An anti-bullet/wave-absorbing structure integrated composite material and a preparing method thereof

A composite material and wave structure technology, used in chemical instruments and methods, protective equipment, other household appliances, etc., can solve the problem of less absorbing materials, and achieve adjustable structural thickness, high elastic resistance, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

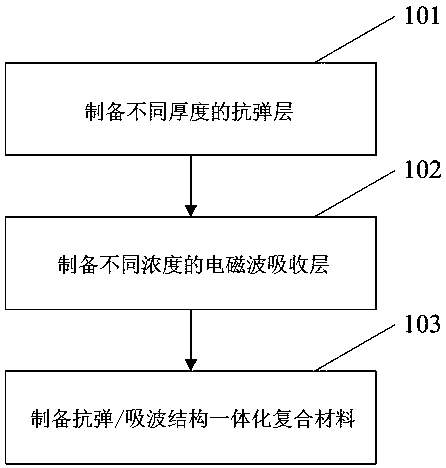

[0039] Such as figure 2 as shown, figure 2 A method for preparing a bullet-resistant / wave-absorbing structurally integrated composite material, comprising the following steps

[0040] In step 101, a certain proportion of resin is evenly coated on the surface of the fiber cloth, and fiber cloth coated with different numbers of resins is laid orthogonally layer by layer to prepare a ballistic layer; the mass ratio of the resin to the fiber cloth = (10~30): (90~70).

[0041] Step 102, uniformly disperse absorbents and resins in different proportions, and evenly coat the surface of high-strength chemical fiber fabrics to prepare electromagnetic wave absorption layers with different concentrations; the mass ratio of absorbents to resins = (20-90): (80~10). The coating method is one or more of dip coating, scraping coating and spray coating.

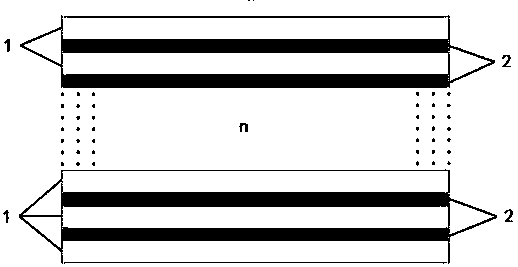

[0042] Step 103, according to the requirements of electromagnetic wave stealth in different frequency bands and different levels of bal...

Embodiment 1

[0045] (1) Evenly dip-coat epoxy resin with a mass ratio of 10:90 on the surface of PE non-weft cloth, and lay 8 sheets of PE non-weft cloth dipped in epoxy resin orthogonally layer by layer to prepare the ballistic layer;

[0046] (2) Evenly disperse flake ferrite with a particle size of 10 μm and epoxy resin with a mass ratio of 20:80, 30:70, 40:60, 50:50, and 80:20, and evenly scrape and coat the surface of the polyester fiber fabric , preparing electromagnetic wave absorbing layers with concentrations of 20%, 30%, 40%, 50%, and 80% respectively;

[0047] (3) Alternately combine the anti-ballistic layer described in step (1) with the electromagnetic wave absorbing layers of different concentrations described in step (2), the anti-ballistic layer is 6 layers, the electromagnetic wave absorbing layer is 5 layers, and the concentration of the electromagnetic wave absorbing layer is 20% from top to bottom , 30%, 40%, 50%, and 80%, through entering the mold, pressurizing, heatin...

Embodiment 2

[0049] (1) Evenly scrape epoxy resin with a mass ratio of 30:70 on the surface of aramid fiber cloth, and lay the 6 sheets of aramid fiber cloth after scraping epoxy resin in an orthogonal manner layer by layer to prepare a ballistic layer;

[0050] (2) Evenly disperse the spherical carbonyl iron and phenolic resin with a particle size of 10 μm in a mass ratio of 20:80, 30:70, 40:60, 50:50, 60:40, 70:30, and 90:10, and spray evenly on the On the surface of the acrylic fiber fabric, the preparation concentration is respectively 20%, 30%, 40%, 50%, 60%, 70%, and 90% electromagnetic wave absorbing layer;

[0051] (3) Alternately combine the anti-ballistic layer described in step (1) with the electromagnetic wave absorbing layers of different concentrations described in step (2), the anti-ballistic layer is 8 layers, the electromagnetic wave absorbing layer is 7 layers, and the concentration of the electromagnetic wave absorbing layer is 20% from top to bottom , 30%, 40%, 50%, 60%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com