Anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and constructing method of anchor-arm static-pressure pile device

A technology of anchor static pressure pile and construction method, which is applied in the field of self-sufficient pressure pile reaction force anchor static pressure pile device, which can solve the problems of high cost, large dragging settlement, building damage, etc., and achieve high pullout bearing capacity , small towing settlement and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

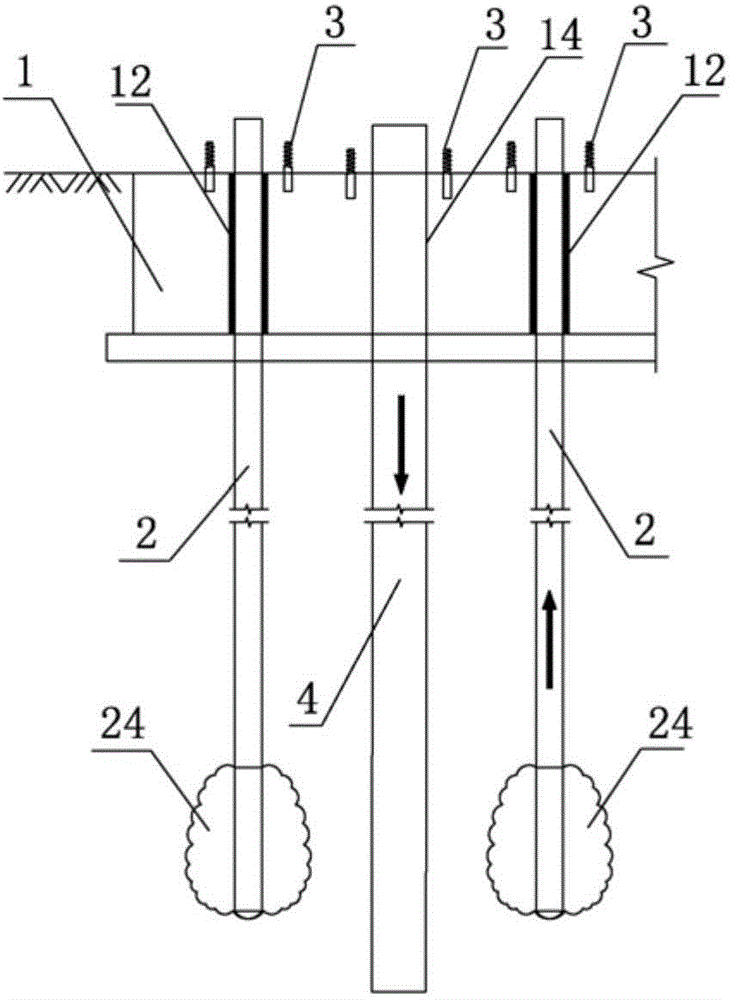

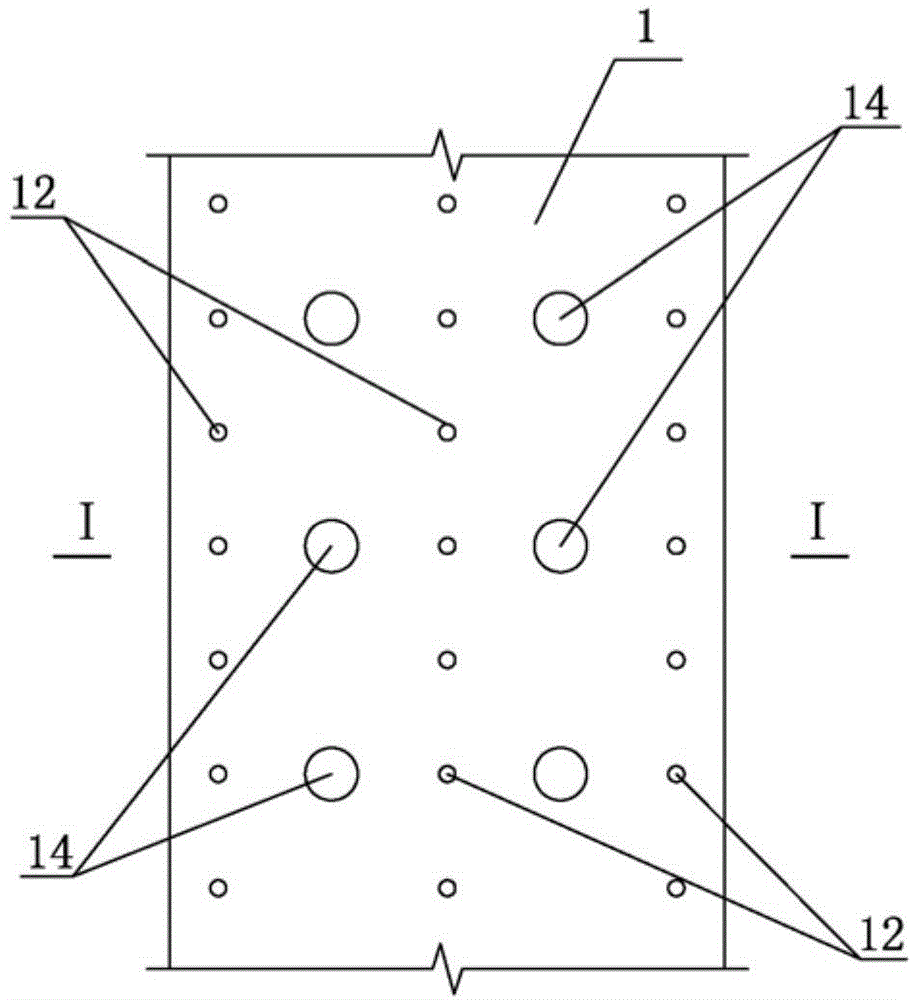

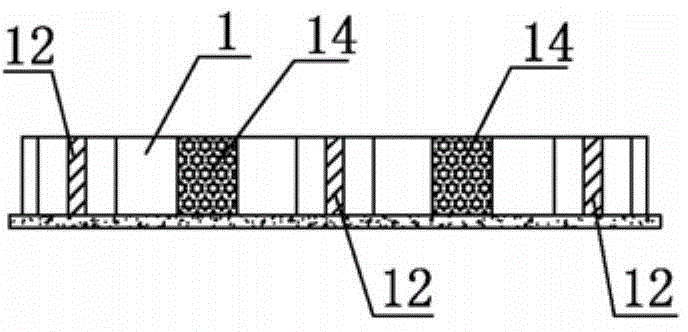

[0037] Such as figure 1 The shown anchor static pressure pile device using the grouted steel pipe pile at the pile end as the reaction force includes a pile bottom plate 1, a steel pipe pile 2 and an anchor rod 3. to combine figure 2 , image 3 As shown, an anchor static pressure pile pressure pile hole 14 and a steel pipe pile pressure pile hole 12 are provided on the pile pressure pile bottom plate 1 . to combine Figure 4-6 As shown, the bottom of the steel pipe pile 2 is closed, and the steel pipe pile 2 is provided with a number of grout holes 21, and the grout holes 21 can be designed to be distributed within the range of 3m above the pile end 20 of the steel pipe pile 2. In this embodiment , the grout holes 21 are distributed in the range of 1.5m above the pile end 20 of the steel pipe pile 2, the pipe wall outside the grout hole 21 is provided with an angle steel barb 22, and the outer wall of the steel pipe pile 2 is also provided with a circular steel plate 23. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com