Steel pipe in construction structure

A technology for building structures and steel pipes, which is applied to building components, building structures, buildings, etc., can solve problems such as buckling instability damage, application restrictions of thin-walled steel pipes, etc., and achieve the effect of easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

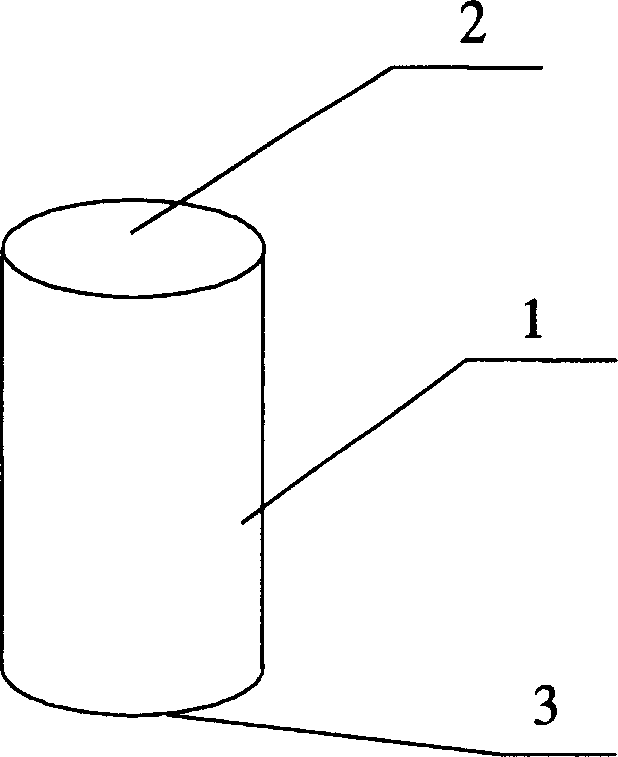

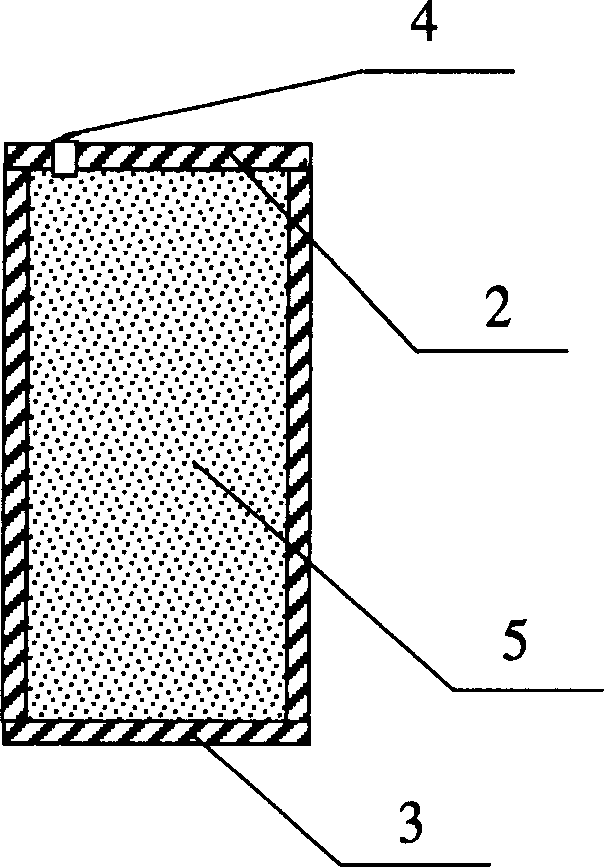

[0014] The steel pipe in the building structure of the present invention is composed of a pipe body 1 and an upper end surface 2 and a lower end surface 3 closed on the upper and lower ends of the pipe body 1 by welding. First seal the two ends of the pipe body 1 by welding and reserve a screw hole 4, then pour water 5 through high pressure to ensure that there is no gas inside, and then seal the screw hole 4.

[0015] The liquid-filled steel pipe can be used as an axial compression member, for example, as a column of a building structure, such an application is to exert force on both end faces of the liquid-filled steel pipe in the axial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com