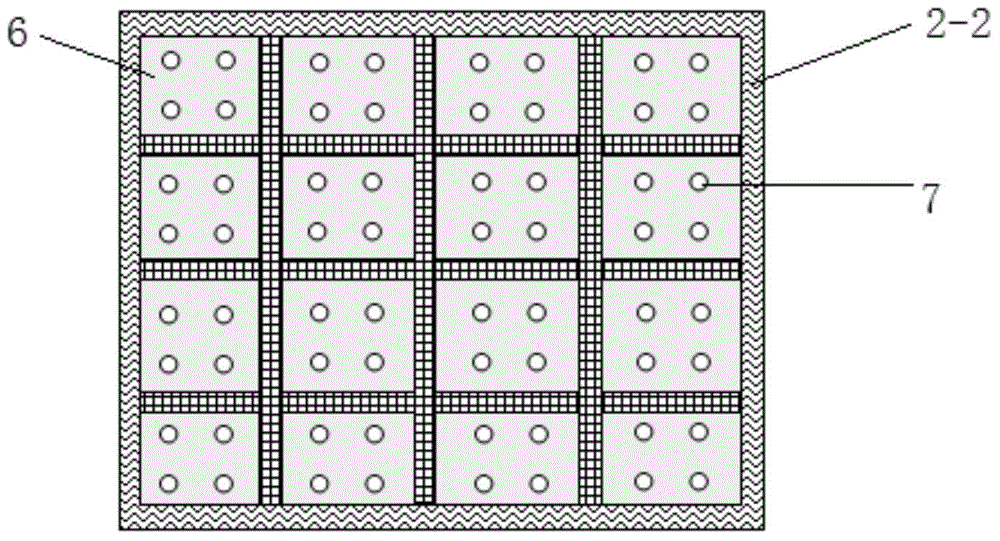

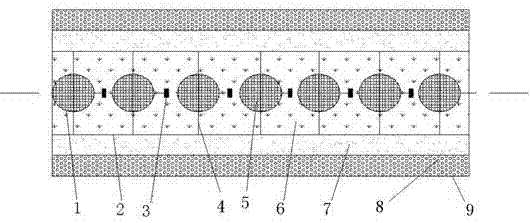

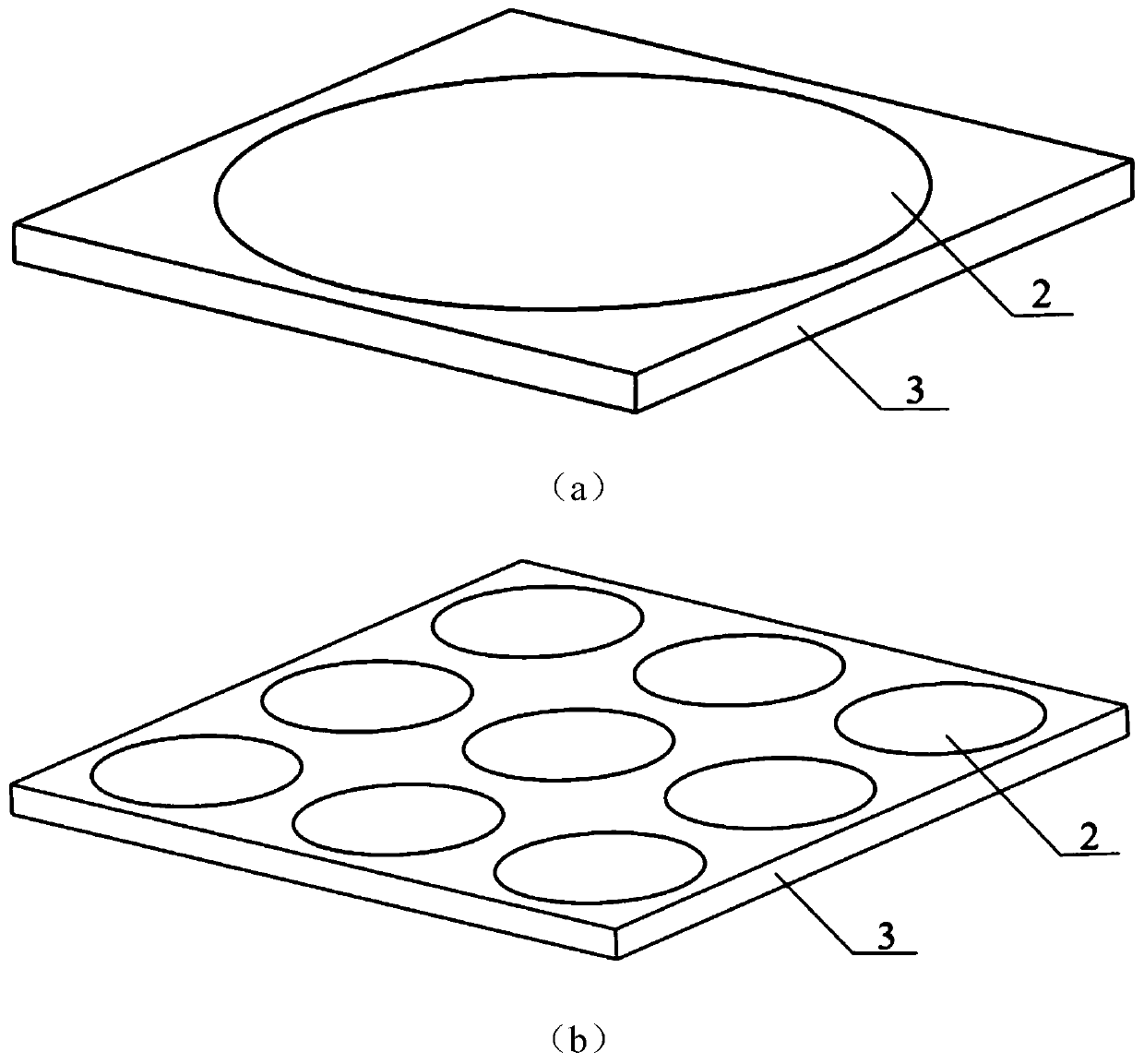

Bulletproof composite board

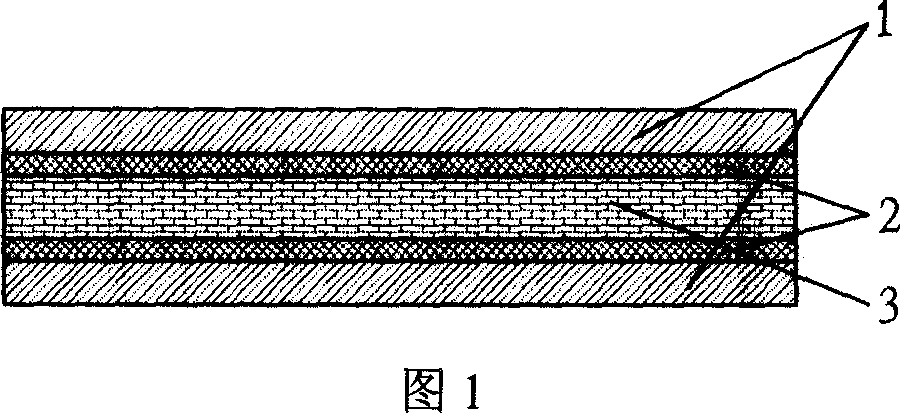

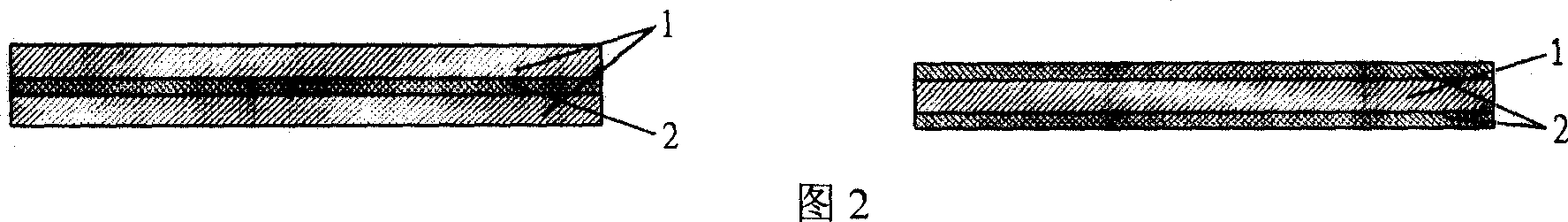

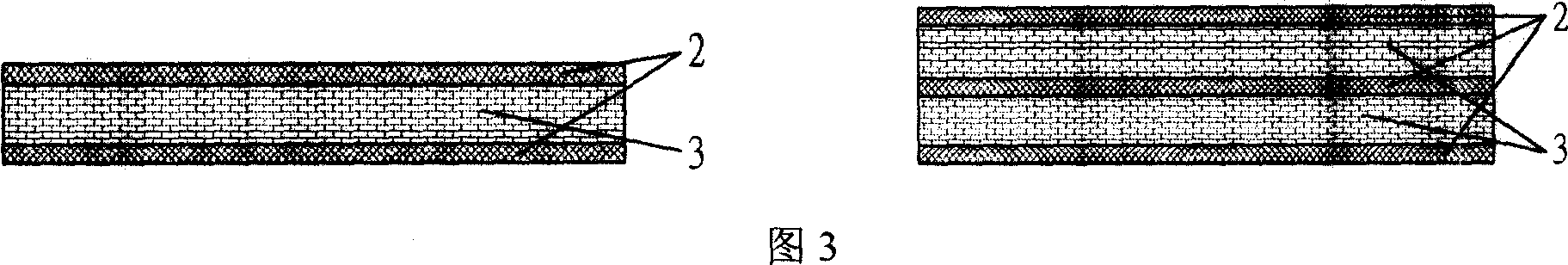

The invention discloses a bulletproof composite board comprising an buffer layer as the external layer, an absorption layer connected with the buffer layer, and a barrier layer connected with the absorption layer, wherein the buffer layer comprises a plurality of disks superposed into a scalelike structure, and the disks are provided with a convex surface towards the external layer; the absorption layer comprises weftless fabric pressure layers and knitted fabrics, which are superposed, and the weftless fabric pressure layers and the knitted fabrics comprise fibers of which the strength is atleast 15 cN / dtex and the modulus is at least 390 cN / dtex; and the barrier layer comprises a metal plate of which the tensile strength is greater than 1000 MPa. A bullet is deflected under the action of the convex surface of the disks, and the penetrating capability of the bullet is reduced; under the alternate actions of the weftless fabrics and the knitted fabrics, the energy of the bullet is quickly transferred and absorbed; and finally, the bullet is effectively prevented when getting into contact with the barrier layer with high strength.

Owner:杨珍芬

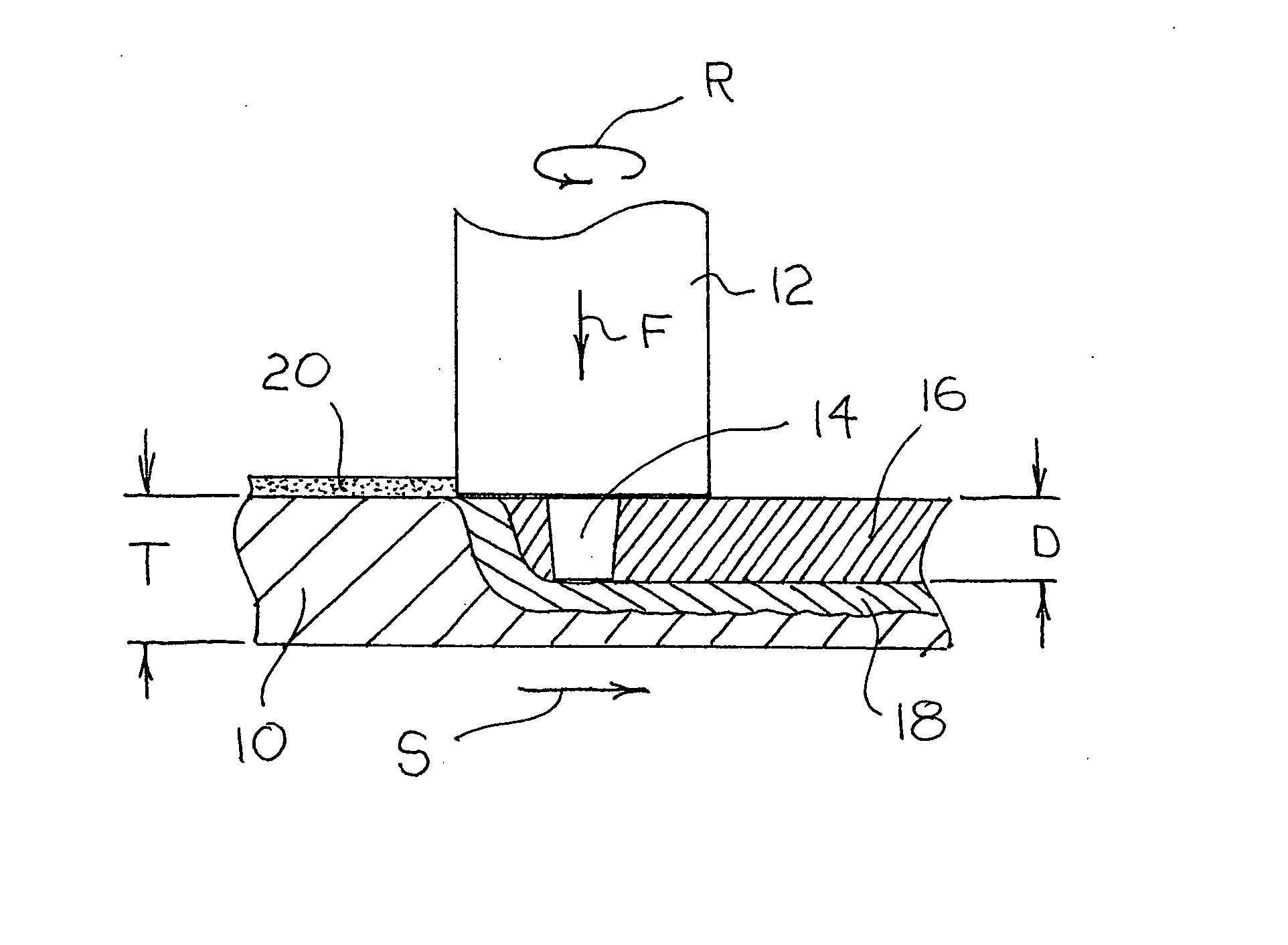

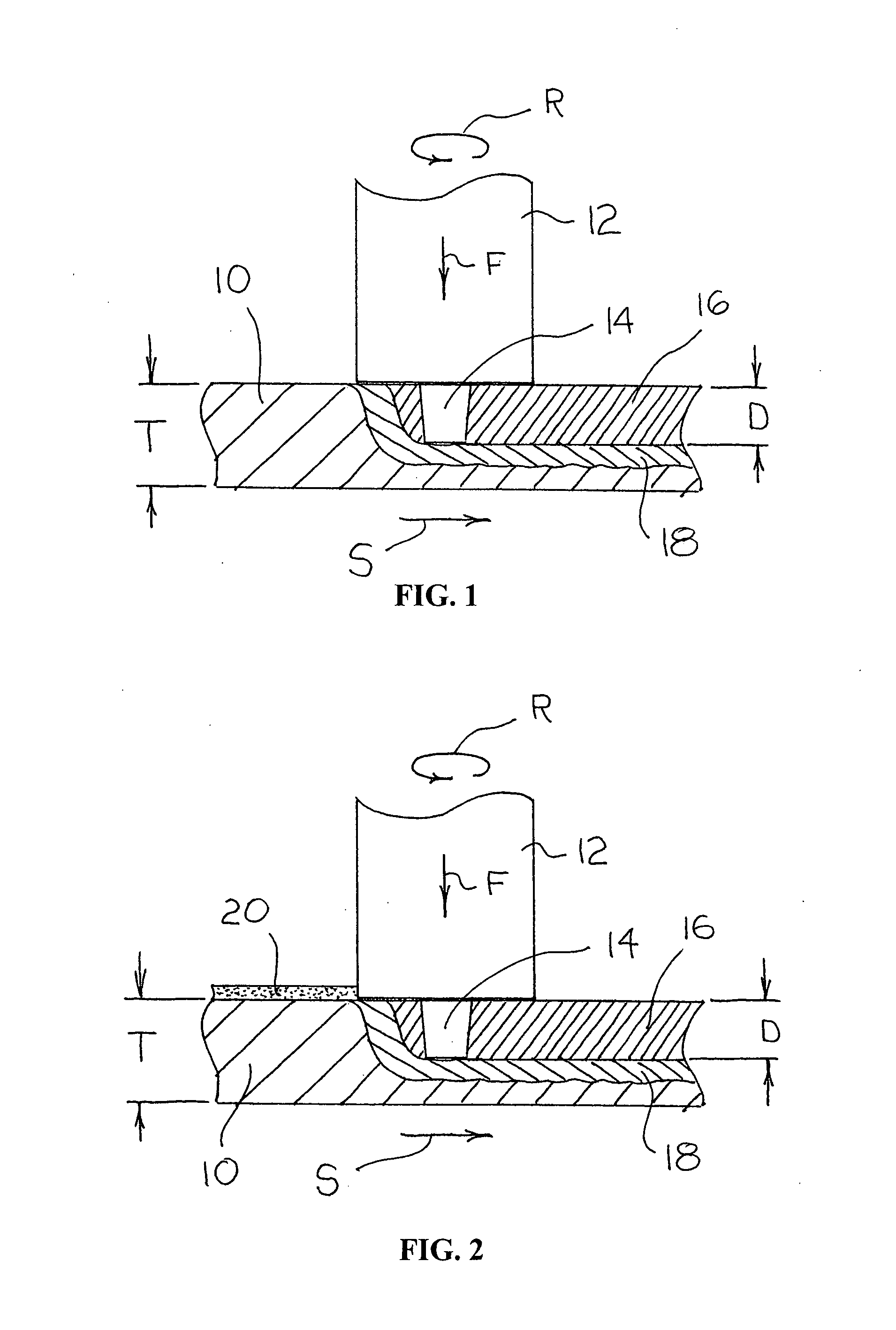

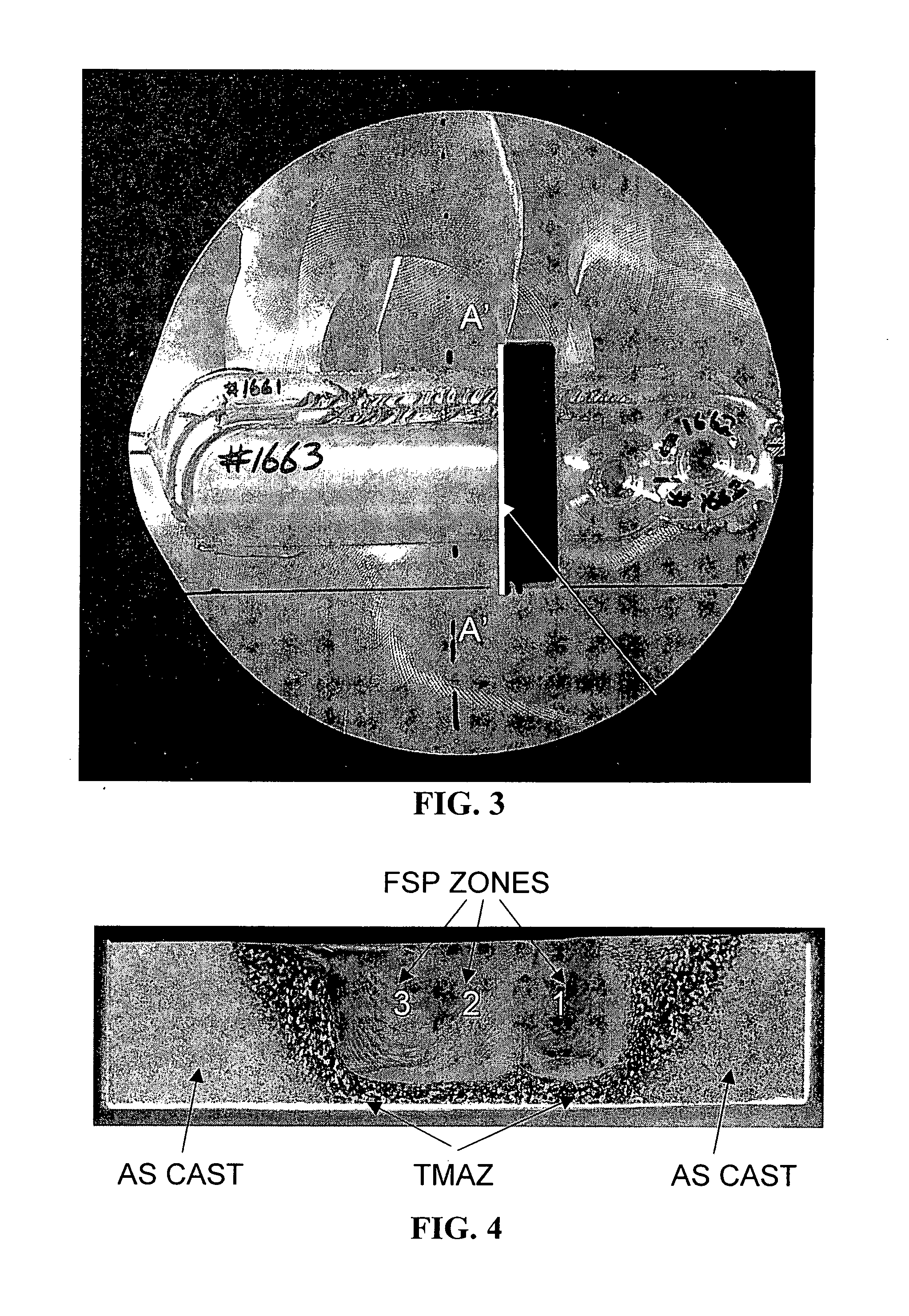

Stir processed cast aluminum-scandium structures and methods of making the same

InactiveUS20070297935A1Improve mechanical propertiesImprove corrosion resistanceAluminium compoundsGallium/indium/thallium compoundsFriction stir processingScandium

Friction stir processing is applied to an aluminum-scandium alloy workpiece in either a wrought or cast state including scandium-containing precipitates. The process selectively modifies the microstructure of the aluminum-scandium workpiece, for example, by reducing grain size and recrystallization of the substrate. Benefits include increased physical properties of the aluminum-scandium alloys as well as the ability to form unique alloy structures.

Owner:LANGAN TIMOTHY +2

Ballistic fabrics with improved antiballistic properties

ActiveUS8080487B2Good physical propertiesImprove propertiesMaterial nanotechnologyWarp knittingFiberYarn

Owner:LOCKHEED MARTIN CORP

Bullet-proof glass

InactiveCN103486908ASimple structureReduce thicknessGlass/slag layered productsShieldsBisphenol-A-polycarbonateLaminated glass

The invention relates to bullet-proof glass. The bullet-proof glass is composited by laminated glass, polyurethane elastomer and a PC (polycarbonate) board. The bullet-proof glass has the advantages of simple structure, thinness, light weight, low cost and good bullet-proof effect. Further, the bullet-proof glass is capable of effectively proofing bullets and avoiding secondary harms to human bodies after being smashed into pieces.

Owner:天津广源新材料科技有限公司

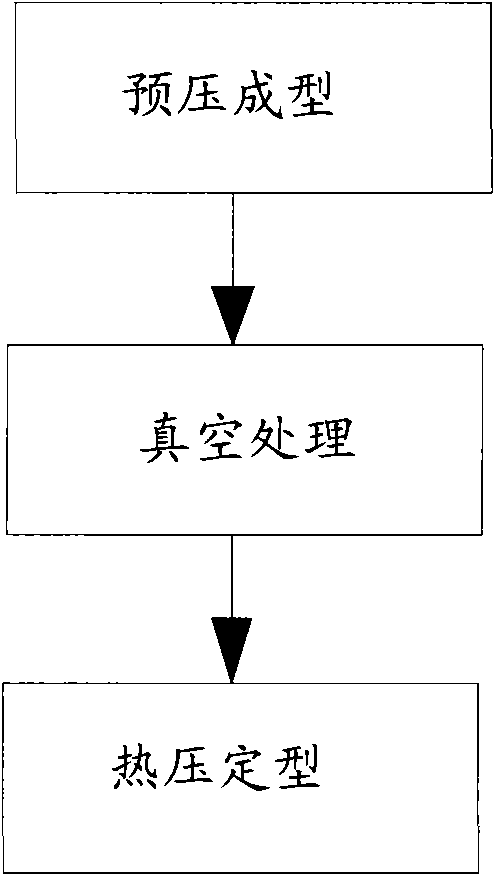

Method for preparing bulletproof formed part

InactiveCN101629794AImprove ballistic performanceImprove liquidityLaminationLamination apparatusFiberAdhesive

The invention discloses a method for preparing a bulletproof formed part, which comprises the steps of: a) overlapping more than two layers of high-performance fiber weftless cloth, imposing the pressure of between 0.1 and 1MPa to ensure that the air among the weftless cloth escapes, then increasing the temperature of the weftless cloth to be between 110 and 120 DEG C, and then imposing the pressure of between 1 and 3MPa for pre-press forming; b) performing heat preservation on the weftless cloth after the pre-press forming for 20 to 120min under the vacuum condition that the temperature is between 120 and 130 DEG C and the pressure is lower than 0.5kpa; and c) imposing the pressure of between 10 and 20MPa on the weftless cloth after the vacuum treatment in a hot pressing mold with a temperature of between 120 and 130 DEG C, performing heat preservation and pressure maintaining for 20 to 60min, and then cooling the weftless cloth to room temperature to obtain the bulletproof formed part. An adhesive in the weftless cloth has good fluidity at high temperature, so the pre-press forming and the subsequent vacuum treatment of the weftless cloth can ensure that the bonding of fiber andthe adhesive is evener, reduce the defects such as pores and the like, and improve the bulletproof performance of the weftless cloth.

Owner:杨珍芬

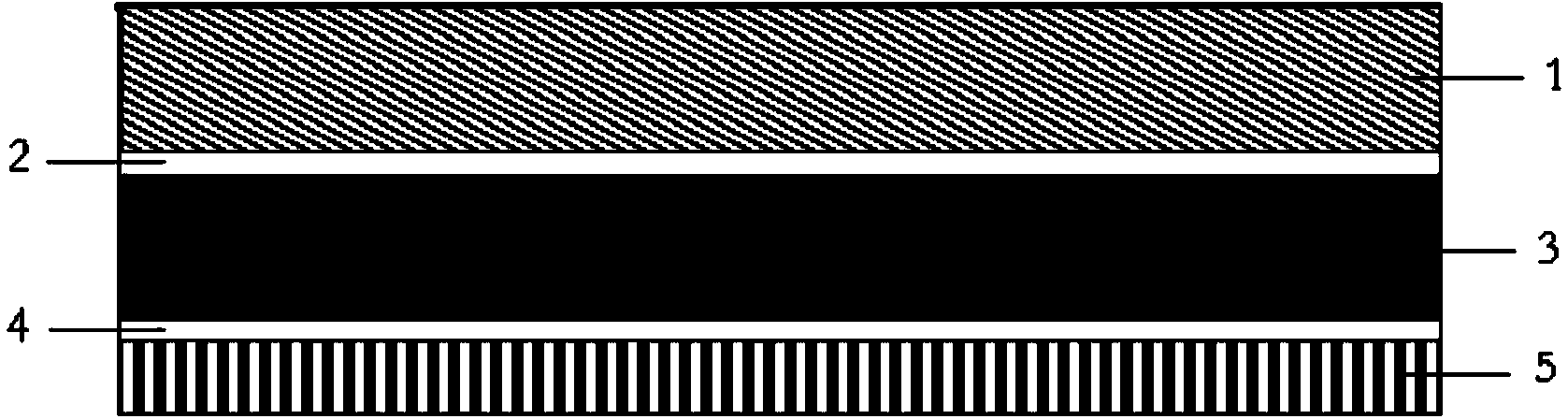

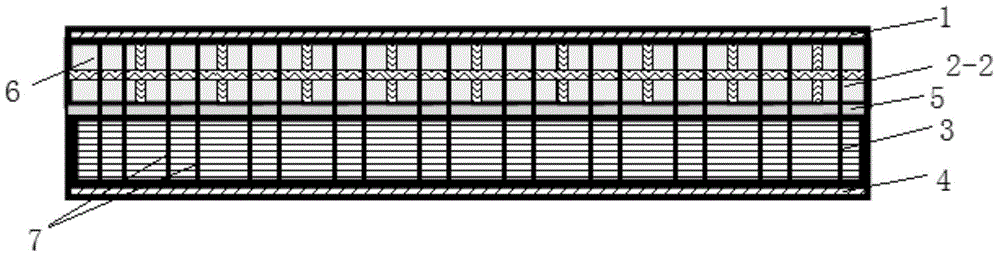

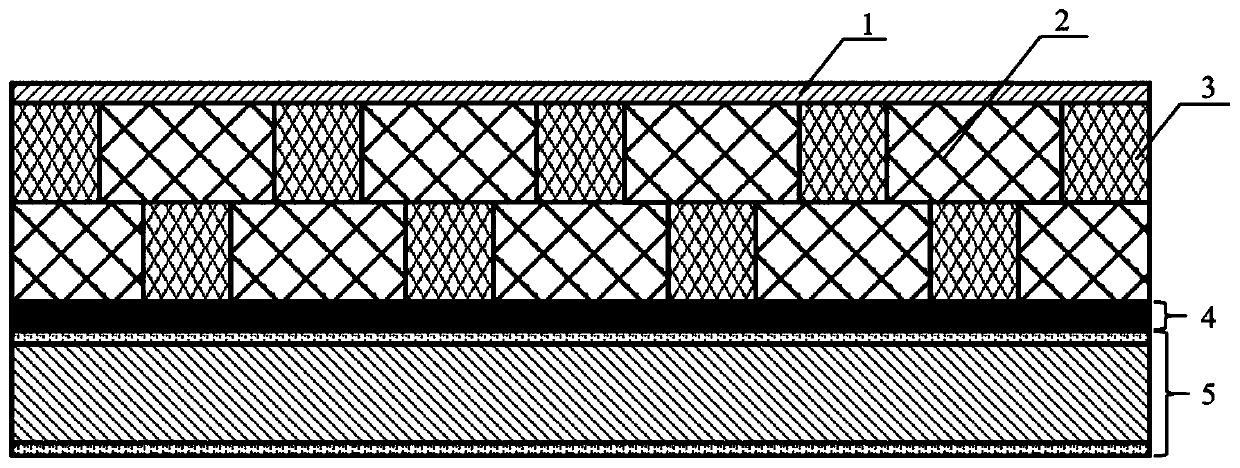

Ceramic composite material bullet-proof chest board and preparation method thereof

ActiveCN104949581AImprove structural impact resistanceGuaranteed bonding strengthSynthetic resin layered productsCeramic layered productsCeramic compositeMetallurgy

The invention discloses a ceramic composite material bullet-proof chest board and a preparation method thereof. The ceramic composite material bullet-proof chest board is composed of a carbon fiber composite surface rigid layer, a ceramic composite material sheet combination layer, a bullet-proof fiber composite material body layer and a back elastic surface carbon fiber composite back-convex-proof layer. The ceramic composite material sheet combination layer is made of special fiber reinforced ceramic matrix materials and is of a needling insertion type combined structure or a three-dimensional crazing-prevention framework structure; a composite cementing and micropore riveting combined technology is adopted between the ceramic composite material layer and the bullet-proof body layer; finally, the ceramic composite material sheet combination layer and the bullet-proof fiber composite material body layer are wrapped in a rigid structure composed of the carbon fiber composite surface rigid layer and the back-convex-proof layer to form a whole. The ceramic composite material bullet-proof chest board has various advantages of being light, low in back convex, stable in high and low temperature structure, long in service life and the like. Meanwhile, the problem that a seam bullet-proof characteristic in a traditional splicing structure of ceramic sheets is poor is effectively avoided, and the ceramic composite material bullet-proof chest board has the overall characteristics of multiple bullet-proof materials.

Owner:山东宽原新材料科技有限公司

Ballistic panels and method of making the same

InactiveUS20110214559A1Improve waterproof performanceImprove ballistic performanceLayered product treatmentSynthetic resin layered productsEngineering

Owner:WL GORE & ASSOC INC

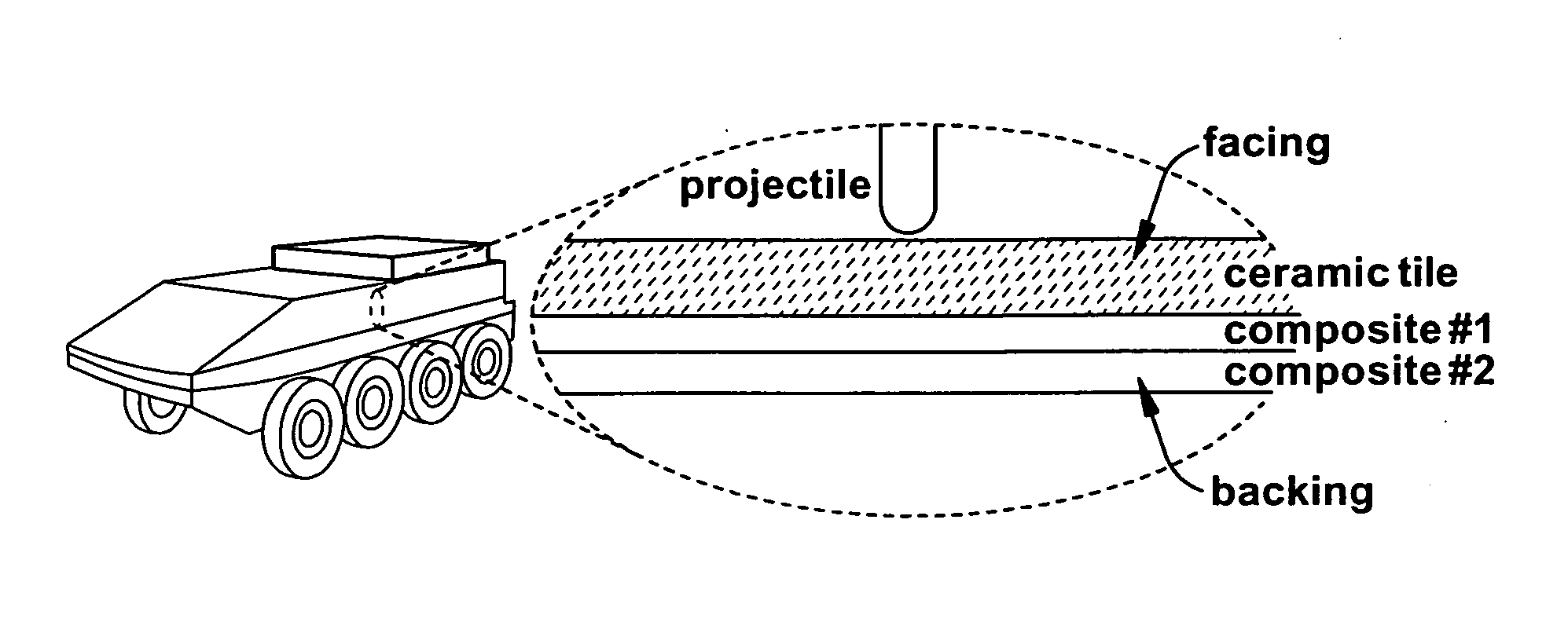

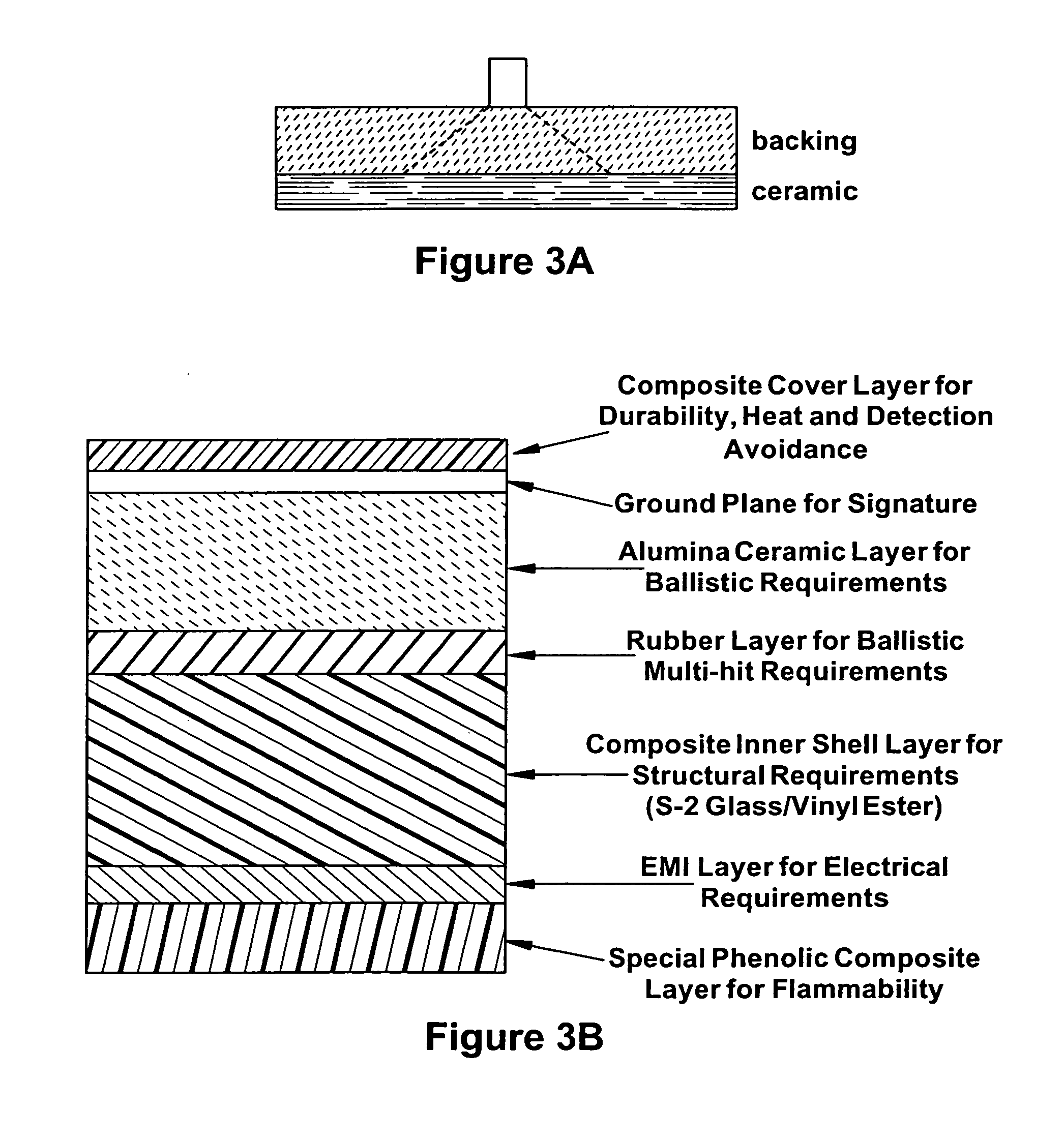

Hybrid composite structures for ballistic protection

InactiveUS20070068377A1Improve impact resistanceImprove energy absorptionArmour platesMechanical engineeringComposite structure

Owner:THE UNIVERSITY OF AKRON

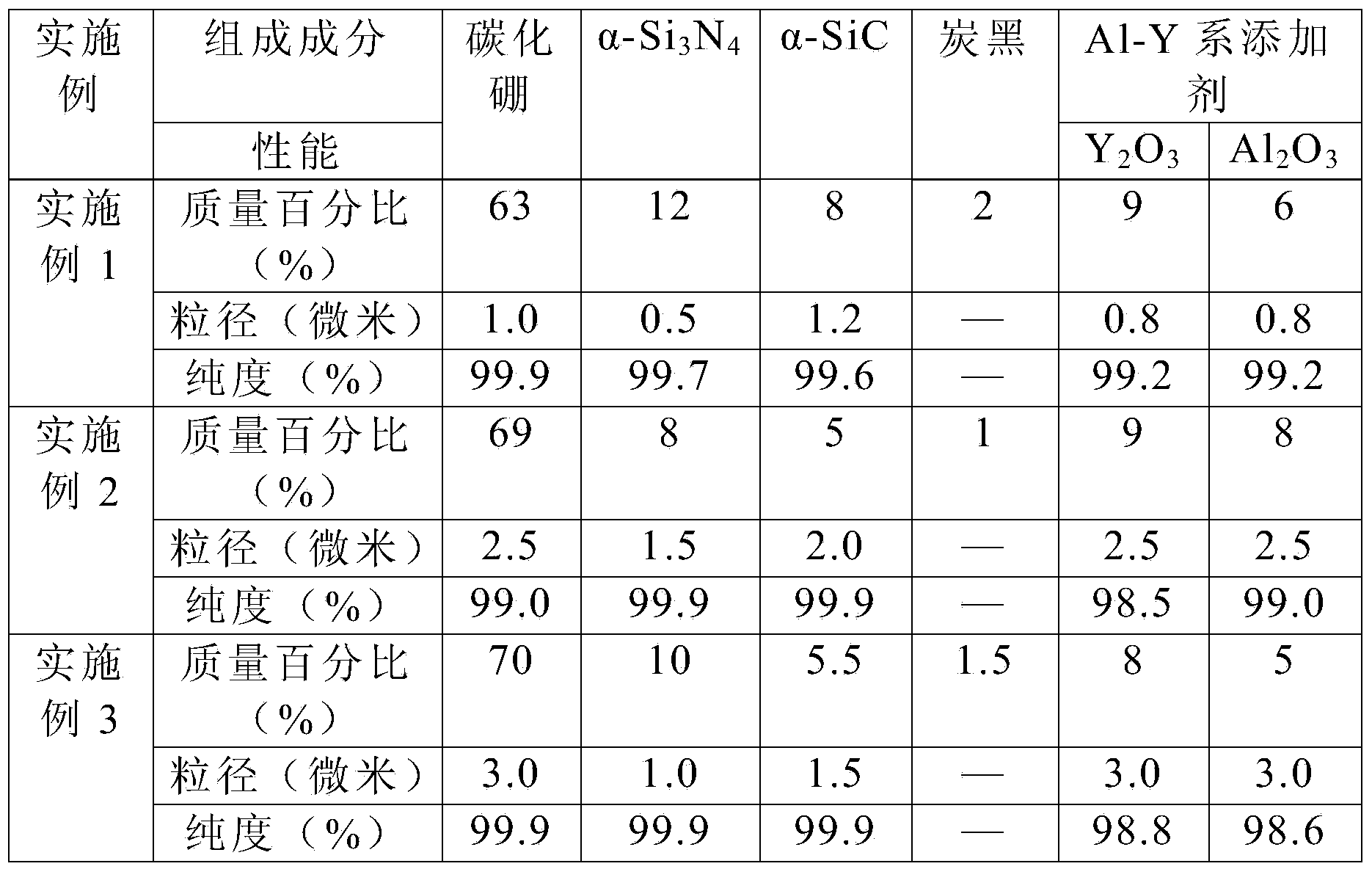

Liquid-phase sintered boron carbide bulletproof material and preparation method thereof

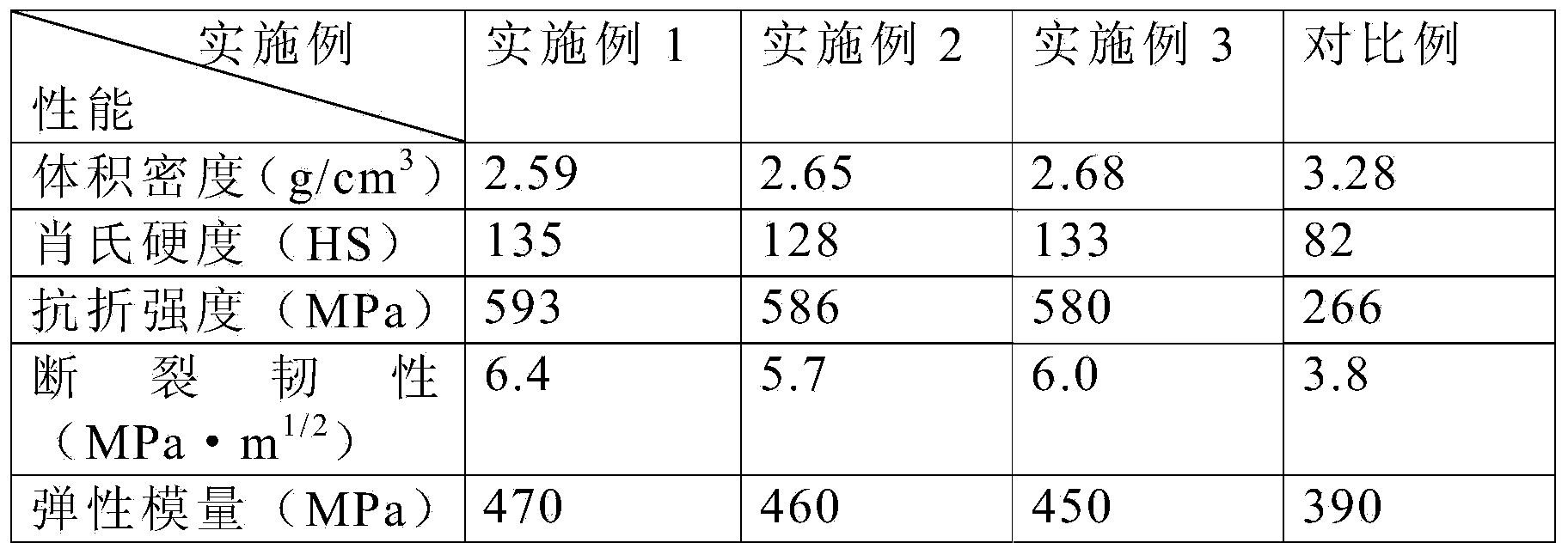

The invention relates to a liquid-phase sintered boron carbide bulletproof material and a preparation method thereof. The bulletproof material comprises the following components by mass: 60 to 98% of boron carbide, 1 to 20% of alpha-Si3N4, 1 to 10% of alpha-SiC, 0 to 3% of carbon black and 0 to 25% of an Al-Y additive. The preparation method comprises the following steps: weighing raw materials, putting the weighed boron carbide, alpha-Si3N4, alpha-SiC and carbon black into a bowl mill and successively carrying out wet milling with deionized water as a medium and screening; then carrying out spray granulation and screening; subjecting obtained slurry to dry-pressing molding so as to prepare a green body; and finally, subjecting a processed biscuit to sintering in the presence of the Al-Y additive under the protection of argon so as to prepare the liquid-phase sintered boron carbide bulletproof material. The bulletproof material provided by the invention has volume density of 2.59 to 2.72 g / cm3 and good hardness, bending strength, breaking tenacity, elasticity modulus, etc., production cost is low, and production efficiency is high.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

Fiber-reinforced metal/ceramic laminar composite material protective board

This invention provides one fiber strengthening metal or ceramics layer compound materials compound protection board in load board technique field, wherein, the protection board has at least one metal layer, fiber layer, ceramics layer structure under high temperature through active welding process, powder bursting process or active metal welding process to connect metal layer, fiber layer and ceramics layer.

Owner:BEIHANG UNIV

Preparation method of continuous fiber-toughened silicon carbide ceramic bullet-proof plate

ActiveCN108253843AHigh hardnessReduce hardnessLamination ancillary operationsLaminationShock resistanceHigh pressure

The invention relates to a preparation method of a bullet-proof plate, particularly to a preparation method of a continuous fiber-toughened silicon carbide ceramic bullet-proof plate. The preparationmethod has the beneficial effects that the continuous fiber-toughened silicon carbide ceramic provided by the invention inherits high hardness and abrasion resistance advantages of a silicon carbide ceramic material, exerts the continuous fiber reinforcing and toughening principle, and overcomes the inherent defects, of pure silicon carbide ceramic, that inherent toughness is poor and external shock load resistance performance is poor, so that the continuous fiber-toughened silicon carbide ceramic has the characteristics like low density, high specific strength, high specific modulus, high hardness and shock resistance, and bullet-proof performance, particularly multi-bullet-proof performance, of the bullet-proof plate can be effectively improved; a continuous fiber-toughened silicon carbide ceramic material is prepared through a polymer high-pressure impregnation pyrolysis technology, the technology is simple, and preparation cost is low; and a setting method provided by the inventionis simple and flexible, and size customization of the bullet-proof plate is facilitated.

Owner:AVIC BASIC TECH RES INST

High performance ballistic composites having improved flexibility and method of making the same

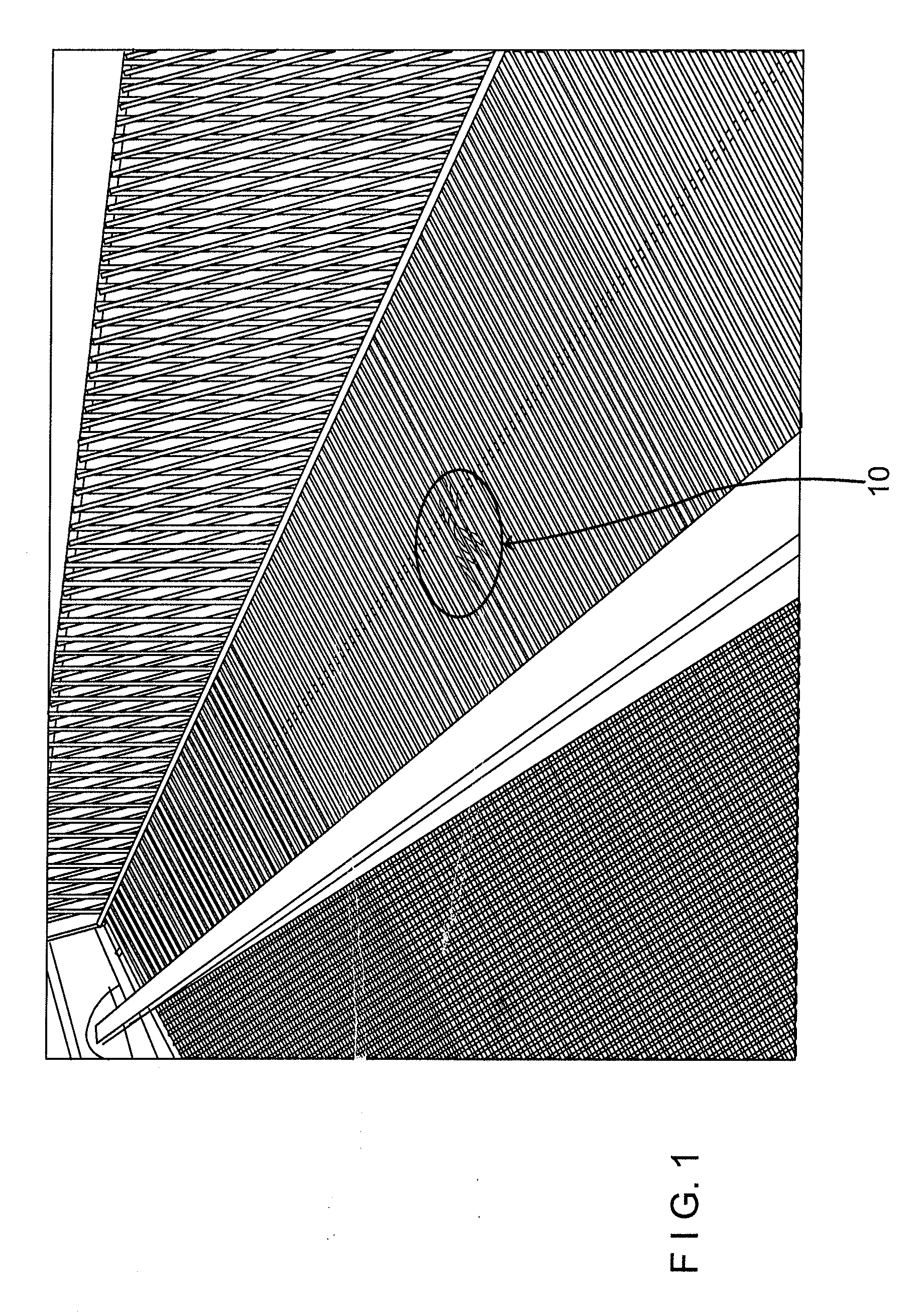

InactiveUS20120196108A1Increase flexibilityImprove comfortArmourProtective equipmentPolymer sciencePliability

Flexible ballistic resistant composite materials are described, having any of a number of important properties, or a combination of properties, including flexibility, comfort, weight, and / or ballistic performance. Representative composite materials comprise a plurality of fibrous layers, such as non-woven fibrous layers, with these fibrous layers comprises fibers (e.g., a network of fibers) having a tenacity of at least about 35 g / d and a tensile modulus of at least about 1200 g / d. Representative fibers include, for example, high tenacity poly(alpha-olefin) fibers. The fibrous layers also comprise a polymeric matrix deposited on the fibers. Advantageously, such composite materials may have an average total areal density per fibrous layer from about 16 g / m2 to about 350 g / m2, and often from about 16 g / m2 to about 300 g / m2, in addition to meeting flexural rigidity and / or stiffness criteria as described herein.

Owner:HONEYWELL INT INC

Flexible spike/ballistic penetration-resistant articles

InactiveUS7340779B2Improve ballistic performanceImprove performanceProtective equipmentProtective fabricsYarnEngineering

Owner:DUPONT SAFETY & CONSTR INC

Light energy consumption bullet-proof explosion-proof wall

InactiveCN107355026AAvoid secondary damageImprove ballistic performanceWallsProtective buildings/sheltersWire gauzeSheet steel

Lightweight energy-consuming bulletproof and explosion-proof wall, including corrugated steel plate, steel wire mesh, bulletproof plate, light-weight crack-resistant concrete and polymer coating. Connected by steel wire mesh connectors of corrugated steel plates, light energy-consuming materials are poured inside the corrugated steel plates, light elastic materials are poured between the corrugated steel plates and the steel mesh, the outer side of the steel mesh is provided with a bulletproof plate, and the outer side of the bulletproof plate is poured with light weight Crack-resistant concrete, the outer side of the lightweight crack-resistant concrete is sprayed with a polymer coating. The beneficial effects of the invention are: good bulletproof effect, strong anti-explosion ability, large deformation ability, high anti-cracking ability, light weight, maximum absorption of blast impact energy, effective prevention of secondary damage caused by explosive fragments, good explosion-proof effect, energy Significantly control explosion disasters and improve defense capabilities.

Owner:SHENYANG JIANZHU UNIVERSITY

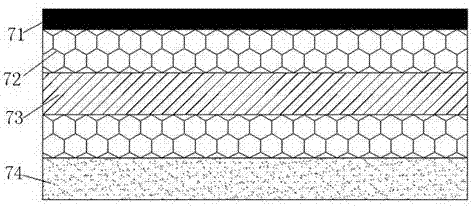

Composite bulletproof armor plate and preparation method thereof

ActiveCN109855473AHigh compressive strengthIncrease elasticitySynthetic resin layered productsLaminationInterference fitCeramic composite

The invention discloses a composite bulletproof armor plate and a preparation method thereof. The composite bulletproof armor plate comprises a protective cover plate, ceramic plates, metal restraining plates, a fiber metal laminated plate and a porous metal sandwich plate; and the ceramic plates and the metal restraining plates are assembled and connected in an interference fit mode, the ceramicplates are supported through the fiber metal laminated plate and the porous metal sandwich plate, and the bullet resistance of a bulletproof armor plate is improved. The preparation technology is simple, the cost is low, compared with a traditional ceramic composite armor plate, the composite bulletproof armor plate is higher in impact resistance at a time and has the multi-time impact resistance,and the composite bulletproof armor plate has the wide application prospects in the bulletproof fields of armed helicopters, armored cars, vessels and the like.

Owner:XI AN JIAOTONG UNIV

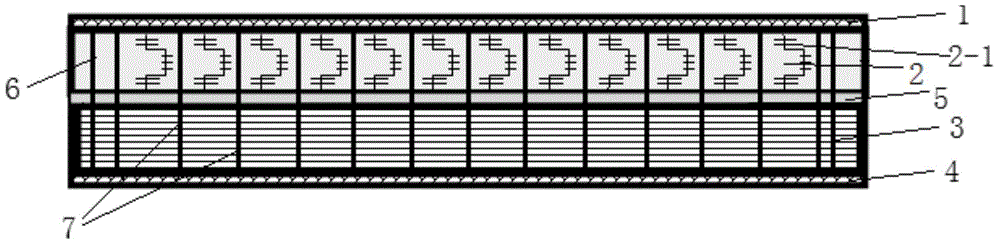

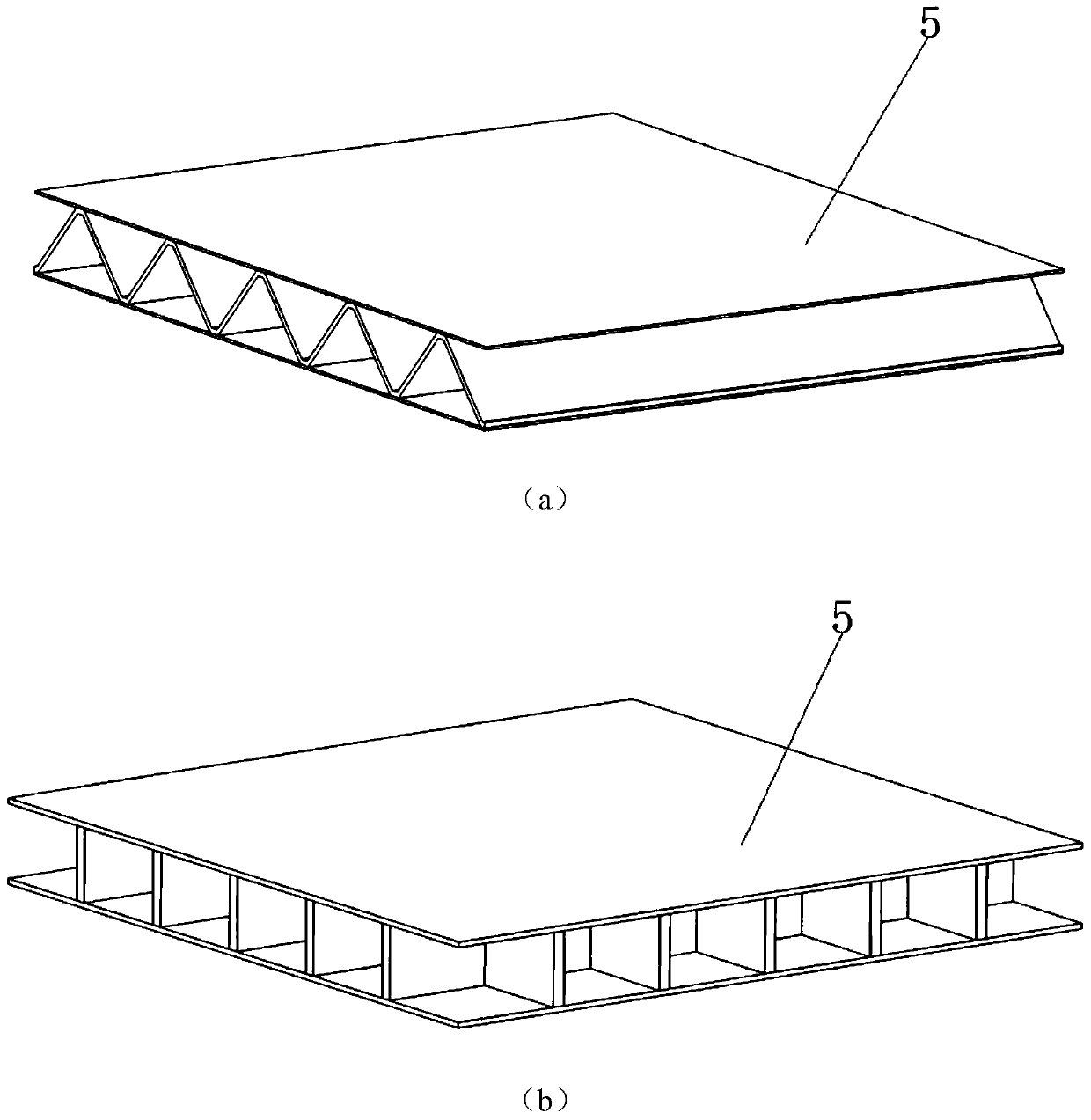

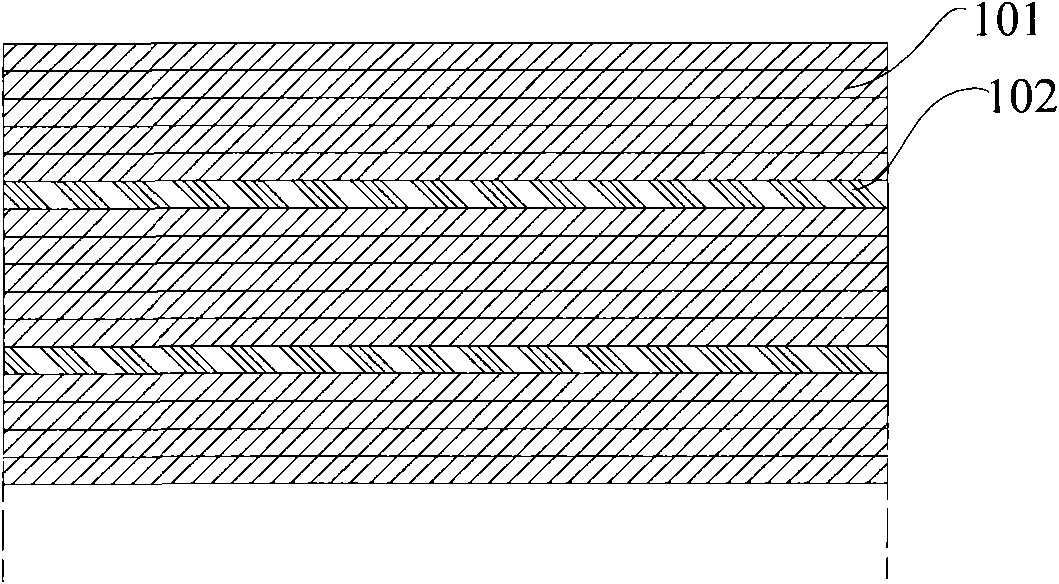

Bulletproof formed part and preparation method thereof

InactiveCN101684990AImprove ballistic performanceAvoid traumaPersonal protection gearFiberUltimate tensile strength

The invention discloses a bulletproof formed part comprising at least two barrier layers and buffer layers between every two barrier layers, wherein the barrier layers and the buffer layers comprise aplurality of superposed weftless fabrics; the weftless fabrics comprises fibers of which the strength is at least 15 cN / dtex and the modulus is at least 390 cN / dtex; in each buffer layer, the anglesformed by the fibers in the adjacent weftless fabrics are 40-60 DEG; and in each barrier layer, the angles formed by the fibers in the adjacent weftless fabrics are 85-95 DEG. The invention also provides a preparation method of the bulletproof formed part. The barrier layers can effectively reduce the bullet speed due to the high strength, and the buffer layers are beneficial to the absorption andthe diffusion of the kinetic energy of the bullets due to the same property in all directions; and therefore, under the alternate actions of the barrier layers and the buffer layers, the bulletproofformed part has favorable bulletproof function and can protect the user from being hurt by bullets when used as a bulletproof helmet or bulletproof vest.

Owner:宁波荣溢化纤科技有限公司

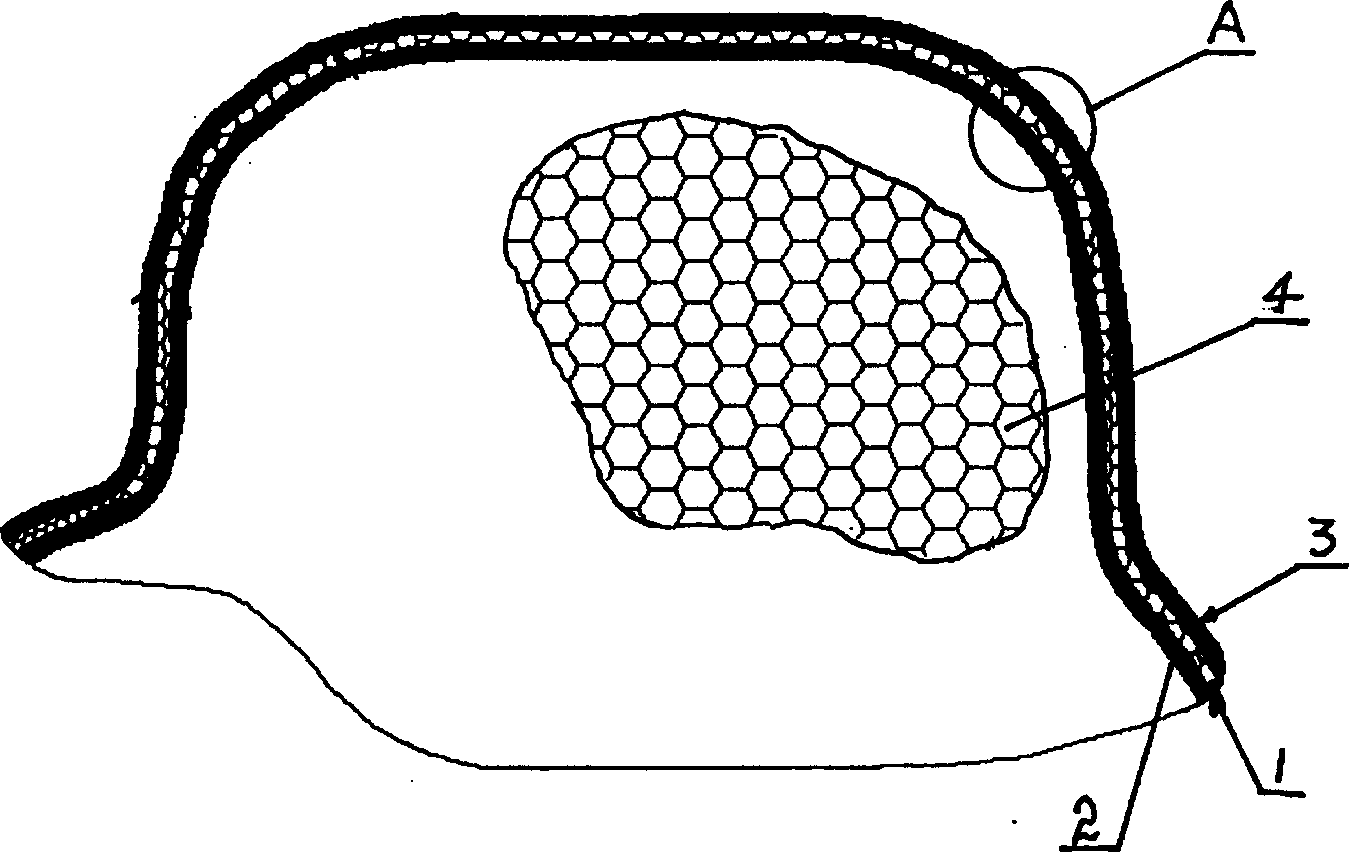

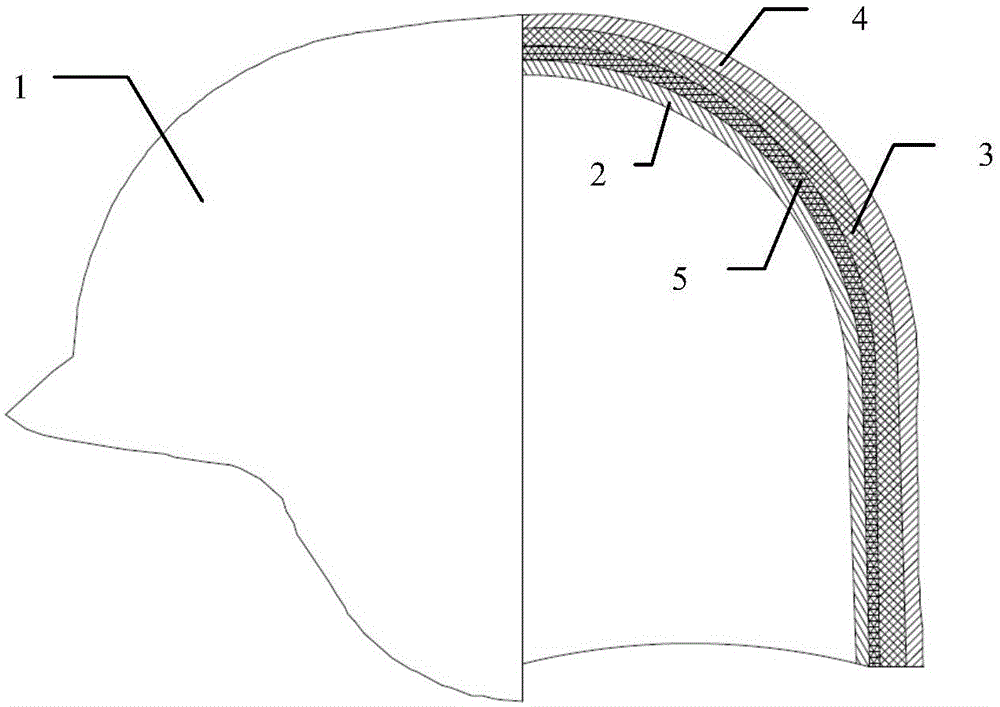

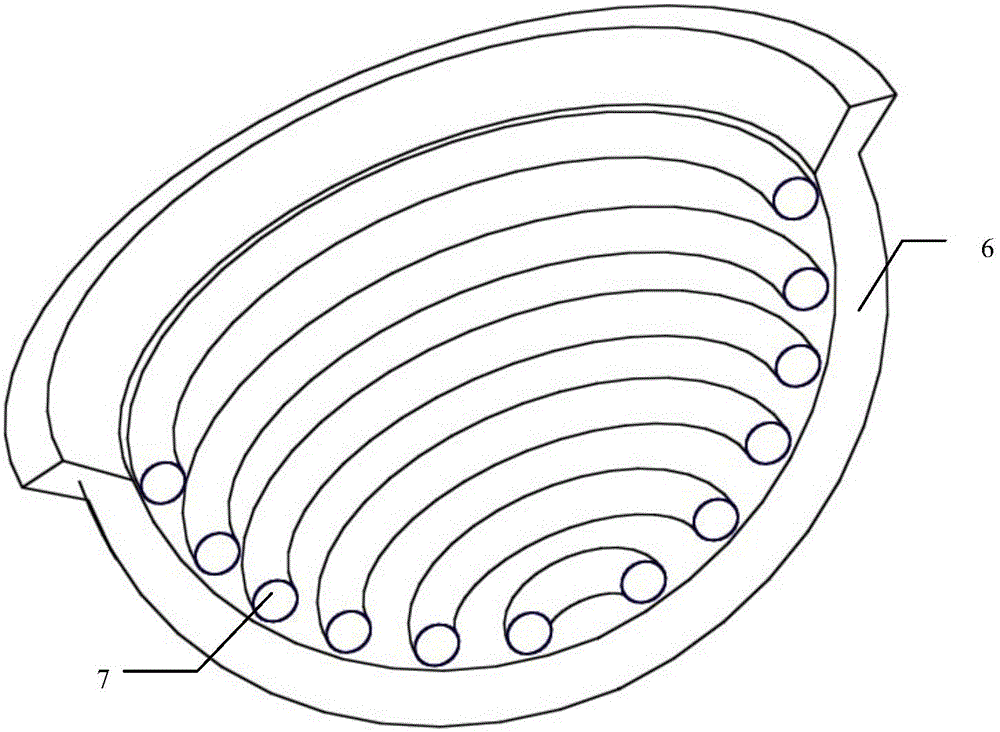

Ceramic base lightweight bulletproof helmet and the production method

The invention discloses a ceramic light-quality bulletproof helmet and preparing method, which is composed of ceramic base layer in the middle of helmet and PE layer on two sides through hot-pressed attaching, wherein the ceramic base layer is split by multiple prismoids, multiple pyramids and multiple bosses. The preparing method comprises the following steps: designing PE layer on the inner side of outer and inner surface of inner mould; splitting a layer of ceramic multiple prismoids, multiple pyramids and multiple bosses on the inner side of PE layer; pressing inner and outer mould through heating.

Owner:马斌 +3

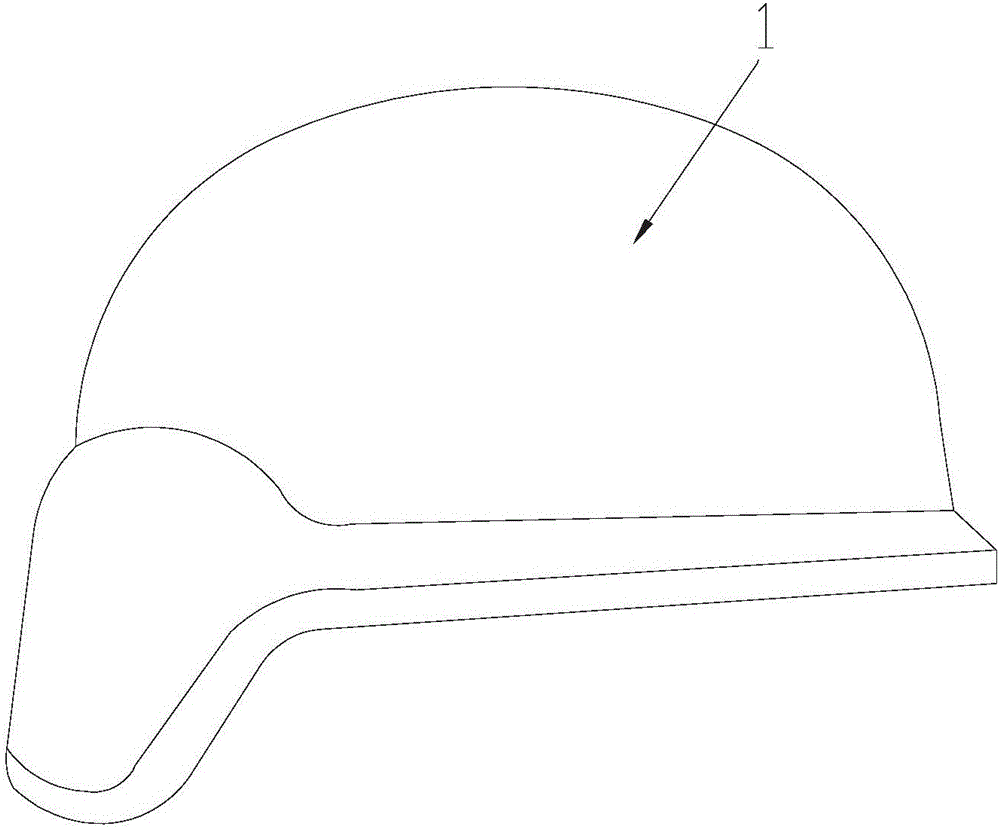

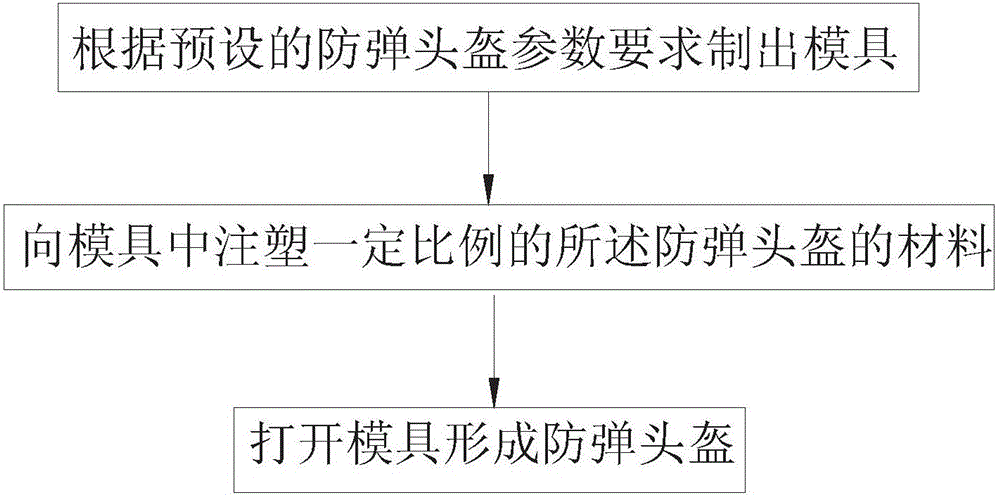

Bullet proof helmet and preparation method thereof

InactiveCN105924957AImprove ballistic performanceIncrease resistancePersonal protection gearDomestic articlesGlass fiberPolymer science

The invention discloses a bullet proof helmet and a preparation method thereof. The bullet proof helmet comprises a thermoplastic high polymer material and a fiber-reinforced composite material, the thermoplastic high polymer material comprises one or more of nylon, makrolon and polypropylene material, the fiber-reinforced composite material is made of one or more of carbon fiber, aramid fiber, fiberglass and high performance fiber, and the bullet proof helmet is integrally formed through an injection molding process; due to integral injection molding, the production efficiency is improved, and the bullet proof helmet has a better bulletproof capability, and can effectively prevent fractures caused by local formation, and the bullet withstanding performance is improved.

Owner:SUZHOU GAOJIA PROTECTION TECH CO LTD

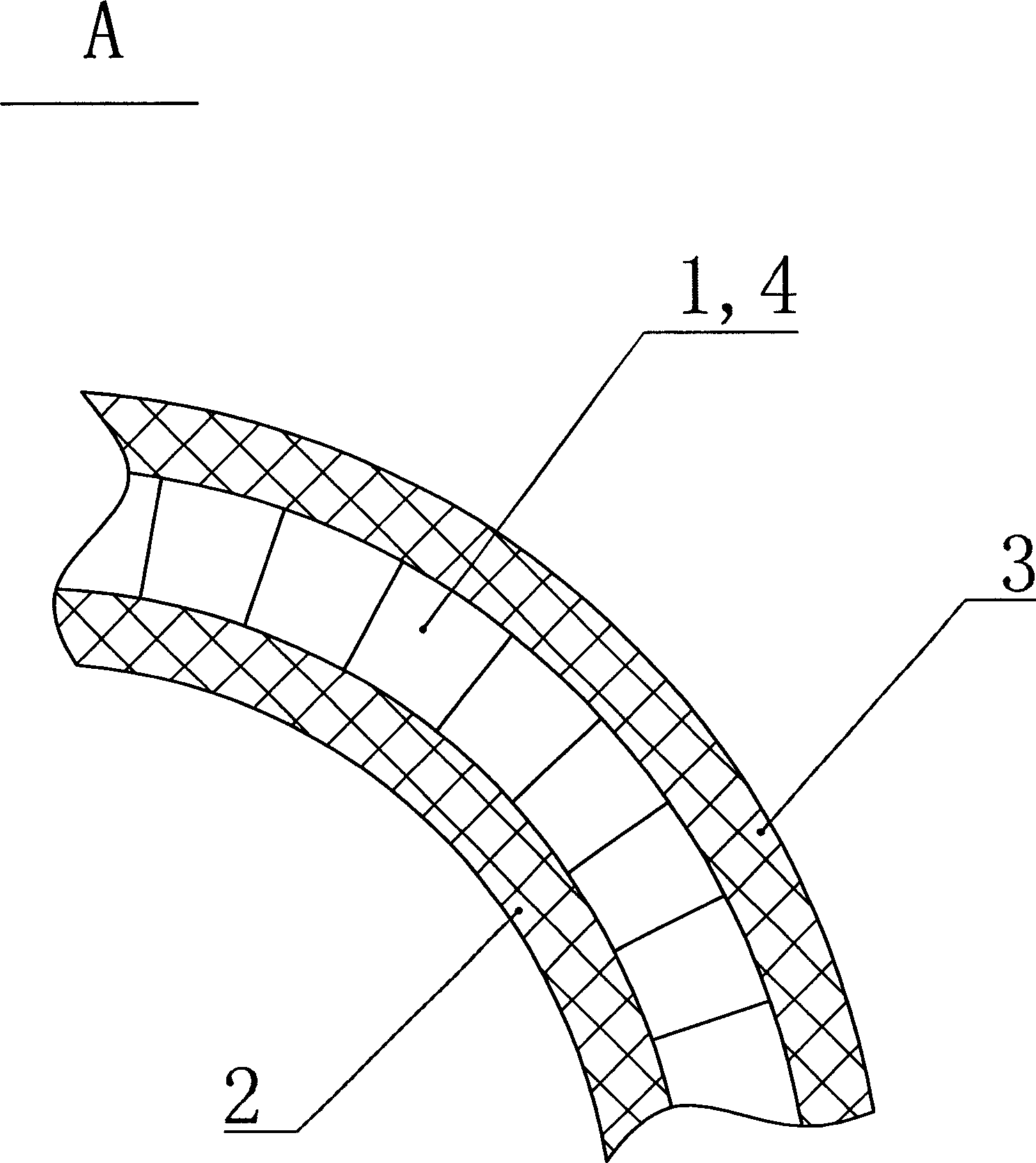

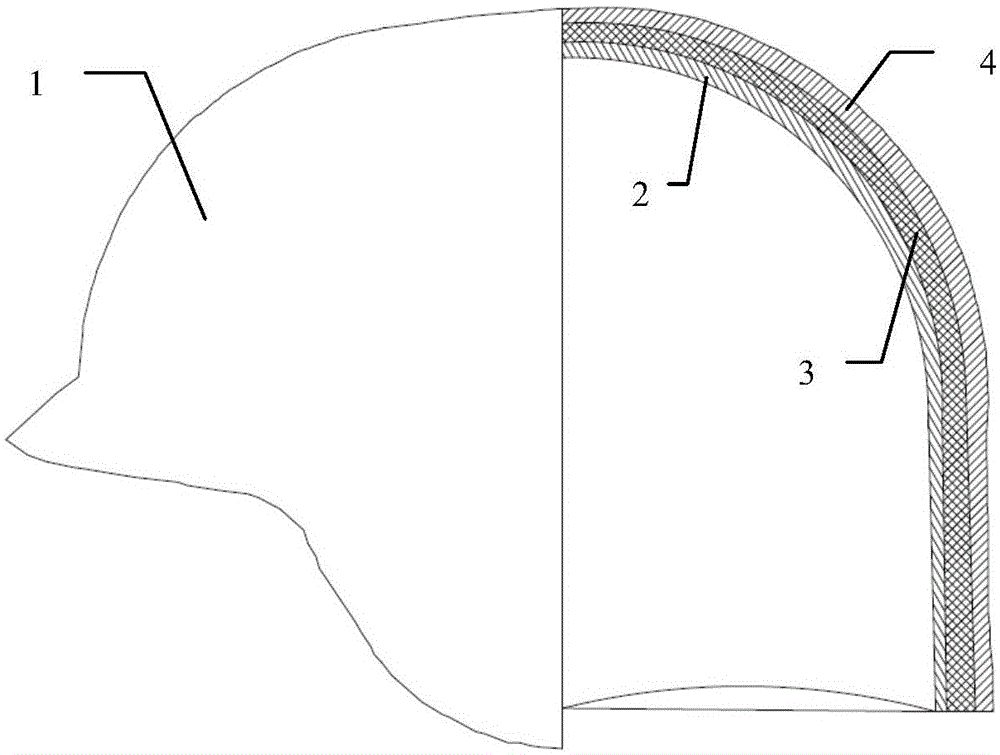

Aramid fiber composite bulletproof helmet of special structural design and forming method of helmet

ActiveCN105066785AGuaranteed rigidityReduced dynamic deformation heightLayered productsPersonal protection gearPolyurethane adhesiveEngineering

The invention provides an aramid fiber composite bulletproof helmet of a special structural design and a forming method of the helmet. The aramid fiber composite bulletproof helmet comprises a shell, a paint layer and a suspension piece, and is characterized in that the shell comprises an inner layer and an outer layer, the inner layer is composed of a plurality of layers of high-rubber-content fabric presoak materials, the outer layer is composed of a plurality of layers of low-rubber-content fabric presoak materials, and a polyurethane adhesive reinforcing layer is arranged between the inner layer and the outer layer of the shell. According to the bulletproof helmet manufactured according to the structural design and the forming process, the high strength of aramid fiber and mechanical properties of composite materials are brought into full play on the aspect of the bulletproof mechanism, the height of a bump generated on the inner side of the helmet after a bullet is shot is effectively reduced, and the injury to the head of a user from the protrusion on the inner side of the helmet is reduced. The number of layers through which the bullet penetrates is effectively reduced, and the safe margin of the helmet is improved. Due to the fact that more low-rubber-content presoak materials are adopted, the overall weight of the helmet is reduced by more than 50 g.

Owner:BEIJING PT PROTECTION TECH

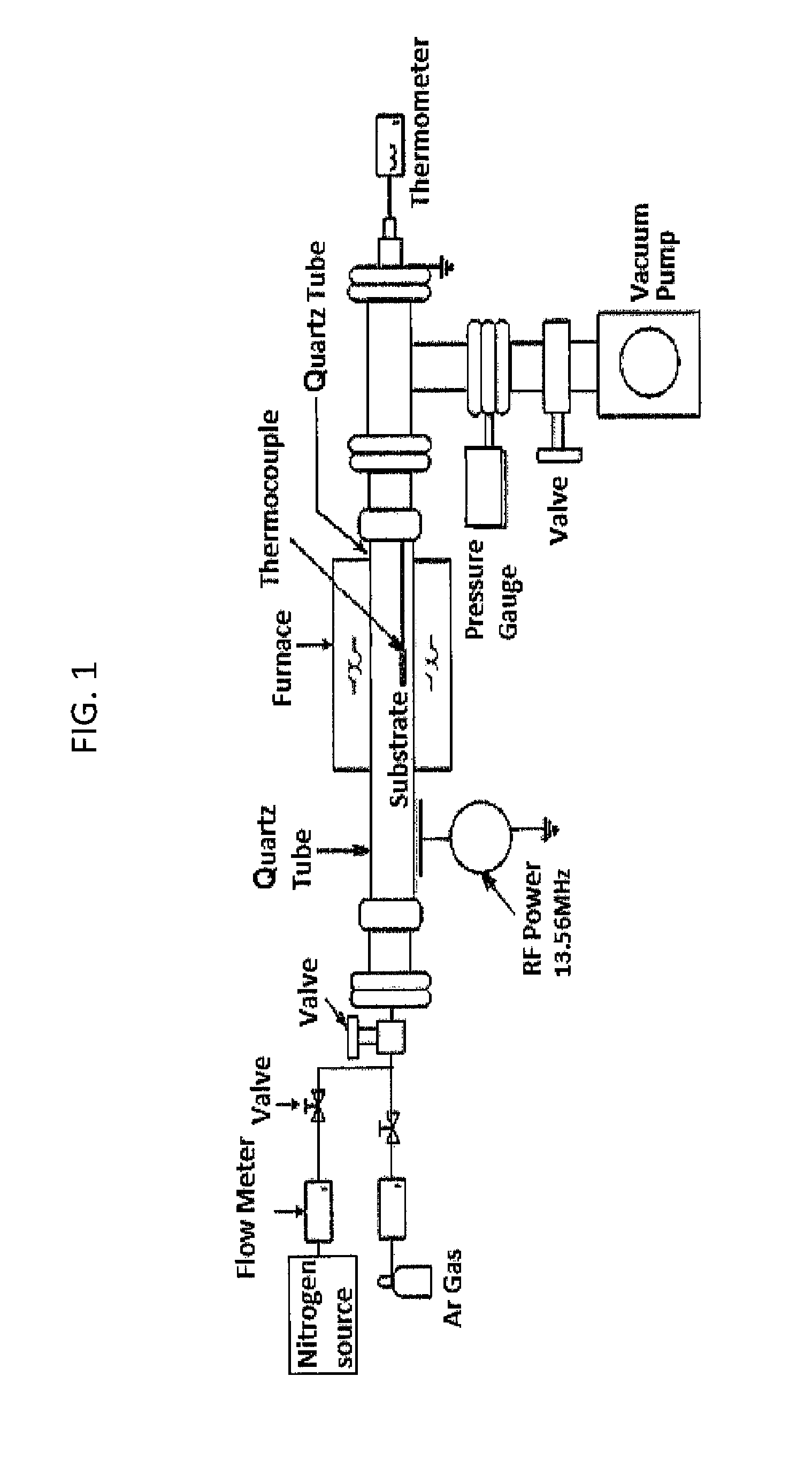

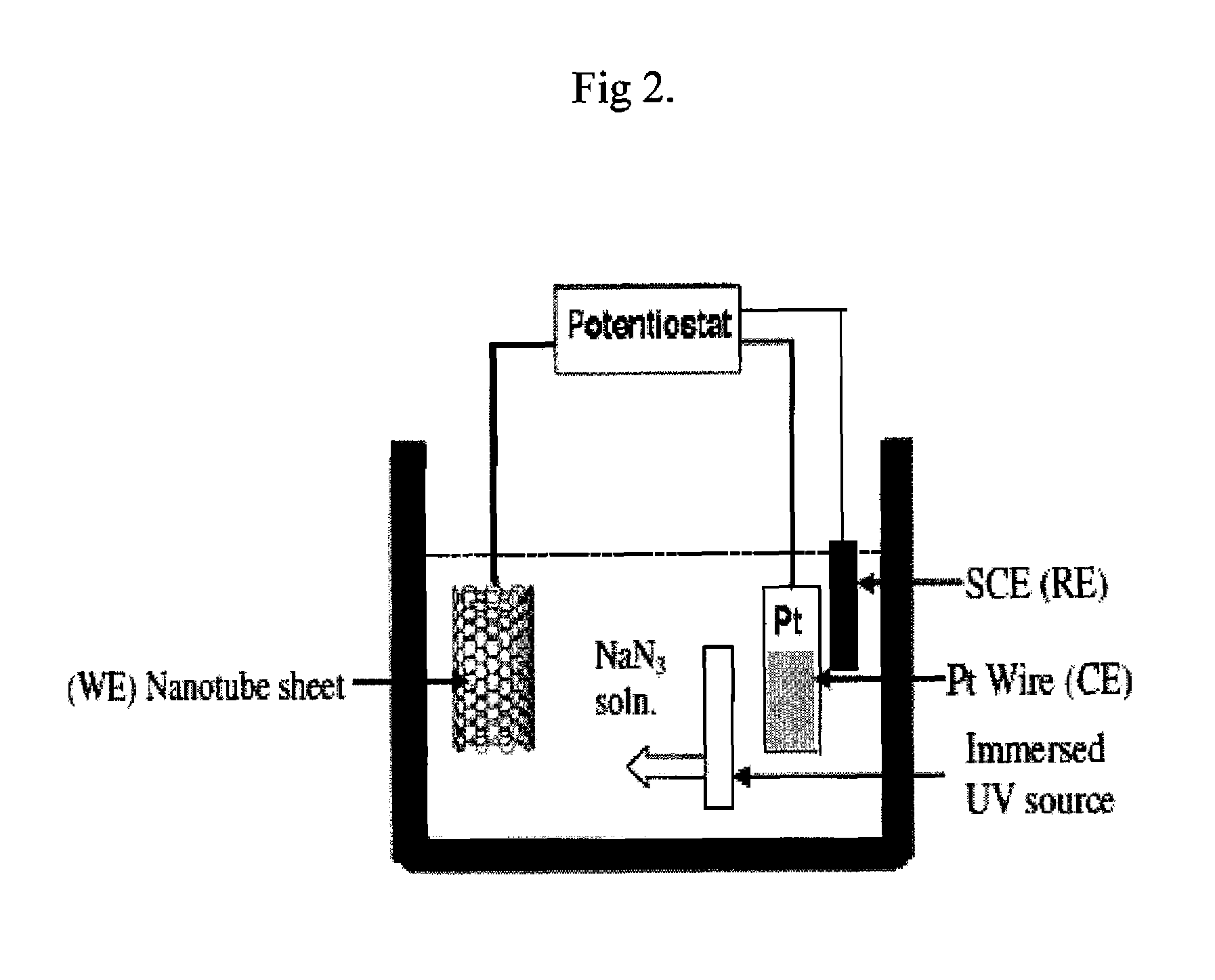

Nitriding of carbon nanotubes

ActiveUS8317978B1Improve ballistic performanceThe implementation process is simpleCellulosic pulp after-treatmentNon-fibrous pulp additionThermal chemical vapor depositionPolystyrene

A method of fabricating a non-brittle, carbon nanopaper from single wall, multiwall, and combination thereof, from carbon nanotubes, using a vacuum deposition, high temperature annealing, and polystyrene polymer rinse process; which nanopaper can be nitrided by either a plasma-enhanced chemical vapor deposition (PECVD) process, or an by an electrochemical method, to obtain a useful chemically functionalized substrate, a substrate containing metastable N4, N8, and longer chain polymeric nitrogen clusters. Such nitrided carbon nanopaper can be used to enhance the ballistic performance of gun propellants, while reducing gun barrel wear and erosion thereof.

Owner:MANNING THELMA G +1

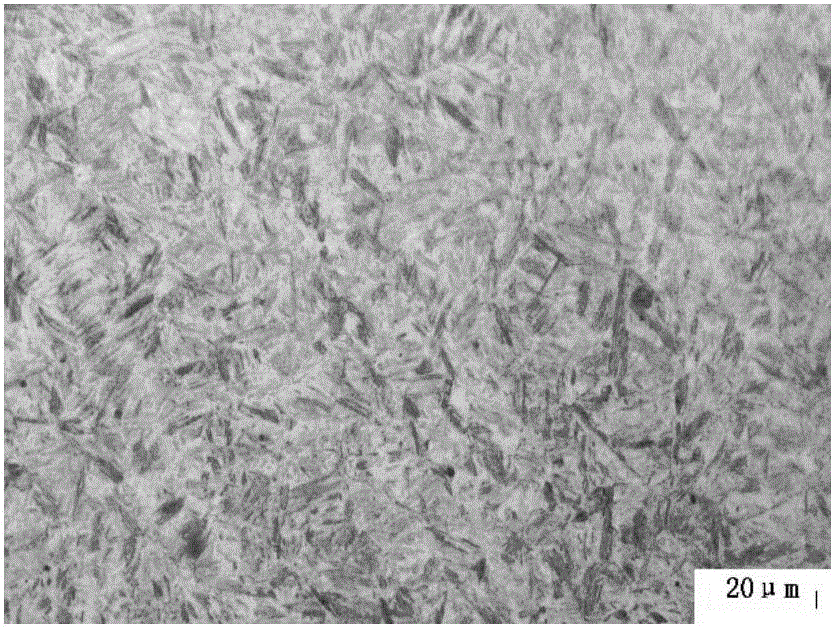

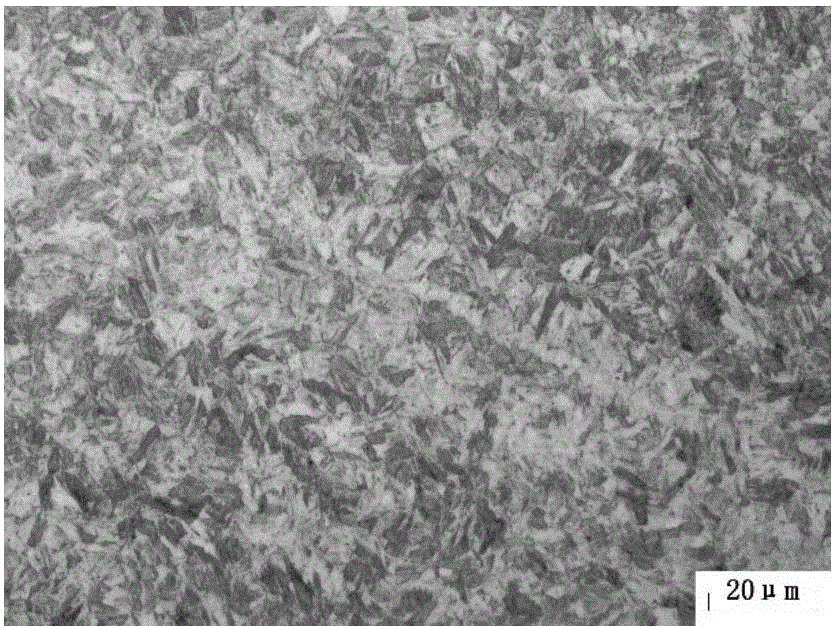

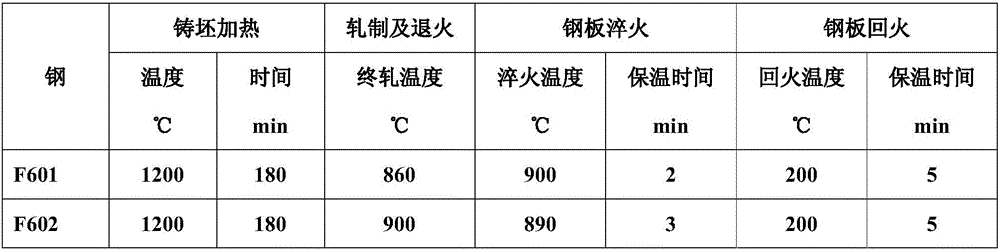

Silicon vanadium steel plate with promoted bulletproof performance and manufacturing method

ActiveCN106319347APlay a role in precipitation strengtheningImprove ballistic performanceChemical elementSilicon

The invention relates to a silicon vanadium steel plate with promoted bulletproof performance and a manufacturing method. The bulletproof performance means the capacity of the silicon vanadium steel plate to resist against bullet shooting or glass breaking. The silicon vanadium steel plate can meet the practical requirements of stability and light weight. The silicon vanadium steel plate comprises the following chemical elements by weight percent: 0.28-0.43% of C, 0.3-2.0% of Si, 0.3-1.0% of Mn, 0.3-1.5% of Cr, 0.3-3.0% of Ni, 0.1-0.6% of Mo, 0.03-0.12% of V, not more than or equal to 0.03% of inevitable impurities and the balance of Fe.

Owner:国研(淮安)新材科技有限公司 +1

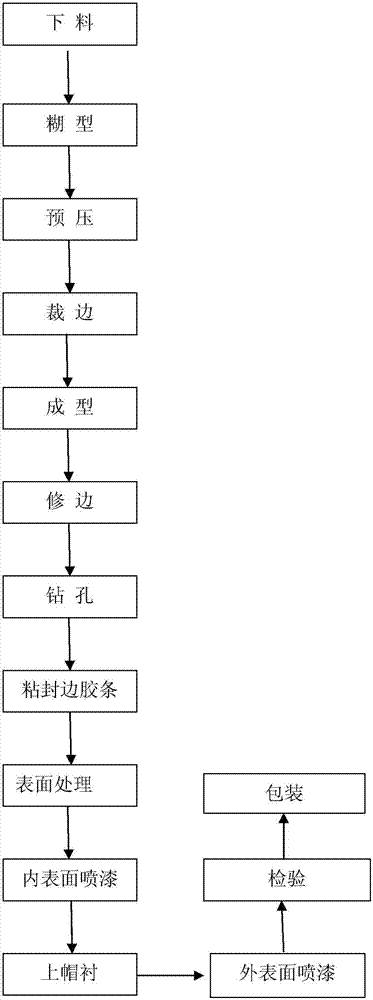

Preparation method of bulletproof helmet

ActiveCN107144173ATight overlapSymmetrical appearanceProtective equipmentLaminationAramidNanotechnology

The invention discloses a preparation method of a bulletproof helmet. The preparation method mainly comprises steps as follows: cutting, pasting forming, prepressing, edge cutting, forming, edge trimming, drilling, bonding of edge sealing rubber strips, surface treatment, paint spraying of the inner surface, bonding of a cap lining, paint spraying of the outer surface, inspecting and packaging. The method has the advantages that a shell of the bulletproof helmet is made of aramid II / III, so that bulletproof performance of the helmet is improved, and mass of the helmet is reduced.

Owner:SHENYANG JIHUA 3547 SPECIAL TYPE ARMAMENT

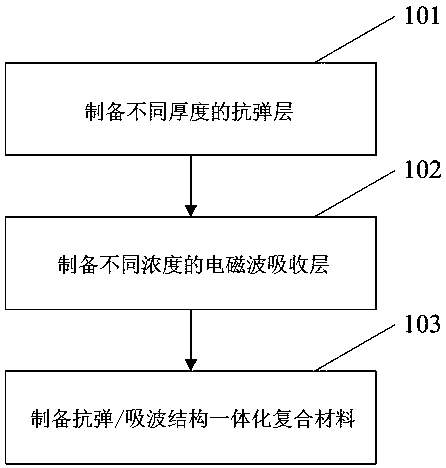

An anti-bullet/wave-absorbing structure integrated composite material and a preparing method thereof

InactiveCN108705819AImprove ballistic performanceIncrease elasticityProtective equipmentLaminationFiberMechanical property

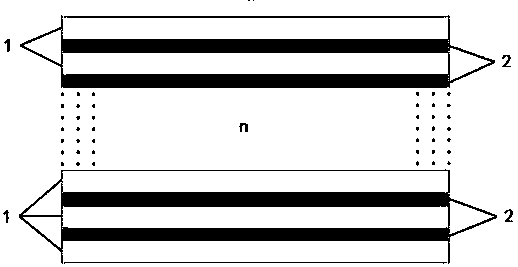

The invention provides an anti-bullet / wave-absorbing structure integrated composite material and a preparing method thereof. The anti-bullet / wave-absorbing structure integrated composite material is formed by combining anti-bullet layers with different thickness and electromagnetic wave-absorbing layers with different concentration to form a multilayer composite structure, and is prepared by the integrated composite heat pressure, and the concentration of the electromagnetic wave-absorbing layers is gradually increased from top to bottom. The preparing method includes the following steps: different numbers of sheets of the fiber cloth coated with resin are orthographically laid layer-by-layer, and the anti-bullet layers are prepared; an absorbent in different ratio and the resin are uniformly dispersed, thereby the electromagnetic wave-absorbing layers with different concentration are prepared; the anti-bullet layers are alternatively combined with the electromagnetic wave-absorbing layers with different concentration, and the anti-bullet / wave-absorbing structure integrated composite material are prepared. The anti-bullet / wave-absorbing structure integrated composite material has the advantages of lightweight, high anti-bullet property, wideband electromagnetic wave-absorbing, adjustable structure thickness, excellent mechanical property, and flame retardation, the preparing method is simple in technology, is convenient in operation, and is economic and environmental-friendly.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

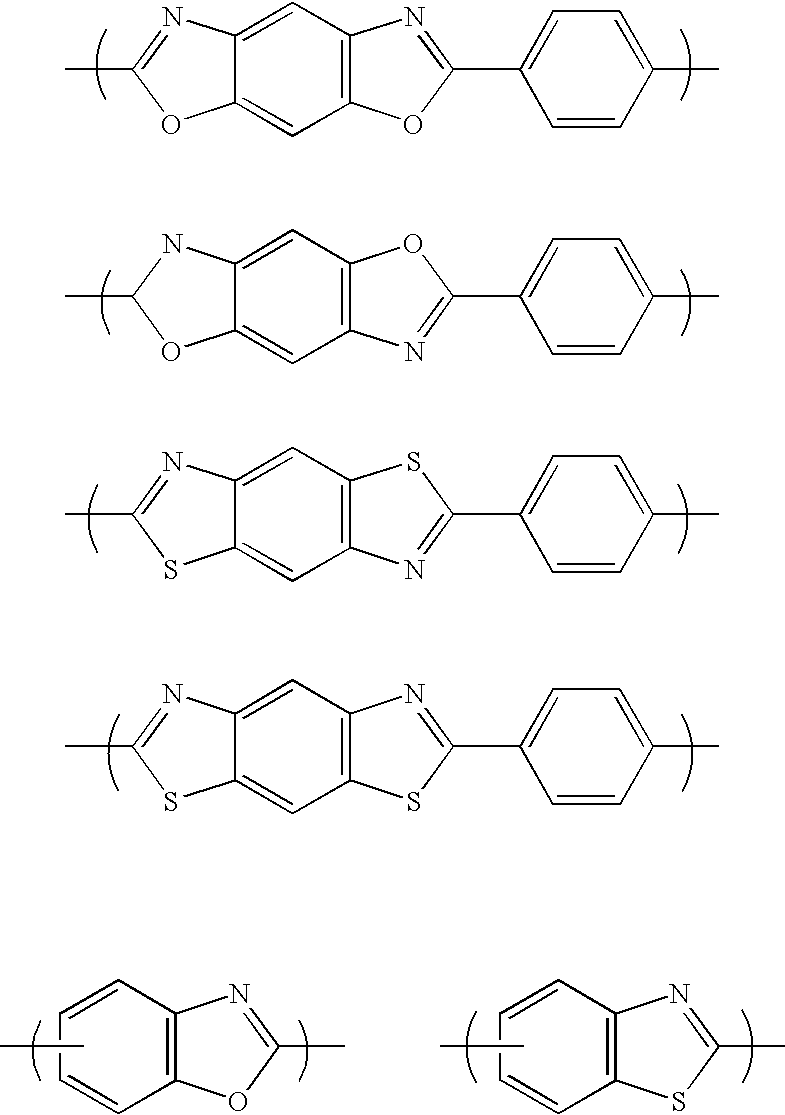

Ballistic Fabric

InactiveUS20080248708A1Improved ballistic propertyHigh strengthShutters/ movable grillesProtective fabricsYarnAramides

Briefly the invention relates to a flexible fabric for use as for example in a roll-up shutter with improved ballistic properties. More specifically, the present invention is directed to a ballistic fabric that is formed from a unique cabled yarn and allows less deformation on impact. The unique cabled yarn may be a metal reinforced aramid yarn for giving the fabric additional strength.

Owner:ALBANY INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com