SCS combined hydropower station pressure underground pipe design method

A design method and technology for hydropower stations, applied to pipes, rigid pipes, mechanical equipment, etc., can solve problems such as hidden dangers of steel lining stability, expansion of excavation sections, waste of steel construction, etc., to reduce the amount of steel bars and concrete scalar, reasonable The effect of utilizing materials and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

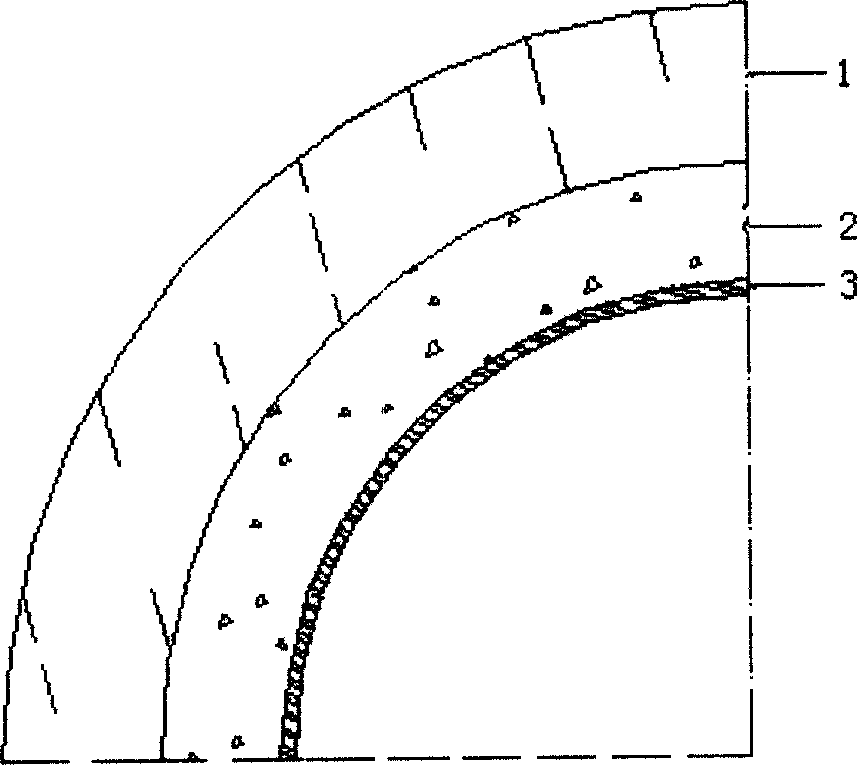

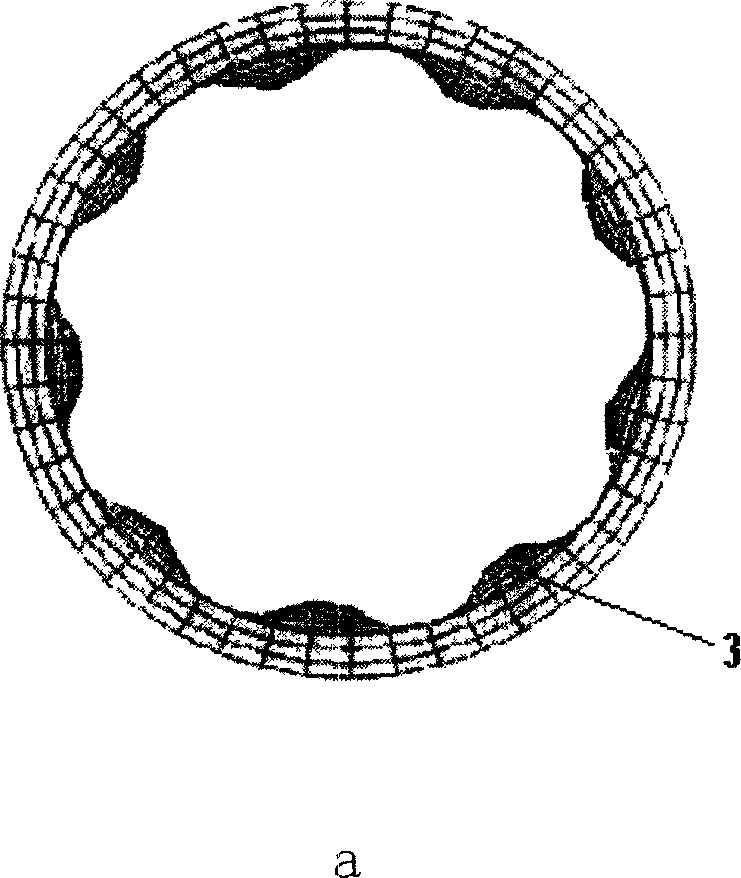

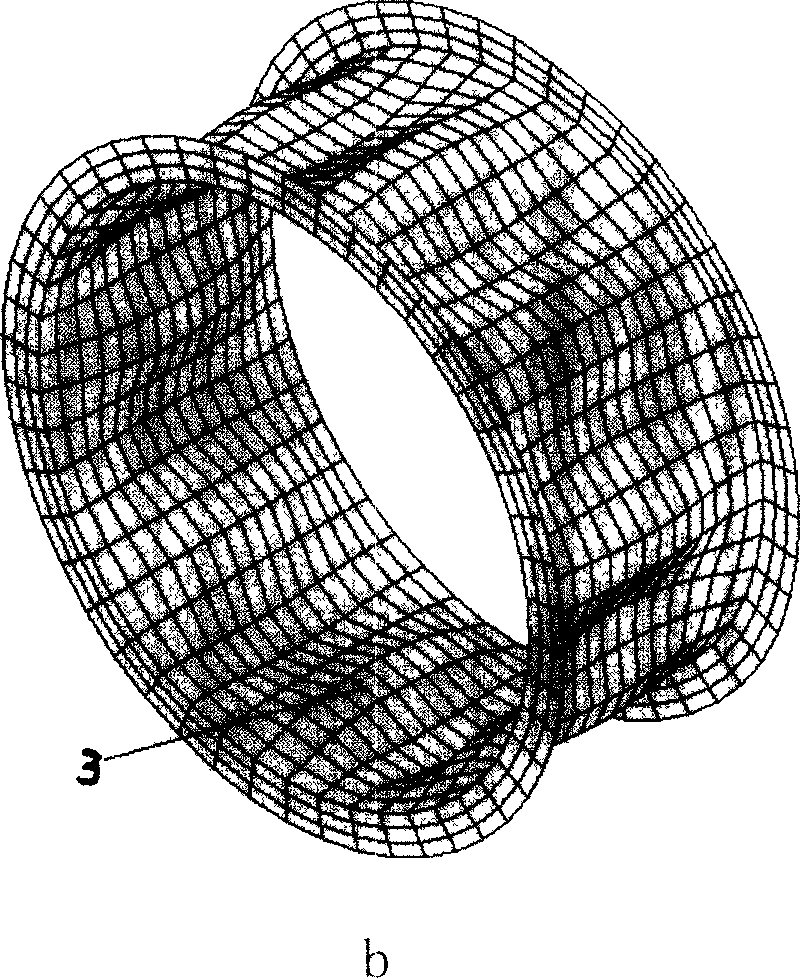

[0018] figure 1 It is a 1 / 4 cross-sectional schematic diagram of a pressure steel pipe in the prior art. Between the inner steel pipe 3 and the surrounding rock 1 is a concrete pipe 2, and the surrounding rock 1 is used to share the load so as to reduce the thickness of the inner steel pipe 3. Under the action of internal and external water, when the inner steel pipe 3, concrete pipe 2, and surrounding rock 1 act together, the deformation is difficult to coordinate, and the brittle concrete pipe 2 and surrounding rock 1 are easily cracked under a small internal pressure , while the ductile inner steel pipe 3 is prone to buckling and instability of the pipe wall under external water pressure, such as figure 2 shown.

[0019] image 3 , Figure 4 It is a schematic diagram of the structure of the pressure buried pipe obtained according to the design method of the present invention, which consists of a thicker inner steel pipe 3, a thin outer steel pipe 4 and a concrete pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com