Full-prefabricated pier-type portal frame inclined supporting pile structure system and construction method thereof

A fully prefabricated pier-type, oblique support technology, applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of debris flying out, large layout area, vibration, etc., to reduce project cost and improve construction efficiency , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

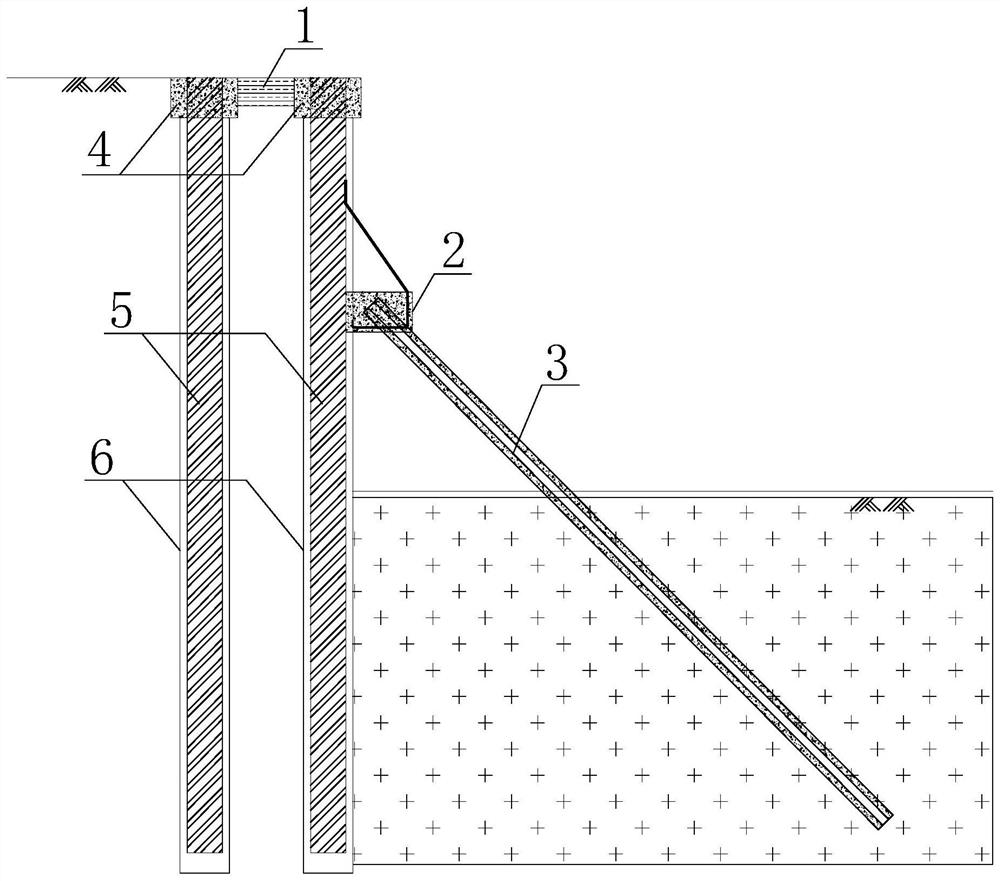

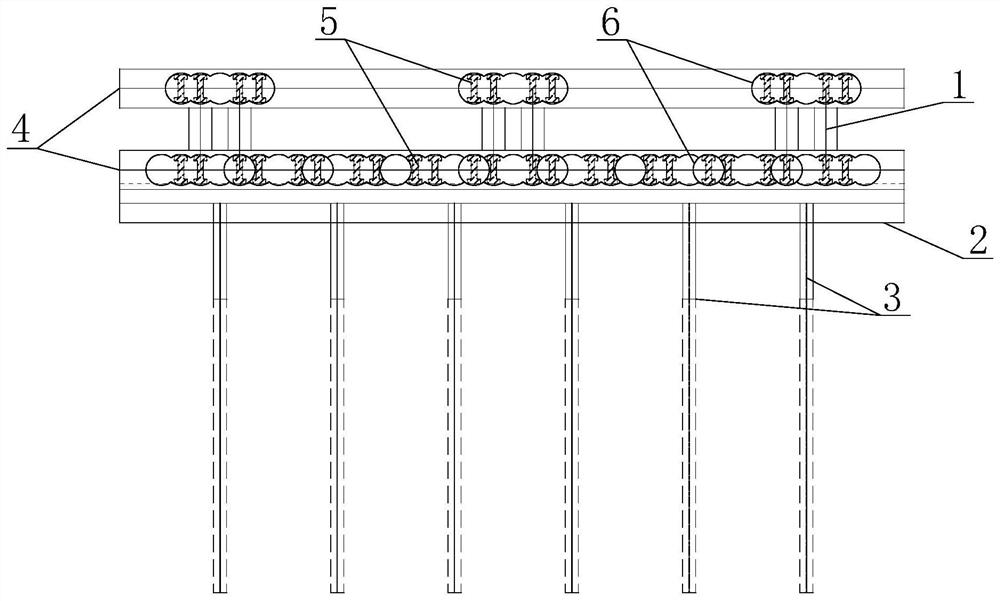

[0033] A fully prefabricated pier-type gantry inclined support pile structure system and a construction method thereof. For the enclosure structure, the prefabricated inclined piles 3 are pressed into the soil layer by the oblique pile driver, and the second purlin 2 in the front row of the pier-type gantry enclosure is integrally connected to form a stable structure with soil retention and anti-overturning properties. .

[0034] A fully prefabricated pier-type gantry inclined support pile structure system and a construction method thereof, characterized in that it comprises the following steps:

[0035] (1) Release the actual sample according to the construction drawing, and open the groove;

[0036] (2) Construction of water-stop curtain of cement-soil mixing pile 6;

[0037] (3) The side pile static pressure mechanical equipment is moved to the position to be constructed, and while the cement-soil mixing pile 6 is formed into a pile, another side pile static pressure mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com