Fully-prefabricated portal frame type K-shaped enclosure structure system and construction method thereof

A technology of enclosure structure and construction method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of debris flying out, large layout area, and long construction period, so as to reduce project cost, improve construction efficiency, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

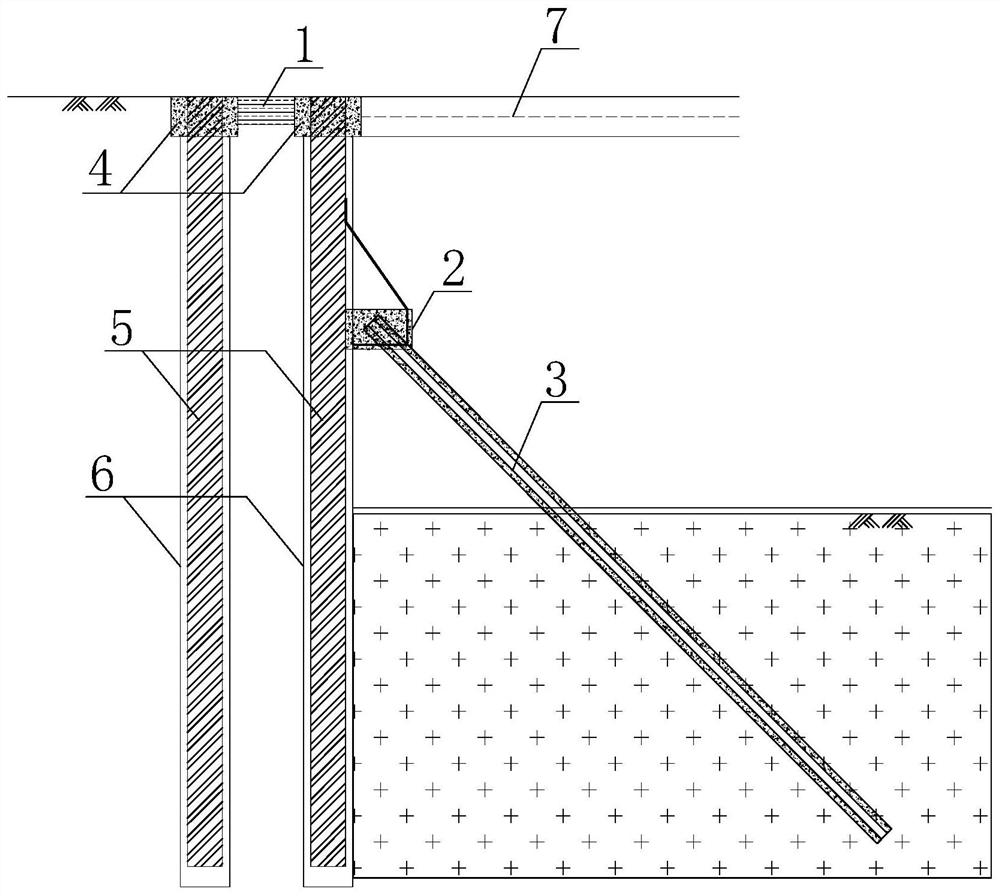

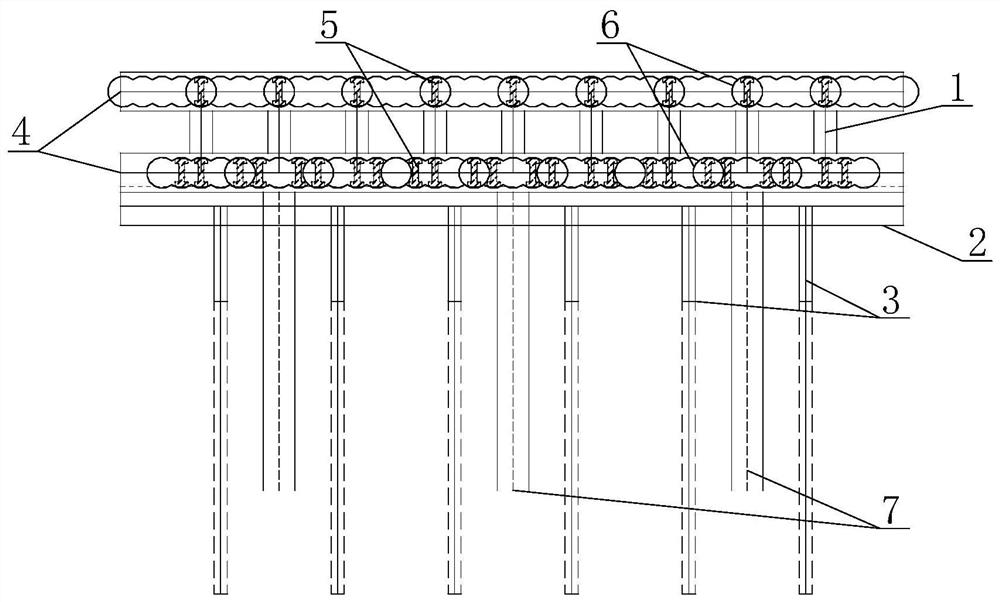

[0034] A fully prefabricated gantry-type K-shaped enclosure structure system and its construction method, the fully prefabricated gantry-type K-shaped enclosure structure system is formed by inserting prefabricated components 3 into cement-soil mixing piles 6 to form a gantry-type vertical enclosure Prefabricated inclined piles 3 are pressed into the soil layer by an inclined pile driver to form an integral connection with the front row of the gantry-type vertical enclosure structure, and the first horizontal support 7 is combined with the gantry-type vertical enclosure structure A gantry-type K-shaped stable structure with soil retaining and overturning resistance is formed, so as to achieve a breakthrough in the enclosure structure of the foundation pit of the second-floor basement without a second horizontal inner support. A fully prefabricated gantry type K-shaped enclosure structure system and its construction method, characterized in that it comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com