Lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam

A technology for concrete beams and stiffening boxes, applied in joists, girders, truss beams, etc., can solve the problems of manpower and financial resources, structural performance deterioration, and low strength utilization rate for the repair and reinforcement of corroded reinforced concrete structures. The effect of construction assembly, prefabrication process is simple and easy, and excellent seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in further detail:

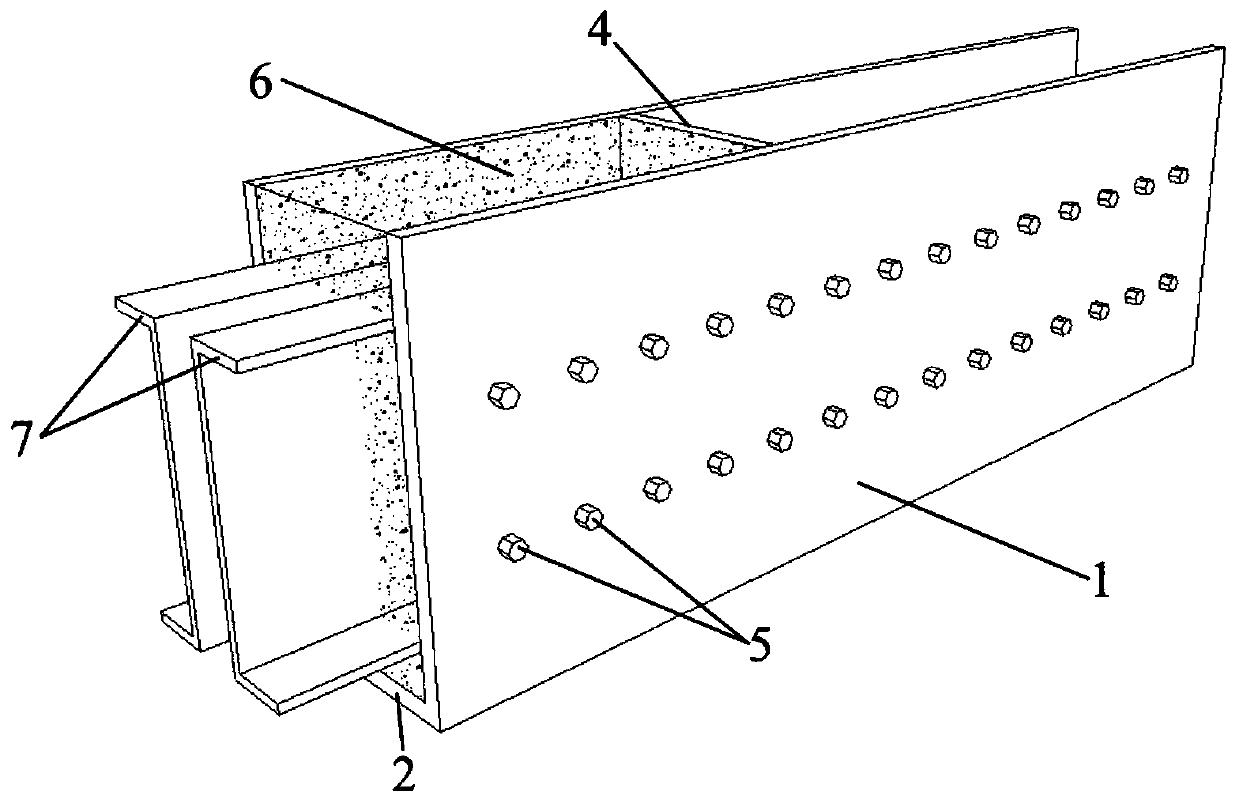

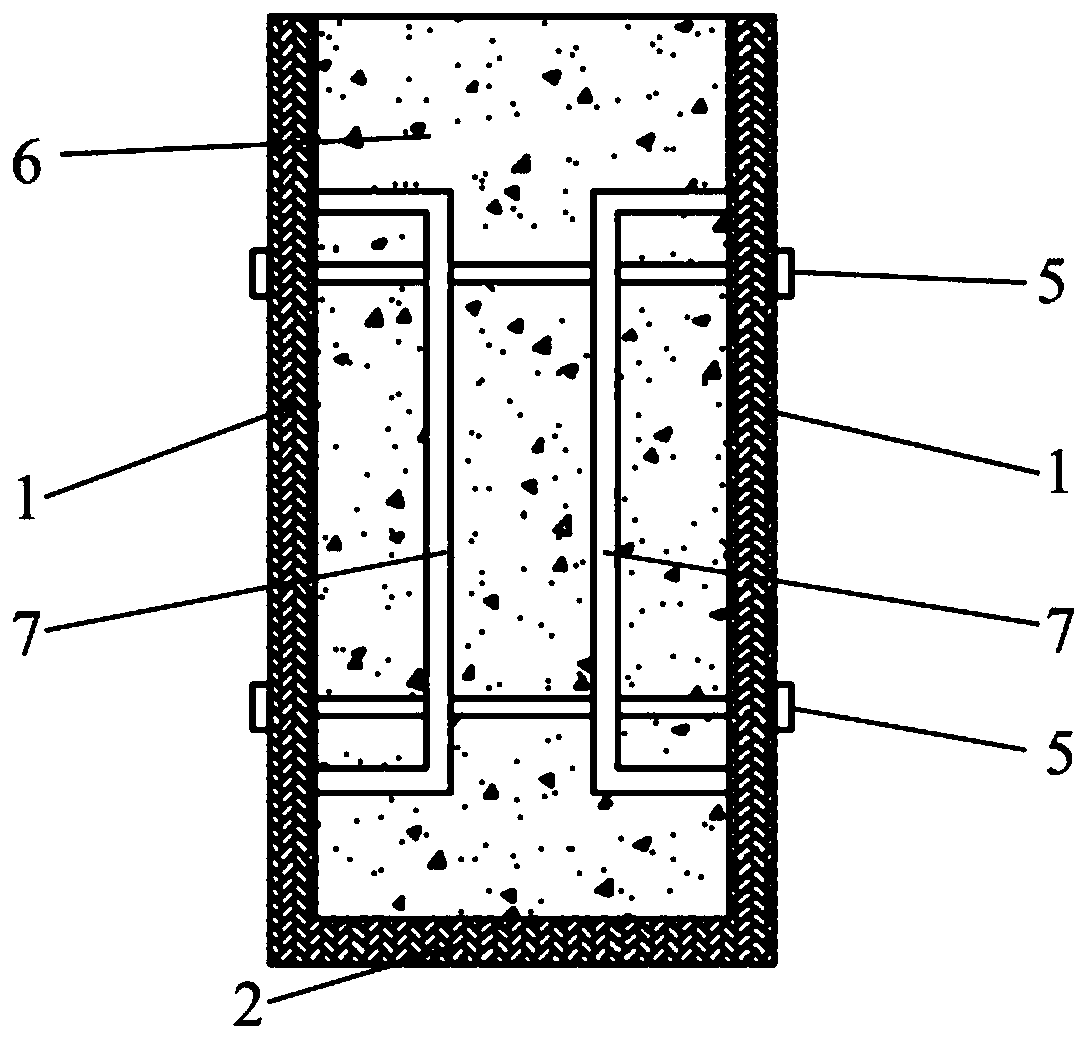

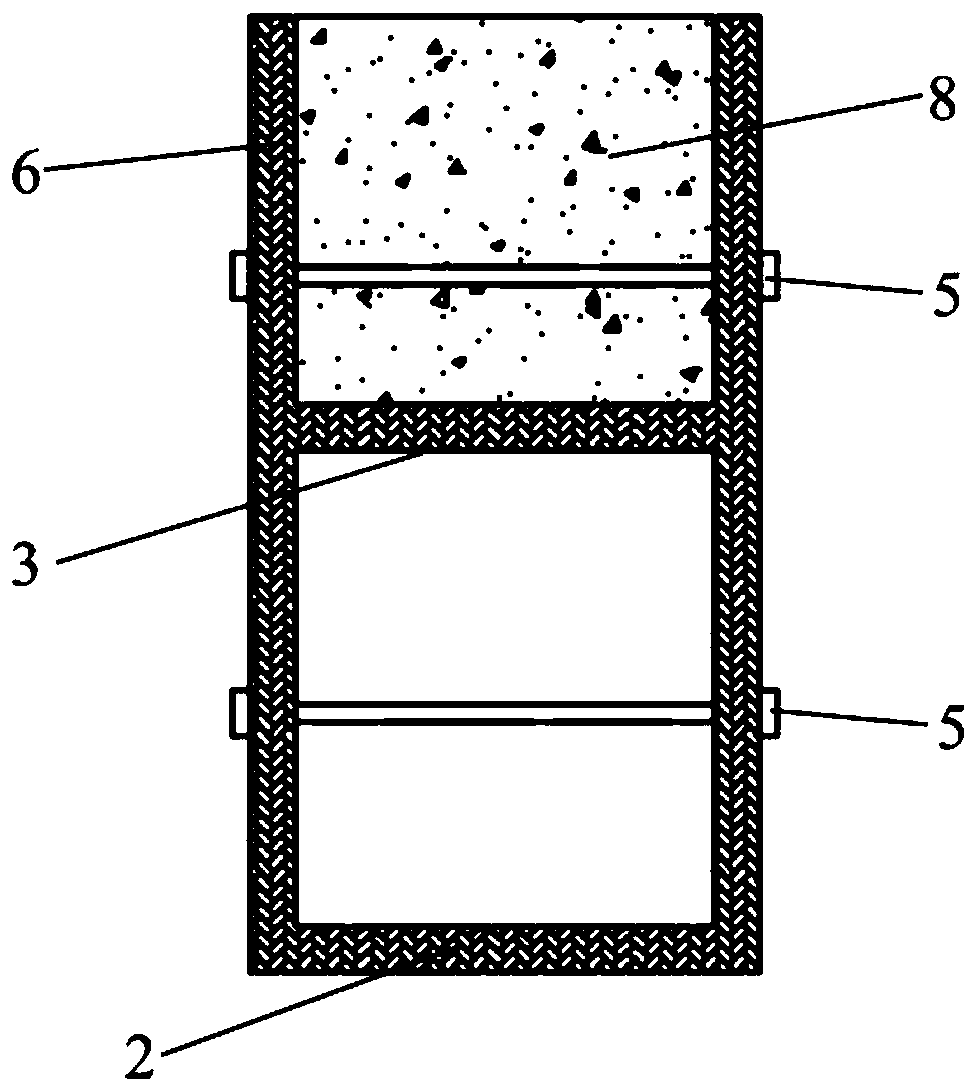

[0027] As shown in the figure, the light-weight assembled stiffened box-groove FRP profile sea-sand concrete beam includes the assembled beam main body, which is characterized in that the FRP beam body of the assembled beam main body is an integrated prefabricated structure, and the FRP beam body is composed of FRP bottom plate 2 and It is surrounded by two FRP side plates 1; it also includes two FRP partition plates 4 for the middle beam section and the end beam section arranged perpendicular to the beam axis of the main body of the assembly beam; the main body of the assembly beam is composed of two pieces along the axis of the FRP beam body The middle beam section and the end beam section are divided into three beam sections by the FRP partition plate 4, which are the middle beam section and two end beam sections; the two end beam sections ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com