Gradient-structure composite bridge pier

A gradient structure and pier technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems that the mechanical properties of steel are not fully exerted, and achieve the effects of shortening the construction period, improving seismic performance, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

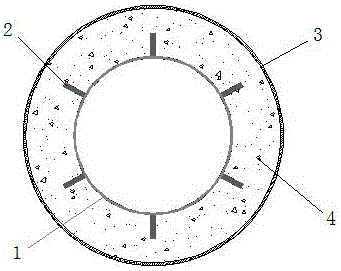

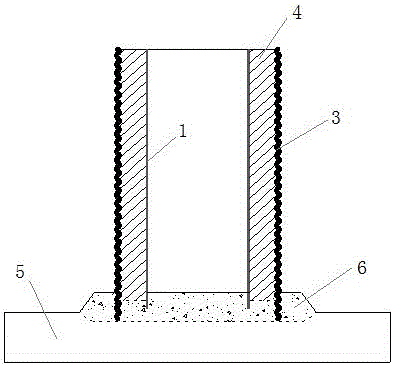

[0020] Taking the circular piers with caps at the bottom commonly used in highway bridges as an example, the specific implementation measures of the present invention are as follows.

[0021] Steel pipe forming. The round steel pipe is formed by cold bending of flat steel plates in the factory, and the joints are welded on both sides. The thickness of the steel plate is 6-10mm, and the low-carbon A3 steel is used. After the round steel pipe is formed, square stiffeners are welded on both sides of the steel pipe. -10mm, width 5-10cm, 6-8 lanes horizontally, vertically through; the corrugated steel pipe is made of SS400 hot-rolled steel plate, with a thickness of 2.5-10mm, formed by a corrugated pipe forming machine, and the wave pitch of the formed corrugated steel pipe is 12.5- 20cm, the wave height is 2.5-6cm, and the vertical height is 5-10cm higher than the round st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com