Anchorage Structure of Steel-Concrete Composite Cable Beams for Cable-Stayed Bridges

A cable-stayed bridge steel and cable-stayed bridge technology, applied in cable-stayed bridges, bridges, bridge parts, etc., can solve problems such as complex local structures, and achieve excellent mechanical performance, improved fatigue performance, and good use effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

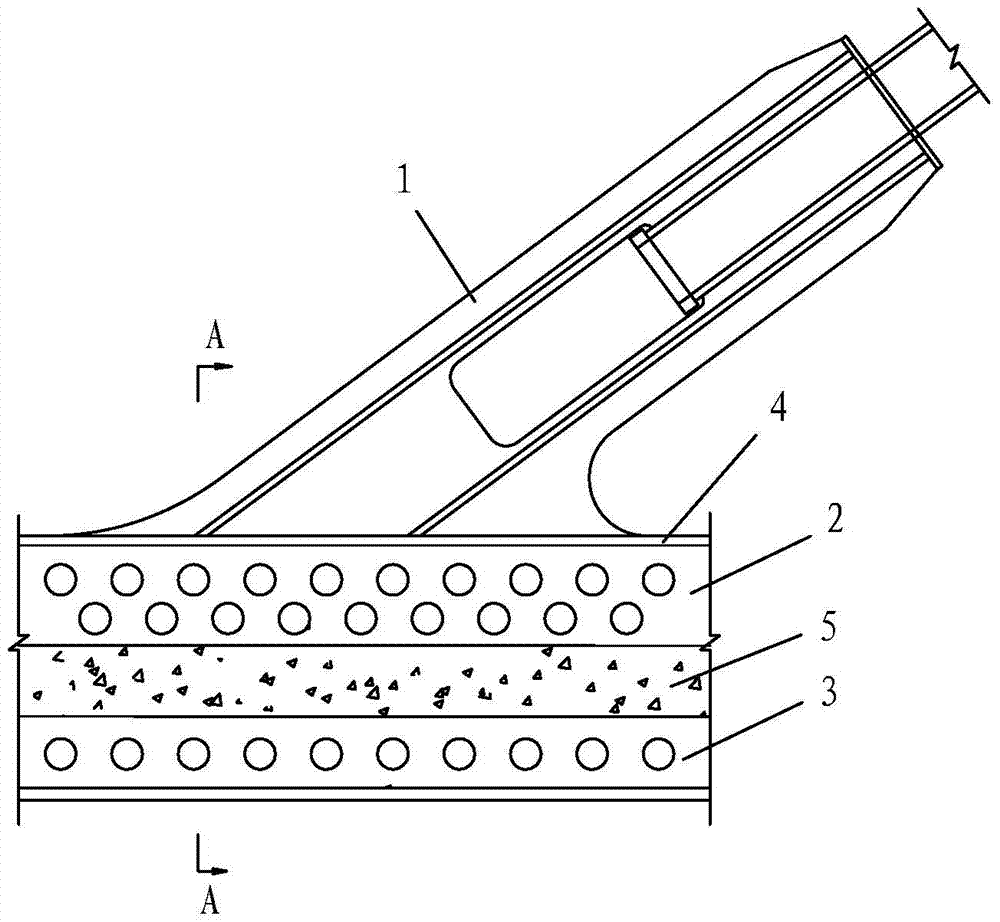

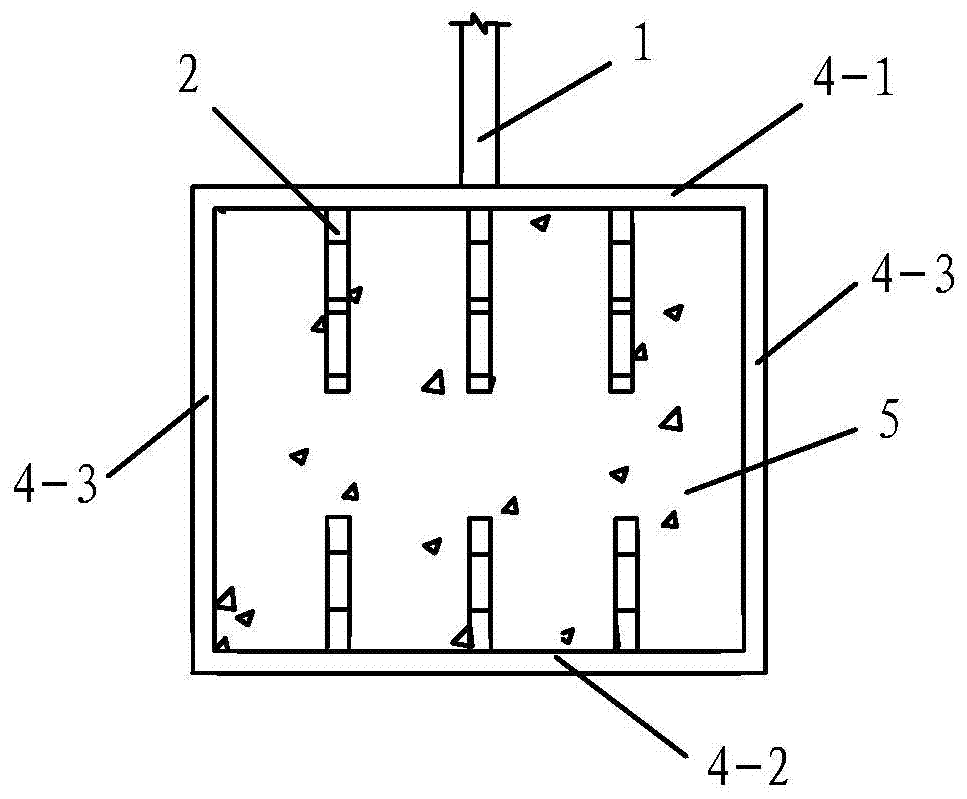

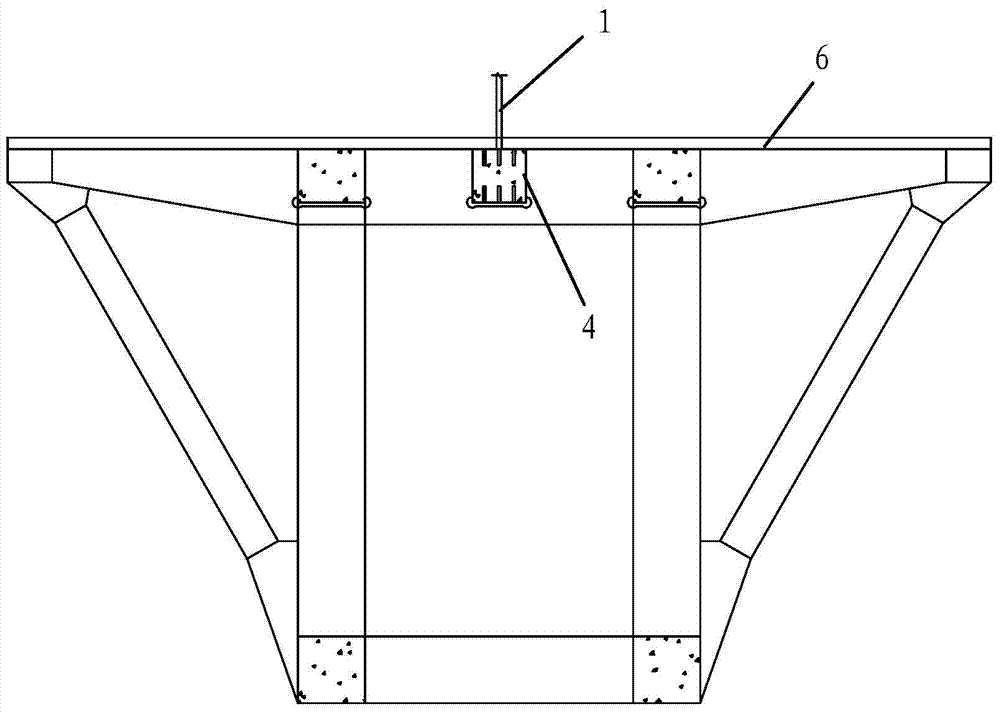

[0033] Such as figure 1 , figure 2 As shown, the present invention includes a rectangular steel pipe 4, a stiffener assembly arranged in the rectangular steel pipe 4, a concrete structure 5 formed by pouring concrete filled in the rectangular steel pipe 4, and a concrete structure 5 arranged on the rectangular steel pipe 4 and applied to the cable-stayed bridge. Anchor plate 1 fixed with stay cables, the stiffener assembly is poured in the concrete structure 5, the rectangular steel pipe 4, the stiffener assembly and the concrete structure 5 form a stiffened steel pipe concrete member, and the stiffened The steel tube concrete member is fastened and fixed on the main girder of the cable-stayed bridge. The rectangular steel pipe 4 is arranged horizontally and along the longitudinal direction of the bridge. The rectangular steel pipe 4 is connected to the top board 4-1 and the bottom board 4-2 directly below the top board 4-1 by the top board 4-1, and two The side plates 4-3 ...

Embodiment 2

[0049] In this example, if Figure 5 As shown, the difference from Embodiment 1 is that the upper opening stiffeners 2 and the lower opening stiffeners 3 are arranged in a staggered manner.

[0050] In this embodiment, the number of the upper opening stiffeners 2 is three, and the number of the lower opening stiffeners 3 is two. During actual construction, the numbers of the upper opening stiffeners 2 and the lower opening stiffeners 3 can be adjusted accordingly according to specific needs.

[0051] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com