Ultra high performance concrete rib with rib bottom steel plate for bridge deck slab

A technology of ultra-high performance and bottom steel plate, applied in bridges, bridge parts, bridge construction, etc., can solve the adverse effects of structural safety, the compression and tensile properties of ultra-high performance concrete cannot be exerted, and the shrinkage and cracking of ultra-high performance concrete To avoid fatigue cracking, improve crack resistance and overload resistance, and improve overall and local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

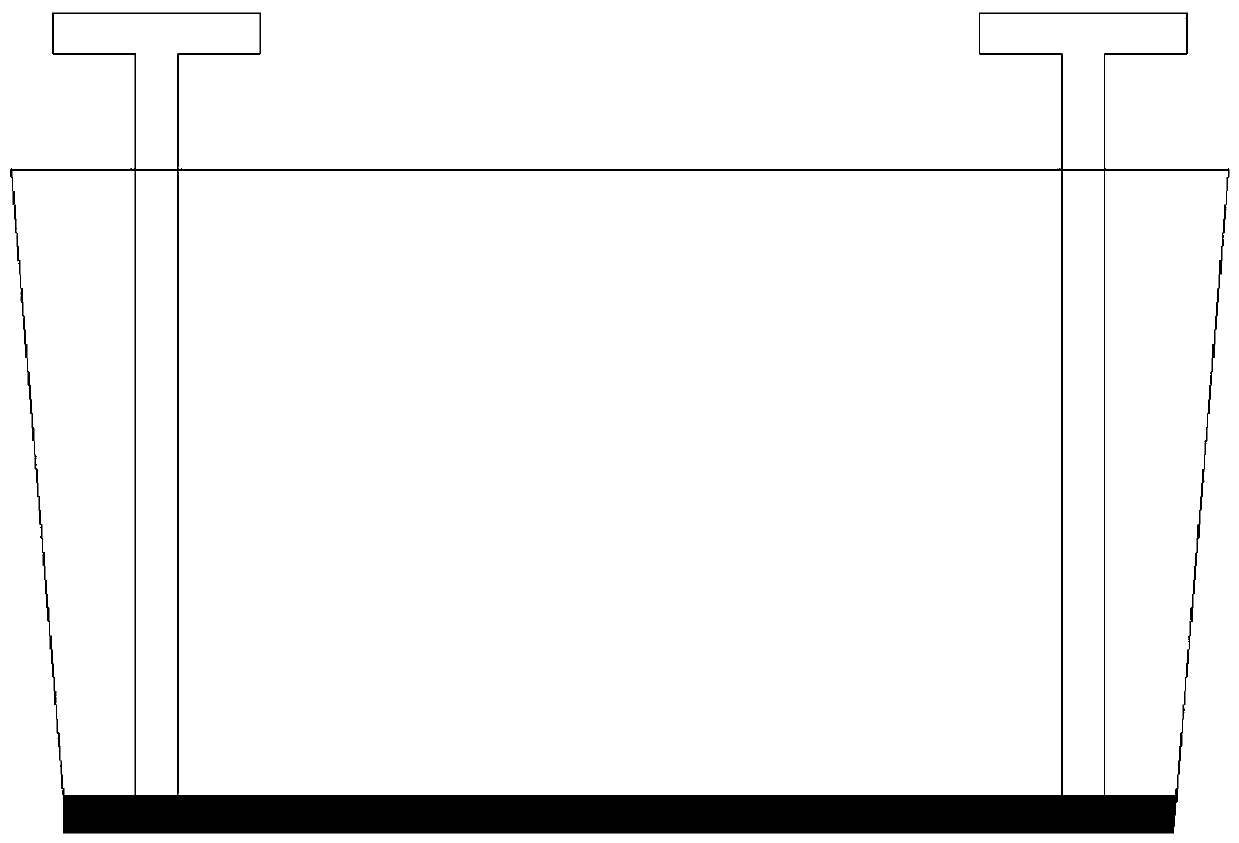

[0032] Example 1, see figure 1 The present invention discloses an ultra-high performance concrete rib with ribbed bottom steel plate for bridge decks. It includes a rib body 7 and a rib bottom steel plate 3. The rib bottom steel plate 3 is provided at the bottom of the rib body 7, and the rib bottom The upper surface of the steel plate 3 is provided with a shear connector 4, and ultra-high performance concrete is poured around the shear connector 4 on the rib bottom steel plate 3 to form the rib body 7, and the upper part of the shear connector 4 is connected with the steel mesh 5 of the bridge deck 1. .

[0033] The height of the rib body 7 is 0.17 m, and the cross section of the plate body 7 is an inverted trapezoid, with an upper edge width of 0.20 m and a lower edge width of 0.18 m.

[0034] The reinforced steel plate 3 is arranged at the bottom of the board body 7 in the form of a flat plate, and the thickness of the reinforced steel plate 3 is 0.006 m.

[0035] The rib body 7 ...

Embodiment 2

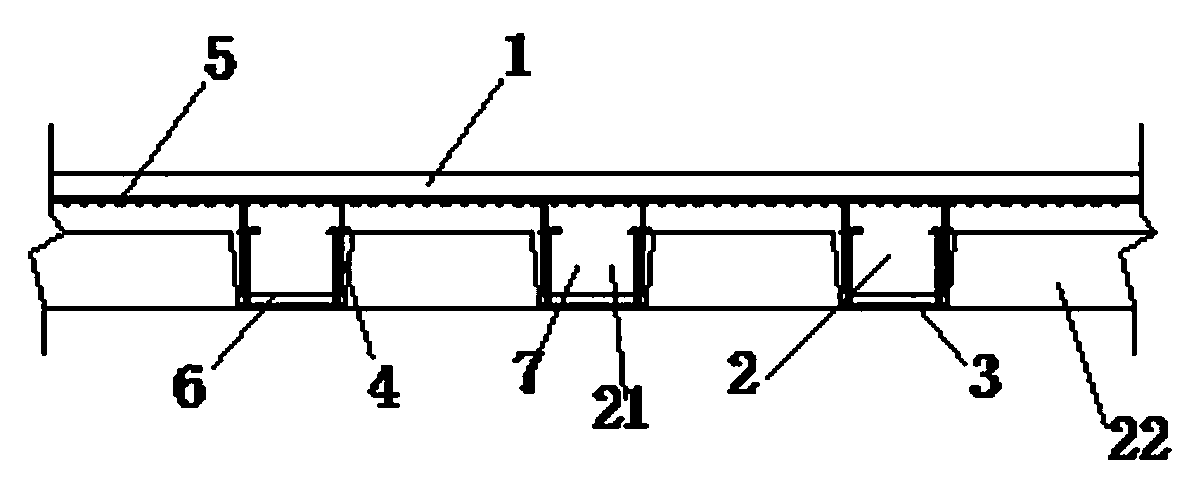

[0037] Example 2, see figure 2 , The rest is the same as in Example 1. The present invention discloses an ultra-high performance concrete rib with a ribbed bottom steel plate for bridge decks. It includes a rib body 7 and a rib bottom steel plate 3. A rib bottom steel plate 3 is arranged at the bottom of the rib body 7, and the rib bottom steel plate The upper surface of 3 is provided with a shear connector 4, ultra-high performance concrete is poured around the shear connector 4 on the rib bottom steel plate 3 to form a rib body 7, and the upper part of the shear connector 4 is connected with the steel mesh 5 in the panel 1.

[0038] The height of the rib body 7 is 0.17m, the section of the plate body 7 is rectangular, the width of the upper edge is 0.18m, and the width of the lower edge is 0.18m.

[0039] The reinforced steel plate 3 is arranged at the bottom of the board body 7 in a unidirectional corrugated form, and the thickness of the reinforced steel plate 3 is 0.006m.

[0...

Embodiment 3

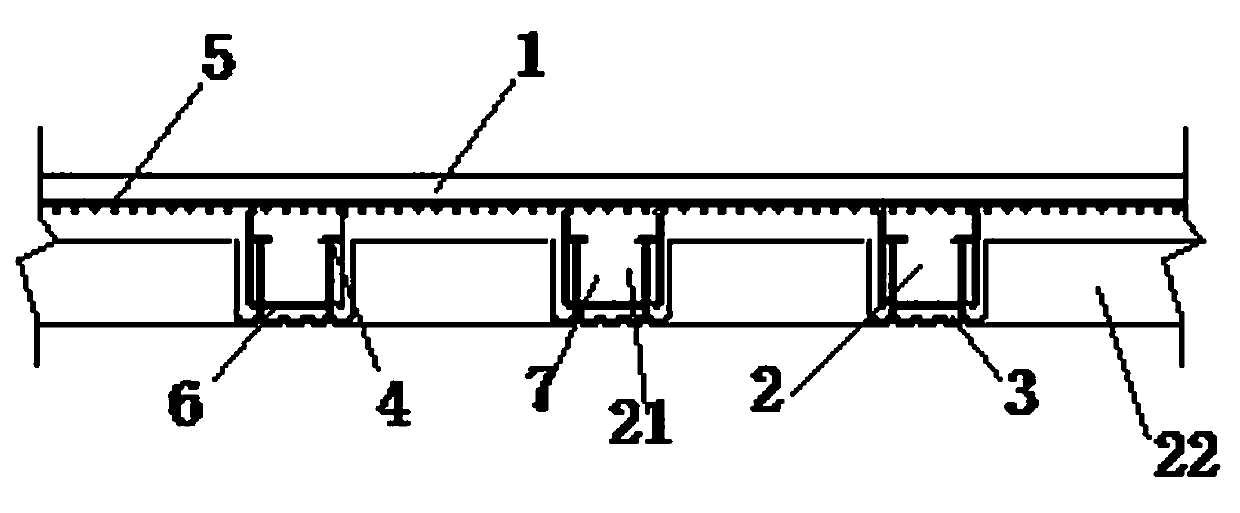

[0042] Example 3, see Figure 3 to 4 , The rest is the same as the above embodiment. The present invention discloses an ultra-high performance concrete rib with a ribbed bottom steel plate for bridge decks. It includes a rib body 7 and a rib bottom steel plate 3. A rib bottom steel plate 3 is arranged at the bottom of the rib body 7, and the rib bottom steel plate The upper surface of 3 is provided with a shear connector 4, ultra-high performance concrete is poured around the shear connector 4 on the rib bottom steel plate 3 to form a rib body 7, and the upper part of the shear connector 4 is connected with the steel mesh 5 in the panel 1.

[0043] The height of the rib body 7 is 0.17m, the section of the plate body 7 is rectangular, the width of the upper edge is 0.18m, and the width of the lower edge is 0.18m.

[0044] The reinforced steel plate 3 is arranged at the bottom of the board body 7 in the form of a flat plate, and the thickness of the reinforced steel plate 3 is 0.006 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com