Patents

Literature

39results about How to "Give full play to the resistance to pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

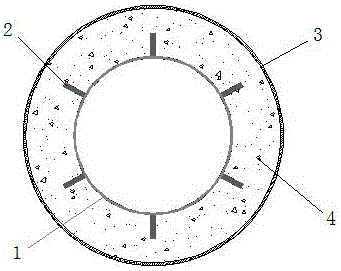

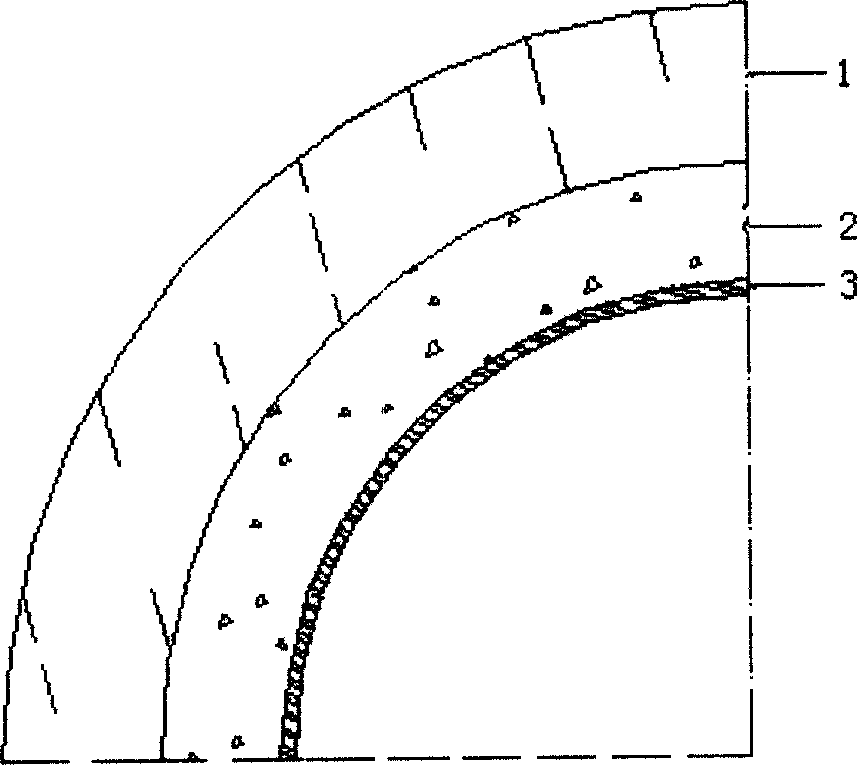

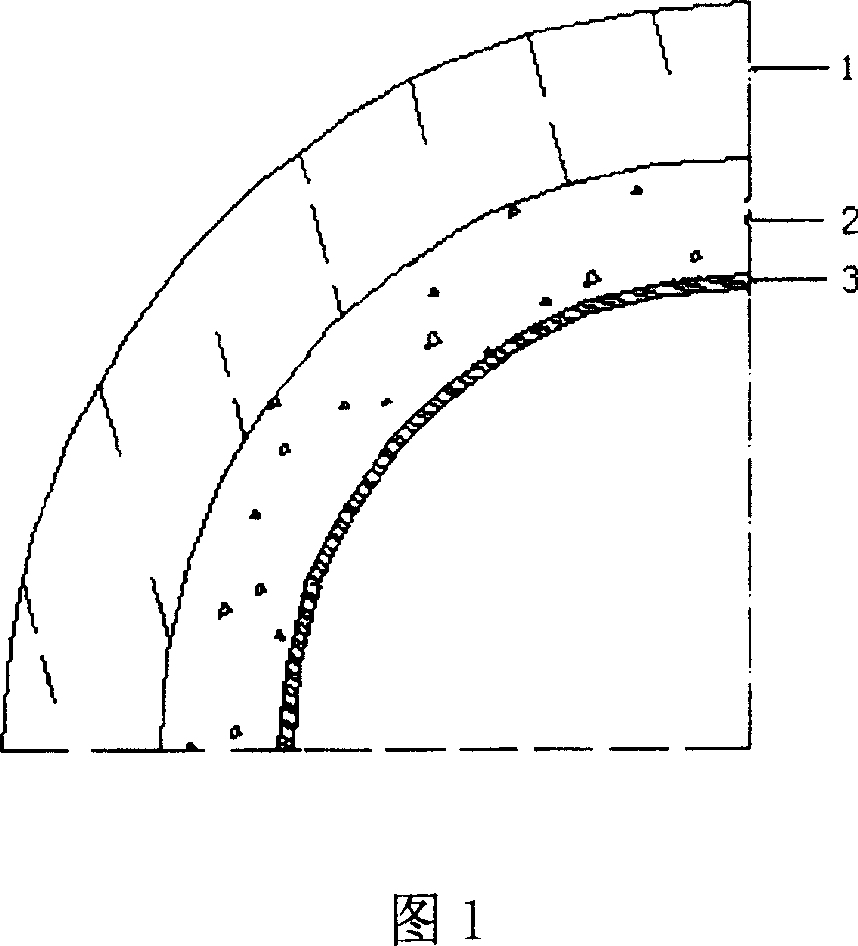

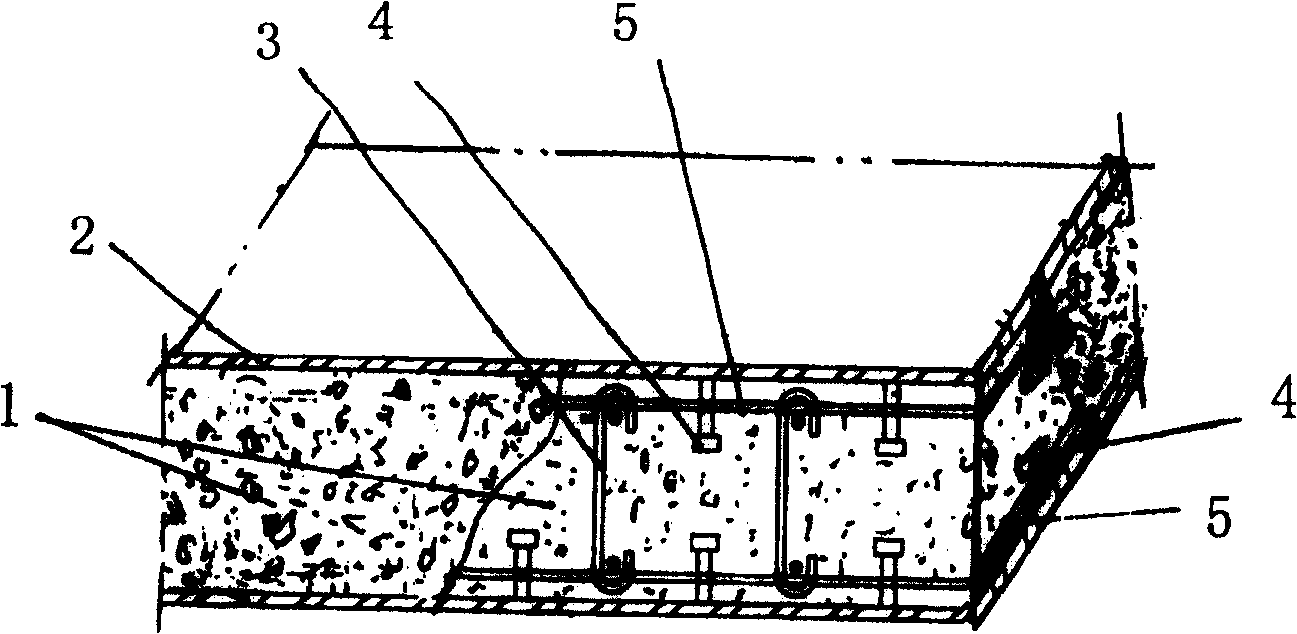

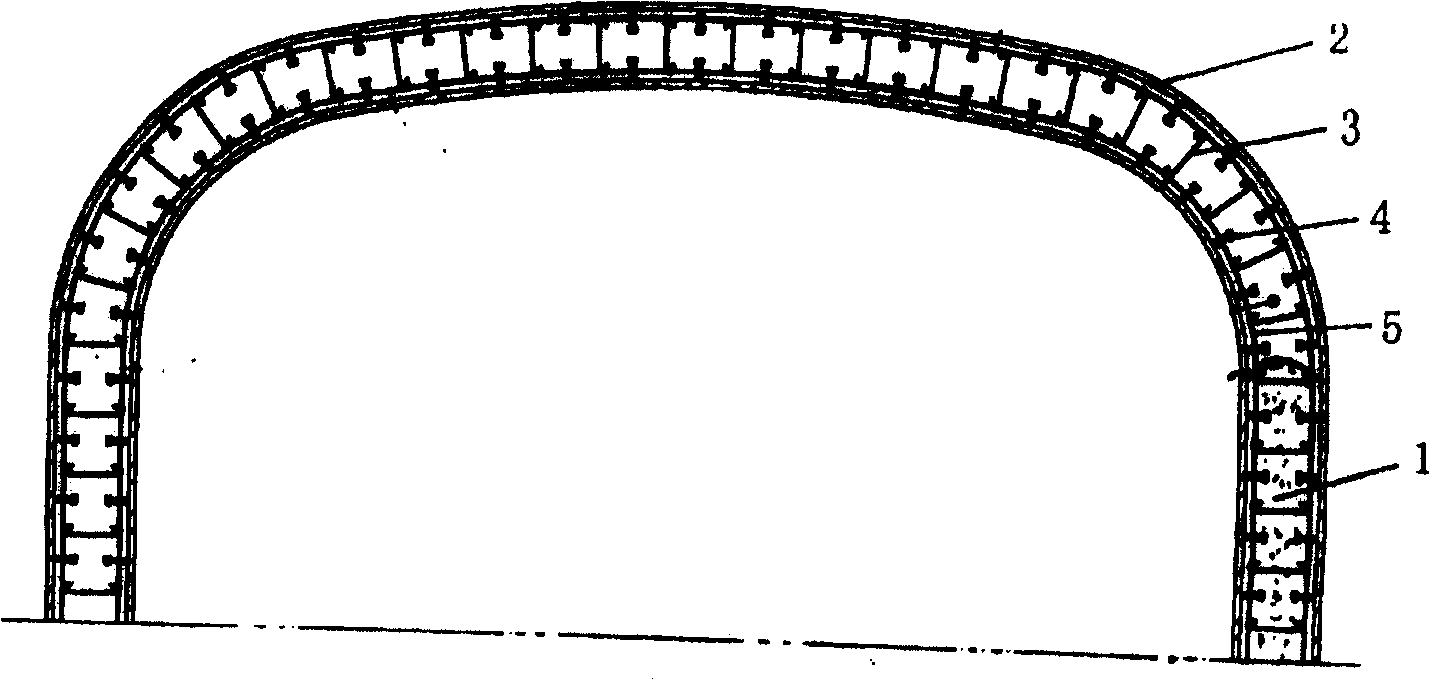

Steel plate-concrete composite lining

InactiveCN1594833AImprove mechanical propertiesLarge bearing capacityUnderground chambersTunnel liningShotcreteSheet steel

The present invention disclose a steel plate-concrete composite lining which combines support and water proof and belongs to tunnel safe support device range. It can be applied for construction of new tunnel with high force bearing and water proof requirement and the reinforcement of existing structures, and includes a circular cross section tunnel, an arched section tunnel or various section shape tunnels or saps. The lining is generally formed in a way of first forming a lining frame by two anti-cut connection elements melted with studs, a reinforcing steel net banded by reinforcing steels and a steel plate and then spraying concrete into the frame. The invention combines the steel plate, the sprayed concrete to a whole structure to bear force, has improved bearing ability and stability than single reinforcing steel concrete lining, can be as support for new tunnel and as the reinforcement device for similar structure. The invention has the advantages of easy in quality guaranty, simple and quick in construction and high in synthetic effect.

Owner:TSINGHUA UNIV

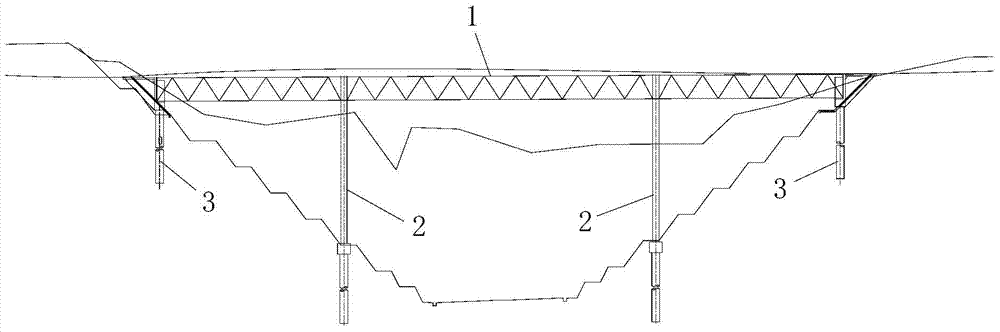

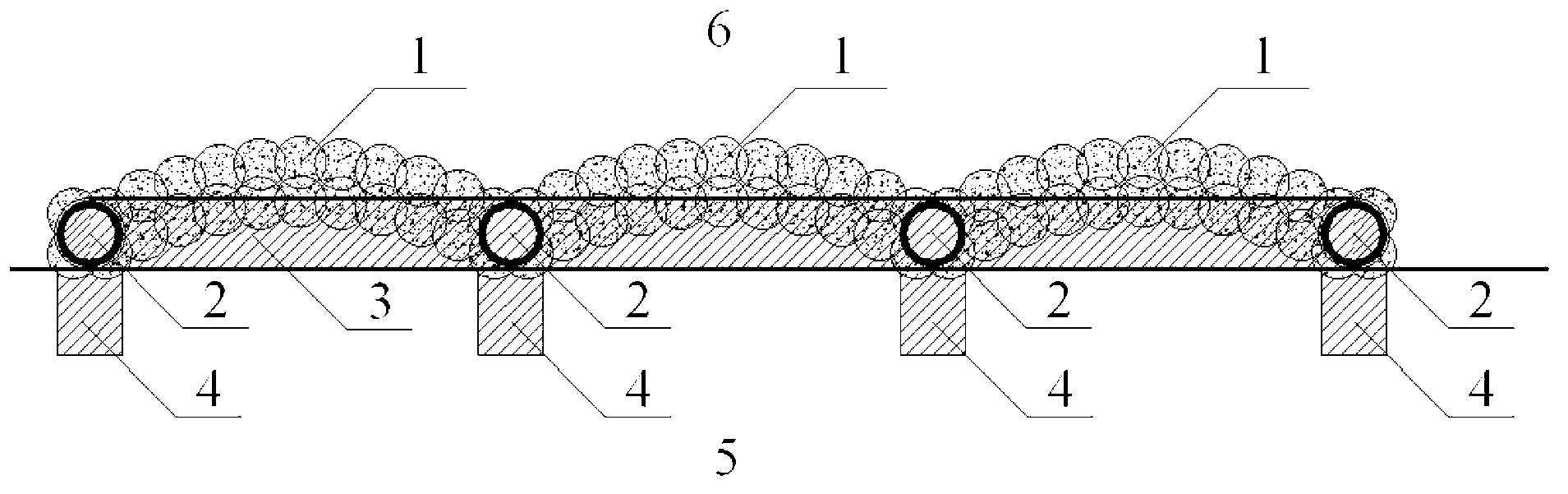

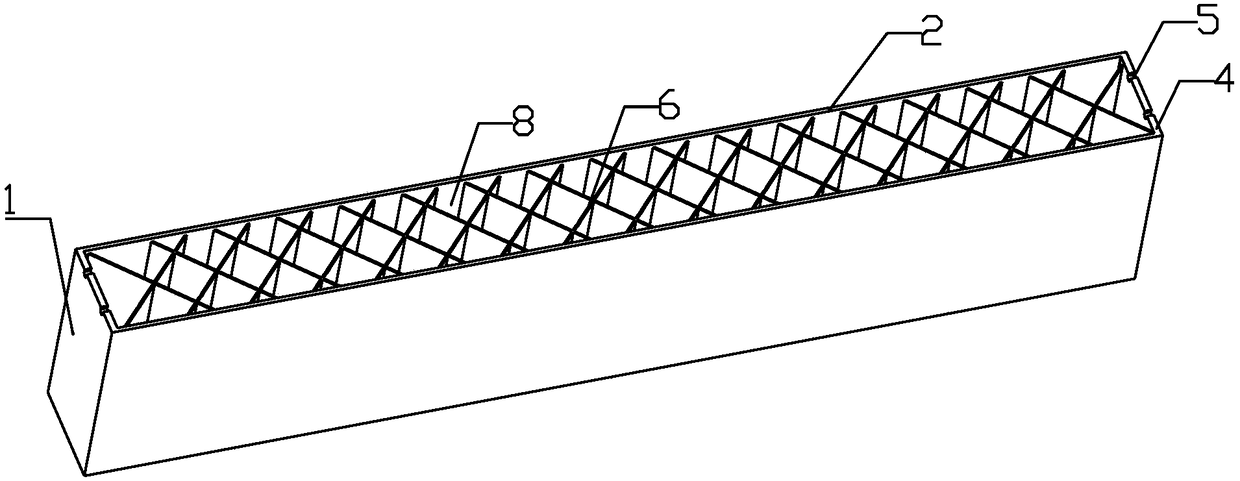

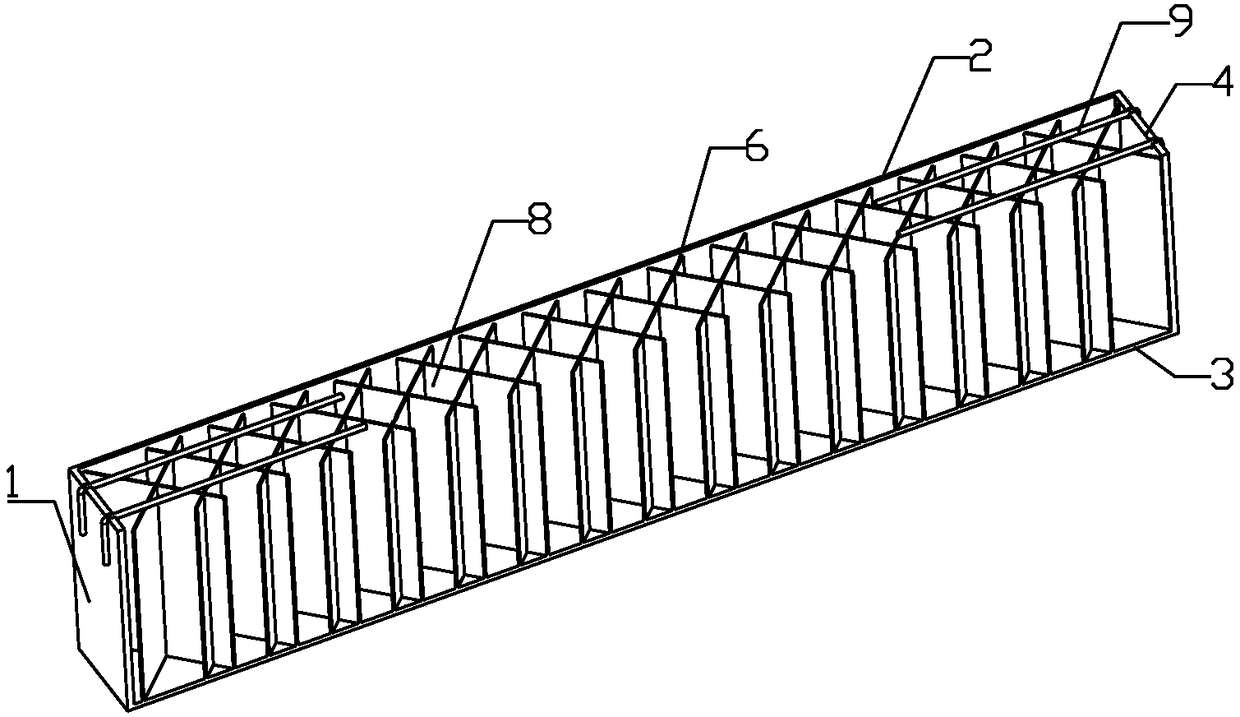

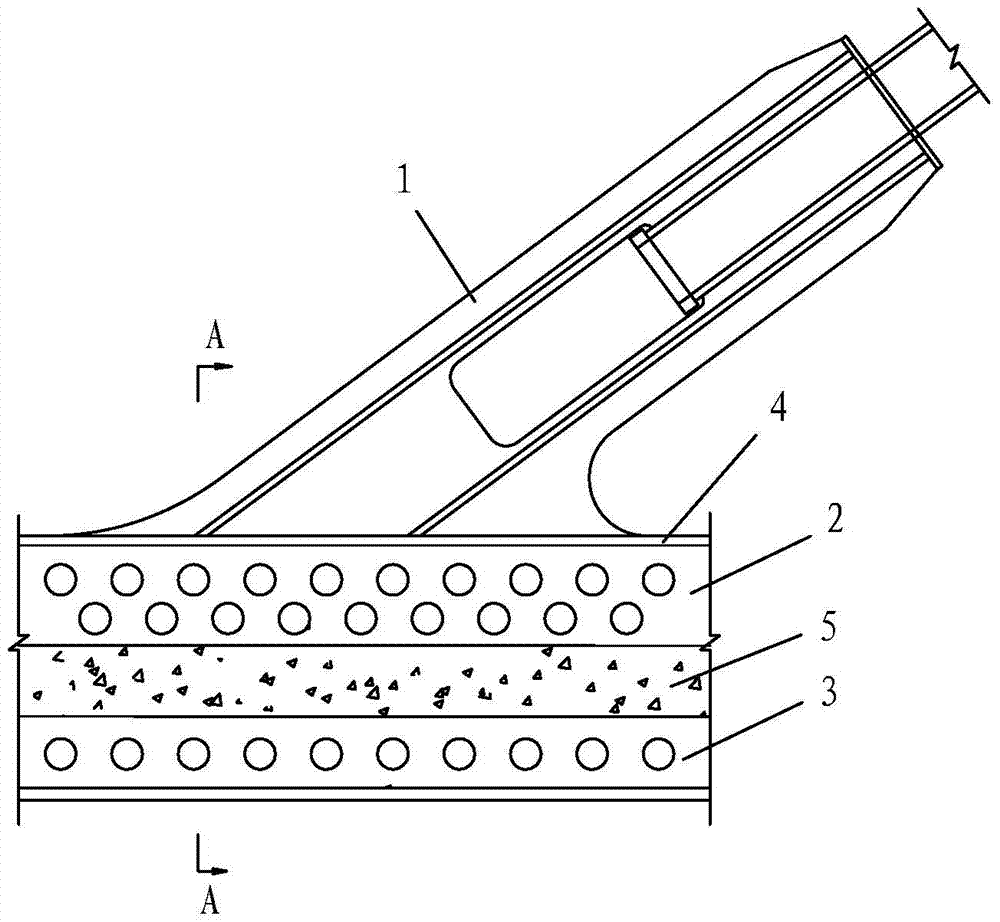

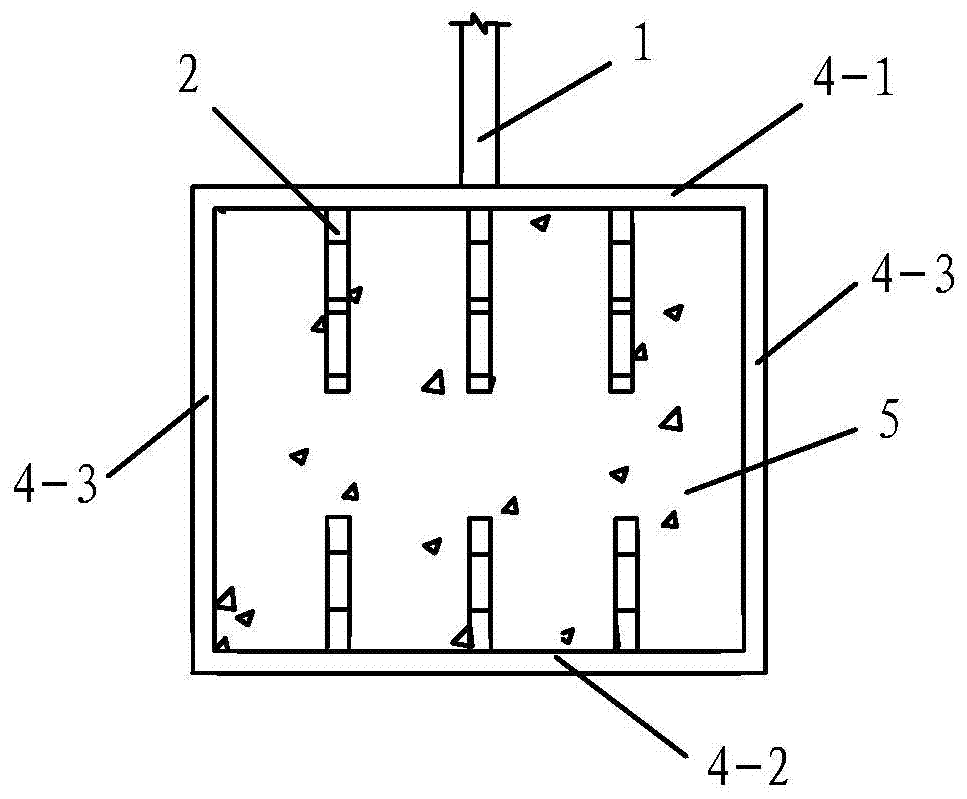

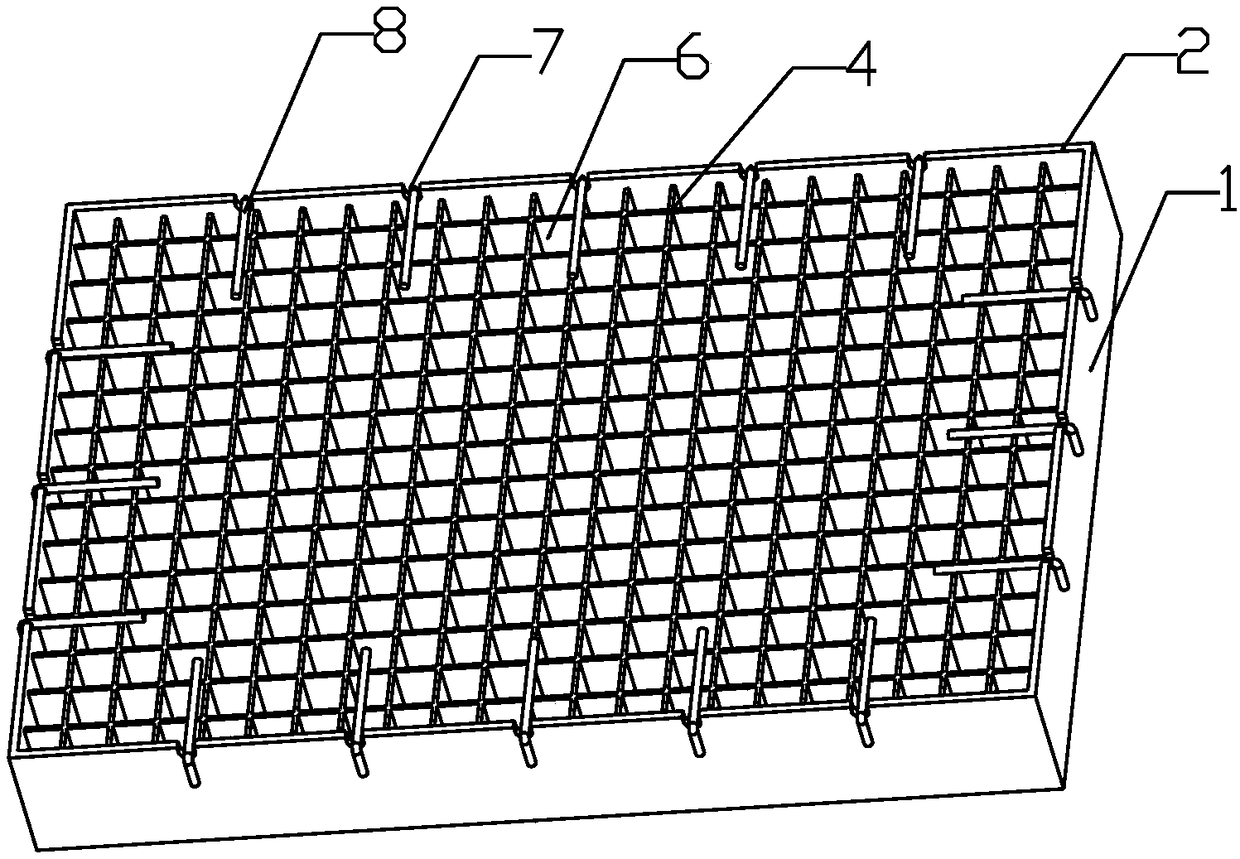

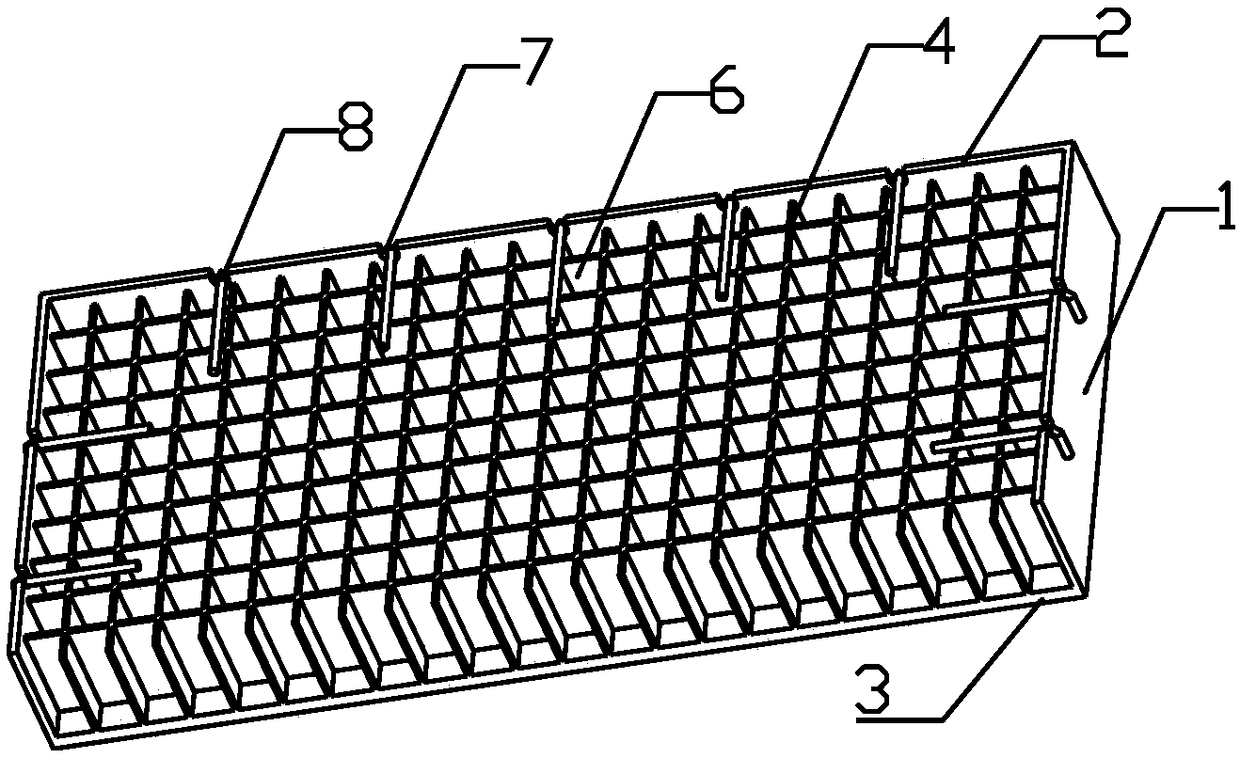

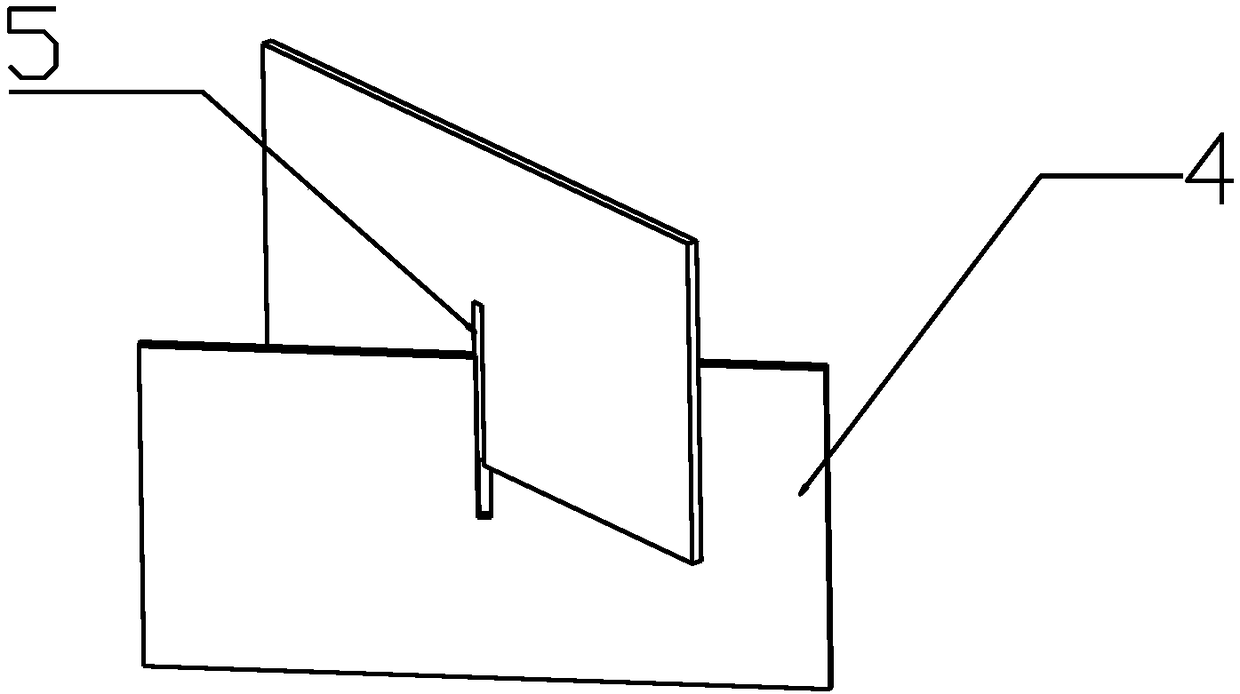

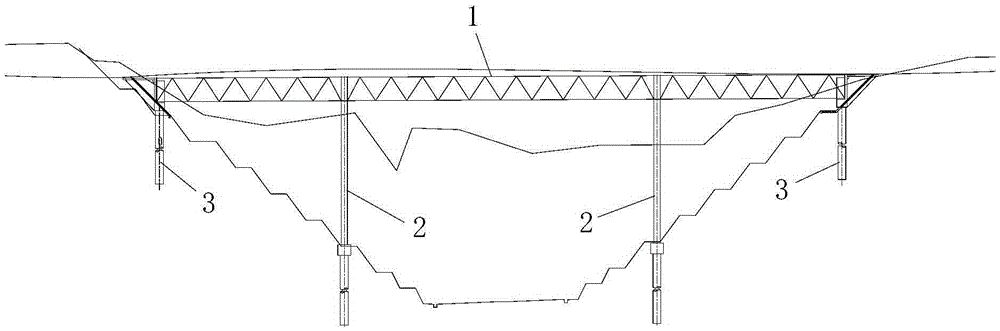

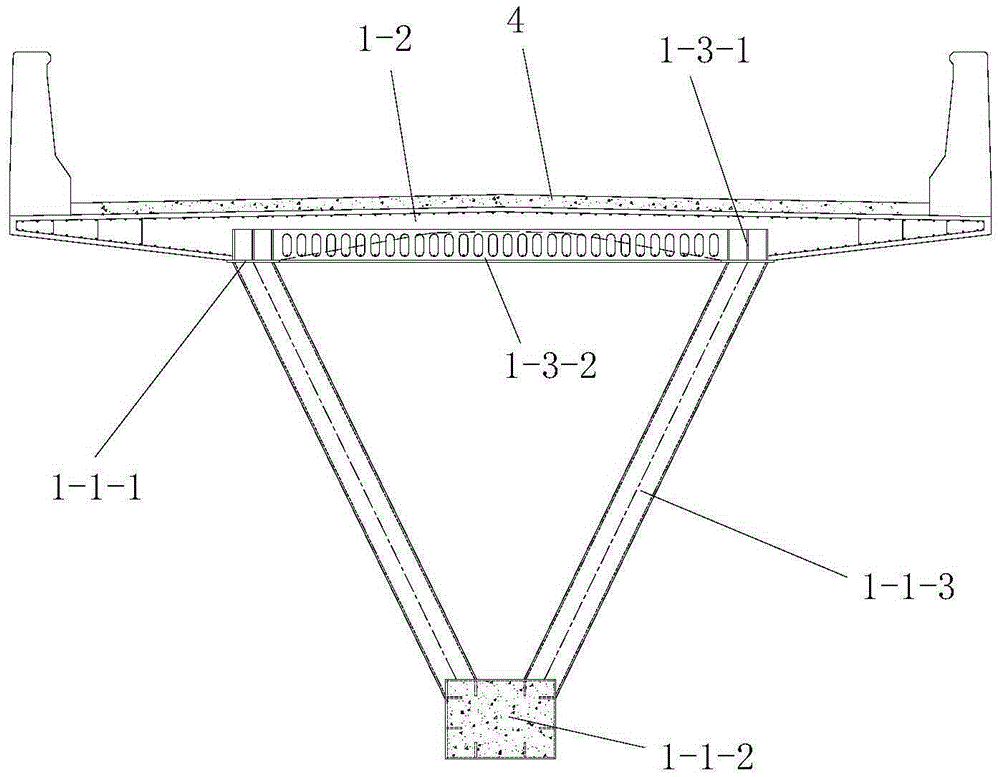

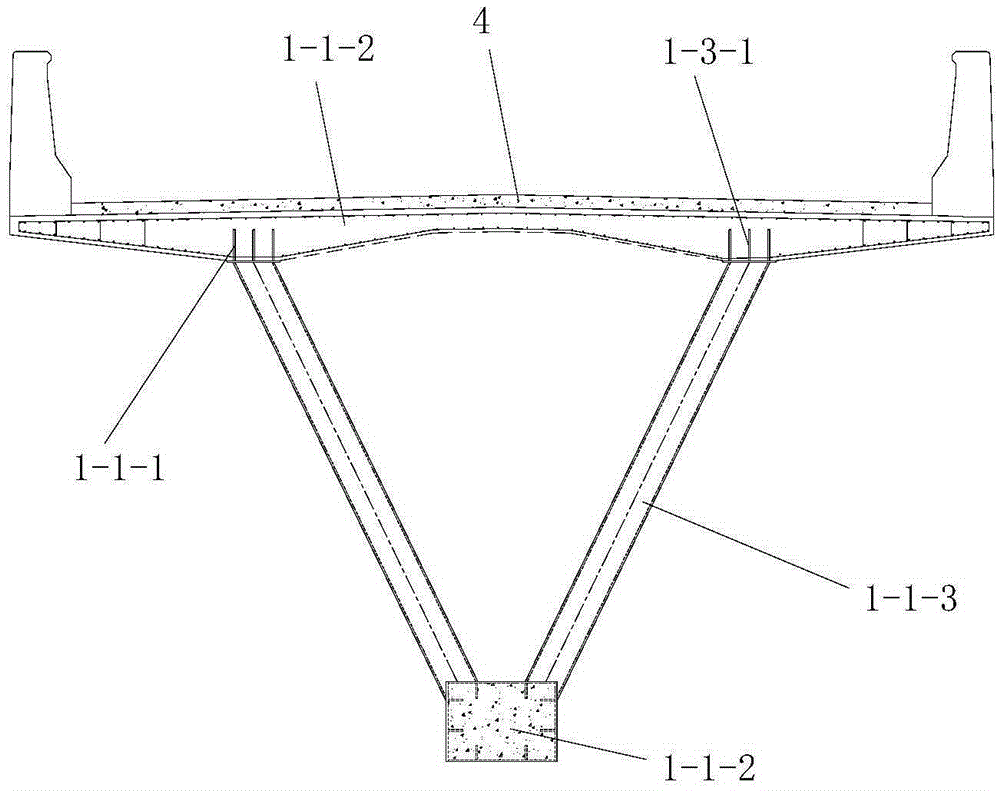

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194ALight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

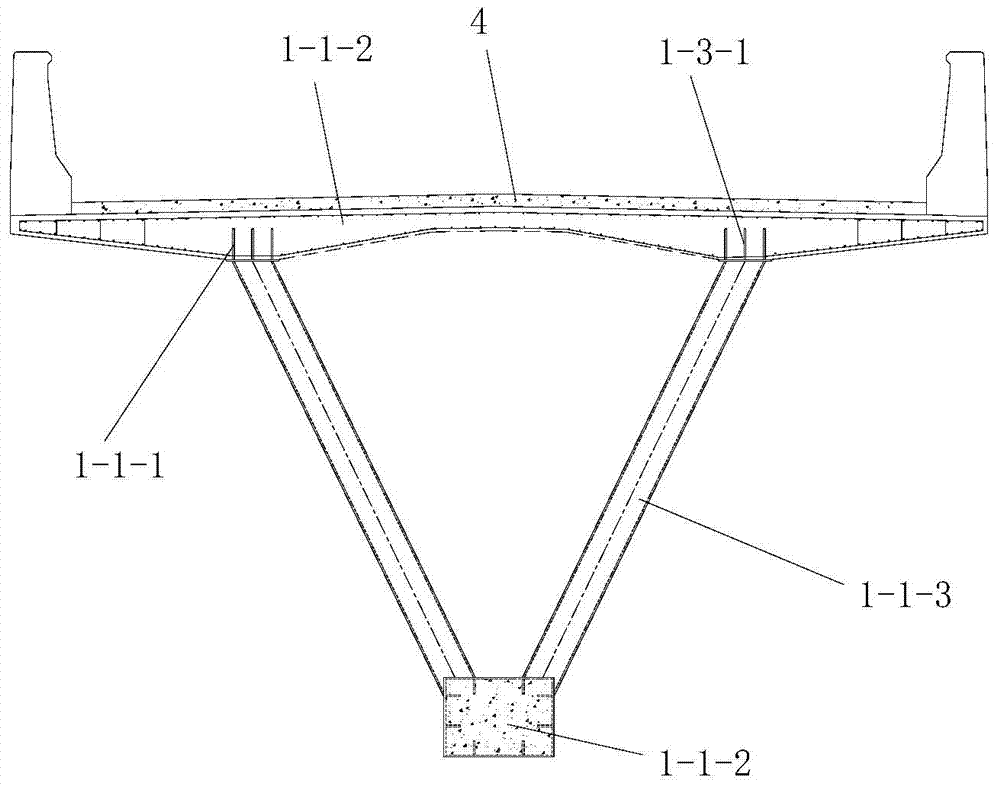

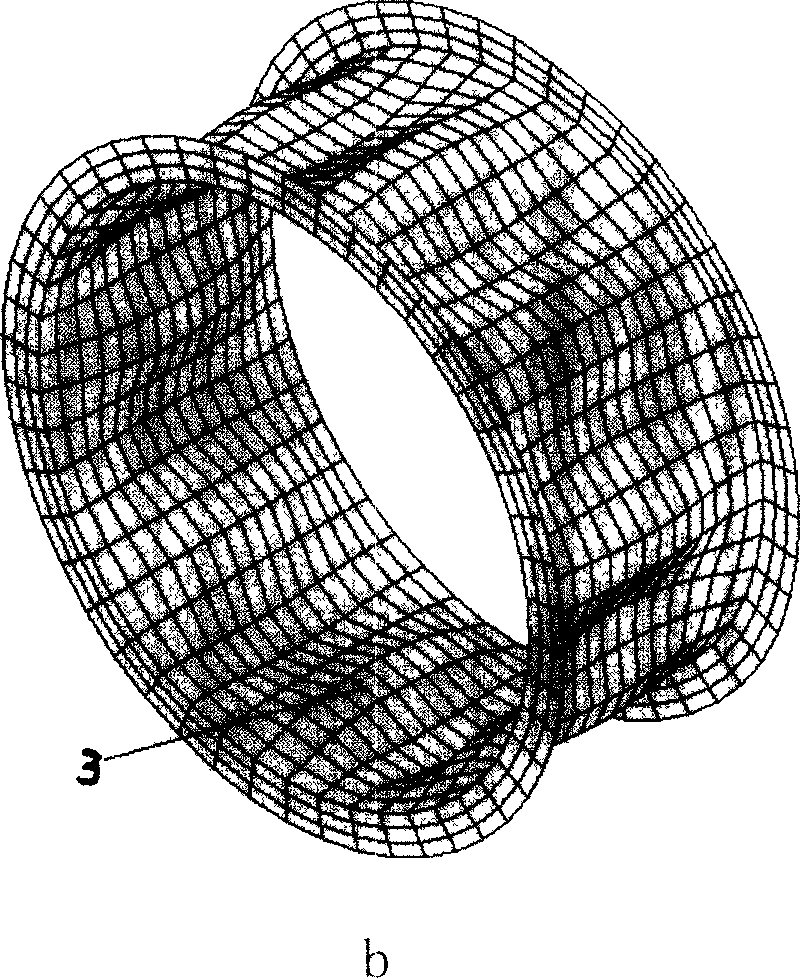

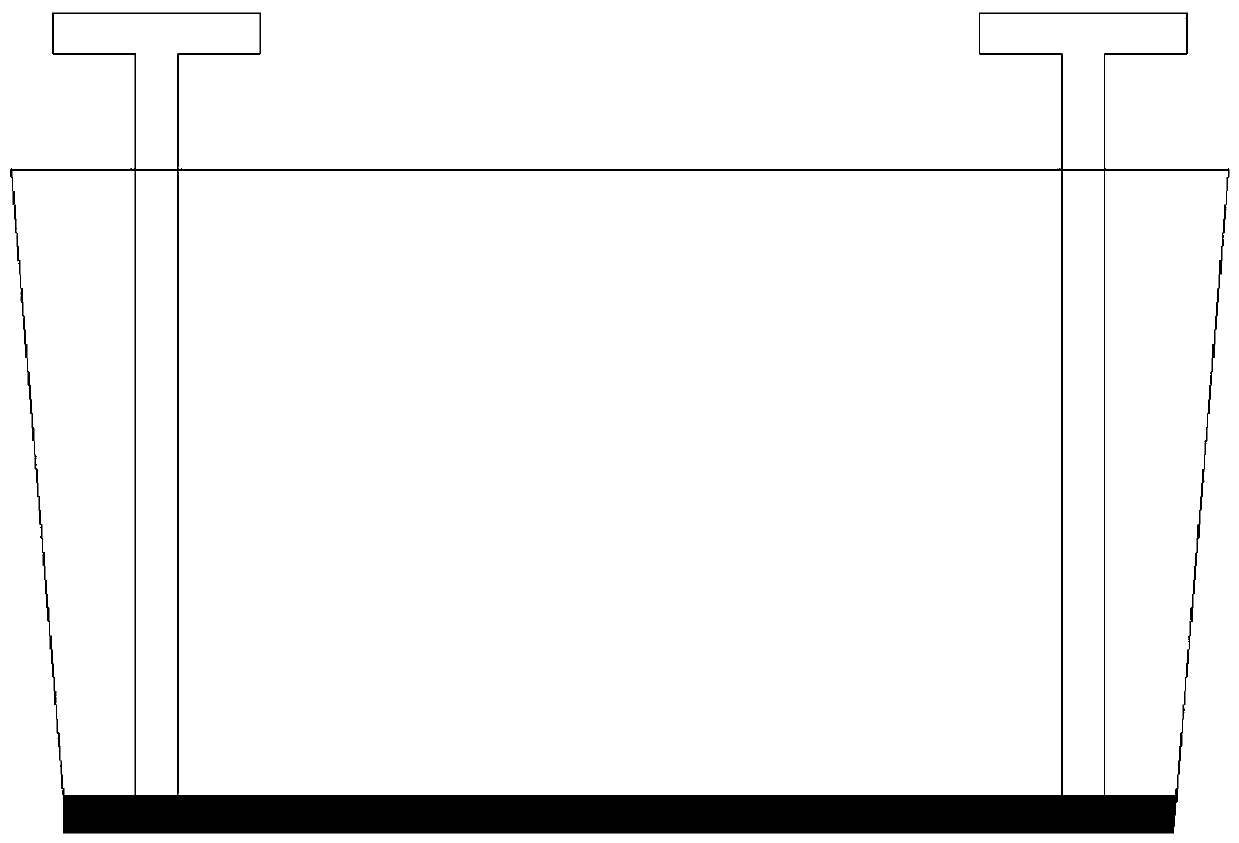

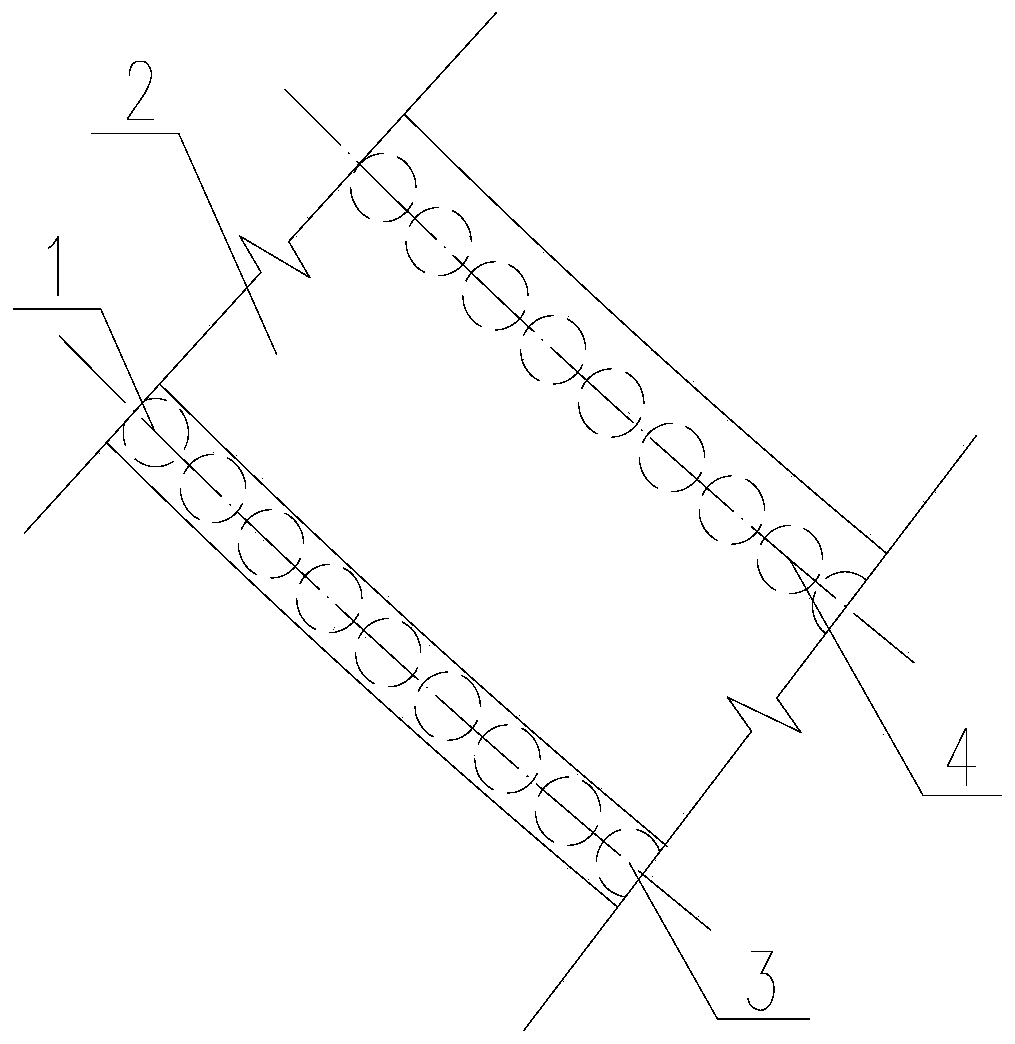

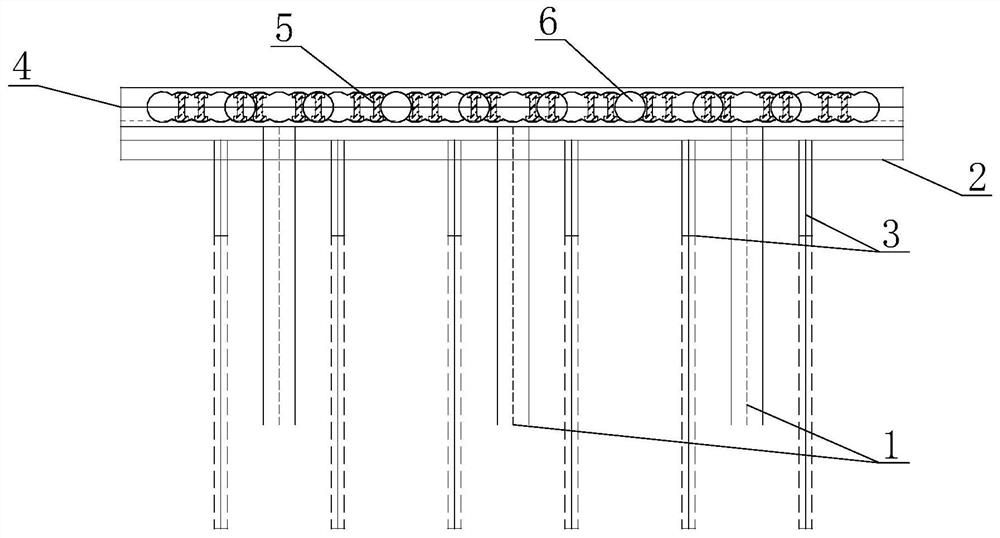

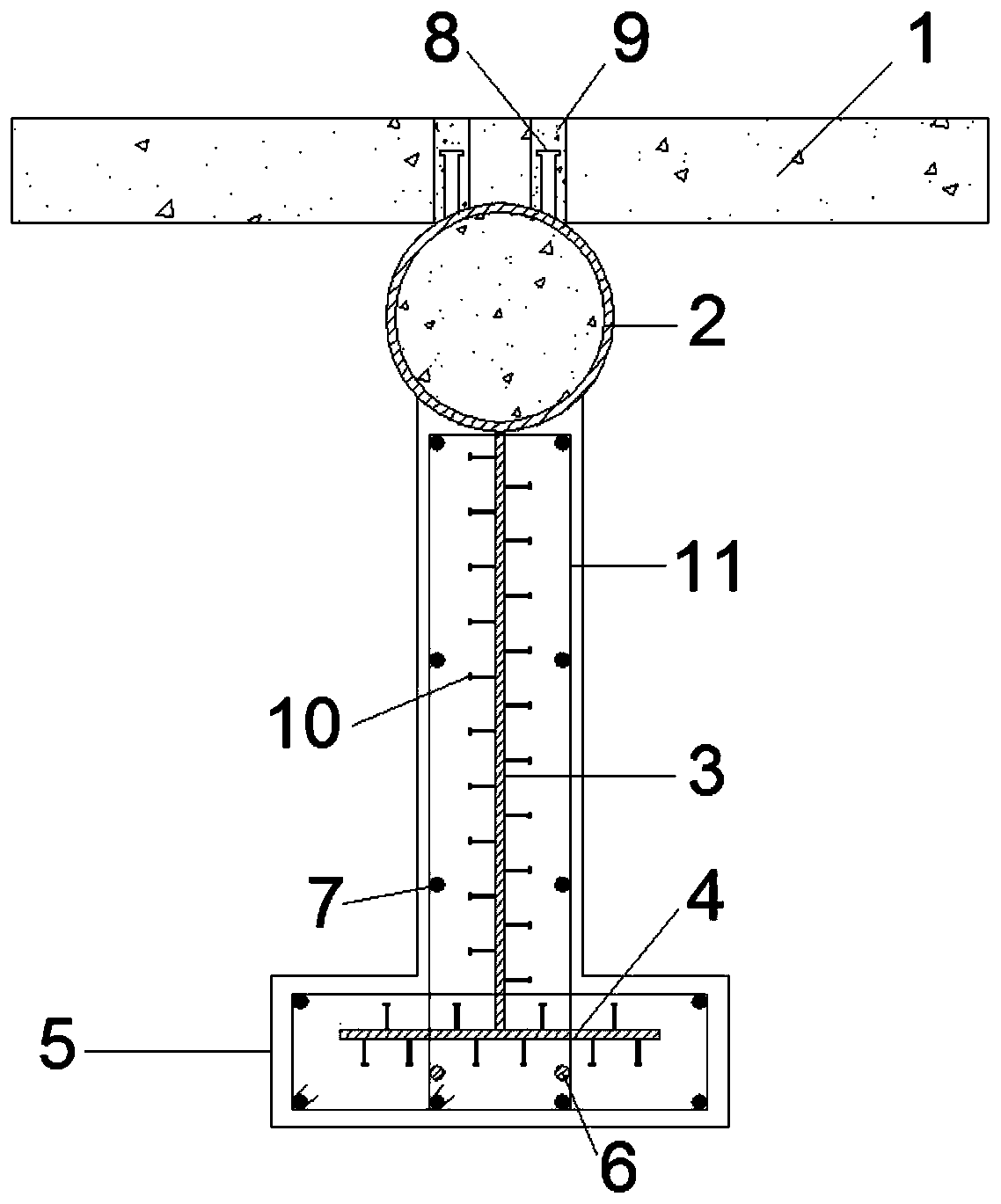

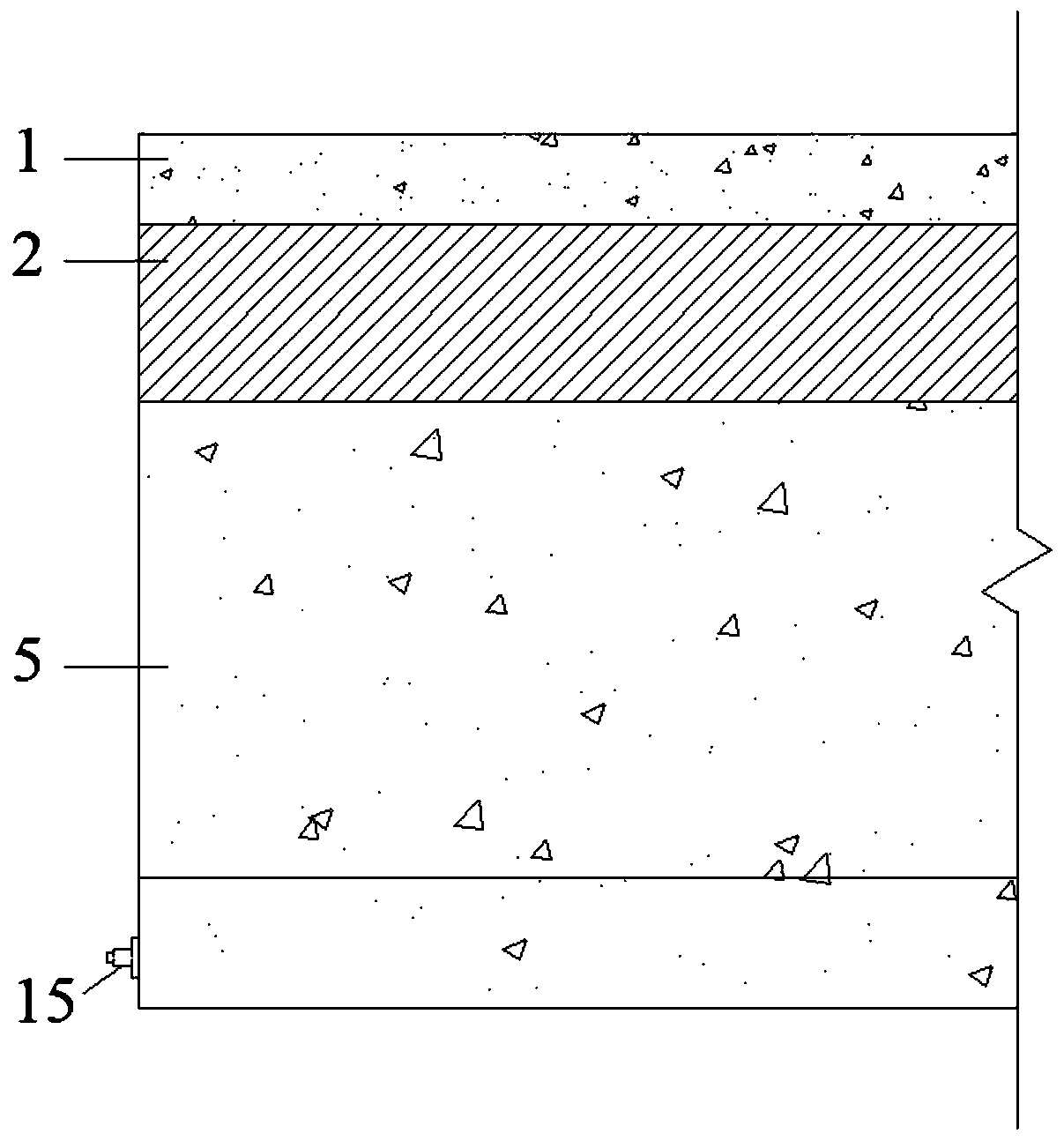

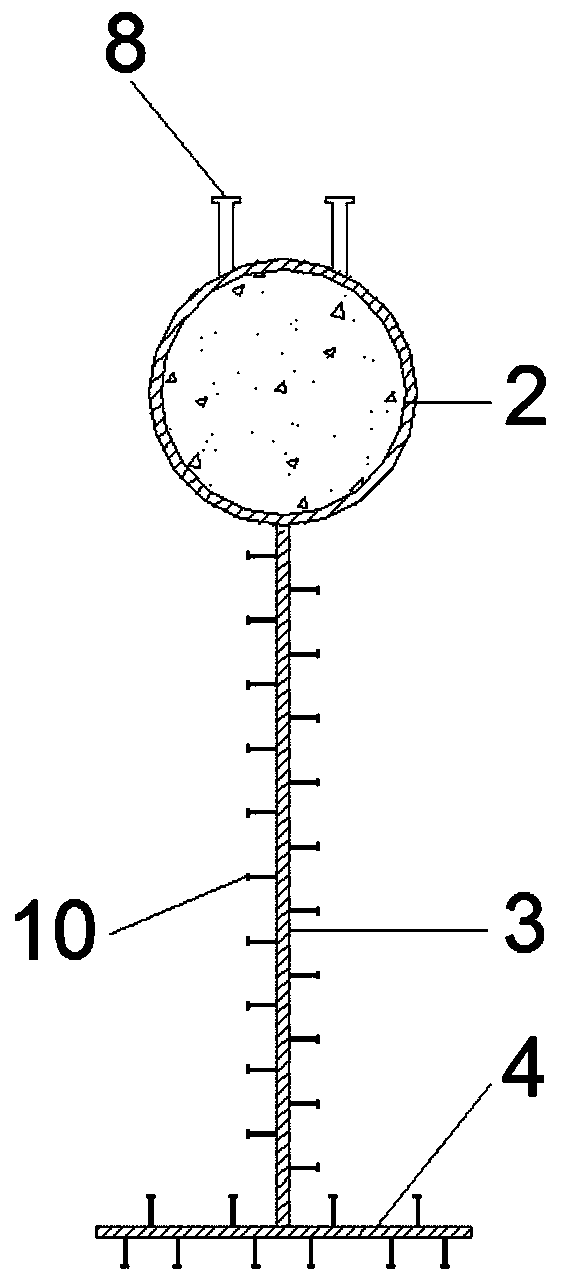

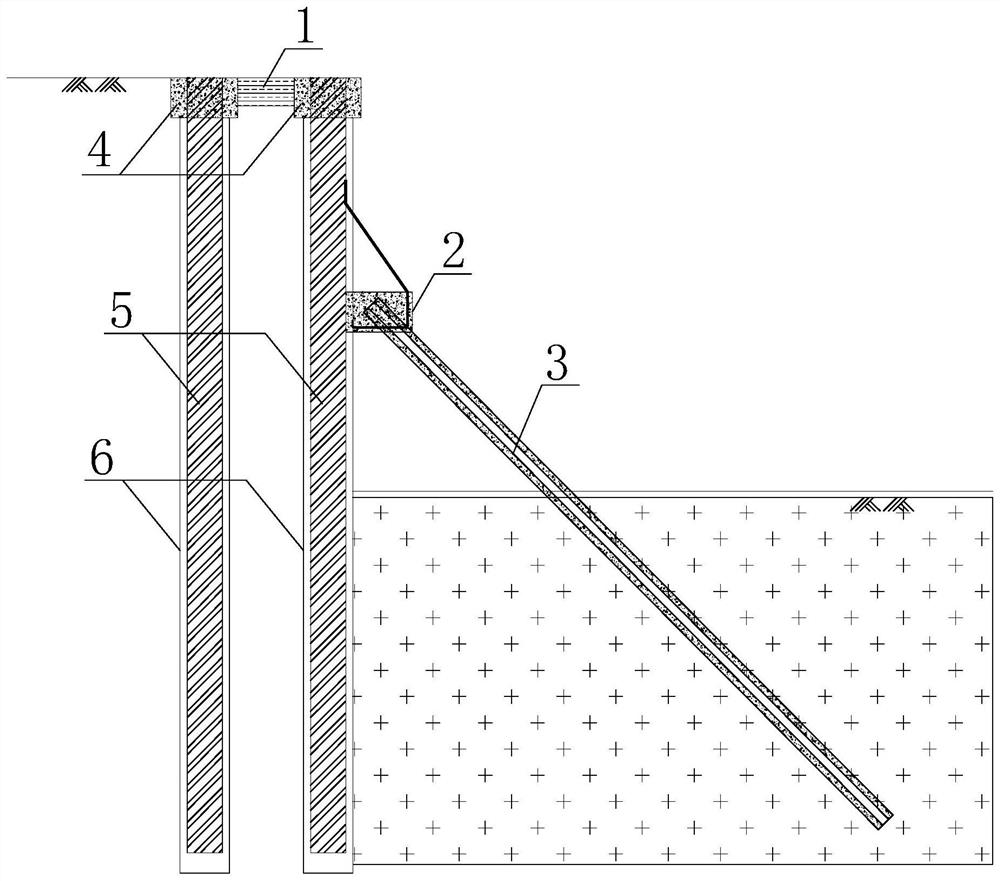

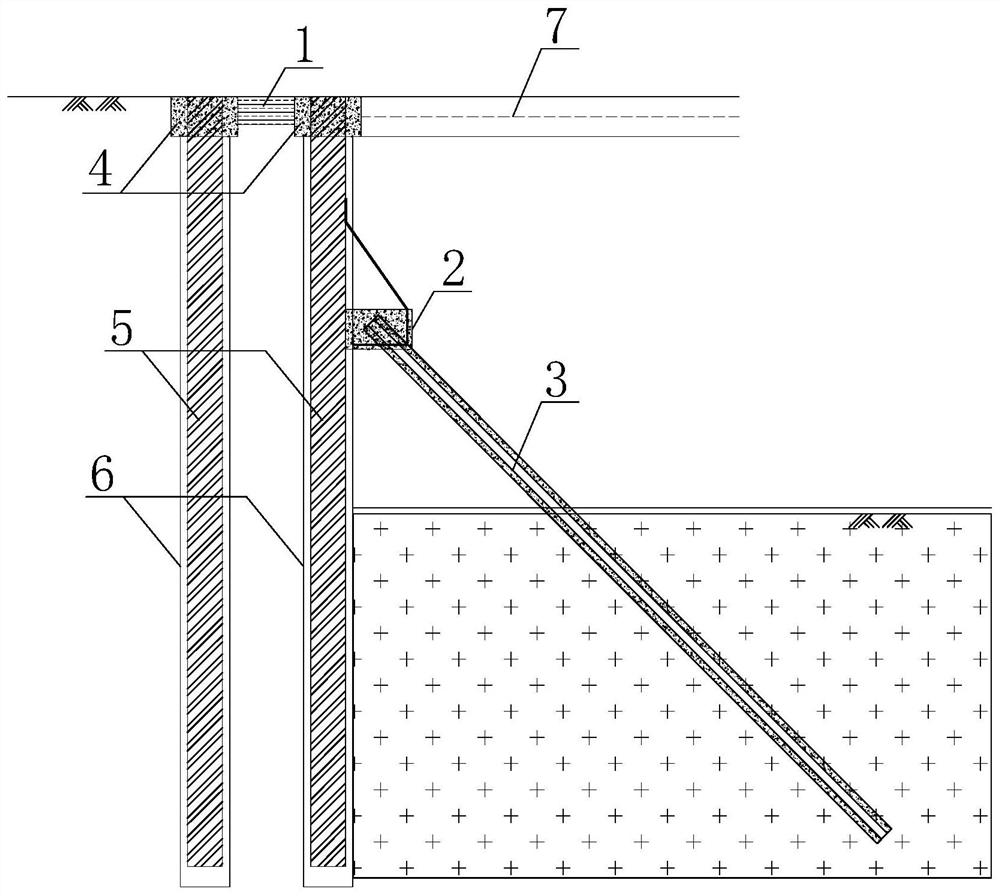

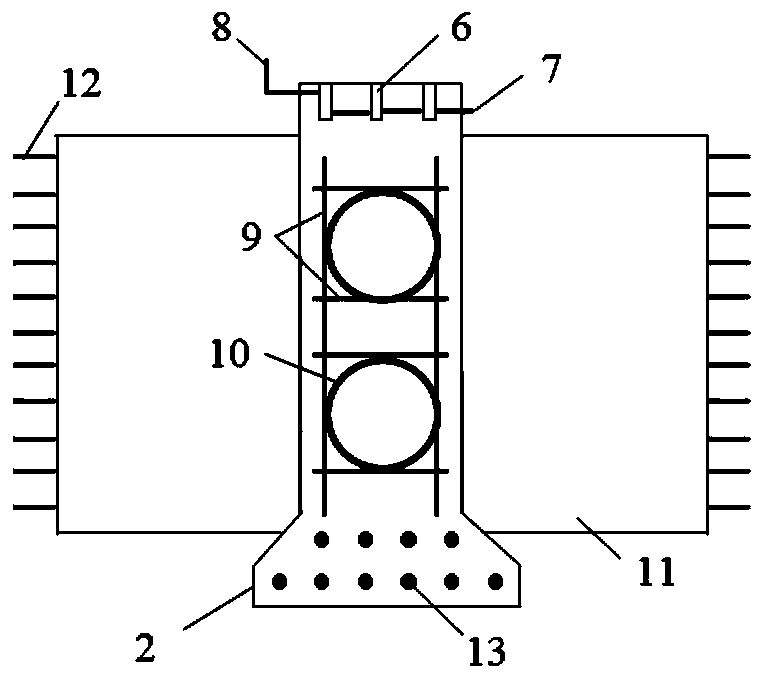

Arch combination foundation pit retaining and protection system and construction method thereof

InactiveCN103290850APlay the role of water stopGive full play to the resistance to pressureExcavationsHigh strength concreteSoil mixing

The invention relates to an arch combination foundation pit retaining and protection system and a construction method of the arch combination foundation pit and protection system, and provides a combination foundation pit retaining and protection system which is simple in structural style, fast in construction method, capable of sufficiently utilizing property advantages of materials and combining the soil blocking function and waterproof function, and suitable for an arch-shaped cement soil mixing pile large in excavating depth and prefabrication of a high-strength concrete thin-wall steel tube pile, and the construction method of the combination foundation pit retaining and protection system. The arch combination foundation pit retaining and protection system comprises arch-shaped cement soil mixing pile walls (1), high-strength concrete thin-wall steel pipe piles (2), pile top beams (3) and inner supports (4), wherein the high-strength concrete thin-wall steel pipe piles (2) are arranged inside the foundation pit in a scattered mode, the pile top beams (3) connect the high-strength concrete thin-wall steel pipe piles into a whole, each inner support (4) is arranged on the outer side of each high-strength concrete thin-wall steel pipe pile (2), each arch-shaped cement soil mixing pile wall (1) is arranged between two high-strength concrete thin-wall steel pipe pile (2) and the arch-shaped cement soil mixing pile walls (1) to be connected into a whole, and the arch-shaped foundation pit retaining and protection system is formed.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

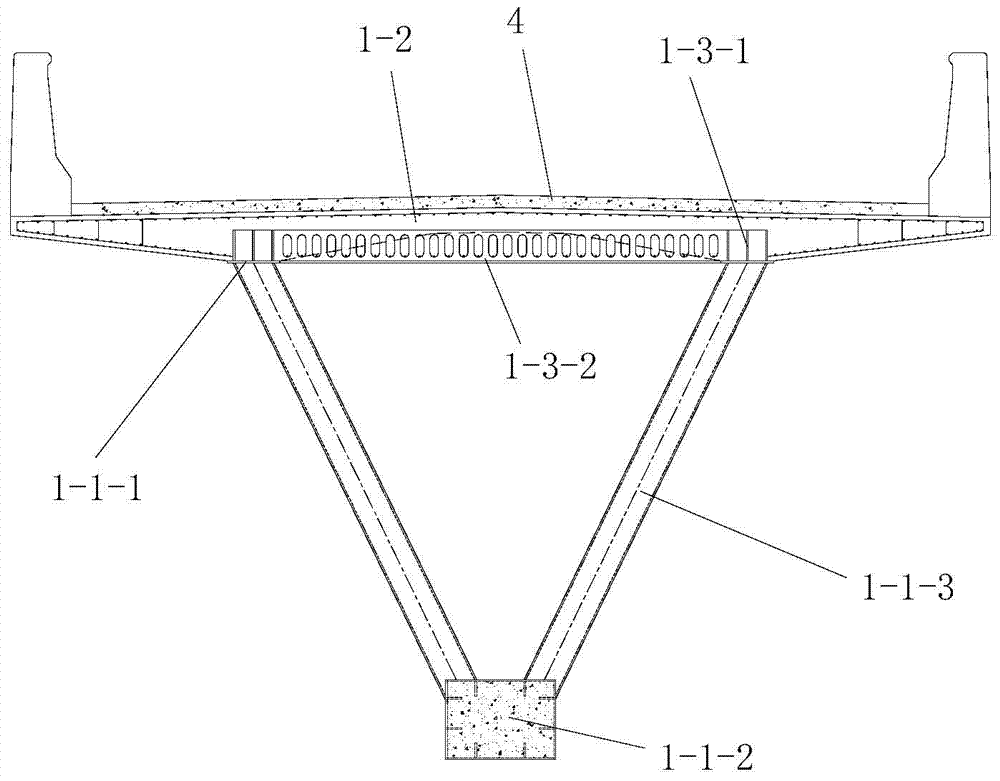

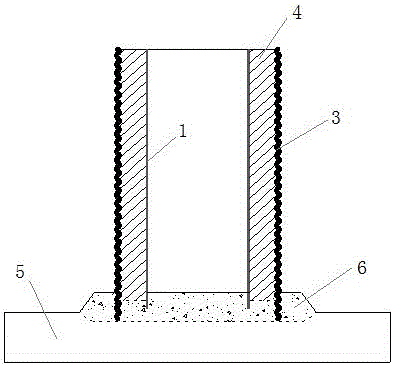

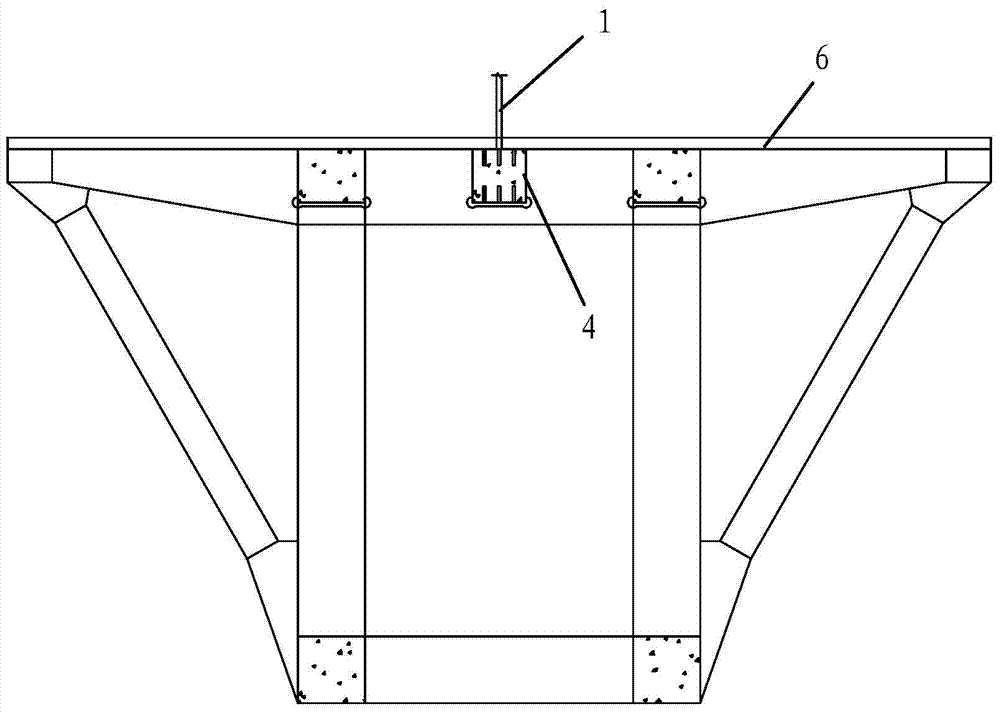

Gradient-structure composite bridge pier

InactiveCN105002819ALose weightImprove carrying capacityBridge structural detailsSteel tubeSelf weight

A gradient-structure composite bridge pier comprises a round steel pipe, fiber-reinforced powder concrete and a corrugated steel pipe from inside to outside. Outward square stiffening ribs are welded to the round steel pipe, and the closed corrugated steel pipe is arranged outside the round steel pipe; and the fiber-reinforced powder concrete is cast between the corrugated steel pipe and the round steel pipe, and the square stiffening ribs are contained in the fiber-reinforced powder concrete. By means of the gradient-structure composite bridge pier, the self weight of the bridge pier can be reduced, and the bearing capacity and the anti-seismic property of the bridge pier can be improved; and through industrialized production and field assemblage, the construction speed of the bridge pier can be increased, and the construction period is shortened.

Owner:EAST CHINA JIAOTONG UNIVERSITY

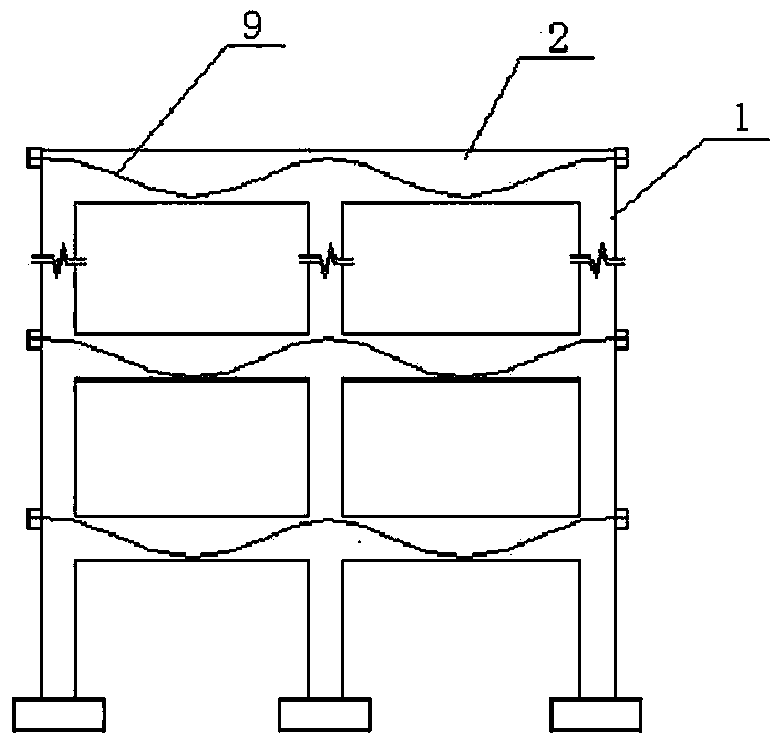

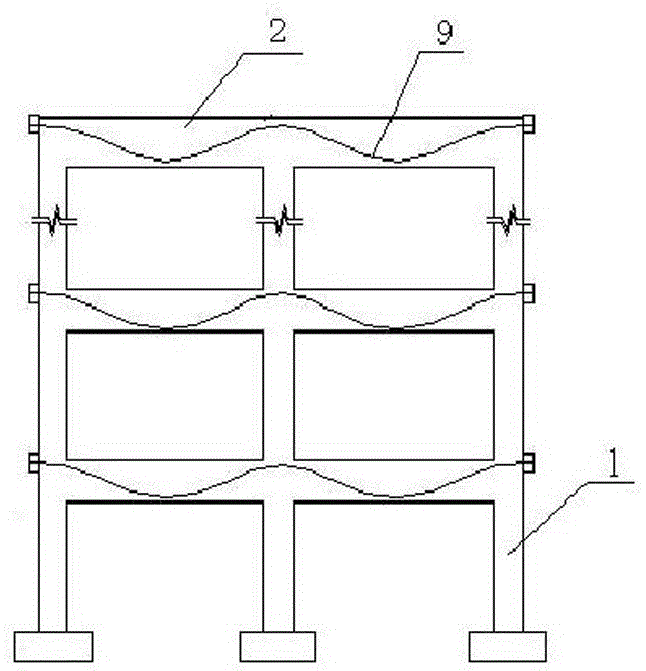

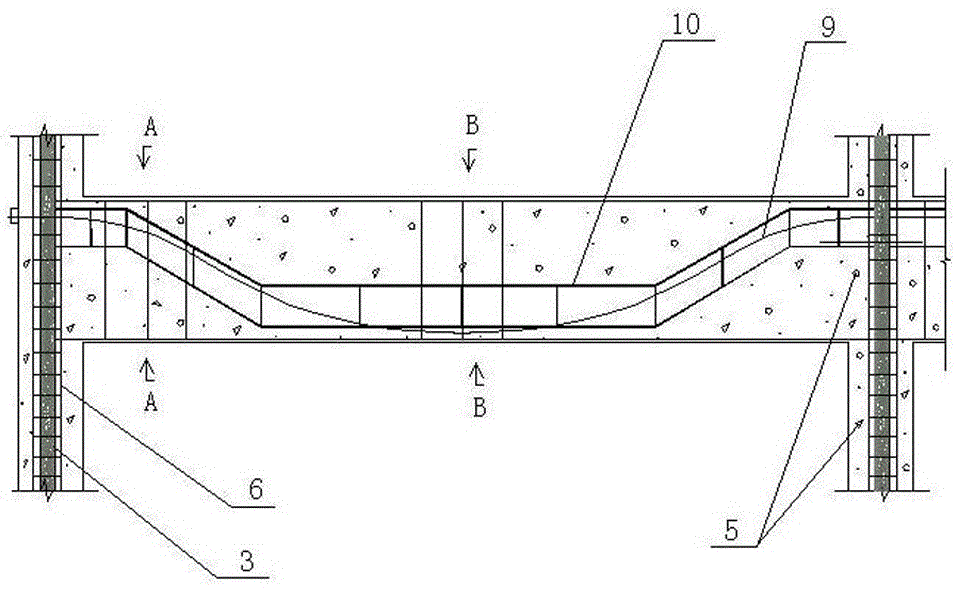

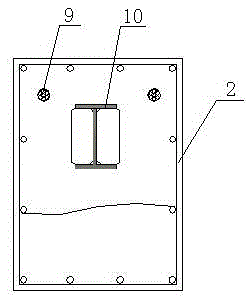

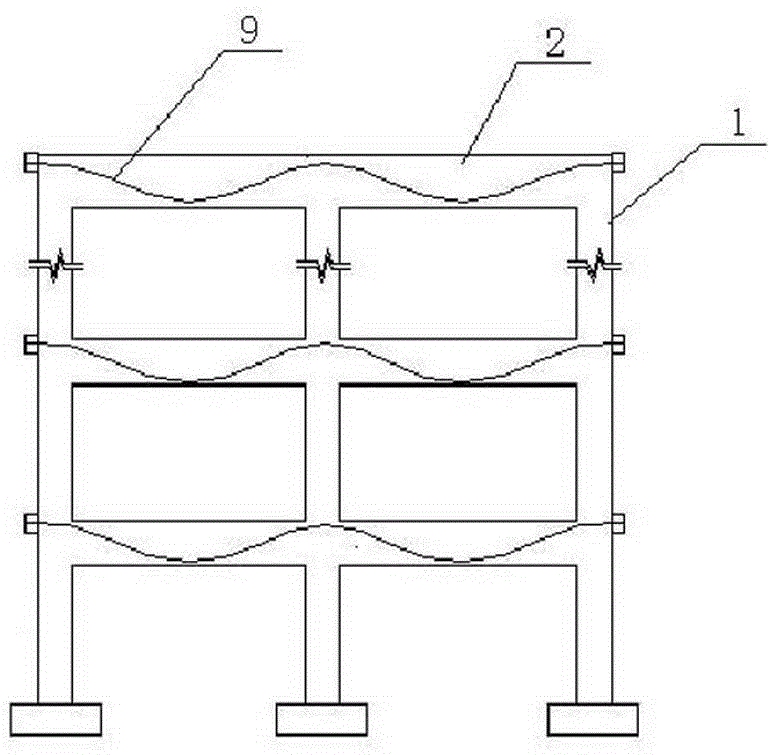

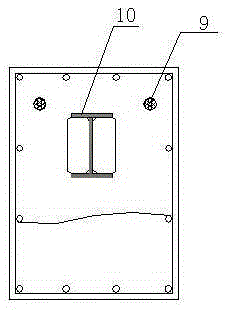

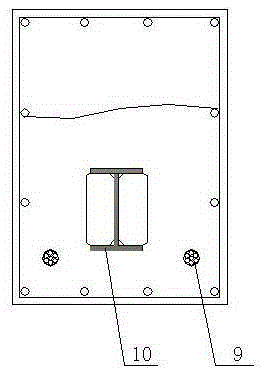

Combination column and combination beam frame with internally-arranged high-strength concrete core columns and construction method thereof

InactiveCN103967128AReduce section sizeReduce workloadBuilding constructionsPre stressControl theory

The invention relates to a combination column and combination beam frame with internally-arranged high-strength concrete core columns and a construction method of the combination column and combination beam frame. The special strong combination column and combination beam frame with the internally-arranged core columns is provided with internally-arranged asymmetric steel rib or plastic rib prestressed concrete combination beams and reinforcing bar concrete combination columns with the internally-arranged core columns, the combination beams are horizontally arranged between the combination columns, and the combination beams are connected with the combination columns at intersections through joints. The core columns are formed by pouring longitudinal ribs, stirrups and concrete together, the longitudinal ribs are distributed around the core columns and are wrapped by the stirrups, and the core columns are placed in the reinforcing bar concrete columns. Transverse stiffening ribs are arranged on steel ribs or plastic ribs in the combination beams, the steel ribs or the plastic ribs at the midspan positions are arranged on the lower portions of the combination beams, the steel ribs or the plastic ribs on supports are arranged on the upper portions of the combination beams, and prestressed ribs are arranged in the combined beams in the length direction. The prestressed ribs on the beam and column joints penetrate through two sides of the core columns, and are tensioned and anchored at the ends of the combination columns. The section size of the columns can be obviously reduced, too wide columns are prevented from existing in a system, and the prestressed ribs in the combination beams can generate evenly-distributed counterforce to eliminate part of external loads.

Owner:NORTHEAST GASOLINEEUM UNIV

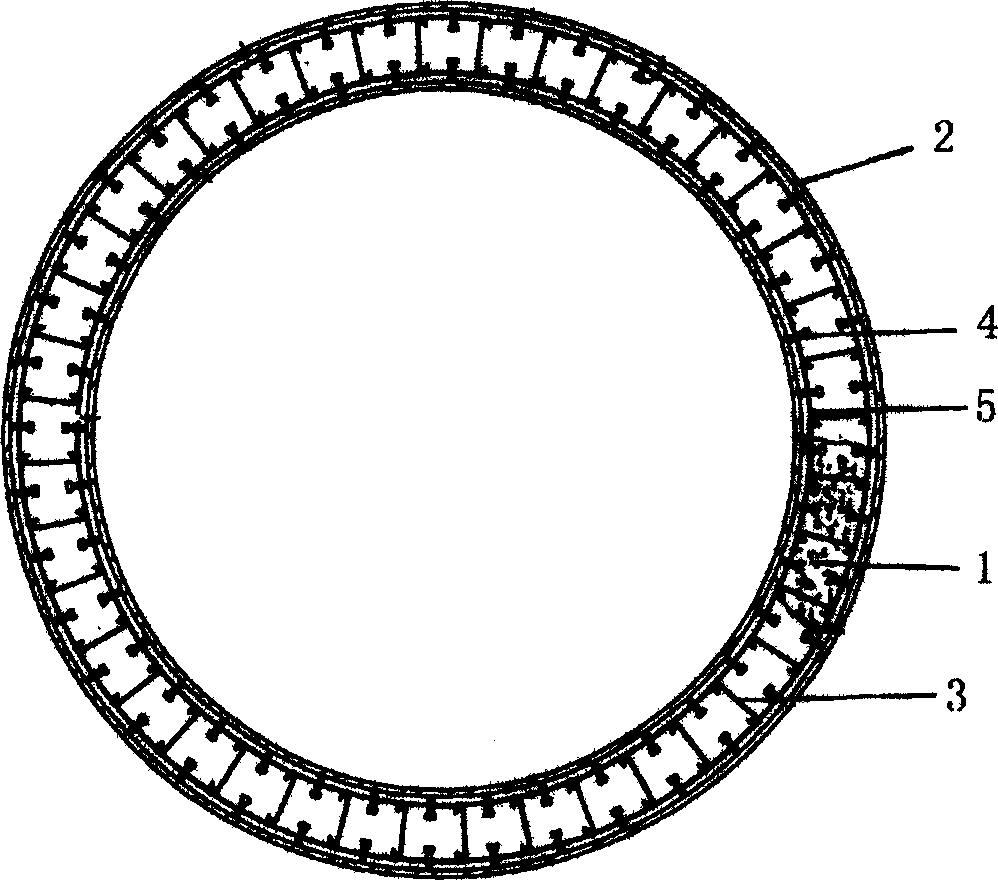

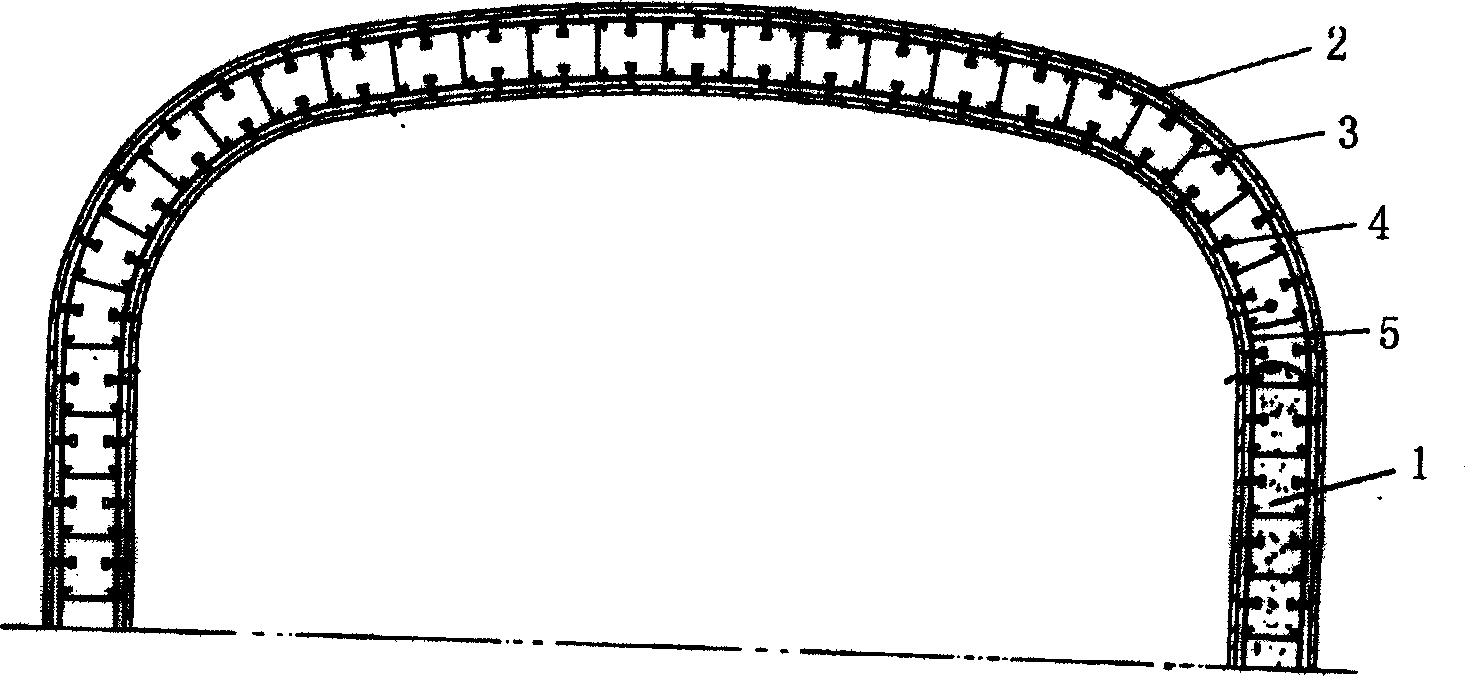

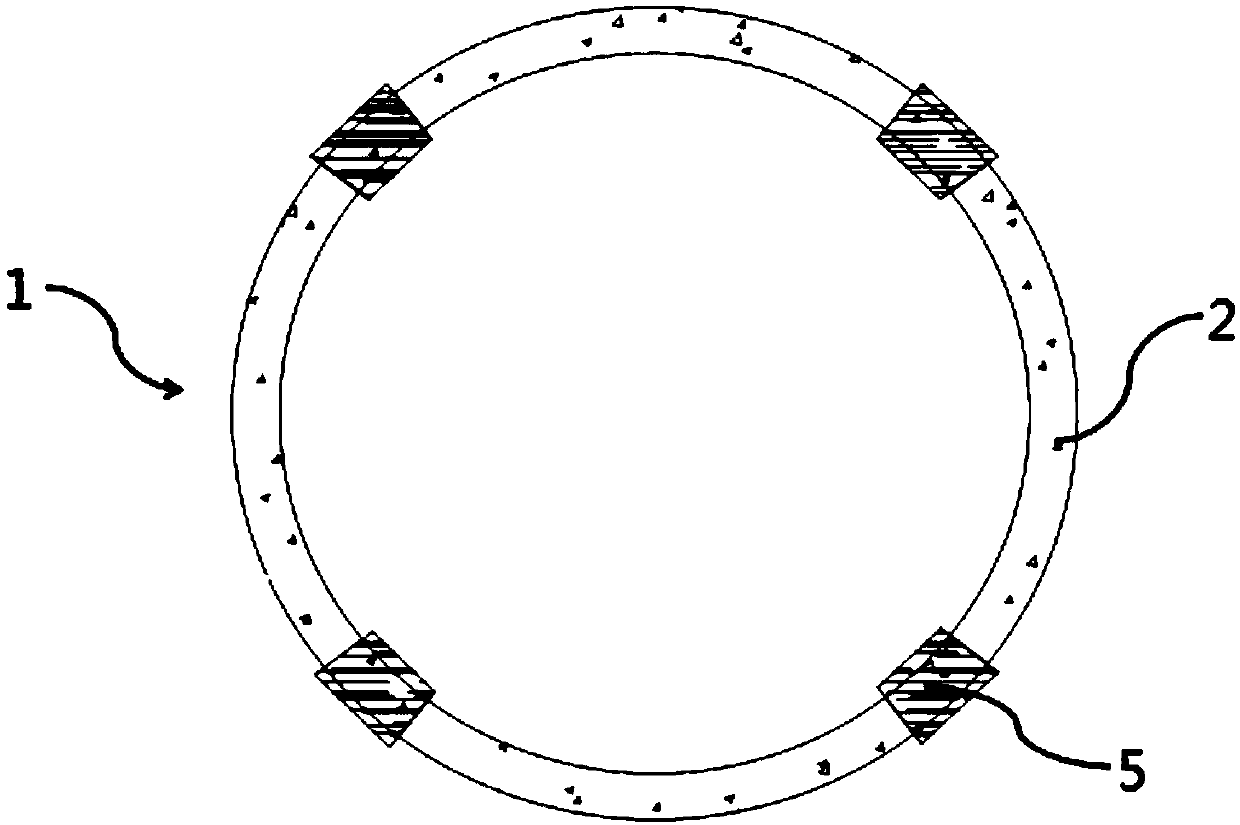

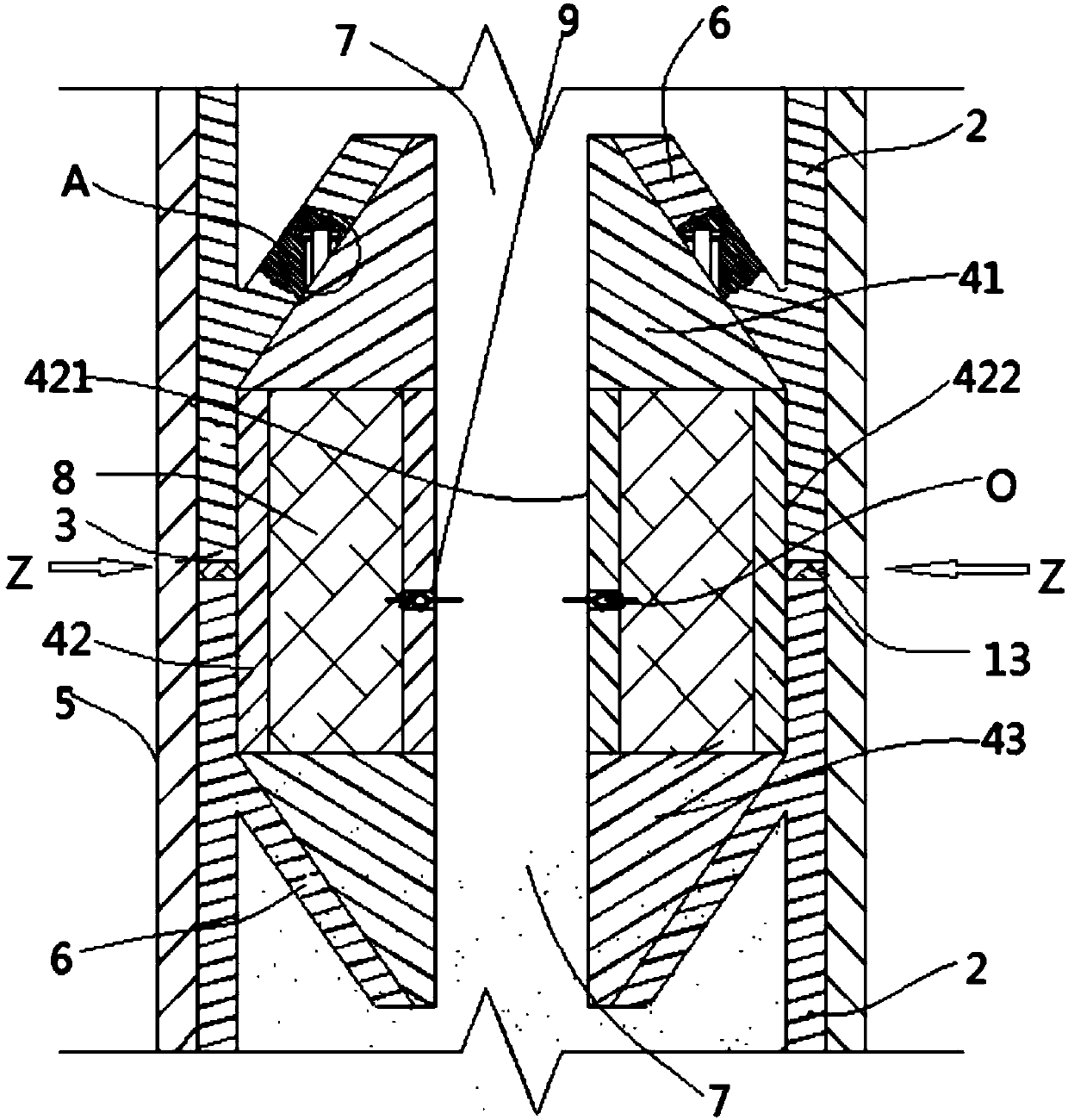

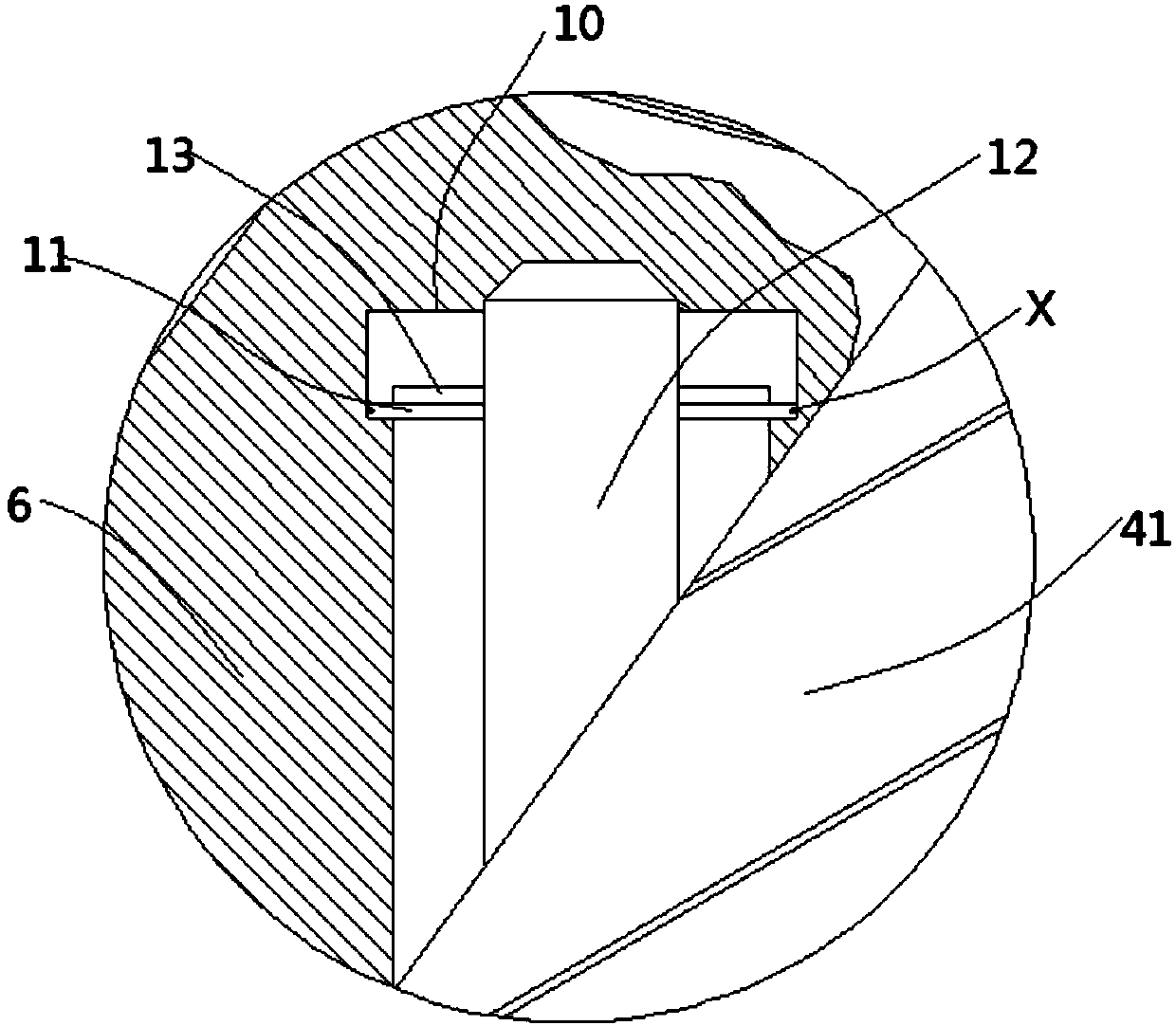

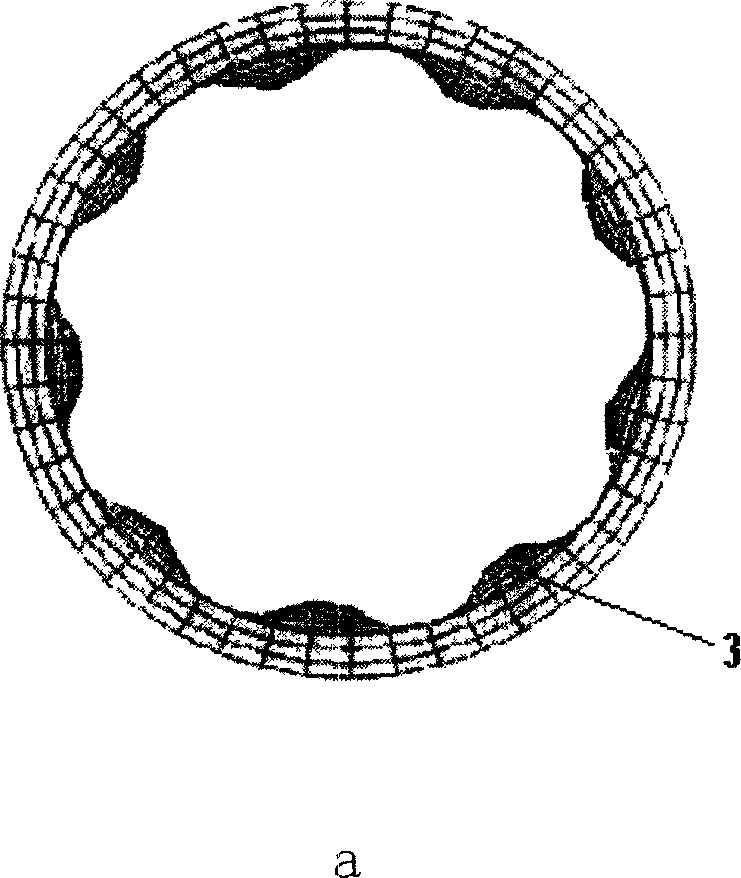

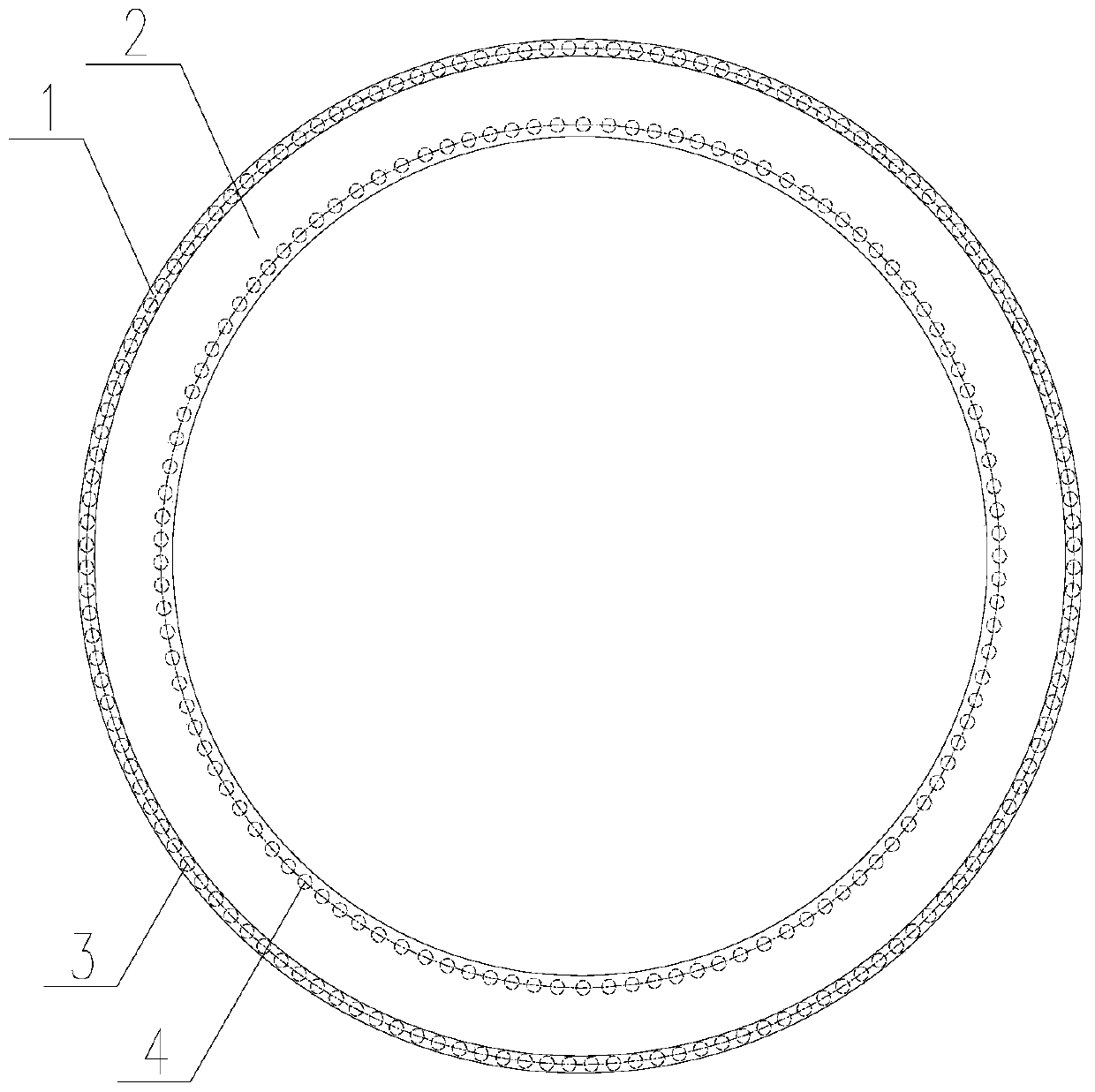

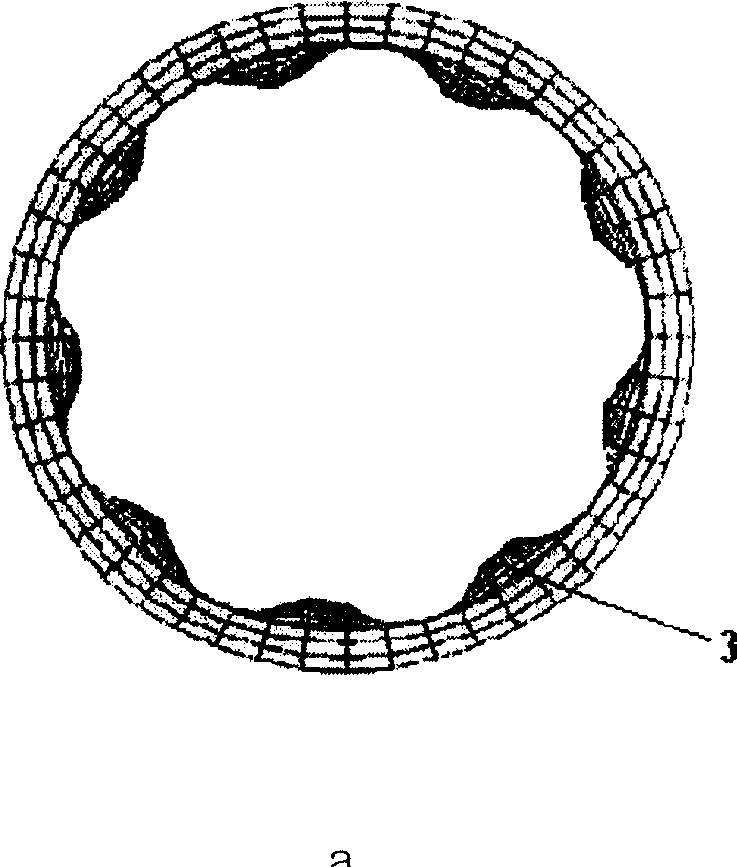

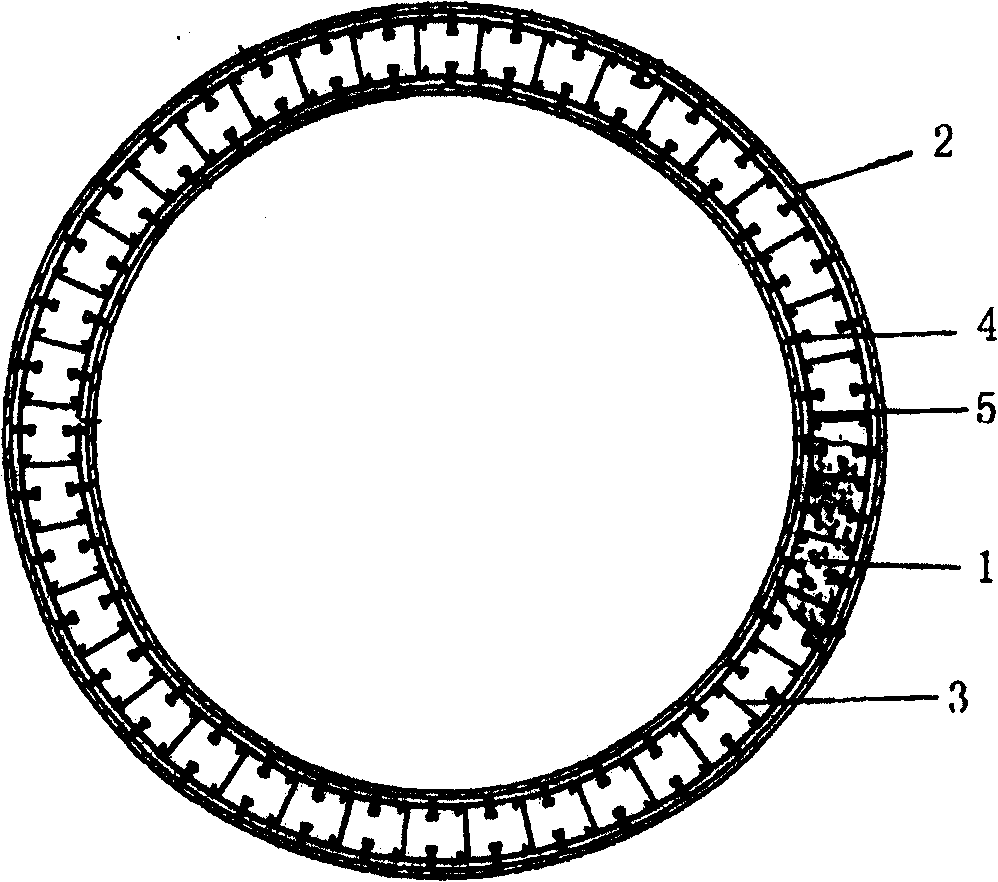

Yielding type annular support and supporting method

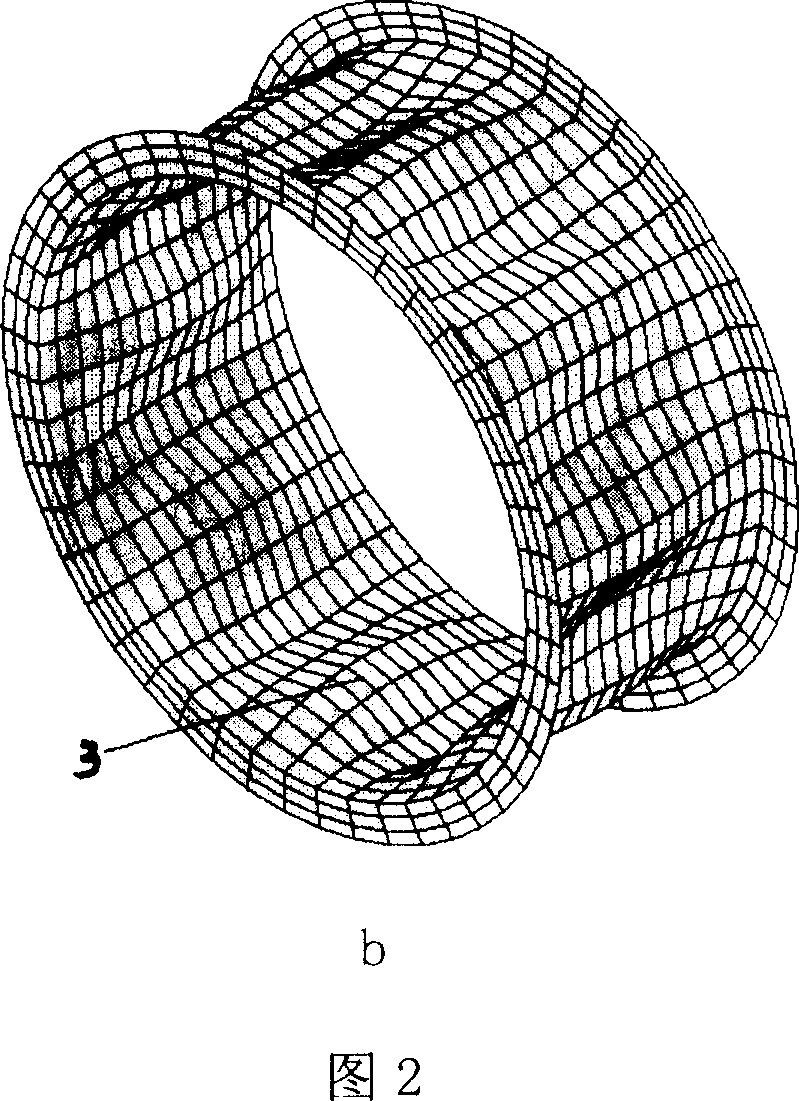

InactiveCN107795328AGive full play to the resistance to pressureAvoid destructive damageProps/chocksEngineeringArches of the foot

The embodiment of the invention discloses a pressure-yielding annular support and a support method, which relate to the technical field of geotechnical engineering and can effectively prevent the support body from being destroyed or at least reduce the degree of damage to the support body. It includes: a ring body, the ring body includes a plurality of sections of arc arches, the arc arches are connected from end to end through arc arch feet, and the two connected arc arch feet are butted with As for the pressure release member, a connecting piece is provided on the circumferential periphery of the junction between the pressure relief member and the arc arch foot, and the connection between the arc arch bottom foot and the pressure relief member is strengthened through the connection piece. The invention is suitable for support projects involving tunnels, roadways and the like in mining, petroleum, subway construction and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

SCS combined hydropower station pressure underground pipe design method

The invention discloses a way to design pressing tube of SCS combined hydraulic power station. Between the steel inside and the round wall fill concrete tube, between the concrete tube and the round wall fill the outside steel tube. The outside steel tube is anti-seepage , the middle concrete tube resists external pressure, and the inside steel tube only resists water pressure inside when operating. It decrease by large the content of steel and concrete and the cost, and it is convenient to transfer the water pressure from inside to outside. The way of design brings the good capability of steel and concrete into play, and apt to the work environment very well. Otherwise, in operation there is no need to add other ways, so it increases the speed of the operation by large.

Owner:XIAN UNIV OF TECH

Steel pipe in construction structure

The present invention relates to a new-type thin-wall steel pipe in building structure, in particular, it is a liquor-charged steel pipe. Said steel pipe is formed from pipe body and upper end face and lower end face which are welded on the upper and lower ends of said steel pipe respectively and used for closing the upper and lower two ends of said steel pipe. It is characterized by that in the interior of steel pipe the liquor is charged, on the pipe body is set a hole through which the water can be injected into the interior of steel pipe by means of high pressure so as to ensure that in the interior of steel pipe the air is not existed, so that it can raise the bearing capacity of steel pipe.

Owner:GUANGZHOU UNIVERSITY

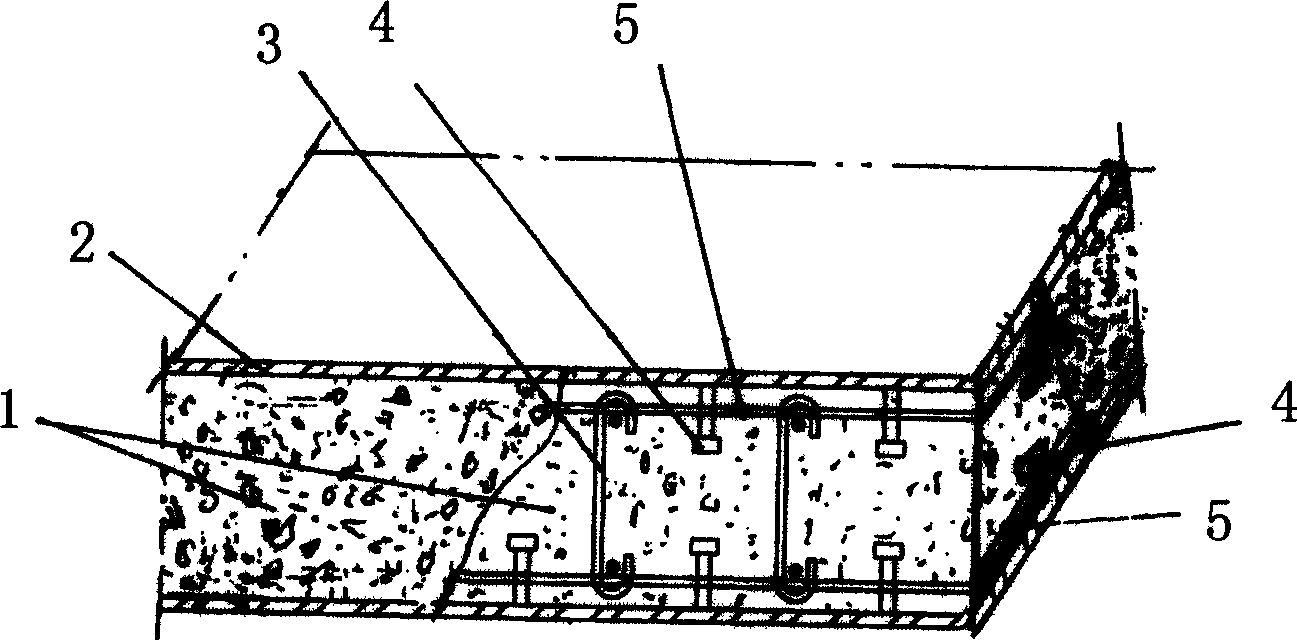

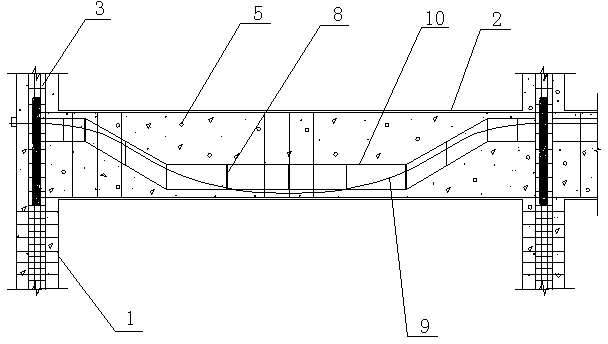

Rotary-cut plate laminated wood-light weight concrete combined floor system

ActiveCN106639095AGive full play to the resistance to pressureIncrease stiffnessFloorsRebarReinforced concrete

The invention discloses a rotary-cut plate laminated wood-light weight concrete combined floor system and belongs to the field of building structures. The rotary-cut plate laminated wood-light weight concrete combined floor system comprises a rotary-cut plate laminated wood grating, shear resistant connecting pieces, self-tapping bolts and a light weight concrete face plate based on ceramsite. The rotary-cut plate laminated wood grating is composed of wooden gratings with certain intervals and a wooden face plate, the shear resistant connecting pieces are fixed to the face plate through fastening bolts, a two-way reinforcement mesh is arranged on the face plate, then ceramsite concrete is poured, and an LLC system is formed. Compared with a common pure wood floor system, deformation, vibration and voice transmission of the floor system are reduced effectively; and compared with a traditional reinforced concrete floor, the self-weight of a combined floor is lower, and the earthquake action borne by a structure and the load transmitted to a foundation by the structure are both smaller. The rotary-cut plate laminated wood-light weight concrete combined floor can be used for floorboards, floors, landscape bridges and pedestrian ways.

Owner:YANGZHOU UNIV

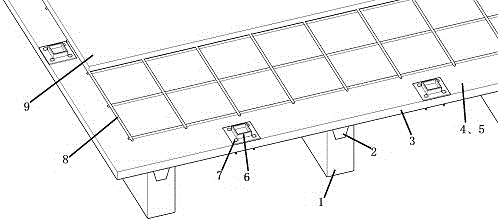

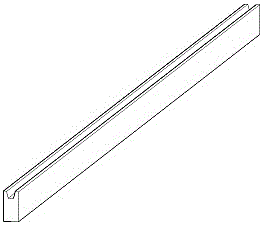

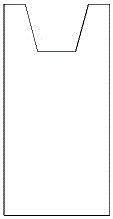

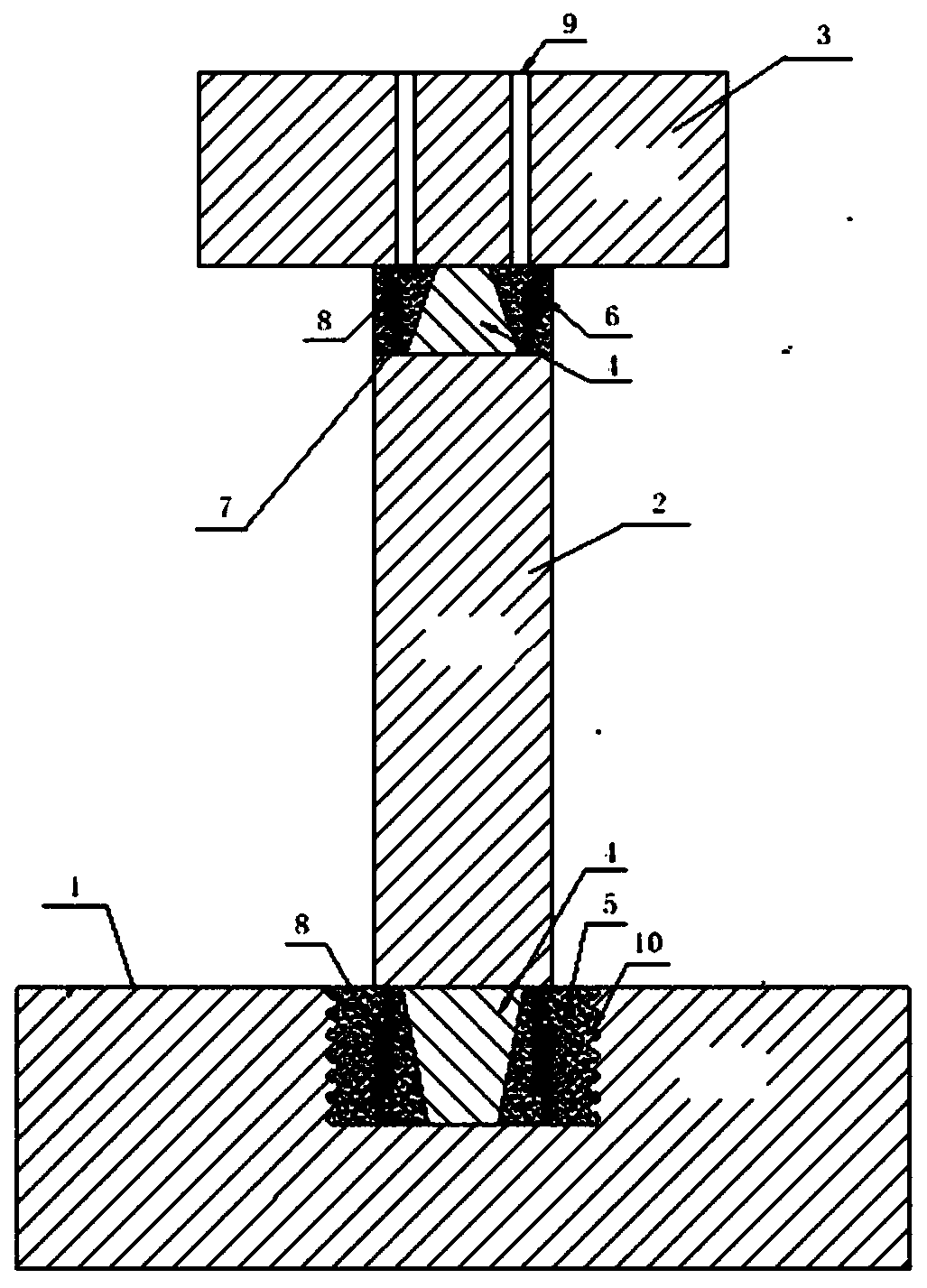

External structure suitable for prefabricated assembled pier stud connection and construction method thereof

PendingCN111485485AStable structureImprove seismic performanceBridge structural detailsFoundation engineeringArchitectural engineeringPier

The invention discloses an external structure suitable for prefabricated assembled pier stud connection and a construction method thereof. The external structure comprises a bearing platform, a pier body and a cover beam which are sequentially arranged from bottom to top; pouring spaces are formed between parts, corresponding to the cover beam and the bearing platform, of the upper end and the lower end of the pier body and are used for pouring concrete, and the cover beam, the pier body and the bearing platform form a fixed whole; the portions, correspondingly connected with the cover beam and the bearing platform, of the upper end and the lower end of the pier body are provided with reinforcing components respectively, and the reinforcing components arranged at the upper end and the lower end of the pier body are both located in the pouring spaces of the corresponding ends of the pier body. The external structure has the technical effects of being stable in structure, reliable in connection, convenient to adjust and capable of being rapidly installed, and can be widely applied to the field of building construction.

Owner:CCCC SECOND HARBOR ENG +1

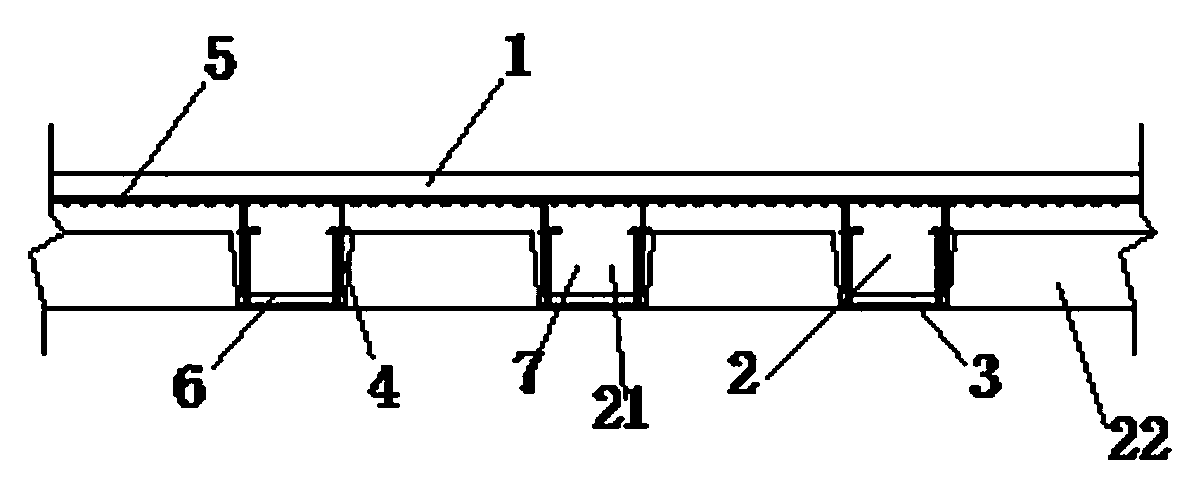

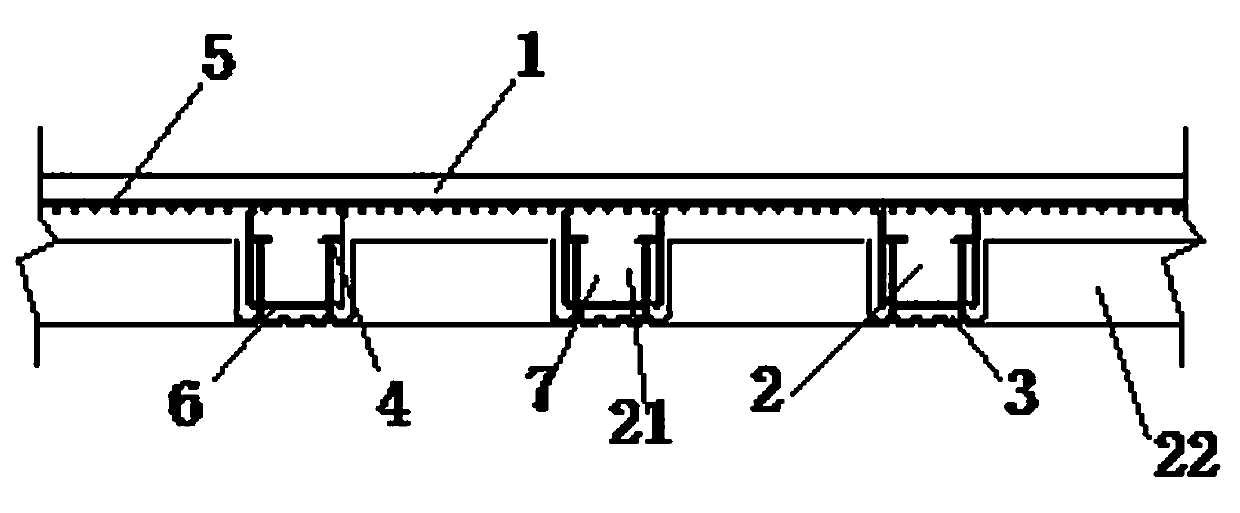

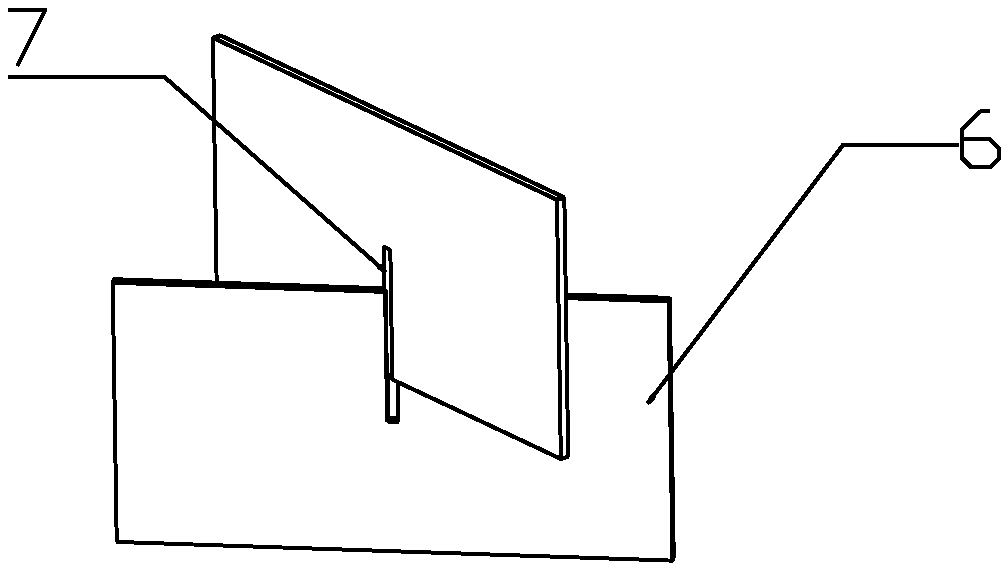

Ultra high performance concrete rib with rib bottom steel plate for bridge deck slab

PendingCN109577188AGive full play to the resistance to pressureGive full play to the tensile strengthBridge structural detailsSheet steelBridge deck

The invention provides an ultra high performance concrete rib with a rib bottom steel plate for a bridge deck slab. The ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab is mainly to solve technical problems, such as easy fatigue cracking, poorer tensile and compressive performance, low section utilization efficiency and high cost, of an existing ultra high performance concrete rib. The key point of the technical scheme is that the ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab comprises a rib body (7) andthe rib bottom steel plate (3); the rib bottom steel plate (3) is arranged at the bottom of the rib body (7); a shear connector (4) is arranged on the upper surface of the rib bottom steel plate (3);ultra high performance concrete is poured around the shear connector (4) on the rib bottom steel plate (3) to form the rib body (7); and the upper part of the shear connector (4) is connected with areinforcing mesh in a panel (1). The ultra high performance concrete rib with the rib bottom steel plate for the bridge deck slab is mainly used for the bridge deck slabs.

Owner:HUNAN UNIV +1

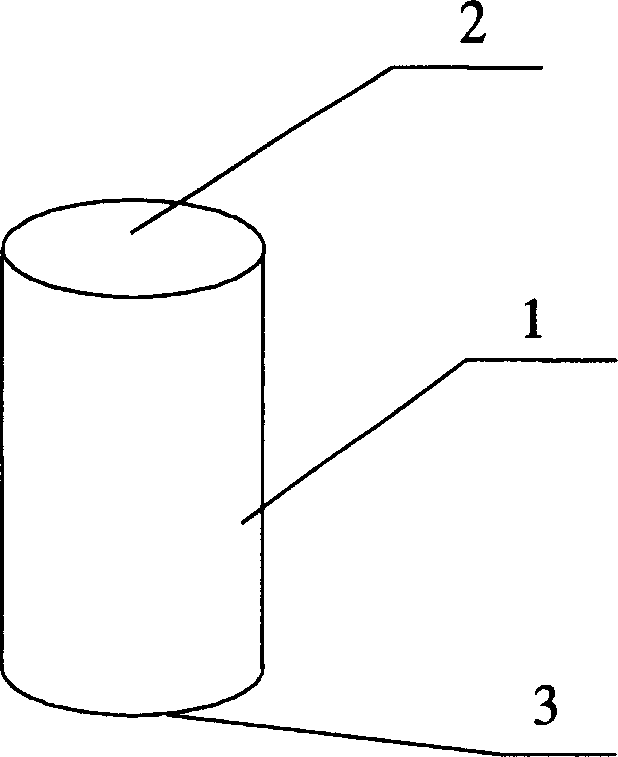

Annular plate support foundation pit supporting structure and construction method thereof

InactiveCN110528535AGive full play to the resistance to pressureForce form scienceExcavationsAxial pressureStructure of the Earth

The invention provides an annular plate support foundation pit supporting structure and a construction method thereof, and relates to the technical field of underground engineering. The annular platesupport foundation pit supporting structure comprises a first supporting pile, a second supporting pile, a ring crown beam and an annular plate support; lateral water and soil pressure at the periphery of a foundation pit is transferred to the annular plate support and the ring crown beam through the first supporting pile and the second supporting pile, and is converted to axial pressure of the annular plate support and the ring crown beam, so that the deformation of the foundation pit is controlled, and the pressure resistance of concrete is fully exerted; the shear force and the bending moment in the annular support plate and the ring crown beam are both lower, so that the stress form is more scientific; and the annular plate support and the ring crown beam annularly arranged around thefoundation pit have no need to reserve space for inner supports and stand columns thereof, so that an earthwork excavation working surface and a soil outlet channel of the foundation pit are arrangedon a plane and a vertical surface more easily, and the technical problem of a supporting structure in the prior art incapable of meeting the foundation pit operation demands under soft soil environments is relieved.

Owner:云南建投第十二建设有限公司

SCS combined hydropower station pressure underground pipe design method

The invention discloses a way to design pressing tube of SCS combined hydraulic power station. Between the steel inside and the round wall fill concrete tube, between the concrete tube and the round wall fill the outside steel tube. The outside steel tube is anti-seepage , the middle concrete tube resists external pressure, and the inside steel tube only resists water pressure inside when operating. It decrease by large the content of steel and concrete and the cost, and it is convenient to transfer the water pressure from inside to outside. The way of design brings the good capability of steel and concrete into play, and apt to the work environment very well. Otherwise, in operation there is no need to add other ways, so it increases the speed of the operation by large.

Owner:XIAN UNIV OF TECH

Building with rescue function

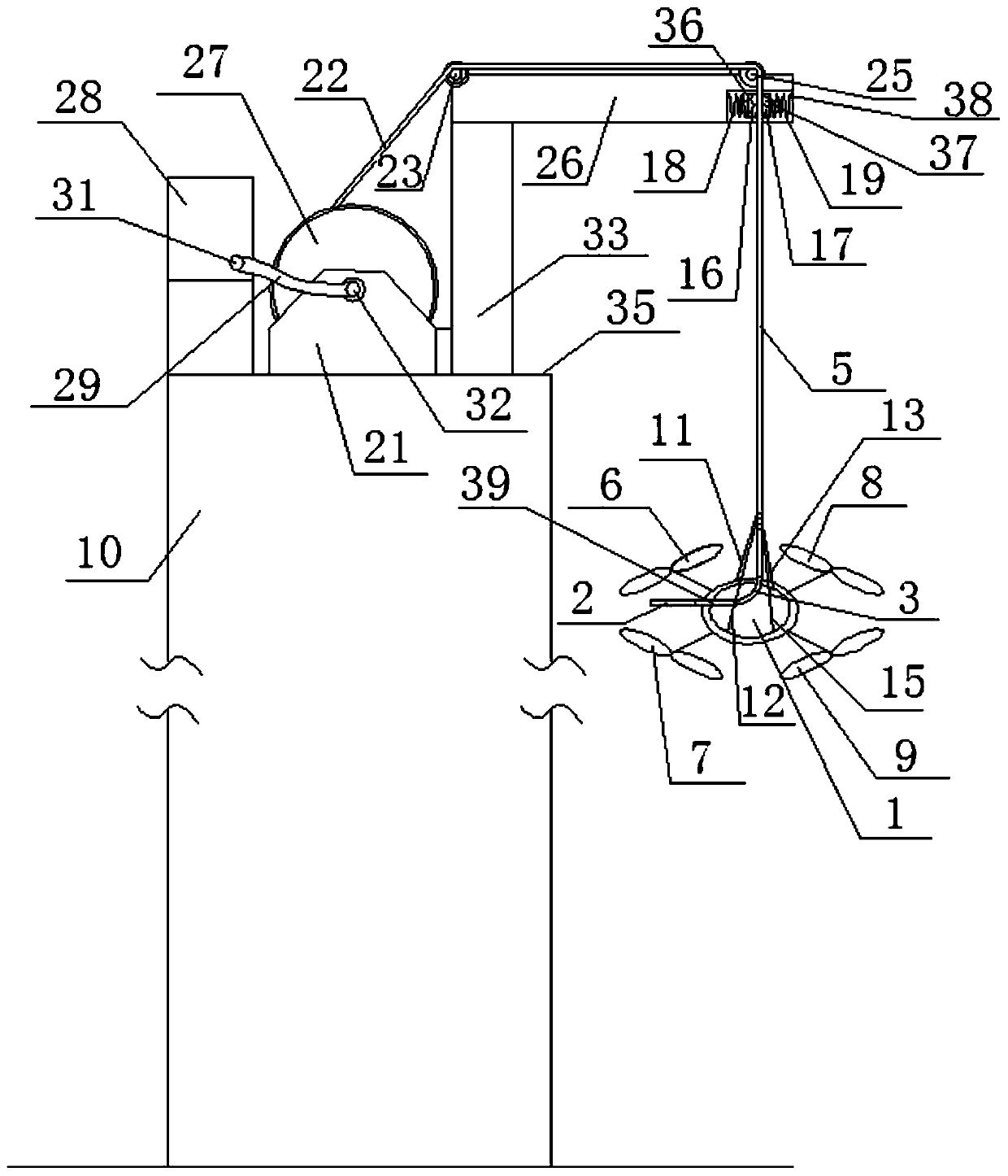

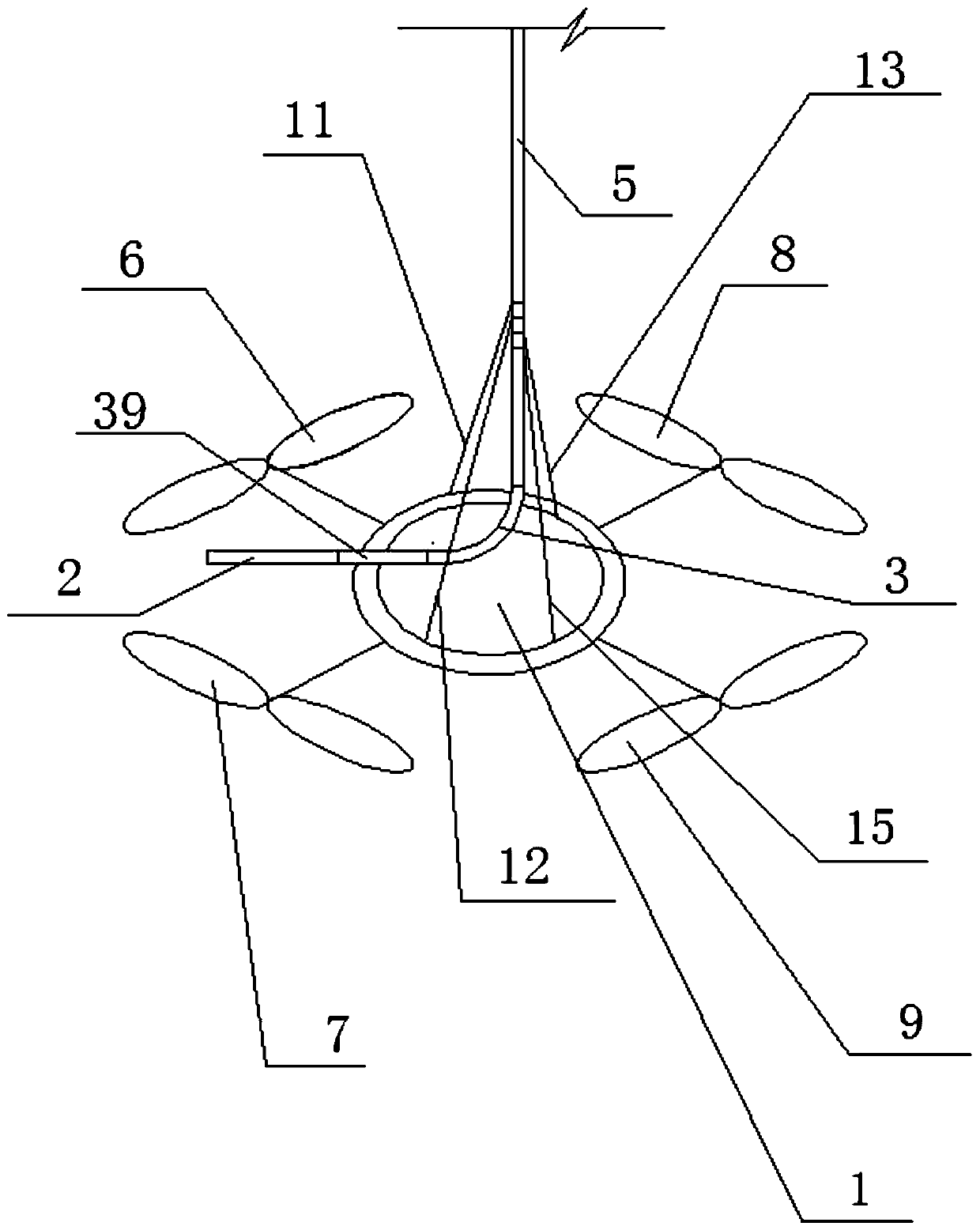

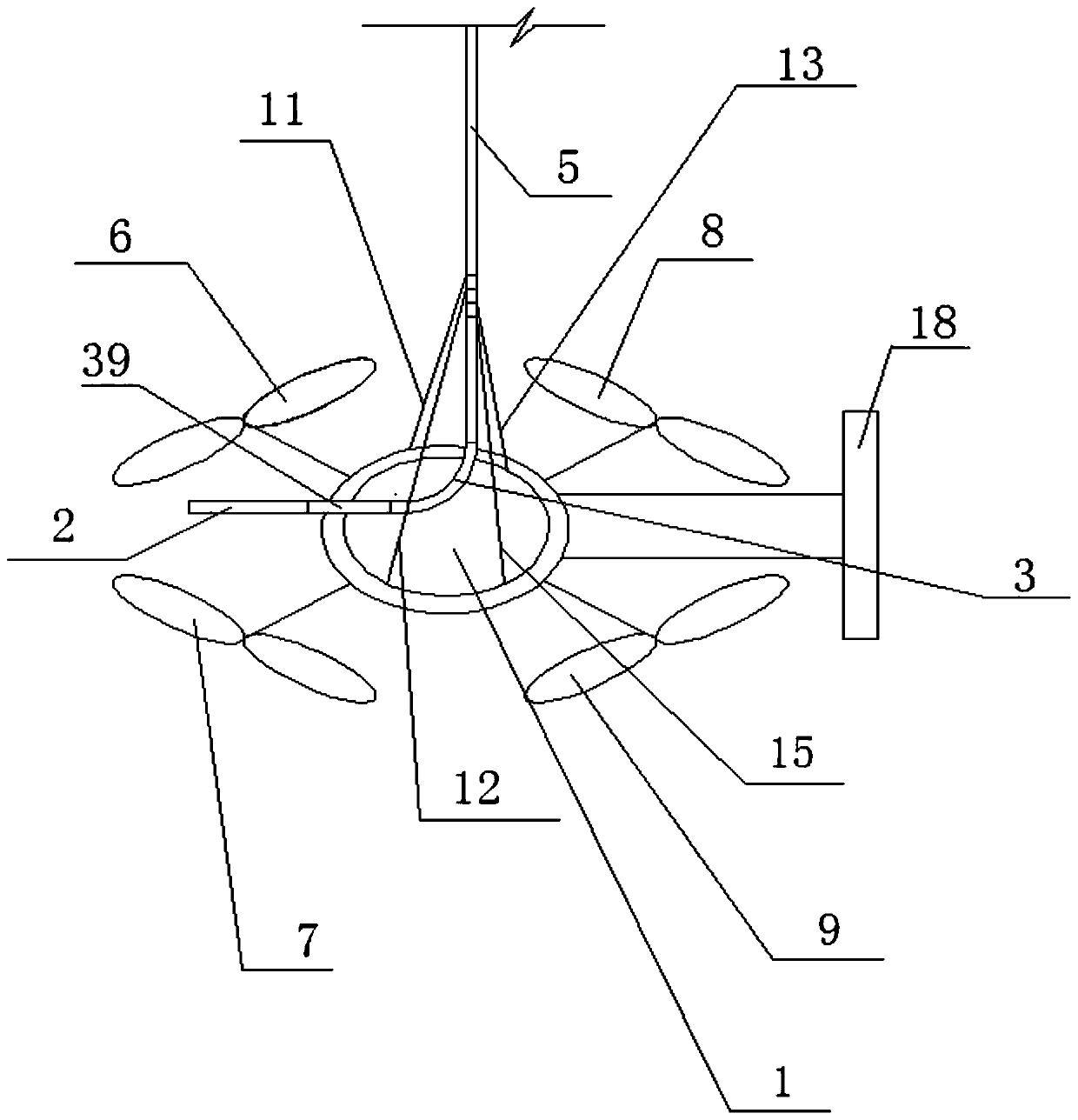

PendingCN111184969AGuaranteed enclosing friction gripNot easy to damageFire rescueRespiratory apparatusArchitectural engineeringCantilever

The invention relates to a building with a rescue function. The building with the rescue function is characterized in that an electric pipe winder, a cantilever mechanism and a spraying mechanism arearranged on a roof or a refuge floor of the building, the spraying mechanism comprises a supporting structure and at least two rotating wings, the rotating wings are distributed on the supporting structure, a spraying gun or a spraying head or a transverse water outlet pipe is transversely connected to the supporting structure, the cantilever mechanism comprises a transverse cantilever, a windingdrum of the electric pipe winder is connected with and wound with a rubber pipe, the rubber pipe wound by the winding drum of the electric pipe winder extends out of the winding drum, extends from theinner side to the outer side of the cantilever and then extends downwards to form a vertical rubber pipe to be connected with a water inlet of the spray gun or the spray head or the transverse wateroutlet pipe, and the supporting structure or the spray gun or the spray head or the transverse water outlet pipe is transversely suspended on the vertical rubber pipe.

Owner:吴旭榕

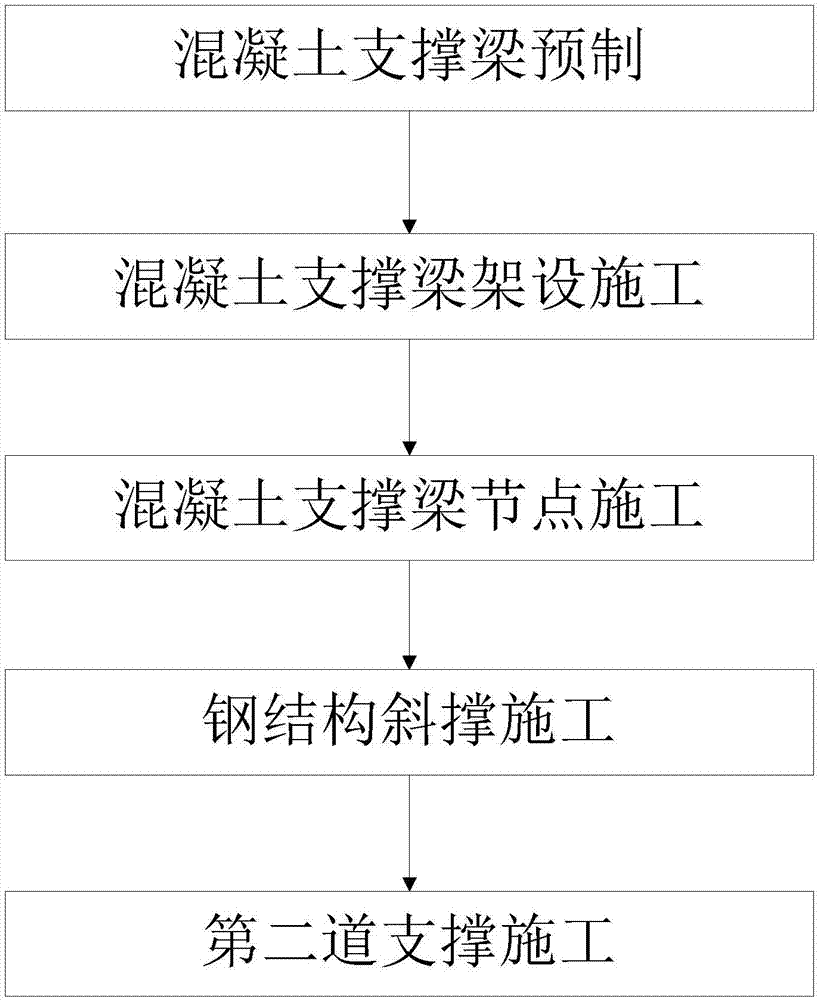

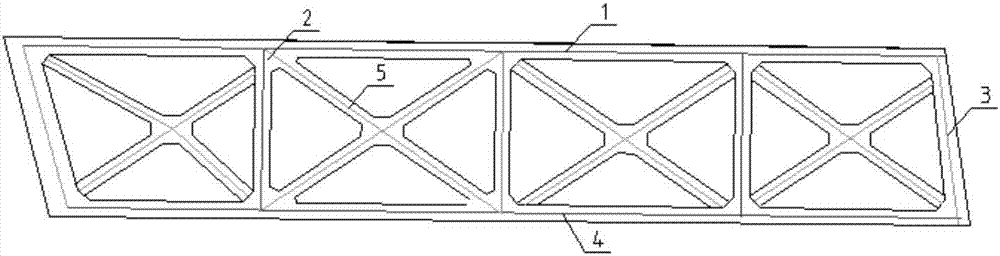

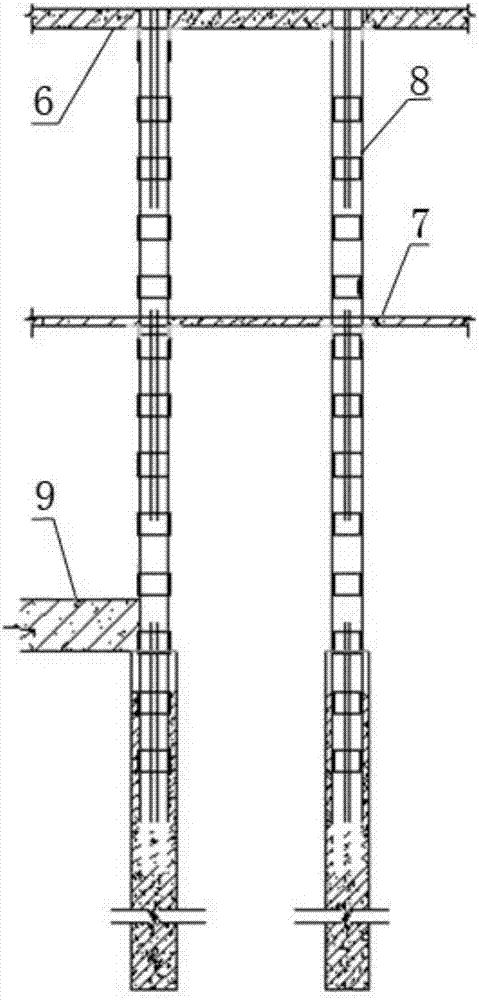

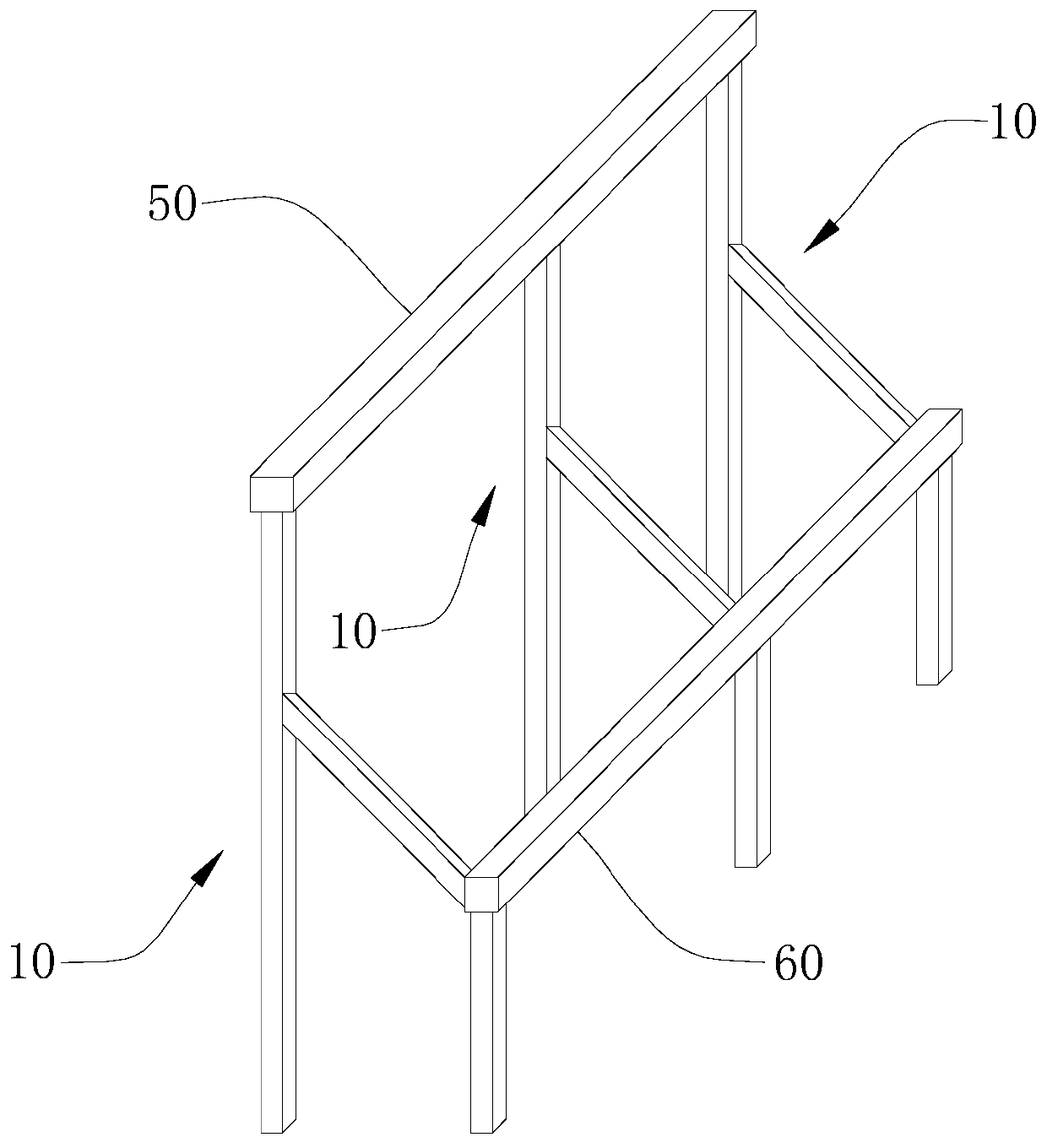

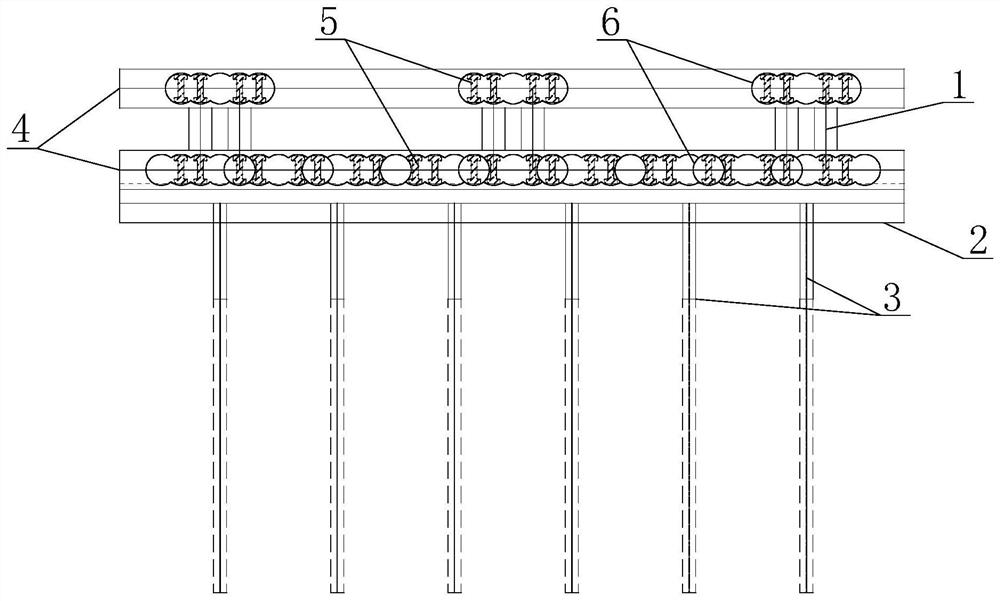

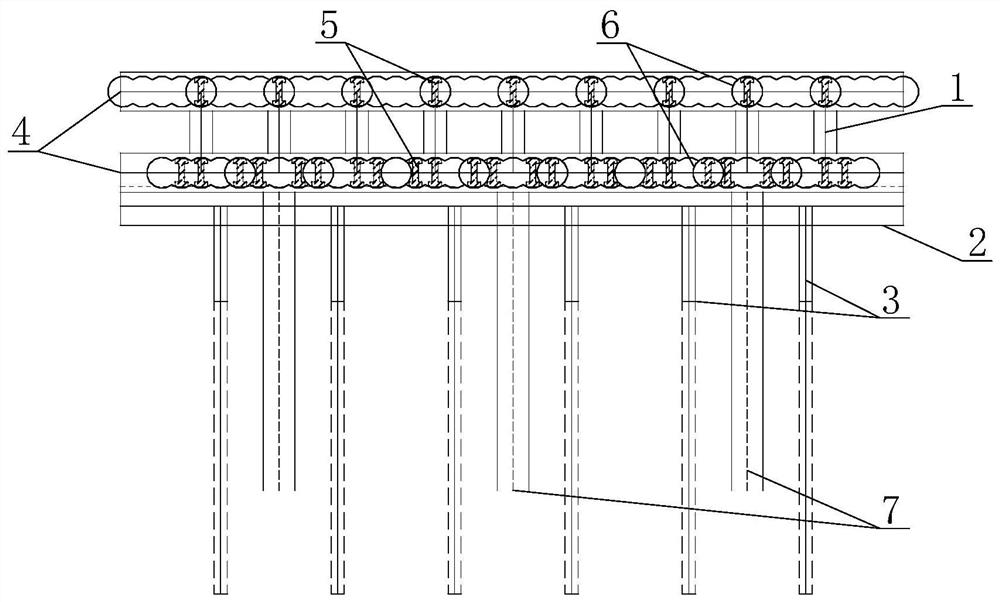

Construction method of preassembly supporting beam combined system

InactiveCN107090835AGive full play to the resistance to pressureGive full play to the tensile strengthExcavationsSupporting systemEngineering

The invention discloses a construction method of a preassembly supporting beam combined system. The construction method includes the following steps of 1, concrete supporting beam prefabrication; 2, concrete supporting beam erection construction; 3, concrete supporting beam joint construction; 4, steel structure inclined strut construction; and 5, second pre-assembly concrete supporting beam and steel structure inclined strut construction according to the steps. An upper support and a lower support are connected through a steel lattice column vertical supporting pile to form the combined supporting system. Concrete supporting beams are preassembled in a factory, construction quality can be guaranteed, the beams can be preassembled in advance according to construction period requirements, and formworks can be used in a circulating manner; and the combined system fully exerts the compressive property of concrete and the tensile property of the steel structure. The concrete supporting beams are assembled and connected together, dismounting is convenient, energy consumption is low, and environmental friendliness is achieved. Steel structure inclined struts are low in steel structure dead weight, high in tensile capacity, rapid to mount and dismount, reusable and free of pollution.

Owner:CHINA FIRST METALLURGICAL GROUP

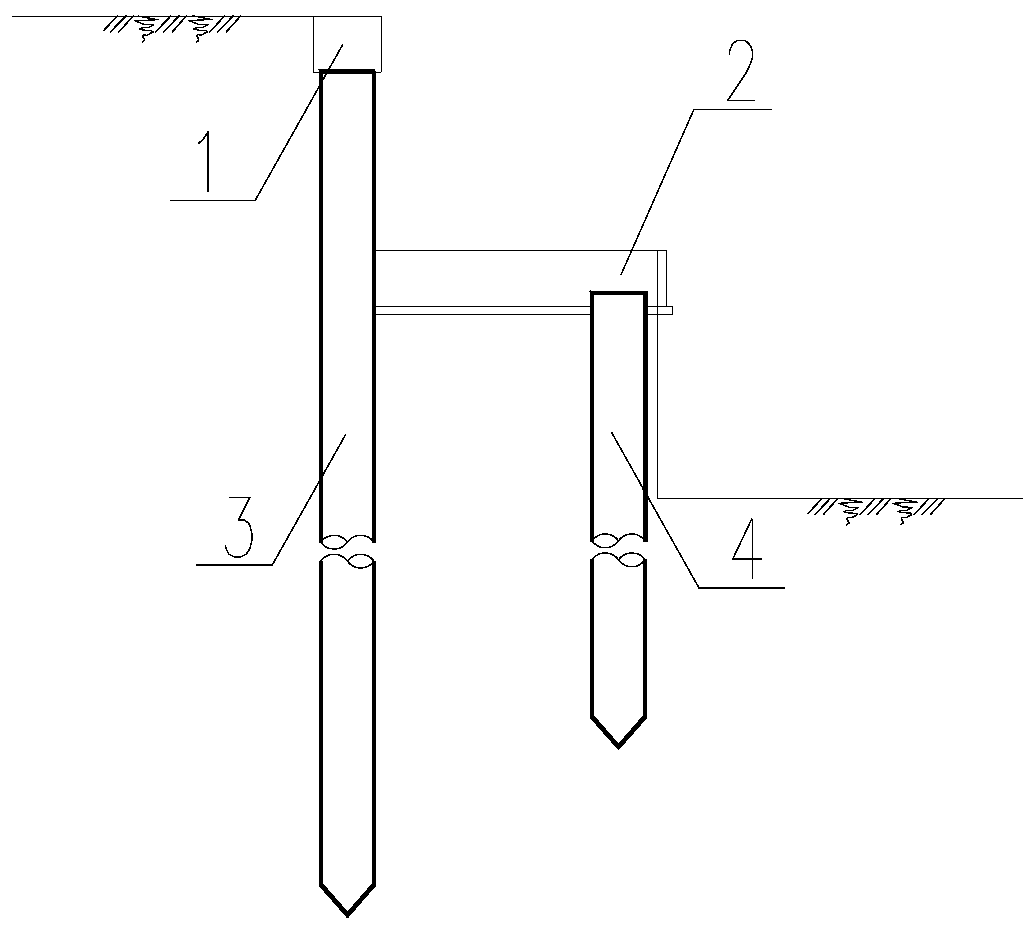

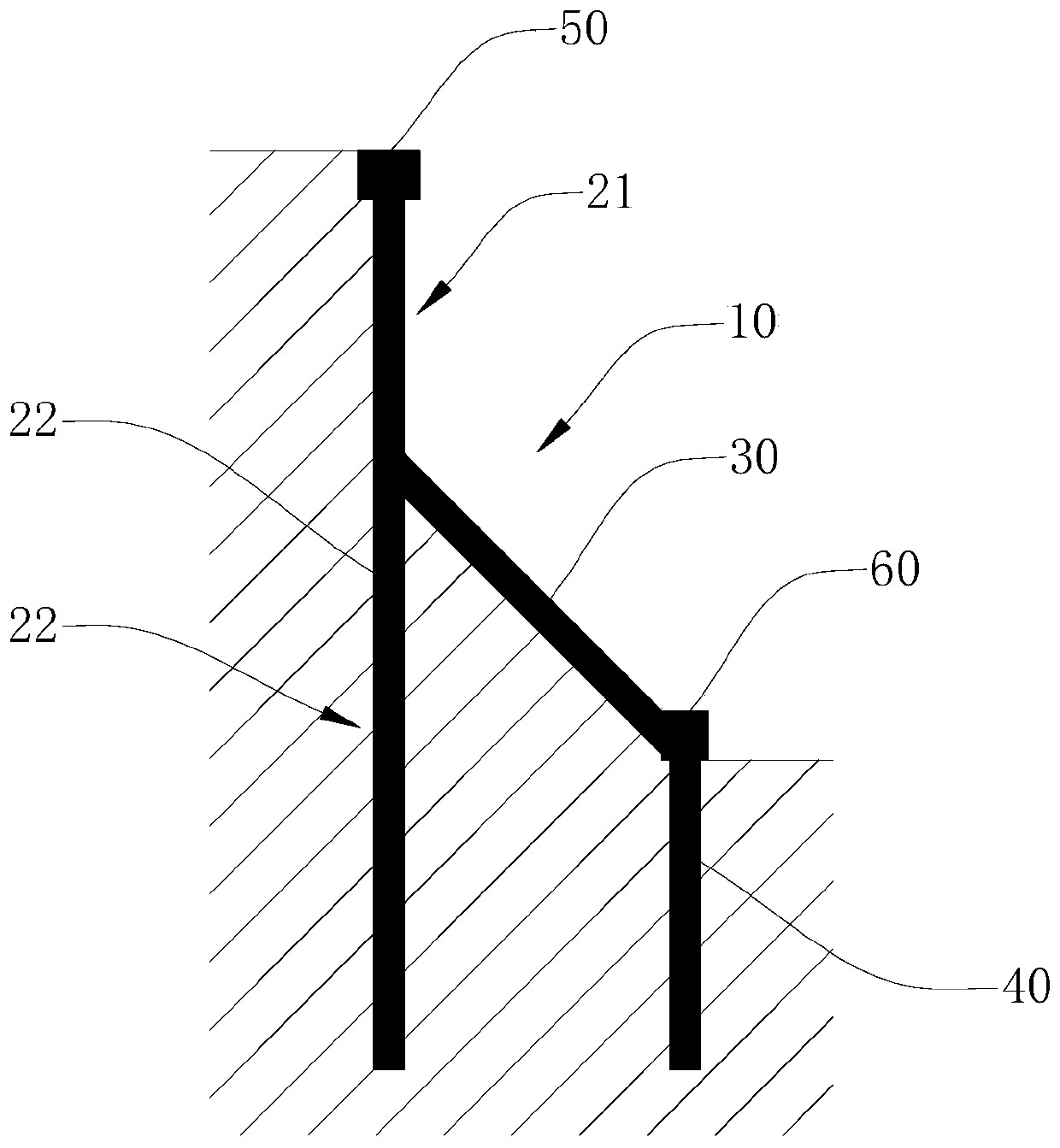

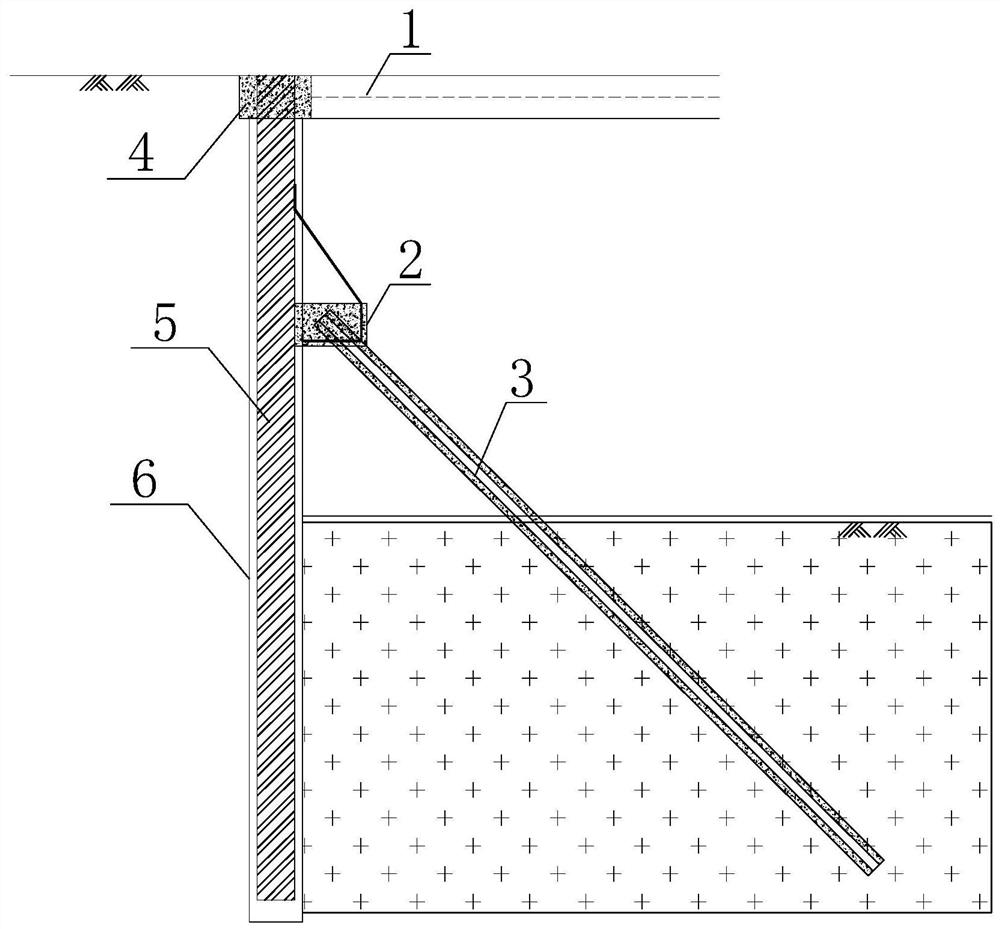

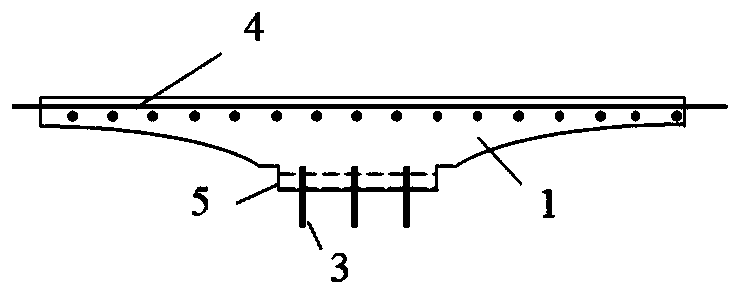

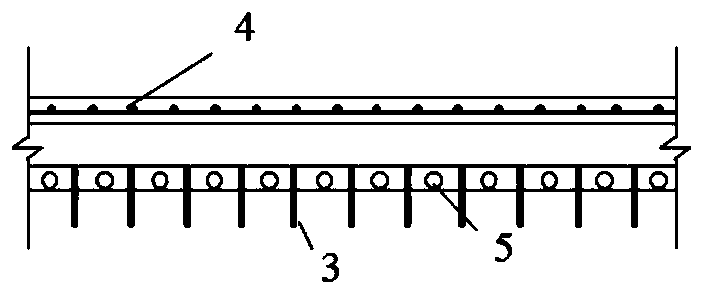

Slope supporting structure and construction method

PendingCN111305237AGive full play to the resistance to pressureAct as counter pressureExcavationsClimate change adaptationArchitectural engineeringStructure support

The invention discloses a slope supporting structure and a construction method, and belongs to the technical field of slope prevention and control. The slope supporting structure includes a pluralityof supporting units arranged at intervals. Each supporting unit comprises a vertical pile, an inclined beam and a pile foundation, wherein the two ends of the inclined beam are separately connected with the vertical pile and the pile foundation. The top ends of the adjacent vertical piles are connected through coping beams, and the adjacent pile foundations are connected through foundation beams.The slope supporting structure can effectively support a slope without need for large equipment, so that the problem that the large equipment is difficult to dispose in place or large disturbance is caused to the slope is avoided; compared with single-row or double-row micro piles, the slope supporting structure has the advantages that stress is more reasonable and the deformation resistance is higher; and compared with multi-row micro piles, the slope supporting structure has the advantages that the construction period is short and the cost is low.

Owner:CCTEG CHONGQING ENG CO LTD

Rhombus multi-cavity steel plate-concrete composite beam

InactiveCN108149843AOvercome crackingGive full play to the resistance to pressureLoad-supporting elementsSheet steelFloor slab

The invention discloses a rhombus multi-cavity steel plate-concrete composite beam, and belongs to the field of constructional engineering. The rhombus multi-cavity steel plate-concrete composite beamcomprises a multi-cavity space steel beam and concrete; the concrete is poured into the rhombus multi-cavity steel beam to form a combined integral component; the rhombus multi-cavity steel beam is composed of a steel plate shell and steel plate cavities with notches; the steel plate is composed of five steel plates in a welding mode; the steel plate cavities with the notches are connected in aninserted mode up and down and welded in the steel plate shell to form a rhombus multi-cavity steel beam; and the concrete is poured into the steel beam to form the rhombus multi-cavity steel plate-concrete composite beam. The rhombus multi-cavity steel plate-concrete composite beam has the beneficial effects that the problems of liable cracking and exposure cracking of traditional concrete components can be solved, the steel plate cavities have a high lateral restraining effect on the concrete, the compressive property of the concrete can be fully played, the self weight is light, the composite beam after molding has better overall performance, the steel plate shell replaces steel bars and structural steels in the traditional floor slab to play the role of the template, the construction operation of traditional form erecting and form stripping is avoided, the rhombus multi-cavity steel plate-concrete composite beam can replace a traditional template in the construction site, the construction progress is increased, and the economic benefit is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

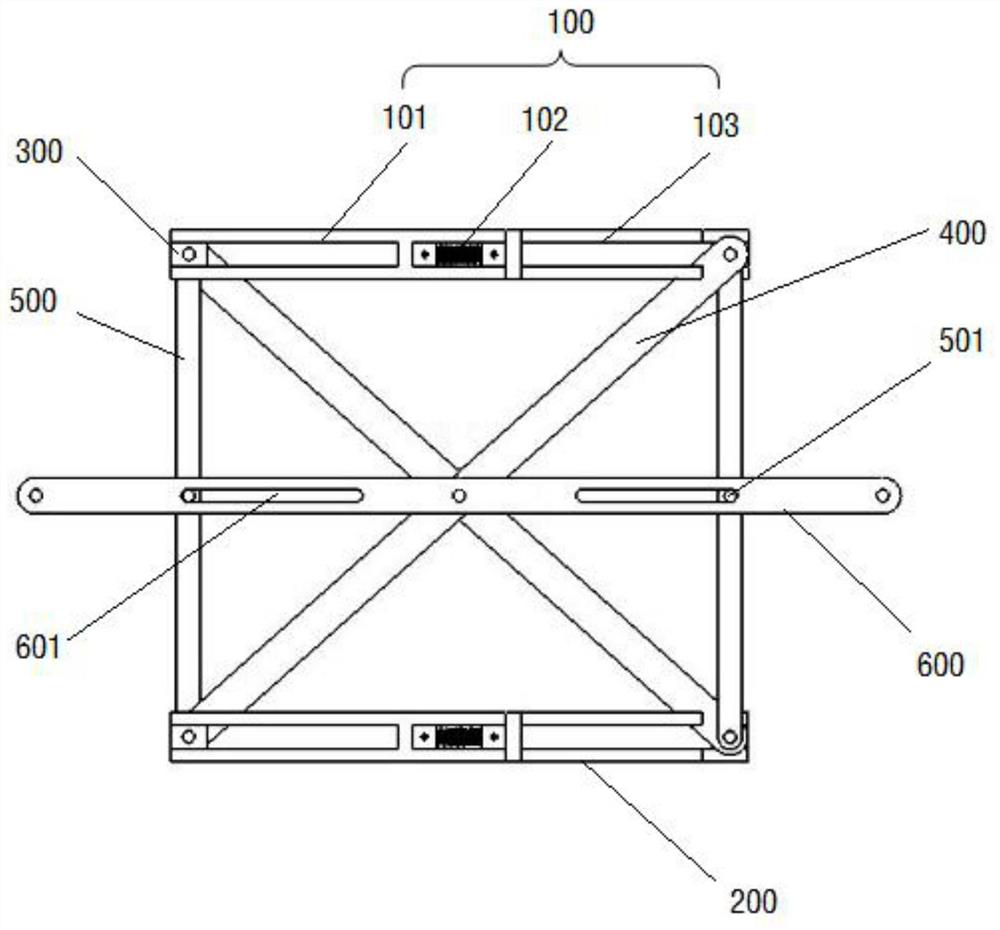

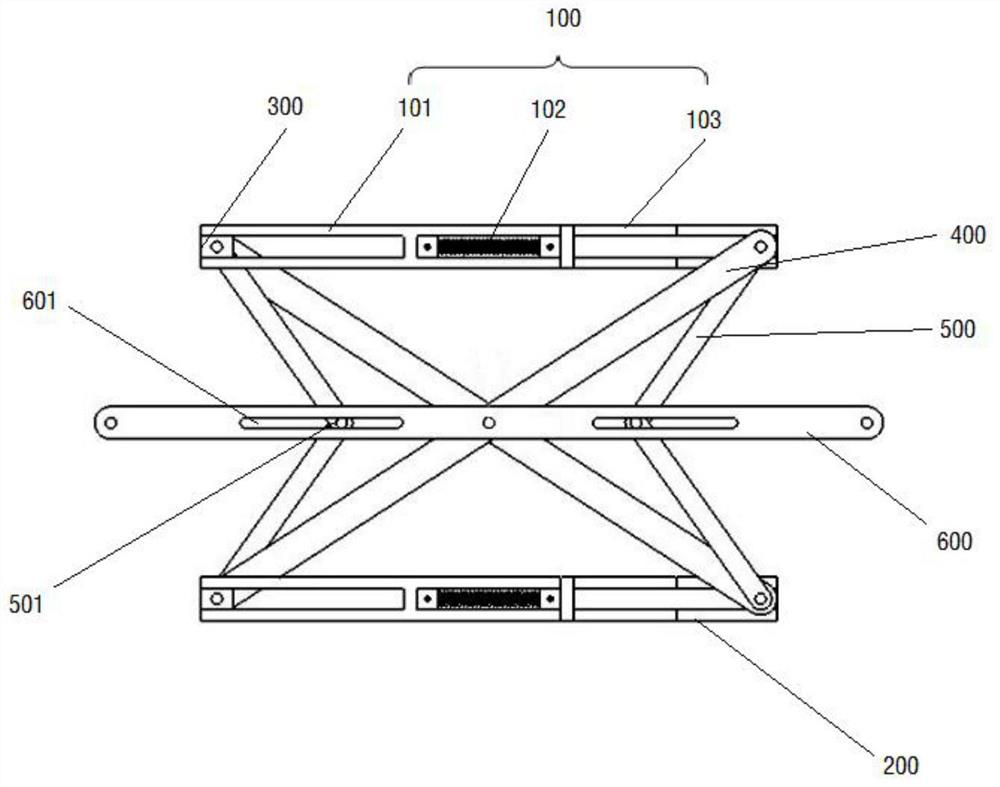

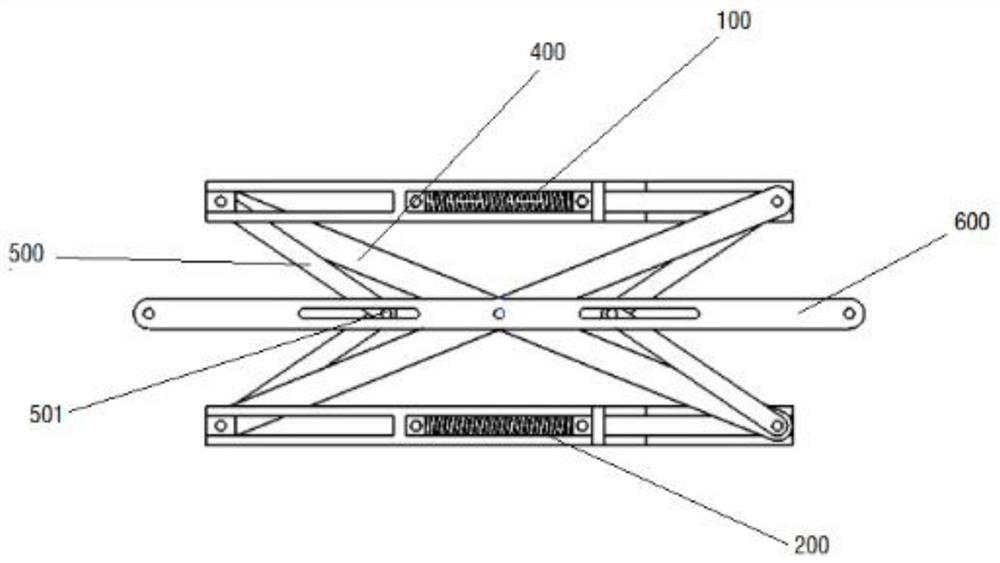

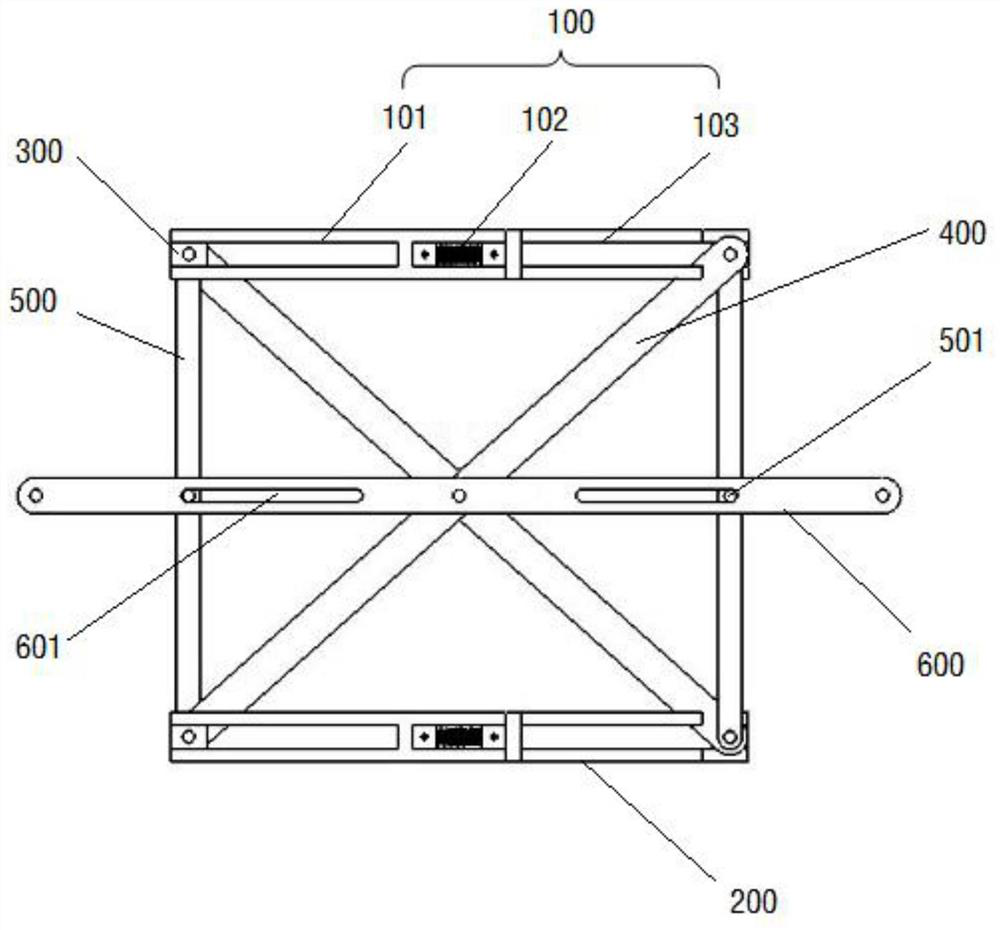

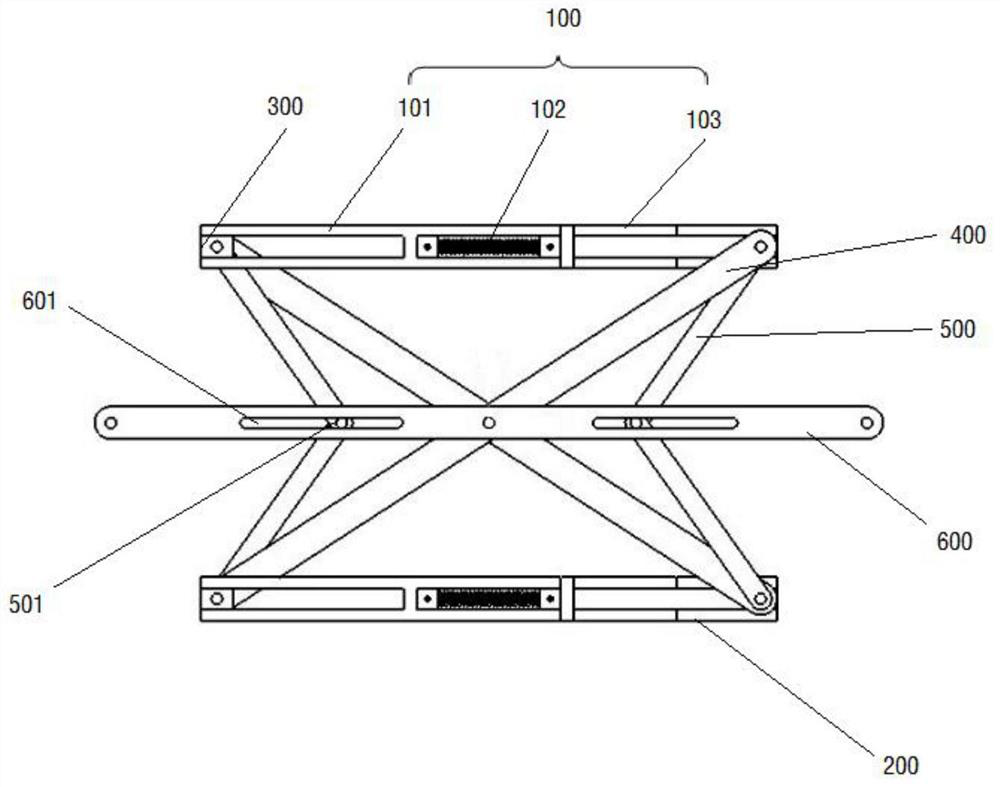

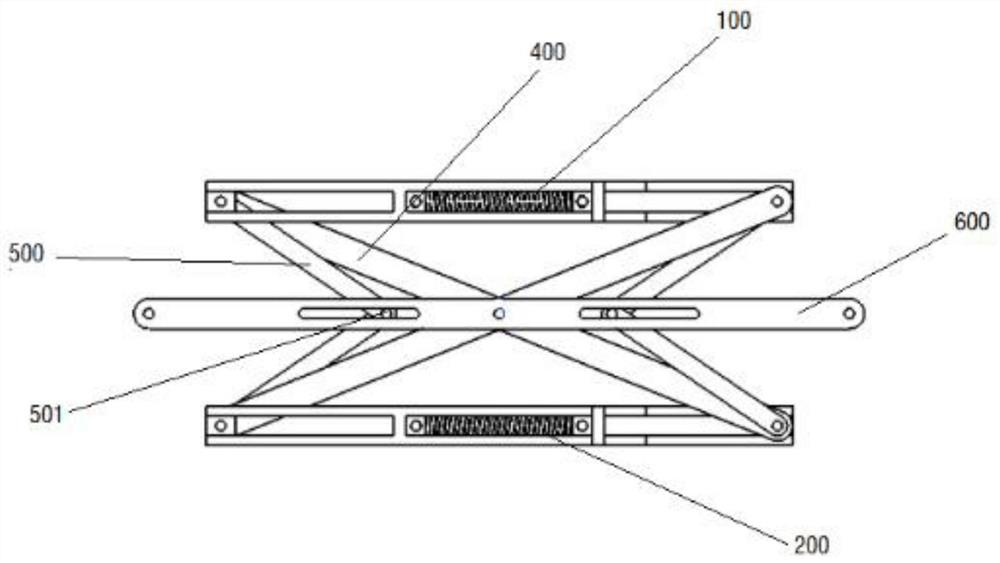

Extensible mechanism damper based on two-rod tensegrity

ActiveCN112815029AGive full play to the resistance to pressureGive full play to the tensile strengthVibration suppression adjustmentsShock absorbersClassical mechanicsDamper

The invention relates to an extensible mechanism damper based on two-rod tensegrity. The extensible mechanism damper comprises a first stretching mechanism and a second stretching mechanism which have the same structure, are parallel to each other and are arranged at a certain interval. Each stretching mechanism comprises a first connecting rod, a second connecting rod and an extension spring, wherein the two ends of the extension spring are correspondingly hooked to the ends, close to each other, of the first connecting rod and the second connecting rod respectively, and fixing blocks are fixed to the ends, away from the extension spring, of the first connecting rod and the second connecting rod. The middles of two long inclined rods are hinged in a crossed mode, a middle hinge point is formed in the middle, and the two ends of each long inclined rod are hinged to the corresponding fixing blocks on the first connecting rods or the second connecting rods in the first stretching mechanism and the second stretching mechanism respectively. One ends of every two short inclined rods are hinged to form a floating hinge point, and the other ends are hinged to the two corresponding fixing blocks on the same side of the first stretching mechanism and the second stretching mechanism respectively. According to the extensible mechanism damper, a large rigidity change is achieved through small deformation, a tensioning mechanism and an extensible mechanism are combined, the stability is high, and the damping effect is good.

Owner:CHANGCHUN UNIV OF TECH

A Deployable Mechanism Shock Absorber Based on Two-Rod Tensioning Integral

ActiveCN112815029BGive full play to the resistance to pressureGive full play to the tensile strengthVibration suppression adjustmentsShock absorbersClassical mechanicsTensegrity

The invention relates to a deployable mechanism shock absorber based on two-rod tensioning integral, comprising a first stretching mechanism and a second stretching mechanism with the same structure, parallel and arranged with a certain interval, both of which include a first connecting rod and a second connecting rod. rod and tension spring; both ends of the tension spring are respectively connected to the close ends of the first connecting rod and the second connecting rod; the ends of the first connecting rod and the second connecting rod far from the tension spring are fixed with fixing blocks; The middle of the long diagonal rods is arranged in a cross-hinged manner, and a middle hinge point is formed in the middle. The two ends of each long diagonal rod are hinged to the first connecting rod or the second connecting rod in the first stretching mechanism and the second stretching mechanism. The corresponding fixed block One end of the two short inclined rods is hinged to form a floating hinge point, and the other end is hinged to two fixed blocks corresponding to the same side of the first stretching mechanism and the second stretching mechanism respectively. The invention realizes a large change in rigidity through small deformation, combines the tensioning mechanism with the expandable, high stability and good shock absorption effect.

Owner:CHANGCHUN UNIV OF TECH

Steel plate-concrete composite lining

InactiveCN100458102CImprove mechanical propertiesLarge bearing capacityUnderground chambersTunnel liningShotcreteSheet steel

The present invention disclose a steel plate-concrete composite lining which combines support and water proof and belongs to tunnel safe support device range. It can be applied for construction of new tunnel with high force bearing and water proof requirement and the reinforcement of existing structures, and includes a circular cross section tunnel, an arched section tunnel or various section shape tunnels or saps. The lining is generally formed in a way of first forming a lining frame by two anti-cut connection elements melted with studs, a reinforcing steel net banded by reinforcing steels and a steel plate and then spraying concrete into the frame. The invention combines the steel plate, the sprayed concrete to a whole structure to bear force, has improved bearing ability and stability than single reinforcing steel concrete lining, can be as support for new tunnel and as the reinforcement device for similar structure. The invention has the advantages of easy in quality guaranty, simple and quick in construction and high in synthetic effect.

Owner:TSINGHUA UNIV

Composite beam frame with different strength composite column and built-in core column and its construction method

InactiveCN103967127BReduce section sizeImprove axial performanceBuilding material handlingPre stressAxial pressure

The invention relates to a special strong combination column and combination beam frame with internally-arranged core columns and a construction method of the special strong combination column and combination beam frame. The special strong combination column and combination beam frame with the internally-arranged core columns is provided with internally-arranged asymmetric steel rib or plastic rib prestressed concrete combination beams and reinforcing bar concrete combination columns with the internally-arranged core columns, the combination beams are horizontally arranged between the combination columns, and the combination beams are connected with the combination columns at intersections through joints. The core columns are formed by pouring steel ribs or plastic ribs and concrete together, longitudinal ribs are distributed around the core columns and are wrapped by stirrups, and the core columns are placed in the reinforcing bar concrete columns. Transverse stiffening ribs are arranged on the steel ribs or the plastic ribs in the combination beams, the steel ribs or the plastic ribs at the midspan positions are arranged on the lower portions of the combination beams, the steel ribs or the plastic ribs on supports are arranged on the upper portions of the combination beams, and prestressed ribs are arranged in the combined beams in the length direction. The prestressed ribs on the beam and column joints penetrate through two sides of the core columns, and are tensioned and anchored at the ends of the combination columns. The axial pressure performance of the columns can be improved, the section size of the combination columns is small, the core columns can be poured on the scene and can also be prefabricated in factories, field mounting is achieved, workloads are reduced, and the construction period is shortened.

Owner:NORTHEAST GASOLINEEUM UNIV

Anchorage Structure of Steel-Concrete Composite Cable Beams for Cable-Stayed Bridges

InactiveCN105133494BSimple structureReasonable designCable-stayed bridgeBridge structural detailsCable stayed

The invention discloses a cable-stayed bridge steel-mixed composite cable girder anchorage structure, which comprises a rectangular steel pipe, a stiffener assembly arranged in the rectangular steel pipe, a concrete structure formed by pouring concrete filled in the rectangular steel pipe, and a rectangular steel pipe arranged in the rectangular steel pipe. The anchor plate on the top, rectangular steel pipes, stiffener components and concrete structure constitute the stiffened CFST members; the rectangular steel pipes are arranged along the longitudinal bridge direction, and the rectangular steel pipes are spliced by the top plate, bottom plate and two side plates, and the stiffener components include multiple An upper opening stiffener fixed on the bottom of the top plate from left to right and a plurality of lower opening stiffeners fixed on the top of the bottom plate from left to right. The invention is simple in structure, reasonable in design, convenient in construction, and good in use effect. It combines the rectangular steel tube concrete structure with opening stiffeners and the traditional anchor plate, under the premise of ensuring reasonable force and reliable force transmission. The pressure-bearing requirement of the horizontal force component of the stay cable is also conducive to improving the fatigue performance of the anchorage part of the cable beam.

Owner:CHANGAN UNIV

Full-prefabricated K-shaped enclosure structure system and construction method thereof

PendingCN113756333AGive full play to the resistance to pressureEasy constructionExcavationsBulkheads/pilesPurlinArchitectural engineering

The invention relates to a full-prefabricated K-shaped enclosure structure system and a construction method thereof. According to the full-prefabricated K-shaped enclosure structure system, a vertical enclosure structure is formed by inserting prefabricated parts into cement mixing piles, prefabricated inclined piles are pressed into a soil layer through an inclined pile pressing machine and integrally connected with the vertical enclosure structure, a K-shaped stable structure with the soil blocking and anti-overturning functions is formed by combining a first horizontal support and the vertical enclosure structure, and therefore the breakthrough that an enclosure structure of a two-layer basement foundation pit is not provided with a second horizontal inner support is achieved. According to the full-prefabricated K-shaped enclosure structure system and the construction method thereof, the prefabricated inclined piles are integrally connected with a second enclosing purlin of the vertical enclosure structure, the K-shaped stable structure with the soil blocking and anti-overturning functions is formed by combining the first horizontal support, the pit is not internally provided with the second horizontal support, excavation construction is convenient, the manufacturing cost is reduced, the construction period is shortened, the compressive property of the prefabricated inclined piles and the friction force between the prefabricated inclined piles and a soil body are brought into full play, construction is easy, efficiency is high, steel can be recycled, and the cost is reduced.

Owner:城地建设集团有限公司 +2

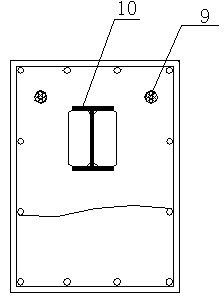

Prefabricated steel pipe-steel web-prestressed concrete composite box girder and construction technology

PendingCN110847000AImprove crack resistanceIncrease stiffnessBridge erection/assemblyBridge materialsCrack resistancePre stress

The invention discloses a prefabricated steel pipe-steel web-prestressed concrete composite box girder and a construction technology. The prefabricated steel pipe-steel web-prestressed concrete composite box girder is divided into three types. The first type is an I-shaped composite box girder, and the I-shaped composite box girder includes a steel pipe, a prefabricated concrete plate, a steel webplate, a lower flange steel plate, steel plate concrete, prestressed steel bars, a steel cage, shear connecting pieces, high-strength bonding mortar, connecting pieces, corrugated pipes and anchoragedevices. The second type is a pi-shaped composite box girder, and the pi-shaped composite box girder includes two steel pipes, a prefabricated concrete plate, two steel web plates, two lower flange steel plates, steel plate concrete, prestressed steel bars, shear connecting pieces, high-strength bonding mortar, connecting pieces, steel cages and transverse steel plates. The third type of composite box girder includes two steel pipes, a prefabricated concrete plate, two steel web plates, a lower flange steel plate, steel plate concrete, prestressed steel bars, shear connecting pieces, high-strength bonding mortar, connecting pieces, steel cages and transverse steel plates. According to the prefabricated steel pipe-steel web-prestressed concrete composite box girder and the construction technology, the shear capacity of the web plates of the box girder is improved, and the prestressed steel bars are used for improving the crack resistance, stiffness and durability of the concrete.

Owner:吉林建筑科技学院

Composite column composite beam frame with built-in high-strength concrete core column and its construction method

InactiveCN103967128BReduce section sizeReduce workloadBuilding constructionsReinforced concrete columnPre stress

The invention relates to a composite column composite beam frame with a built-in high-strength concrete core column and a construction method thereof, wherein the composite column composite beam frame with a built-in core column of different strength has a built-in asymmetrical steel bone or plastic bone prestressed concrete composite beam, The reinforced concrete composite column with built-in core column, the composite beam is horizontally arranged between the composite columns, and the two are connected by nodes at the intersection; the core column is formed by pouring longitudinal bars, stirrups, and concrete together, and the longitudinal bars are distributed in the core column The stirrups are wrapped around the longitudinal reinforcement, and the core column is placed in the reinforced concrete column; the steel frame or plastic frame in the composite beam is provided with transverse stiffeners, the steel frame or plastic frame at the mid-span is located at the lower part of the composite beam, and the steel frame at the support The bone or plastic bone is located on the upper part of the composite beam, and the prestressed tendons are arranged in the composite beam along the length direction; the prestressed tendons pass through both sides of the core column at the beam-column node, and are tensioned and anchored at the end of the composite column. The invention can obviously reduce the cross-sectional size of the column, and avoid excessive fat columns in the system; the prestressed tendon in the composite beam can generate uniformly distributed reaction force to offset part of the external load.

Owner:NORTHEAST GASOLINEEUM UNIV

Square multi-cavity steel plate-concrete composite floor

The invention discloses a square multi-cavity steel plate-concrete composite floor, and belongs to the field of constructional engineering. The square multi-cavity steel plate-concrete composite floorcomprises a multi-cavity space steel floor and concrete; the concrete is poured into the square multi-cavity steel floor to form a combined integral component; the square multi-cavity steel floor iscomposed of a steel plate shell and steel plate cavities with notches; the steel plate is composed of five steel plates in a welding mode; the steel plate cavities with the notches are connected in aninserted mode up and down and welded in the steel plate shell to form the square multi-cavity steel floor; and the concrete is poured into the steel floor to form the square multi-cavity steel plate-concrete composite floor. The square multi-cavity steel plate-concrete composite floor has the beneficial effect that the problems of liable cracking and exposure cracking of traditional concrete components can be solved, the steel plate cavities have a high lateral restraining effect on the concrete, the compressive property of the concrete can be fully played, the self weight is light, the composite floor after molding has better overall performance, the steel plate shell replaces steel bars and structural steels in a traditional floor slab to play the role of the framework, the constructionoperation of traditional form erecting and form stripping is avoided, the square multi-cavity steel plate-concrete composite floor can replace a traditional framework in the construction site, the construction progress is increased, and the economic benefit is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Full-prefabricated pier-type portal frame inclined supporting pile structure system and construction method thereof

PendingCN113152484AGive full play to the resistance to pressureEasy constructionExcavationsBulkheads/pilesPurlinSoil mixing

The invention relates to a fully-prefabricated pier-type portal frame inclined supporting pile structure system and a construction method thereof. The fully-prefabricated pier-type portal frame inclined supporting pile structure system is characterized in that a pier-type portal frame enclosure structure is formed by inserting prefabricated parts into cement-soil mixing piles, prefabricated inclined piles are pressed into a soil layer through an inclined pile pressing-in machine, and integral connection is formed with a second enclosing purlin in the front row of the pier-type portal enclosure structure to form a stable structure with soil retaining and overturning resistance, so that the breakthrough that the enclosure structure of a two-layer basement foundation pit has no horizontal inner support is realized. According to the fully-prefabricated pier-type portal frame inclined supporting pile structure system, the inclined prefabricated piles are integrally connected with the second enclosing purlin in the front row of the pier-type portal enclosure structure to form the stable structure with soil retaining and overturning resistance, so that no horizontal support construction exists in the pit, excavation construction is facilitated, the manufacturing cost is reduced, the construction period is shortened, the compression resistance of the inclined prefabricated piles and the friction force between the inclined prefabricated piles and the soil body are fully exerted, construction is simple, efficiency is high, steel can be recycled, and the cost is saved.

Owner:城地建设集团有限公司 +2

Fully-prefabricated portal frame type K-shaped enclosure structure system and construction method thereof

PendingCN113897972ASimple constructionImprove efficiencyExcavationsBulkheads/pilesStructural systemSoil mixing

The invention relates to a fully-prefabricated portal frame type K-shaped enclosure structure system and a construction method thereof. According to the fully-prefabricated portal frame type K-shaped enclosure structure system, a portal frame type vertical enclosure structure is formed by inserting prefabricated parts into cement-soil mixing piles, and prefabricated inclined piles are pressed into a soil layer through an inclined pile press; and the prefabricated inclined piles are integrally connected with the front row of the portal frame type vertical enclosure structure, and a first horizontal support and the portal frame type vertical enclosure structure are combined to form a soil-retaining and anti-overturning portal frame type K-shaped stable structure, so that the breakthrough that the enclosure structure of a two-layer basement foundation pit is not provided with a second horizontal inner support is achieved. According to the fully-prefabricated portal frame type K-shaped enclosure structure system and the construction method thereof, the prefabricated inclined piles and the portal frame type vertical enclosure structure are adopted to form the soil-retaining and anti-overturning portal frame type K-shaped stable structure, so that no second horizontal support exists in the pit, excavation construction is facilitated, the manufacturing cost is reduced, the construction period is shortened, the compression resistance of the prefabricated inclined piles and the friction force between the prefabricated inclined piles and a soil body are brought into full play, construction is easy, the efficiency is high, and the steel can be recycled. The cost is saved.

Owner:城地建设集团有限公司 +2

Prefabricated frp reinforced seawater sea sand concrete-uhpc composite beam bridge structure and construction method

ActiveCN109797661BReduce shipping costsReasonable forceBridge erection/assemblyFiberMesh reinforcement

The invention relates to an assembly type FRP (fiber reinforce plastic) reinforcing bar seawater marine sand concrete-UHPC (ultra high performance concrete) superposed beam bridge structure, which comprises a T-type beam bridge upper part flange component prepared by adopting UHPC, an FRP reinforcing bar seawater marine sand concrete T-type beam bridge web component and a transverse bridge direction prestressing force FRP pull rod system; the T-type beam bridge upper part flange component prepared by adopting the UHPC comprises a pre-buried top plate reinforcing mesh, a reserved transverse ribpenetrating pore channel and multiple anti-shearing steel bars, and a transverse bridge direction prestressing force FRP pull rod is penetrated in the reserved transverse rib penetrating pore channel; the FRP reinforcing bar seawater marine sand concrete T-type beam bridge web component comprises multiple corrugated pipes which are uniformly distributed, the corrugated pipes are communicated witha grouting material inlet and a grouting material outlet, and the anti-shearing steel bars match with the corrugated pipes; the bottom of the web component is provided with a prestressing force FRP rib, the middle is provided with an FRP wrapping steel pipe, the web component is provided with a diaphragm plate in the beam bridge span direction, and the FRP rib is arranged in the diaphragm plate.The assembly type FRP reinforcing bar seawater marine sand concrete-UHPC superposed beam bridge structure uses local materials, seawater and marine sand are used for preparing concrete, the material transportation cost is reduced, and the problem of constructing a highly durable structure rapidly in a marine environment is solved.

Owner:SOUTHEAST UNIV

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194BLight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com