Light energy consumption bullet-proof explosion-proof wall

An explosion-proof wall, lightweight technology, applied in the direction of walls, building components, building types, etc., can solve the problems of explosion-proof wall rupture and secondary damage, and achieve the effect of preventing secondary damage, large deformation capacity, and high crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

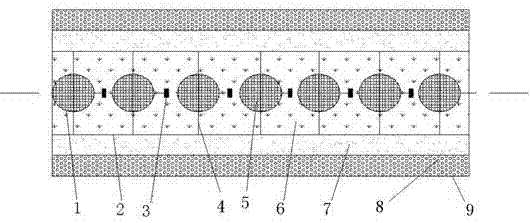

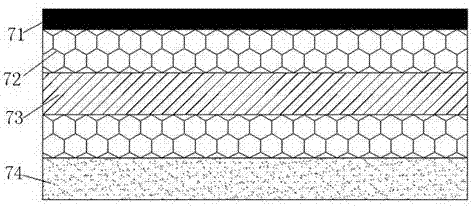

[0021] Such as figure 1 with figure 2 As shown, a lightweight energy-consuming bulletproof explosion-proof wall includes a corrugated steel plate (1), a steel wire mesh (2), a corrugated steel plate connector (3), a steel wire mesh connector (4), and a lightweight energy-consuming material (5) , Lightweight elastic material (6), bulletproof board (7), lightweight crack-resistant concrete (8) and polymer coating (9).

[0022] The centerline of the light-weight energy-consuming bulletproof explosion-proof wall is preferably arranged symmetrically; on both sides of the centerline, corrugated steel plates (1) are set respectively, and the troughs of the corrugated steel plates (1) are opposite to the troughs, and the troughs on both sides are made of corrugated steel plates on the center line The connecting pieces (3) are connected, and the corrugated steel plate connectors (3) are preferentially distributed evenly, and arranged horizontally and vertically; the wave crests of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com