Combination column and combination beam frame with internally-arranged high-strength concrete core columns and construction method thereof

A technology of high-strength concrete and construction methods, which is applied in the direction of architecture and building construction, can solve the problems of large section size and difficult layout of prestressed tendons, etc., and achieve the effects of reducing section size, shortening construction period, and large span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

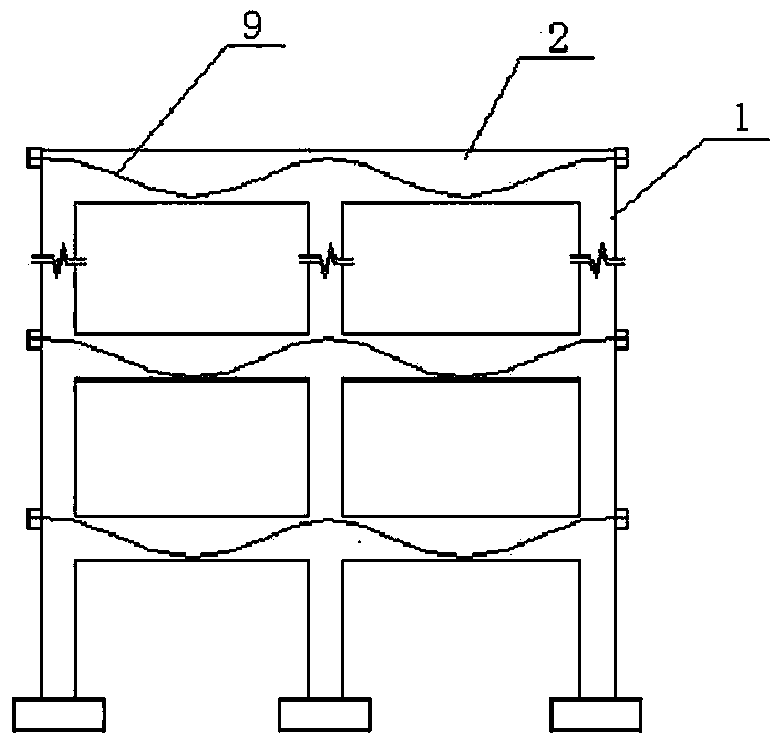

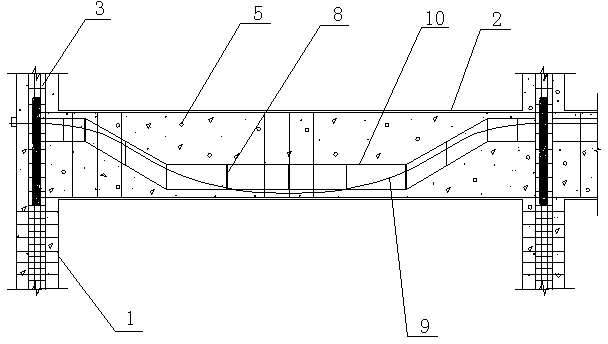

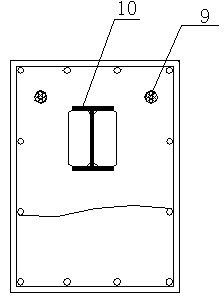

[0046] like figure 1 As shown, the composite column composite beam frame with built-in high-strength concrete core column has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam, a reinforced concrete composite column 1 with a built-in core column 3, and the composite beam 2 is horizontally arranged on Between composite columns 1, the two are connected by nodes at the intersection. to combine Figure 8 , Figure 15 As shown, the prestressed tendon 9 at the beam-column node passes through both sides of the core column 3, and is stretched and anchored at the end of the composite column. The H-shaped steel or plastic bone in the composite beam and the vertical steel / plastic bone in the core column The bone connector 4 is connected, of course, the H-shaped steel or plastic bone in the composite beam can also be connected with the core column vertical core steel pipe 12 or the vertical core plastic tube, see Figure 9 . In this embodiment, the same...

Embodiment 2

[0058] This composite beam frame with different strength composite columns with built-in core columns has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam 2, a reinforced concrete composite column 1 with built-in core columns, and the composite beam 2 is horizontally arranged on the composite column 1 Between them, the two are connected by nodes at the intersection; the core column 3 is formed by pouring longitudinal bars 6, stirrups 7, and concrete 5 together, the longitudinal bars 6 are distributed around the core column 3, and the stirrups 7 are wrapped in the longitudinal bars 6 In addition, the core column 3 is placed in a reinforced concrete column, and the density of the stirrups 7 in the core column is greater than the density of the stirrups in the reinforced concrete column; the cross-section of the composite beam 2 is rectangular, and the steel bone 10 or plastic bone is H-shaped , the steel frame 10 or plastic frame is provided with ...

Embodiment 3

[0066] This composite column composite beam frame with built-in high-strength concrete core column has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam 2, a reinforced concrete composite column 1 with a built-in core column, and the composite beam 2 is horizontally arranged on the composite column 1 Between them, the two are connected by nodes at the intersection; the core column 3 is formed by pouring longitudinal bars 6, stirrups 7, and concrete 5 together, the longitudinal bars 6 are distributed around the core column 3, and the stirrups 7 are wrapped in the longitudinal bars 6 In addition, the core column 3 is placed in a reinforced concrete column, and the density of the stirrups 7 in the core column is greater than that of the reinforced concrete column; the cross-section of the composite beam 2 is rectangular, and the built-in steel bone 10 or plastic bone is H type, the steel frame 10 or plastic frame is provided with transverse stiffeners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com