Aramid fiber composite bulletproof helmet of special structural design and forming method of helmet

A special structure, bulletproof helmet technology, applied in protective equipment, offensive equipment, layered products, etc., can solve the problems of single bulletproof core material, poor high temperature resistance, high thickness of the helmet shell, etc., and achieve overall weight reduction and high mechanical strength , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

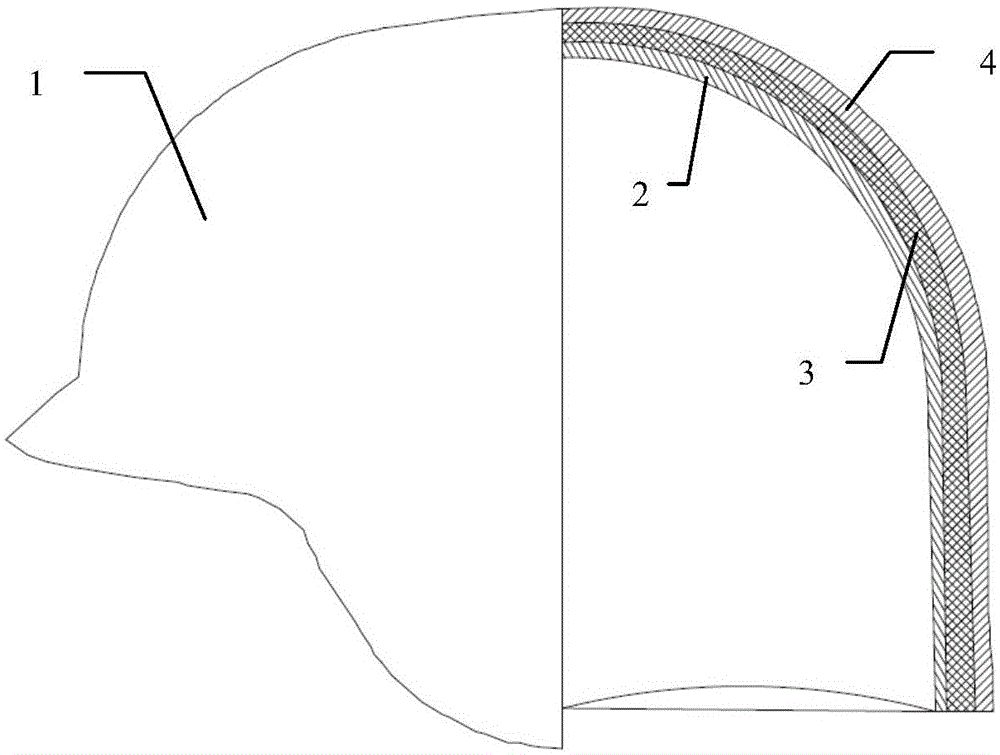

[0040] refer to figure 1 , preferred embodiment 1 of the present invention provides a kind of aramid composite ballistic helmet of special structural design, comprises housing 1, spray paint layer 4 and hanger, is characterized in that, housing 1 comprises inner layer 2 and outer layer 3, inner layer 2 is composed of 2 layers of high rubber content fiber fabric prepreg, and the outer layer 3 is composed of 14 layers of low rubber content fiber fabric prepreg.

[0041] A layer of flame-retardant fiber fabric can also be attached to the outer side of the shell outer layer 3 .

[0042] The fiber fabric prepreg with high glue content is an aramid non-woven fabric or aramid woven fabric or carbon fiber fabric or S-grade glass fiber fabric prepreg with a glue content of 25% by weight.

[0043] The fiber fabric prepreg with low glue content is an aramid non-woven fabric or aramid woven fabric prepreg with a glue content of 13% by weight.

[0044] Wherein the adhesive for the prepre...

Embodiment 2

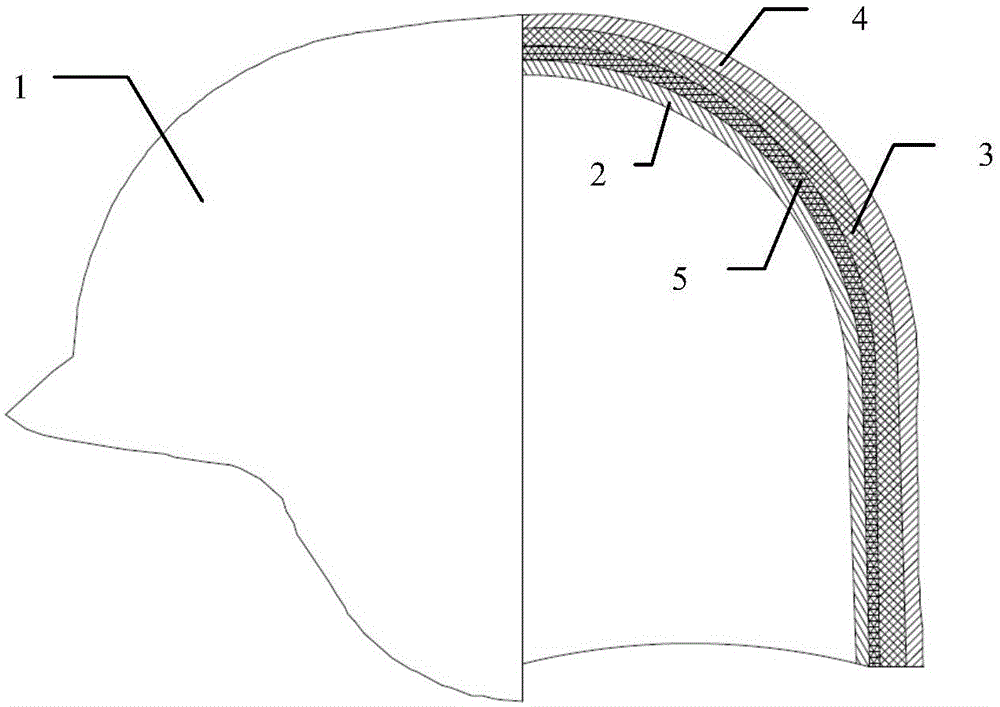

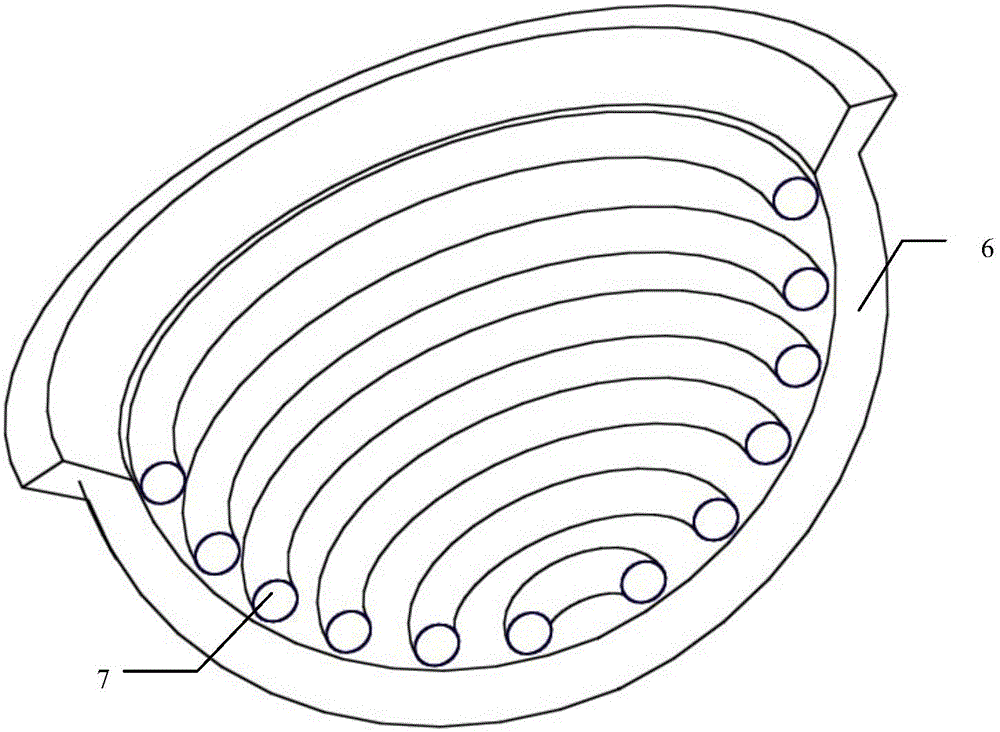

[0049] refer to figure 2 and image 3 , preferred embodiment 2 of the present invention provides a kind of aramid composite ballistic helmet of special structural design, comprises housing 1, spray paint layer 4 and hanger, is characterized in that, housing 1 comprises inner layer 2 and outer layer 3, inner layer 2 is composed of 2 layers of high rubber content fiber fabric prepreg, and the outer layer 3 is composed of 14 layers of low rubber content fiber fabric prepreg.

[0050] The fiber fabric prepreg with high glue content is an aramid non-woven fabric or aramid woven fabric or carbon fiber fabric or S-grade glass fiber fabric prepreg with a glue content of 25% by weight.

[0051] The fiber fabric prepreg with low glue content is an aramid non-woven fabric or aramid woven fabric prepreg with a glue content of 13% by weight.

[0052] Wherein the adhesive for the prepreg is a modified phenolic or modified epoxy adhesive.

[0053] There is also a polyurethane viscose rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com