Rolling element accommodating tool

A technology of rolling elements and receiving parts, which is applied in the direction of anti-centrifugal force rotating parts, bearing elements, linear motion bearings, etc., and can solve the problems of shortened life of direct motion devices, inability to obtain sufficient tensile strength, and inability to effectively strengthen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

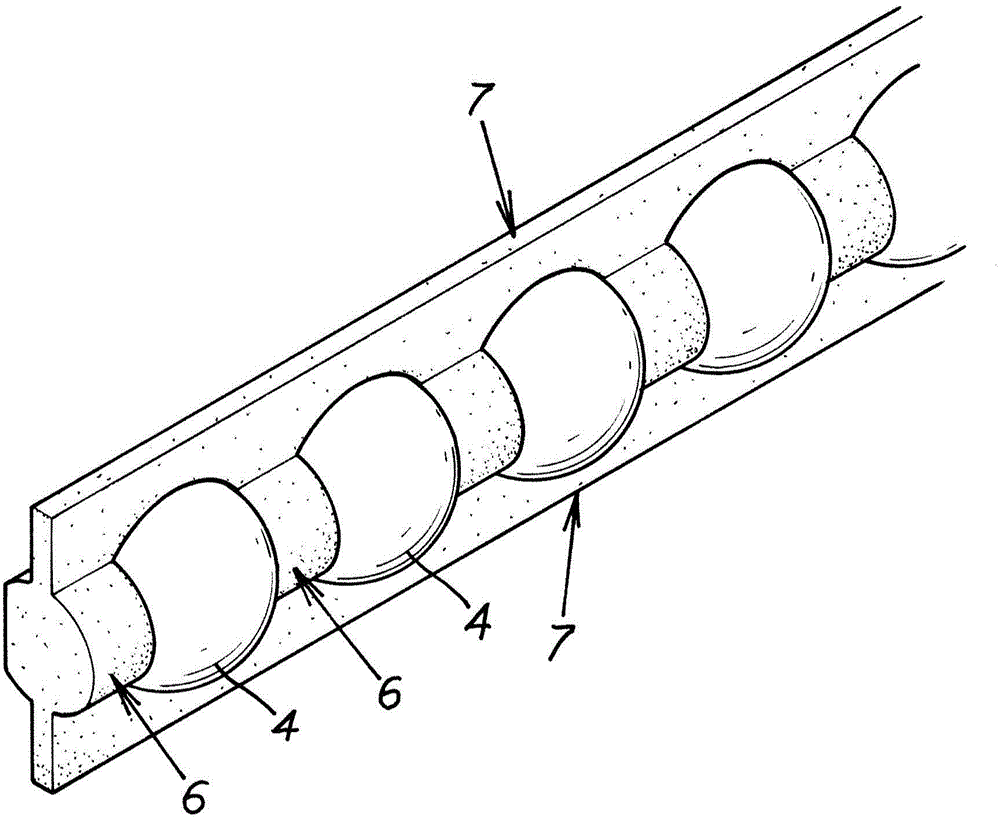

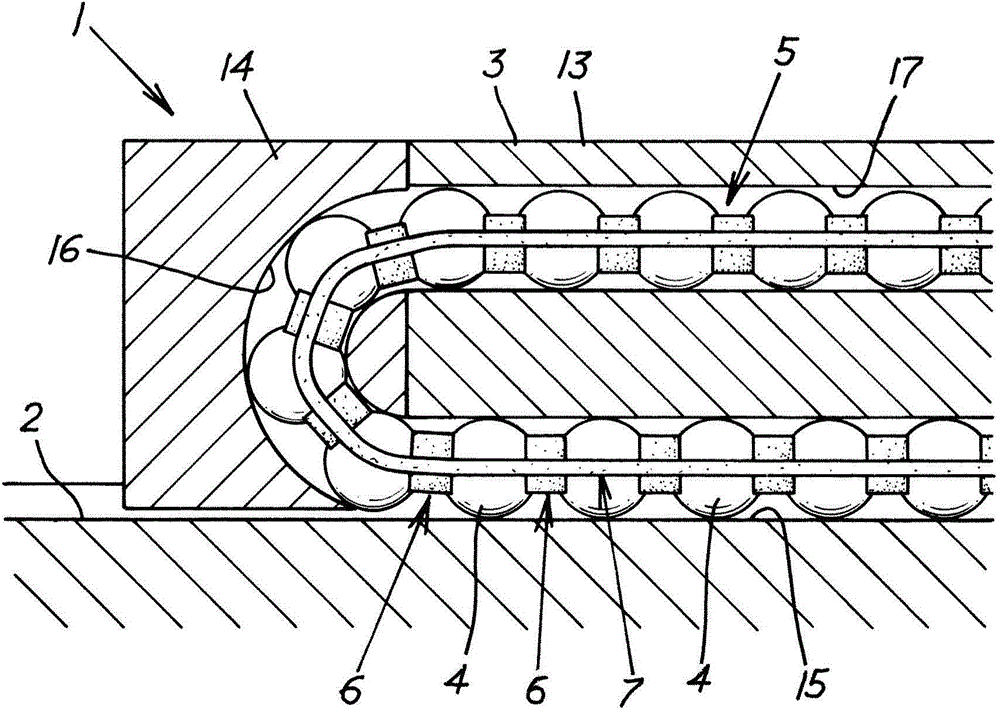

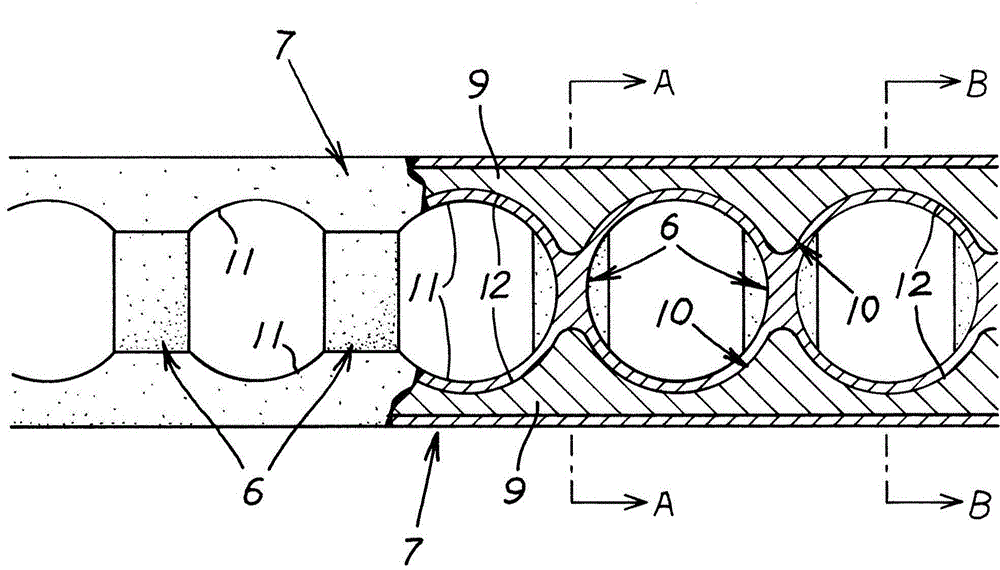

[0049] Specific embodiments of the present invention will be described based on the drawings.

[0050]This embodiment is a belt-shaped rolling element storage piece (rolling element storage belt), the linear motion device 1 is composed of a rail body 2 and a linear motion body 3 that moves linearly relative to the rail body 2, and the linear motion device 1 is provided with a rolling body for rolling. The infinite circulation channel 5 through which the rolling element 4 circulates. The rolling element storage member is arranged in the infinite circulation channel 5 in the linear motion device 1, and stores a plurality of rolling elements 4 at predetermined intervals so as to be rotatable. state, wherein, the rolling body receiving part has a main body, and the main body is composed of a spacer 6 and a connection setting part 7, and the spacer 6 is respectively arranged between adjacent rolling bodies 4, and the connection setting part 7 protrudes to both sides of the rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com