Slope supporting structure and construction method

A technology of supporting structure and construction method, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems that the supporting structure cannot fully meet the requirements of slope support and the emergency treatment of the deformed slope, etc. The effect of avoiding difficulty in position, reasonable force and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

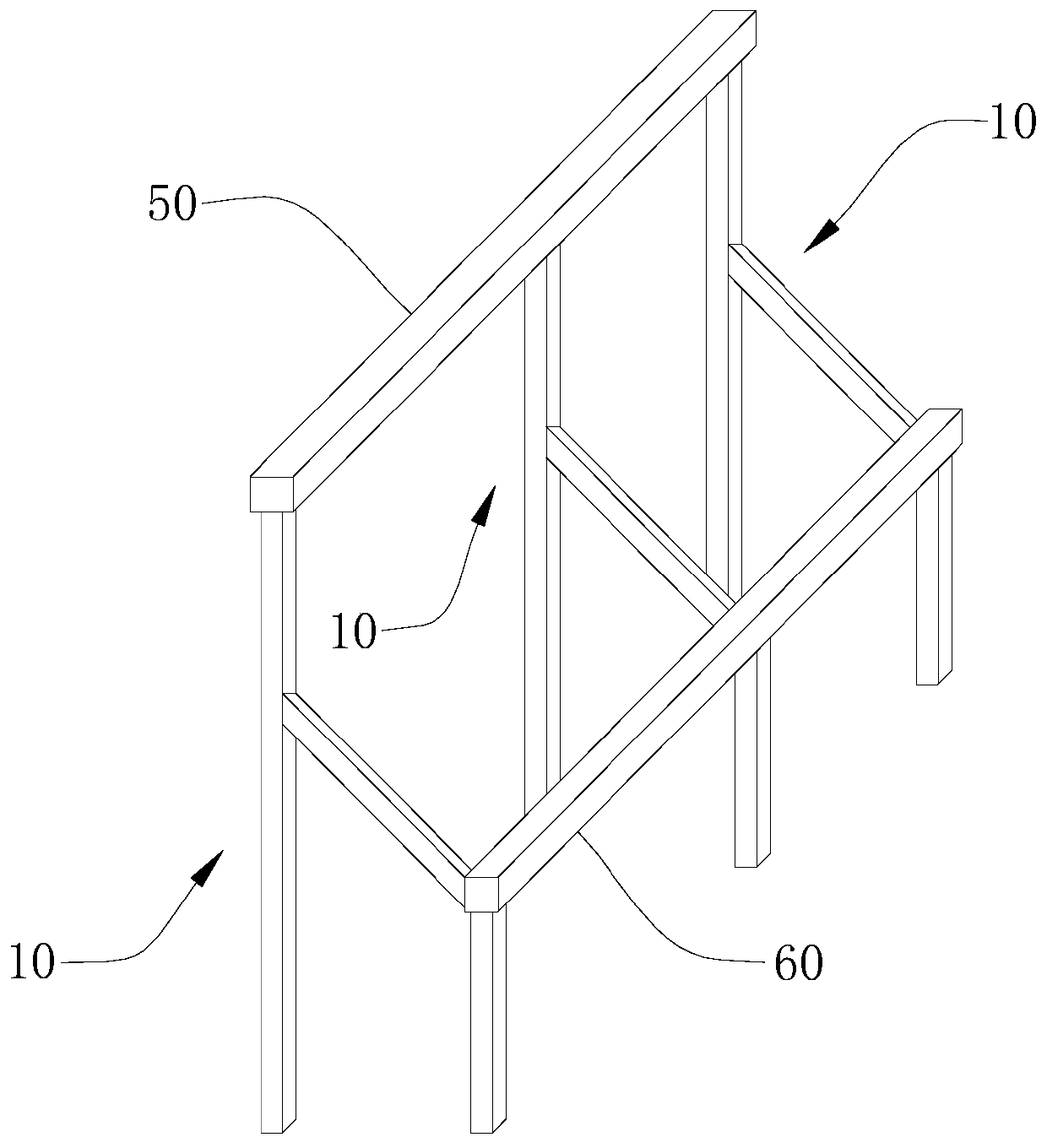

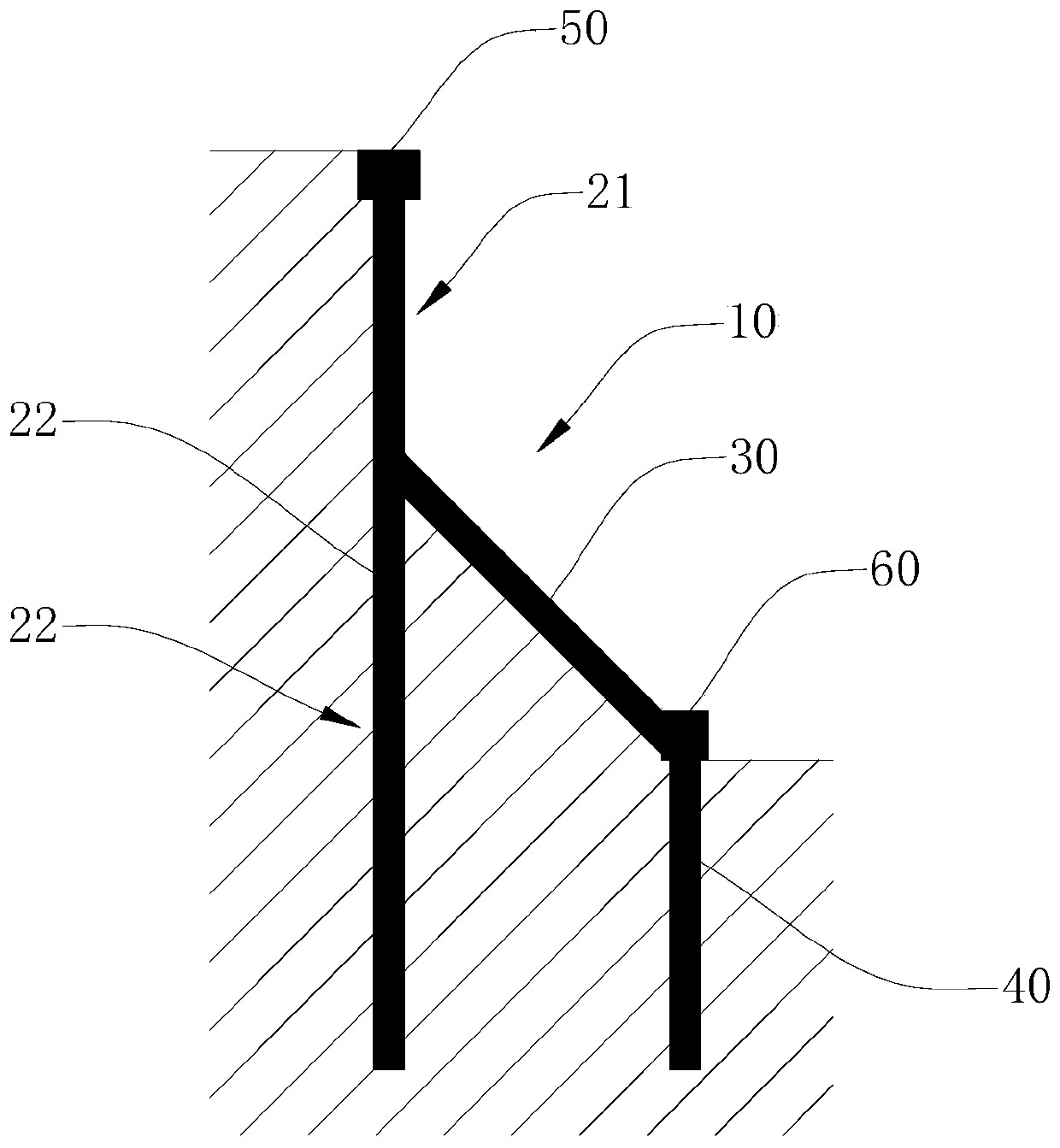

[0034] Please refer to figure 1 and figure 2 , a slope support structure, comprising: a plurality of support units 10 arranged at intervals in sequence. The support unit 10 includes vertical piles 20 , inclined beams 30 and pile foundations 40 . The vertical pile 20 extends downwards from the top of the slope, and the pile foundation 40 extends downwards from the bottom of the slope. The pile foundation 40 is connected. The tops of adjacent vertical piles 20 are connected by a top beam 50 , and adjacent pile foundations 40 are connected by a foundation beam 60 .

[0035] The vertical pile 20 includes a cantilever section 21 and an embedded section 22, the cantilever section 21 is located outside the slope crest, and the embedded section 22 is located in the soil layer. The top of the inclined beam 30 is connected to the joint between the cantilever section 21 and the embedded section 22 , and the bottom end of the inclined beam 30 is connected to the top of the pile found...

Embodiment 2

[0039] A construction method based on the slope support structure of embodiment 1, comprising the following steps:

[0040] S1: Drill a hole at the slope top of the side slope, and place a vertical pile 20 made of a steel pipe in the hole, and make the top of the vertical pile 20 outside the soil layer;

[0041] S2: Place a top beam 50 made of a steel pipe at the top of the adjacent vertical pile 20, and connect the two ends of the top beam 50 with the vertical pile 20 by bolts or by welding;

[0042] S3: drilling a hole at the bottom of the slope, and placing a pile foundation 40 made of steel pipes in the hole;

[0043] S4: Carry out grading and excavation along the inclined direction on the slope slope to form a placement groove, place an inclined beam 30 made of steel pipes in the placement groove, and connect the top of the inclined beam 30 to the vertical pile 20 by bolts or welding connection, since the inclined beam 30 extends along the inclination direction of the sl...

Embodiment 3

[0048] A construction method based on the slope support structure of embodiment 1, comprising the following steps:

[0049] S1: Drill a hole at the top of the slope, place a reinforcement cage in the hole, and make the top of the reinforcement cage outside the soil layer, reserve reinforcement along the slope at the position where the reinforcement cage contacts the soil layer, and place a reinforcement cage at the top of the reinforcement cage Reserving reinforcing bars on both sides, pouring concrete into the reinforcing cage at last, and forming vertical pile 20 after curing;

[0050] S2: Connect the reserved steel bars at the tops of the adjacent vertical piles 20 through steel bars, pour concrete, and form the capping beam 50 after curing;

[0051]S3: Drill a hole at the bottom of the slope, place a reinforcement cage in the hole, reserve reinforcement along the slope at the top of the reinforcement cage, reserve reinforcement on both sides at the top of the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com