Patents

Literature

70results about How to "Give full play to the tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

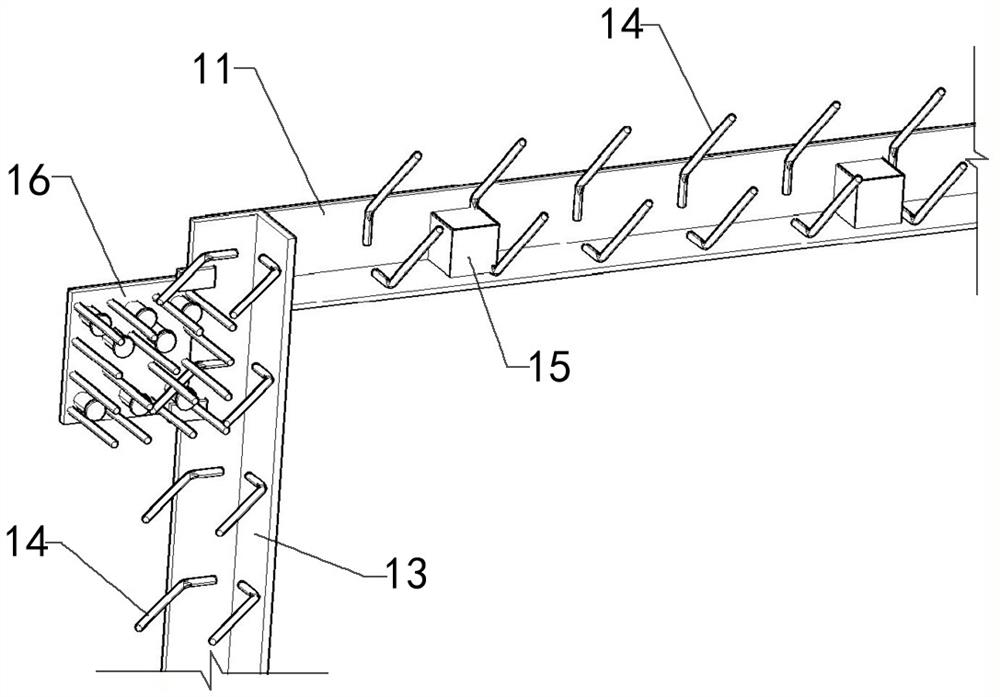

Mutually-embedded ecological building block retaining wall and construction method thereof

InactiveCN102677695AImprove practicalityAdapt to the requirements of inclination changesArtificial islandsCoastlines protectionArchitectural engineeringRetaining wall

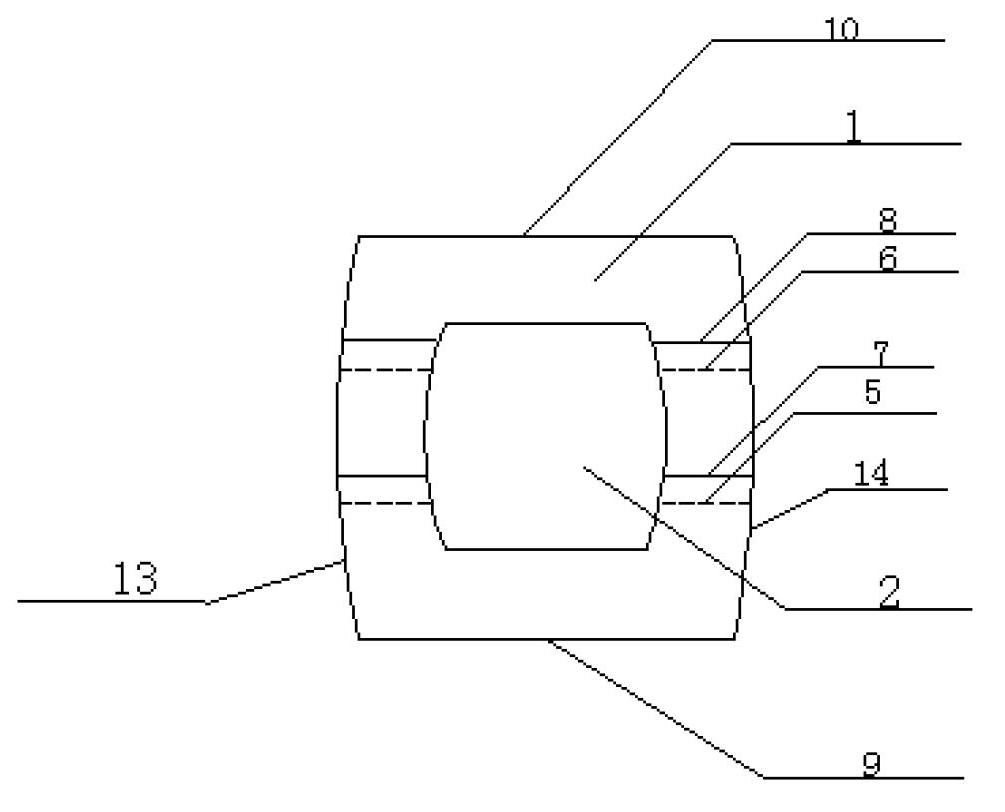

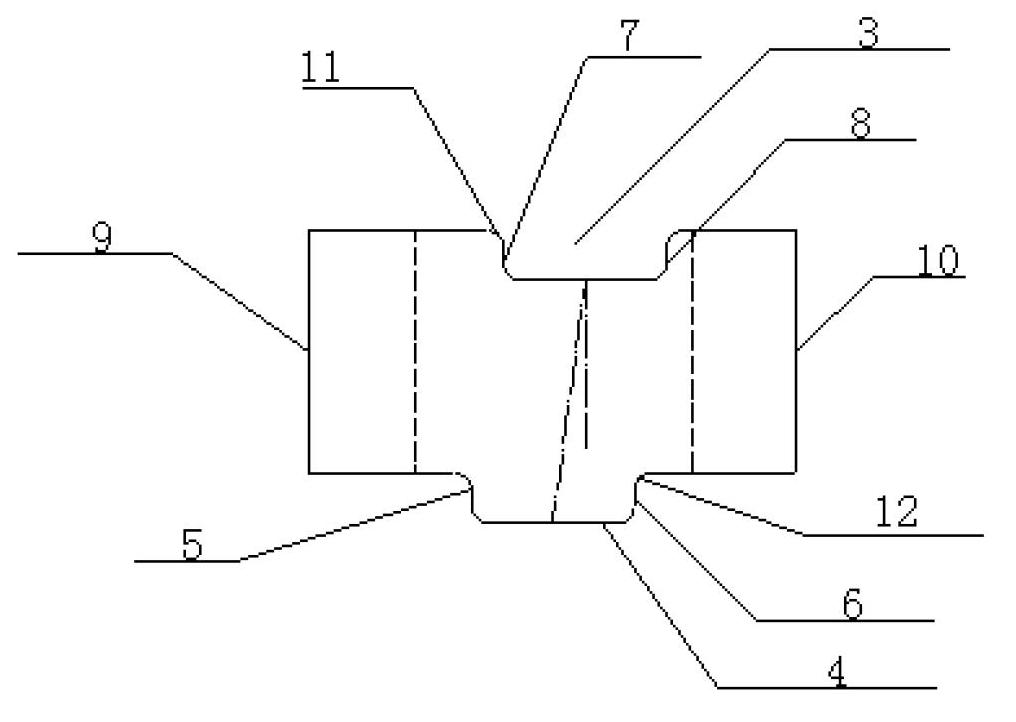

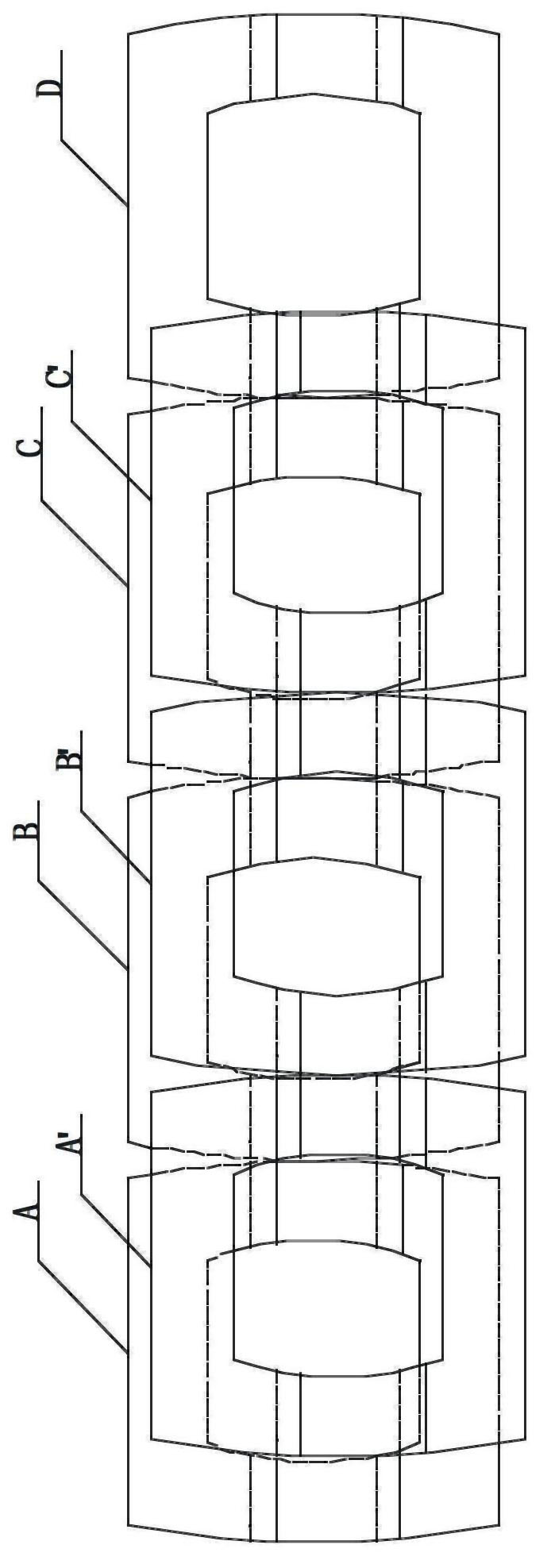

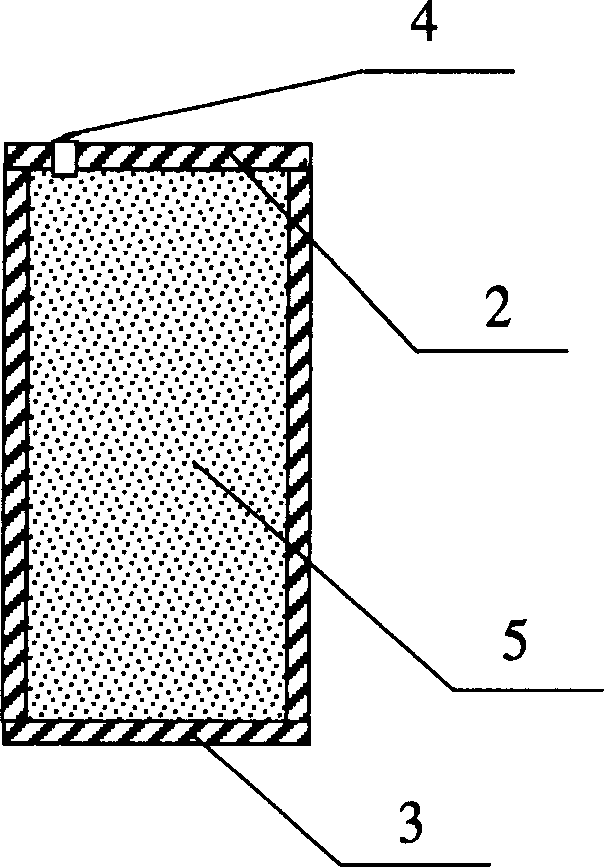

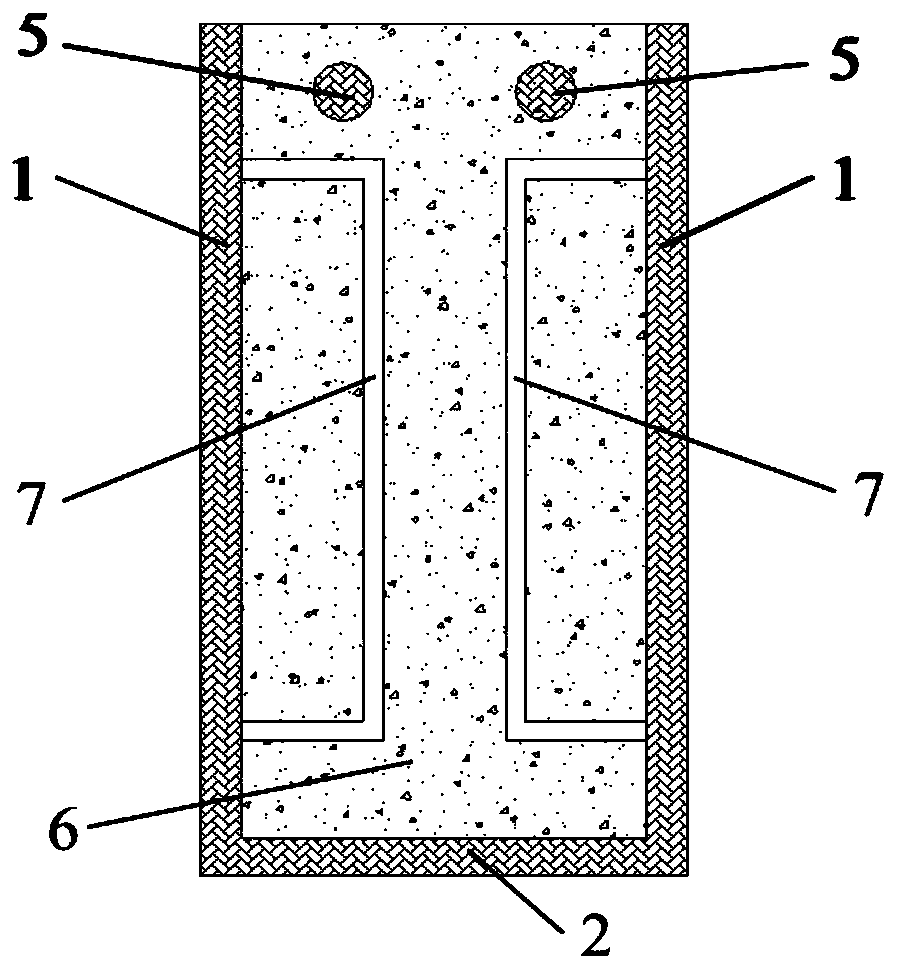

The invention provides a mutually-embedded ecological building block retaining wall and a construction method thereof, and belongs to the field of buildings. The mutually-embedded ecological building block retaining wall is formed by two or more than two layers of mutually embedded ecological building blocks which are arranged transversely side by side and stacked upwards; each of the mutually embedded ecological building blocks has a front surface of the building block and a back surface of the building block which are parallel to each other; a hole is formed in the middle part of the building block; a groove is formed on the top part of the building block; the front surface of the groove and the back surface of the groove are respectively parallel to the front surface of the building block and the back surface of the building block; a bump is arranged on the bottom part of the building block; the groove is matched with the bump in size; and the bump of the building block on the upper layer is embedded into the groove of the building block on the lower layer. The construction method comprises the following steps of: placing a building block on a construction foundation to serve as a first layer; placing a building block on the first layer building block to serve as a second layer, wherein the bump on the bottom part of the second layer building block is completely embedded into the groove of the first layer building block; and repeatedly placing the building blocks to a designed height. Grass-like vegetation and vine-like plants can be grown in openings of the building blocks and gaps among the building blocks, so that a good ecological effect is achieved.

Owner:HOHAI UNIV

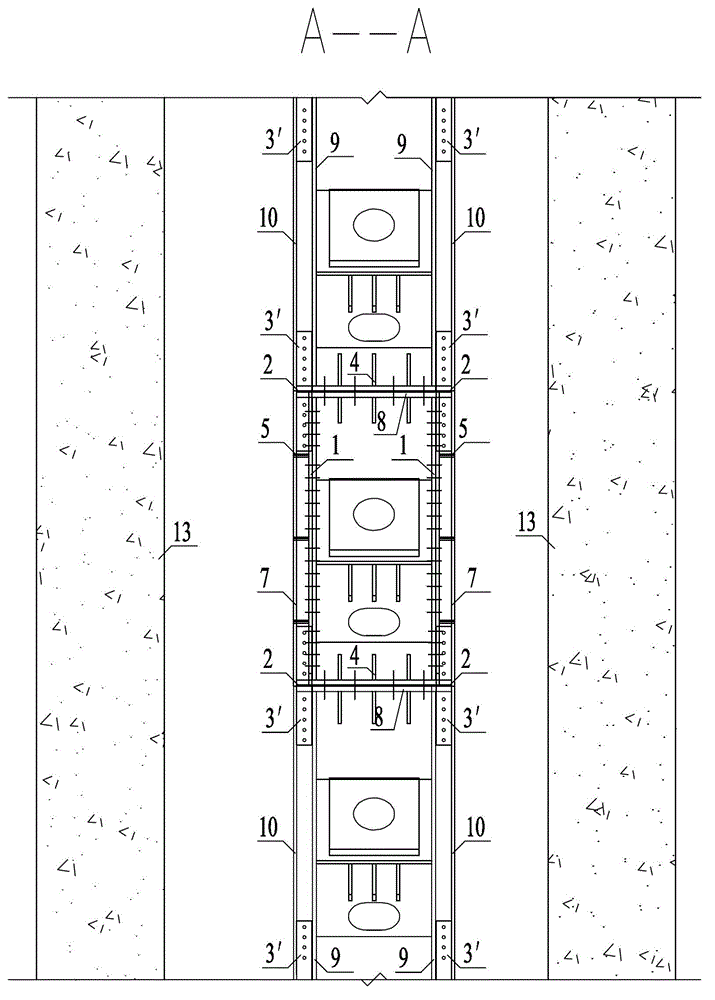

Anchor device of first sliding and then fixing type combined steel anchor boxes of cable stayed bridge and construction method thereof

ActiveCN102864742AGive full play to the tensile strengthAvoid unfavorable working conditionsBridge structural detailsBridge erection/assemblyCable stayedTower

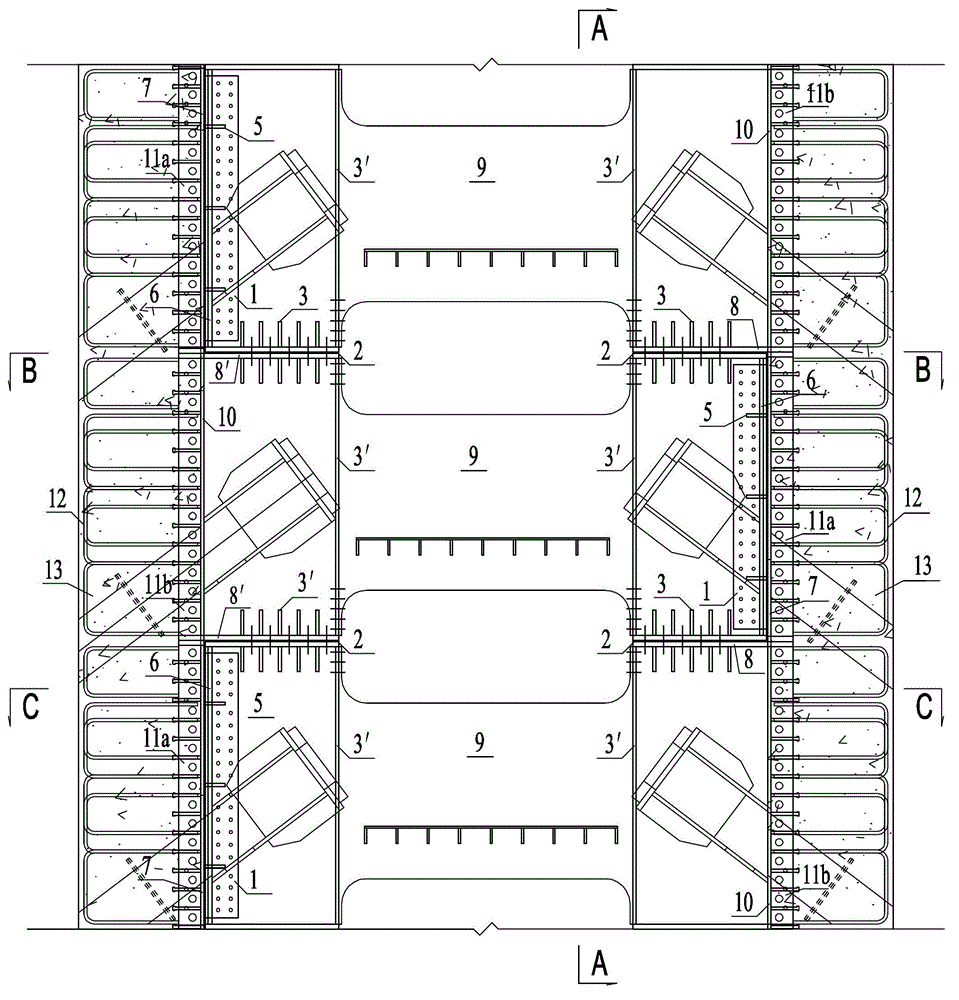

The invention discloses an anchor device of first sliding and then fixing type combined steel anchor boxes of a cable stayed bridge and a construction method thereof. The anchor device comprises multiple anchor box segments continuously arranged in the vertical direction, wherein each anchor box segment is provided with an anchor box side pulling plate, a bolting end and a fixed end; the anchor box side pulling plate is positioned in the middle; the bolting end and the fixed end are respectively arranged at the left and right ends of the anchor box side pulling plate; the bolting ends and fixed ends in the adjacent anchor box segments in the vertical direction are arranged in a staggered manner; sliding pairs are arranged between the bolting ends and fixed ends in the adjacent anchor box segments in the vertical direction; and both the bolting ends and fixed ends of the anchor box segments are provided with connection structures combined with concrete in the tower wall of a cable stayed bridge tower. The device can give full play to the tensile strength of anchor box steel, simultaneously avoids transferring excessive horizontal pull to the tower wall, avoids that the steel anchor boxes prevent contraction of the tower wall, and avoids that the concrete tower wall is unilaterally stressed when the stay cables are replaced or broken. The invention also provides a construction method of the anchor device.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

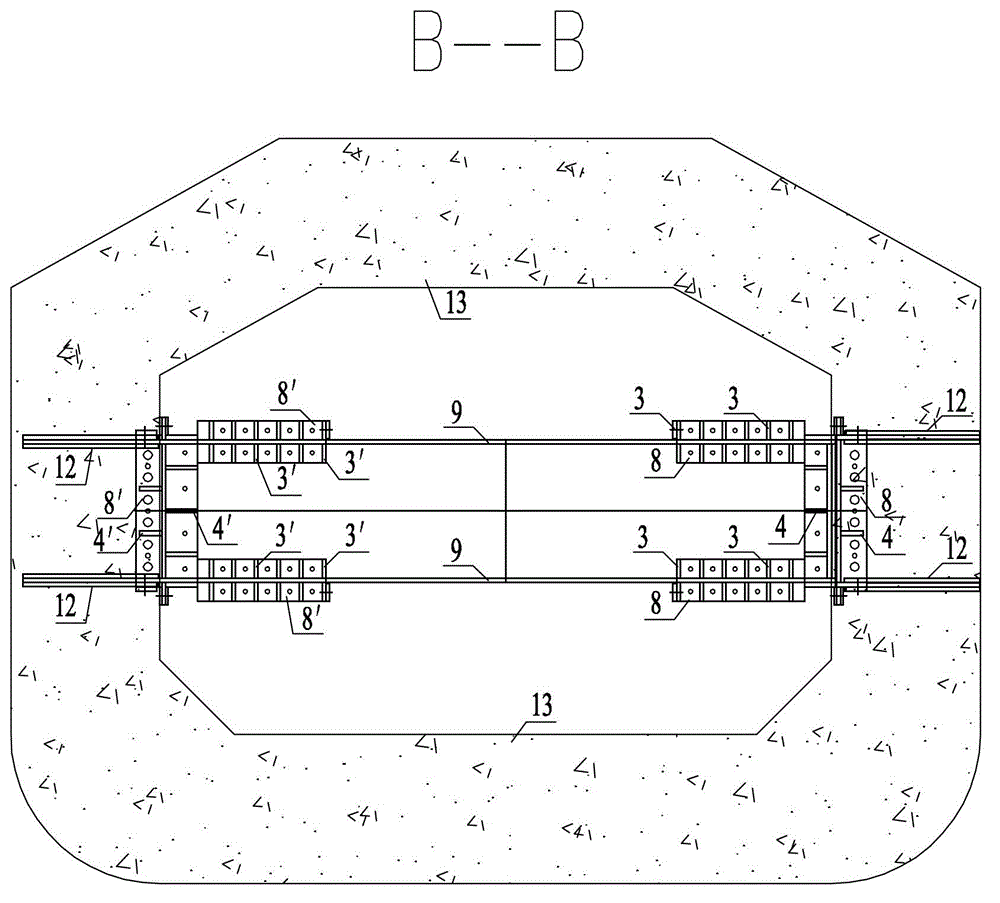

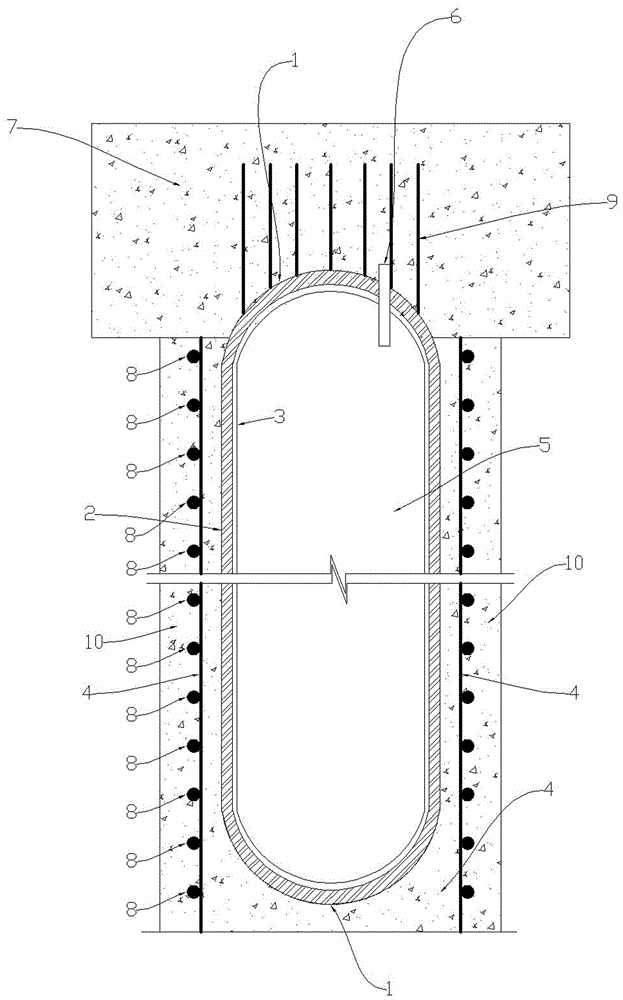

Method for enhancing pulling-resistant and tensile-resistant capability of soft and weak soil layer anchor rod/anchor rope

The invention relates to a method for enhancing pulling-resistant and tensile-resistant capability of a soft and weak soil layer anchor rod / anchor rope. The method comprises the following steps: evenly stirring soil body and a solidifying agent in the soft and weak soil layer by using pile-forming equipment and grout injecting equipment, and forming a stirring pile; drilling holes at the positionof a central shaft in a stirring pile by using drilling equipment when unconfined compressive strength of the stirring pipe reaches 0.7MPa to 1.5MPa, and cleaning detritus in the holes; and placing the anchor rod / anchor rope rod body embedded with a grout injecting pipe into the bottom of the holes, and carrying out grout injection from the hole bottom to top to form the pulling-resistant and tensile-resistant anchor rod / anchor rope. The method solves the problem that the soil layer anchor rod / anchor rope can not be used in soft soil areas, solves a series of problems of slurry pollution, longconstruction period, complex technique, high cost and the like due to pile injecting by the use of the pulling-resistant drilling and solves the problems of easy corrosion and nondurability of a reinforced pile anchor.

Owner:凌光荣 +1

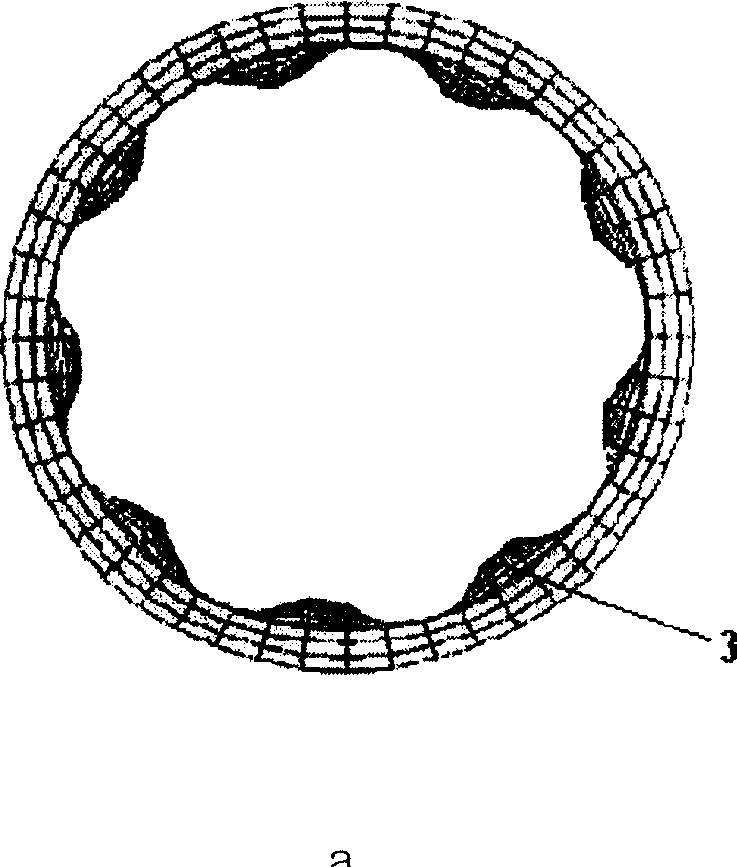

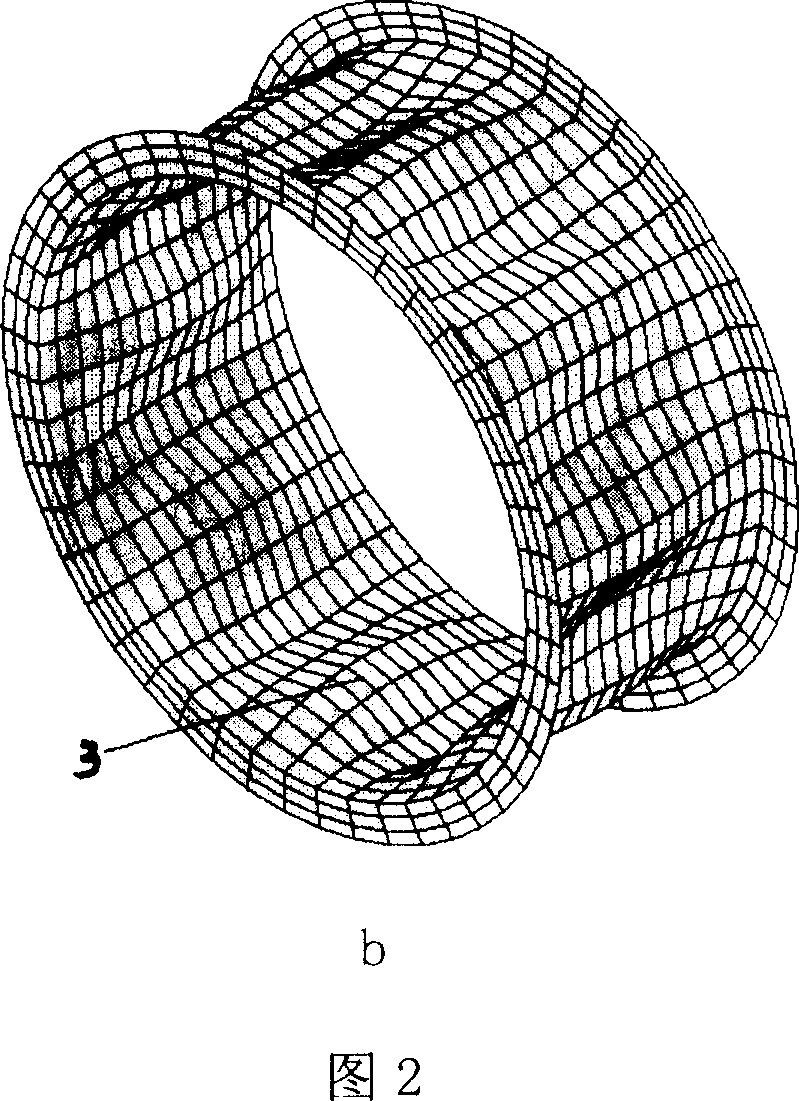

Pressure bearing pipe damage repair process

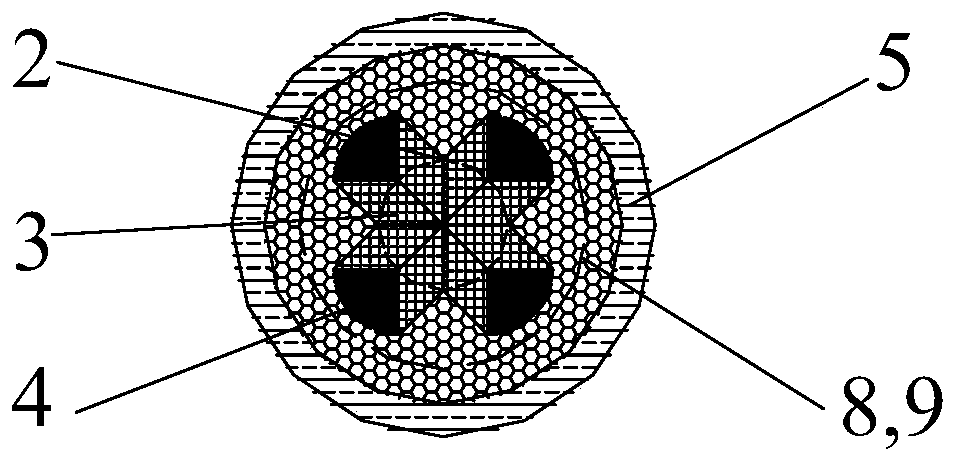

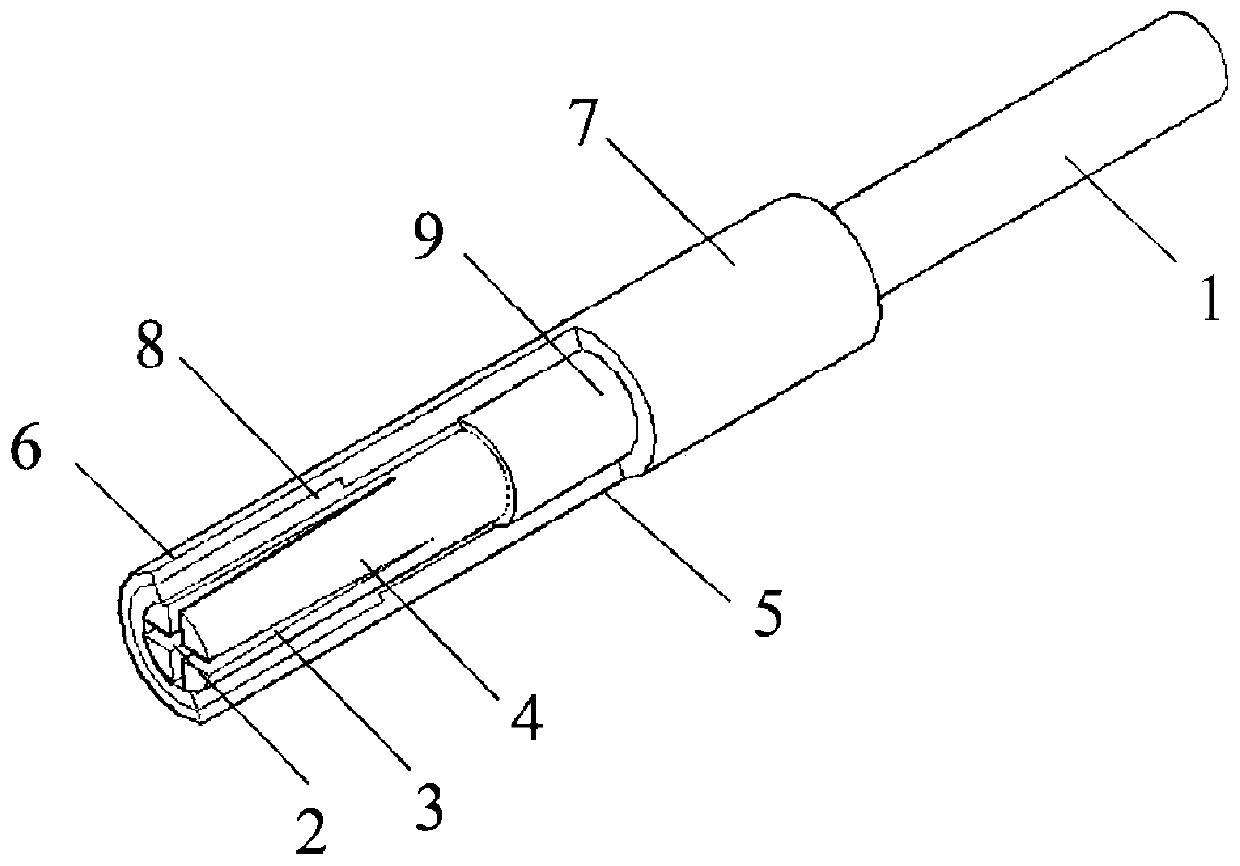

InactiveCN105090676AIncrease cracking loadIncreased bending stiffnessPipe elementsFiberForeign matter

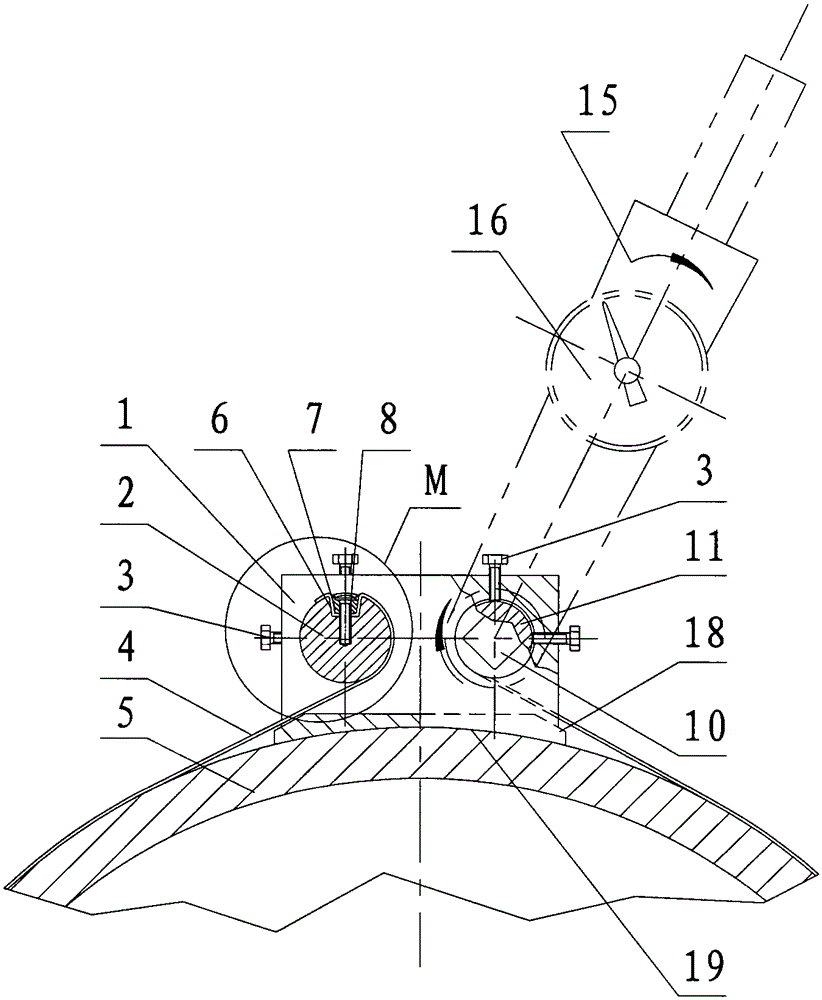

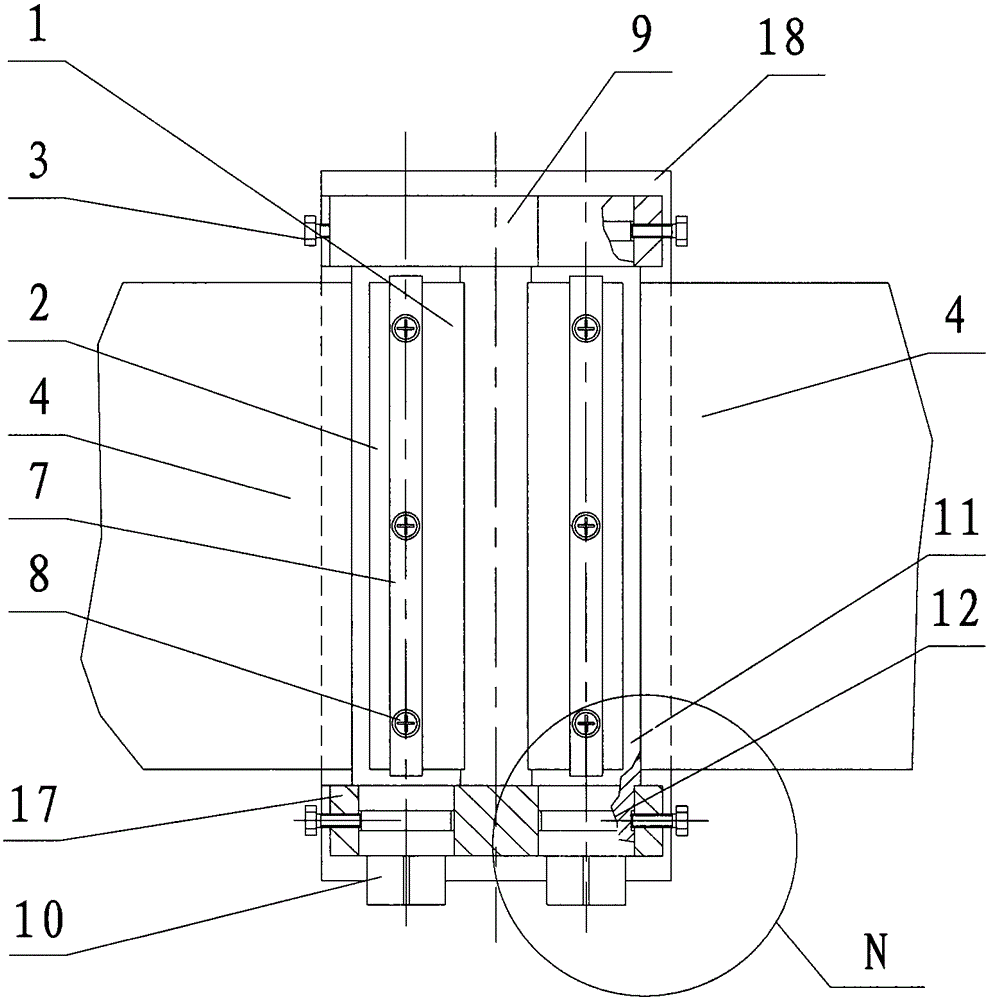

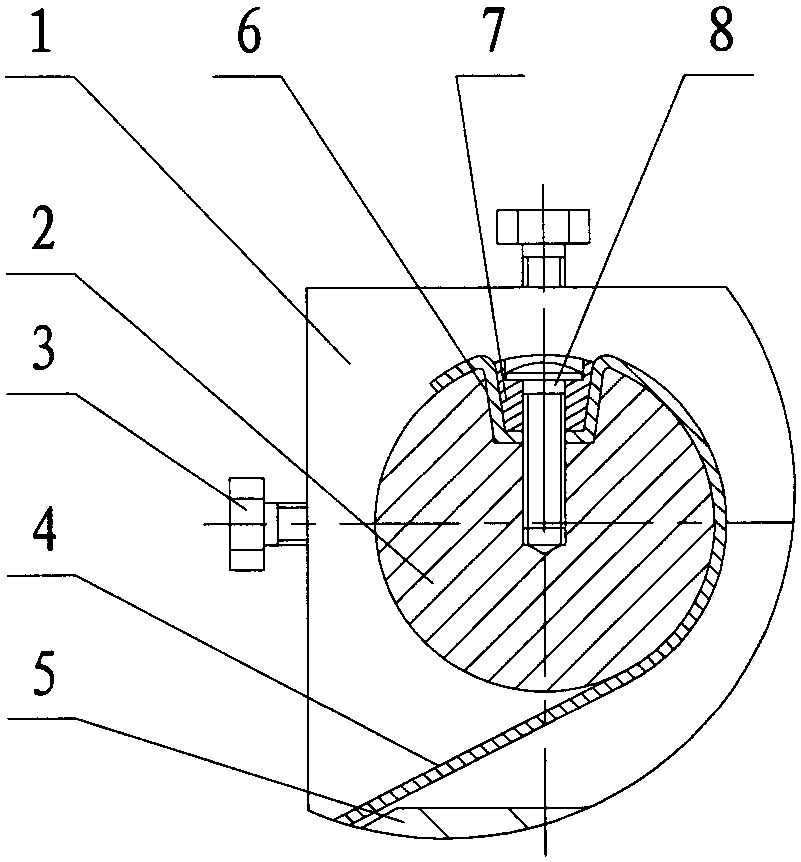

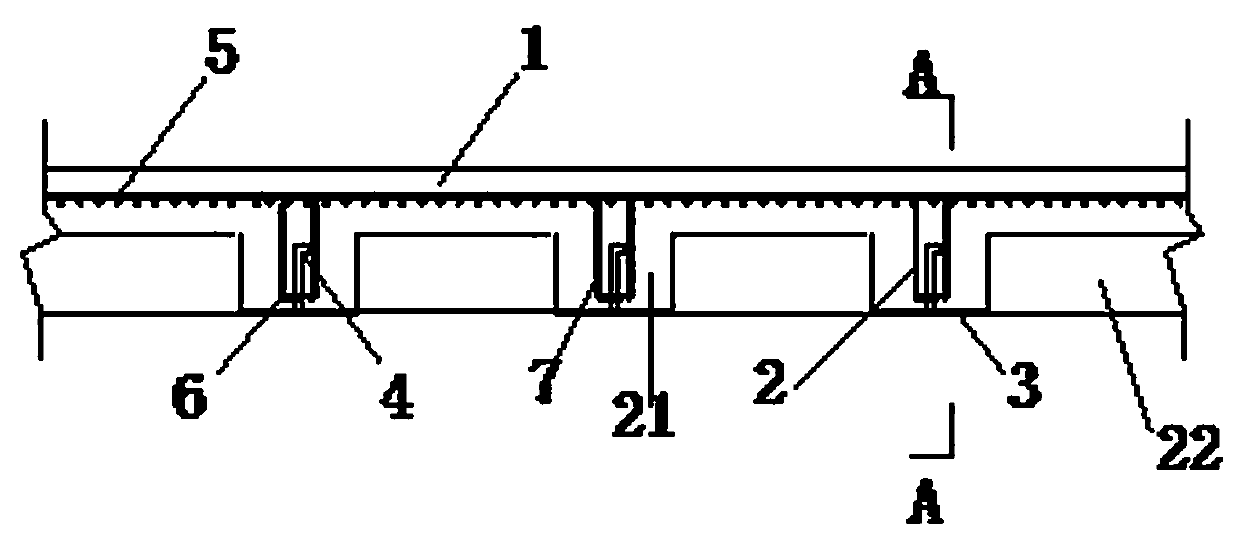

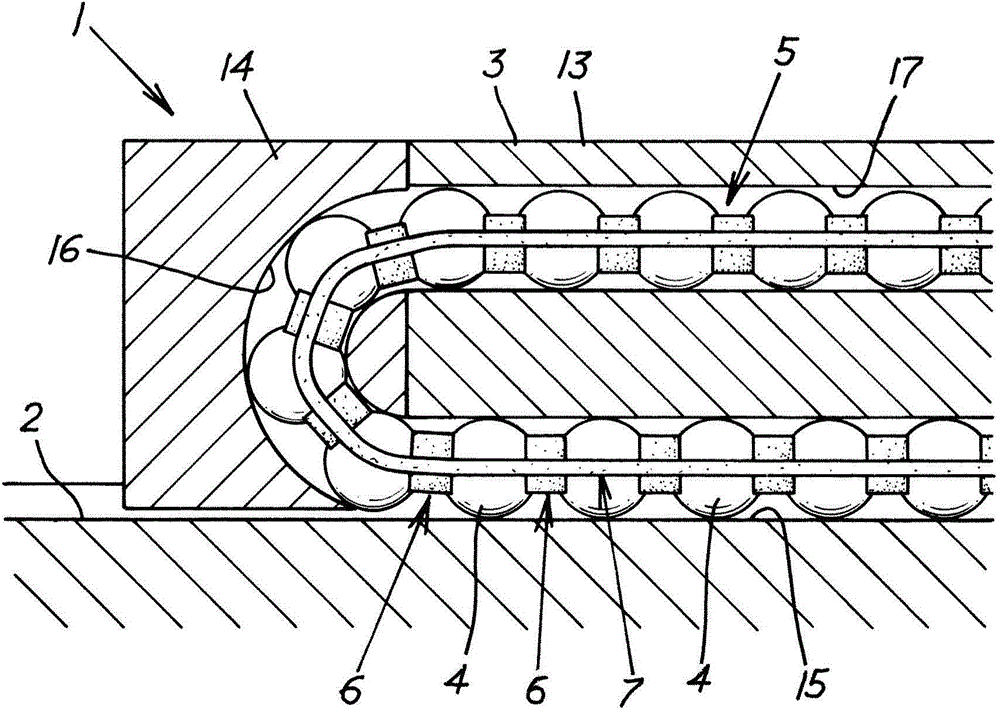

The invention discloses a pressure bearing pipe damage repair process. The process is performed by the following steps: a carbon fiber fabric (4), a repair agent, adhesive, a torque spanner (15) and a tensioning device (1) are prepared; the damage positioning is performed for a pressure bearing pipe (5), and an obstacle is removed; a foreign matter at a damage part is removed, and an area to be repaired is determined; after the repair agent is coated on the area to be repaired, the adhesive is coated; the carbon fiber fabric (4) is bonded on the adhesive, and the left and right ends of the carbon fiber fabric (4) are tightened by the tensioning device (1); the torque spanner (15) is clamped on a shaft head (10), and is wrenched to enable a finger of a dial (16) to reach preset torsion; all locking screws (3) are tightened, and the prestress of the carbon fiber fabric (4) is constant; the adhesive is uniformly coated on the surface of the carbon fiber fabric (4); and after the adhesive reaches the stated condensation period, the tensioning device (1) is disassembled to finish one-time repair process.

Owner:SOUTHWEAT UNIV OF SCI & TECH

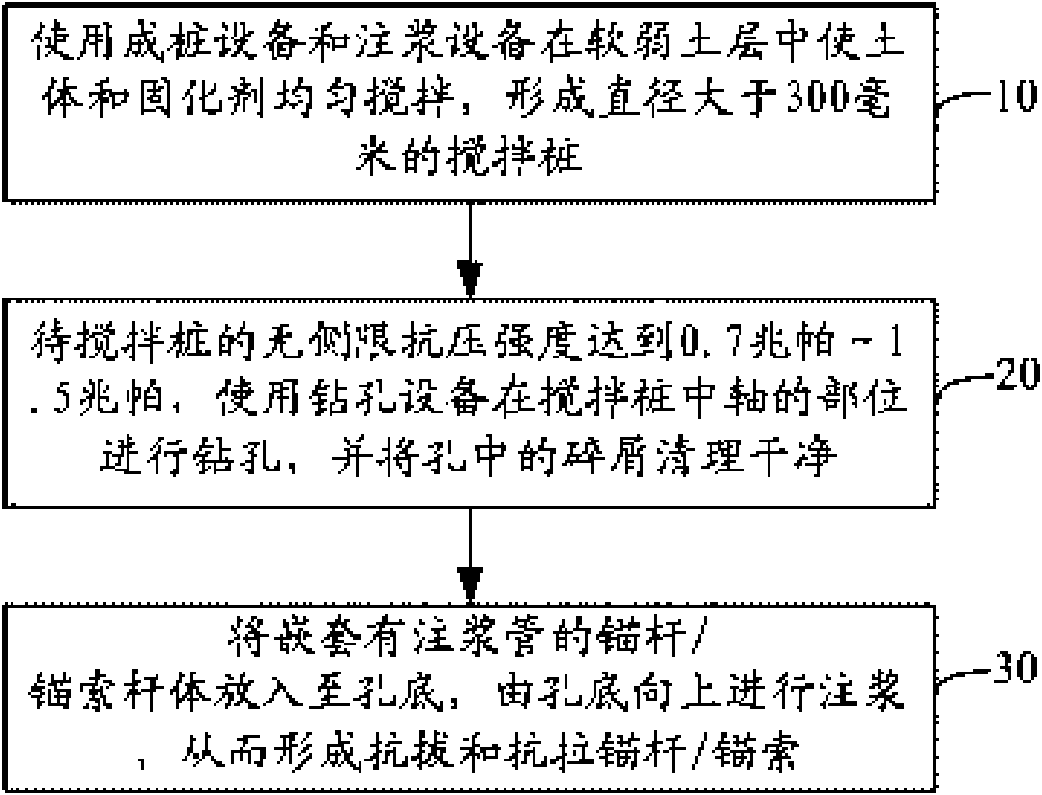

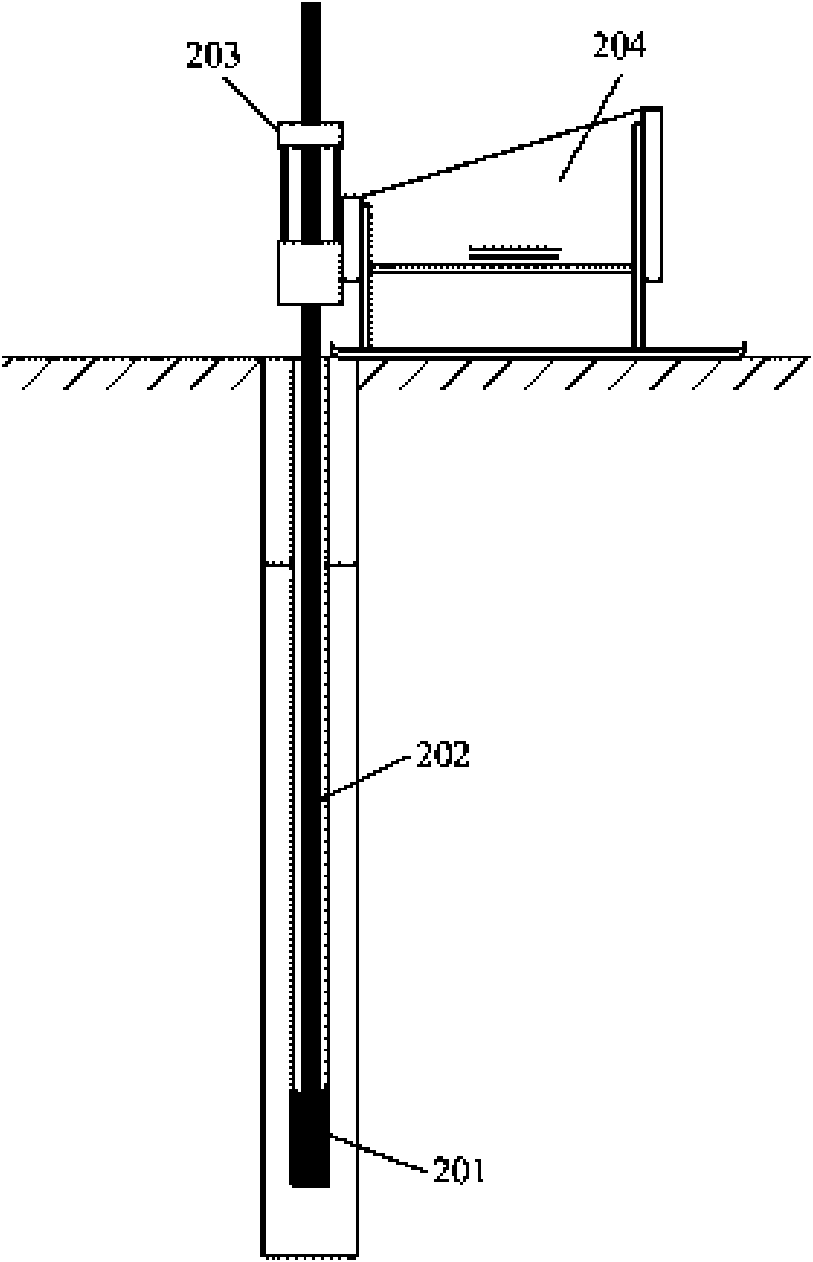

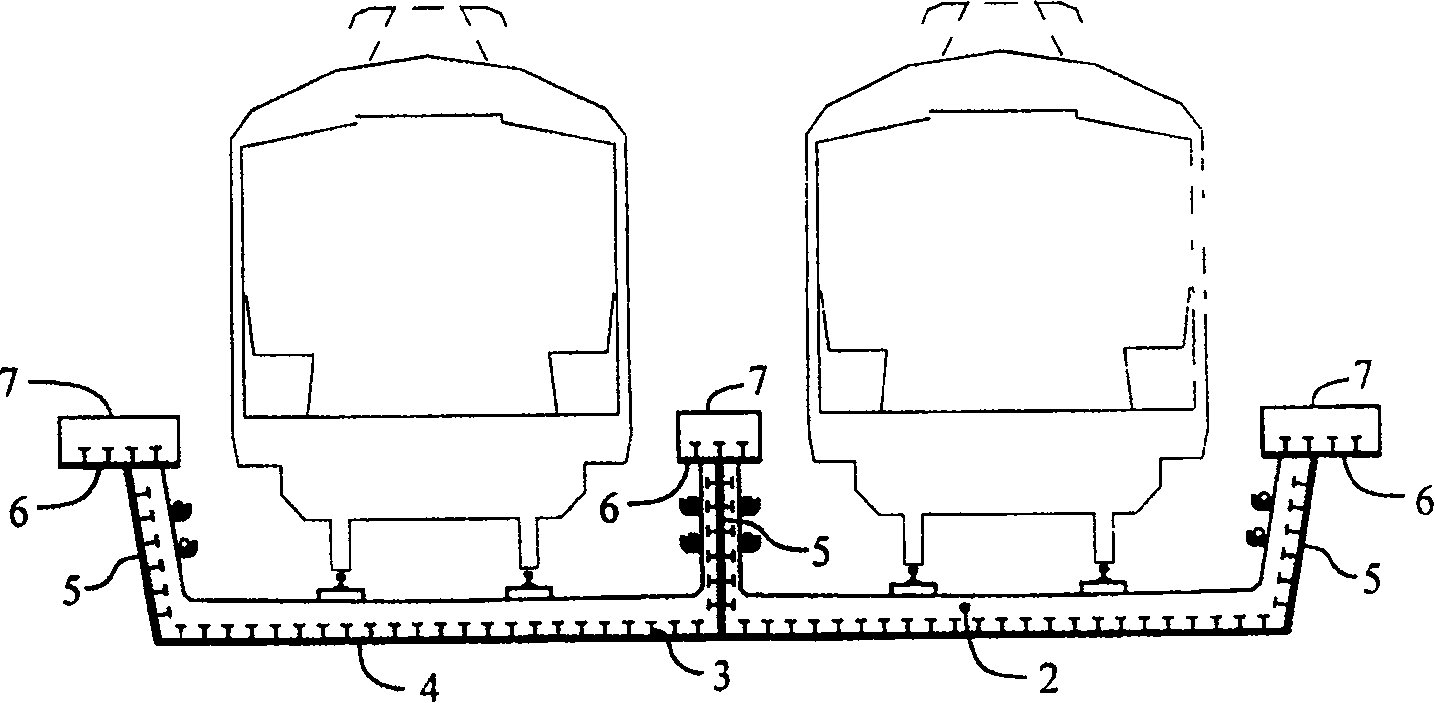

Anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and constructing method of anchor-arm static-pressure pile device

The invention relates to an anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and a constructing method of the anchor-arm static-pressure pile device, and aims to provide the anchor-arm static-pressure pile device with the self-sufficient pile pressing counter-force. When an indoor construction pile foundation cannot provide a pile pressing counter-force, construction requirements can be realized by self-sufficient pile pressing counter-force, so that the efficiency is high, the cost is relatively lower, and pollution to the environment is avoided. The anchor-arm static-pressure pile device adopting steel pipe piles of which the pile tips are filled with slurry to provide counter-force comprises a pressure pile baseplate, the steel pipe piles and anchors, wherein anchor-arm static-pressure pile pressing holes and steel pipe pile pressing holes are formed in the pressure pile baseplate; the steel pipe piles are inserted through the steel pipe pile pressing holes and pressed to a certain depth; the slurry is arranged in the pile tips of the steel pipe piles; the tops of the steel pipe piles are connected with the press pile baseplate through grouting material tamping; the anchors are arranged outside the steel pipe pile pressing holes and the anchor-arm static-pressure pile pressing holes respectively, connected with a press pile counter-force rack and used for pressing the steel pipe piles or anchor-arm static-pressure piles to certain depths.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG +1

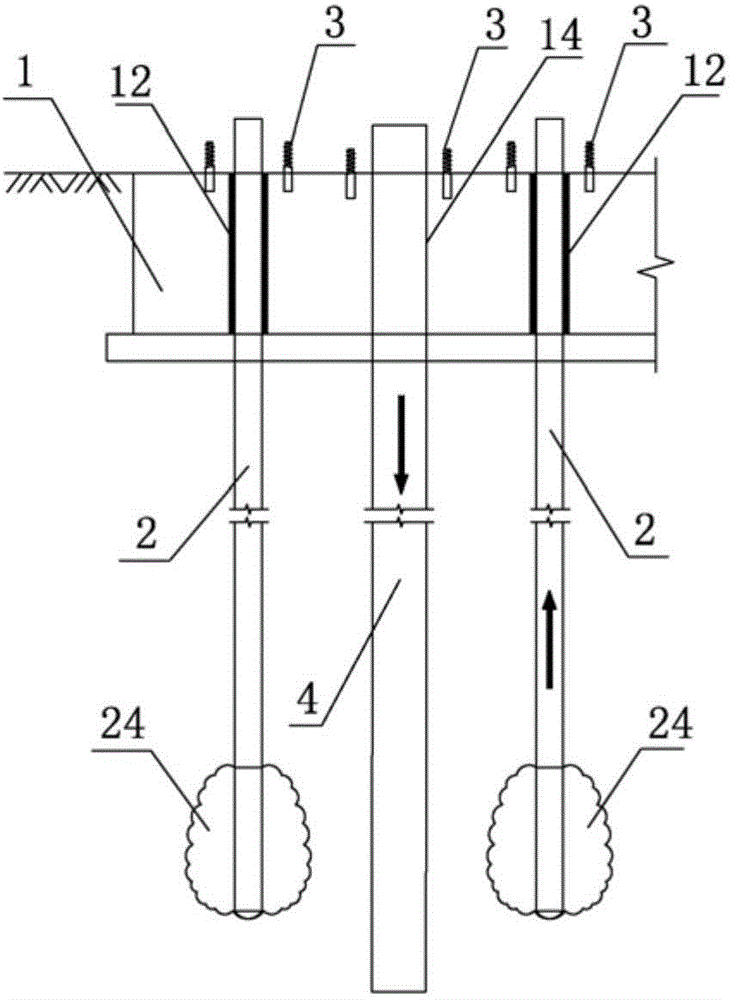

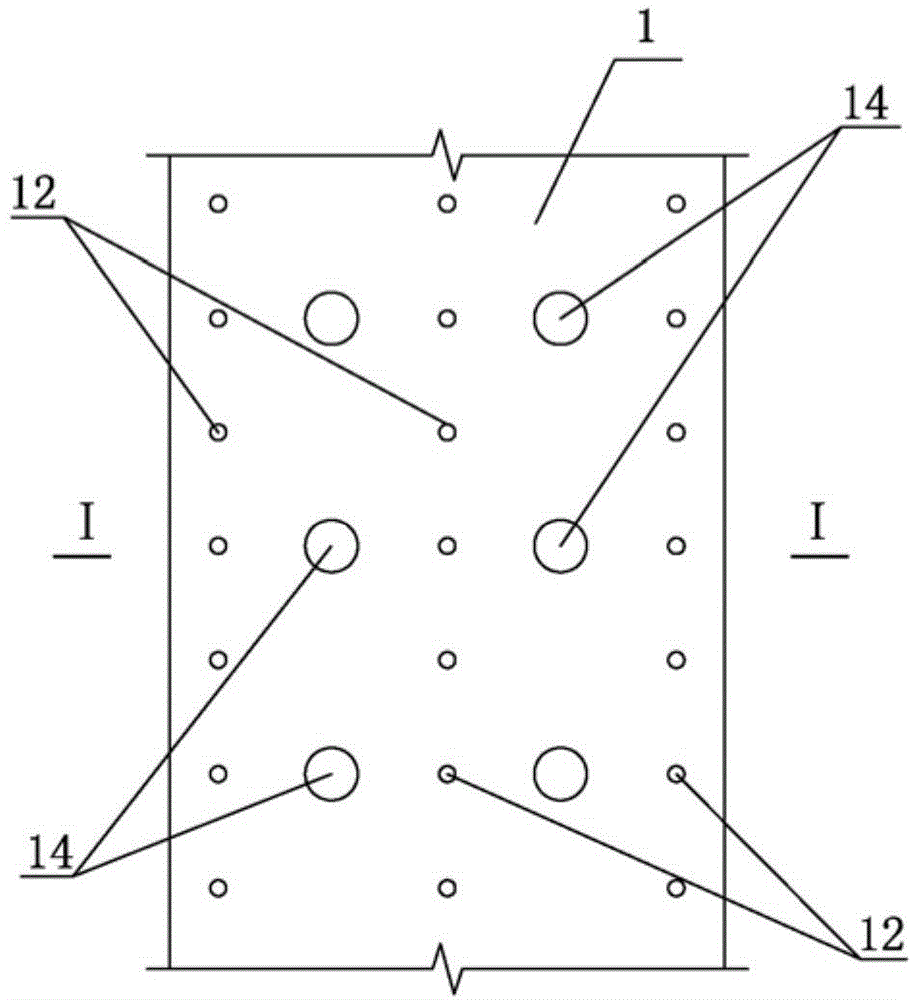

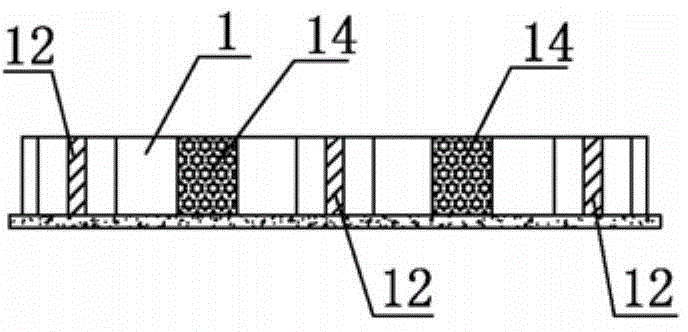

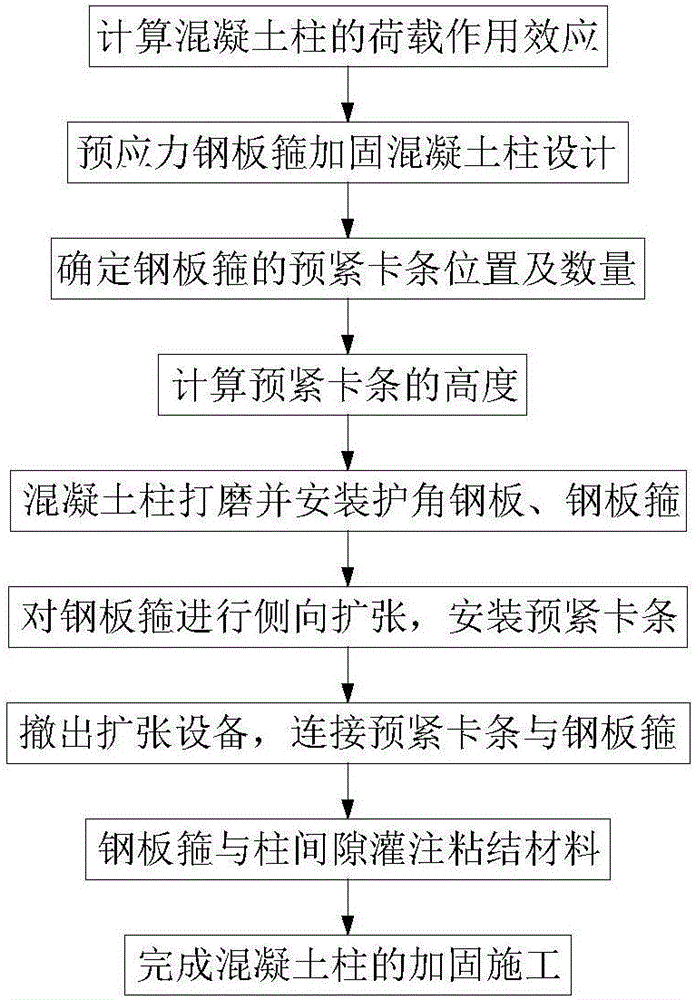

Method for reinforcing rectangular-section concrete columns through prestressed steel plate hoops

InactiveCN105926961AGive full play to the tensile strengthImprove bearing capacityBuilding repairsSheet steelAxial compression

The invention discloses a method for reinforcing rectangular-section concrete columns through prestressed steel plate hoops. The method is mainly characterized in that the steel plate hoops are mounted on the concrete columns and are subjected to lateral expansion through an expanding tool, pre-tightening clamping bars are mounted and are connected with the steel plate hoops through point welding after the expanding tool is withdrawn, and the rectangular-section concrete columns are reinforced through the prestressed steel plate hoops. According to the reinforcing method, the effective active constraint functions on the corners and the four edges of each rectangular column are achieved, the basically uniform annular constraint effect can be formed, and concrete is in a stressed state in three directions, so that the performance of bearing capacity, ductility and the like of the concrete columns is improved more effectively, and the method is suitable for reinforcing construction of the rectangular-section concrete columns under axial compression or small eccentric compression.

Owner:郭猛

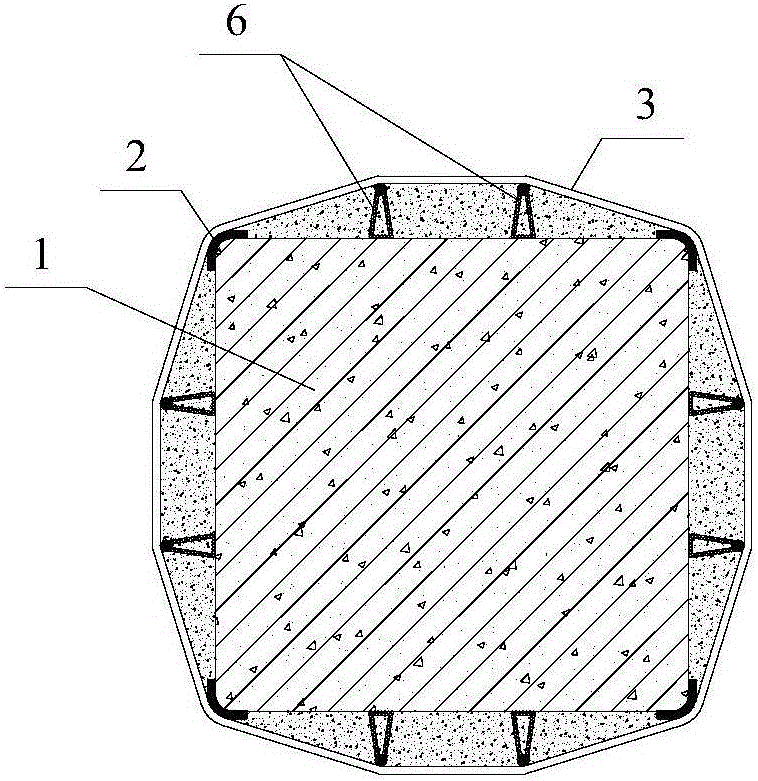

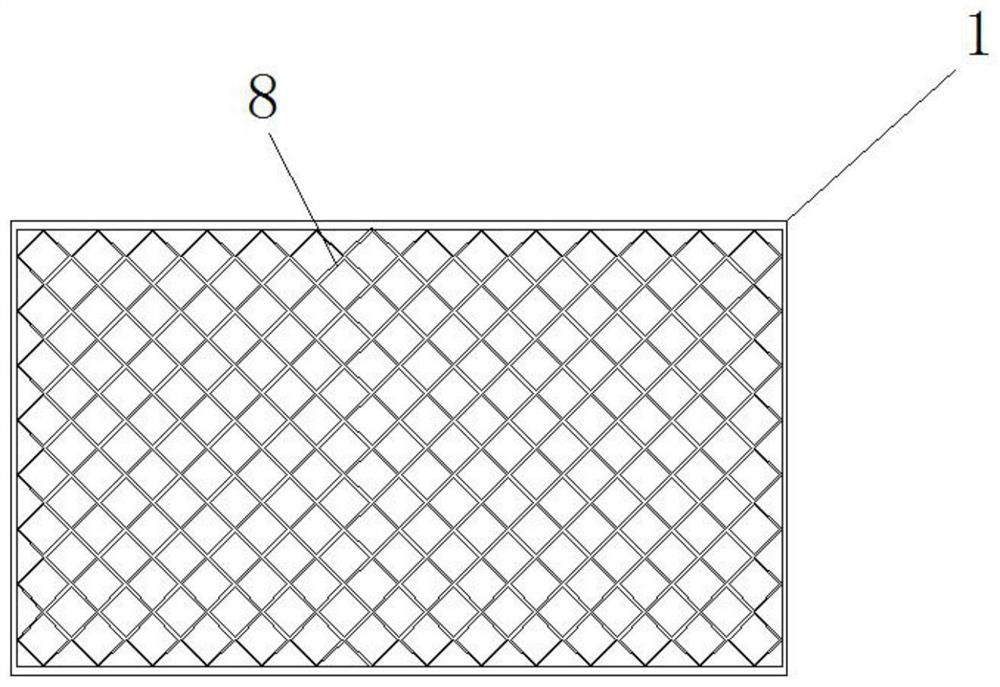

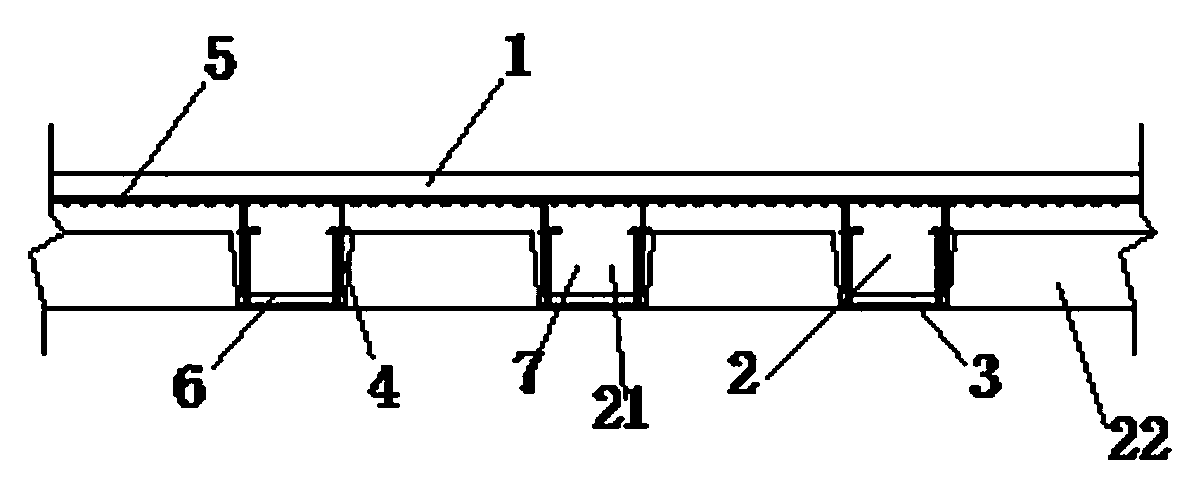

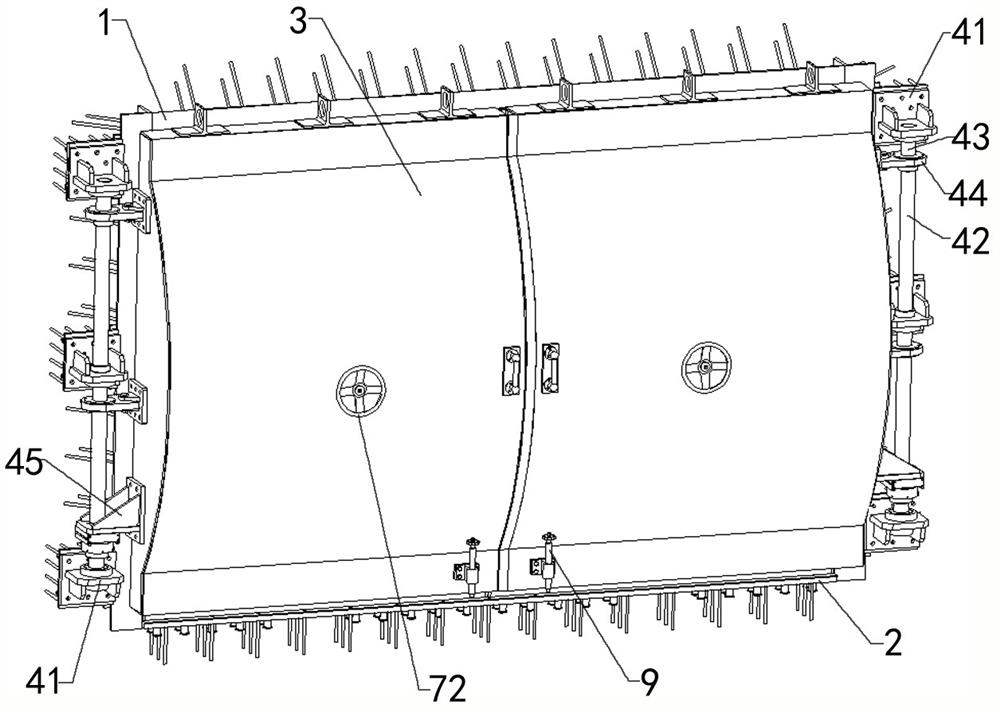

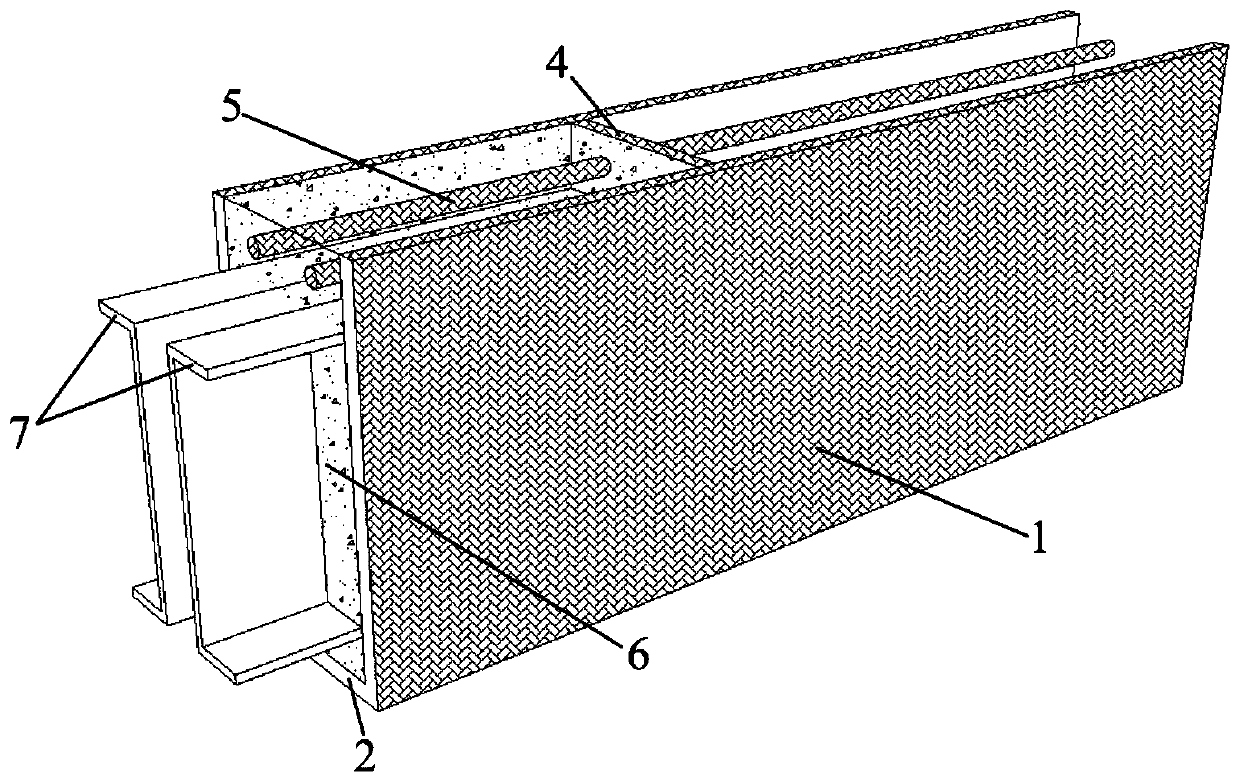

Ultra high performance concrete rib plate with rib bottom steel plate and machining method thereof

PendingCN109577189AGive full play to the tensile strengthImprove crack resistanceCeramic shaping apparatusBridge structural detailsSheet steelWhole body

The invention provides an ultra high performance concrete rib plate with a rib bottom steel plate and a machining method thereof. The ultra high performance concrete rib plate with the rib bottom steel plate is mainly to solve technical problems, such as easy fatigue cracking, poorer tensile and compressive performance, low section utilization efficiency and high cost, of an existing ultra high performance concrete rib plate. The key point of the technical scheme is that more than three plate ribs (2) are arranged at the bottom of a panel (1) to be connected with the panel (1) to form a wholebody; a reinforcing mesh (5) is arranged in the panel (1); the rib bottom steel plate (3) is arranged at the bottom of a rib body (7); a shear connector (4) is arranged on the upper surface of the ribbottom steel plate (3); a hoop (6) is arranged at the lower part of the reinforcing mesh (5); the hoop (6) is fixedly connected with the shear connector (4) so that the reinforcing mesh (5) is connected with the hoop (6) and the shear connector (4) to form an integral reinforcement structure; and ultra high performance concrete is poured outside the reinforcing mesh (5), the hoop (6) and the shear connector (4) to form the panel (1) and the plate ribs (2) which are connected to form a whole body.

Owner:HUNAN UNIV +1

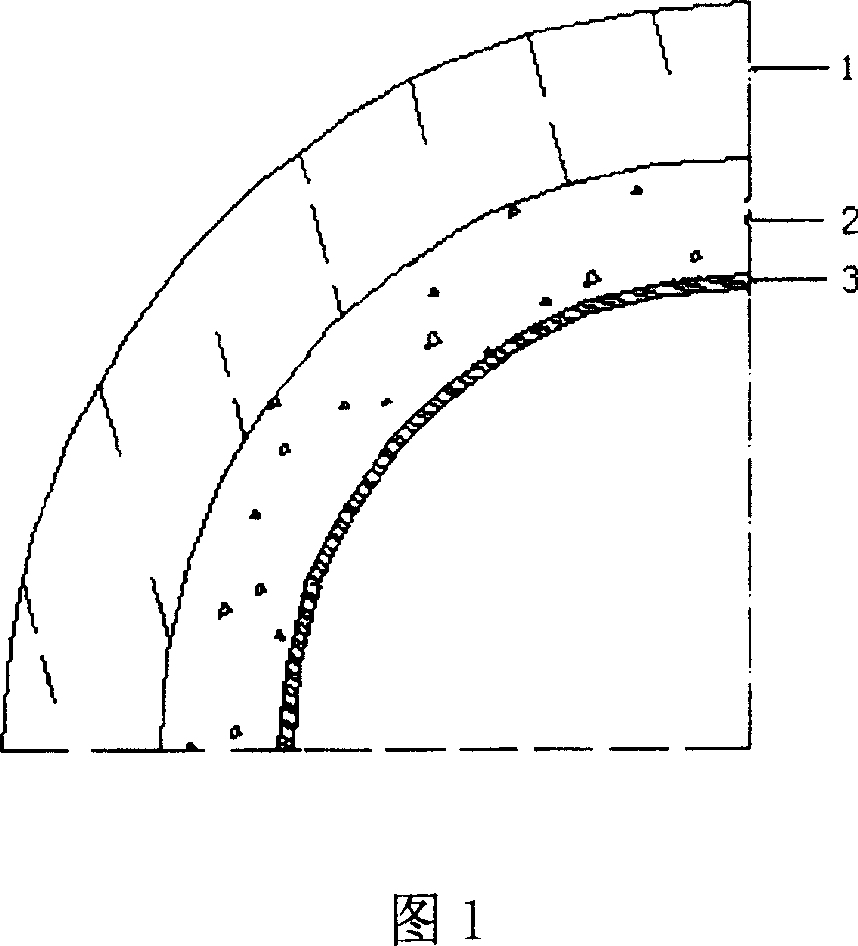

SCS combined hydropower station pressure underground pipe design method

The invention discloses a way to design pressing tube of SCS combined hydraulic power station. Between the steel inside and the round wall fill concrete tube, between the concrete tube and the round wall fill the outside steel tube. The outside steel tube is anti-seepage , the middle concrete tube resists external pressure, and the inside steel tube only resists water pressure inside when operating. It decrease by large the content of steel and concrete and the cost, and it is convenient to transfer the water pressure from inside to outside. The way of design brings the good capability of steel and concrete into play, and apt to the work environment very well. Otherwise, in operation there is no need to add other ways, so it increases the speed of the operation by large.

Owner:XIAN UNIV OF TECH

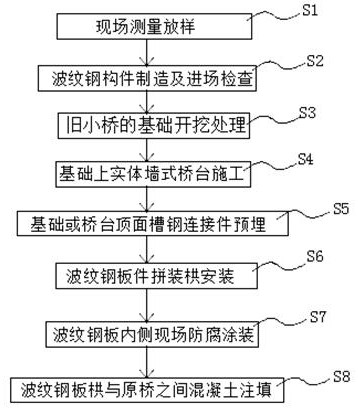

Existing old small bridge and culvert corrugated steel reinforcing construction method

InactiveCN111676836ASolve the disease problemReliable factory production materialsBridge erection/assemblyBridge strengtheningDiseaseSolid wall

The invention discloses an existing old small bridge and culvert corrugated steel reinforcing construction method. The method comprises the steps: S1, carrying out on-site survey setting-out; S2, carrying out corrugated steel component manufacturing and entry inspection; S3, excavating the foundation of the old small bridge; S4, constructing a solid wall type abutment on the foundation;S5, pre-burying channel steel connecting pieces on the top surface of the foundation or the abutment;S6, carrying out corrugated steel plate piece assembling and arch installation; S7, carrying out anticorrosivecoating on the inner side of the corrugated steel plate on site; and S8, filling the space between the corrugated steel plate arch and the original bridge with concrete. The method has the advantagesof being safe and rapid in construction, short in construction period, environmentally friendly in construction, low in construction cost, remarkable in benefit, capable of effectively solving the problem that diseases are gradually generated in the using process of existing old small bridges and culverts and the like.

Owner:青海路拓工程设施制造集团有限公司

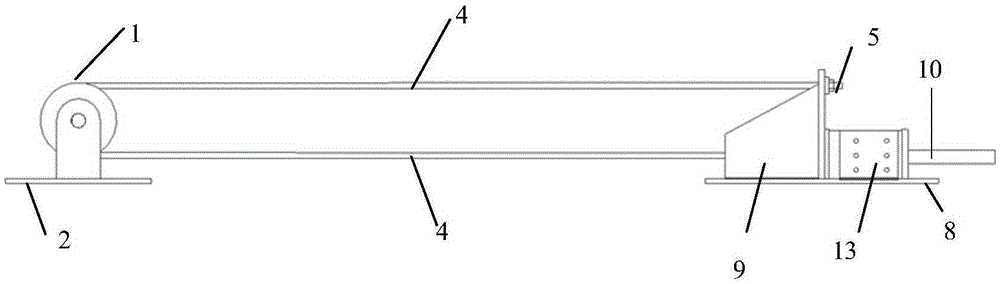

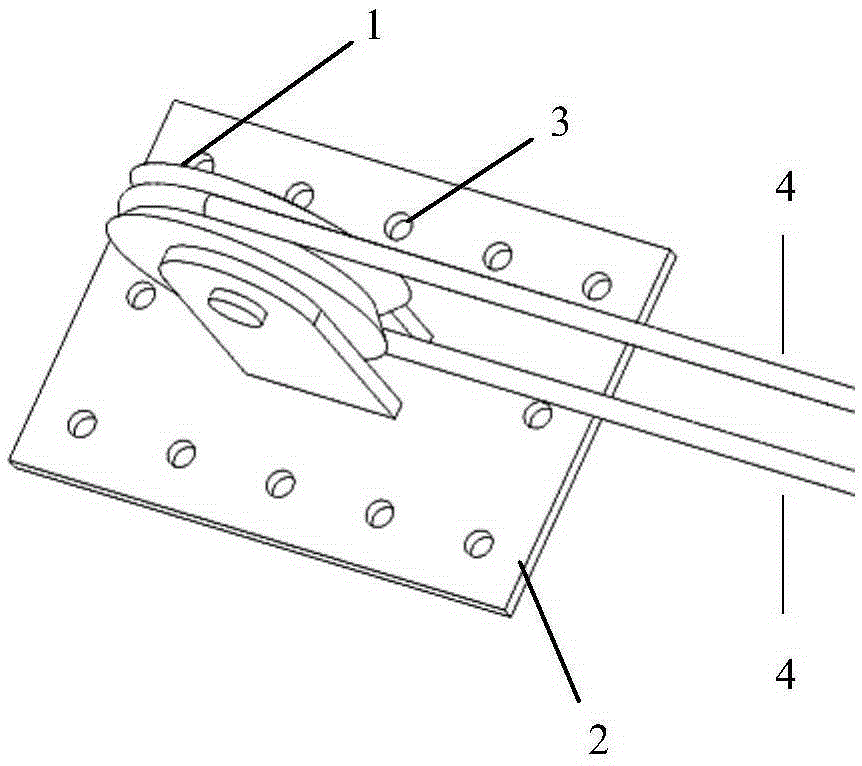

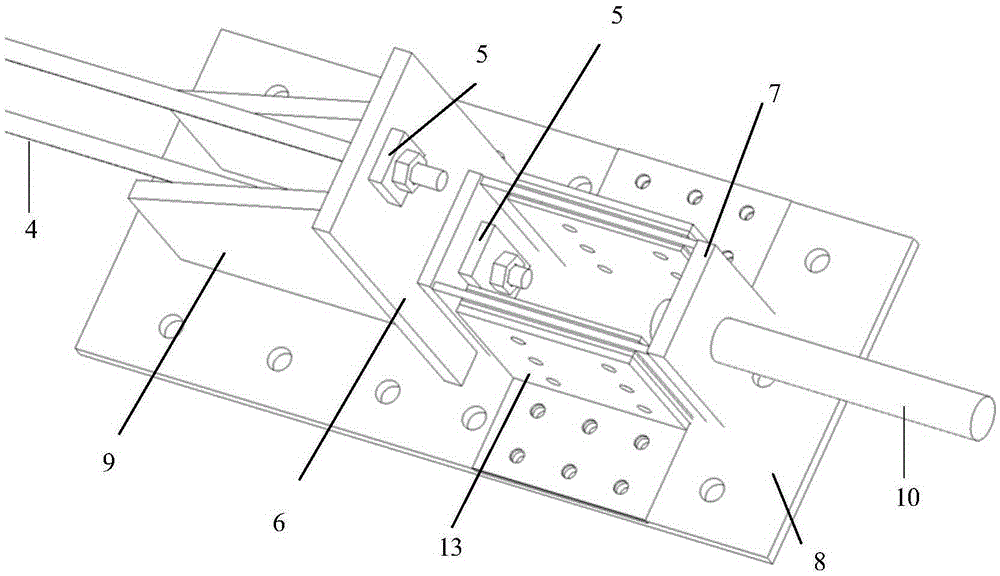

Self-resetting energy consumption inhaul cable support

ActiveCN105421608AReduced elastic elongation requirementsBroaden your optionsShock proofingWork performanceEngineering

The invention discloses a self-resetting energy consumption inhaul cable support which comprises a pulley, a pulley base, a prestress reset rib, an anchorage device, a limiting plate, a sliding frame, a bottom plate, a high-strength steel cable, a friction plate, a steel base plate and a connecting plate. The pulley is fixed to the pulley base. The pulley base is fixed to a main structure through a bolt. One end of the prestress reset rib is anchored to the limiting plate through the anchorage device. The other end of the prestress reset rib winds around the pulley, and builds prestress through a post-tensioning method to be connected with the sliding frame. The self-resetting energy consumption inhaul cable support has the advantages that the resetting capability of the support is enhanced exponentially, or the selection range of the reset rib material is widened exponentially, the structure complexity degree of the support is simplified, and the working performance of the support is ensured; 2, the cross section of the support is reduced, and therefore the earthquake effect is effectively reduced; 3, the yield stiffness designability is provided for the support.

Owner:NANJING UNIV OF TECH

Steel pipe in construction structure

The present invention relates to a new-type thin-wall steel pipe in building structure, in particular, it is a liquor-charged steel pipe. Said steel pipe is formed from pipe body and upper end face and lower end face which are welded on the upper and lower ends of said steel pipe respectively and used for closing the upper and lower two ends of said steel pipe. It is characterized by that in the interior of steel pipe the liquor is charged, on the pipe body is set a hole through which the water can be injected into the interior of steel pipe by means of high pressure so as to ensure that in the interior of steel pipe the air is not existed, so that it can raise the bearing capacity of steel pipe.

Owner:GUANGZHOU UNIVERSITY

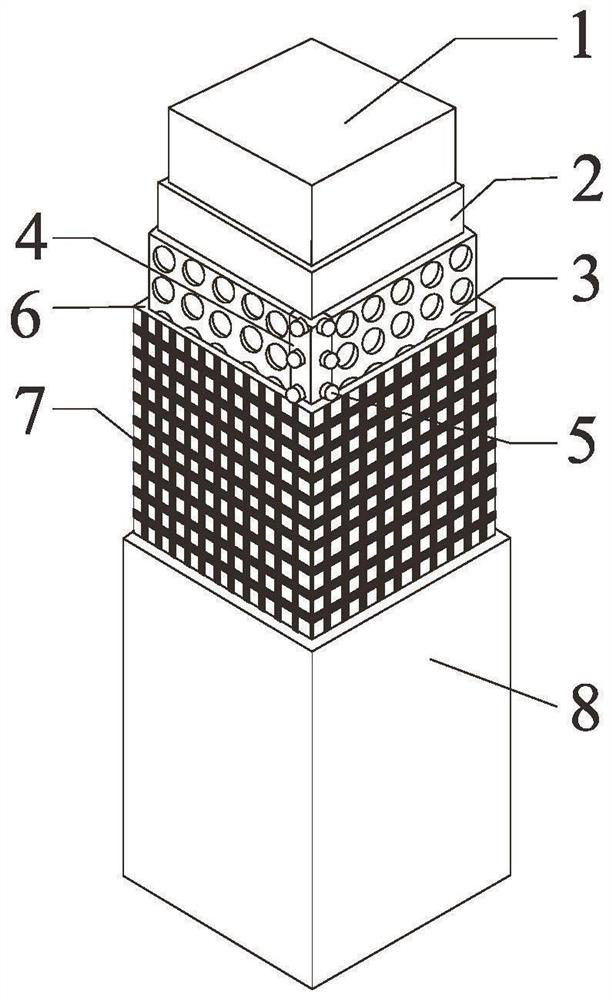

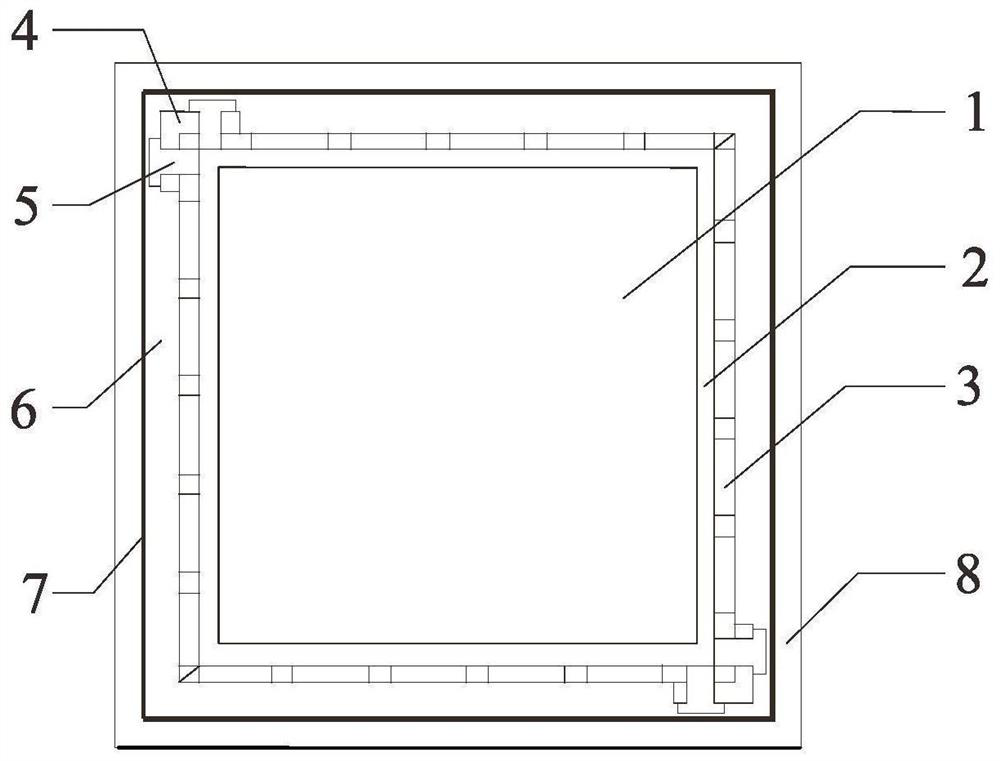

Concrete column reinforcement structure and construction method thereof

PendingCN111809908AMake the most of the interconnectionIncrease profitStrutsBuilding repairsReinforced concrete columnStructural engineering

The invention discloses a concrete column reinforcement structure and a construction method thereof. The concrete column reinforcement structure comprises a UHPC substrate layer, a porous steel plate,a UHPC bonding layer, a fiber woven net and a UHPC protective layer which sequentially coats the side wall of a to-be-reinforced concrete column from inside to outside, wherein the porous steel plateis provided with through holes; and the UHPC bonding layer is bonded with the UHPC substrate layer through the through holes of the porous steel plate. Through the adoption of the UHPC substrate layer, the higher compatibility between a reinforcement layer and an original concrete structure can be achieved, as well as the aging-resistant, high-temperature-resistant and moisture-resistant properties can be good; through the fiber net connection mode, the fiber material interconnection effect of a fiber composite material can be sufficiently exerted, and the fiber material utilization ratio canbe improved; the UHPC substrate and the UHPC bonding layer are tightly bonded through the through holes of the porous steel plate, so that not only can the internal and external UHPC bonding capability be enhanced, but also the corrosion-resistant property and the fire-resistant property can be improved; and all the components of the concrete column reinforcement structure can be combined to forma whole subjected to common stress and deformation, and the mechanical properties of the to-be-reinforced concrete column can be improved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

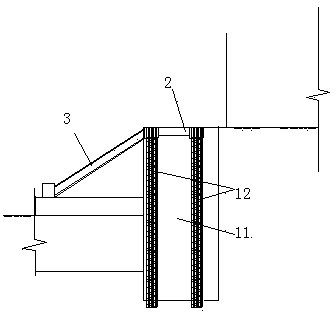

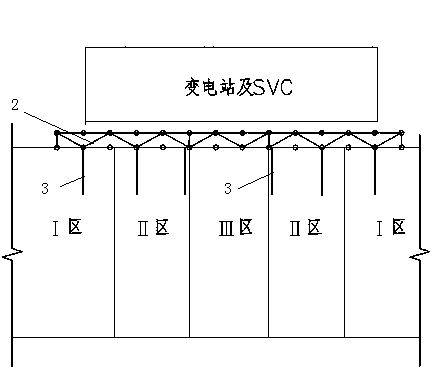

Cement mixing pile composite supporting system provided with peripheral concrete members

The invention relates to a foundation pit supporting system, in particular to a cement mixing pile composite supporting system. The cement mixing pile composite supporting system provided with peripheral concrete members comprises composite piles, concrete trusses and steel inclined struts, wherein the composite piles are arranged around foundation pits, the concrete trusses are respectively arranged at top parts of the composite piles, and the steel inclined struts are respectively arranged between bottoms of foundation pits of each two composite piles. The cement mixing pile composite supporting system provided by the invention is higher in tensile strength and bending resistance.

Owner:CHINA MCC20 GRP CORP

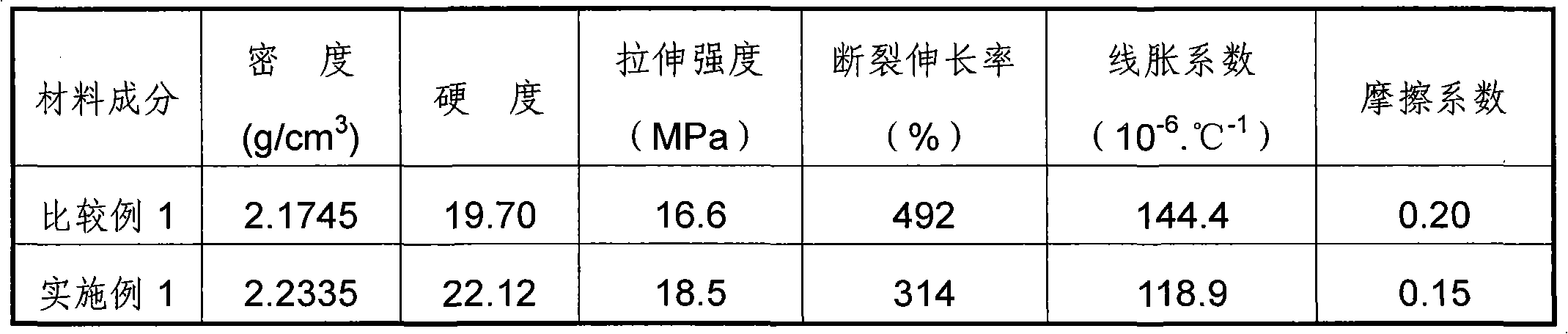

Filled modified teflon seal material and its preparation method

Disclosed are a filled modified teflon seal material and its preparation method. The filled modified teflon seal material comprises the following components of: by weight, 5-15% of nanometer Fe3O4 with its surface modified by oleic acid and 95-85% of a teflon powder. The preparation method comprises the following steps of: firstly mixing the nanometer Fe3O4 with its surface modified by oleic acid and the pretreated teflon powder according to the above mass percent; placing the uniformly mixed raw materials into a pressing die for compression molding while the molding pressure is 50-60MPa, the pressurization speed is 5-10MPa / min and pressure maintaining lasts for 15-30min; insulating at the temperature of 28-30 DEG C for 24 hours, heating to 300-320 DEG C at the heating rate of 60-100 DEG C / h, insulating for 0.5-1 hour, continuously heating to 370-390 DEG C, insulating for 1 hour; cooling to 300-320 DEG C in a furnace, insulating for 0.5-1 hour, cooling to room temperature, followed by simple processing and outside dimension detection, and preserving at constant temperature.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

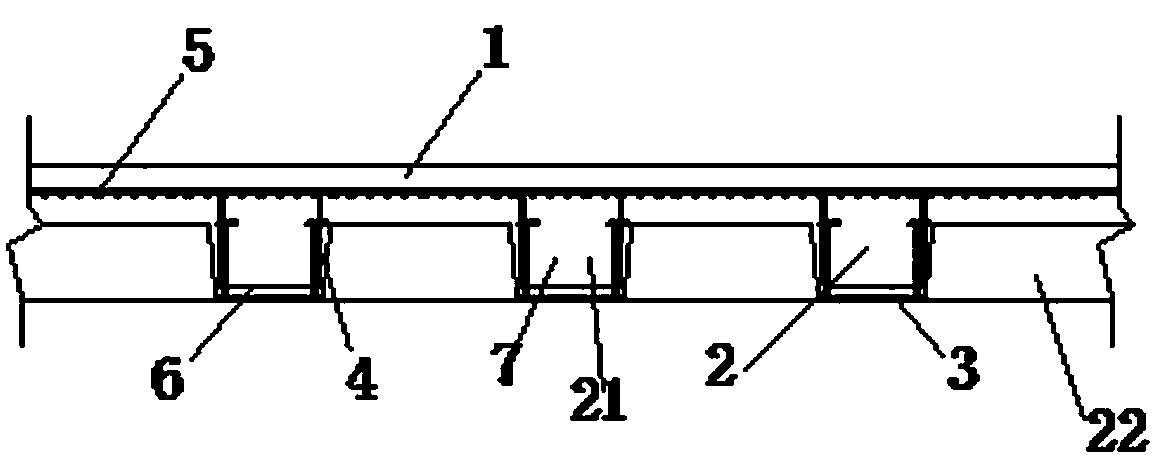

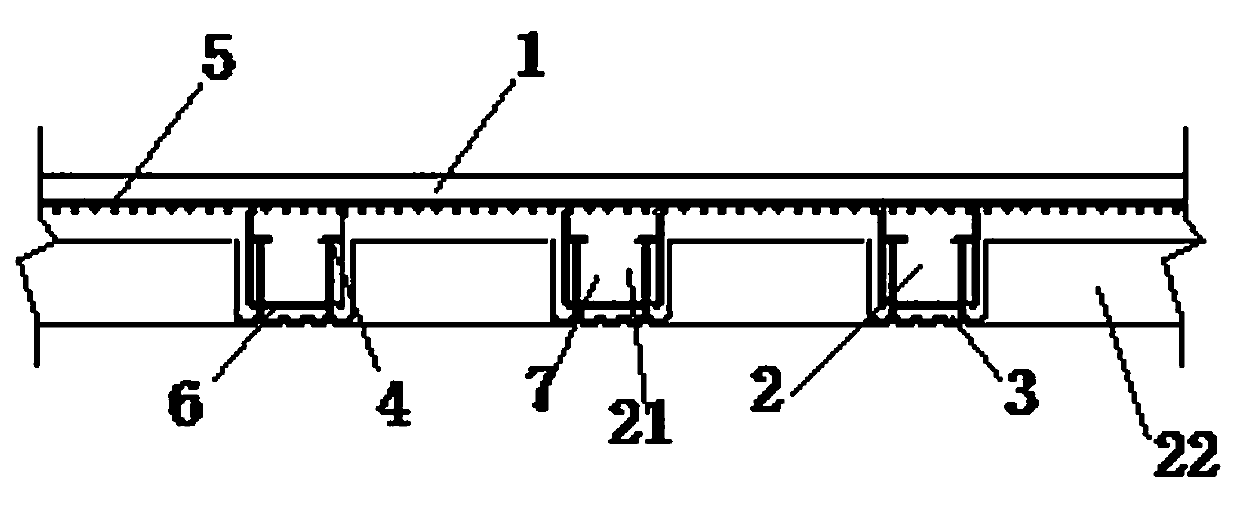

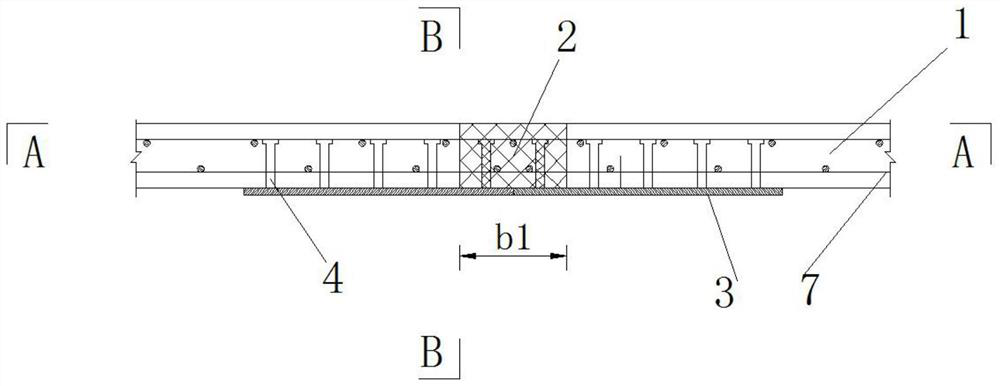

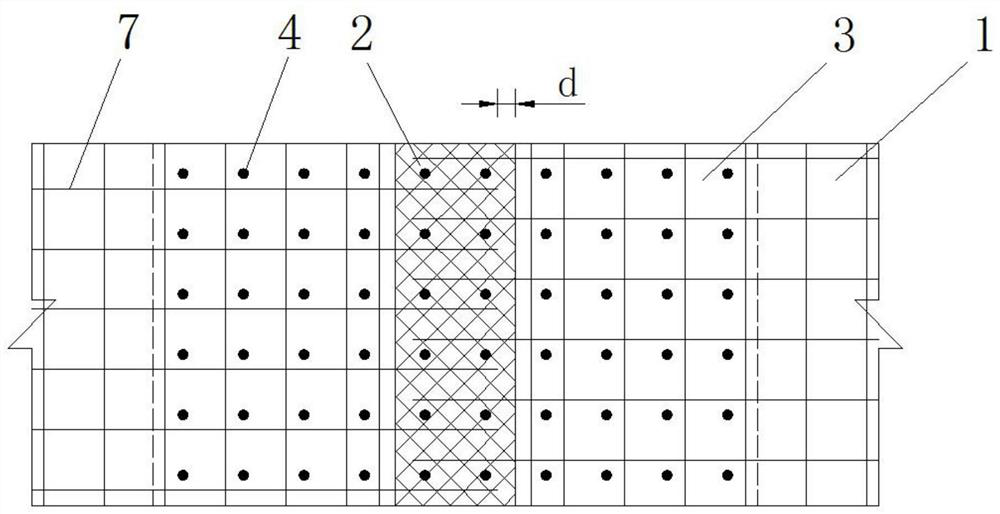

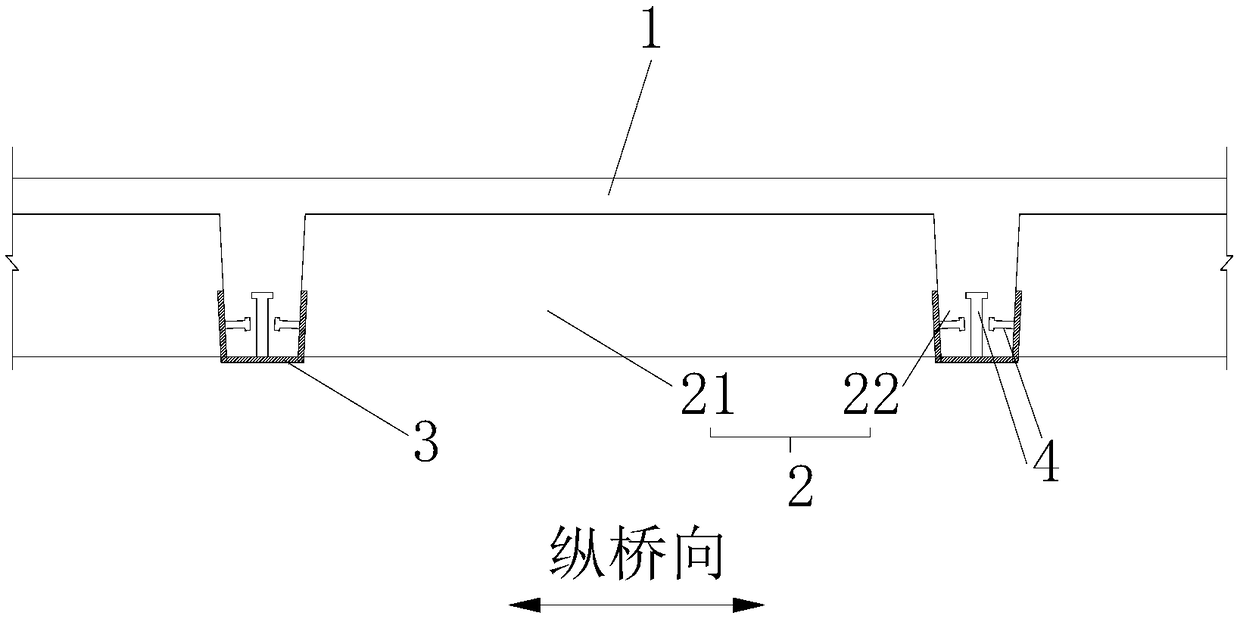

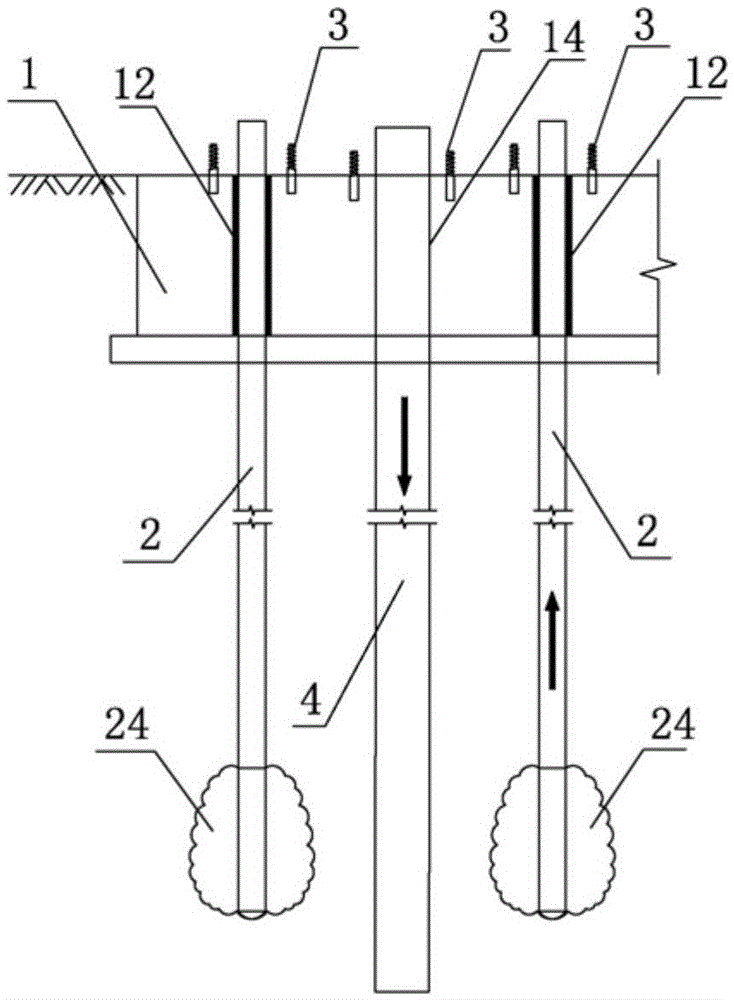

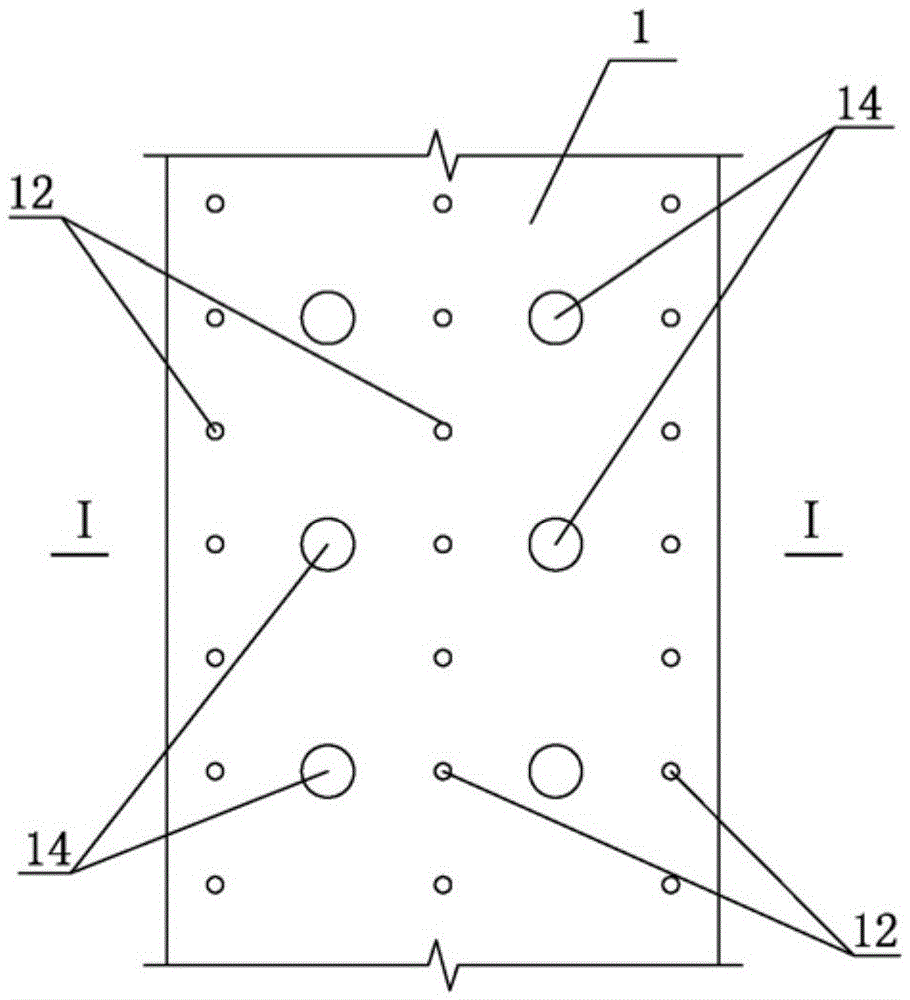

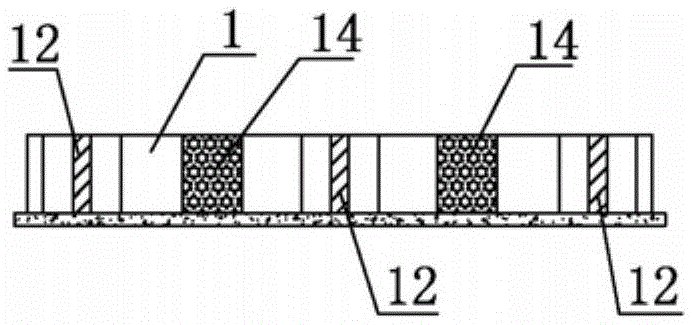

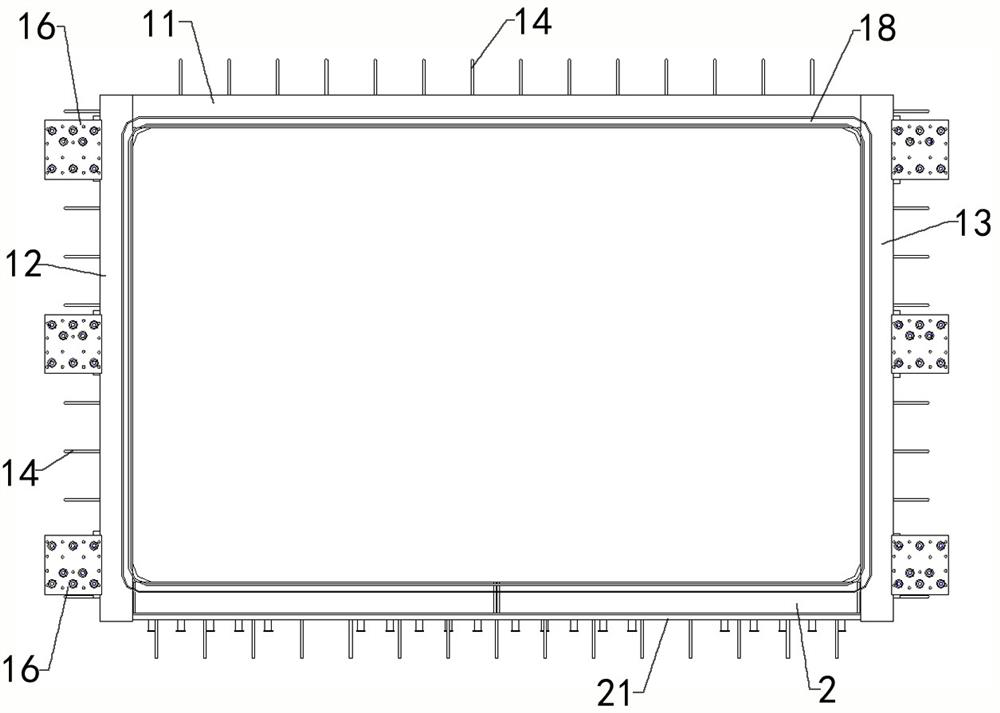

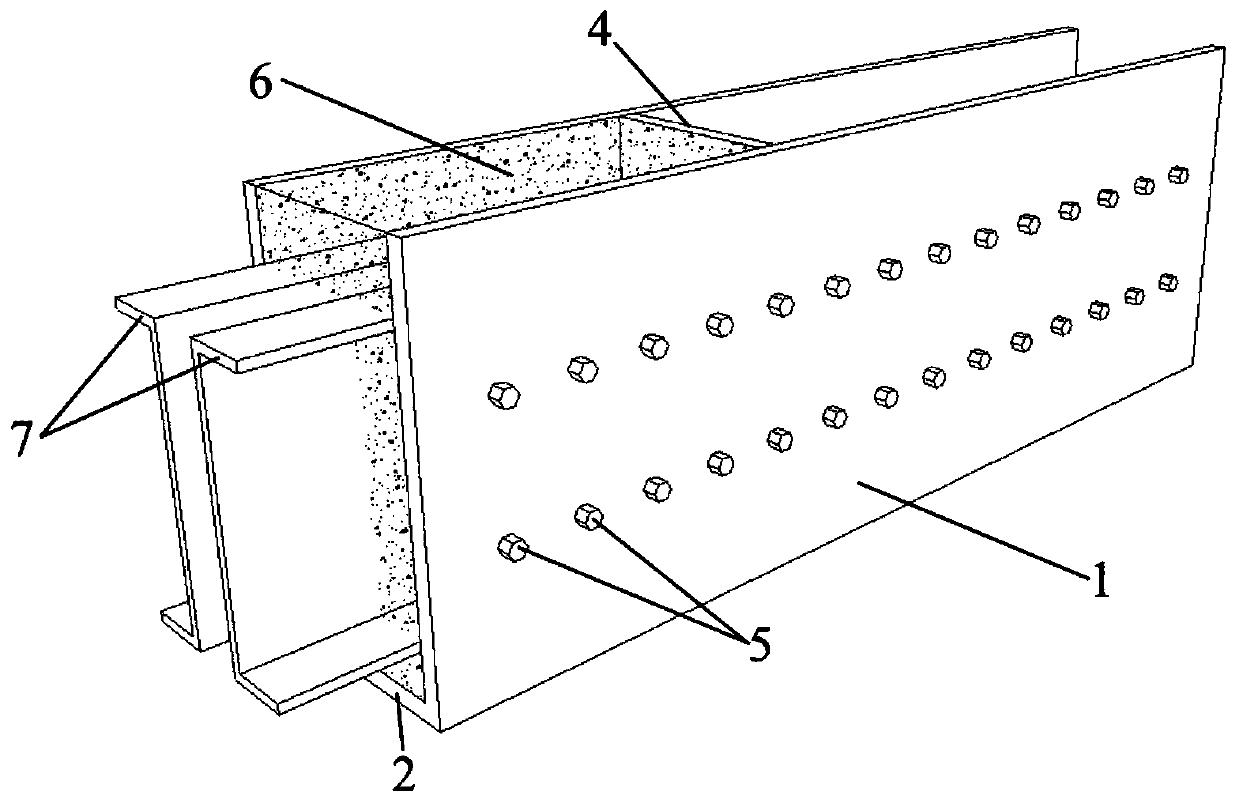

Cast-in-place joint structure of UHPC beam plate with embedded reinforcing steel components and construction method thereof

ActiveCN111705650AImprove local stiffnessGive full play to the tensile strengthBridge structural detailsBridge erection/assemblyBridge deckStructural engineering

The invention discloses a cast-in-place joint structure of a UHPC beam plate with embedded reinforcing steel components. The structure comprises a pair of adjacently-arranged prefabricated UHPC beam plates and a cast-in-place UHPC joint cast in place between the pair of prefabricated UHPC beam plates, wherein the bottom of each prefabricated UHPC beam plate is fixedly provided with an embedded reinforcing steel component extending to the cast-in-place UHPC joint, and the end parts of the adjacent embedded reinforcing steel components are fixedly connected; and the side wall of the end part ofthe prefabricated UHPC beam plate is provided with a latticed groove. The invention further provides a construction method of the cast-in-place joint structure of the UHPC beam plate with the embeddedreinforcing steel components. According to the invention, through the mutual synergistic effect of the latticed grooves and the embedded reinforced steel components, the latticed grooves and the embedded reinforced steel components are mutually matched, so that the problem of weak stress of the UHPC bridge deck wet joint connection can be effectively solved, the stress performance of the new andold UHPC interfaces is remarkably improved, the interfaces cannot crack under the action of service load, and the durability and the service performance of the structure are improved.

Owner:HUNAN UNIV

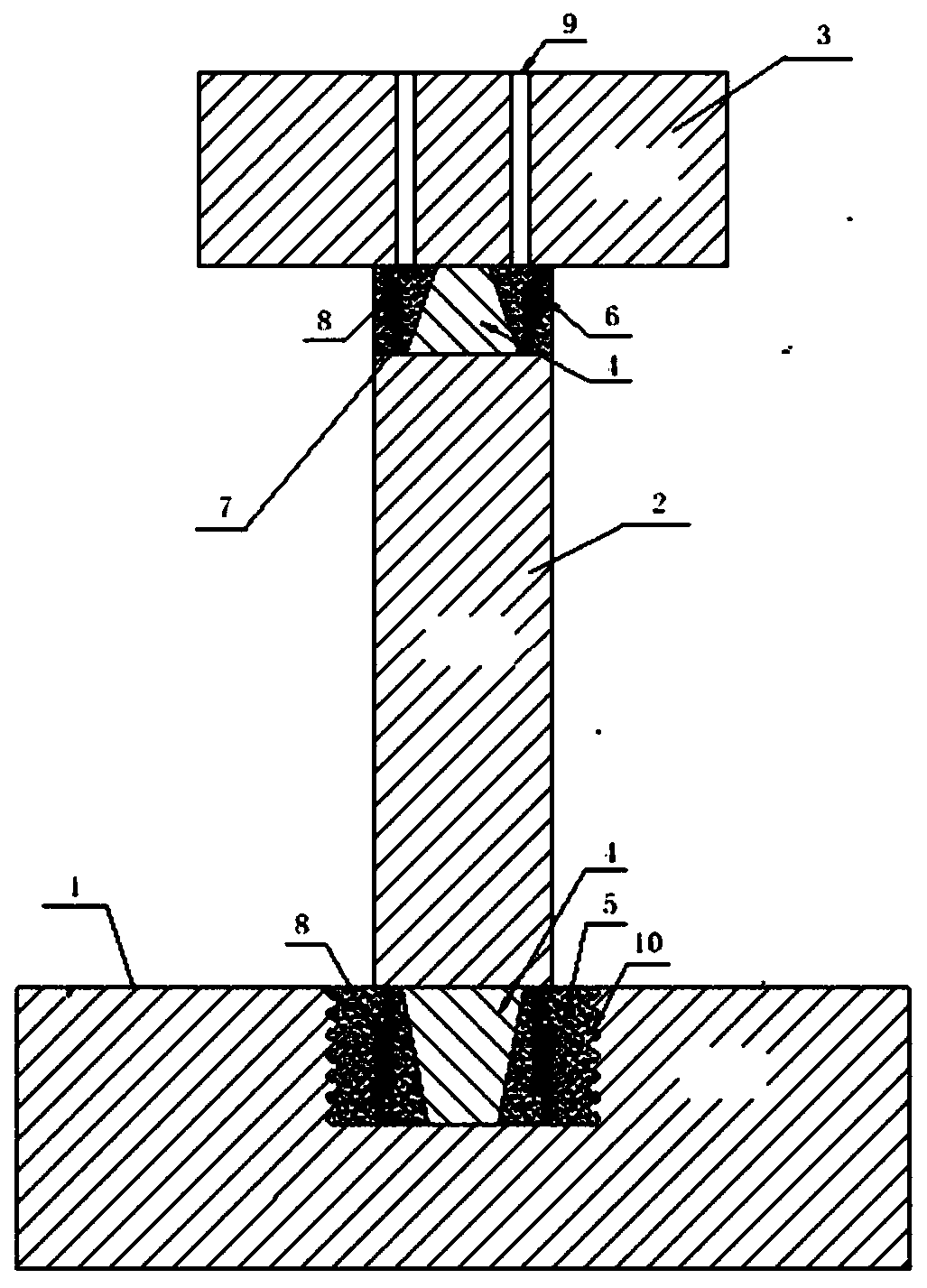

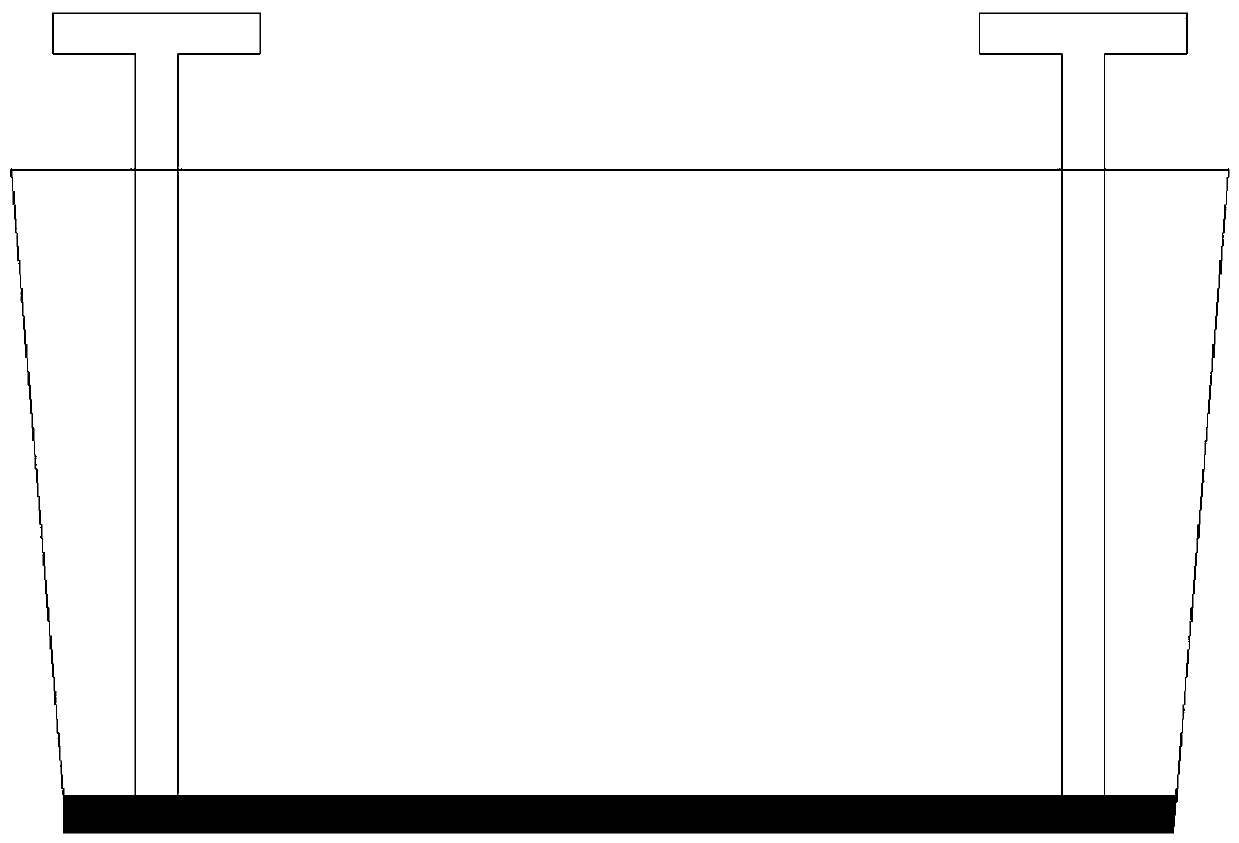

External structure suitable for prefabricated assembled pier stud connection and construction method thereof

PendingCN111485485AStable structureImprove seismic performanceBridge structural detailsFoundation engineeringArchitectural engineeringPier

The invention discloses an external structure suitable for prefabricated assembled pier stud connection and a construction method thereof. The external structure comprises a bearing platform, a pier body and a cover beam which are sequentially arranged from bottom to top; pouring spaces are formed between parts, corresponding to the cover beam and the bearing platform, of the upper end and the lower end of the pier body and are used for pouring concrete, and the cover beam, the pier body and the bearing platform form a fixed whole; the portions, correspondingly connected with the cover beam and the bearing platform, of the upper end and the lower end of the pier body are provided with reinforcing components respectively, and the reinforcing components arranged at the upper end and the lower end of the pier body are both located in the pouring spaces of the corresponding ends of the pier body. The external structure has the technical effects of being stable in structure, reliable in connection, convenient to adjust and capable of being rapidly installed, and can be widely applied to the field of building construction.

Owner:CCCC SECOND HARBOR ENG +1

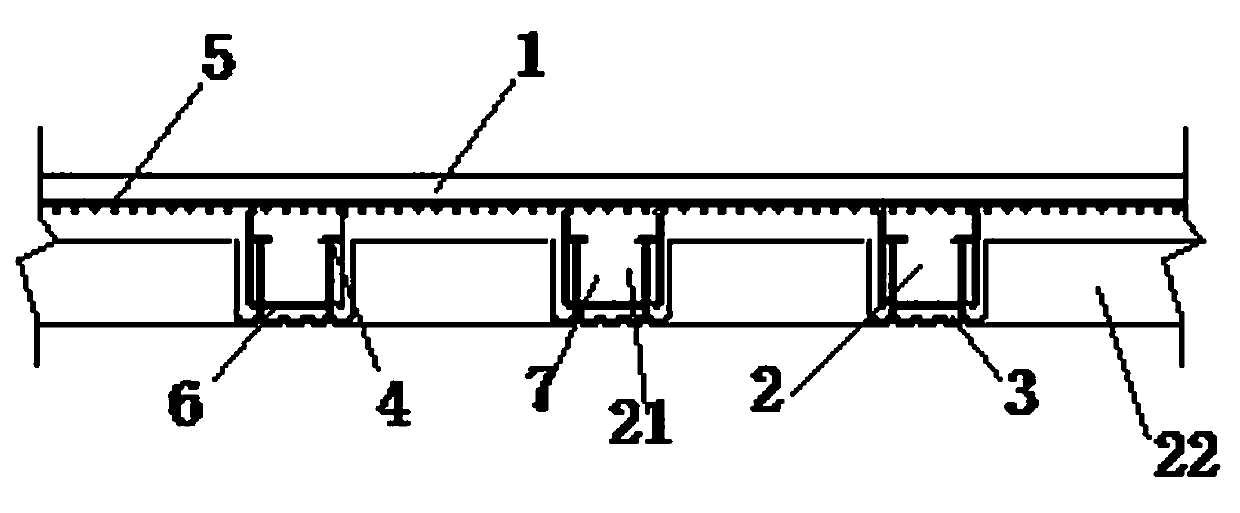

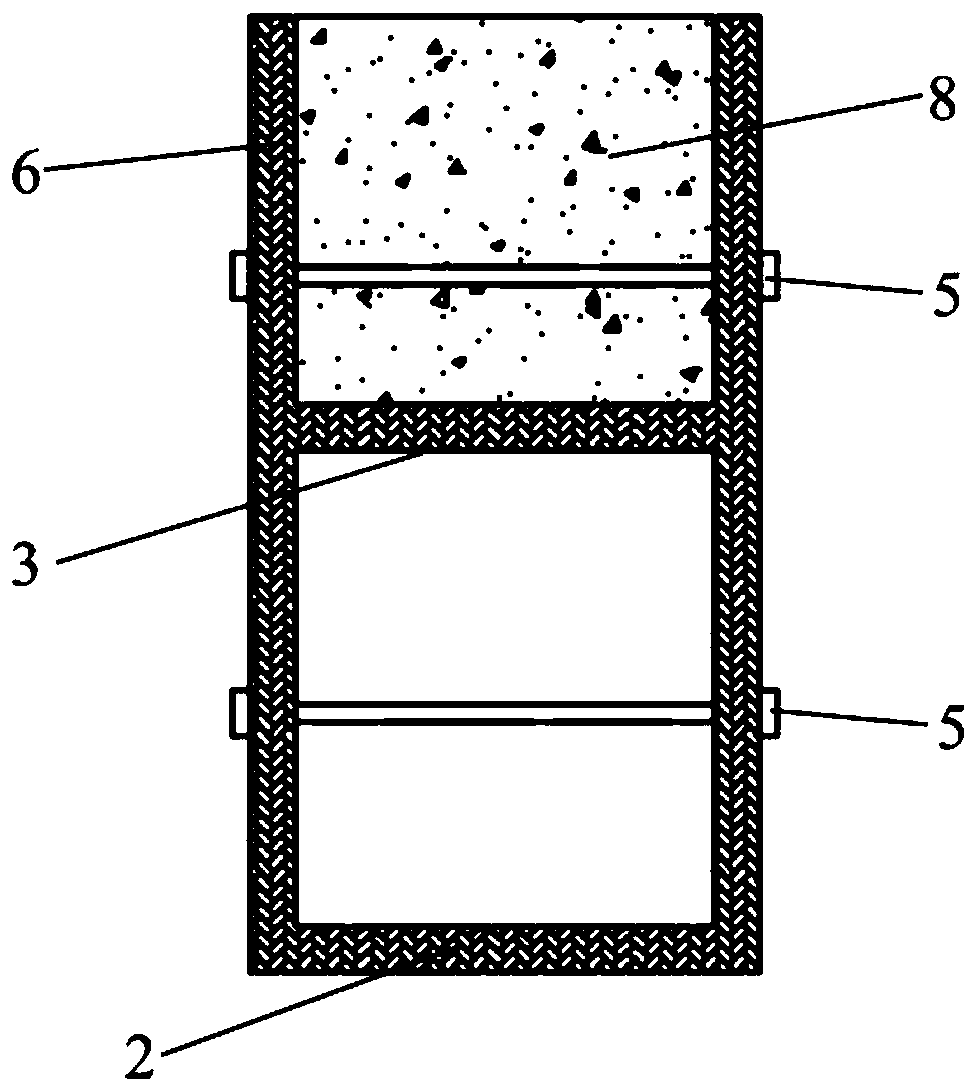

Ultra high performance concrete rib with rib bottom steel plate for bridge deck slab

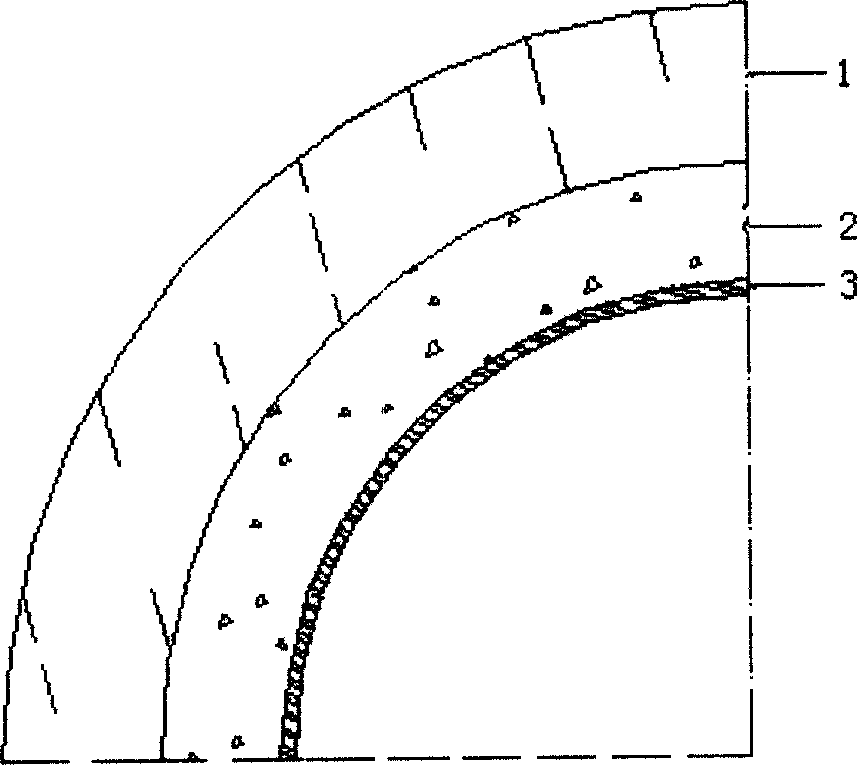

PendingCN109577188AGive full play to the resistance to pressureGive full play to the tensile strengthBridge structural detailsSheet steelBridge deck

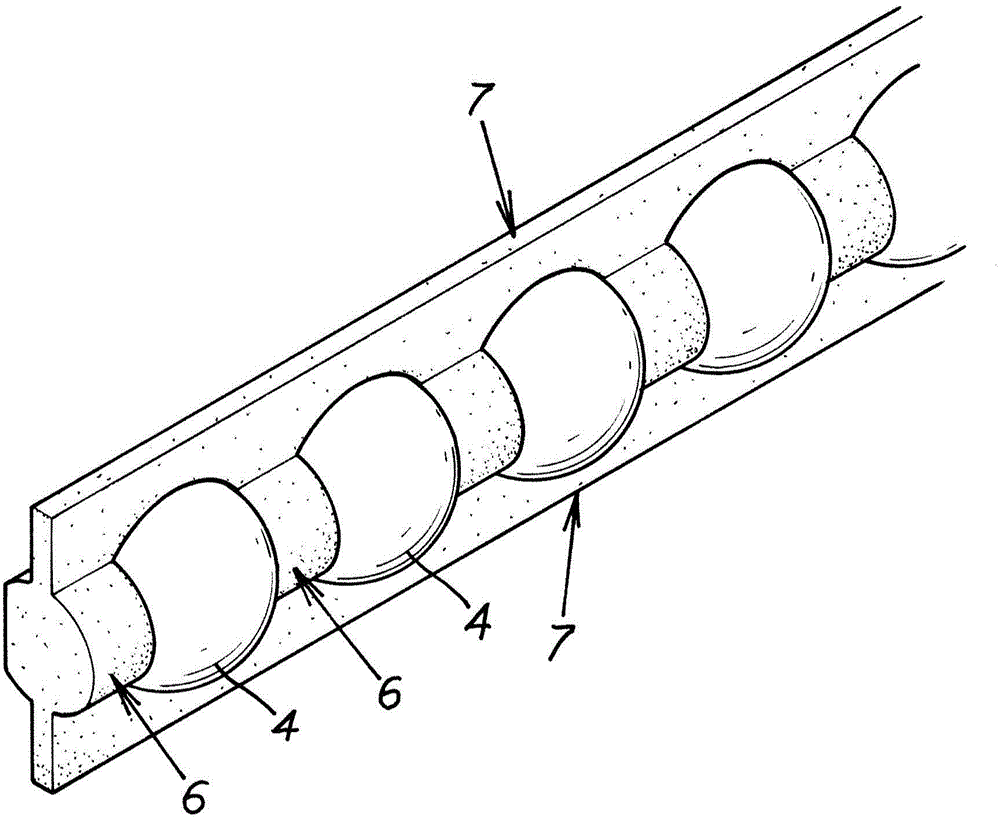

The invention provides an ultra high performance concrete rib with a rib bottom steel plate for a bridge deck slab. The ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab is mainly to solve technical problems, such as easy fatigue cracking, poorer tensile and compressive performance, low section utilization efficiency and high cost, of an existing ultra high performance concrete rib. The key point of the technical scheme is that the ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab comprises a rib body (7) andthe rib bottom steel plate (3); the rib bottom steel plate (3) is arranged at the bottom of the rib body (7); a shear connector (4) is arranged on the upper surface of the rib bottom steel plate (3);ultra high performance concrete is poured around the shear connector (4) on the rib bottom steel plate (3) to form the rib body (7); and the upper part of the shear connector (4) is connected with areinforcing mesh in a panel (1). The ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab is mainly used for the bridge deck slabs.

Owner:HUNAN UNIV +1

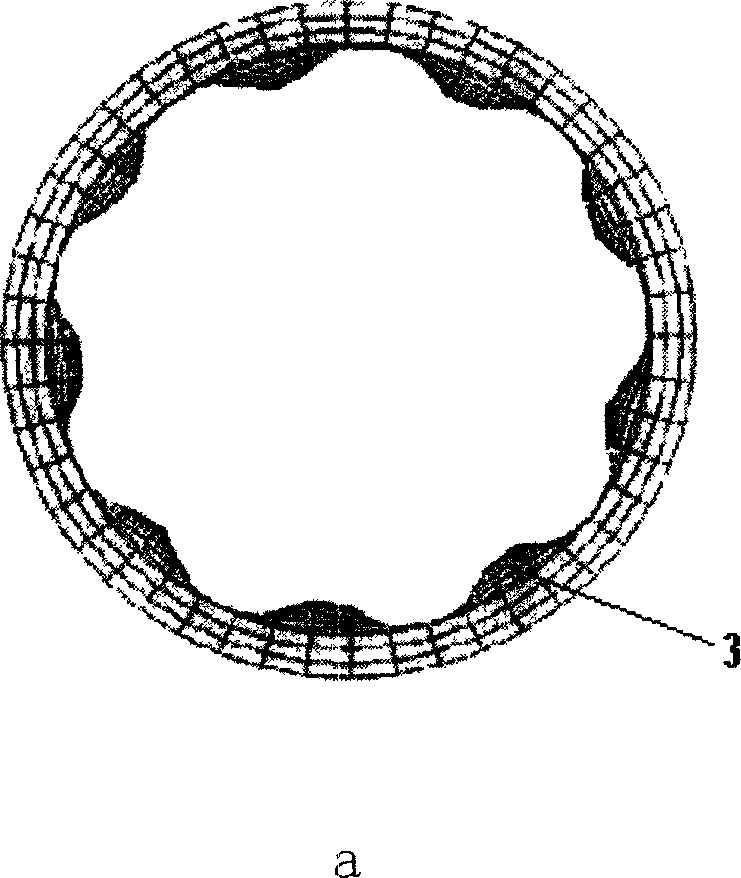

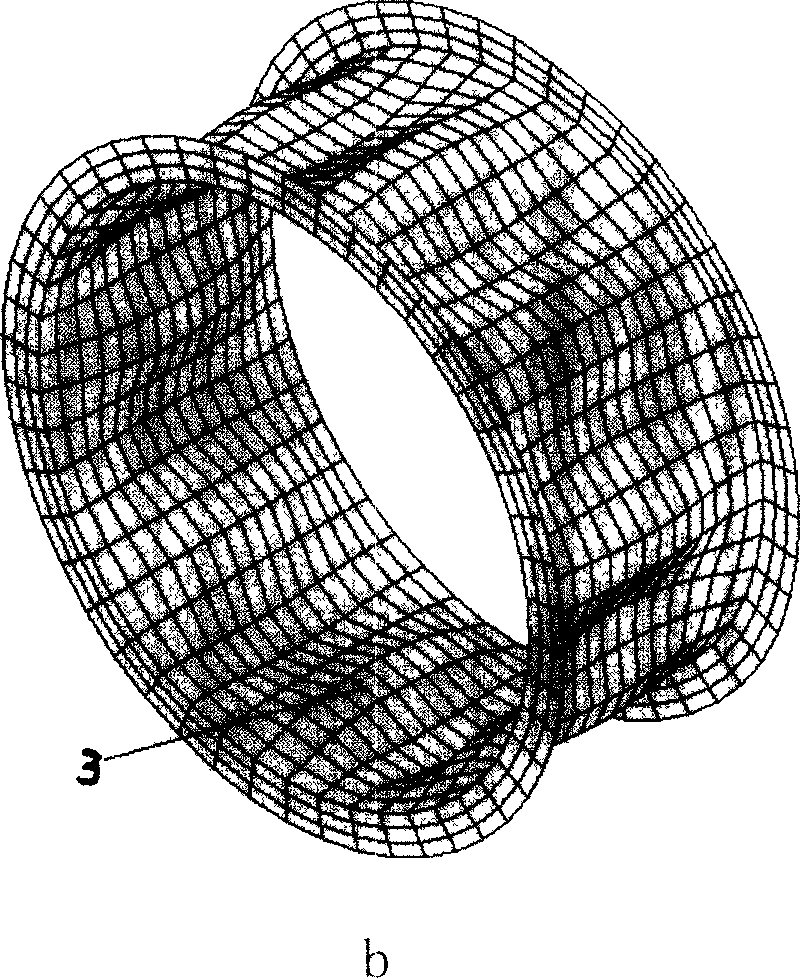

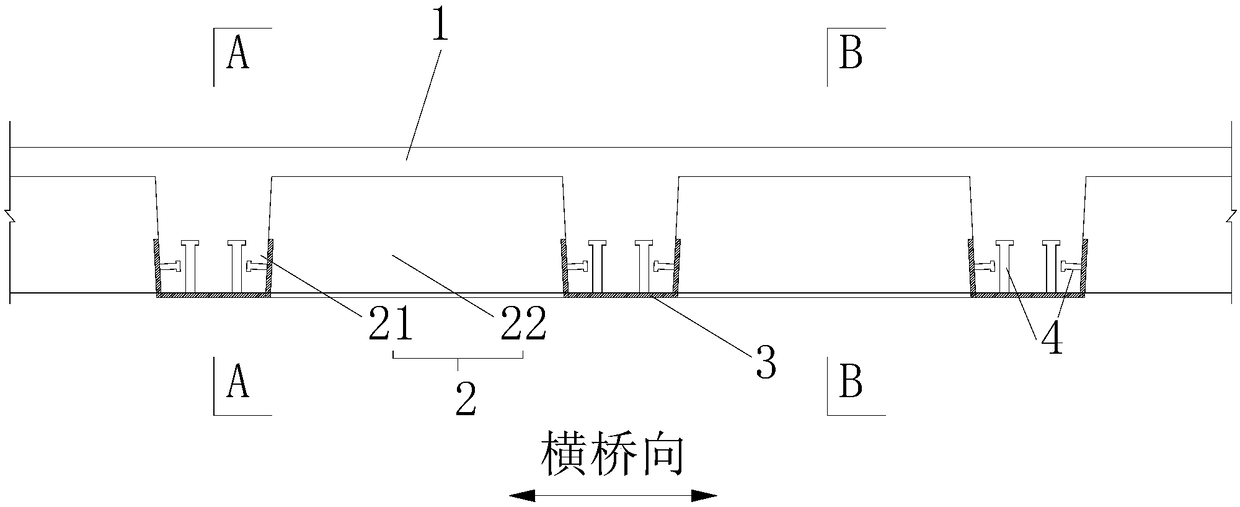

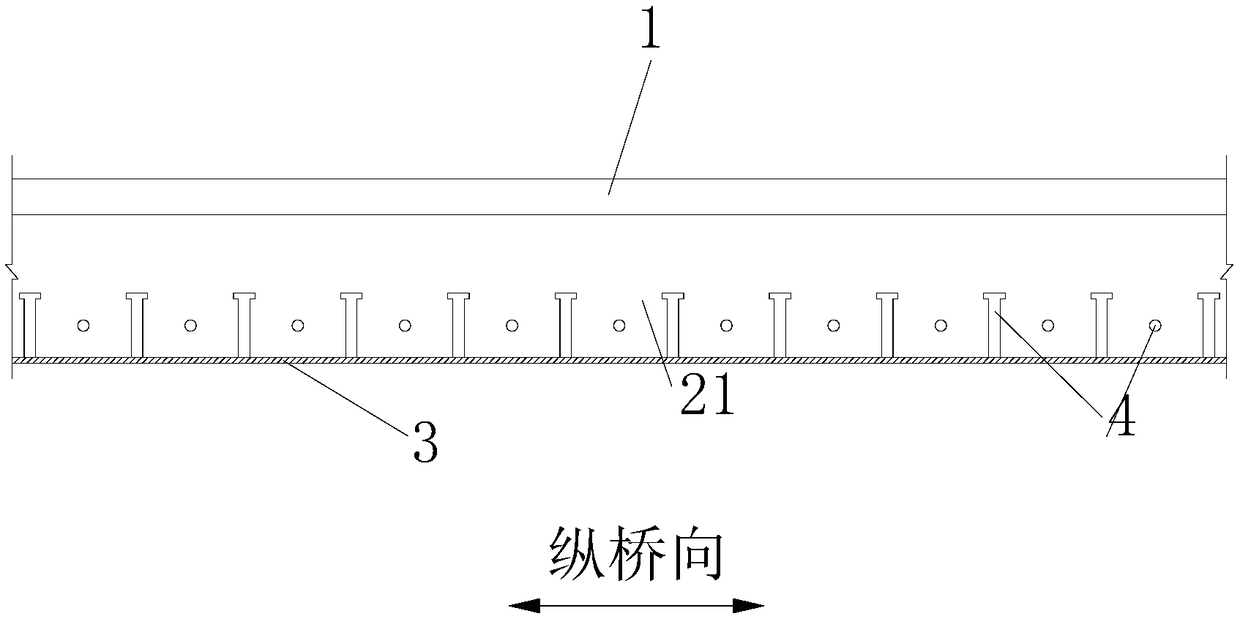

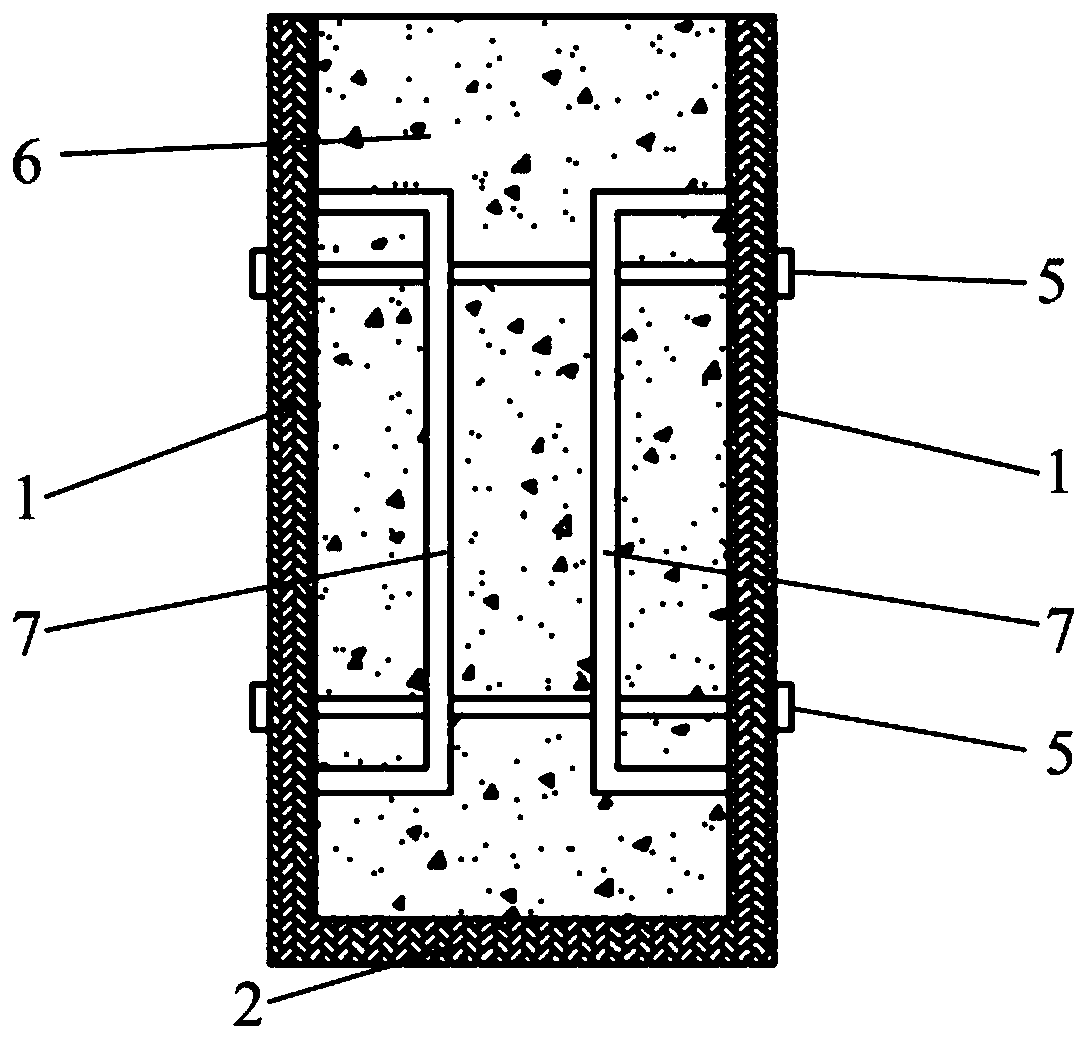

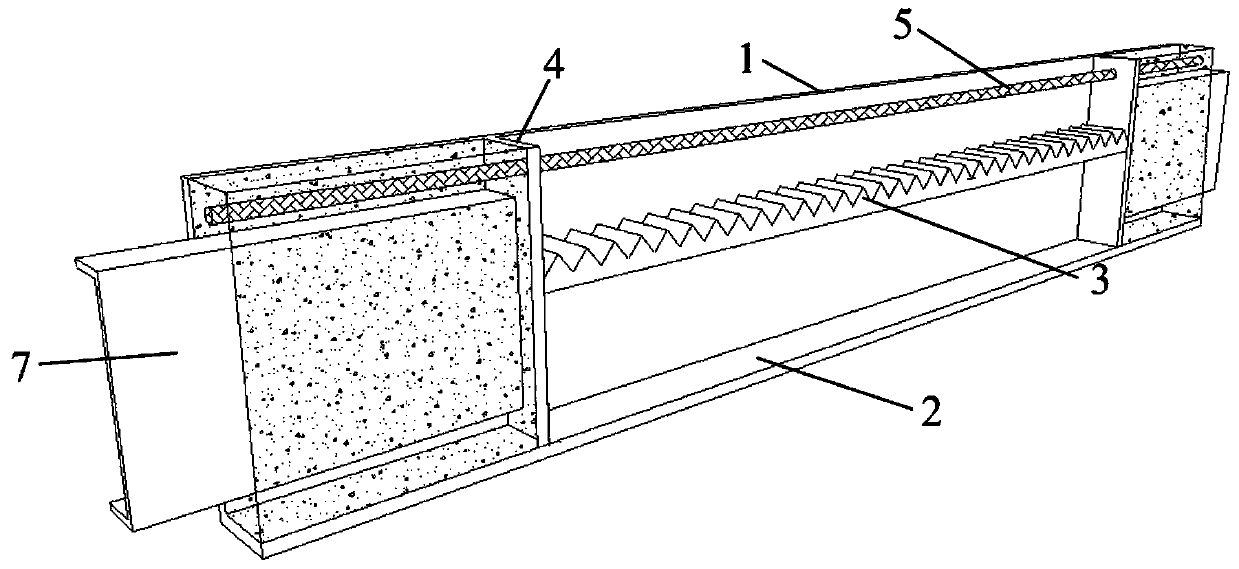

Lightweight steel-ultrahigh-performance concrete stiffened combination rib plate and construction method thereof

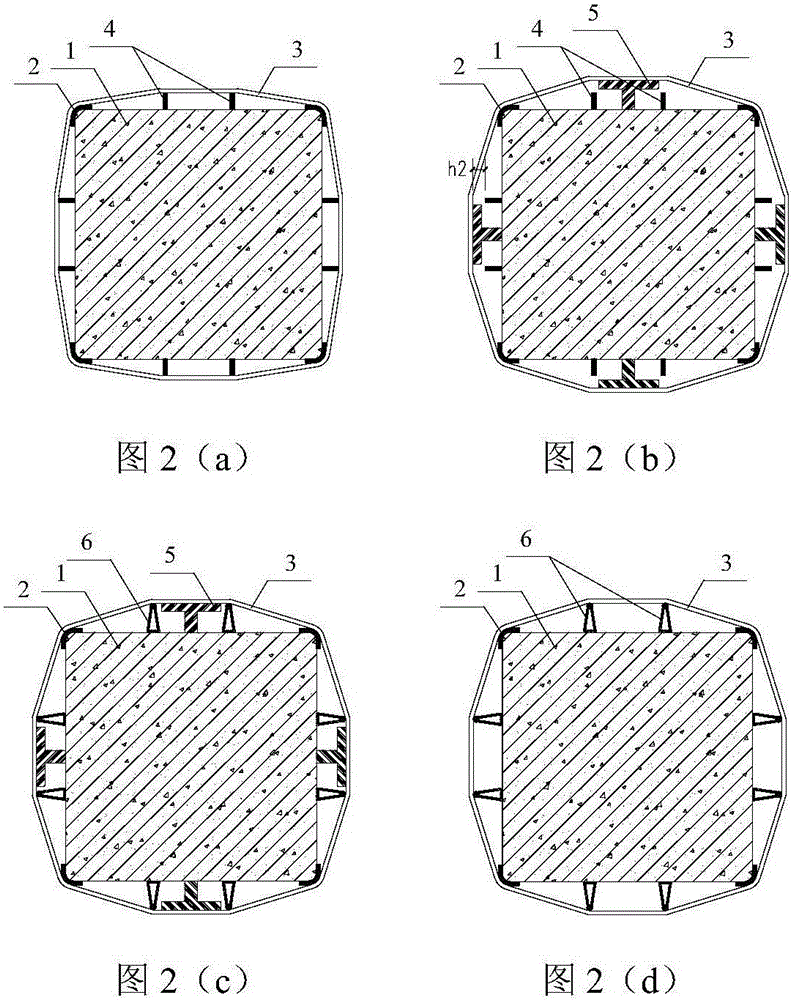

PendingCN109356016AIncrease the moment of inertiaIncrease stiffnessBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a lightweight steel-ultrahigh-performance concrete stiffened combination rib plate and a construction method thereof. The combination rib plate comprises a panel (1), a slab rib (2), a stiffened strengthening component (3) and a shear connecting part (4), the stiffened strengthening component (3) is arranged on the bottom of the slab rib (2) and has the equal width with thebottom face of the slab rib (2), the slab rib (2) and the stiffened strengthening component (3) are connected into a whole through the shear connecting part (4), the top of an edge plate rib on the edge of the combination rib plate is provided with a notch (5), and a plurality of wedge-shaped ports (6) are formed under the notch (5) in the length direction of the edge plate rib. The lightweight steel-ultrahigh-performance concrete stiffened combination rib plate and the construction method thereof have the advantages that the problem that the steel-ultrahigh-performance concrete rib plate fatigues and cracks easily is solved, the crack resistance of a wet joint between precast slabs is significantly improved, the excellent tensile and compressive properties of ultrahigh-performance concrete and steel material can be fully utilized, the structural self-weight is lighter, the utilization efficiency of the cross section is higher, the integral and local rigidity of a bridge deck slab ofthe stiffened combination rib plate is higher, the anti-crack and anti-overload capacity is strong, and the construction is convenient.

Owner:HUNAN UNIV +1

An anchor static pressure pile device with self-sufficient pressure pile reaction force and its construction method

ActiveCN104060610BSmall towing settlementGive full play to the tensile strengthBulkheads/pilesSlurryPipe

The invention relates to an anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and a constructing method of the anchor-arm static-pressure pile device, and aims to provide the anchor-arm static-pressure pile device with the self-sufficient pile pressing counter-force. When an indoor construction pile foundation cannot provide a pile pressing counter-force, construction requirements can be realized by self-sufficient pile pressing counter-force, so that the efficiency is high, the cost is relatively lower, and pollution to the environment is avoided. The anchor-arm static-pressure pile device adopting steel pipe piles of which the pile tips are filled with slurry to provide counter-force comprises a pressure pile baseplate, the steel pipe piles and anchors, wherein anchor-arm static-pressure pile pressing holes and steel pipe pile pressing holes are formed in the pressure pile baseplate; the steel pipe piles are inserted through the steel pipe pile pressing holes and pressed to a certain depth; the slurry is arranged in the pile tips of the steel pipe piles; the tops of the steel pipe piles are connected with the press pile baseplate through grouting material tamping; the anchors are arranged outside the steel pipe pile pressing holes and the anchor-arm static-pressure pile pressing holes respectively, connected with a press pile counter-force rack and used for pressing the steel pipe piles or anchor-arm static-pressure piles to certain depths.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG +1

Smooth FRP bar anchoring method

ActiveCN111024491AAvoid pinchingAvoid direct clampingMaterial strength using tensile/compressive forcesFiberEngineering

The invention discloses a smooth FRP (fiber reinforced plastic) bar anchoring method which comprises the following steps: 2-4 kerfs for dividing an anchoring end of a smooth FRP bar into a plurality of parts capable of being opened are formed in the anchoring end of the smooth FRP bar along the axial direction of the bar from the end surface; filler is arranged among a plurality of expandable parts of the anchoring end to enable the anchoring end to form an expanded end, and the expanded end is anchored through a sleeve arranged at the anchoring end in a sleeving mode. The sleeve is a steppedinner-diameter sleeve and comprises a sleeve free end and a sleeve loading end, and the inner diameter of the sleeve free end is larger than that of the sleeve loading end; the expanded end is a conical expanded end; a resin-quartz sand mixture is poured into a gap between the free end of the sleeve and the conical expanded end, and the gap between the loading end of the sleeve and the smooth FRPbar is filled and cured with resin. According to the smooth FRP bar anchoring method, anchoring and connecting of the smooth FRP bars can be effectively and reliably achieved, the tensile strength ofthe smooth FRP bars is brought into full play, and the smooth FRP bars are subjected to ideal middle section complete explosion breaking type damage.

Owner:SOUTHEAST UNIV

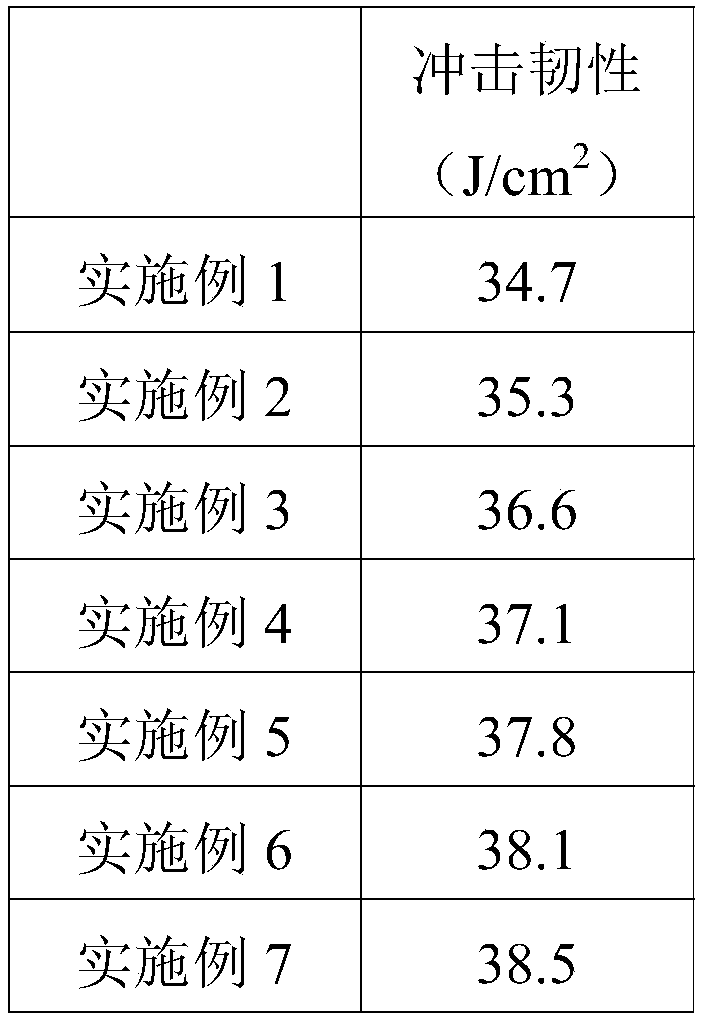

Low-temperature-resistant asphalt concrete and preparation method thereof

PendingCN111056768APerformance is not affectedGive full play to the tensile strengthAsphalt concreteFatigue resistance

The invention discloses low-temperature-resistant asphalt concrete and a preparation method thereof. The low-temperature-resistant asphalt concrete is prepared from the following substances: coarse aggregate, fine aggregate, mineral powder, asphalt and diatomite. The low-temperature-resistant asphalt concrete disclosed by the invention has outstanding ageing resistance and fatigue resistance; thelow-temperature-resistant concrete has the advantages that good temperature resistance is kept under high and low temperature conditions, cracking of the low-temperature concrete is avoided, excellentfatigue resistance and loosening and cracking resistance are achieved especially in low-temperature seasons and weather alternation seasons of a seasonal freezing area or a cold temperature area, theservice life of the concrete is prolonged, and the preparation is convenient.

Owner:罗登峰

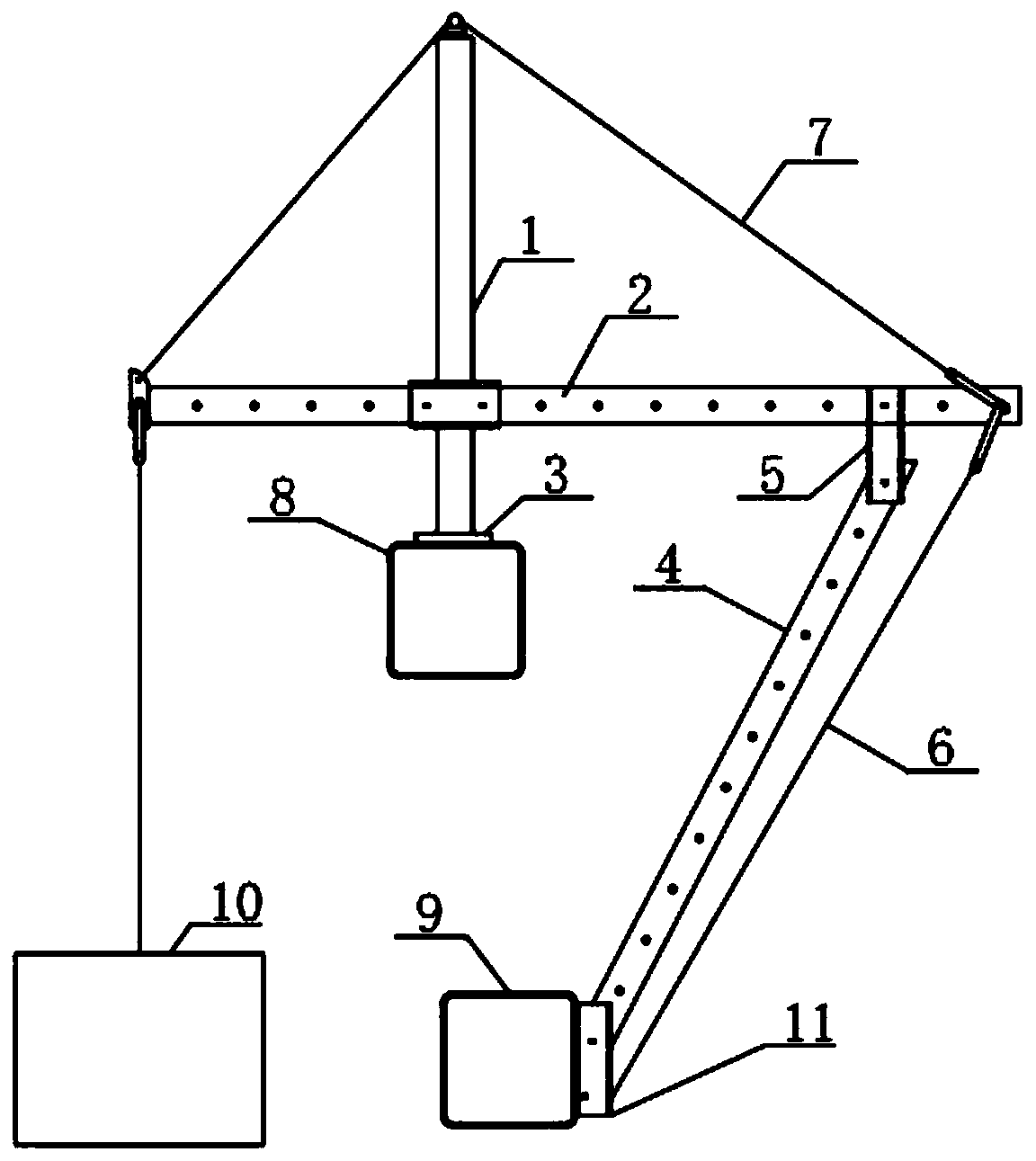

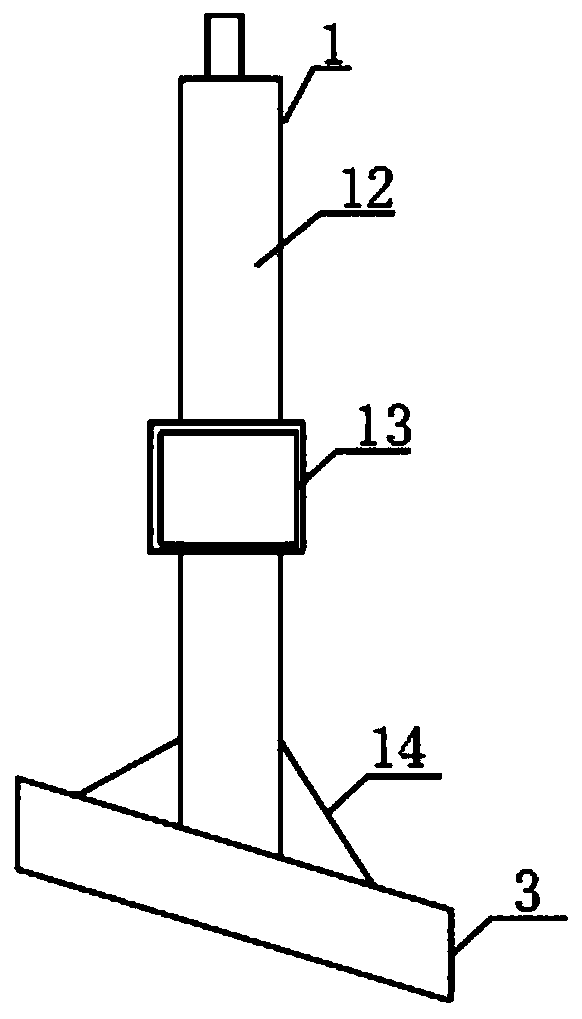

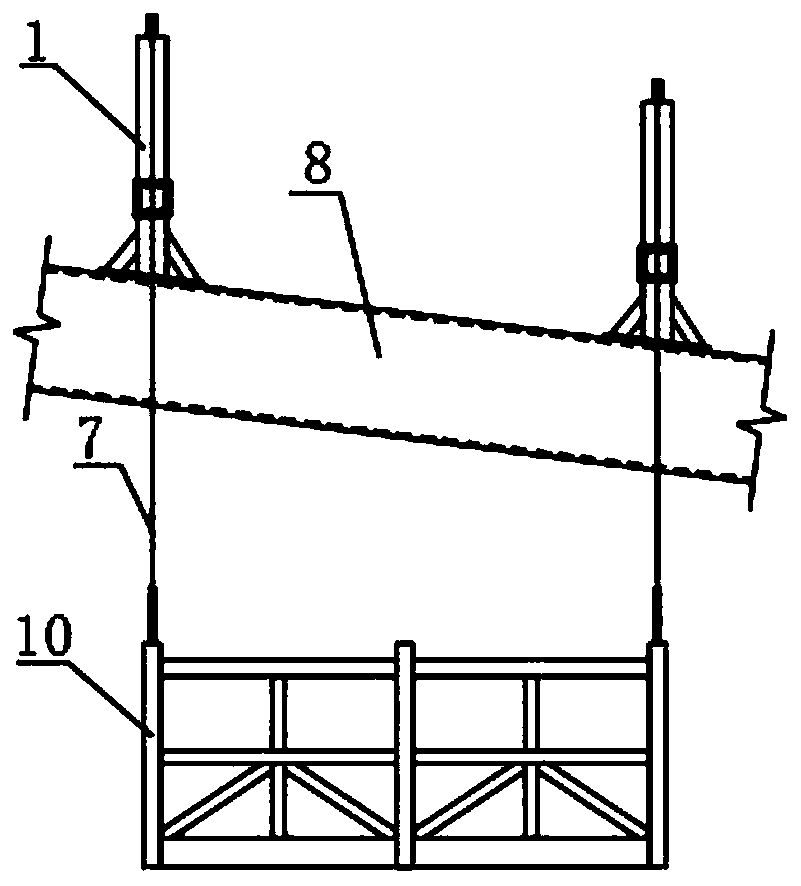

Hanging basket hanging mechanism for steel structure oblique beam and construction method of hanging basket hanging mechanism

PendingCN110029808ASave spaceReduce intensityWindow cleanersScaffold accessoriesSteel platesSteel tube

The invention discloses a hanging basket hanging mechanism for a steel structure oblique beam. The hanging basket hanging mechanism comprises a supporting vertical column, the supporting vertical column comprises a square steel pipe, a steel sleeve is welded to the position, close to the lower part, of the middle of the inner side of the square steel pipe, a steel plate base is welded to the bottom end of the supporting vertical column, stiffening steel plates are connected between the two side walls of the supporting vertical column and the top end of the steel plate base, an oblique steel beam is welded to the bottom end of the steel plate base, a crossbeam is connected to the inner surface of the steel sleeve in a sleeving mode, the upper end of the supporting vertical column is connected with a main steel wire rope, one end of the main steel wire rope is connected with an electric hanging basket, the other end of the main steel wire rope is fixedly connected with the rear end of the crossbeam, the rear end of the crossbeam is connected with a connecting part, the rear end of the connecting part is connected with the limiting oblique beam, and a lug plate is connected to the position, close to the lower part, of the front end of the limiting oblique beam. The hanging basket hanging mechanism for the steel structure oblique beam is easy and convenient to mount, convenient toconstruct, high in humanization degree, low in cost and suitable for being used and promoted.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

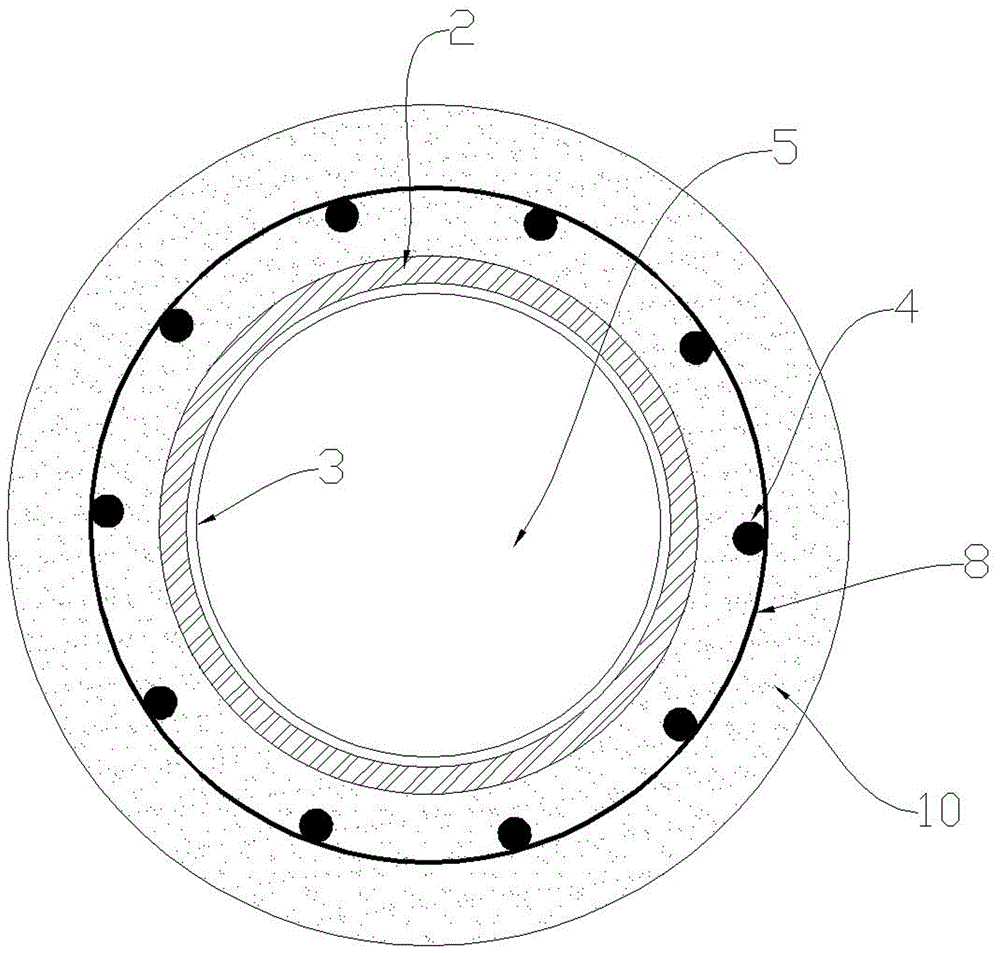

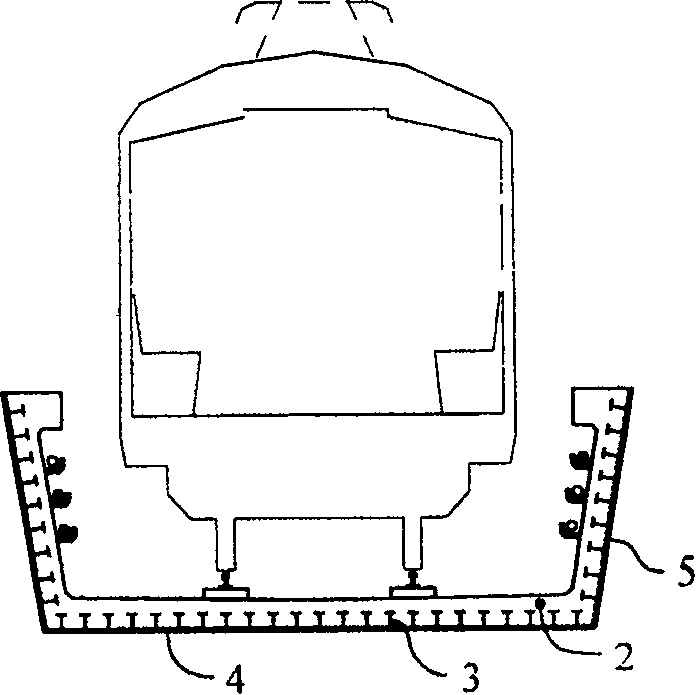

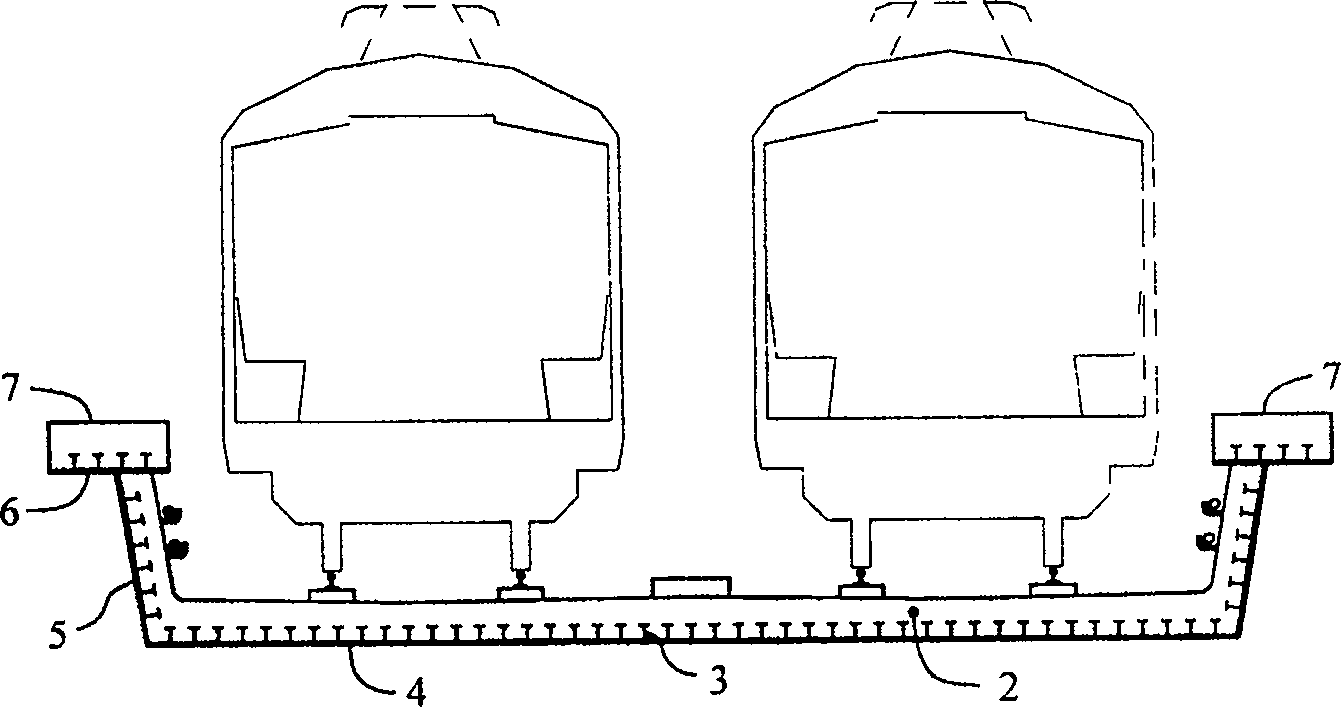

Composite pile combining reinforced concrete bored pile with pneumatic prestressed steel pipe pile

ActiveCN106759294AGive full play to the tensile strengthImprove bearing capacityBulkheads/pilesPile capReinforced concrete

The invention relates to a composite pile combining a reinforced concrete bored pile with a pneumatic prestressed steel pipe pile. The composite pile is mainly used as a pile foundation in the field of constructional engineering. The reinforced concrete bored pile and the pneumatic prestressed steel pipe pile are combined for bearing force together, thus the bearing capacity of the pile foundation is increased, and the tensile property of steel can be fully exerted. The composite pile is mainly composed of the pneumatic prestressed steel pipe pile, the reinforced concrete bored pile, a pile cap and anchor steel bars, wherein the steel pipe pile is mainly composed of a fore transmission cover, a drum body, a pneumatic membrane, an empty chamber and an air inlet pipe, and the reinforced concrete bored pile is mainly composed of vertical bearing force steel bars, stirrups and a pile body. The main construction method of the composite pile comprises the steps: constructing a pile hole, and then pouring concrete of the pile body; sinking the steel pipe pile and a steel bar cage together to a preset elevation, then continuing to pour the concrete of the pile body to a designed elevation, constructing the pile cap, and finally inputting high-pressure air into the air inlet pipe of the steel pipe pile. After the pressure value of the high-pressure air in the empty chamber reaches a preset value, the air inlet pipe is closed, and the pile foundation construction is completed.

Owner:启东霓辉新材料科技有限公司

Grooved steel-concrete combination beam

The invention relates to a groove steel-concrete integration beam, belonging to the bridge support element area, which can be used in track bridge; railway bridge; and road Bridge. The invention comprises a steel box beam whose top is open, concrete filled in the inner side of steel box beam and the anti-cutting connection element welded on the inner side of steel box beam. wherein, said open steel box beam is formed by a bottom plate and a middle plate, whose sections are in U or W shape; the anti-cutting connection element can integrate the steel beam and the concrete as a whole to display the anti-compression property of concrete; the steel plate can resist the pulling stress of each direction and avoid surface breakage; and the anti-cutting connection element can transfer the shearing force between steel box beam and concrete and avoid their separation. The invention has the advantages of simple operation, application of avoiding surface breakage and wider application prospect, as well as the advantages of initial stress concrete groove beam.

Owner:TSINGHUA UNIV

Double-leaf steel structure arch pulling plate protective air-tight door and air-tight method thereof

InactiveCN112112530AReduce weightReduce thicknessWing accessoriesFrame fasteningDoor thresholdClassical mechanics

The invention relates to the technical field of civil air defense engineering, and discloses a double-leaf steel structure arch pulling plate protective airtight door. The door comprises a door frameand left and right double arched door leaves, the door frame comprises a fixedly-arranged door-shaped frame and a detachably-arranged movable threshold, and each arched door leaf is provided with a set of locking system. The fixed ends of the arched door leaves are rotatably connected with the two sides of the door frame through hinge assemblies, each hinge assembly comprises hinge bases used forbeing connected with the door frame, a concentric pipe, hinge shafts and connecting bases, the concentric pipes and the hinge shafts are longitudinally connected with the adjacent hinge bases, and theconnecting bases are used for being connected with the arched door leaves. The hinge shafts are coaxially connected with the concentric pipes and vertically arranged in the axial direction, one end of each hinge shaft is rotationally connected with the corresponding hinge bases, and the other ends of the hinge shafts are inserted into the concentric pipes and fixed. The two ends of each concentric pipe are inserted and fixedly connected with the corresponding hinge shafts on the two sides. The hinge shafts at the bottoms are rotationally connected with bearing bases, and ball mechanisms and thrust bearings are arranged below the bearing bases. The door is good in air-tight performance and has higher resistance, and construction and use are convenient.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

SCS combined hydropower station pressure underground pipe design method

The invention discloses a way to design pressing tube of SCS combined hydraulic power station. Between the steel inside and the round wall fill concrete tube, between the concrete tube and the round wall fill the outside steel tube. The outside steel tube is anti-seepage , the middle concrete tube resists external pressure, and the inside steel tube only resists water pressure inside when operating. It decrease by large the content of steel and concrete and the cost, and it is convenient to transfer the water pressure from inside to outside. The way of design brings the good capability of steel and concrete into play, and apt to the work environment very well. Otherwise, in operation there is no need to add other ways, so it increases the speed of the operation by large.

Owner:XIAN UNIV OF TECH

Lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam

The invention discloses a lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam. The fabricated beam is jointly composed of a middle FRPhollow box-groove section beam section and a pre-poured concrete filled beam section at both ends. The middle FRP hollow box-groove section beam section comprises a lower FRP box chamber and an upperFRP groove, a box-groove partition plate between the lower hollow box chamber and the upper groove adopts an FRP corrugated plate, and corrugations on the plate are used as shear-resisting connectingkeys between an FRP and the concrete. According to the lightweight fabricated reinforced box-groove-shaped FRP profile and sea sand concrete beam, the beam weight is decreased through the two aspectsof materials and structure, transportation is convenient, fast and reliable connection can be achieved with the plate and the column, construction is convenient and fast, good adaptability to severeengineering environments with severe corrosion such as coastal ports is achieved, and the good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

Fabricated box and slot type FRP sectional material light fiber sea sand concrete beam

The invention relates to a fabricated box and slot type FRP sectional material light fiber sea sand concrete beam. A main body of a fabricated beam is constituted by an FRP hollow box and slot sectionbeam section in the middle and precast concrete filled beam sections at the two ends jointly; and the FRP hollow box and slot section beam section in the middle comprises a lower FRP box chamber andan upper FRP slot, an FRP corrugated plate is adopted as a box and slot partition plate between the lower hollow box chamber and the upper slot, and on-plate corrugations are adopted as anti-shear connecting keys between FRP and concrete. According to the main body of the fabricated beam, the self-weight of a beam body is reduced from the two aspects of material and structure, thus transporting isconvenient, the beam can be quickly and reliably connected with the plate and a column, construction is easy, convenient and rapid, good adaptability to the severe engineering environments, with serious corrosivity, such as coastal ports is achieved, and good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

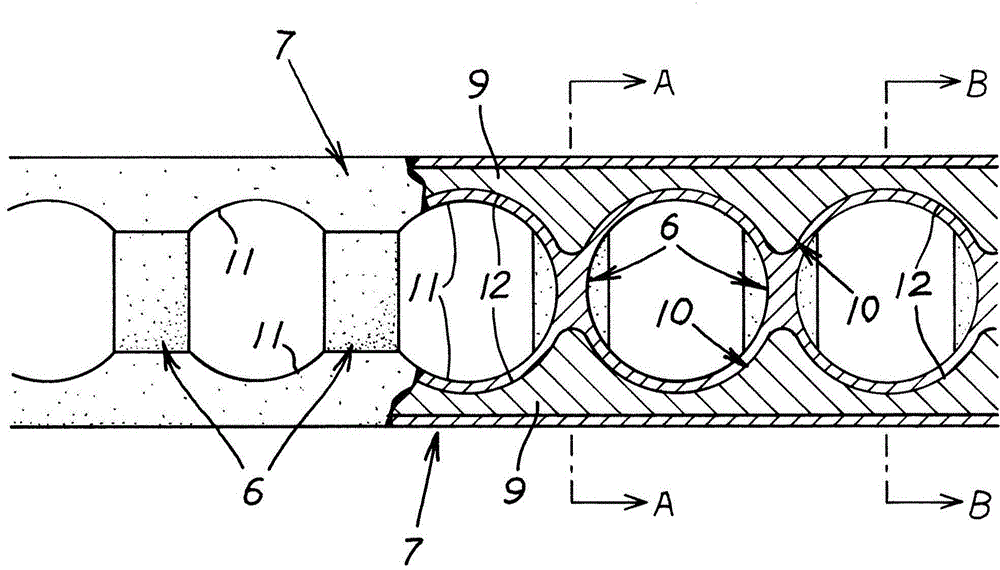

Rolling element accommodating tool

InactiveCN104019127AGive full play to the tensile strengthLinear bearingsShaftsLinear motionEngineering

Owner:NIPPON BEARING

Unidirectional tension metal sheet space structure and construction method

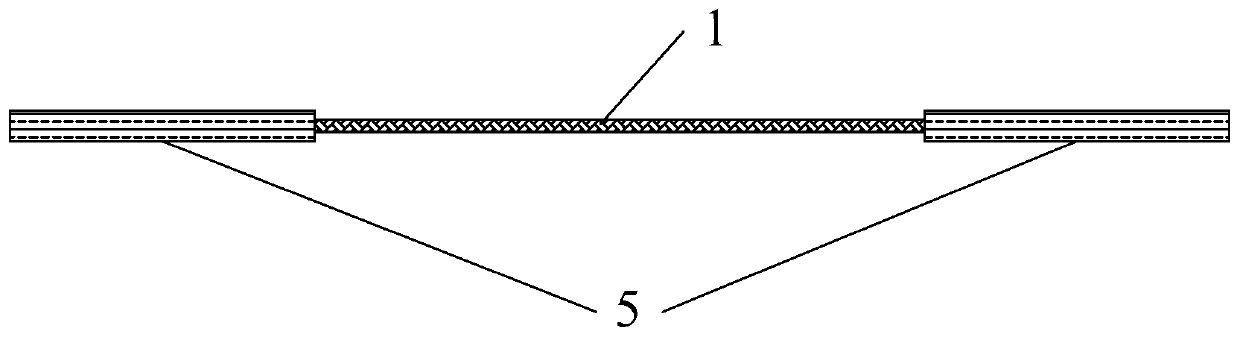

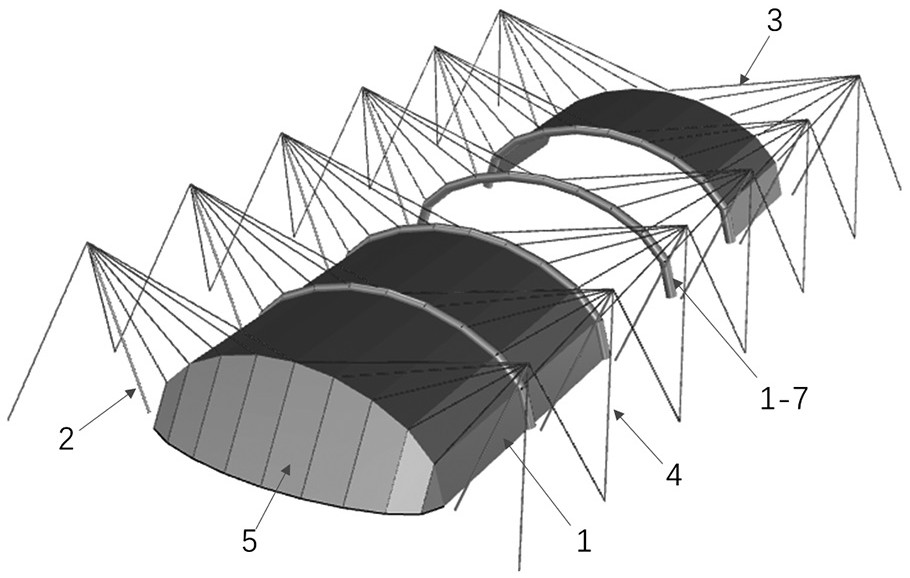

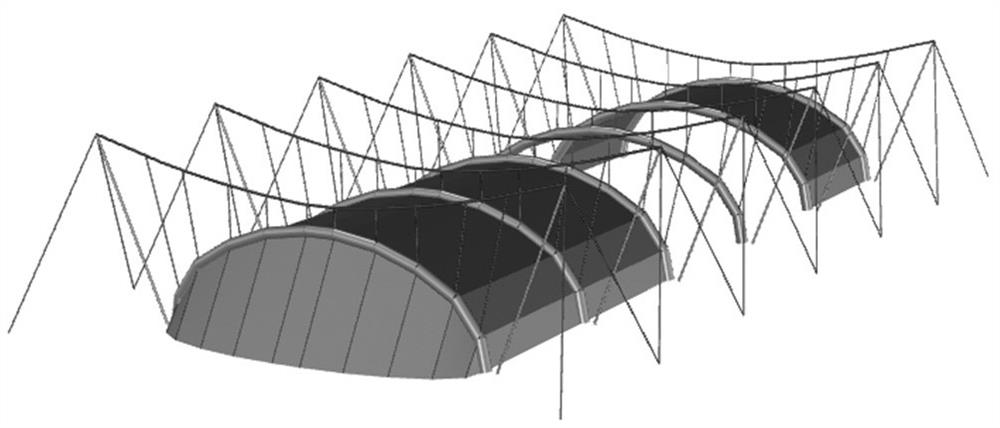

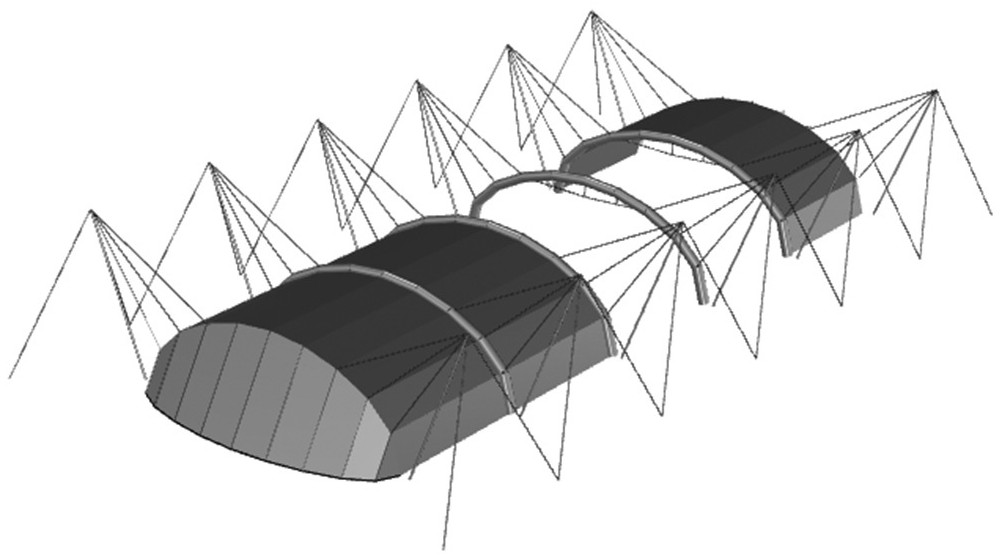

ActiveCN114517532AReasonable forceLess materialBuilding roofsArched structuresPre stressSpatial structure

The invention relates to a one-way tension metal sheet space structure, which is used for a large-span building, and comprises a metal sheet which is formed by tension and forms the space structure; the steel columns are arranged on the two sides of the space structure span; one ends of the tension cables are fixedly connected to the top ends of the steel columns on the two sides, and the other ends are connected with the metal sheets from the two sides of the space structure span; one end of the back cable is connected with the top end of the steel column; and the gable plates are arranged at the two ends of the metal thin plate and provided with gable back cables. The stress structure and the building envelope structure are integrally designed, the metal sheets are formed by applying in-plane prestress in a tensioning mode, the whole structure can be continuously arranged in a multi-span mode, and good plane adaptability and good economic performance are achieved. The structure system can be used for building a super-large-span temporary and permanent closed stockyard engineering structure system with the span exceeding 300 m, and has the advantages of being safe, reliable, reasonable in design, economical in material, easy and convenient to construct and the like.

Owner:NORTH CHINA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com