Ultra high performance concrete rib plate with rib bottom steel plate and machining method thereof

An ultra-high performance, bottom steel plate technology, applied in manufacturing tools, ceramic molding machines, construction, etc., can solve the problem that the compressive and tensile properties of ultra-high-performance concrete cannot be exerted, the ultra-high-performance concrete shrinks and cracks, and the structural safety is unfavorable. It can avoid fatigue cracking, improve crack resistance and overload resistance, and improve overall and local stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

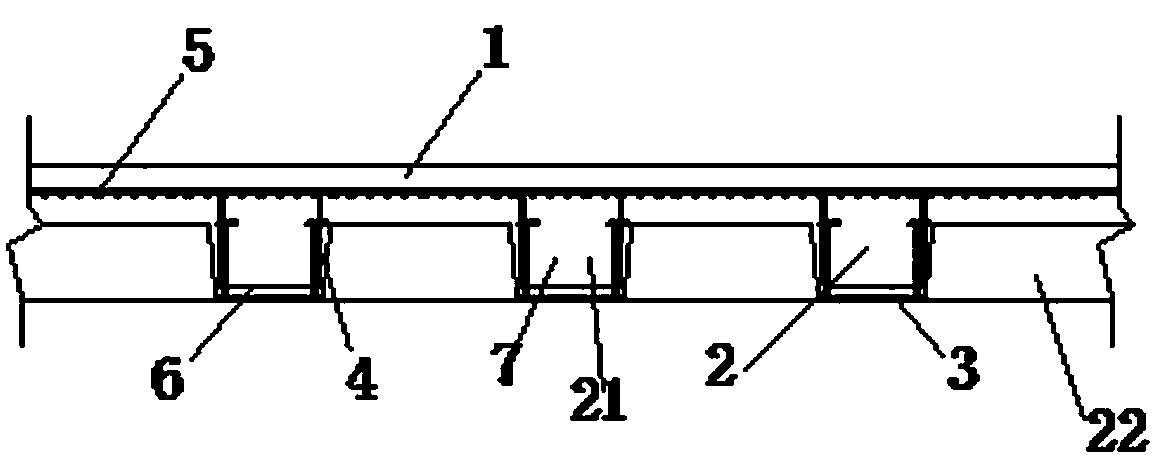

[0031] Embodiment 1, refer to figure 1 , the invention discloses an ultra-high performance concrete rib slab using a rib-bottom steel plate, which includes a panel 1 and ribs 2 poured from ultra-high performance concrete, and more than three ribs 2 are arranged at the bottom of the panel 1 and the rib 2 The panel 1 is connected as a whole, and a steel mesh 5 is arranged in the panel 1, and the feature is that the plate rib 2 includes a rib body 7 and a rib bottom steel plate 3, and a rib bottom steel plate 3 is arranged at the bottom of the rib body 7, and a rib bottom steel plate is arranged on the rib bottom steel plate The upper surface of 3 is provided with a shear connector 4, and a stirrup 6 is arranged at the bottom of the steel mesh 5, and the stirrup 6 is fixedly connected with the shear connector 4, so that the steel mesh 5 is connected with the stirrup 6 and the shear connector 4 To form an integral reinforcement structure, pour ultra-high performance concrete outsi...

Embodiment 2

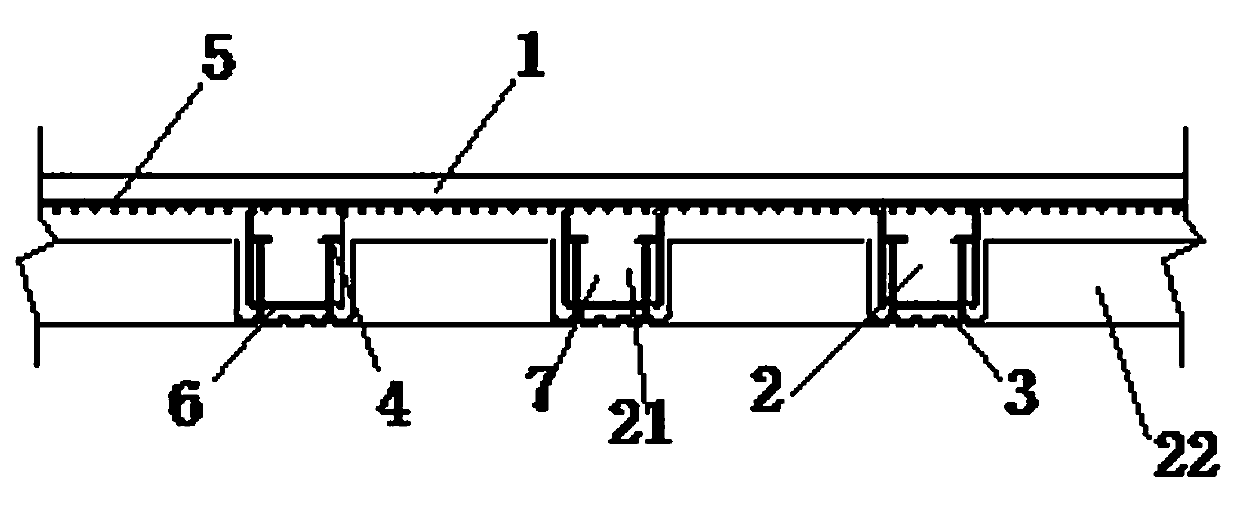

[0039] Embodiment 2, refer to figure 2 , the invention discloses an ultra-high-performance concrete rib plate using a rib-bottom steel plate, which includes a panel 1 cast from ultra-high-performance concrete, and plate ribs 2, and more than three plate ribs 2 are arranged at the bottom of the panel 1 It is connected with the panel 1 as a whole, and a steel mesh 5 is arranged in the panel 1, and its characteristic is that the plate rib 2 includes a rib body 7 and a rib bottom steel plate 3, and a rib bottom steel plate 3 is arranged at the bottom of the rib body 7, and a rib bottom steel plate 3 is arranged at the bottom of the rib The upper surface of the steel plate 3 is provided with a shear connector 4, and a stirrup 6 is arranged at the bottom of the reinforcement mesh 5, and the stirrup 6 is fixedly connected with the shear connector 4, so that the reinforcement mesh 5, the stirrup 6 and the shear connector 4 It is connected to form an integral steel structure, and ultr...

Embodiment 3

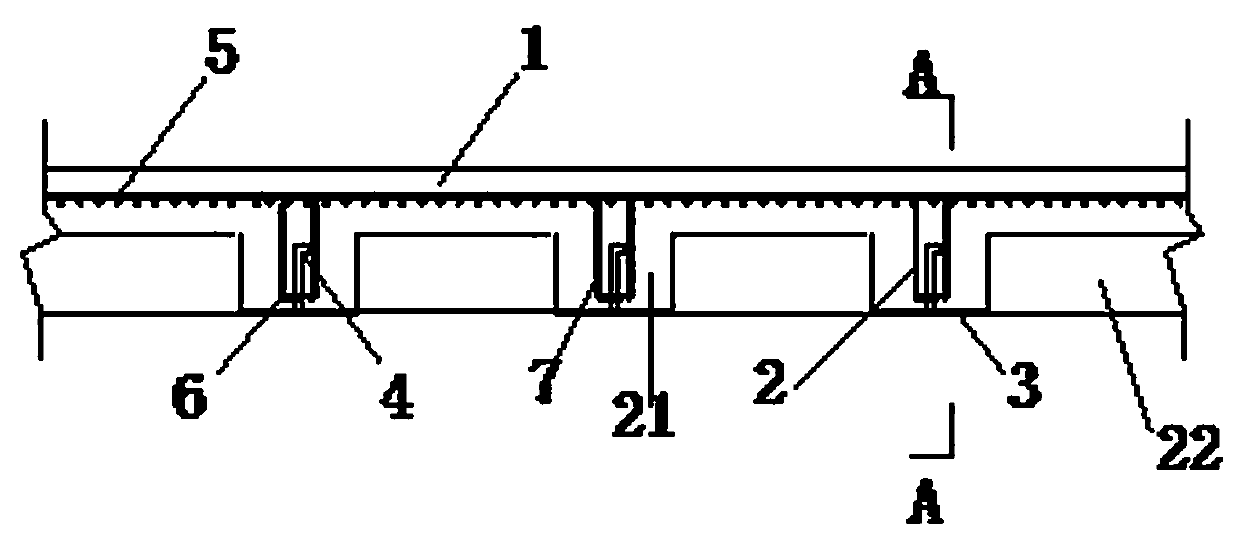

[0046] Embodiment 3, refer to Figures 3 to 4 , the invention discloses an ultra-high-performance concrete rib plate using a rib-bottom steel plate, which includes a panel 1 cast from ultra-high-performance concrete, and plate ribs 2, and more than three plate ribs 2 are arranged at the bottom of the panel 1 It is connected with the panel 1 as a whole, and a steel mesh 5 is arranged in the panel 1, and its characteristic is that the plate rib 2 includes a rib body 7 and a rib bottom steel plate 3, and a rib bottom steel plate 3 is arranged at the bottom of the rib body 7, and a rib bottom steel plate 3 is arranged at the bottom of the rib The upper surface of the steel plate 3 is provided with a shear connector 4, and a stirrup 6 is arranged at the bottom of the reinforcement mesh 5, and the stirrup 6 is fixedly connected with the shear connector 4, so that the reinforcement mesh 5, the stirrup 6 and the shear connector 4 It is connected to form an integral steel structure, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com