Prefabricated steel pipe-steel web-prestressed concrete composite box girder and construction technology

A steel plate concrete and prefabricated concrete slab technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of heavy installation weight of single-piece box girder, complicated prefabrication construction, and high construction cost, achieve superior compressive performance, improve resistance to The effect of shearing ability and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

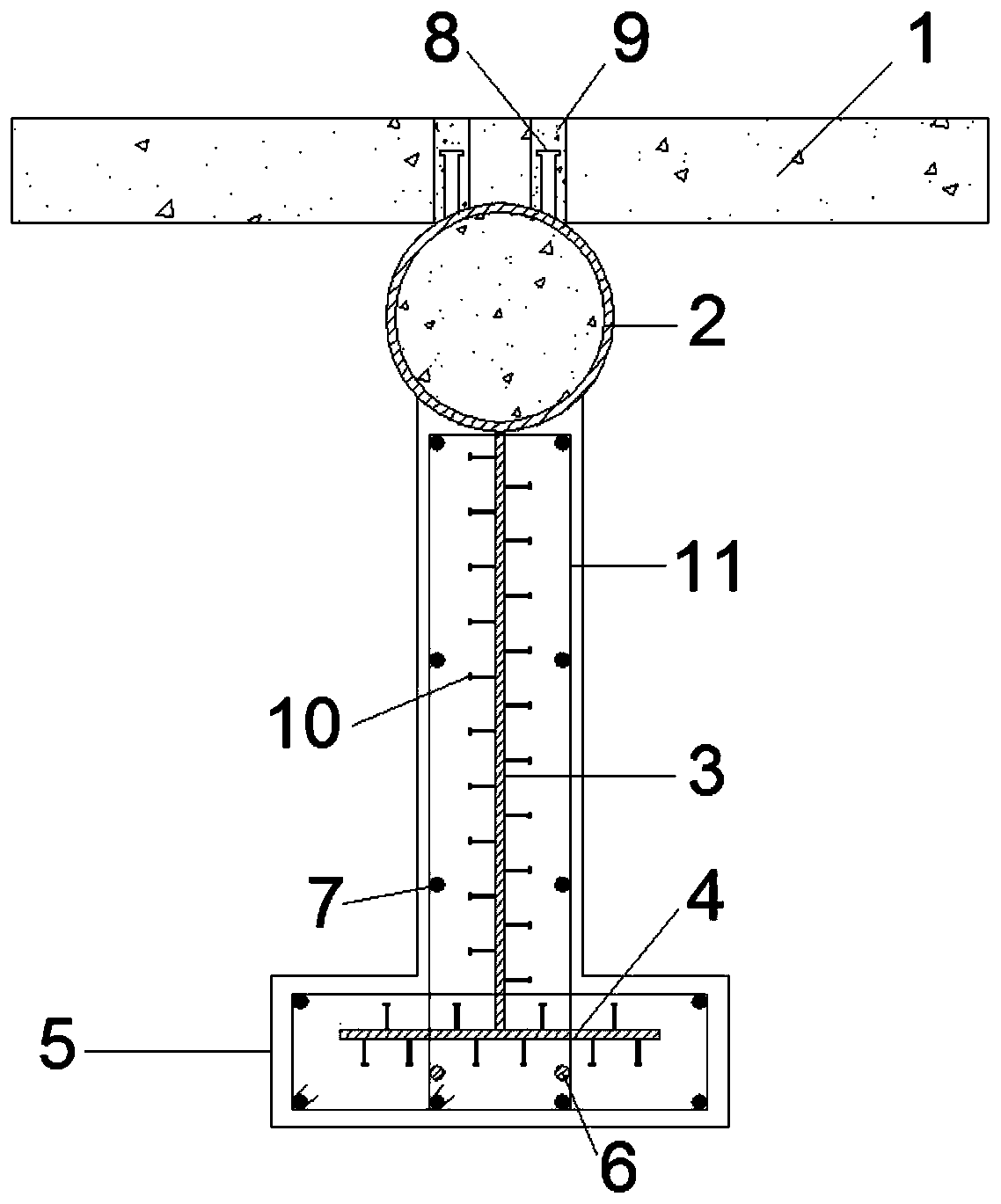

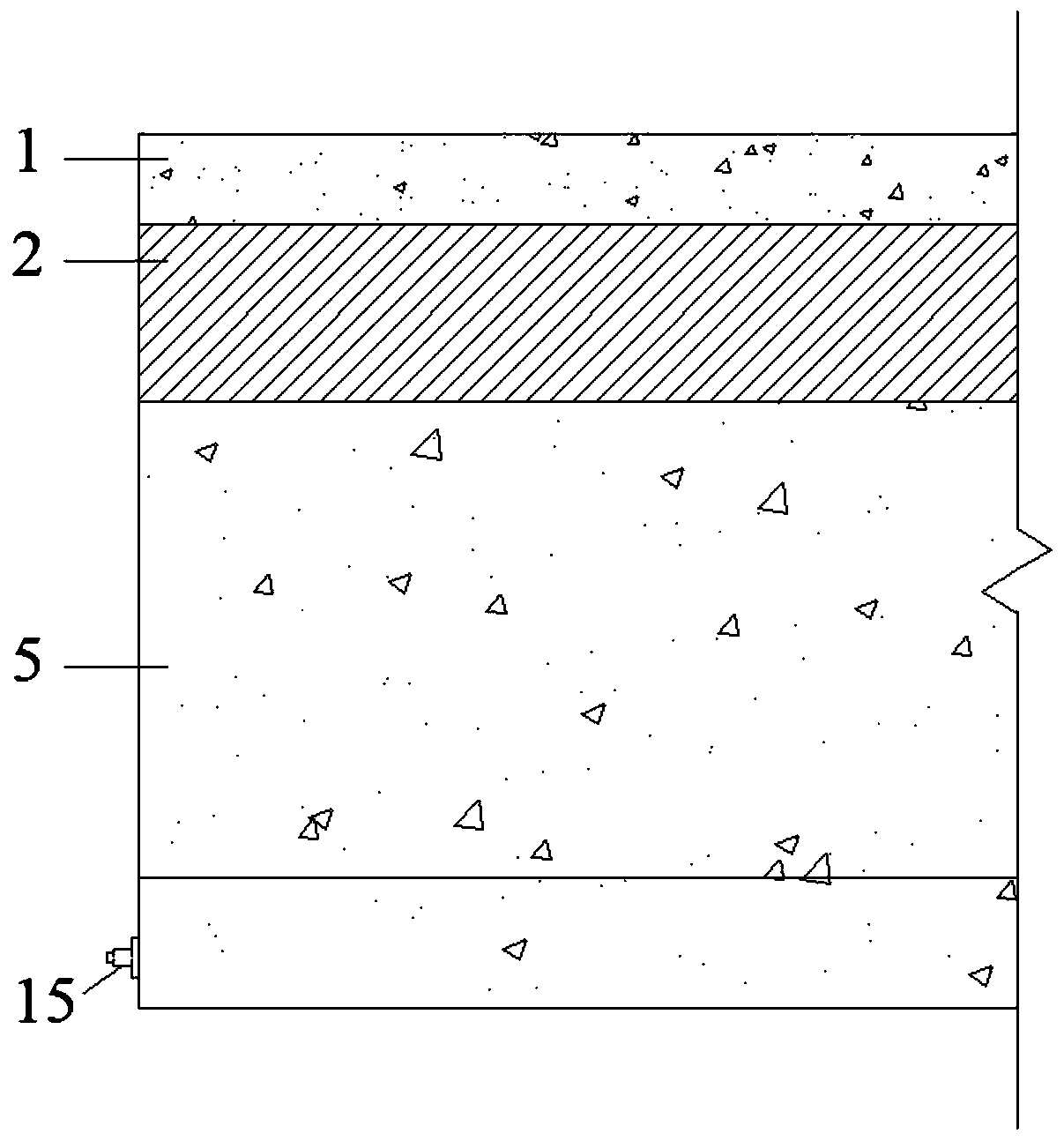

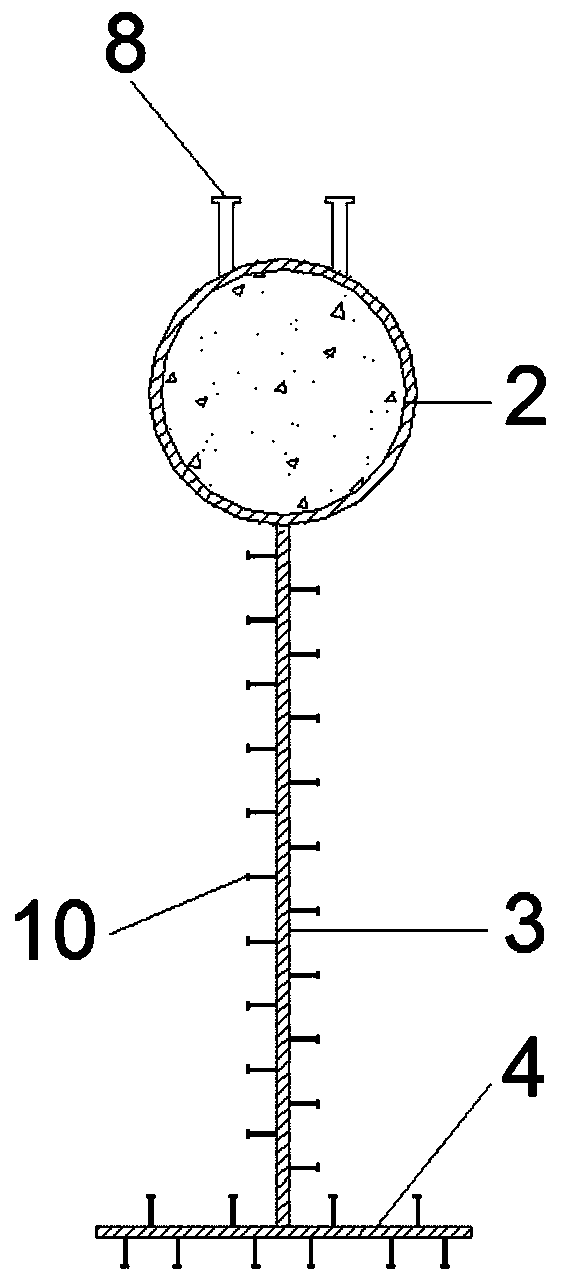

[0052] In this embodiment, the prefabricated steel pipe-steel web-prestressed concrete composite box girder is I-shaped, the steel pipe 2 is a round steel pipe, and the connecting piece is a stud 10 .

[0053] Such as Figure 1 to Figure 12 As shown, the prefabricated steel pipe-steel web-prestressed concrete composite box girder is an I-type composite box girder, comprising a steel pipe 2 filled with concrete, the top of the steel pipe 2 is provided with a prefabricated concrete slab 1, and the steel pipe 2 is filled with concrete. 2 A number of shear connectors 8 welded at the top correspond to a number of reserved holes 13 on the precast concrete slab 1 and are fixed by high-strength bonding mortar 9. The bottom end of the steel pipe 2 is welded to one end of the steel web 3, and the steel web 3 The other end is welded to the lower flange steel plate 4, and the connecting piece is evenly welded on the wide surface of the steel web 3 and the lower flange steel plate 4, and t...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is that the steel pipe 2 adopts a square steel pipe, such as Figure 13 to Figure 15 shown.

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that the connector is a steel strip 1001 with holes, such as Figure 16 and Figure 17 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com