Steel plate-concrete composite lining

A concrete and shotcrete technology, applied in wellbore lining, tunnel lining, earth-moving drilling, etc., can solve the problems of affecting the normal use of the tunnel, poor impermeability and waterproof performance, corrosion of steel reinforcement in the structural layer, etc., achieving significant comprehensive benefits and concrete resistance. The effect of good compressive performance, bearing capacity and structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

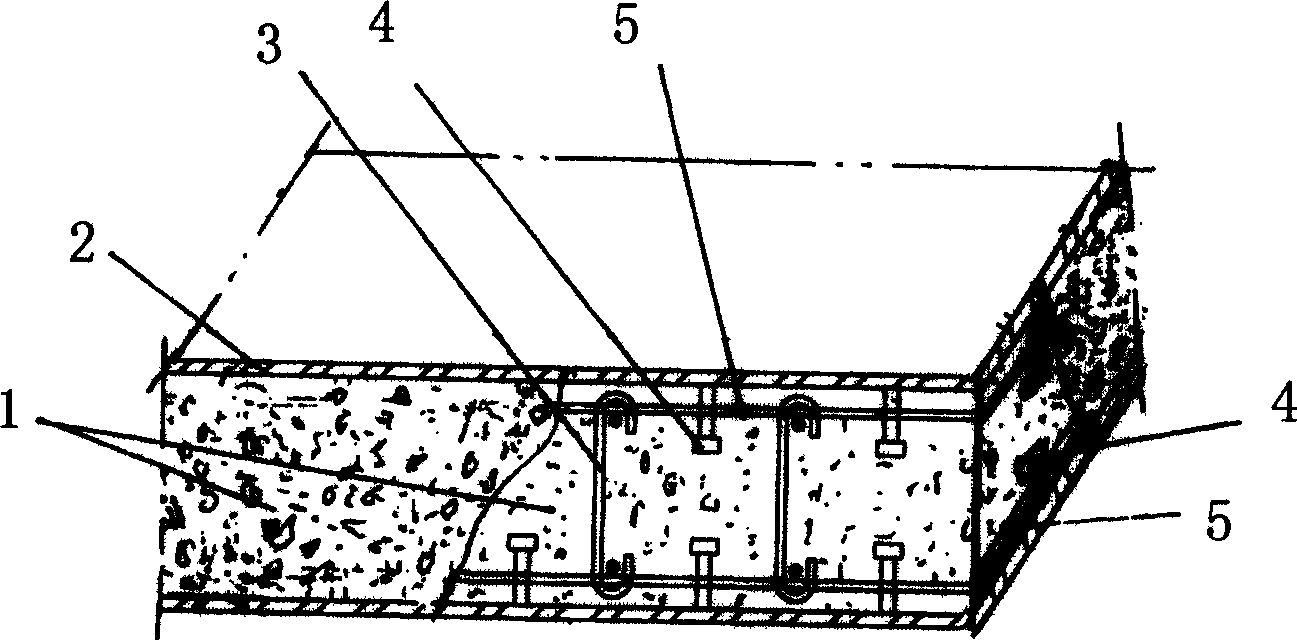

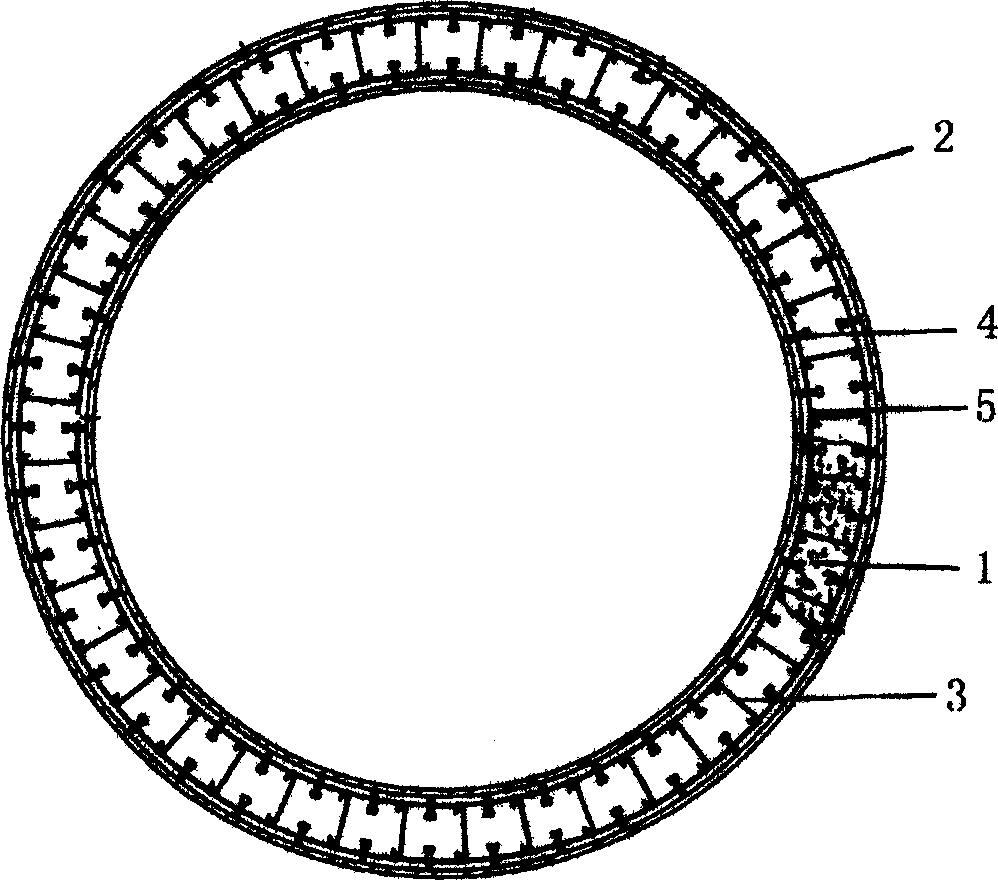

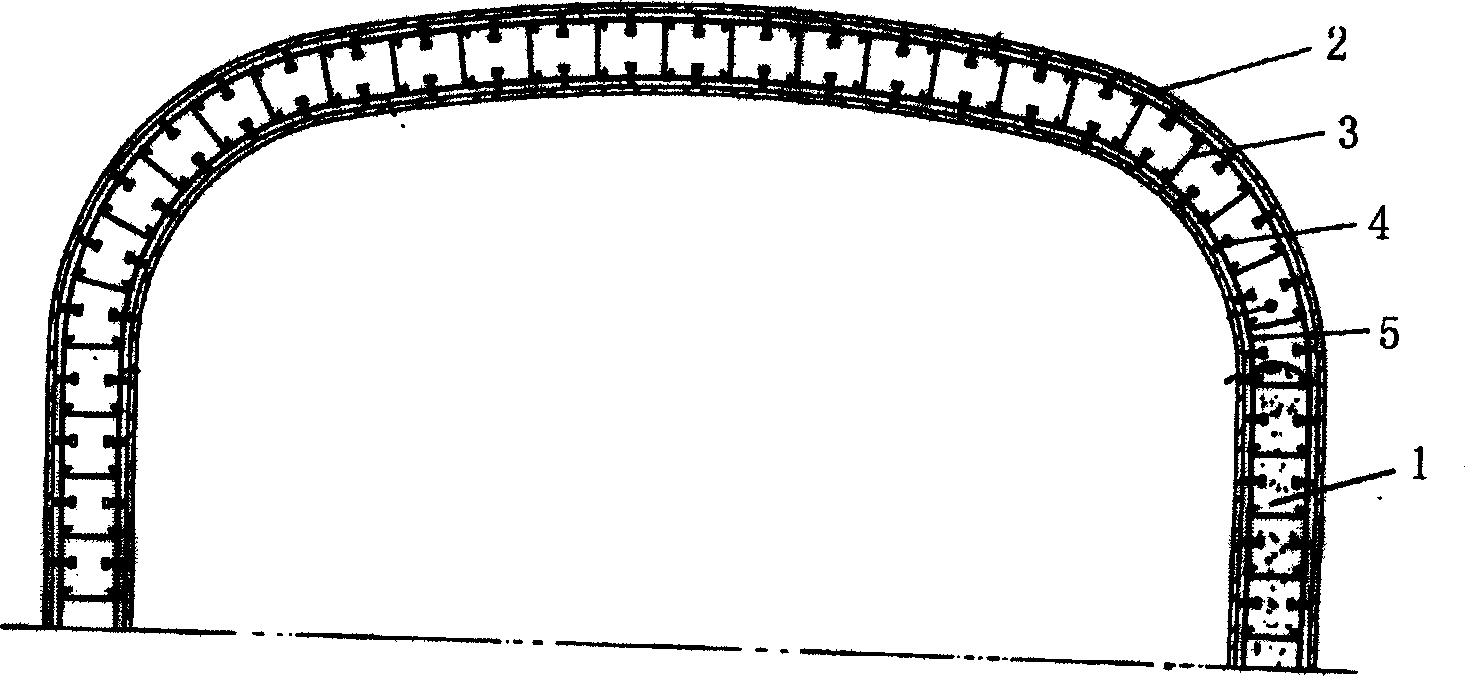

[0009] The invention provides a steel plate-concrete composite lining that can be applied to the construction of new tunnels with high requirements on stress and waterproof and the reinforcement of existing structures. It is a steel plate-concrete composite lining that combines support and waterproofing. The partial section is as follows: figure 1 shown. On one side of the steel plate 2 where concrete is poured, the shear connector pegs 4 should be welded. On this side of the steel plate 2, the steel mesh 5 connected and formed by double-hook tension bars 3 should be bound, and the sprayed concrete should be sprayed through the shear connector pegs 4. 1 Combined with each part to form an integral lining.

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] The basic components of steel plate-concrete composite lining are steel plate 2, shear connector stud 4, steel mesh 5 and shotcr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com