Yielding type annular support and supporting method

A technology of ring support and yielding support, which is applied in the direction of pillars/supports, earth drilling, mining equipment, etc., and can solve problems such as inability to actively and effectively support the roadway, and destructive damage to the support body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

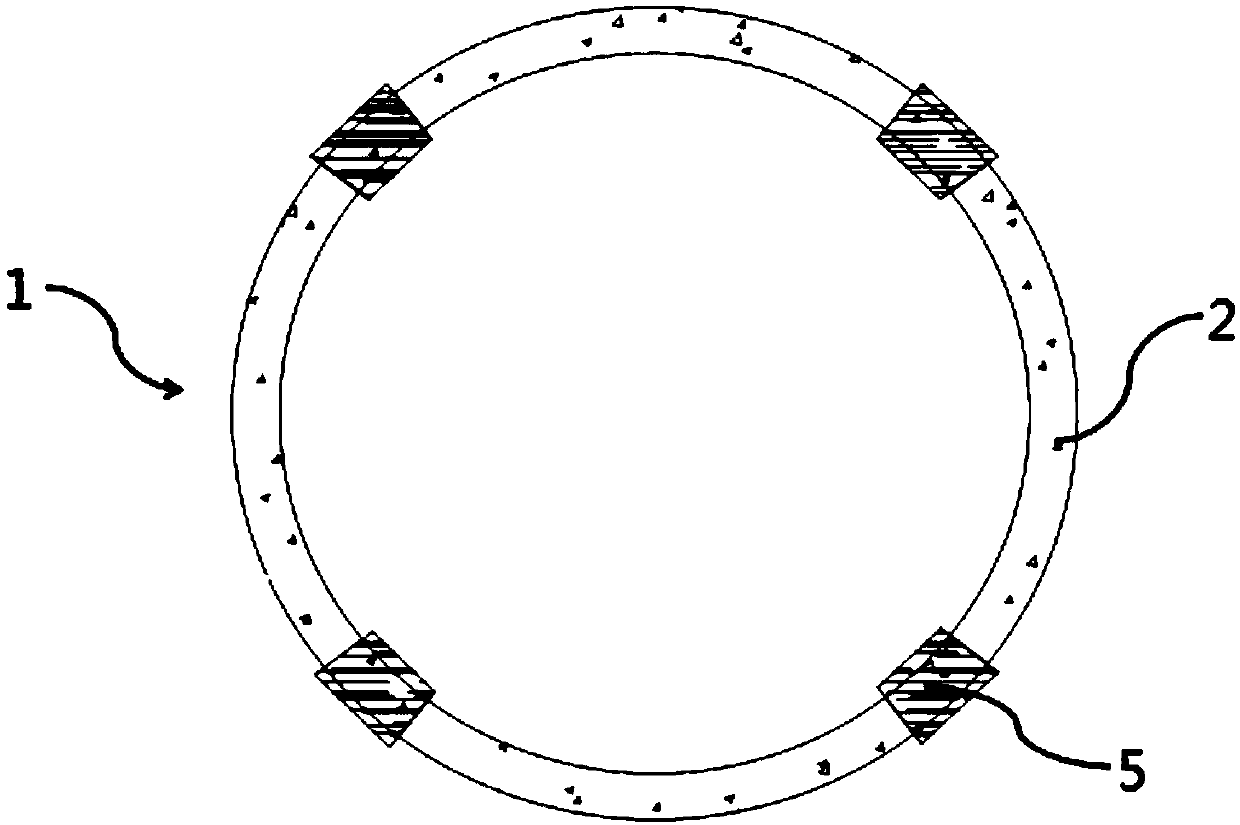

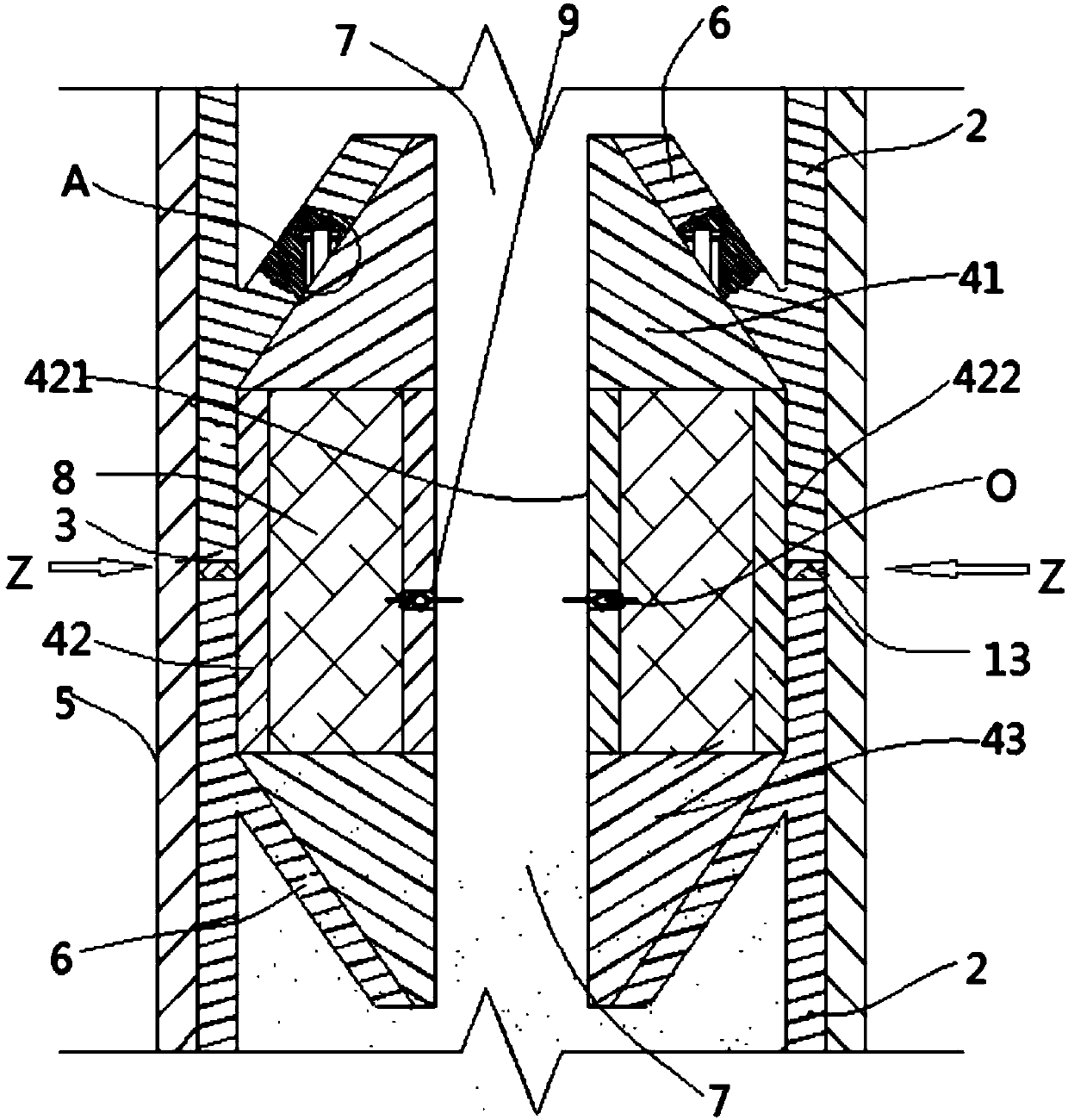

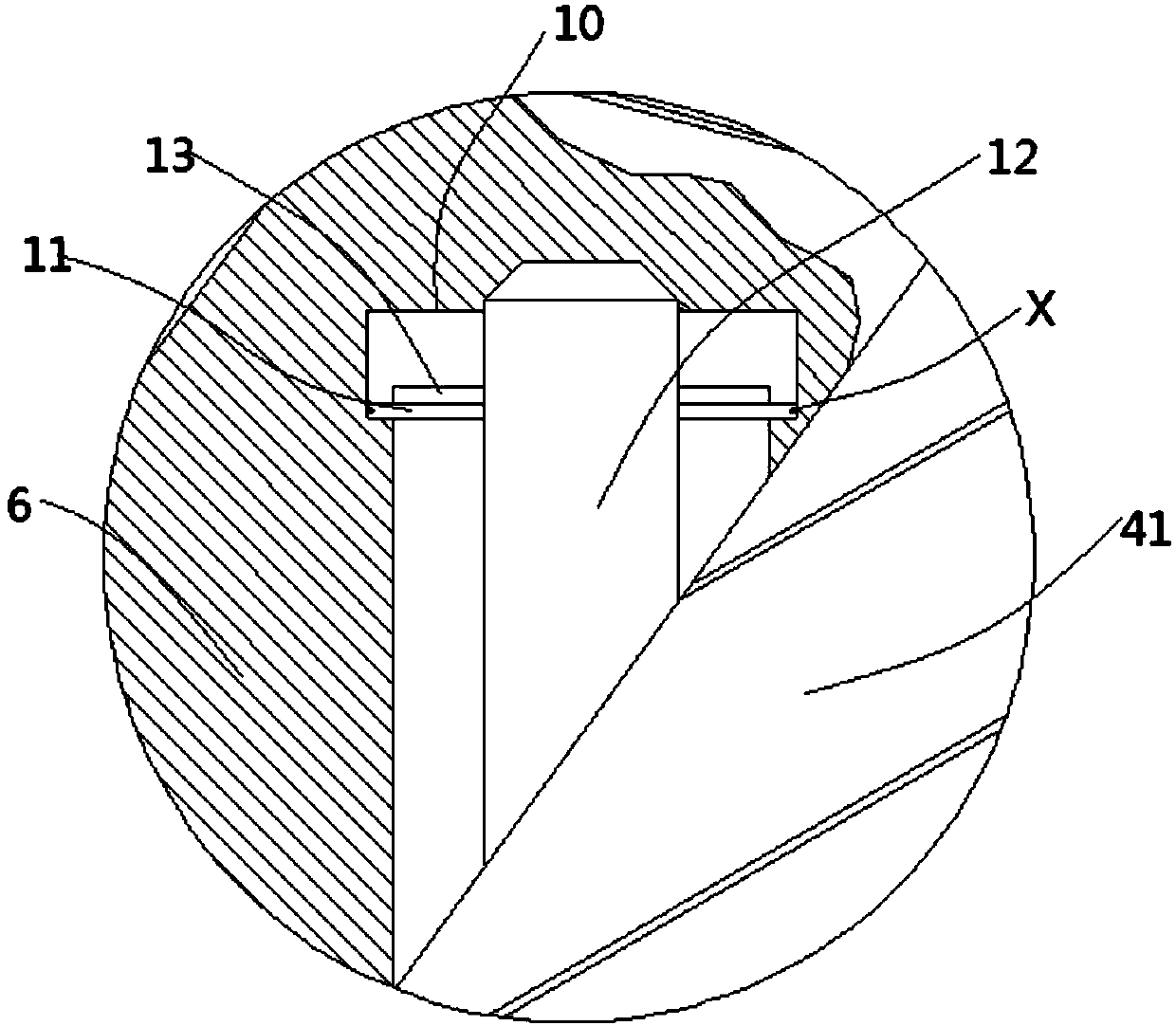

[0064] see figure 1 , figure 2 and Figure 5 As shown, the embodiment of the present invention is a pressure-yielding annular support, which can be applied to but not limited to mining, petroleum, subway construction, etc., involving tunnels, roadways and other support projects, especially suitable for large buried depth and fast pressure. , long-term support of the dynamic pressure soft rock roadway with large deformation and high stress, which can ensure the safe use of the roadway; including: a ring body 1, the ring body 1 includes a multi-section arc arch 2, and the arc arch 2 The arc arch feet 3 are connected in sequence from end to end, and there is a pressure relief member 4 connected between the two connected arc arch feet 3, and the pressure relief member 4 and the arc arch foot 3 A connecting piece 5 is arranged on the circumferential periphery of the butt joint, and the connection between the arc arch foot 3 and the pressure release member 4 is strengthened throu...

Embodiment 2

[0078] An embodiment of the present invention provides a support method for a yielding support, comprising the steps of:

[0079] Make pressure-yielding brackets; support the pressure-yielding brackets in roadways or tunnels. For specific structures, refer to Figure 6 As shown; the roadway or tunnel is supported by the pressure relief support; the production of the pressure relief support includes the steps of: making a number of arc arches with steel pipes; at or near the foot of the arc arch, located A rounded table shell structure is arranged on the inner wall of the circular arc arch, and a concrete flow channel extending into the rounded table shell is reserved on the top of the rounded table shell structure; hole; use steel columns to make a number of round tables with the same taper as the outer surface of the inverted round table shell structure, and the concrete flow channel is provided at the center line of the round table; make a ring cavity; The cavity is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com