Prefabricated frp reinforced seawater sea sand concrete-uhpc composite beam bridge structure and construction method

A concrete and prefabricated technology, which is applied in the erection/assembly of bridges, bridge construction, construction, etc., can solve the problems of high cost, high cost, uneconomical tensile force, etc., to save cost, avoid inefficient use, and reasonable force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

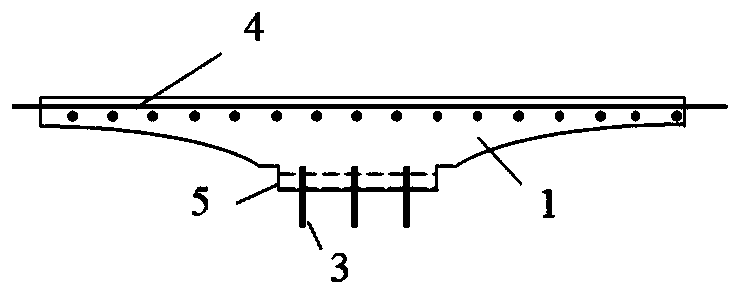

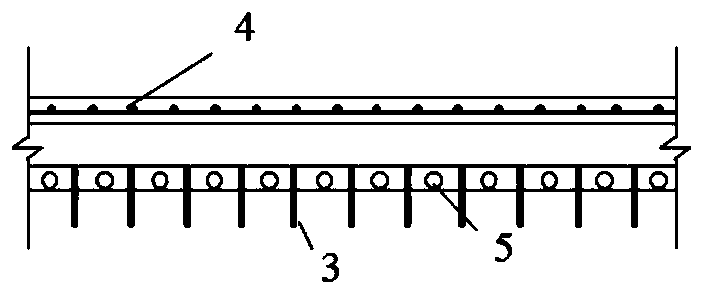

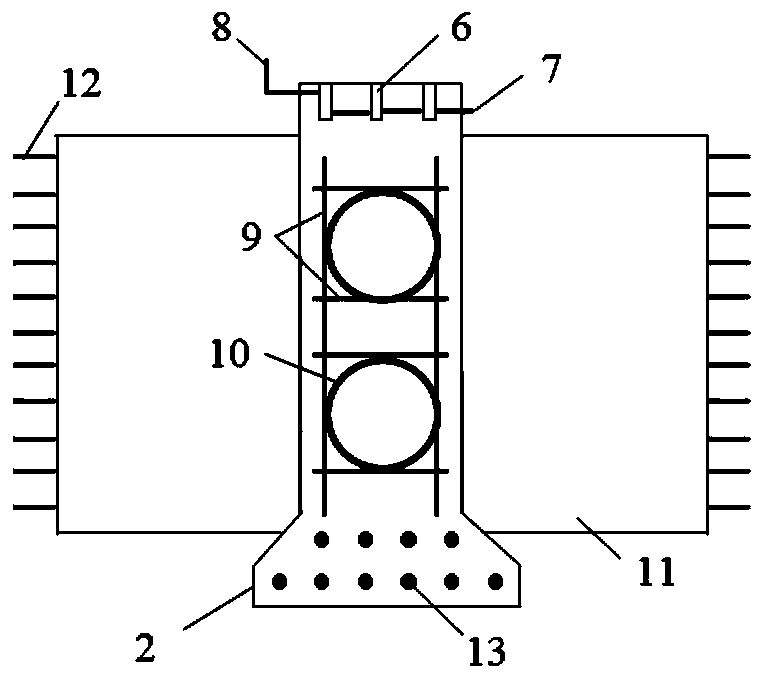

[0041] Such as Figure 1 to Figure 4 As shown, a prefabricated FRP reinforced seawater sea sand concrete-UHPC composite girder bridge structure of the present invention includes a T-beam bridge upper flange part 1 prepared by UHPC and a FRP reinforced seawater sea sand concrete T-beam The bridge web part 2; among them, the upper flange part 1 of the T-beam bridge prepared by UHPC includes the pre-embedded shear reinforcement 3, the roof reinforcement mesh 4 and the reserved transverse reinforcement tunnel 5; the reserved transverse reinforcement tunnel 5 through as Figure 7 The cross-bridge prestressed FRP tie rod 20 shown in the cross-bridge direction includes a nut 17, a threaded steel pipe 18, and a steel backing plate 19; the FRP reinforced seawater sand concrete T-shaped beam bridge web part 2 includes A plurality of plastic corrugated pipes 6 made of cloth, the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com