Bulletproof formed part and preparation method thereof

A molding, angled technology, used in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of low elongation of composite materials, unfavorable energy absorption and diffusion, and poor performance of buffering bullet kinetic energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

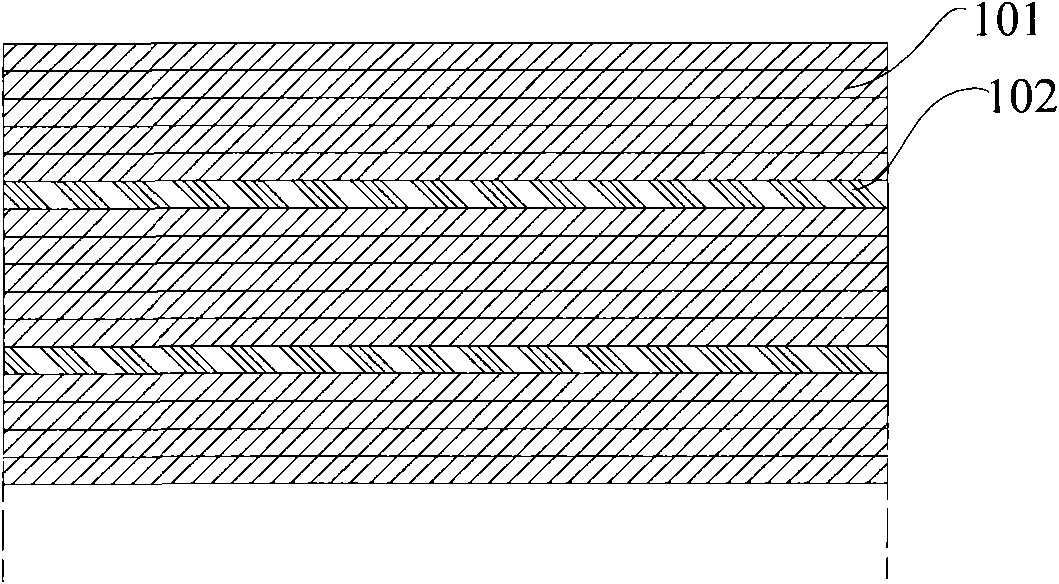

[0026] Get the ultra-high molecular weight polyethylene fiber of the Dyneema SK75 type (intensity is 35cN / dtex, modulus is 1100cN / dtex) that the fineness that Holland DSM company produces is 400 deniers, and KRATONG-1650 is dissolved in No. 120 according to the weight ratio of 22%. Solvent naphtha (2,3-butanedione) is used as adhesive, and above-mentioned fiber and adhesive are compounded according to the method in the patent US4916000 and make surface density be 38g / m 2 unidirectional non-weft fabric. The weight ratio of fiber to adhesive in the laid fabric was 88:12.

[0027] Take 4 layers of non-weft cloth and arrange them according to the fibers as [0° / 90°] 2 In order to protect the product from being damaged by friction with the outside world, the two sides of the four-layer cloth are compounded with LDPE protective film. The pre-press molding temperature is 100°C and the molding pressure is 2.5MPa. , constant temperature and pressure for 15 minutes to obtain a barrier ...

Embodiment 2

[0032] Get the Dyneema SK75 type (intensity is 35cN / dtex, modulus is 1100cN / dtex) ultra-high molecular weight polyethylene fiber that the fineness that Holland DSM company produces is 400 deniers, KRATON D-1107 is dissolved in No. 120 according to the weight ratio of 24%. Solvent naphtha is made tackiness agent, and above-mentioned fiber and tackiness agent are compounded according to the method identical with embodiment 1 and make area density be 40g / m 2 unidirectional non-weft fabric. The weight ratio of fiber to adhesive in the laid fabric was 86:14.

[0033] Take 4 layers of non-weft cloth and arrange them according to the fibers as [0° / 90°] 2 In order to protect the product from being damaged by friction with the outside world, the two sides of the four-layer cloth are compounded with LDPE protective film. The pre-press molding temperature is 100°C and the molding pressure is 2.5MPa. , constant temperature and pressure for 15 minutes to obtain a barrier layer.

[0034]...

Embodiment 3

[0038] Get the Dyneema SK75 type (intensity is 35cN / dtex, modulus is 1100cN / dtex) ultra-high molecular weight polyethylene fiber that the fineness that Holland DSM company produces is 800 deniers, KRATON G-1650 is dissolved in No. 120 solvent according to weight ratio 22% Oil is used as tackiness agent, and above-mentioned fiber and tackiness agent are compounded according to the method identical with embodiment 1 and make area density be 79g / m 2 unidirectional non-weft fabric. The weight ratio of fiber to adhesive in the laid fabric was 88:12.

[0039] Take 4 layers of non-weft cloth and arrange them according to the fibers as [0° / 90°] 2 In order to protect the product from being damaged by friction with the outside world, the two sides of the four-layer cloth are compounded with LDPE protective film. The pre-press molding temperature is 100°C and the molding pressure is 2.5MPa. , constant temperature and pressure for 15 minutes to obtain a barrier layer.

[0040] Then tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com