Rotary-cut plate laminated wood-light weight concrete combined floor system

A technology of lightweight concrete and combined floor slabs, which is applied to floors, building components, buildings, etc., can solve the problems of sound insulation, poor vibration isolation, low rigidity of pure wooden floors, and self-heavyness, etc., to achieve light weight and save nature The effect of low resources and self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

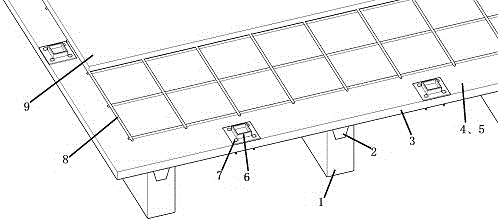

[0029] Such as figure 1 As shown, a rotary-cut glulam-lightweight concrete composite floor (LLC) system includes a rotary-cut glulam grating, trapezoidal wooden strips 2 with small top and large bottom, shear connectors 6, and general connectors 7 (self-tapping bolts), two-way steel mesh 8 and ceramsite concrete panel 9.

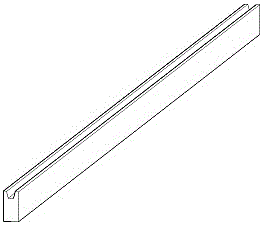

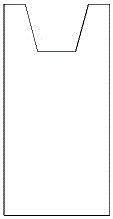

[0030] The rotary cut board glued wood grill is composed of wooden panels 3 and wooden grill 1. The top of the wooden grill 1 has a trapezoidal notch 10 with a large top and a small bottom. match (or the top of the wooden grid has a notch slightly smaller than the size of the trapezoidal wood bar, that is, the trapezoidal wood bar and the trapezoidal notch have an interference fit), and the length of the trapezoidal wood bar is the same as the short side of the wooden panel 3.

[0031] The top of the trapezoidal wooden strip 2 is connected with the bottom of the wooden panel 3 with PF glue, and the trapezoidal wooden strip 2 is evenly arranged on the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com